Application of multi-element random copolymer in improvement of phase state structure and phase state stability of polyester/styrene resin alloy

A styrene-based resin and random copolymer technology, applied in the field of special compatibilizers, can solve the problems of re-aggregation of dispersed phases, large differences in solubility parameters between polyester and styrene-based resins, and easy phase separation, etc., to achieve High efficiency, good cost performance, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0036] According to the composition ratio of raw materials in Table 1, a special compatibilizer for improving the phase distribution and stability of polyester / styrene resin alloys was prepared, Examples 1-4, 14 and Comparative Example 1-2 (preparation method Consistent with the examples, conventional adjustment of feeding). And these compatibilizers are used to prepare polyester / styrene resin alloys to study the improvement of the phase state and phase stability of such alloys.

[0037]

Embodiment 5~9

[0039] The PC resin is PCI250WP (the relative number average molecular weight is 22,000g / mol, and the glass transition temperature is 140°C) from Teijin Corporation of Japan; the ABS resin is P / D190 (the relative weight average molecular weight is 120,000g / mol, The weight percentage content of butadiene is 50%, the weight percentage content of acrylonitrile is 15%, and the weight percentage content of styrene is 35%.

[0040]

[0041] Put the above components into the high mixer according to the proportion and mix them for 3 minutes, discharge the material, and then use the screw extruder to extrude and granulate. The rotation speed of the twin-screw extruder is 2000rpm, and the aspect ratio of the twin-screw extruder is 36.

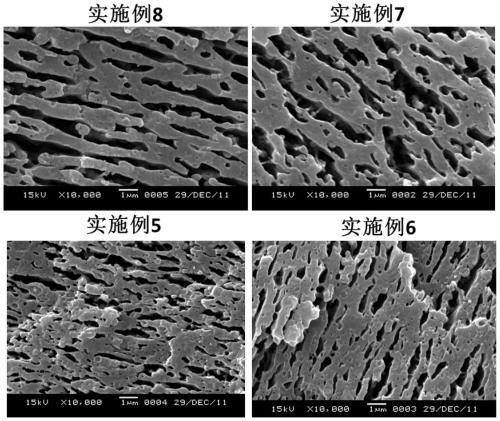

[0042] According to the particles prepared in Examples 5 to 8, sheets are obtained by conventional injection molding, which are samples 1 to 4 respectively. After the samples are cooled and brittle with liquid nitrogen, the rubber phase is etched, and...

Embodiment 5

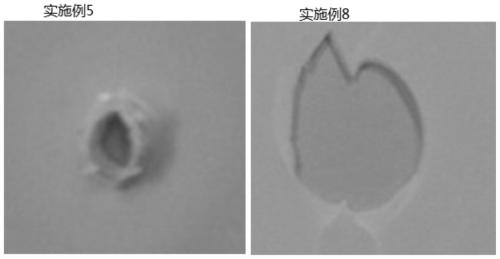

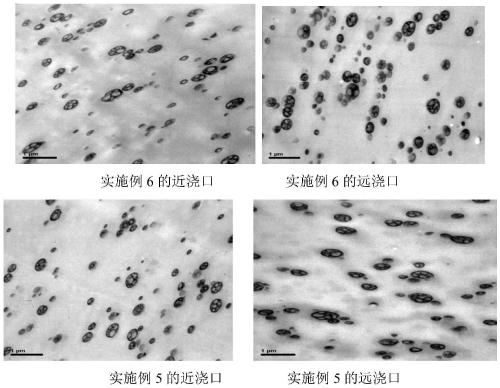

[0045] The phase state structure of embodiment 5,6 has difference, combines image 3 The scanning electron microscope, the injection molded parts of embodiment 5 and embodiment 6 were sampled at the near gate position and the far gate position, and the phase structure was analyzed by transmission electron microscope after slicing to observe its phase stability. In order to illustrate the influence of the compatibilizer of the present invention on the stability of the alloy phase distribution, the conventional injection molding of a large mold is used to prepare an injection molded part with a length of 30 cm and a width of the standard width of the notched impact spline, and the spline closest to the gate and the nearest spline are respectively taken. Test the spline far away from the gate; it can be seen that in the injection mold, due to the existence of the shear-tensile force field, the phase structure of Example 6 is unstable, and the phase structure at the far gate is rel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative number average molecular weight | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Relative weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com