Halogen-free flame-retarding ultrahigh-molecular weight polyethylene material and preparation method of same

A technology of ultra-high molecular weight polyethylene, which is applied in the field of halogen-free flame-retardant polyethylene, can solve the problems of affecting the mechanical properties of materials and the low degree of intermolecular fusion, and achieve good thermal stability, good flame-retardant effect, and char-forming performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

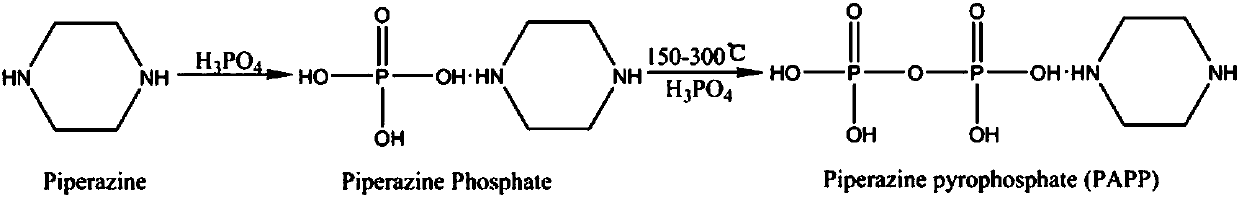

[0046] Preparation of pyro(poly)piperazine phosphate: add phosphoric acid and piperazine phosphate in the same molar ratio into a three-necked flask, heat in a water bath to 80° C., stir at 40 rpm, and react for 2 hours. After the reaction was complete, it was cooled to room temperature, filtered and dried to obtain a white intermediate product. Mix the white intermediate product with phosphoric acid again at a molar ratio of 1:1, heat the oil bath to 200°C, and continue to stir for 2 hours at a stirring rate of 40rpm. After the reaction is complete, cool, filter and dry, and finally grind to a particle size below 100μm. That is, the product pyro(poly)piperazine phosphate (PAPP) is obtained. Synthesis process see figure 1 .

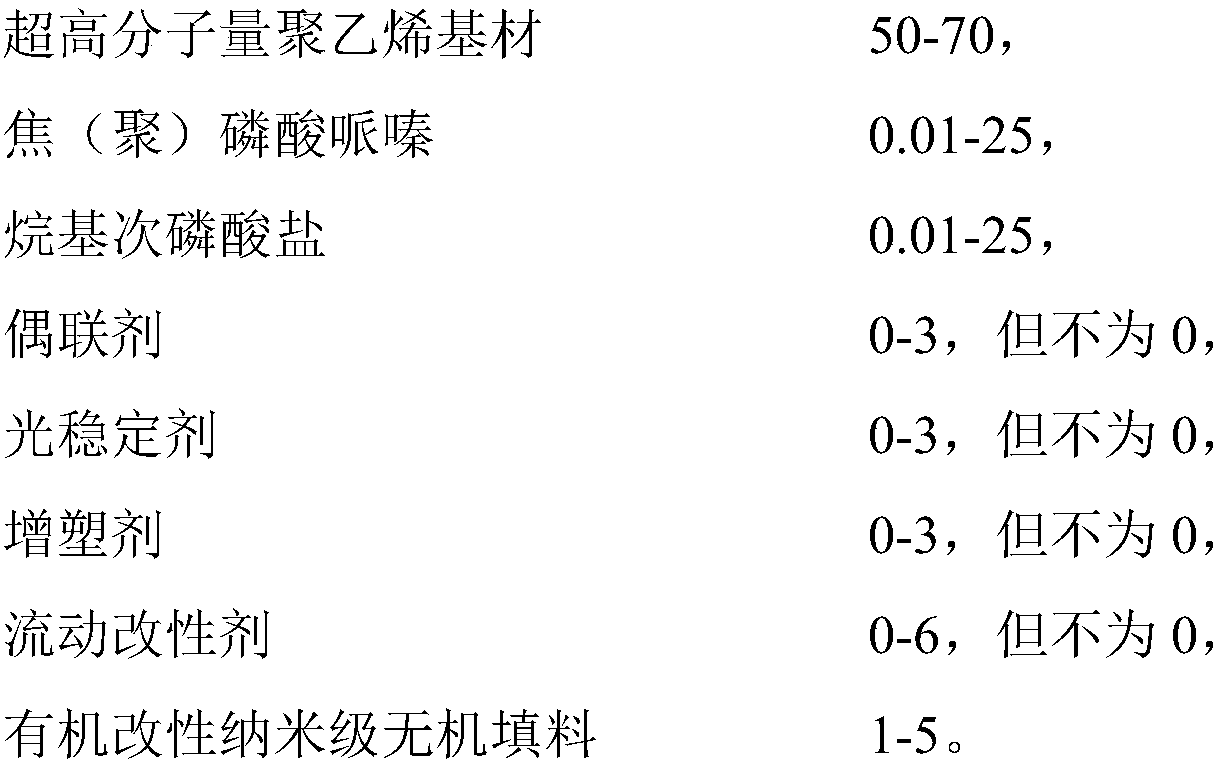

[0047] Preparation of halogen-free flame-retardant ultra-high molecular weight polyethylene material: 9 parts of pyro(poly)piperazine phosphate (particle diameter <100 μm), 16 parts of diethyl aluminum hypophosphite are pre-mixed in a high-speed mixer t...

Embodiment 2

[0050] The preparation of pyro(poly)piperazine phosphate: with embodiment 1.

[0051] Preparation of halogen-free flame-retardant ultra-high molecular weight polyethylene material: 16 parts of pyro(poly)piperazine phosphate (particle diameter <100 μm), 9 parts of diethyl aluminum hypophosphite are pre-mixed in a high-speed mixer to obtain halogen-free flame retardant Combustion agent, then add 68 parts of ultra-high molecular weight polyethylene (molecular weight is 2 million) substrate, 1 part of coupling agent (KH560), 1 part of light stabilizer (brand 788), 1 part of plasticizer aliphatic dibasic acid ester 2 parts, flow modifier medium density polyethylene 2 parts, organically modified nano-scale inorganic filler nickel-based montmorillonite 2 parts, mixed by extruder, the mixing temperature is 180-200 ℃, and then injection molded to prepare a standard sample bar, test performance. The results obtained are summarized in Table 2.

[0052] The vertical combustion test of t...

Embodiment 3

[0054] The preparation of pyro(poly)piperazine phosphate: with embodiment 1.

[0055] Preparation of halogen-free flame-retardant ultra-high molecular weight polyethylene material: 18 parts of pyro(poly)piperazine phosphate (particle diameter <100 μm), 7 parts of diethyl aluminum hypophosphite were pre-mixed in a high-speed mixer to obtain halogen-free flame retardant Combustion agent, then add 68 parts of ultra-high molecular weight polyethylene (molecular weight is 2 million) base material, 1 part of coupling agent (KH570), 1 part of light stabilizer (brand 292), 1 part of phosphate ester plasticizer, flow 2 parts of modifier low-density polyethylene and 2 parts of organically modified nano-scale inorganic filler artificially synthesized mica are mixed by extruder at a mixing temperature of 180-200°C, and then prepared by injection molding into standard specimens for performance testing. The results obtained are summarized in Table 2.

[0056] The vertical combustion test o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com