High-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding

A technology of laser deep penetration welding and metal sheet, applied in welding/welding/cutting articles, welding equipment, metal processing, etc. Improvement of laser energy utilization, strong engineering value and application prospects, and the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A high-efficiency laser deep penetration welding method for realizing single-sided welding and double-sided forming of metal sheets, which includes the following main steps:

[0029] Step 1: Clean the surface to be welded.

[0030] The cleaning process includes:

[0031] 1. Use alkaline solution (composed of 5%~10% by volume NaOH+residual alcohol (or acetone) solution) to remove the oil on the surface of the metal sheet to be welded, and after drying, sand the surface to be welded with sandpaper to remove the surface oxide layer ;

[0032] 2. Pickling the polished metal sheet with an acidic solution (mixed with 30-40ml of hydrofluoric acid, 300ml of nitric acid and the rest of deionized water per liter);

[0033] 3. Ultrasonic cleaning is carried out with absolute ethanol, and the cleaned metal sheet is dried for use;

[0034] Step 2: Secure the reflective backing.

[0035] When fixing the reflective backing plate: first, choose a metal plate that reflects the laser...

Embodiment 2

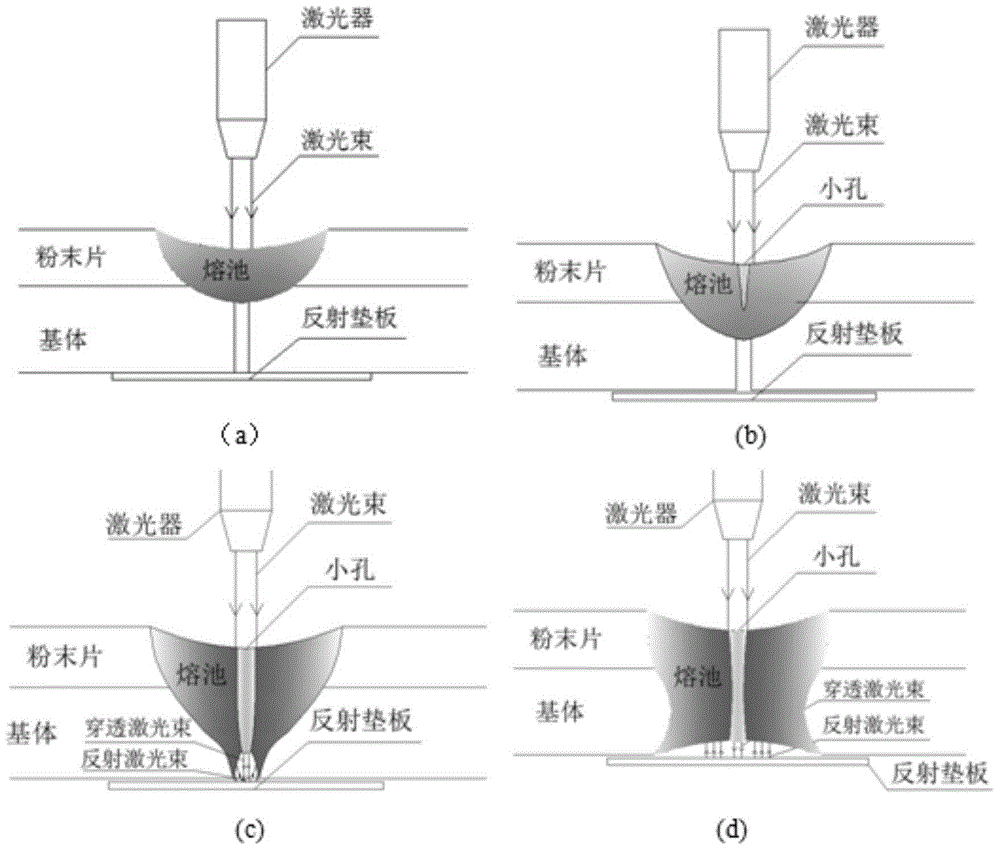

[0038] Such as Figure 2-4 shown.

example 1

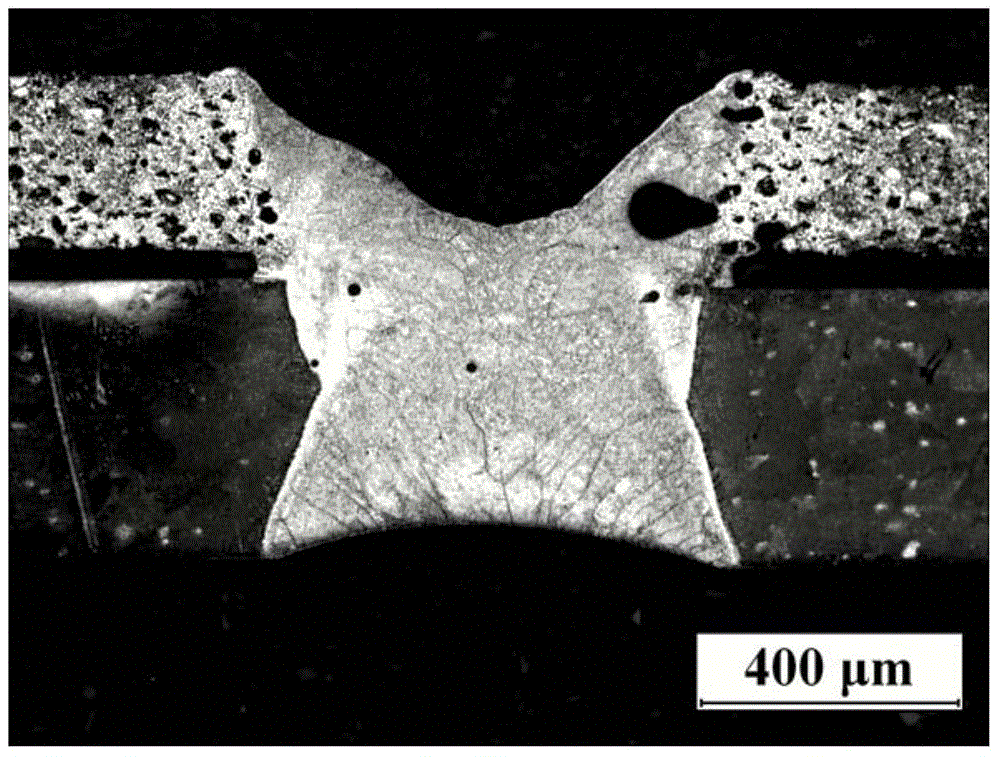

[0042] The metal thin plate sample, powder flakes, laser equipment and laser process parameters used in Example 1 are all the same as those described in Comparative Example 1. The difference between it and Comparative Example 1 is that it adopts the technical solution of the present invention, and the reflective backing plate is After treatment, the surface is dark gray TC4 alloy sheet. Welding is carried out one by one according to the steps described in the foregoing embodiment 1, and the cross-sectional appearance of the obtained laser deep penetration welding metal sheet is as follows image 3 shown. from image 3 It can be seen from the figure that the appearance of the metal sheet laser deep penetration welding weld obtained by the method of the present invention is an hourglass shape (X shape), and the cross-sectional area of the weld zone is 0.7598mm 2 , the laser energy utilization rate is evaluated by the cross-sectional area of the weld seam obtained under the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com