Method for improving low-temperature impact toughness of high-strength steel hot rolled plate coil for engineering machines

A technology of low temperature impact toughness and engineering machinery, which is applied to the improvement of low temperature toughness of low-alloy high-strength engineering machinery steel, and the field of improving the low-temperature impact toughness of high-strength engineering machinery steel hot-rolled coils, and can solve the problems of low temperature impact toughness reduction, etc. Achieve the effect of improving toughness, reducing damage, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

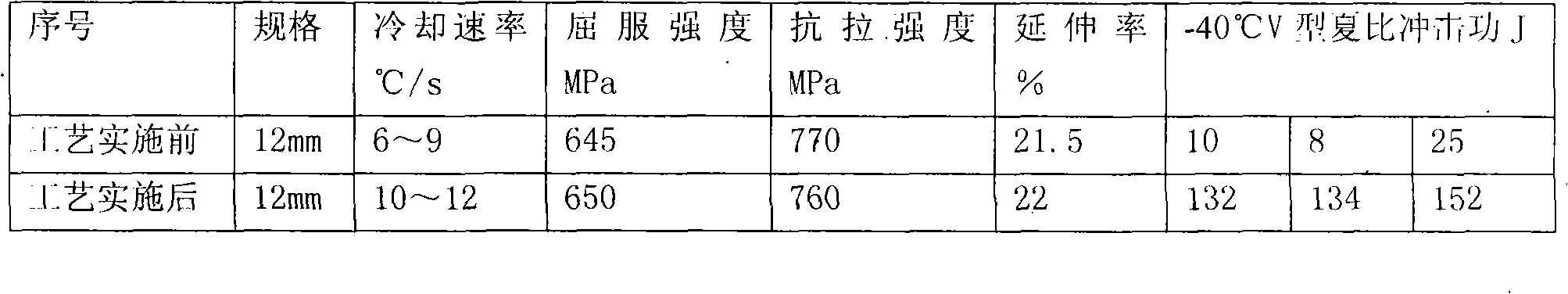

[0011] The present invention will also further describe the 550MPa level high-strength construction machinery steel hot-rolled coil and its production method in conjunction with examples:

[0012] Table 1 lists the chemical composition of the present invention for the production of 550Mpa high-strength construction machinery steel hot-rolled coils. The production method is as follows: hot metal desulfurization in the steelmaking plant, 210t converter smelting, and LF furnace refining. Then the molten steel required in Table 1 is cast into a slab of 230mm×1300~1800mm cross-section, which is sent to hot continuous rolling mill.

[0013] Table 1 Chemical composition of the present invention, wt%

[0014] Element

C

Si

mn

P

S

Alt

Nb

Ti

content

0.073

0.19

1.47

0.012

0.003

0.035

0.05

0.09

[0015] The main points of implementation of the present invention include: 1. The process route ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com