Composite enzyme for soaking corn starch and applications thereof

A corn starch and compound enzyme technology, which is applied in the field of starch processing, can solve the problems of trace residues of sulfite in products, affecting the use effect of starch, affecting the flavor and quality of beer, etc., so as to reduce the amount of use, improve the utilization rate of equipment, and improve the economic value. and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

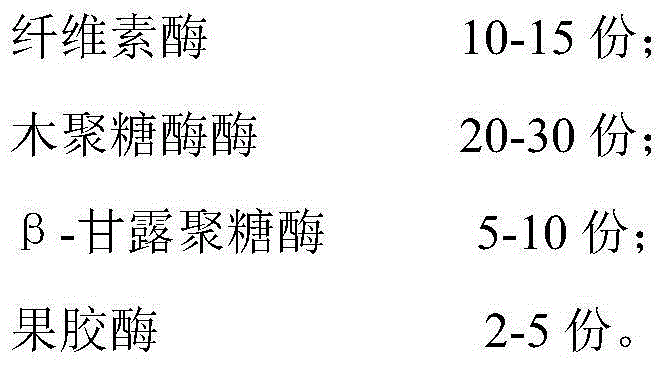

Method used

Image

Examples

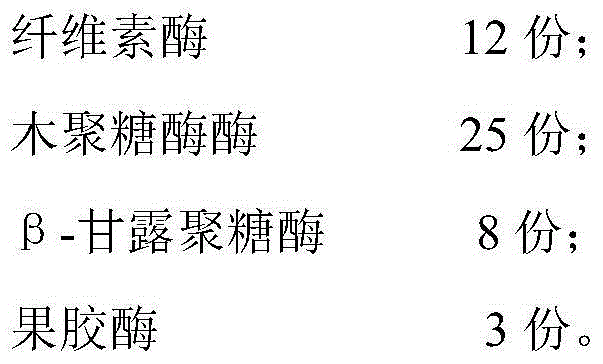

Embodiment 1

[0028] According to the following proportions, each component was weighed: 12 kg of cellulase, 25 kg of xylanase, 8 kg of β-mannanase, and 3 parts of pectinase.

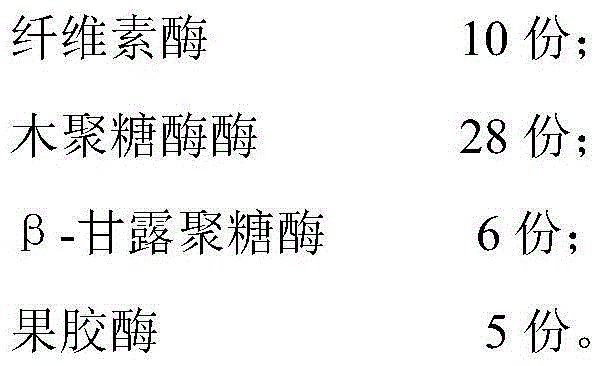

Embodiment 2

[0030] Each component was weighed according to the following ratio: 10 kg of cellulase, 20 kg of xylanase, 6 kg of β-mannanase, and 4 parts of pectinase.

[0031] Under the conditions of 50°C soaking solution, 0.1% sulfurous acid concentration, and 0.03% compound enzyme concentration, the corn was soaked for 12 hours, and the starch yield was 80.7%.

Embodiment 3

[0033] Each component was weighed according to the following ratio: 11 kg of cellulase, 25 kg of xylanase, 5 kg of β-mannanase, and 4 parts of pectinase.

[0034] Under the conditions of 50°C soaking solution, 0.1% sulfurous acid concentration, and 0.03% compound enzyme concentration, the corn was soaked for 12 hours, and the starch yield was 80.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com