Patents

Literature

49results about How to "Taking into account the mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

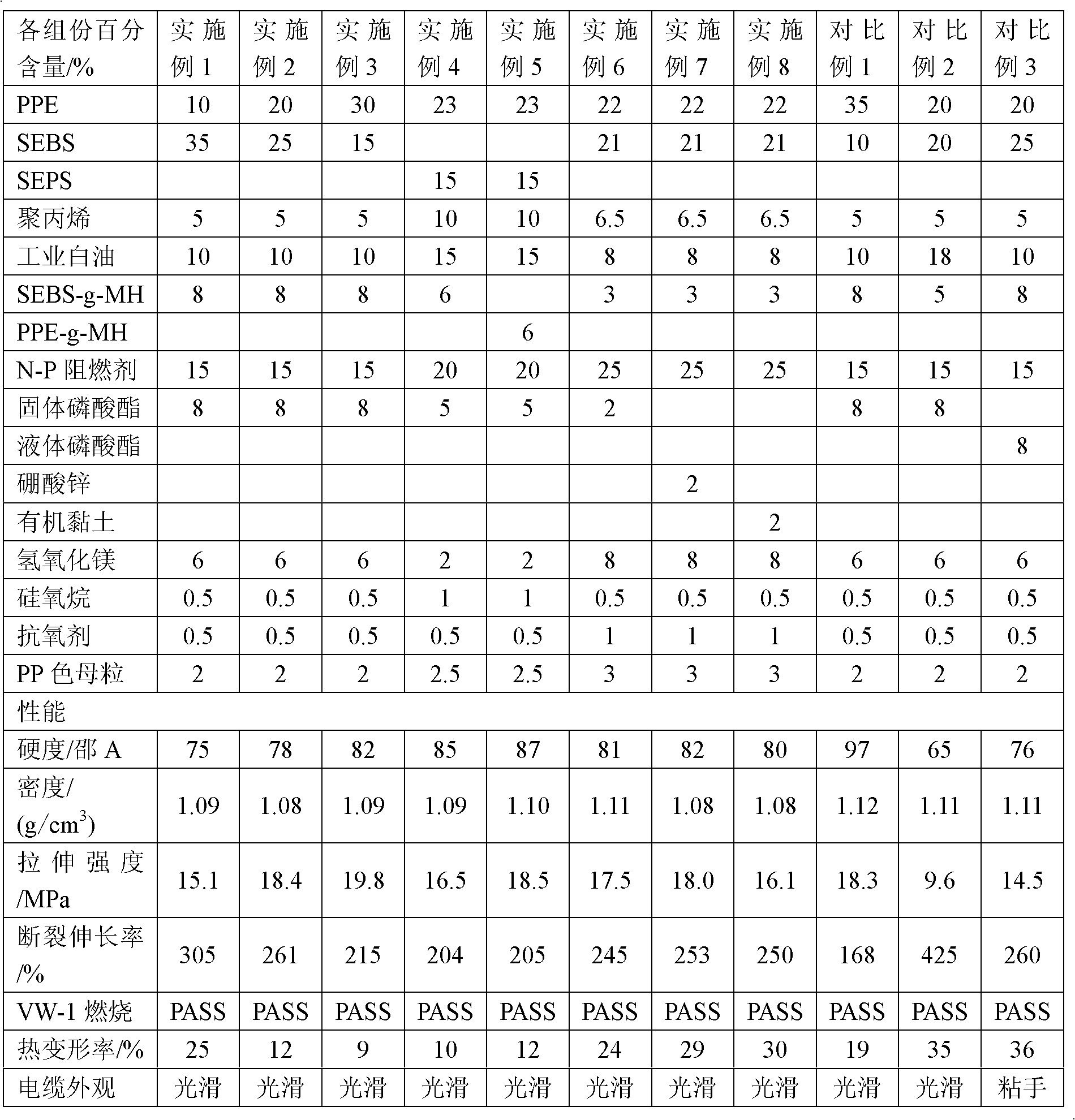

Flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and preparation method thereof

InactiveCN102585428ANo migrationImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesElastomerPolyolefin

The invention relates to the field of halogen-free flame-retardant electric wire cable shield materials, in particular to a flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material and a preparation method thereof. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material is characterized by comprising the following raw materials in percentage: 10 to 30 percent of polyphenyl ether resin; 15 to 35 percent of styrene elastomer; 5 to 10 percent of polyolefin; 8 to 15 percent of plasticizing agent; 3 to 8 percent of compatilizer; 15 to 25 percent of main flame retardant; 2 to 8 percent of synergistic flame retardant; 2 to 8 percent of smoke suppressant; 0.5 to 1 percent of lubricant; 0.5 to 1 percent of antioxygen; and 2 to 3 percent of masterbatch. The flexible halogen-free flame-retardant polyphenyl ether electric wire cable shield material has favorable mechanical property, flexibleness, flame retardant property, heat resistance and processability.

Owner:浙江北化阻燃材料有限公司 +1

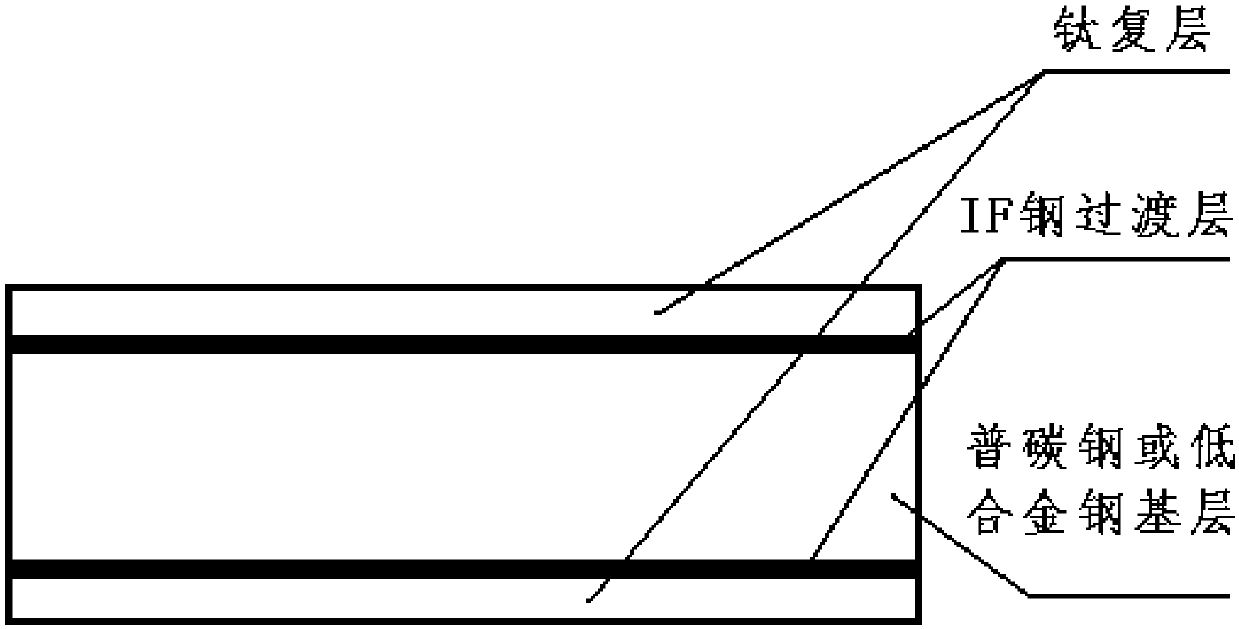

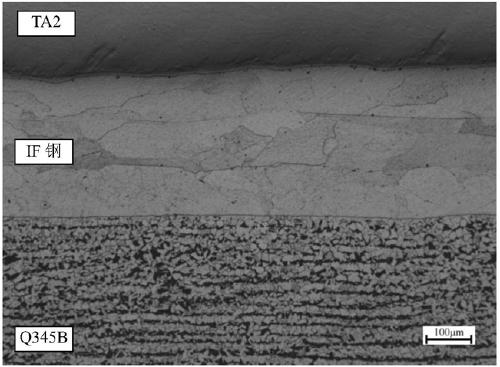

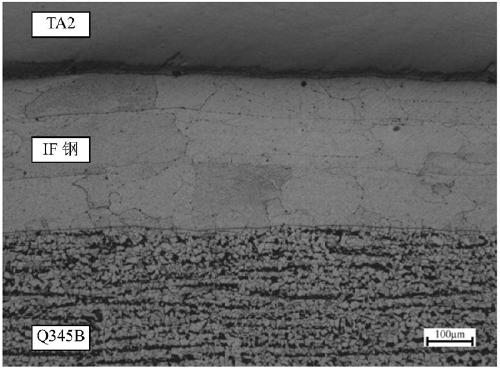

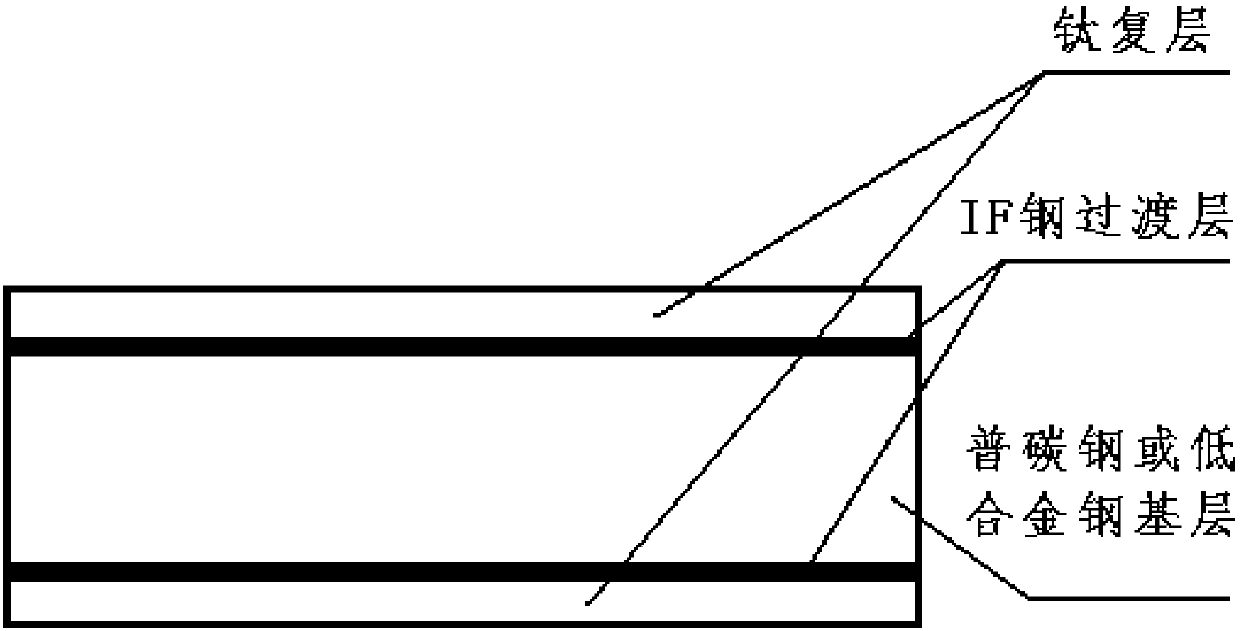

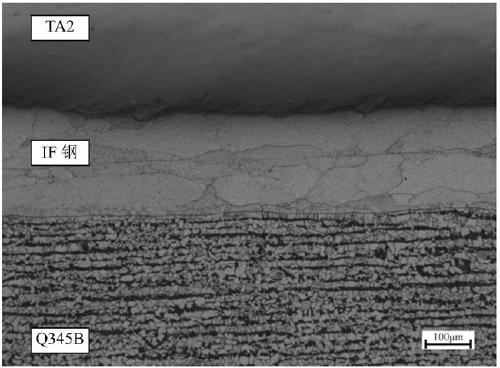

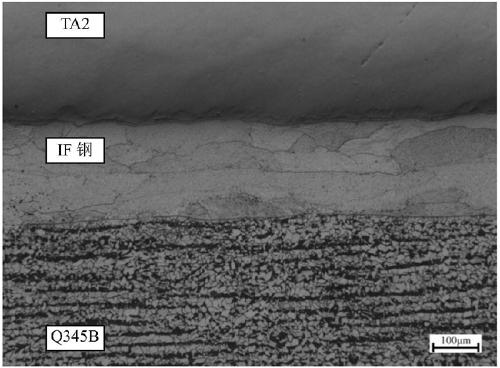

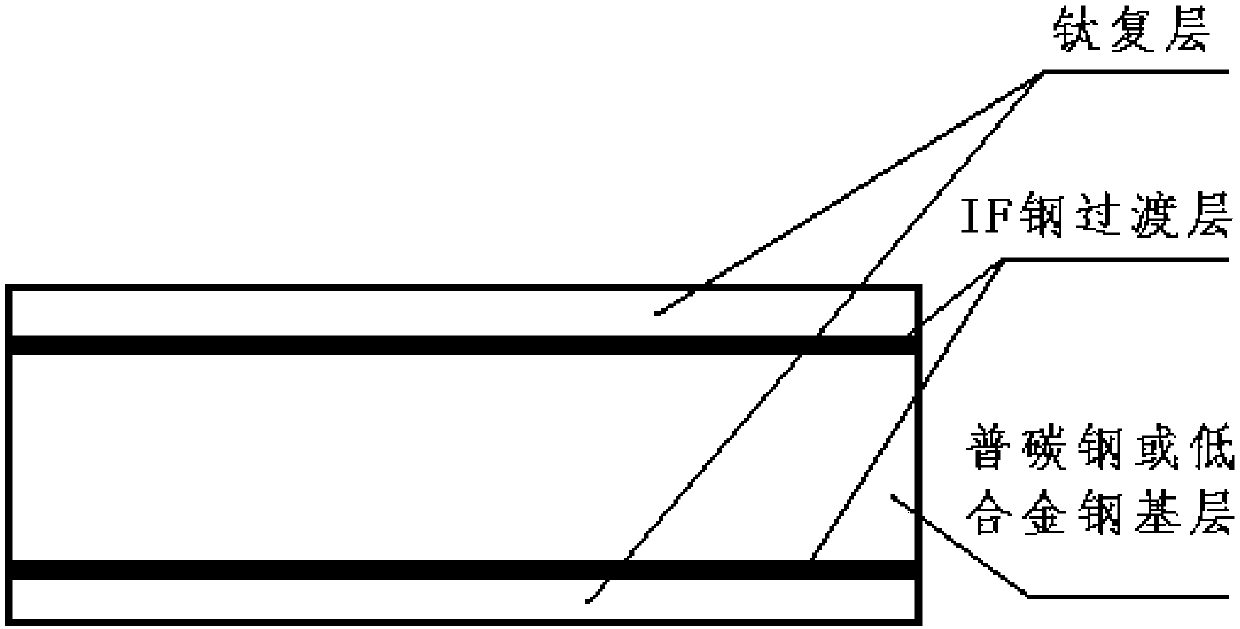

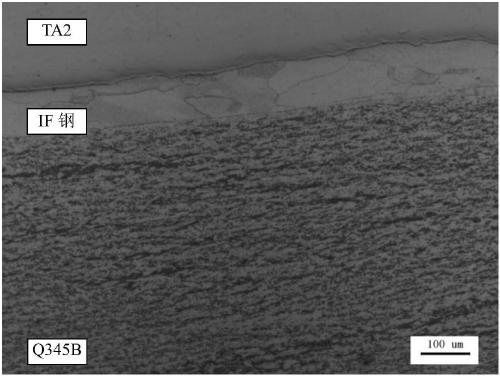

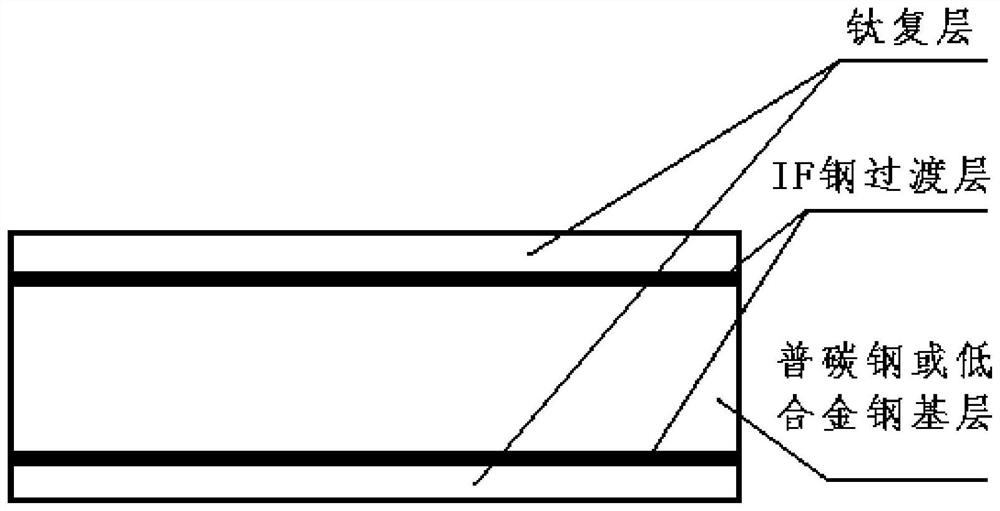

Double-sided titanium steel composite plate taking IF steel as transition layer and high-temperature preparation method thereof

ActiveCN109695000AImprove distributionImprove and enhance bond qualityMetal layered productsComposite plateMechanical property

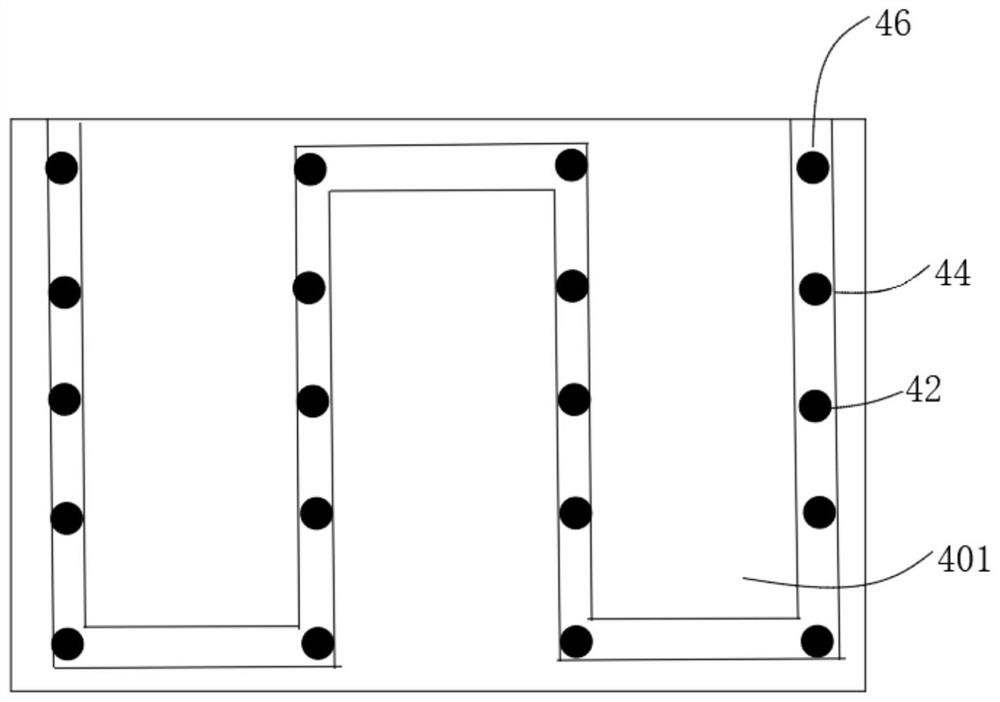

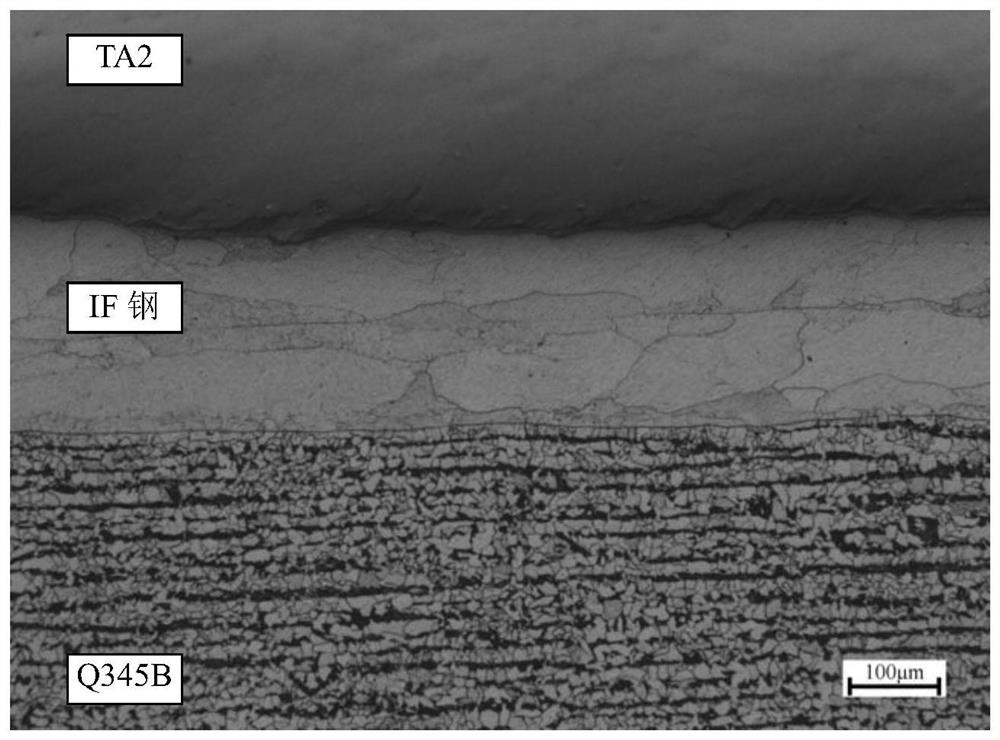

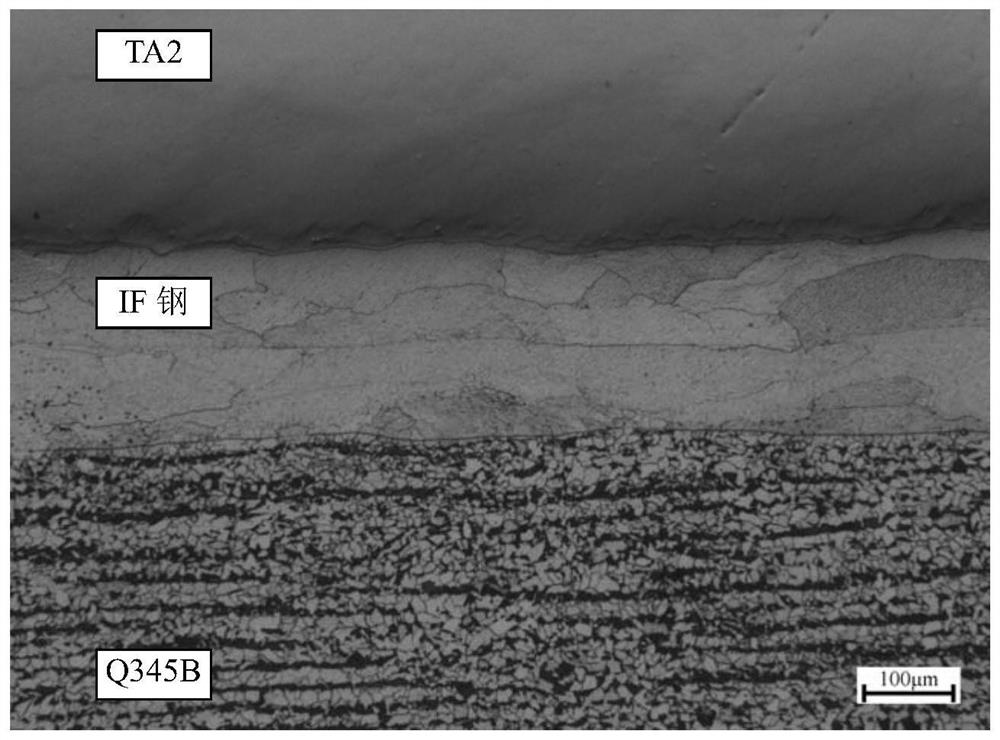

The invention discloses a double-sided titanium steel composite plate taking IF steel as a transition layer and a high-temperature preparation method thereof. A composite blank for preparing the composite plate comprises a base material, the IF steel and a titanium composite material, wherein the base material is plain carbon steel or low alloy steel with C less than or equal to 0.22%, the titanium composite material is industrial pure titanium TA2, the thickness ratio of the base material to the titanium composite material is 5-10, the length and width of the titanium composite material are smaller than those of the base material, and the margin between the titanium composite material and four sides of the base material is 60-100 mm; and the vacuum welded composite blank is heated to 1040-1060 EDG C for heat preservation, the heat preservation time is 1 min / mm * the total thickness of the composite blank, the initial rolling temperature is 1020-1040 DEG C, the single-pass reduction rate is 15%-25%, the total reduction rate is greater than or equal to 70%, the finish rolling temperature is greater than or equal to 850 DEG C, air cooling is carried out to a room temperature, the thickness of the rolled IF steel transition layer is 280-320 [mu]m, and the double-sided titanium steel composite plate with the thickness of 6-75 mm is obtained after plate splitting, and excellent corrosion resistance and mechanical properties are achieved.

Owner:ANGANG STEEL CO LTD

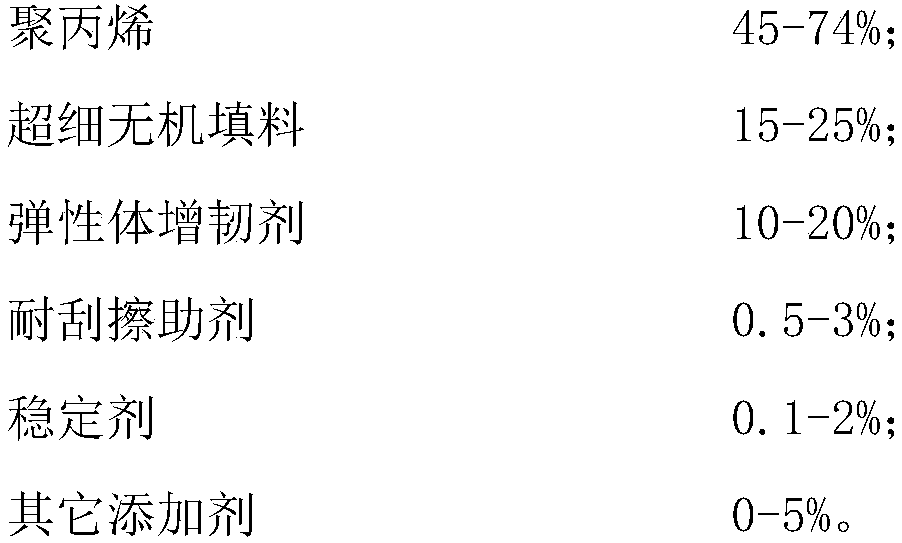

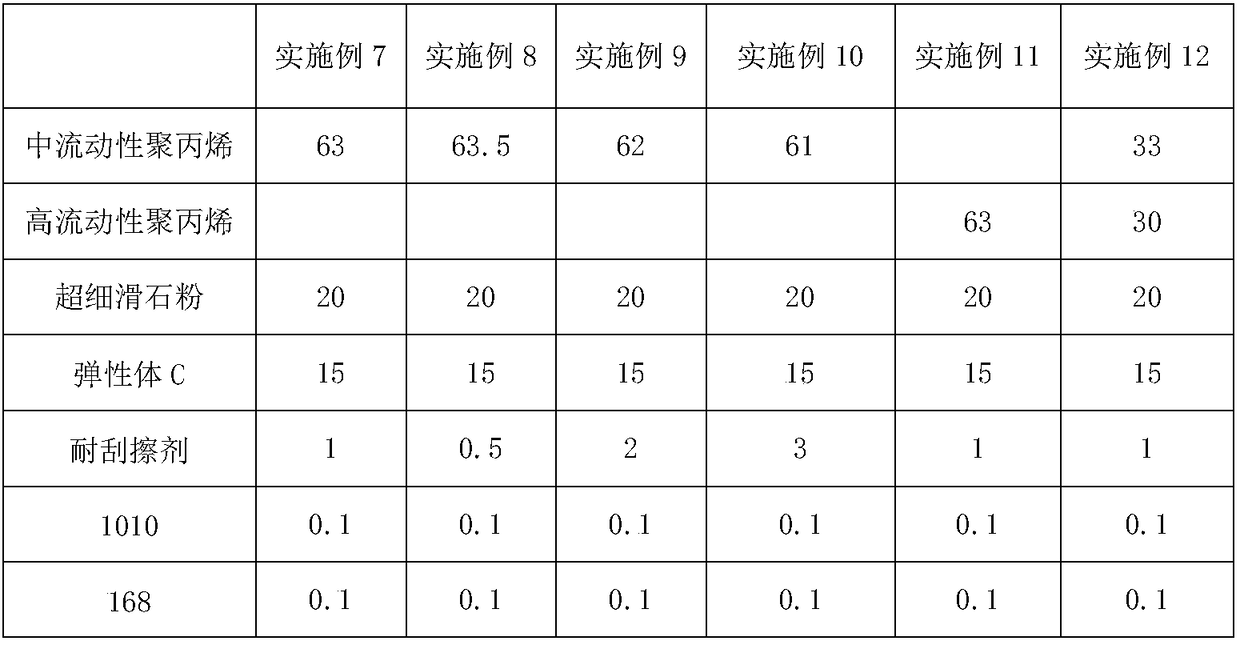

High-performance polypropylene composite material for vehicle seamless airbag instrument board, and preparation method thereof

InactiveCN108546385AImprove mechanical propertiesImprove low temperature toughnessInorganic fillerLow emission

The invention discloses a high-performance polypropylene composite material for a vehicle seamless airbag instrument board, and a preparation method thereof, wherein the high-performance polypropylenecomposite material comprises the following raw materials by weight: 45-74%of polypropylene, 15-25% of an ultrafine inorganic filler, 10-20% of an elastomer toughening agent, 0.5-3% of a scratch-resistant aid, 0.1-2% of a stabilizer, and 0-5% of other additives. According to the present invention, through the synergistic action of the ultrafine inorganic filler and the special-structure elastomertoughening agent, the optimal balance between the rigidity and the ultrahigh toughness can be obtained, and the product integrates low-temperature impact resistance and heat deformation resistance, further has good scratch resistance, no sticking, low emission, continuous-illumination resistance, long-term heat resistance and the like, further has excellent processing property, and is suitable forvehicle hard plastic seamless airbag instrument boards and related components.

Owner:SHANGHAI PRET COMPOSITES +5

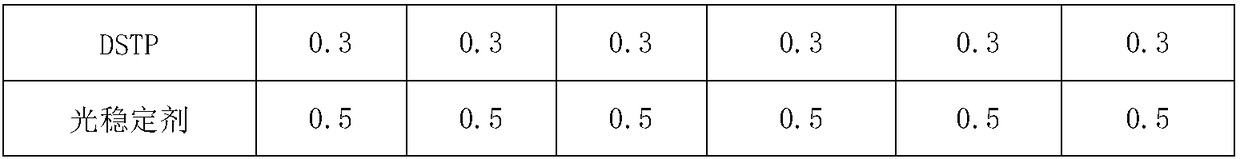

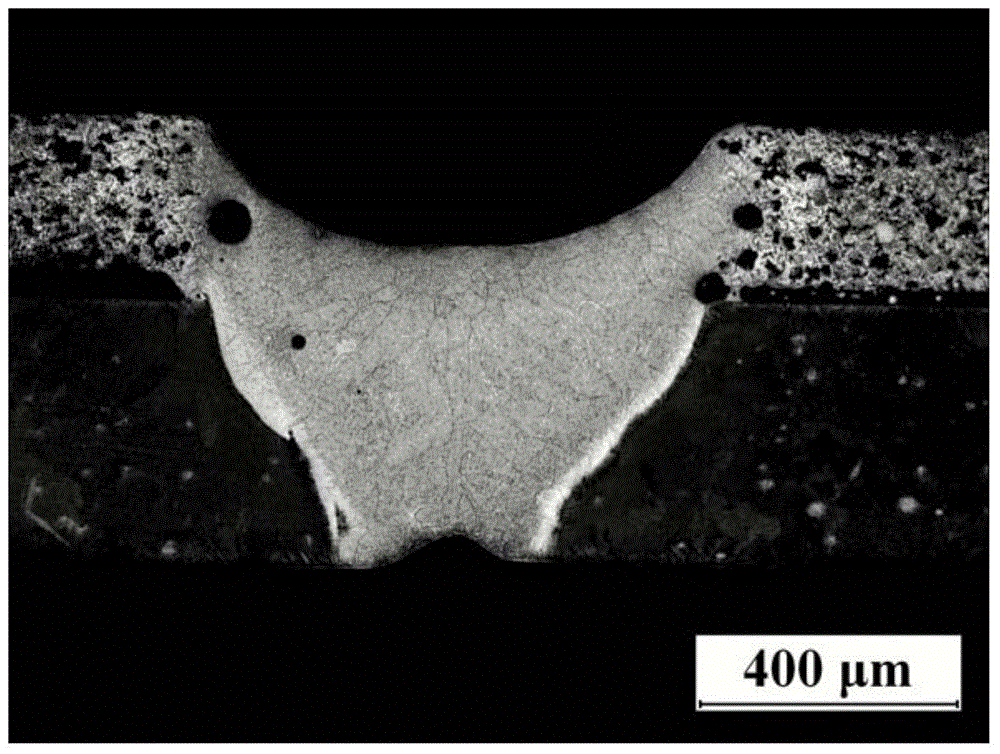

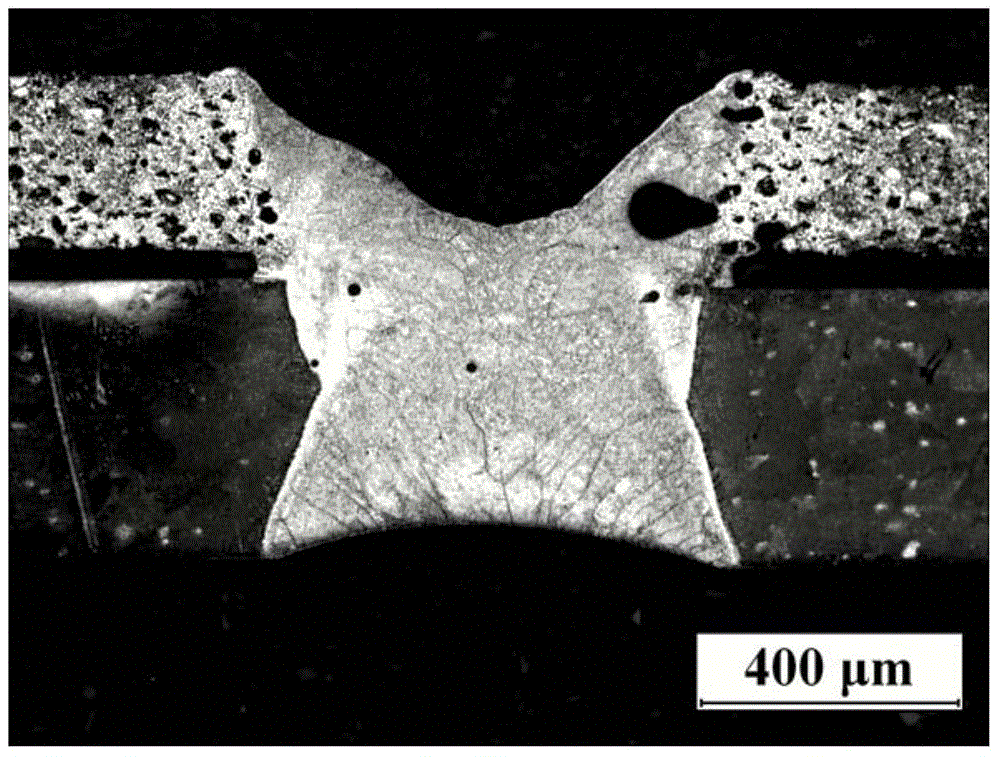

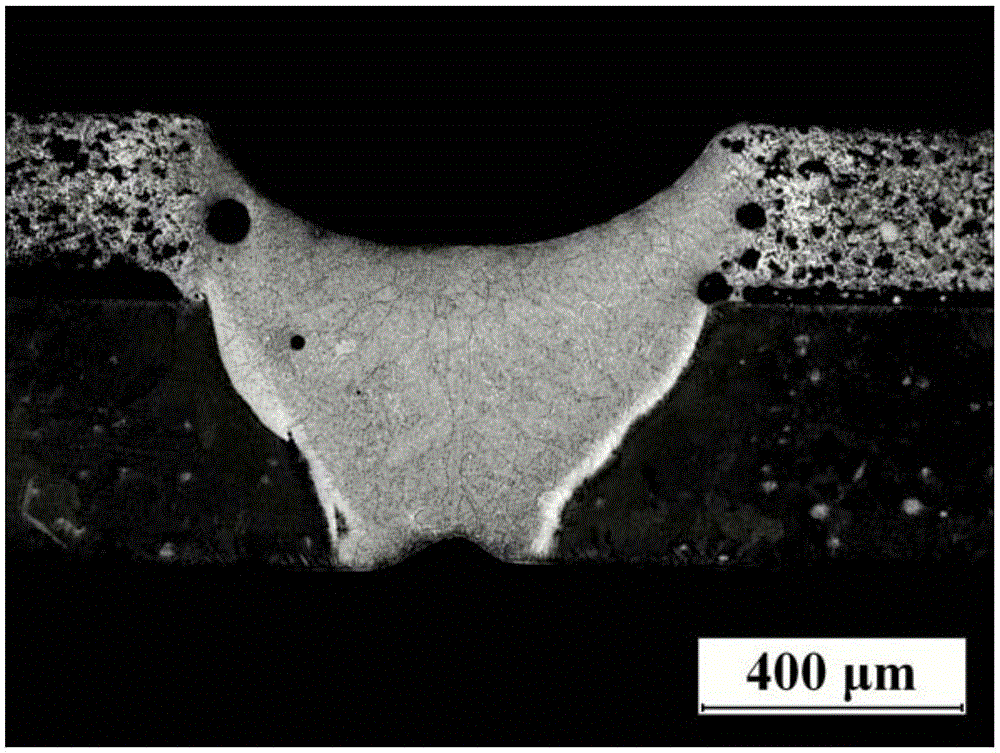

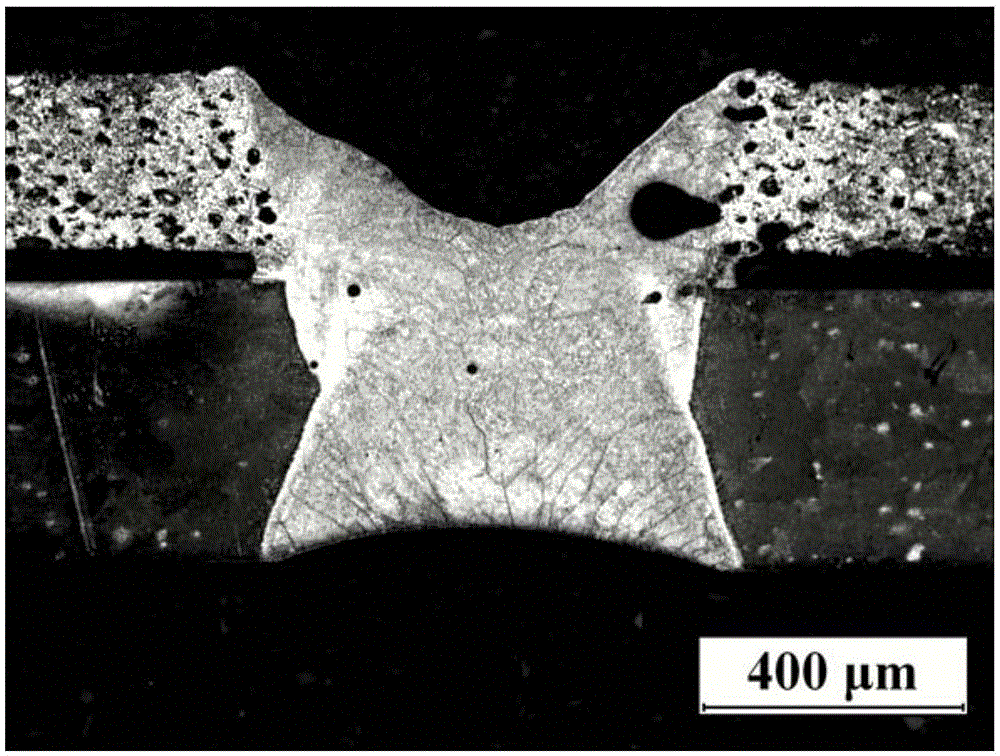

High-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding

ActiveCN103978309AControl thermal deformationControlling the heat-affected zoneWelding/soldering/cutting articlesMetal working apparatusHeat-affected zoneWeld seam

A high-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding is characterized in that a reflection cushion plate is added on the back of the laser welding sheet metal to utilize the reflection cushion plate to reflect instantaneous laser of laser full penetration sheet metal back to a welding area to conduct secondary heating on the welding area to further achieve a double-side forming hourglass-shaped (X-shaped) welding seam through single-side welding. The method is mainly composed of steps of cleaning the surface to be welded, fixing the reflection cushion plate, conducting laser welding on the sheet metal and the like. The method achieves the aim that the single-side welding is conducted on the sheet metal to achieve double-side forming under the low heat input condition, breaks through the defect that the existing sheet laser deep penetration welding can obtain the hourglass-shaped (X-shaped) welding seam only under the high heat input condition, achieves double effects of considering welding seam dynamic performance and controlling heat deformation and heat effects of the sheet and lays a foundation for promotion of wide application of a laser deep penetration welding technology in the sheet metal welding field.

Owner:佛山市金晓宝净化彩板有限公司

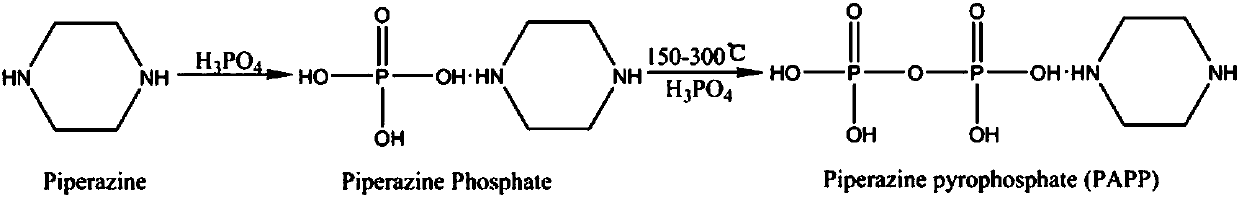

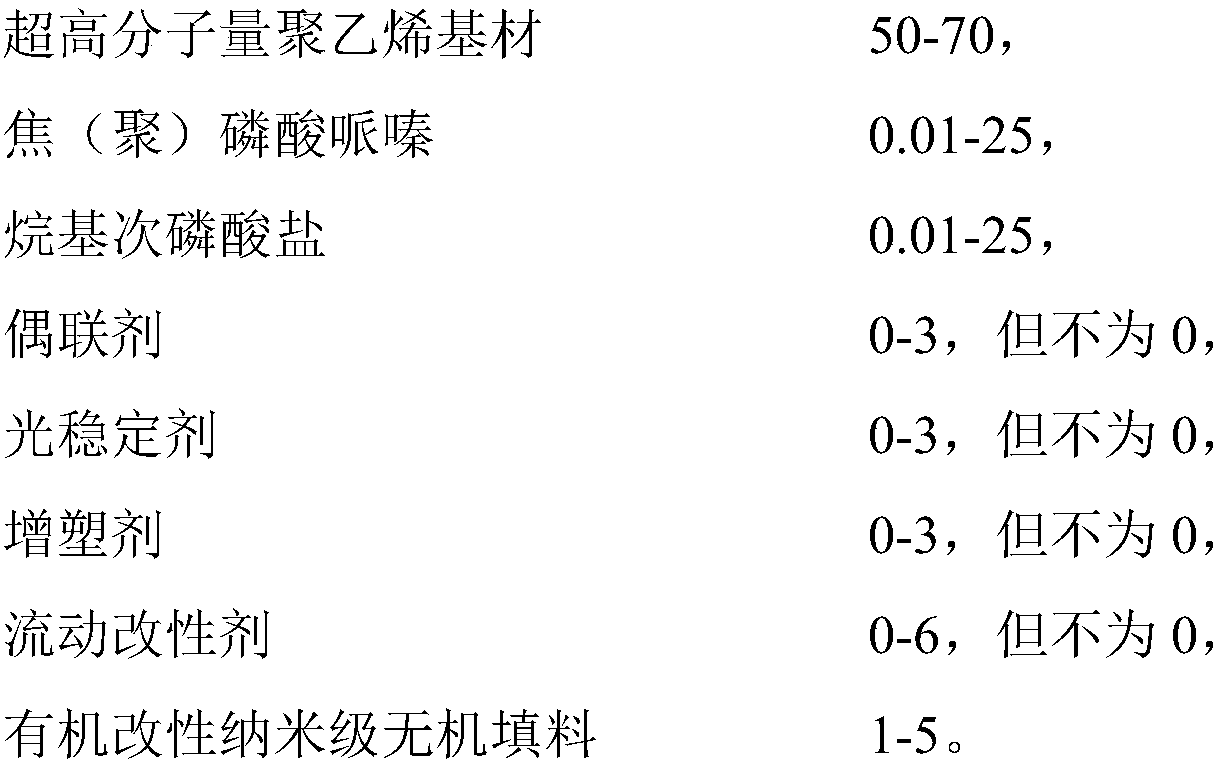

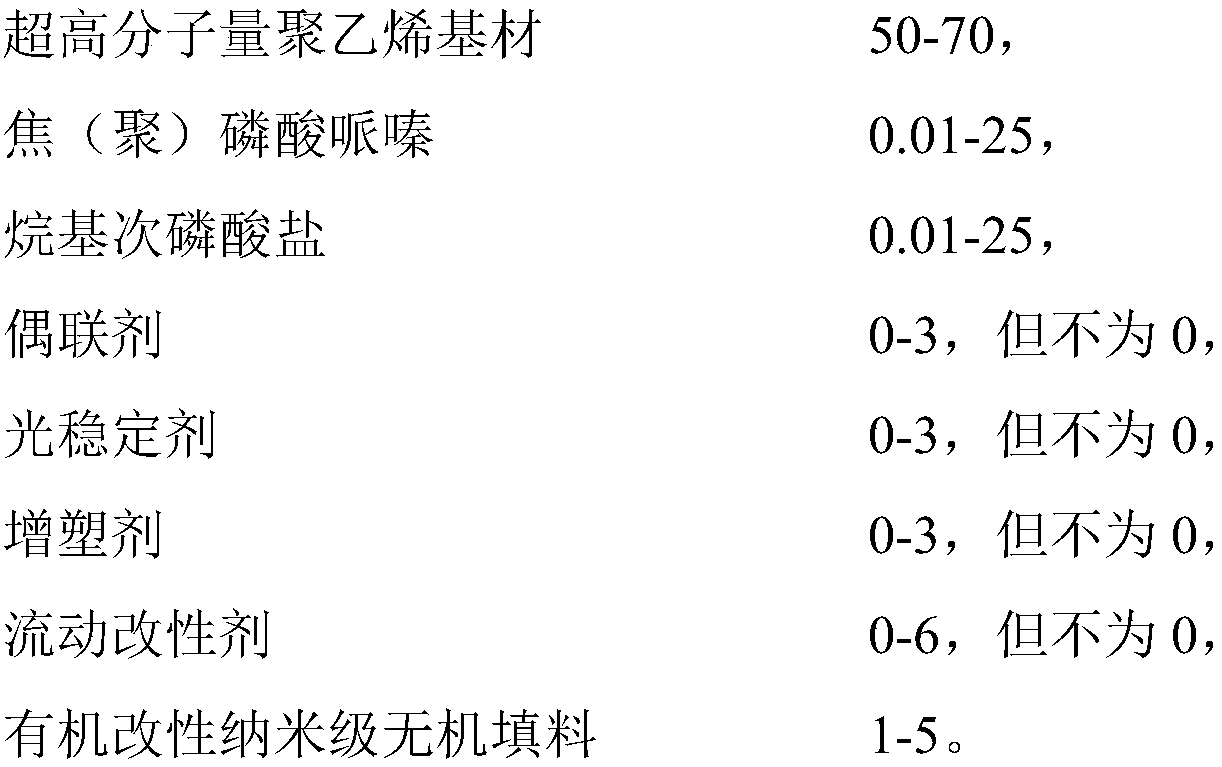

Halogen-free flame-retarding ultrahigh-molecular weight polyethylene material and preparation method of same

The invention relates to a halogen-free flame-retarding ultrahigh-molecular weight polyethylene material and a preparation method of same. The material is prepared from: 50-70 parts of a ultrahigh-molecular weight polyethylene base material, 0.01-25 parts of piperazine (poly) pyrophosphate, 0.01-25 parts of alkyl hypophosphite, 0-3 (not equal to 0) parts of a coupling agent, 0-3 (not equal to 0) parts of a photo-stabilizer, 0-3 (not equal to 0) parts of a plasticizer, 0-6 (not equal to 0) parts of a flow modifier, and 1-5 parts of an organically modified nano inorganic filler. The flame-retarding ultrahigh-molecular weight polyethylene material is free of halogens and has good flame-retarding effect reaching UL94 V-0 grade, and also has excellent mechanical performance.

Owner:SHANGHAI RES INST OF CHEM IND

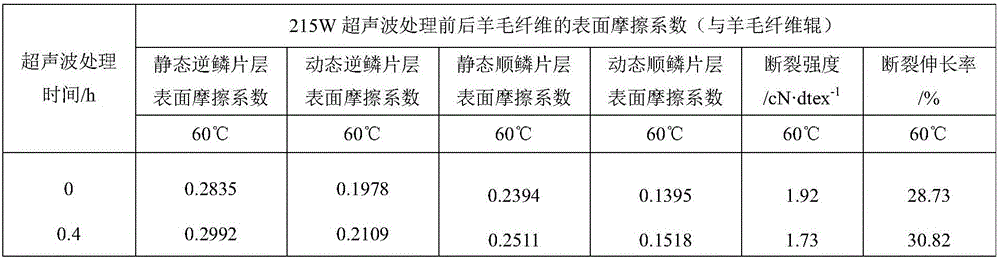

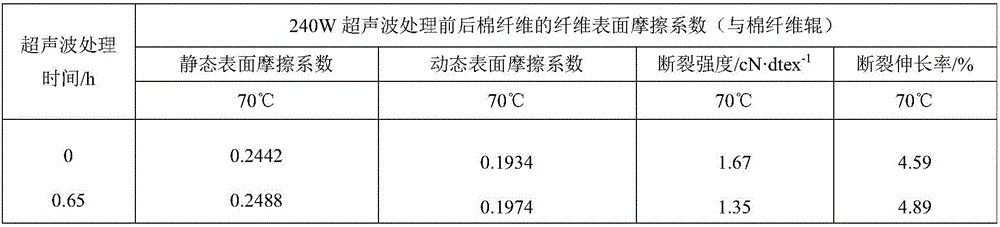

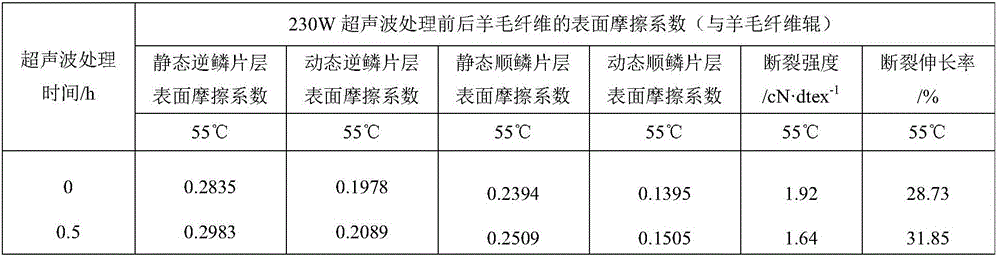

Spinning process for improving cohesive force between cotton-wool blended yarn fibers

InactiveCN105671718AImprove mechanical propertiesIncreased coefficient of friction on the fiber surfaceUltrasonic/sonic fibre treatmentYarnCotton fibreYarn

The invention discloses a spinning process for improving cohesive force between cotton-wool blended yarn fibers. The spinning process comprises the following steps: S1, placing wool fibers in an environment with the temperature of 55 to 65 DEG C and the ultrasonic power of 200 to 230 W for ultrasonic treatment; and placing cotton fibers into an environment with the temperature of 60 to 80 DEG C and the ultrasonic power of 230 to 250 W for ultrasonic treatment; S2, respectively performing cotton opening, cotton carding and drawing procedures on the wool fibers and the cotton fibers which are subjected to ultrasonic treatment in S1; and S3, performing mixed drawing, roving, spinning and spooling procedures on the wool fibers and the cotton fibers which are drawn in S2, to obtain cotton-wool blended yarns. The cohesive force between the cotton fibers and the wool fibers in the finally prepared cotton-wool blended yarn is perfect, and the mechanical property of the cotton-wool blended yarn is excellent.

Owner:佛山市顺德区德俊纺织有限公司

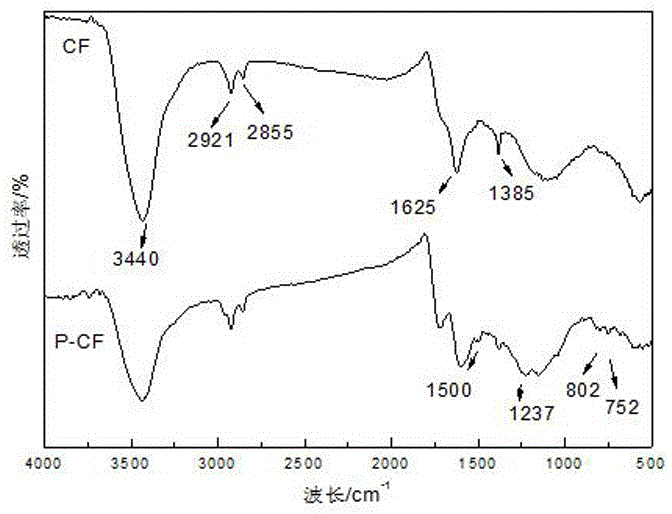

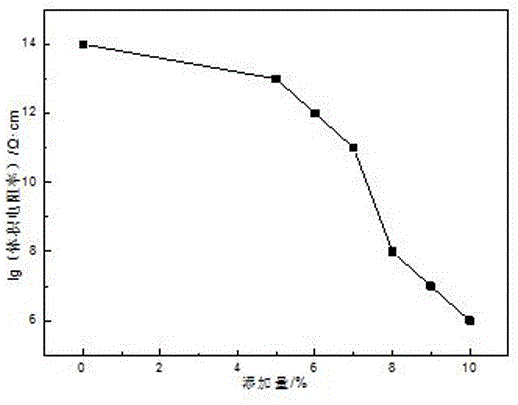

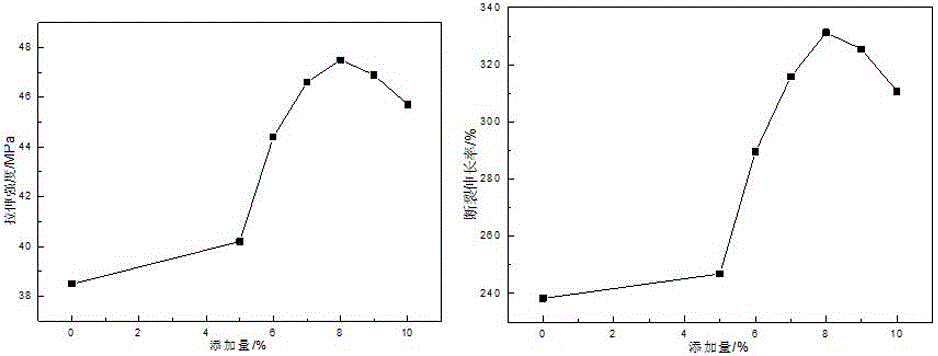

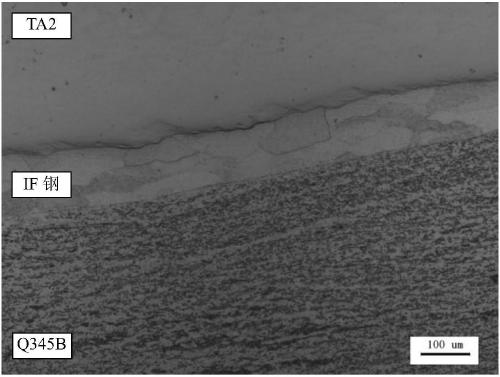

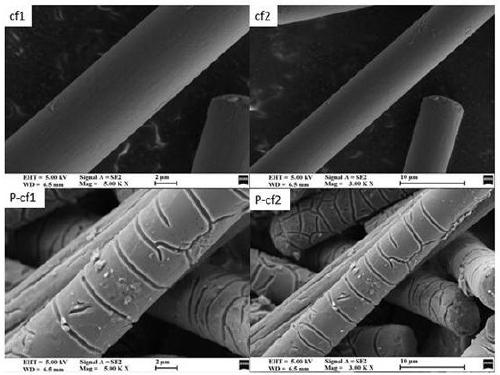

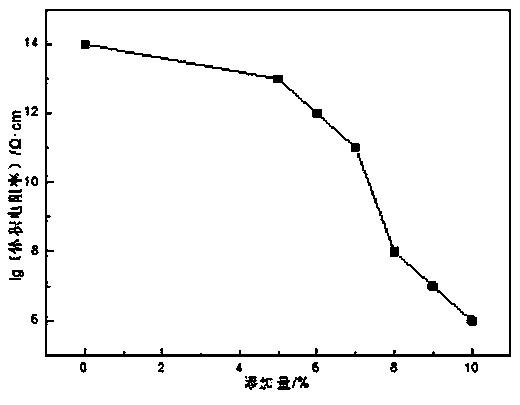

Antistatic EVA foamed composite and preparation method thereof

The invention discloses an antistatic EVA foamed composite and a preparation method thereof. First, a surface active agent is adopted for improving the surfaces of carbon fibers, then aniline is loaded on the carbon fibers in an in-situ polymerization mode, and modified carbon fibers are formed; crystalline flake graphite and the modified carbon fibers are mixed according to the mass ratio of 1:1-5:1 to form an antistatic agent, and then the antistatic agent and an EVA substrate are subjected to melt blending and cross-linking foaming to prepare the antistatic EVA foamed composite. The prepared EVA foamed composite has a good antistatic property, and compared with a pure EVA foamed material, the volume resistivity of the EVA foamed composite is lowered by about seven orders of magnitudes; moreover, due to introduction of the carbon fibers, the tensile strength and elongation at break are also improved, and the antistatic EVA foamed composite is especially suitable for protective packaging of some sensitive elements and military instruments and has extensive social and economic benefits.

Owner:FUZHOU UNIV

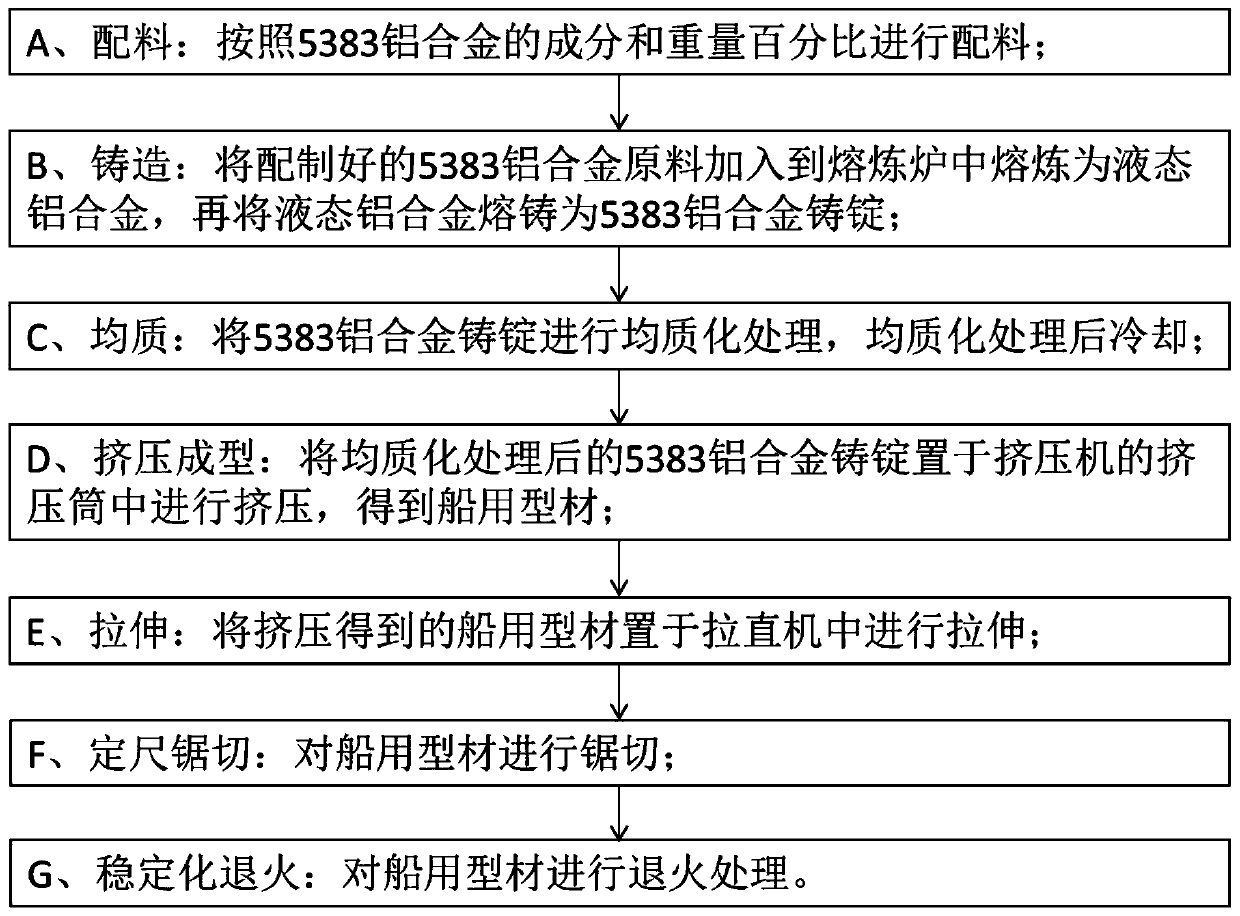

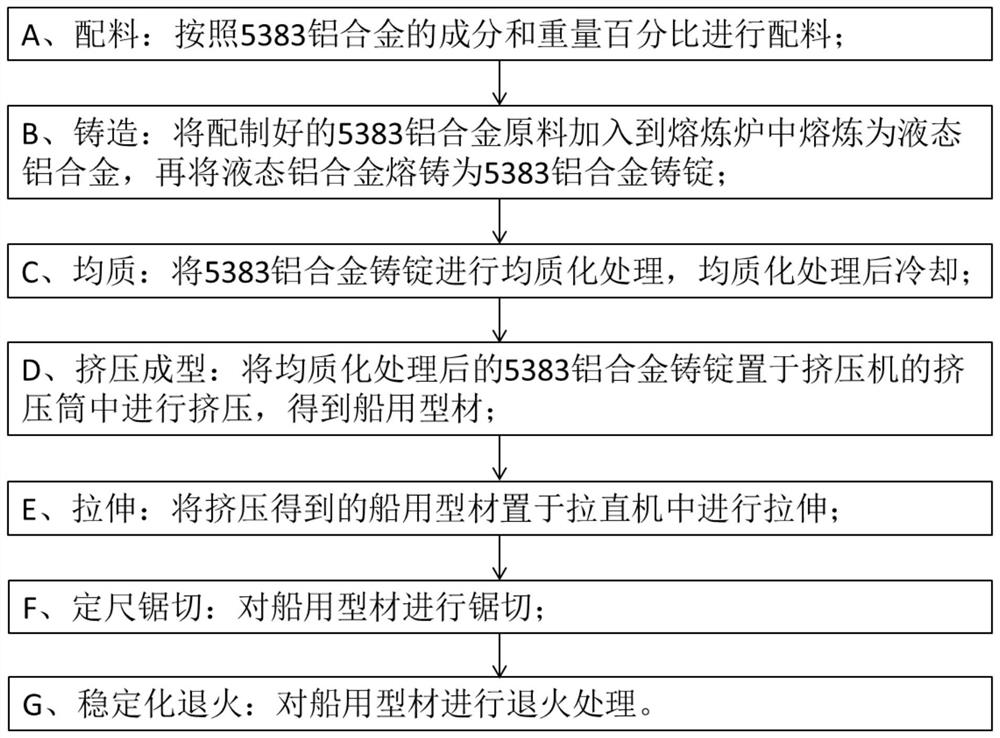

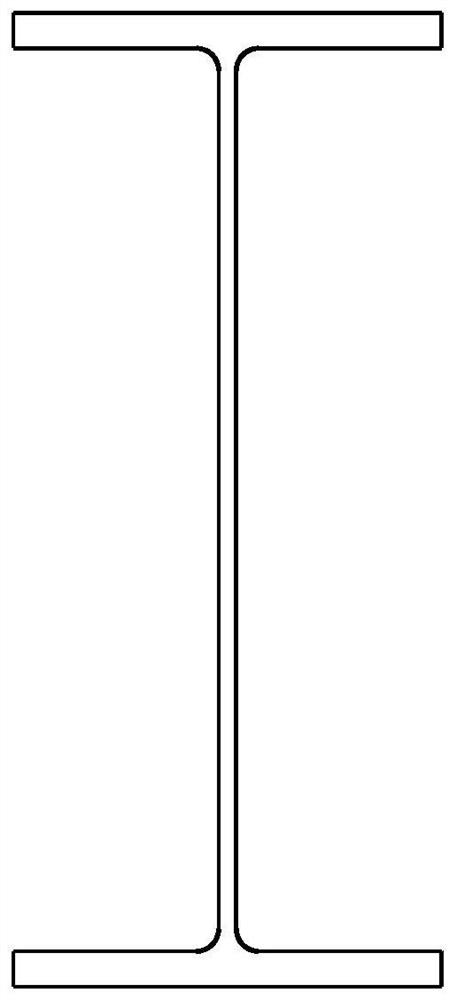

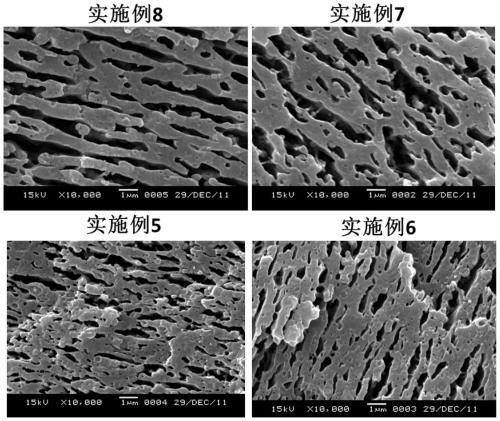

High-strength corrosion-resistant 5383 aluminum alloy and preparation process of marine sectional material

ActiveCN111549264AImprove structural strengthHigh dimensional accuracyUltimate tensile strengthMechanical property

The invention discloses a high-strength corrosion-resistant 5383 aluminum alloy and a preparation process of a marine sectional material. The 5383 aluminum alloy has the advantages of high structuralstrength, good corrosion resistance and good machinable formability, and the mechanical property, the corrosion resistance and the production cost are taken into consideration; moreover, the preparation process is simple, the produced sectional material is controllable in size and low in reject ratio, the sectional material has higher dimensional precision, the yield strength can reach 220 MPa orabove and is improved by 10% or above compared with an existing 5383 aluminum alloy sectional material, the strength of the sectional material is greatly improved, meanwhile, the production efficiencyis high, the material is high in corrosion resistance, and therefore the marine high-strength aluminum alloy extruded sectional material with high strength and corrosion resistance is obtained.

Owner:中铝特种铝材(重庆)有限公司

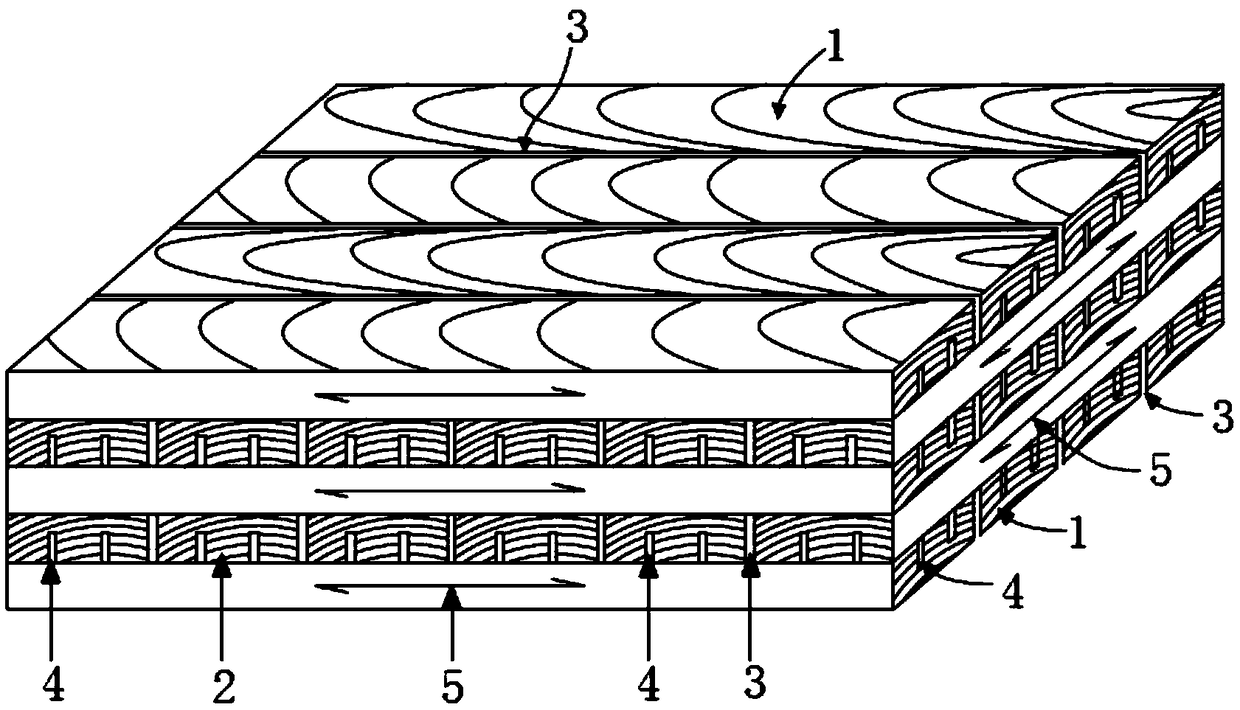

Cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and preparation method thereof

PendingCN109434975AImprove mechanical propertiesImprove fire resistanceLaminationLamination apparatusMechanical propertyAdverse effect

The invention discloses cross laminated timber combining fast growing timber material characteristics and meeting building structure requirements and a preparation method thereof, and belongs to the field of timber structures. A laminated board of the cross laminated timber comprises a fast growing timber laminated board with cracks, the fast growing timber laminated board is a whole cracked board, and lengths of all laminated boards of the cross laminated timber are consistent in the horizontal direction. In the preparation method, adjacent layers formed by the fast growing timber laminated board or fast growing timber laminated board combination are assembled and configured in a manner that wood textures are perpendicular to each other in the thickness direction of laminated wood. According to the cross laminated timber combining the fast growing timber material characteristics and meeting the building structure requirements and the preparation method thereof, the material characteristics that the fast growing timber is soft in material and prone to be made into the laminated board with the cracks in a rotary cutting mode are fully utilized, structural stock lumber is replaced for preparing the cross laminated timber, the utilization of the fast growing timber in the field of building structures is expanded, the material cost of a conventional component is greatly reduced, the component preparation process is simplified, the production period is shortened, and the problem that adverse effects on the mechanical property, durability and fireproof performance of the component are caused through gaps in laminated boards of a structural material cross laminated timber component is solved.

Owner:NANJING UNIV OF TECH

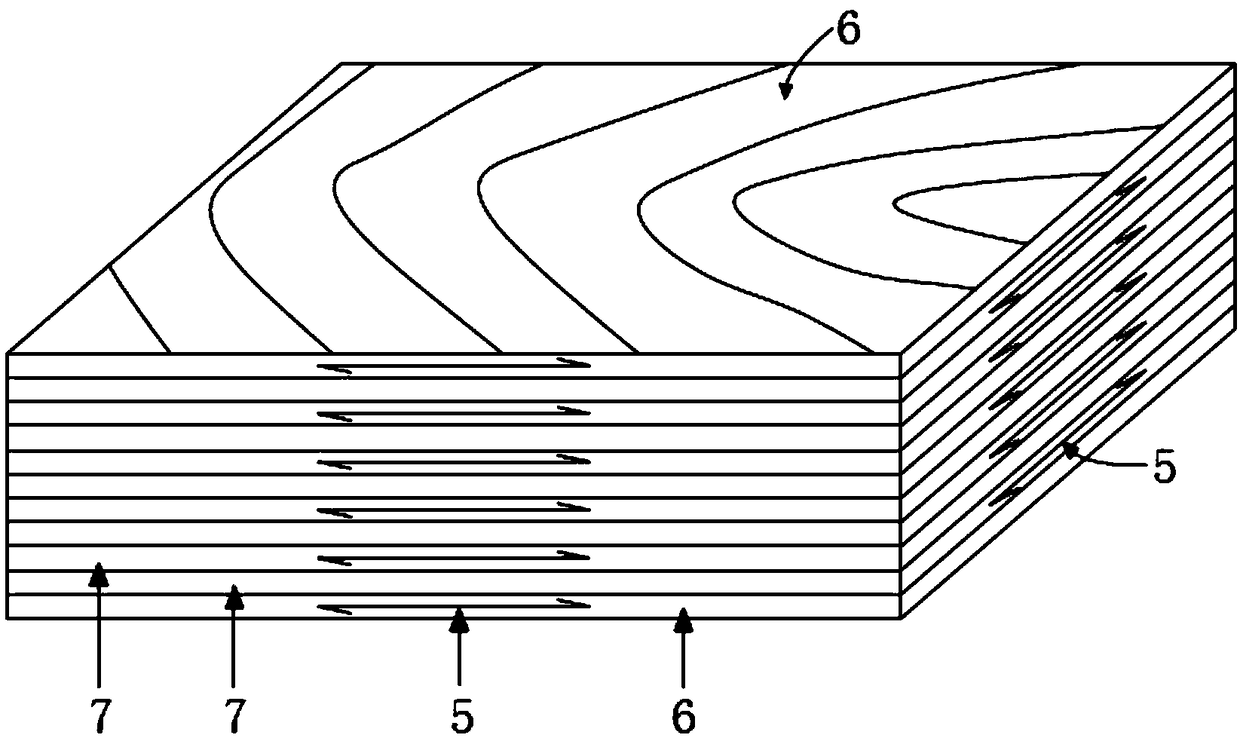

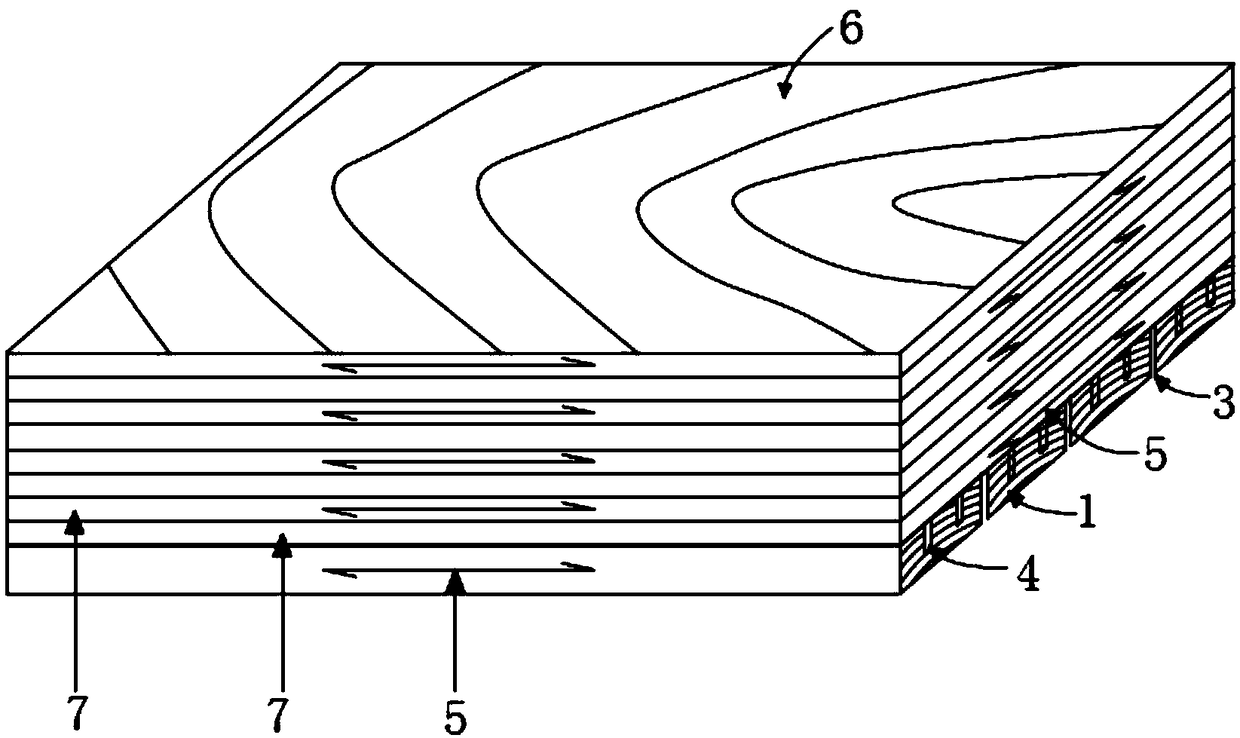

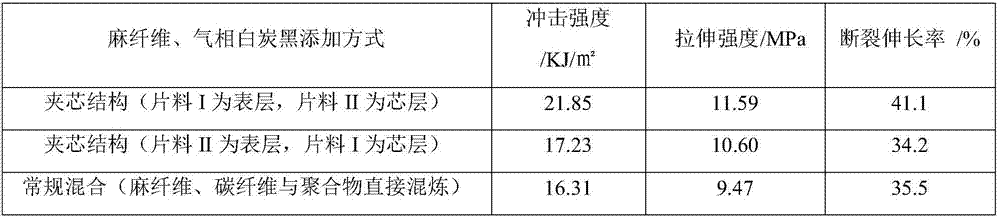

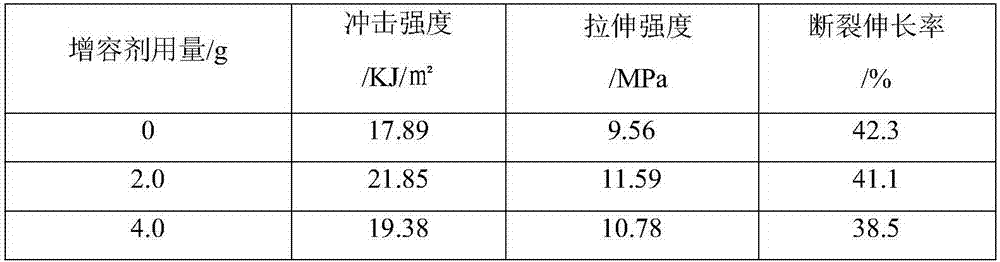

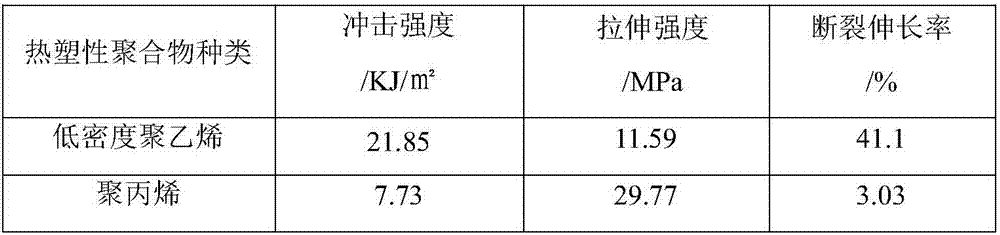

Chopped ramie fiber/carbon fiber/thermoplastic polymer composite plate

ActiveCN107310216AComposite goodProminent sandwich structureSynthetic resin layered productsLaminationCarbon fibersSurface layer

The invention discloses a chopped ramie fiber / carbon fiber / thermoplastic polymer composite plate. The composite plate is of a sandwich structure and manufactured by thermally pressing an upper surface layer, a lower surface layer and an intermediate core layer, wherein the upper surface layer and the lower surface layer are chopped ramie fiber / thermoplastic polymer sheets; and the intermediate core layer is a chopped carbon fiber / thermoplastic polymer sheet. According to the chopped ramie fiber / carbon fiber / thermoplastic polymer composite plate, the ramie fiber and the carbon fiber are correspondingly mixed with half amount of thermoplastic polymer to form sheets, and then the sheets are overlapped and pressed to form a special sandwich structure, so that the problem of difficulty in mixing of the thermoplastic polymer and plant fiber and the carbon fiber can be effectively solved; and the plant fiber and the carbon fiber can be uniformly dispersed in the thermoplastic polymer, and thus the performances of the composite material can be improved. The chopped ramie fiber / carbon fiber / thermoplastic polymer composite plate has the characteristics of being simple in technical processes, and simple to operate. The prepared chopped fiber / thermoplastic polymer composite plate integrates a plurality of advantages of the carbon fiber, the plant fiber and the thermoplastic fiber, and is outstanding in mechanical property, recoverable, and degradable; and the preparation method is simple to operate.

Owner:CHONGQING UNIV OF TECH

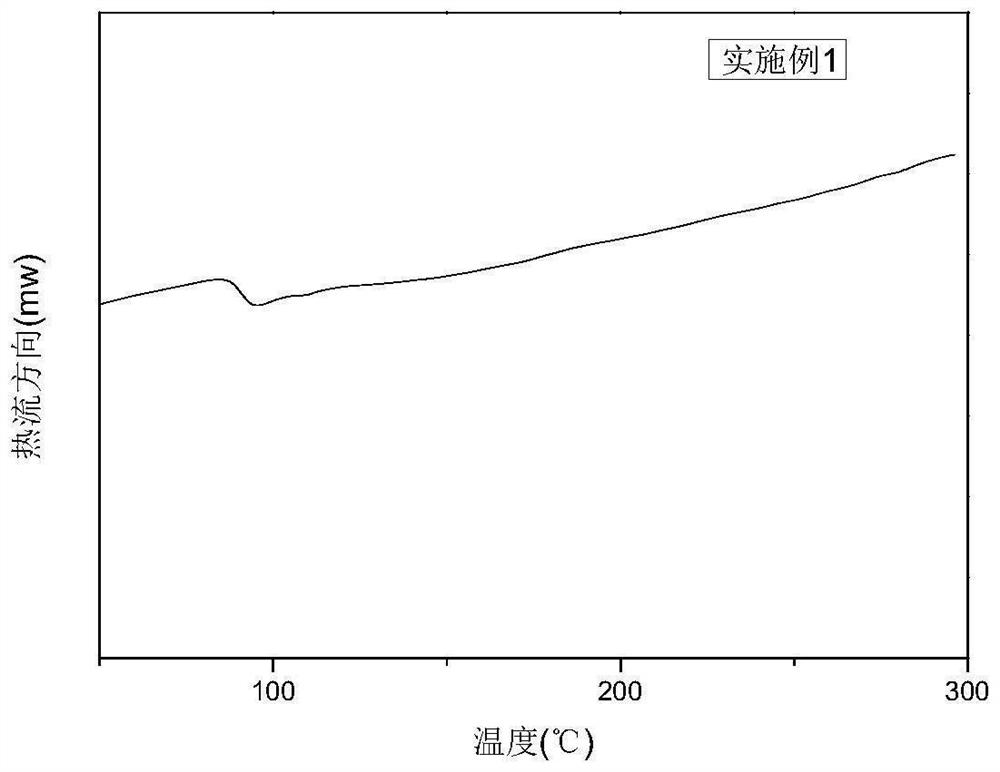

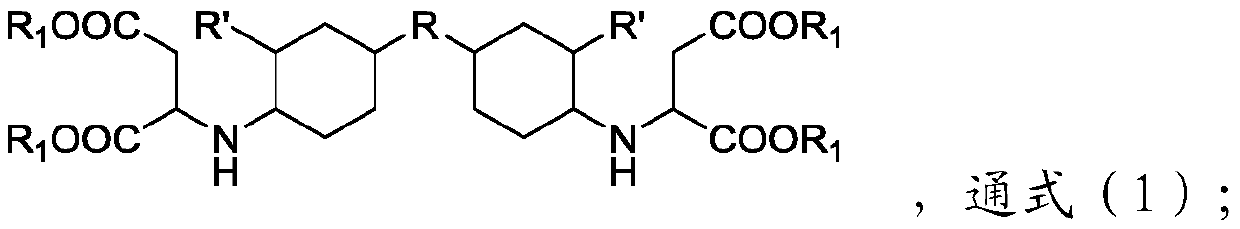

Degradable modified polyester with high heat resistance and good mechanical properties and preparation method thereof

The invention discloses degradable modified polyester with high heat resistance and good mechanical properties and a preparation method thereof, and belongs to the technical field of polyester material preparation. The structural general formula of the degradable modified polyester is as follows. The preparation method of the degradable modified polyester comprises the steps of raw material pulping, esterification under pressure, condensation polymerization, granulation, drying and the like. By introducing bio-based rigid dihydric alcohol and straight-chain aliphatic bio-based dihydric alcoholand regulating the ratio of the bio-based rigid dihydric alcohol to the straight-chain aliphatic bio-based dihydric alcohol, the heat resistance of the polyester is improved, the mechanical propertyis considered, and the polyester also has degradability.

Owner:JILIN UNIV

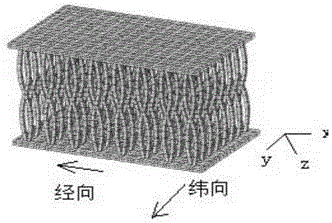

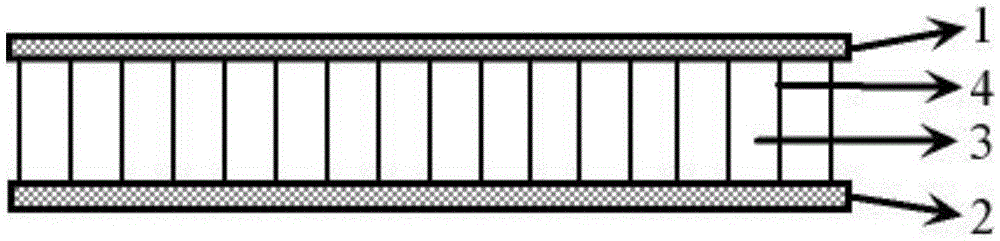

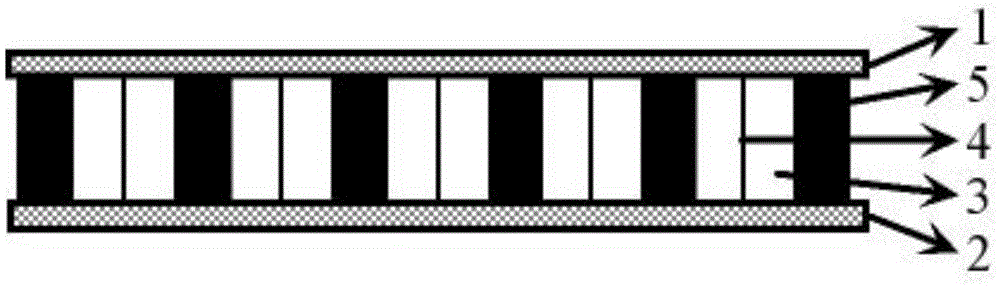

High-compression-resistance three-dimensional hollow composite floor and manufacturing method thereof

InactiveCN105544926ATaking into account the mechanical propertiesAchieve weight lossFlooringGlass fiberHoneycomb

The invention discloses a high-compression-resistance three-dimensional hollow composite floor and a manufacturing method thereof and aims at solving the technical problems that in the prior art which is mentioned in the background technology, a three-dimensional hollow composite floor is low in compressive strength, compression resistance of a composite material is improved to a certain extent by increasing the pile warp density only through structural design of a three-dimensional hollow fabric, but the preparation process of the hollow fabric can be caused difficult by pile warp densification, the pile warp densification range is limited, and the requirements are still hard to satisfy. According to the technical scheme, the high-compression-resistance three-dimensional hollow composite floor comprises a three-dimensional hollow fabric constituting the overall frame of the three-dimensional hollow composite floor and one or more intermediate reinforcing ribs which are arranged in gaps in a pile warp structural layer of the three-dimensional hollow fabric. The high-compression-resistance three-dimensional hollow composite floor has the advantages that the special structure of the floor integrates mechanical performance, in particular to compressive strength, of traditional solid glass fiber reinforced plastic and that of carbon steel, and the weight reduction effect is achieved for a three-dimensional composite board, foam and a honeycomb sandwich composite material.

Owner:SINOMA SCI & TECH

Double-sided titanium steel composite plate using IF steel as transition layer, and preparation method thereof

ActiveCN109693433AImprove corrosion resistanceImprove adaptabilityLamination ancillary operationsLaminationThermal insulationPipe fitting

The invention discloses a double-sided titanium steel composite plate using IF steel as a transition layer, and a preparation method thereof. According to the present invention, the composite billet for manufacturing a composite plate comprises IF steel, a titanium composite material and a base material, wherein the base material is common carbon steel or low alloy steel with a C content of less than or equal to 0.22%, the titanium composite material is industrial pure titanium TA2, a thickness ratio of the base material to the titanium composite material is 5-10, the length and the width of the titanium composite material are smaller than the length and the width of the base material, and the distance between the titanium composite material and the four edges of the base material is 60-100 mm; the composite billet after sealing welding treatment is heated to a temperature of 900-920 DEG C, a thermal insulation time is 1 min / mm*the total thickness of the composite billet, the rolling starting temperature is 880-900 DEG C, the rolling finishing temperature is more than or equal to 800 DEG C, the single-pass reduction is 15-20%, and the total reduction is more than or equal to 70%; the thickness of the transition layer of the IF steel after rolling is 180-220 [mu]m; the thickness of the produced double-sided titanium steel composite plate is 6-45 mm; and the product is suitable for pipelines for chlor-alkali, soda ash, petrochemical industry, salt production and seawater desalination, and offshore oil drilling and pipe fittings.

Owner:ANGANG STEEL CO LTD

High-performance double-sided titanium steel clad plate taking IF steel as transition layer, and preparation method thereof

InactiveCN109693075AImprove and enhance bond qualityImprove and enhance binding propertiesMetal layered productsComposite plateMechanical property

The invention discloses a high-performance double-sided titanium steel clad plate taking IF steel as a transition layer, and a preparation method thereof. A composite blank for manufacturing the cladplate includes IF steel, a titanium composite and a base material; the base material is plain carbon steel or low alloy steel with C being less than or equal to 0.22%; the titanium composite is industrial pure titanium TA2, the thickness ratio of the base material to the composite is 5-10, the length and width of the titanium composite are less than that of the base material, and the edge distances of the titanium composite from the four edges of the base material are 60-100 mm; the composite blank after seal welding can be heated to 900-920 DEG C to perform heat preservation, the heat preservation time is 1 min / mm * the total thickness of the composite blank, an initial rolling temperature is 880-900 DEG C, a finish rolling temperature is greater than or equal to 800 DEG C, air cooling can be performed to room temperature, a single pass reduction rate is greater than or equal to 15%, the first three pass reduction rates are greater than or equal to 20%, and the total reduction rate isgreater than or equal to 75%; and the thickness of the produced clad plate is 6-45 mm, and the thickness of an IF steel transition layer is 80-120 [mu]m. Thus, the clad plate is suitable for structures which have corrosion resistance requirements for inner and outer surfaces and consider integral mechanical properties.

Owner:ANGANG STEEL CO LTD

Cellulose-graphene porous composite aerogel and preparation method thereof

ActiveCN113621167ASolve the problem of fragmentationTaking into account the mechanical propertiesAerogel preparationColloidal chemistry detailsCelluloseFreeze-drying

The invention belongs to the technical field of composite materials, and particularly relates to cellulose-graphene porous composite aerogel and a preparation method thereof. The product is prepared by the steps of: sequentially taking 80-100 parts by weight of cellulose, 0.5-1.5 parts by weight of graphene oxide with the particle size distribution range of 5-20 nm and 2-5 parts by weight of reduced graphene with the particle size distribution range of 100-500; dissolving the cellulose in an ionic liquid to obtain an ionic liquid solution of cellulose; adding the graphene oxide and the reduced graphene into the ionic liquid solution of cellulose, ultrasonically dispersing well, and dialyzing by using deionized water to remove the ionic liquid, so as to obtain composite hydrogel; and freeze-drying the obtained composite hydrogel to obtain the product. In the obtained product, the graphene material is uniformly dispersed, and a relatively good reinforcing effect can be achieved through a relatively small addition amount.

Owner:吴玉晓 +1

A kind of antistatic eva foam composite material and preparation method thereof

The invention discloses an antistatic EVA foamed composite and a preparation method thereof. First, a surface active agent is adopted for improving the surfaces of carbon fibers, then aniline is loaded on the carbon fibers in an in-situ polymerization mode, and modified carbon fibers are formed; crystalline flake graphite and the modified carbon fibers are mixed according to the mass ratio of 1:1-5:1 to form an antistatic agent, and then the antistatic agent and an EVA substrate are subjected to melt blending and cross-linking foaming to prepare the antistatic EVA foamed composite. The prepared EVA foamed composite has a good antistatic property, and compared with a pure EVA foamed material, the volume resistivity of the EVA foamed composite is lowered by about seven orders of magnitudes; moreover, due to introduction of the carbon fibers, the tensile strength and elongation at break are also improved, and the antistatic EVA foamed composite is especially suitable for protective packaging of some sensitive elements and military instruments and has extensive social and economic benefits.

Owner:FUZHOU UNIV

High-efficiency laser deep penetration welding method for single-sided welding and double-sided forming of metal sheets

ActiveCN103978309BControl thermal deformationTaking into account the mechanical propertiesWelding/soldering/cutting articlesMetal working apparatusHeat-affected zoneEngineering

A high-efficiency laser deep penetration welding method for achieving double-side forming of sheet metal through single-side welding is characterized in that a reflection cushion plate is added on the back of the laser welding sheet metal to utilize the reflection cushion plate to reflect instantaneous laser of laser full penetration sheet metal back to a welding area to conduct secondary heating on the welding area to further achieve a double-side forming hourglass-shaped (X-shaped) welding seam through single-side welding. The method is mainly composed of steps of cleaning the surface to be welded, fixing the reflection cushion plate, conducting laser welding on the sheet metal and the like. The method achieves the aim that the single-side welding is conducted on the sheet metal to achieve double-side forming under the low heat input condition, breaks through the defect that the existing sheet laser deep penetration welding can obtain the hourglass-shaped (X-shaped) welding seam only under the high heat input condition, achieves double effects of considering welding seam dynamic performance and controlling heat deformation and heat effects of the sheet and lays a foundation for promotion of wide application of a laser deep penetration welding technology in the sheet metal welding field.

Owner:佛山市金晓宝净化彩板有限公司

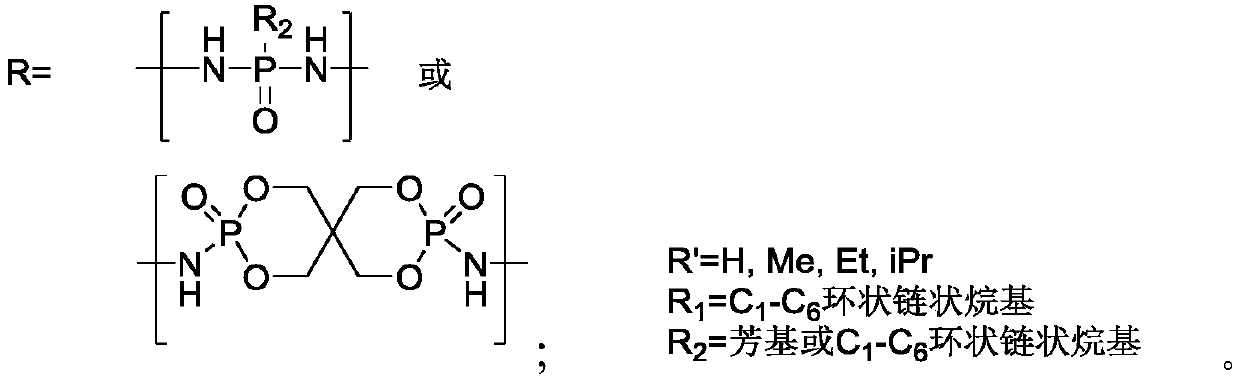

Flame-retardant polyurea and synthesis method thereof

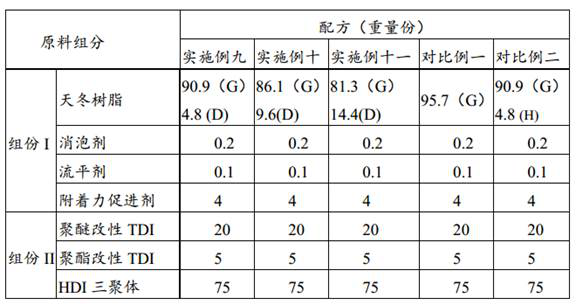

ActiveCN111349234ATaking into account the mechanical propertiesThe synthesis method is simpleFireproof paintsPolyureas/polyurethane adhesivesChemistryComposite material

The invention discloses flame-retardant polyurea and a synthesis method thereof, and relates to the technical field of polyurea materials. According to the flame-retardant polyurea provided by the invention, phosphoryl groups are introduced into a molecular structure, and the aspartic polyurea resin with flame retardance is constructed on the basis of original performance. Experiments prove that compared with traditional aspartic polyurea resin, the flame-retardant polyurea provided by the invention has more excellent flame retardancy, can be matched with the traditional aspartic polyurea resin together to prepare a coating, gives consideration to the mechanical properties of the traditional aspartic polyurea resin, enhances the excellent flame retardancy, greatly widens the application ofthe polyurea resin, and has market value.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

A kind of anti-yellowing reinforced nylon 66 material and preparation method thereof

The invention provides an anti-yellowing reinforced nylon 66 material and a preparation method thereof. The preparation method comprises steps as follows: functional monomers and phosphate heat stabilizers are dispersed in coupling agents, ethanol is added for dilution and alcoholysis, and PH value of a slurry is adjusted to be 3.2-3.8; glass fiber is soaked in the prepared slurry and dried, and processed glass fiber is obtained; nylon 66, long-carbon-chain nylon and antioxidants are evenly mixed by a high-speed mixer and added from a main feeding port of a twin-screw extruder, the processed glass fiber is added from a side feeding port and subjected to extrusion, bracing and pelletizing, and the anti-yellowing reinforced nylon 66 material is obtained. The anti-yellowing performance of the prepared material is far higher than that of other ordinary reinforced materials.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

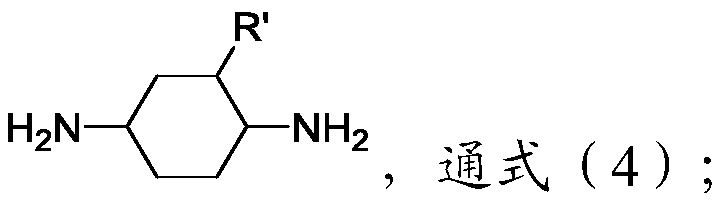

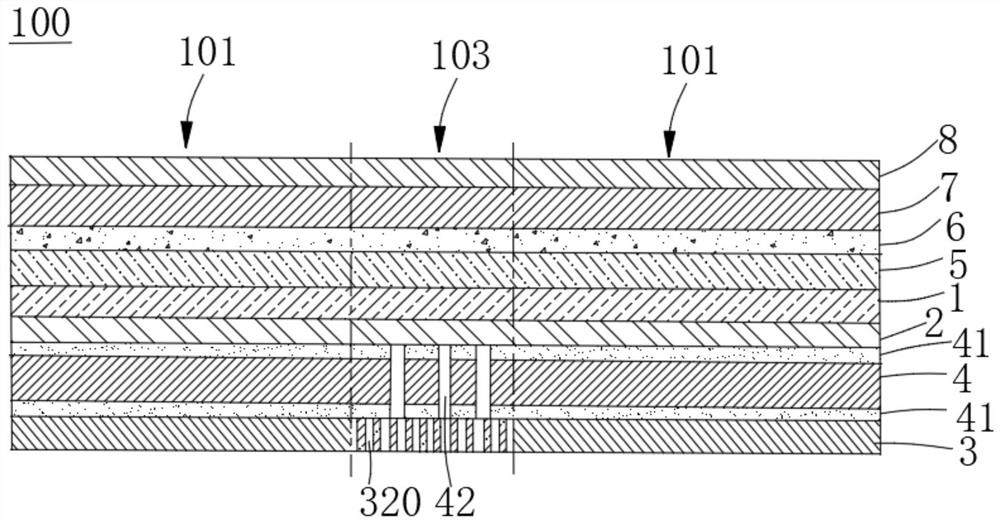

Flexible display screen

The invention provides a flexible display screen, which comprises a non-folding area and a folding area, and further comprises a display panel, the back plate is attached to the backlight surface of the display panel; the supporting component is located on the side, away from the display panel, of the back plate; the buffering material is located on the surface, facing the back plate, of the supporting component, the buffering material is made of at least one of foam, rubber, silica gel and plastic, and the density of the buffering material ranges from 0.8 g / cm < 3 > to 1.2 g / cm < 3 >. According to the flexible display screen provided by the invention, the buffer material with proper density is selected to consider the overall mechanical performance of the screen and the special position of the folding area, so that the bulge phenomenon in the folding area is avoided, and the appearance and the performance of the flexible display screen are improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

A kind of double-sided titanium-steel composite plate with IF steel as transition layer and preparation method thereof

ActiveCN109693433BImprove corrosion resistanceImprove adaptabilityLamination ancillary operationsLaminationThermal insulationOil drilling

The invention discloses a double-sided titanium steel composite plate using IF steel as a transition layer, and a preparation method thereof. According to the present invention, the composite billet for manufacturing a composite plate comprises IF steel, a titanium composite material and a base material, wherein the base material is common carbon steel or low alloy steel with a C content of less than or equal to 0.22%, the titanium composite material is industrial pure titanium TA2, a thickness ratio of the base material to the titanium composite material is 5-10, the length and the width of the titanium composite material are smaller than the length and the width of the base material, and the distance between the titanium composite material and the four edges of the base material is 60-100 mm; the composite billet after sealing welding treatment is heated to a temperature of 900-920 DEG C, a thermal insulation time is 1 min / mm*the total thickness of the composite billet, the rolling starting temperature is 880-900 DEG C, the rolling finishing temperature is more than or equal to 800 DEG C, the single-pass reduction is 15-20%, and the total reduction is more than or equal to 70%; the thickness of the transition layer of the IF steel after rolling is 180-220 [mu]m; the thickness of the produced double-sided titanium steel composite plate is 6-45 mm; and the product is suitable for pipelines for chlor-alkali, soda ash, petrochemical industry, salt production and seawater desalination, and offshore oil drilling and pipe fittings.

Owner:ANGANG STEEL CO LTD

A high-strength and corrosion-resistant 5383 aluminum alloy and a preparation process for marine profiles

ActiveCN111549264BImprove structural strengthHigh dimensional accuracyUltimate tensile strengthMachinability

The invention discloses a high-strength and corrosion-resistant 5383 aluminum alloy and a preparation process for marine profiles. The 5383 aluminum alloy has the advantages of high structural strength, corrosion resistance and good processability, and takes into account mechanical properties, corrosion resistance and production. cost; and, the preparation process is simple, and the produced profiles are not only controllable in size and low in defect rate, but also have higher dimensional accuracy, and the yield strength can reach more than 220MPa, which is 10% higher than that of the existing 5383 aluminum alloy profiles. More than %, the strength of the profile is greatly improved, and at the same time, the production efficiency is high, and the corrosion resistance of the material is strong, and a high-strength and corrosion-resistant high-strength aluminum alloy extruded profile for ships is obtained.

Owner:中铝特种铝材(重庆)有限公司

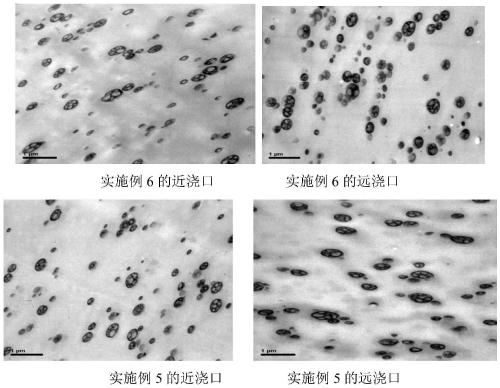

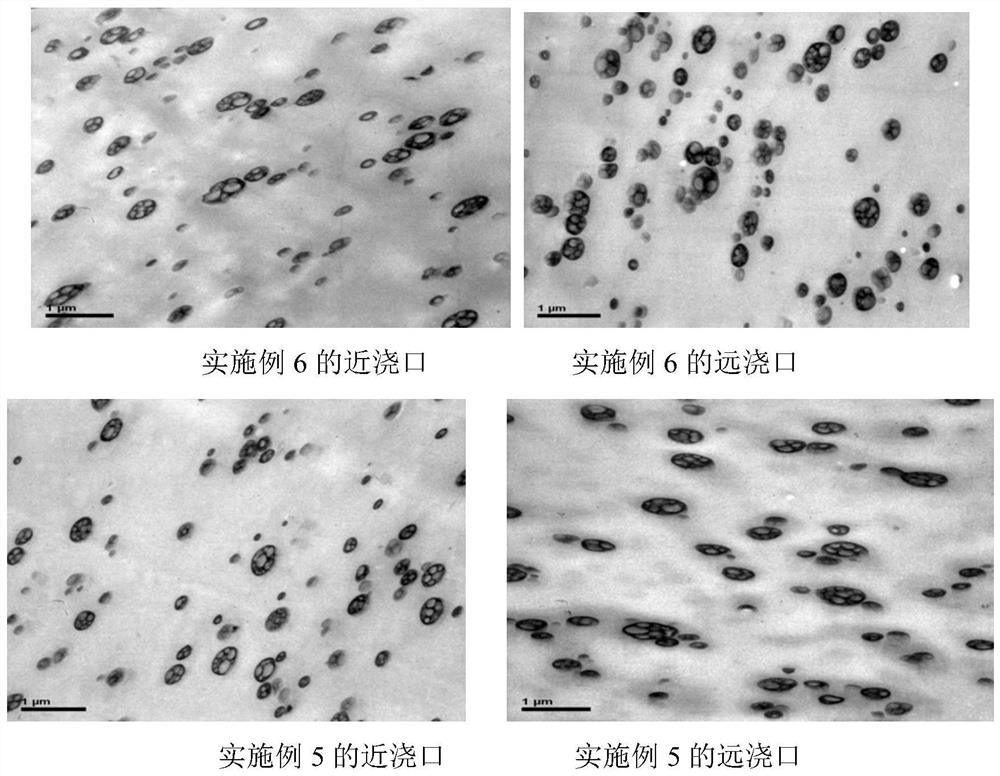

Application of multi-element random copolymer in improvement of phase state structure and phase state stability of polyester/styrene resin alloy

ActiveCN111499791AGood thermal stabilityAppropriate contentPlastic recyclingPolyesterGlycidyl methacrylate

The invention discloses an application of a multi-element random copolymer in improvement of a phase state structure and phase state stability of a polyester / styrene resin alloy or an application of the multi-element random copolymer in preparation of the polyester / styrene resin alloy. The multi-element random copolymer is formed by copolymerizing an aromatic vinyl monomer, an acrylonitrile monomer and glycidyl methacrylate. The special compatilizer for the polyester / styrene resin alloy is blended with other raw materials, and the mixture is extruded and granulated; the polyester / styrene resinalloy with excellent phase state structure and phase state stability can be simply and effectively prepared with convenience in use and low cost; the alloy maintains excellent mechanical properties,and also has special effects brought by phase state stability, such as repeatable processing, excellent multi-axis impact, low notch sensitivity and the like, so that the application field of the alloy can be broadened.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

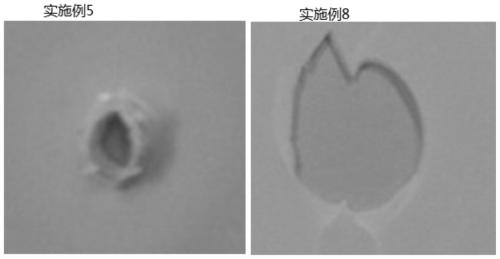

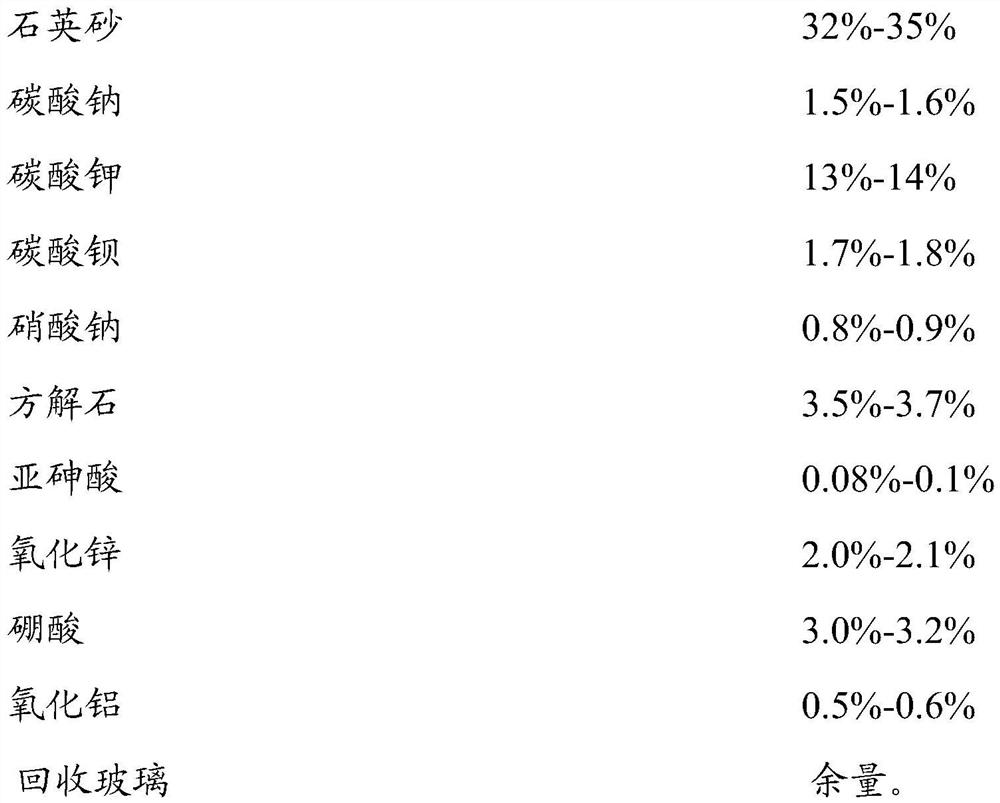

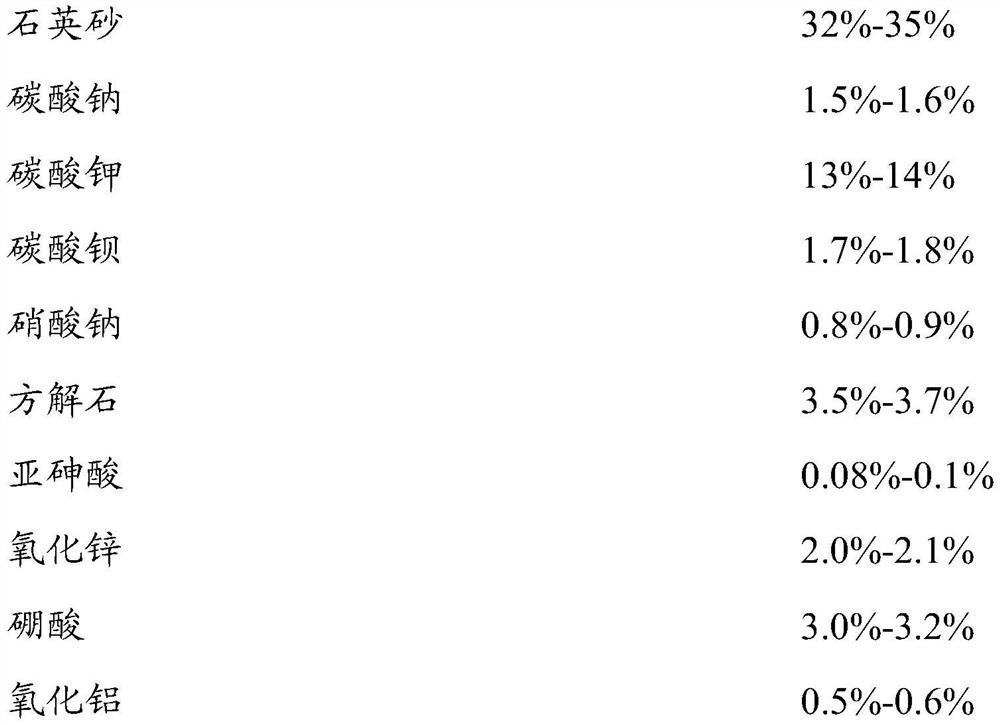

Potassium-barium glass for lens, and preparation method and application thereof

ActiveCN112745025ASolve the problem of vomiting acidTaking into account the mechanical propertiesGlass shaping apparatusRoad vehiclesSoda-lime glassMineralogy

The invention belongs to optical glass, and particularly relates to potassium-barium glass for a lens, and a preparation method and application thereof. Production raw materials of the potassium-barium glass for the lens comprise silicon dioxide, potassium carbonate, barium carbonate and sodium carbonate, and the weight percentage content of the sodium carbonate is 2% or below; the total weight percentage of the potassium carbonate and the barium carbonate is 12-18%; and the weight ratio of the potassium carbonate to the barium carbonate is (6-9): 1. The preparation method comprises the steps of burdening, melting, forming and annealing. According to the technical scheme provided by the invention, potassium carbonate and barium carbonate are used for replacing part of sodium carbonate in soda-lime glass, so that the content of sodium carbonate in the formula is reduced, and the problem of acid spitting of the lens is solved; and all the components have a synergistic effect and are matched with a proper processing technology, so the comprehensive performance requirement of the lens for an automobile lamp is met.

Owner:CARICAN UOG OPTICS SUZHOU CO LTD

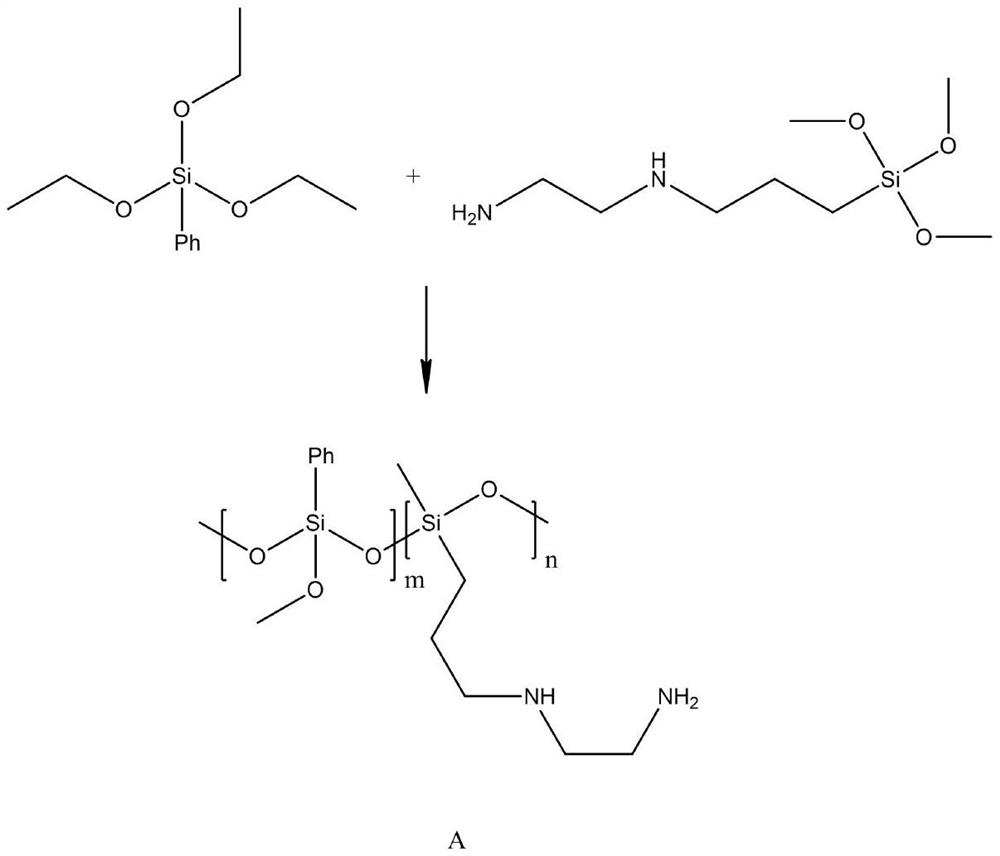

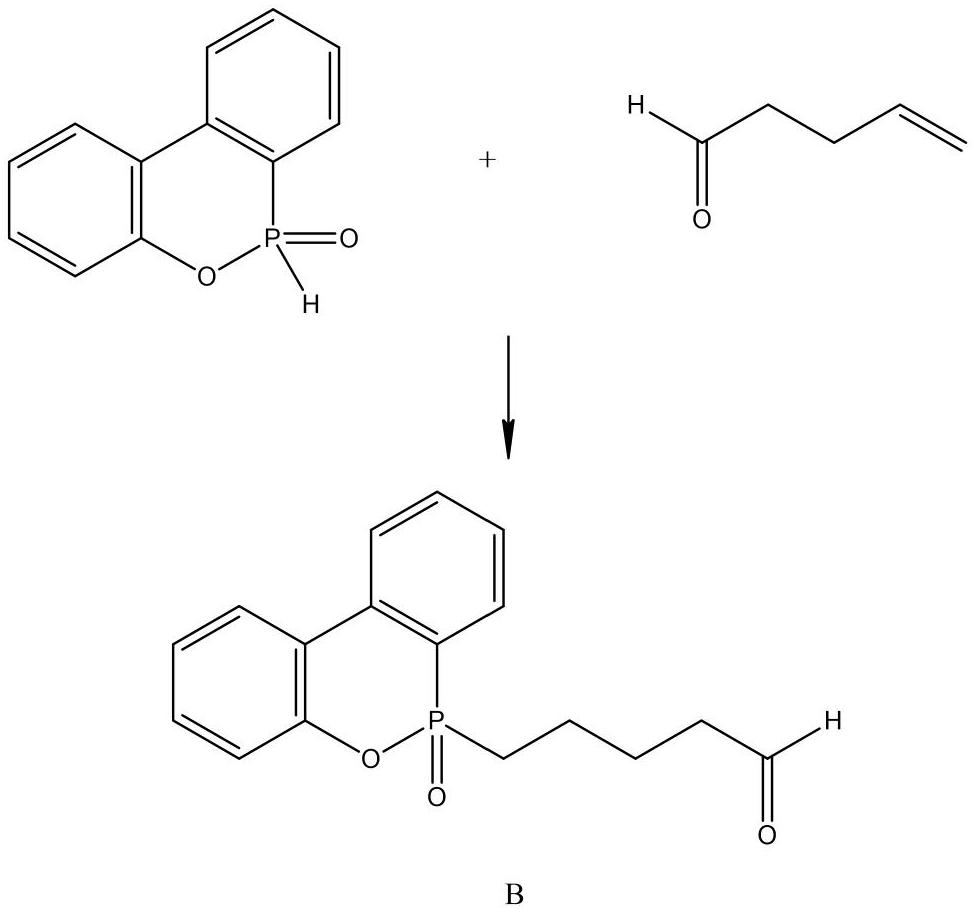

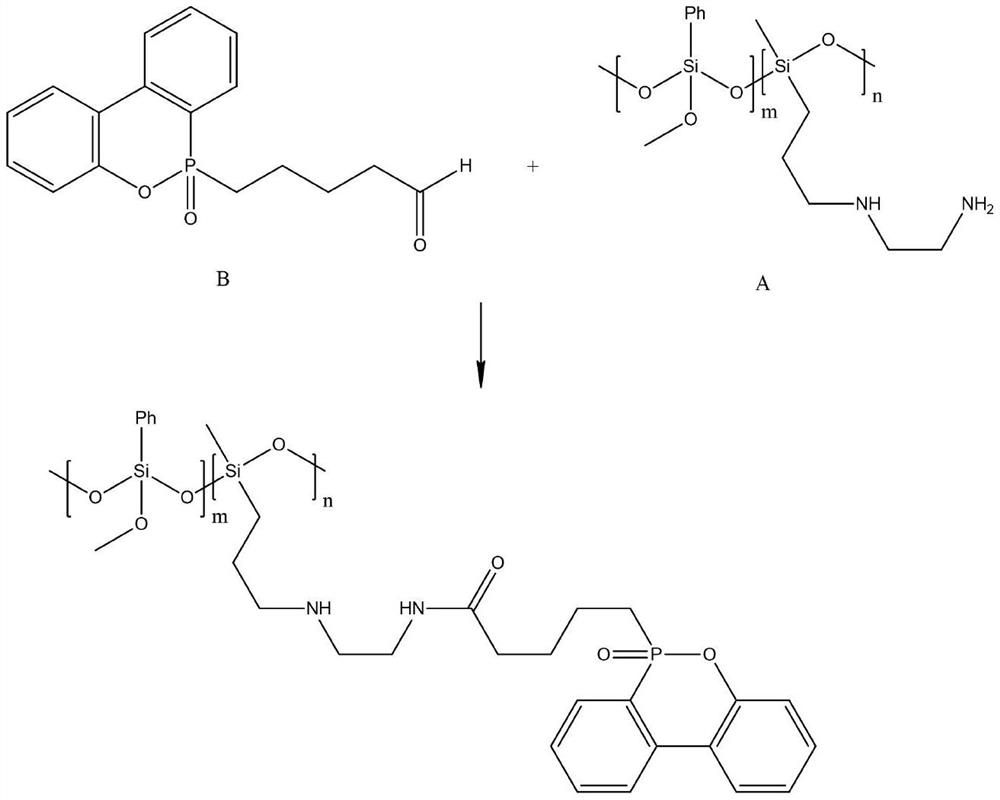

A kind of flame-retardant phosphorus-containing polyaspartic acid ester and its synthesis method

ActiveCN111349234BThe synthesis method is simpleTaking into account the mechanical propertiesFireproof paintsPolyureas/polyurethane adhesivesPolymer sciencePolyaspartic acid

The invention discloses a flame-retardant phosphorus-containing polyaspartic acid ester and a synthesis method thereof, and relates to the technical field of polyaspartic acid ester materials. The flame-retardant phosphorus-containing polyaspartic acid ester provided by the invention introduces phosphoryl groups into the molecular structure, and constructs the phosphorus-containing polyaspartic acid ester with flame-retardant performance on the basis of the original performance. Experiments have proved that the flame-retardant phosphorus-containing polyaspartic acid ester provided by the present invention has better flame-retardant performance than traditional aspartic polyurea resins, and can be prepared into coatings together with traditional aspartic polyurea resins, taking into account the The traditional aspartic polyurea resin has excellent mechanical properties, and has added an excellent flame-retardant type, which greatly expands the application of polyaspartic acid ester and has market value.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

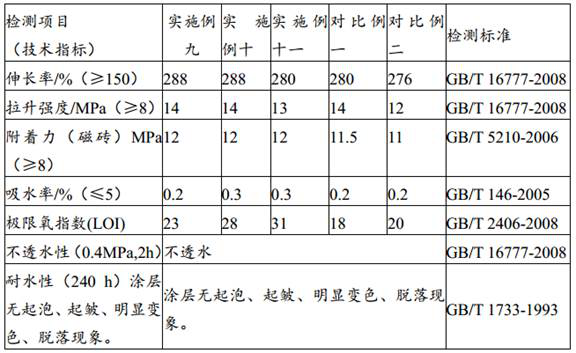

Preparation method of corrosion-resistant EVA foamed sheet

The invention relates to the technical field of EVA foaming material preparation, and discloses a preparation method of a corrosion-resistant EVA foaming sheet. Thepreparation method comprises the following steps: sufficiently preparing the required materials, and proportionally distributing the required ethylene-octene copolymer (POE) composite foaming material, ethylene-vinyl acetate copolymer (EVA) and EVA grafted maleic anhydride (EVA-g-MA) to obtain the corrosion-resistant EVA foaming sheet. The preparation method comprises the following steps: fully and uniformly mixing 52 parts by weight of EVA, 1-8 parts by weight of EVAgMA and 2-6 parts by weight of POE in an internal mixer. According to the preparation method of the corrosion-resistant EVA foamed sheet, the compatibility of EVA and TPU can be remarkably improved through EVA-g-MA; meanwhile, a POE material with high resilience is introduced, so that the prepared EVA / TPU / POE composite foamed material has good mechanical performance, the tensile strength is 2.09 to 2.44 MPa, the elongation at break is 278.2% to 314.2%, the tearing strength is 4.10 to 5.13 N / mm, and the peel strength is 2.70 to 3.72 N / mm. Meanwhile, the material has good resilience of 55-62%, compression set of 25-42% and low density of 0.2-0.25 g / cm3.

Owner:尹志贵

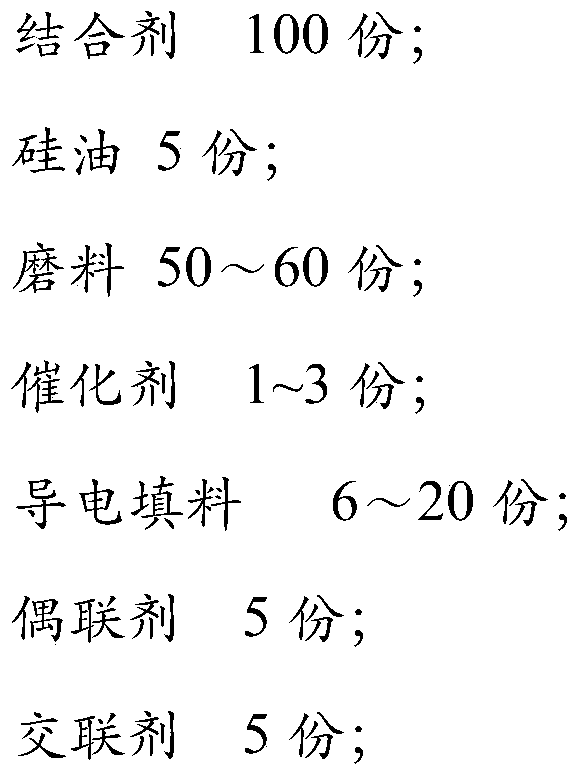

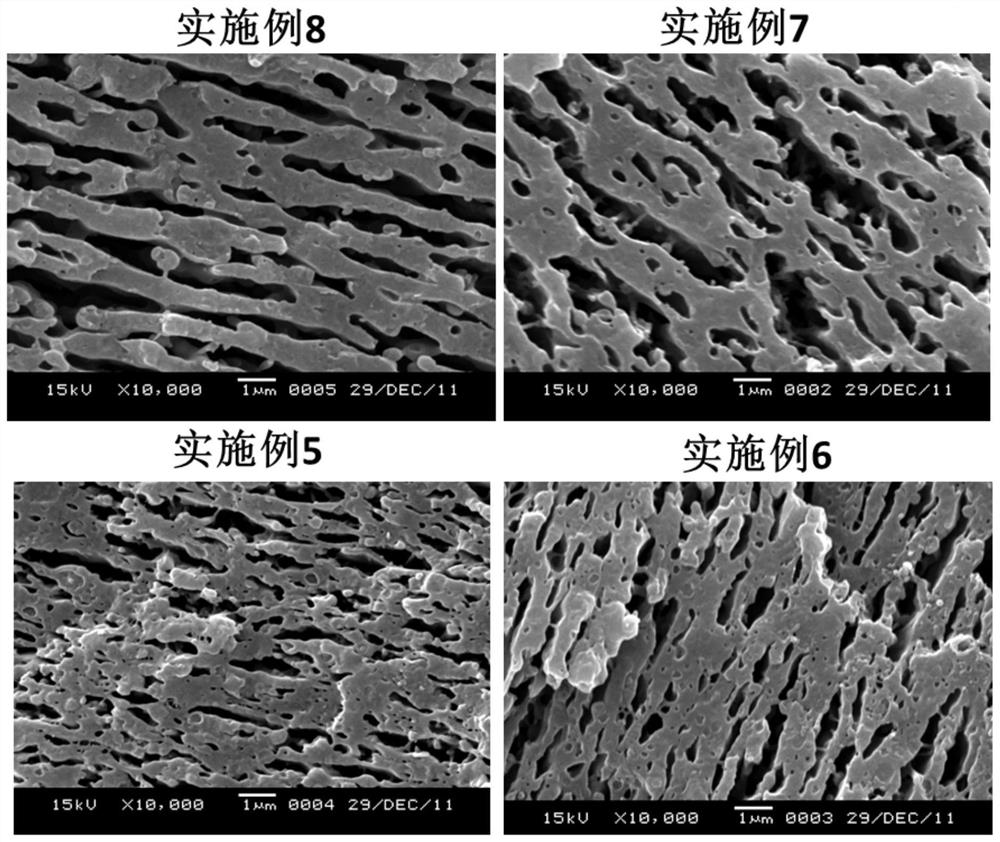

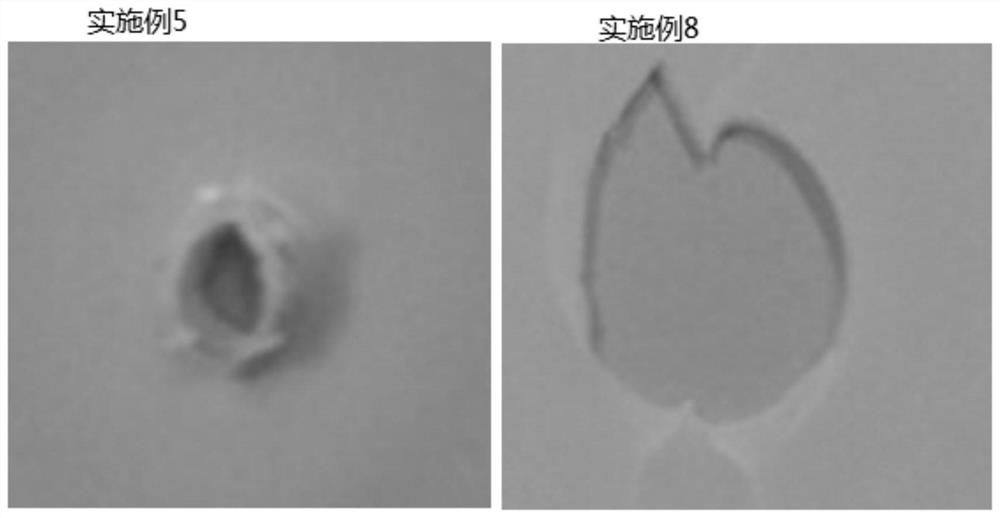

A kind of conductive flexible abrasive tool and preparation method thereof

ActiveCN105058250BRealize rapid prototypingTaking into account the mechanical propertiesAbrasion apparatusGrinding devicesCross-linkRapid prototyping

The invention discloses a conductive flexible grinding tool and a preparation method thereof. The mainly components of the conductive flexible grinding tool comprise a grinding material, an organic binding agent, a conductive filling material, a cross-linking agent, a catalyst and the like. The invention also provides a method for preparing the above grinding tool. Compared with the prior art, the conductive flexible grinding tool is advantaged in that the grinding tool can be molded quickly, the grinding tool has good manufacturability, and the grinding tool is high in mechanical property and good in conductive performance. The conductive flexible grinding tool is suitable for electrolytic combined processing of complex curved surfaces, and the processing precision, the surface quality and the processing efficiency are improved.

Owner:诚硕电气有限公司

Application of Multi-component Random Copolymer in Improving Phase Structure and Phase Stability of Polyester/Styrene Resin Alloy

ActiveCN111499791BGood thermal stability of co-extrusionHigh reactivityPlastic recyclingPolyesterPolymer science

The invention discloses the application of a multi-component random copolymer in improving the phase structure and phase stability of a polyester / styrene resin alloy or the application of a multi-component random copolymer in the preparation of a polyester / styrene resin alloy Application: The multi-component random copolymer is formed by copolymerizing aromatic vinyl monomer, acrylonitrile monomer and glycidyl methacrylate. The special compatibilizer for polyester / styrene resin alloy provided by the present invention can be prepared with excellent phase structure and State-stable polyester / styrene resin alloy, while maintaining excellent mechanical properties, this alloy also has special effects brought about by phase stability, such as repeatable processing, excellent multi-axial impact, Low notch sensitivity, etc., which can broaden the application field of this type of alloy.

Owner:FINE BLEND POLYMER SHANGHAI CO LTD

High-temperature-resistant heat-insulating protective clothing and preparation process thereof

PendingCN114474913AThe synthesis process is simpleEasy to storeChemical protectionHeat protectionPolytetrafluoroethyleneFire retardant

The invention discloses a high-temperature-resistant heat-insulating protective garment and a preparation process thereof, and relates to the field of protective garments, and the high-temperature-resistant heat-insulating protective garment is prepared by selecting a polysulfonamide fabric, performing flame-retardant finishing by using an after-finishing flame retardant, soaking the polysulfonamide fabric in an anti-static liquid, dipping, drying, and coating the surface of the fabric with a polytetrafluoroethylene coating, thereby obtaining the high-temperature-resistant heat-insulating protective garment. The anti-static breathable layer, the heat insulation layer and the flame-retardant layer are sequentially compounded, and the problems that an existing protective garment is poor in heat insulation performance, cannot well block heat energy outside the protective garment and is not ideal in flame-retardant effect are solved; the compounding of organic and inorganic materials can realize complementary advantages, and gives consideration to the mechanical property, weaving property, heat insulation and open fire resistance of polysulfonamide, so that the heat insulation property of the fabric is improved, the flame-retardant layer can prevent combustion products from escaping and inhibit thermal decomposition of materials under the layer, the flame-retardant, low-smoke and low-toxicity effects are achieved, a cracked carbon layer is formed on the surface of the polysulfonamide, and the flame-retardant, flame-retardant and flame-retardant effects are achieved. And the oxidation resistance of the cracked carbon layer is improved, so that the flame-retardant purpose is achieved.

Owner:安徽上造智能设备科技有限公司

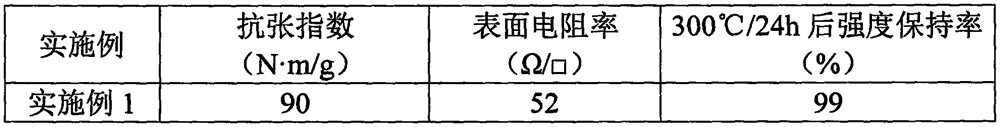

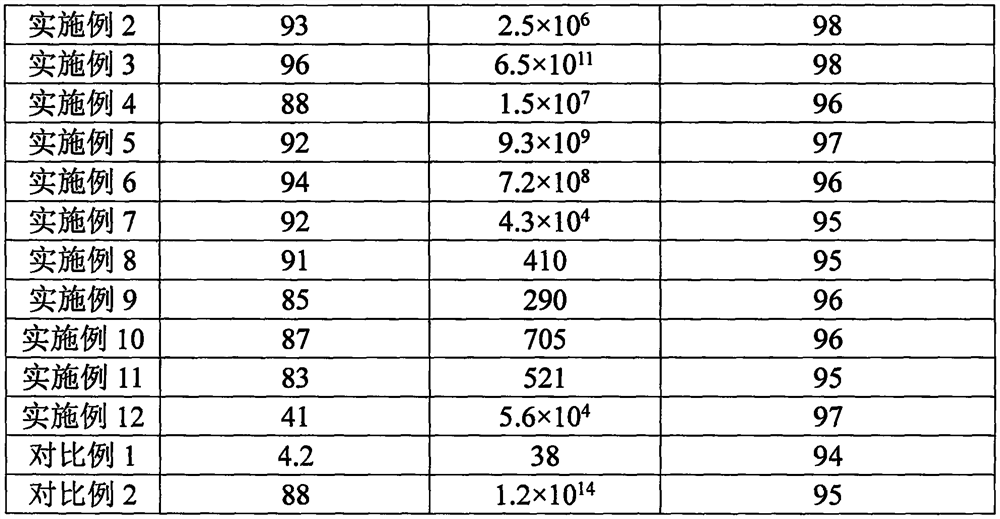

A polyimide paper with controllable electrical properties and its preparation method

ActiveCN105672025BElectrical performance regulationSimplify production stepsSynthetic cellulose/non-cellulose material pulp/paperPhysical paper treatmentPolymer scienceSurface resistivity

The invention relates to the field of high-performance specialty paper products. The invention provides a preparation method of a piece of polyimide paper with controllable electrical property, and also provides the polyimide paper with controllable electrical property. The polyimide paper realizes controllable electrical property, and compared with prior polyimide paper, the strength and high temperature resistance of the polyimide paper are more excellent; concretely, the density of the polyimide paper with controllable electrical property is 0.4-1.4 g / cm<3>, the surface resistivity is controllable between 50-10<13> ohm / sq, tensile index reaches 41-96N.m / g, and after 24 hours at 300 DEG C, the strength retention reaches 95-99%.

Owner:JIANGSU XIANNUO NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com