Patents

Literature

209results about How to "Damage reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

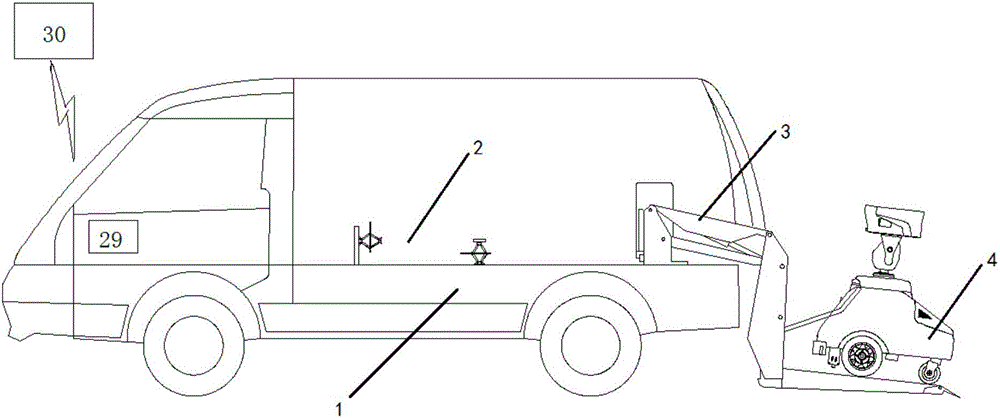

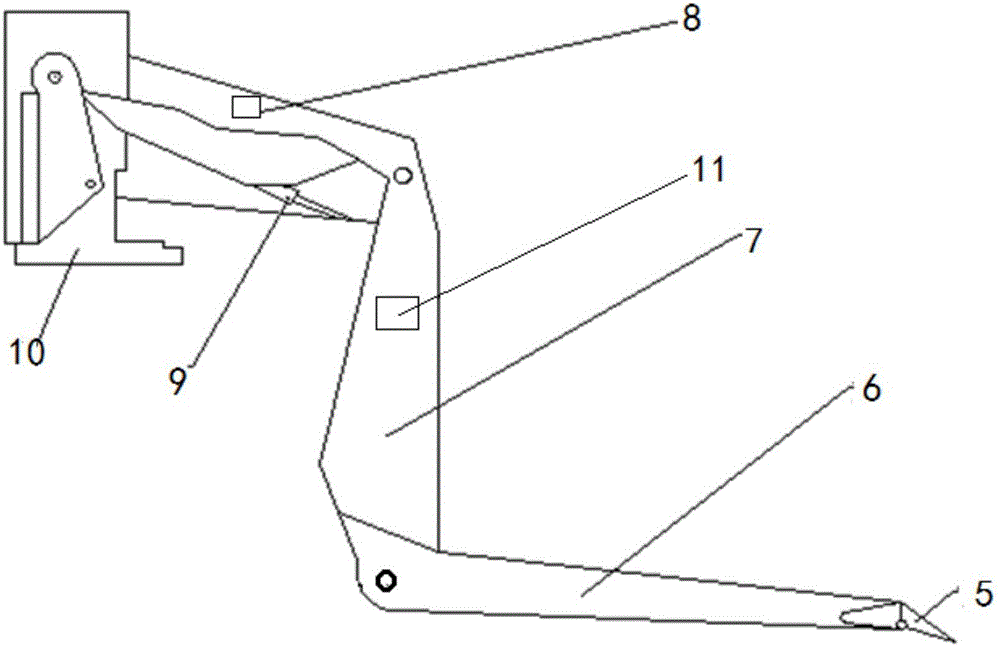

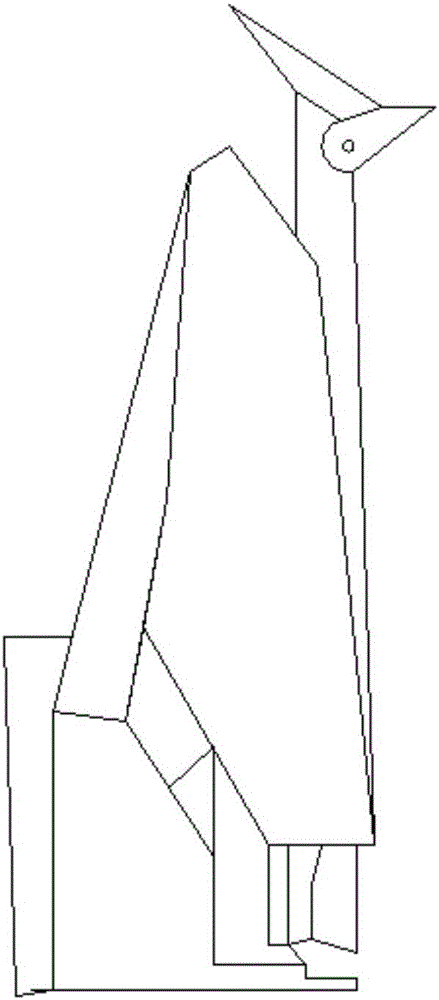

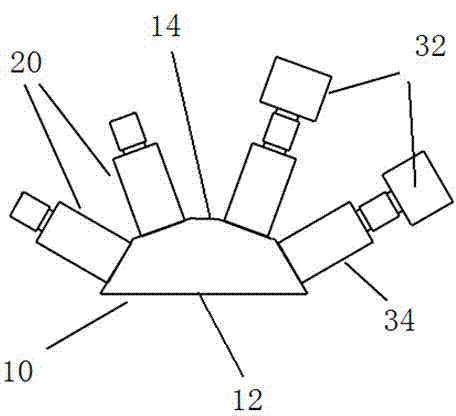

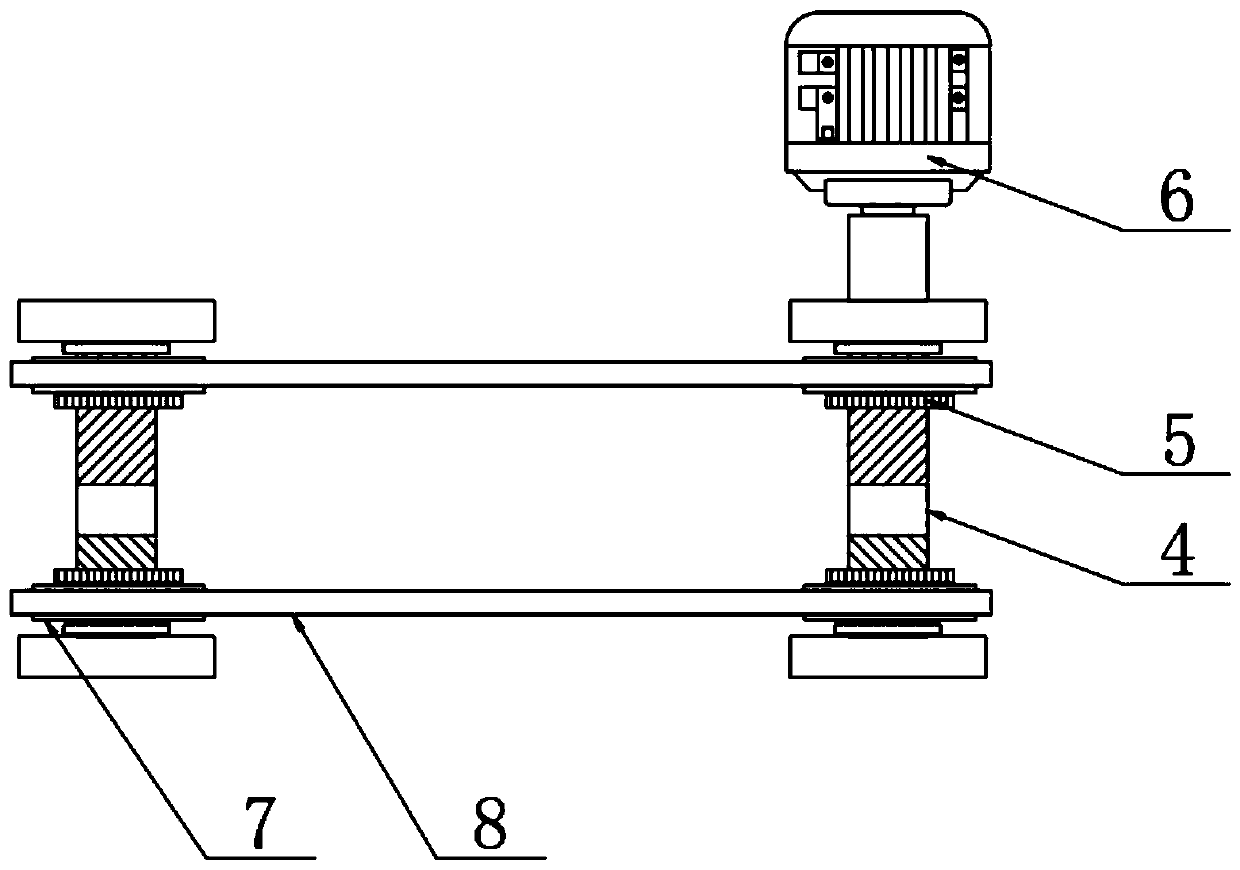

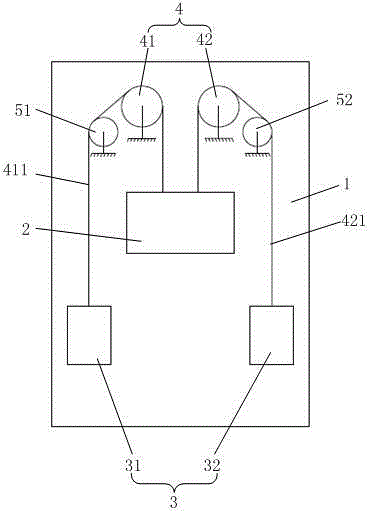

Centralized dispatching system and method for inspection robots in transformer substation

ActiveCN105128031ADamage reductionEnsure safetyVehicle with raised loading platformCircuit arrangementsPower substationTransport engineering

The invention discloses a centralized dispatching system and method for inspection robots in a transformer substation. According to the centralized dispatching system, both a lifting platform and a fixing device are fixed to an inspection robot transport platform, and the lifting platform is connected with a lifting control device; the inspection robot transport platform is connected with a communication module, the communication module communicates with a dispatching server, and the dispatching server sends a dispatching command to the inspection robot transport platform; and the inspection robots are fixed to the inspection robot transport platform through the fixing device, and the inspection robots can be moved in or out of the inspection robot transport platform through the lifting platform. The centralized dispatching system has the beneficial effects that movement of the inspection robots can be limited effectively in the transport process, damage to robot bodies and related electronic components is reduced in the transport process, and the safety of the inspection robots is guaranteed in the transport process.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

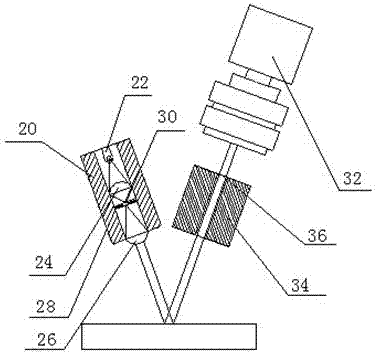

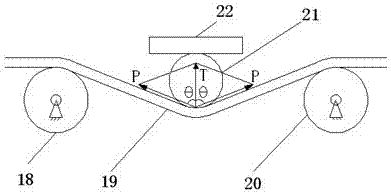

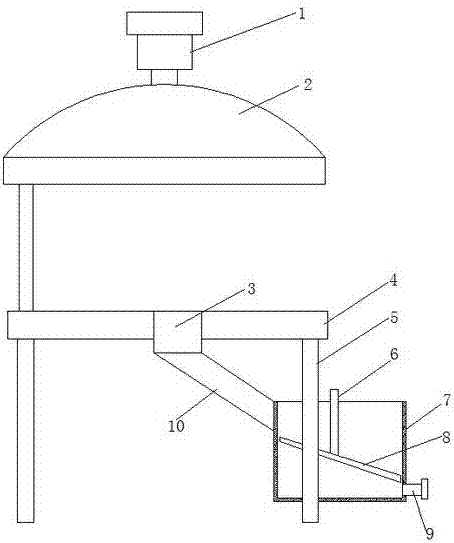

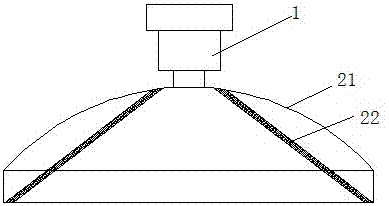

Non-contact vancometer

InactiveCN103674903ADamage reductionImprove accuracyScattering properties measurementsPhysicsCcd camera

The invention discloses a non-contact vancometer, which comprises a hollow shell. A perforated observation hole is formed in the shell. At least one light source which is obliquely aligned with the observation hole is arranged in the shell. By taking the surface where the observation hole is located as a reflecting surface, a glossiness analyzer for receiving reflected light rays is arranged on a reflecting line of light rays emitted by the light source. The non-contact vancometer is characterized in that the glossiness analyzer comprises a CCD (Charge Coupled Device) camera, the CCD camera is connected with an analysis host and the analysis host is used for making analysis according to images transmitted by the CCD camera. The non-contact vancometer has the advantages that since a non-contact design is adopted, the direct contact with a product is prevented, the damage to the product is reduced and the accuracy of the inspection result of the product is also improved; besides, since the CCD camera is used to replace a traditional photosensitive sensor and a specific area is analyzed through a computer, the glossiness analysis of fine parts and irregular areas can be realized.

Owner:APS SUZHOU AUTOMATION TECH

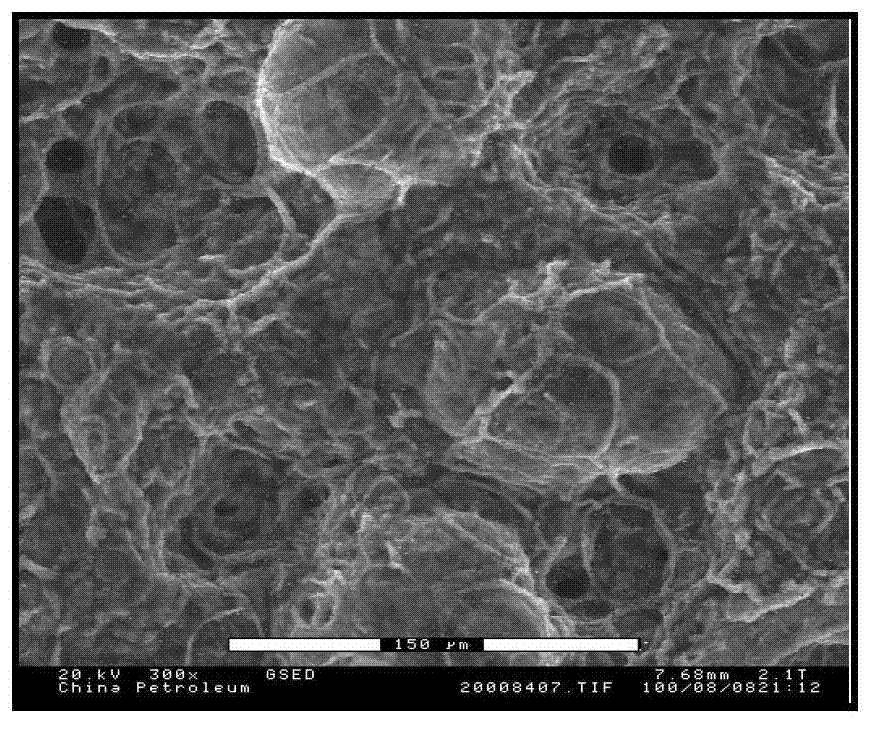

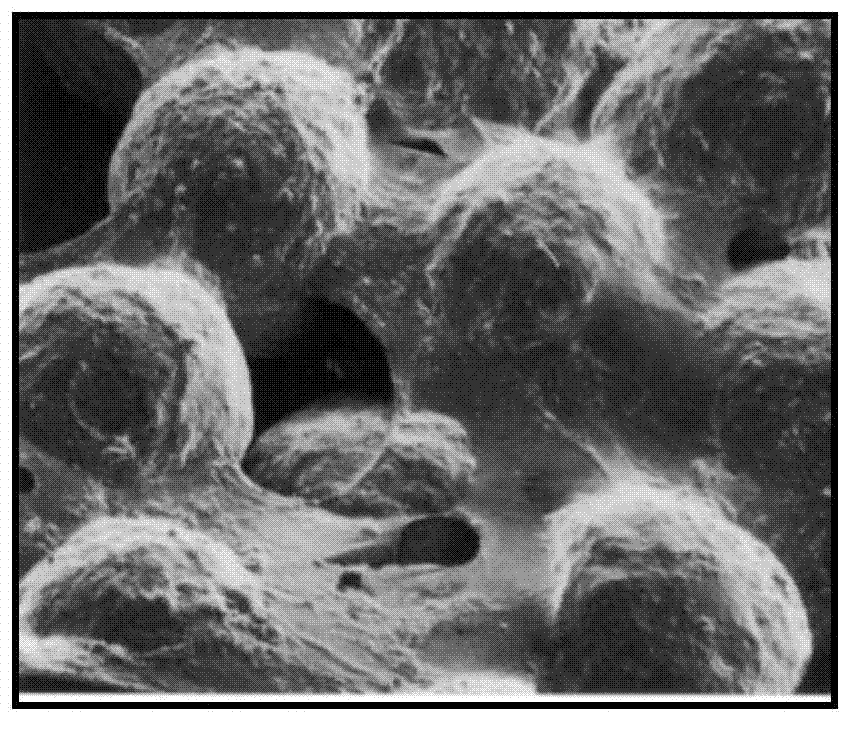

Low-damage fracturing fluid and fracturing method

ActiveCN102952534AReduce dosageDamage reductionFluid removalDrilling compositionSupport beltGuar gum

The invention relates to a low-damage fracturing fluid and a fracturing method. The fracturing fluid is an aqueous fracturing fluid, and contains sand-suspended fibers, wherein the sand-suspended fiber is selected from hydrophilic high-strength organic fiber or inorganic fiber; and the content of the thickening agent in the fracturing fluid is lower than 0.08wt%, and the content of the crosslinking agent is lower than 0.02wt%. The fracturing fluid serving as a sand-carrying fluid in the fracturing method is injected into formation fractures, wherein the sand-carrying fluid comprises the following injection parameters including 50 to 2,000 cubic meters of dosage, and 2.0 to 15.0 cubic meters per minute of speed. According to the fracturing fluid, a high-viscosity buoyant proppant of guar gum is replaced by a three-dimensional reticular structure formed in the fracturing fluid by using the fiber, so that the dosage of guar gum can be greatly reduced, or the guar gum is not required, the damage to the wall surface and the support belt of the formation fractures can be minimized, and the economic benefit of fracture reformation can be improved.

Owner:PETROCHINA CO LTD +1

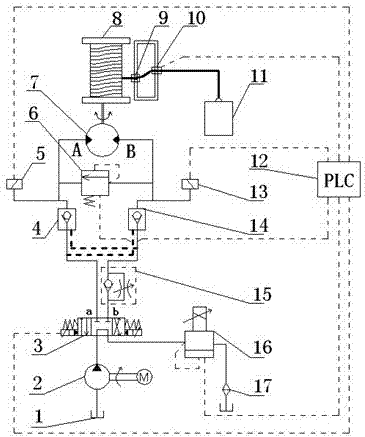

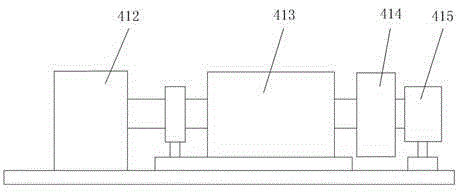

Constant tension control device of hydraulic winch

The invention discloses a constant tension control device of a hydraulic winch, which is particularly applied to constant tension control. An electro-hydraulic control system comprises an oil tank, a power pump group, an electromagnetic reversing valve, hydraulic locks, pressure sensors, a motor safety valve, a hydraulic motor, a winch, a cable arranger, a tension sensor, a load, a programmable logic controller (PLC), a one-way throttling valve, an electric-hydraulic proportional overflow valve and a cooling valve, wherein the power pump group is connected with an oil inlet of the electromagnetic reversing valve; oil outlets a and b of the electromagnetic reversing valve are connected with the hydraulic locks and the one-way throttling valve, respectively; an oil return inlet of the electromagnetic reversing valve is connected with an oil inlet of the electric-hydraulic proportional overflow valve; an oil outlet of the electric-hydraulic proportional overflow valve is connected with the cooling valve; an oil return inlet of the cooling valve is connected with the oil tank; the two symmetric hydraulic locks on oil paths corresponding to the two oil outlets of the electromagnetic reversing valve are connected with openings A and B of the hydraulic motor, respectively; the motor safety valve is arranged in parallel between two oil cavity openings A and B of the hydraulic motor. The constant tension control device of the hydraulic winch has functions for setting and measuring the tension state of a cable and making the tension state constant under complicated sea conditions, and is high in response speed and high in anti-interference performance.

Owner:SHANGHAI OCEAN UNIV

Conveying device with rotation function for paperboard double-sided printer and conveying method

ActiveCN109941789ADamage reductionImprove work efficiencyOverturning articlesArticle feedersRotation functionSurface plate

The invention discloses a conveying device with a rotation function for a paperboard double-sided printer and a conveying method. The device comprises a base and a double-sided printer body, a bottomcleaning member is arranged on the left side of the outer wall of the front side of a panel through a supporting frame, a rotation mechanism which cooperates with a conveying belt is arranged in the center of the top of the base, and a top cleaning member is arranged on the part, close to the right side, between the two limiting plates. According to the device, a rotary disc is driven through a connecting motor, two groups of moving plates are pulled by two groups of pull rods to perform reciprocating movement from front to back to rub one side of a paperboard so as to efficiently and rapidlyremove dust remaining on the paperboard, a rotation mechanism is arranged, a moving block is driven to move through a hydraulic rod to allow a turning rod to drive a turning plate to rotate to turn the paperboard, manual turning is not needed, normal transmission is not influenced, the working efficiency is greatly improved, dust on the other side of the paperboard is removed by an arranged dust absorbing roller and a dust removing membrane, and therefore double-sided dust removing is achieved.

Owner:深圳市耀隆彩色印刷有限公司

Biological organic fertilizer and preparation method therefor

The invention discloses a biological organic fertilizer. The biological organic fertilizer comprises the following main raw material components in parts by weight: 30-50 parts of livestock manure, 8-15 parts of silkworm excretions, 3-6 parts of straw ash, 4-7 parts of wheat hulls, 1-4 parts of bagasse, 2-4 parts of sugercane leaves, 5-7 parts of cornstalks, 2-5 parts of peels of Radix Puerariae, 1-3 parts of sawdust, 5-9 parts of pumpkins and 10-15 parts of rotten fruits. A preparation method for the biological organic fertilizer comprises the steps of: firstly crushing and drying raw materials; then carrying out fermentation twice, respectively; and then drying and packaging the raw materials to obtain the product disclosed by the invention. By adopting the product disclosed by the invention to plant crops, the disease resistance and drought resistance of the crops can be effectively improved. As an organic fertilizer, the product does little damage to the soil, the output of the crops is increased, and the organic fertilizer is simple in production and low in cost, so that wastes are turned into wealth. The organic fertilizer contains various nutrients required by plant growth and is not suitable for various plants to use.

Owner:YINGSHANG XINQUAN ORGANIC AGRI TECHDEV CO LTD

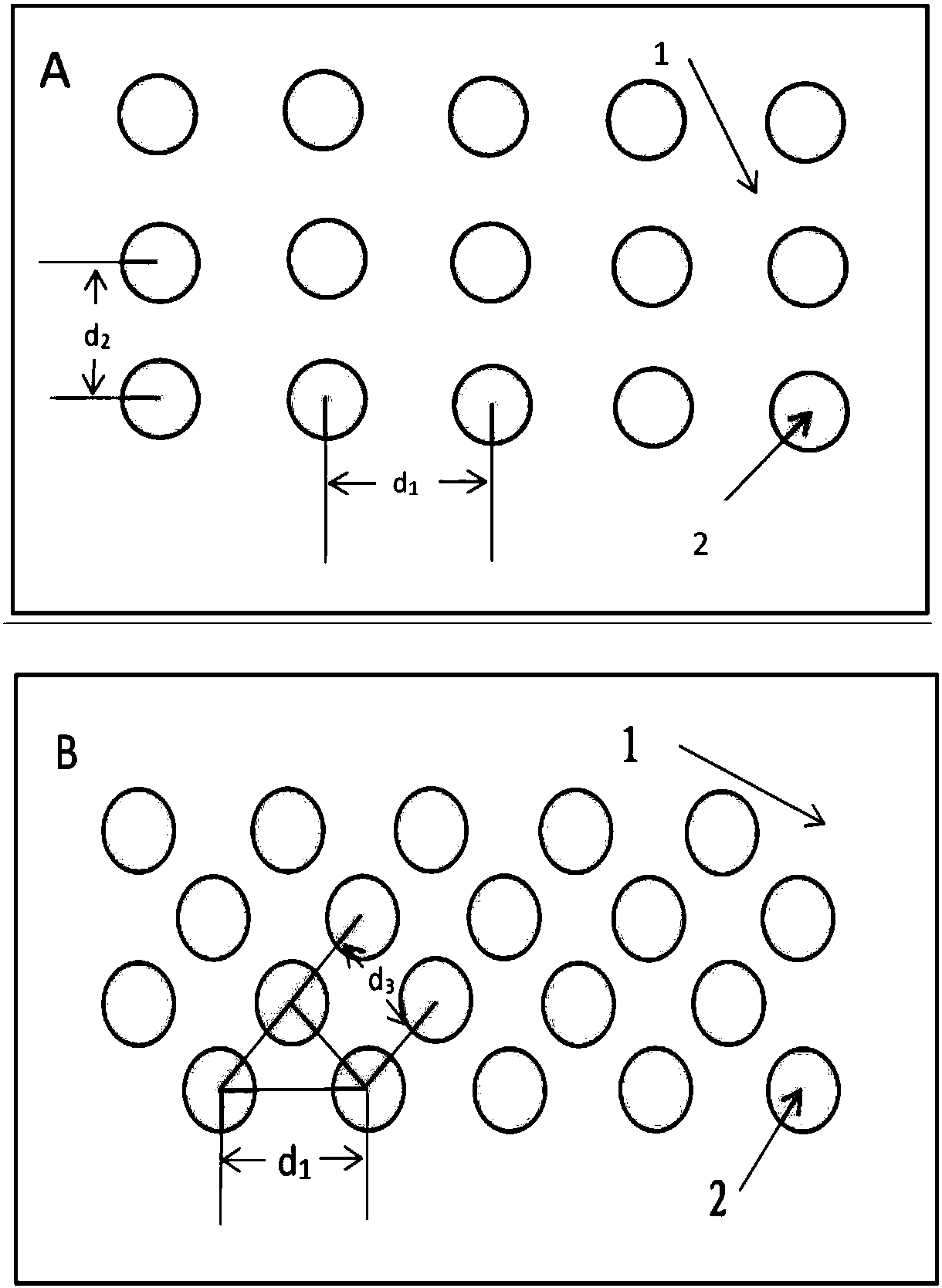

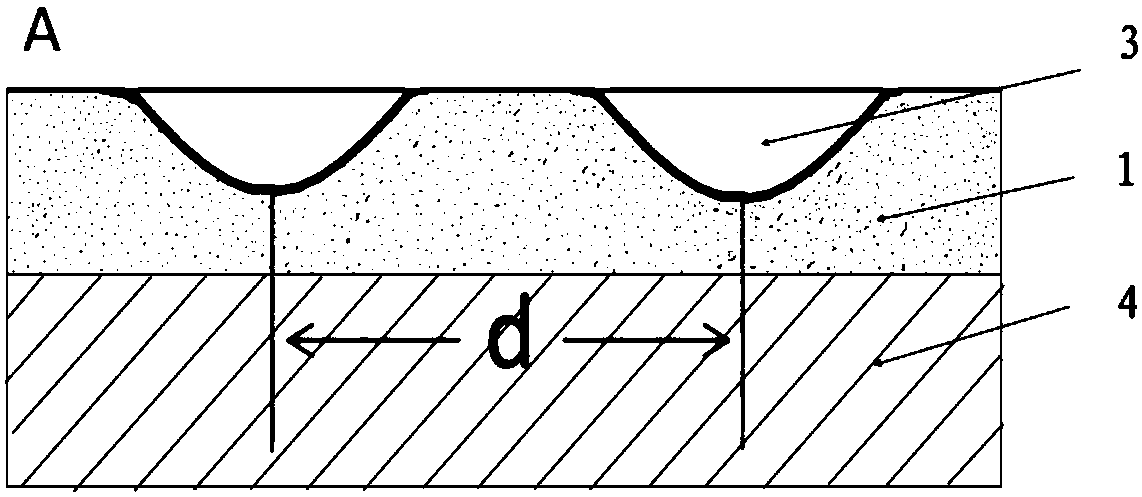

Surface treatment method regulating and controlling transition interface structure of thermal barrier coating through laser shock

InactiveCN107841704AInhibition of TGO growth rateDamage reductionMolten spray coatingSurface finishingBonding strength

The invention discloses a surface treatment method regulating and controlling a transition interface structure of a thermal barrier coating through laser shock. A single circular light spot is adopted, a pit is formed in the surface of a bonding material through laser shock treatment, a special geometrical morphology of the surface layer of a bonding layer is formed, thus, the bonding strength between a plasma-spray ceramic layer and the bonding layer is improved, prefabrication residual stress is formed on the surface, in the high-temperature cyclic oxidation process, thermal stress of the thermal barrier coating can be adjusted, the TGO growth speed and formation of contiguous TGO are effectively restrained, and damage of thermal stress to bonding force of the bonding layer and the ceramic layer is reduced. Through thermal shock property tests, the service life of the thermal barrier coating after bonding layer shock is greatly prolonged. The thermal barrier coating interface structure regulating method is simple in process, easy to operate and convenient to implement.

Owner:JIANGSU UNIV

Fluorescent powder coating liquid of white light emitting diode as well as preparation method and coating method thereof

ActiveCN102002269ADamage reductionReduce heat quenchingLiquid surface applicatorsLuminescent paintsQuenchingUltrasound attenuation

The invention provides a method for configuring a fluorescent powder coating liquid of a white light emitting diode. The fluorescent powder coating liquid of the white light emitting diode includes the fluorescent powder and a binder, wherein the binder is an inorganic compound nanometer silica sol, and the inorganic compound nanometer silica sol and the fluorescent powder have weight percentage ratios of 60-85% and 40-15%. The method includes: slowly pouring the silica sol into a ball mill with 15%-40% of fluorescent powder, then adding ball mill balls with diameters of phi6, phi10, phi15 and a weight ratio of 2:1:1 for mixing and milling. The fluorescent powder coating liquid has the advantages that the membrane enveloping effect on the fluorescent powder is realized by utilizing the nano silica sol; the damage of the harmful ultraviolet radiation on the fluorescent powder is reduced; and the hot quenching property of the fluorescent powder is lowered so that the attenuation of the fluorescent powder and the color bleaching of the light emitting diode are reduced, and the aging resistance property of the light emitting diode is improved.

Owner:FOSHAN NATIONSTAR OPTOELECTRONICS CO LTD

Method for judging internal fault of transformer using excitation property

Technical scheme of the invention is as follows. If it is supposed that L1, L2 are as inductances of windings at primary side and subsidiary side; R1, R2 are as resistances of windings at primary side and subsidiary side. Relation between terminal voltage u1 of a winding of transformer, current i1 of flowing into the winding and mutual inductance chain of transformer is as U1 - R1í‡i1 - Lí‡di1 / dt = dPhi / di. In the mutual inductance chain, cancellation between i1 and i2 is carried out. Thus, the differential current is as excitation surge current. Advantages are: raising action speed of differential protection of transformer, discriminating each internal fault in transformer by using less time, reducing harms on transformer and running system from faults of transformer, and increasing safety and stability of power system.

Owner:GUODIAN NANJING AUTOMATION

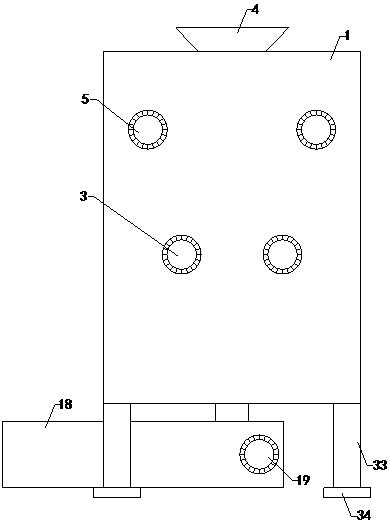

Environment-friendly waste gas treatment device

InactiveCN108126467AReduce waste of resourcesDamage reductionCombination devicesGas treatmentWater tanksNozzle

The invention discloses an environment-friendly waste gas treatment device which comprises a device body, wherein through holes are formed in the upper part and lower part of the device body; a firstframe and a second frame are respectively arranged inside the through holes; filtering nets are arranged inside the first frame and the second frame; a water sprinkling plate is arranged on the innerwall of the device body; a fixing hole is arranged on a side face of the device body; a filter cartridge is arranged inside the fixing hole and comprises a base and a sealing cover; fixing rings are arranged on the outer sides of the base and the sealing cover; a screen is arranged inside the filter cartridge; a water tank is arranged at the bottom end of the device body; and a nozzle is arrangedat the upper end of the device body. The structure is simple, resource waste and environmental pollution are reduced, damage of equipment is reduced, and the maintenance is reduced. Moreover, the device is wholly convenient to detach, the filtering net and the screen are cleaned and replaced, the filtering effect is excellent, and the device is safe and convenient to use.

Owner:潘建明

Continuous coal mining machine paste filling mining method

ActiveCN104500070ADamage reductionImprove economic efficiencyUnderground miningSurface miningCoal miningFilling materials

The invention belongs to the technical field of application of coal mining equipment and coal mining method, and for solving the problems that conventional 'three unders (under building, railways and water bodies)' unexploited coal filling is high in cost and low in efficiency, matched filling materials are mostly solid filling materials, the transport project amount is large, the filling speed is slow, transportation and filling are difficult to match and synchronize, and the goaf compacting effect is not ideal after filling, provides a continuous coal mining machine paste filling mining method; a main lane and an auxiliary lane are arranged at the middle part of a mining area, the two lanes are connected through connection lanes at intervals, two sides of the main lane and the auxiliary lane are each provided with remining branched lanes, and two sides of each branched lane are each provided with mining adits for re-mining. A continuous coal mining machine performs re-mining at the one-side branched lanes, and a paste filling system performs goaf filling in the-other-side branched lanes. The mining and filling parallel operation is achieved, damage of coal mining on ground buildings (structures) and ecological environments is reduced, the economic benefits of the 'three unders' coal mining is increased, the mining and filling efficiency is high, equipment movement is flexible, the process is advanced, and the method is the quite ideal 'three unders' unexploited coal mining method.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

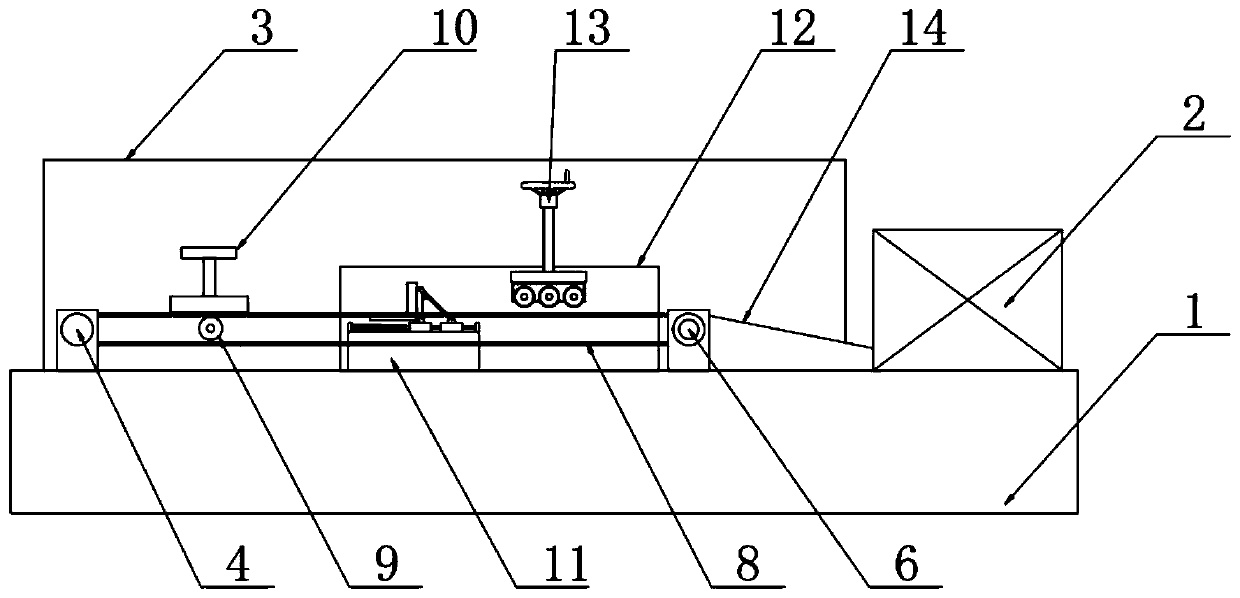

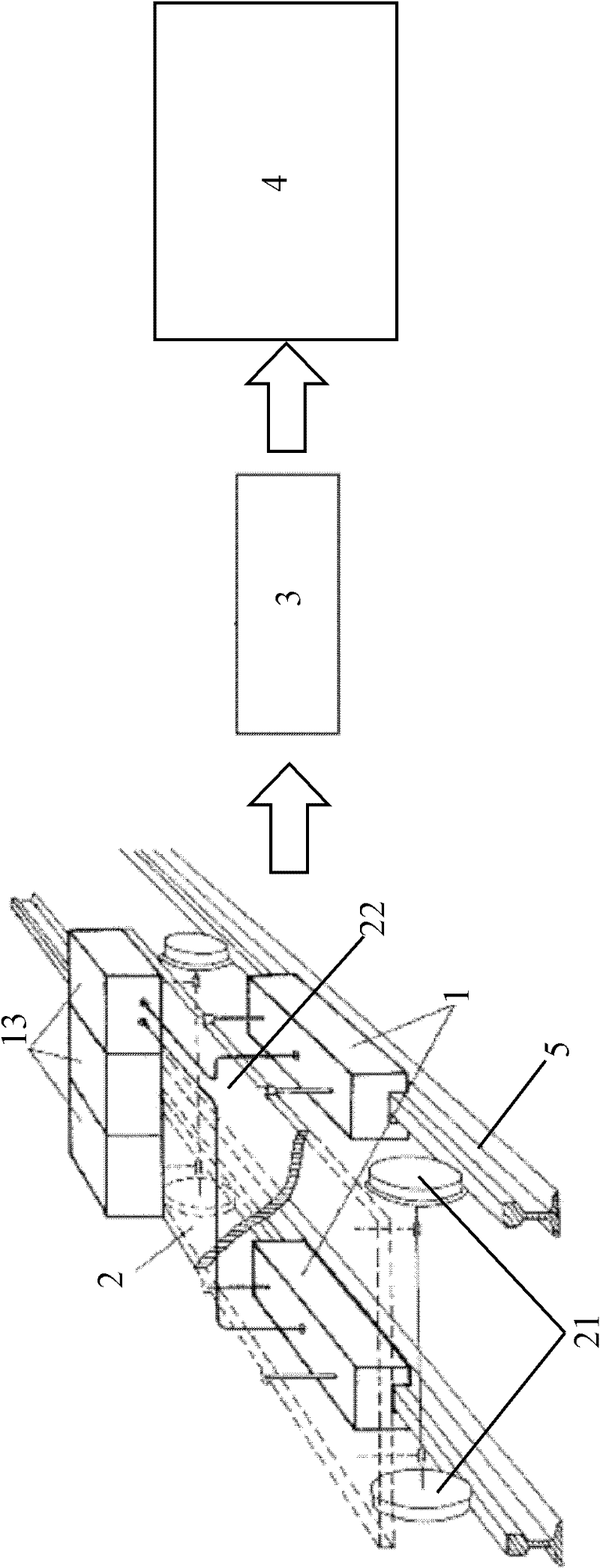

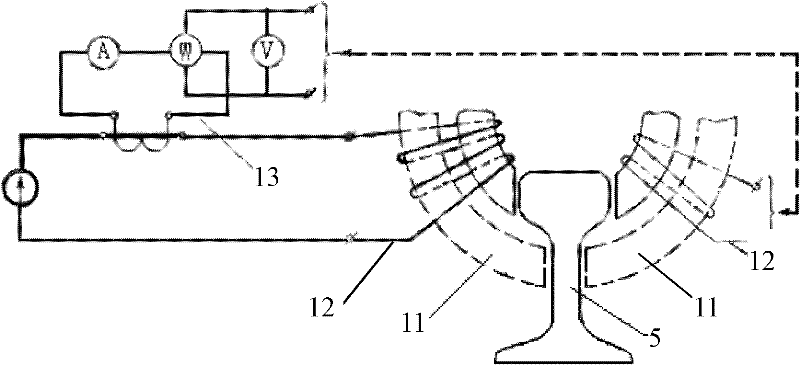

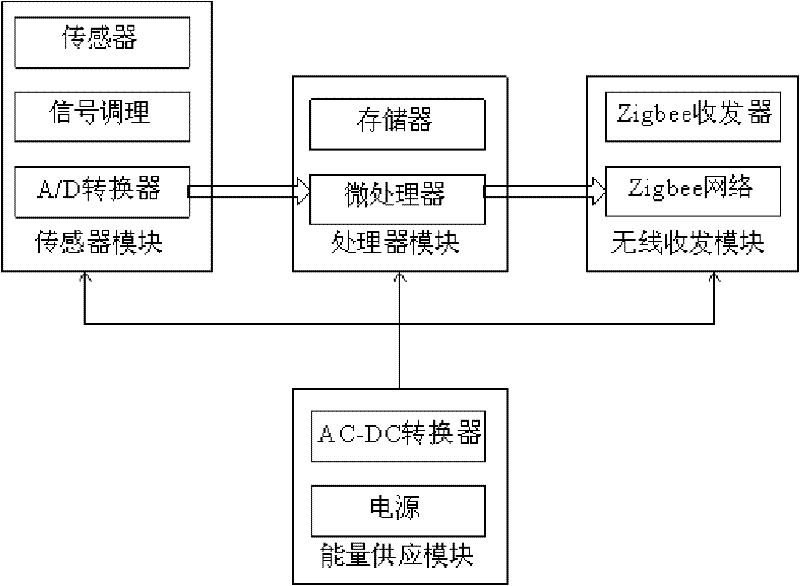

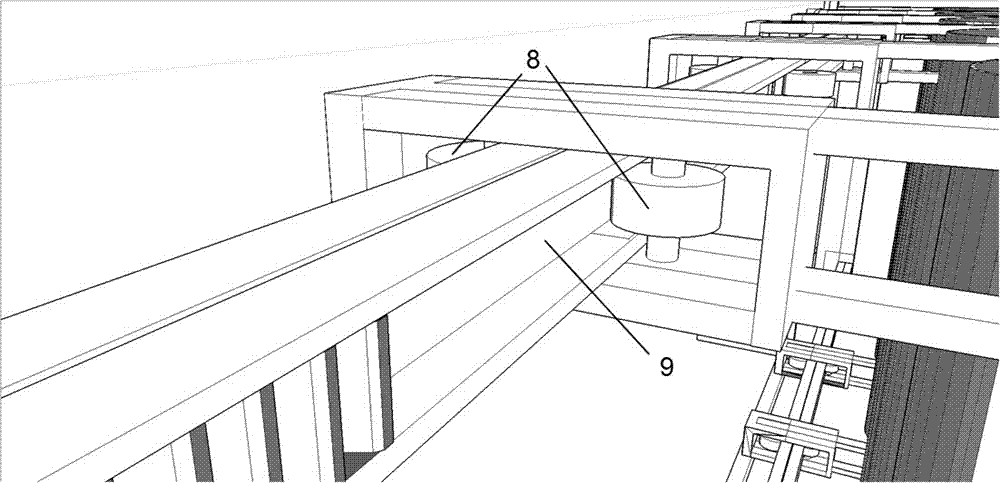

Seamless line locking rail temperature pretreatment system

InactiveCN102296501ADamage reductionReduce the difficulty of operationRailway track constructionElectromagnetic inductionMagnetic flux

The invention discloses a seamless line locking rail temperature pretreatment system, comprising: an electromagnetic induction heating device installed on a walking control system for generating magnetic flux to a seamless line rail; On the rail, it is used to control the electromagnetic induction heating device to move along the longitudinal direction of the rail; the transmission system is used to collect various parameters in the process of seamless line locking rail temperature preprocessing and transmit them to the host computer for data processing system, and correspondingly transmit the control signal sent by the host computer data processing system to the electromagnetic induction heating device and the walking control system; the host computer data processing system is used to process and analyze the For various parameters, the control signal is sent through the transmission system, and the information of the processing process is displayed to the user. The invention effectively reduces the damage to the track surface in the pretreatment process, and improves the working efficiency of the seamless line laying operation.

Owner:CHINA AGRI UNIV

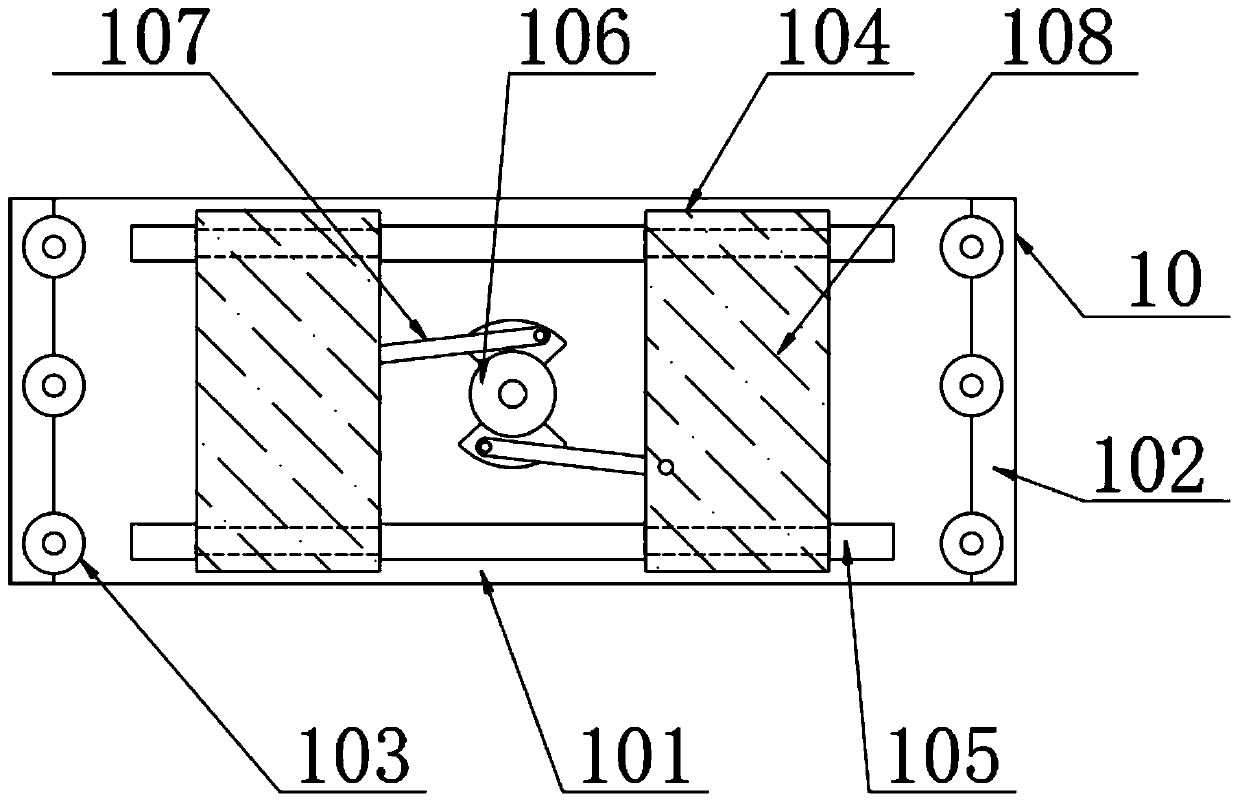

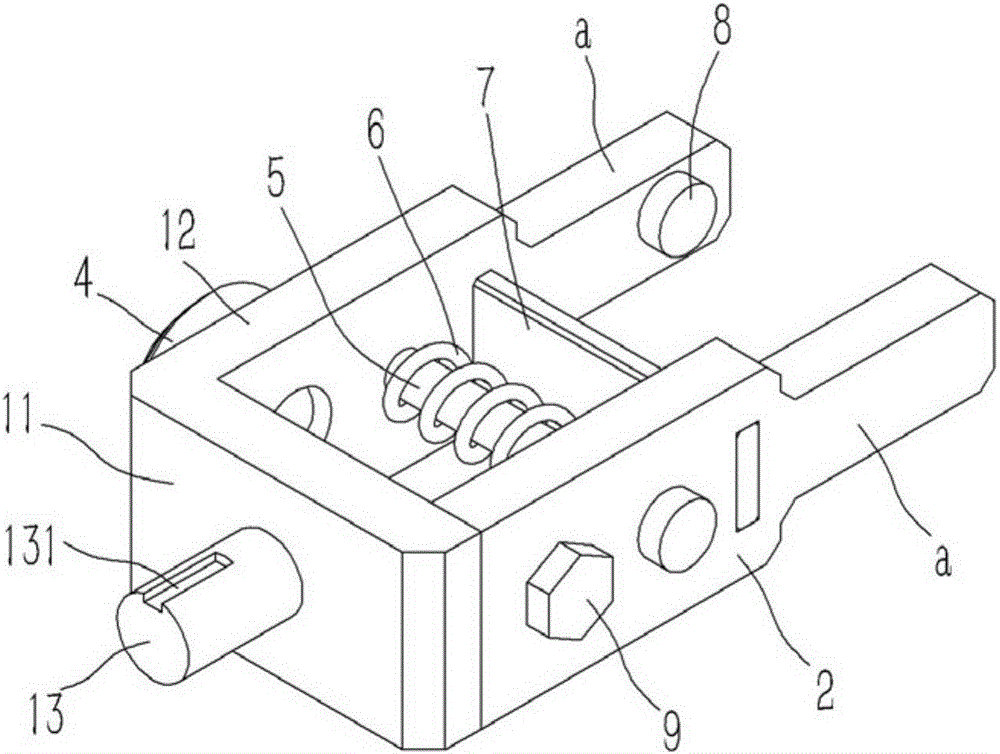

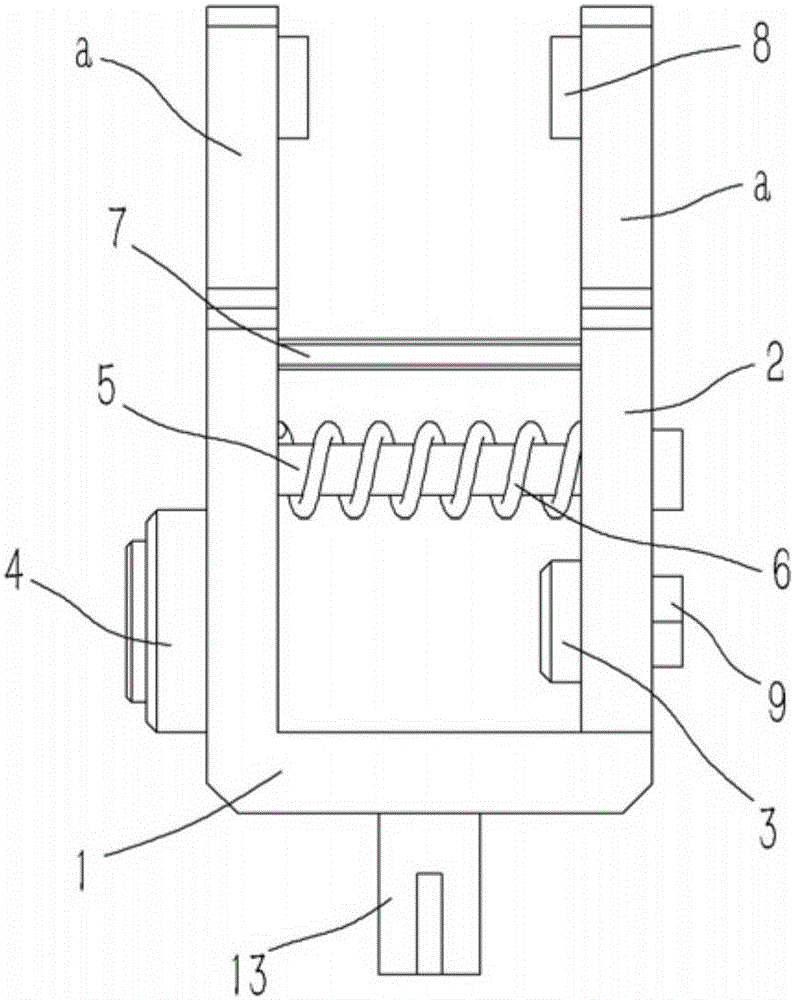

Improved manipulator clamping jaw on component arranging equipment

The invention discloses an improved gripper of a manipulator on a piece placing device, comprising an L-shaped positioning seat and a clamping plate, the positioning seat is composed of a transverse part and a longitudinal part, and the rear end of the clamping plate abuts on the inner wall of the transverse part of the positioning seat, An iron block is fixed on the inner side wall of the rear end of the splint, an electromagnet opposite to the iron block is fixed on the longitudinal part of the positioning seat, and a T-shaped guide rod is inserted into the splint on the front side of the iron block, and the guide rod is fixed on the positioning seat. On the longitudinal part, a compression spring is inserted into the guide rod, and the two ends of the compression spring are respectively pressed against the positioning seat and the clamping plate. A vertical baffle is inserted into the clamping plate on the front side of the guiding rod, and the baffle is fixed. on the longitudinal portion of the positioning seat. The invention adopts magnetic clamping instead of the cylinder to clamp the material, and the clamping force can be changed by the current, so that the damage to the material can be reduced during clamping.

Owner:DONGGUAN SHENGRONG AUTOMATION TECH CO LTD

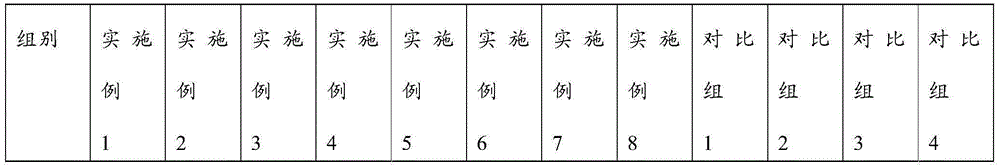

Coconut oil extraction method

InactiveCN105132118AIncrease the speed of enzymatic hydrolysisDamage reductionFatty-oils/fats productionCoconut oilOrganic solvent

The invention discloses a coconut oil extraction method, which comprises the following steps of grinding coconut flesh into pulp; performing microwave ultrasonic processing on the coconut pulp; performing enzymolysis and centrifugation; taking upper layer clean oil to obtain coconut oil. When the coconut oil extraction method provided by the invention is used, under the conditions of not using organic solvents or not adopting high-temperature processing, the damage to nutrition substances is reduced; the method is simple and safe; the oil yield is high; the cost is low; the energy consumption is low; residue liquid after the oil and grease extraction contains rich protein and polypeptide and can be recovered and reused; the residue solid contains rich dietary fiber and polysaccharide, and can be used as animal feed or can provide carbon sources for microorganism fermentation; waste water can be easily processed; substances harmful to environment cannot be generated; the prepared coconut oil is clear and transparent, has intense coconut fragrance and has good application prospects.

Owner:HAINAN UNIVERSITY

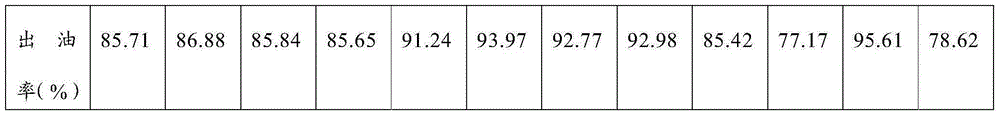

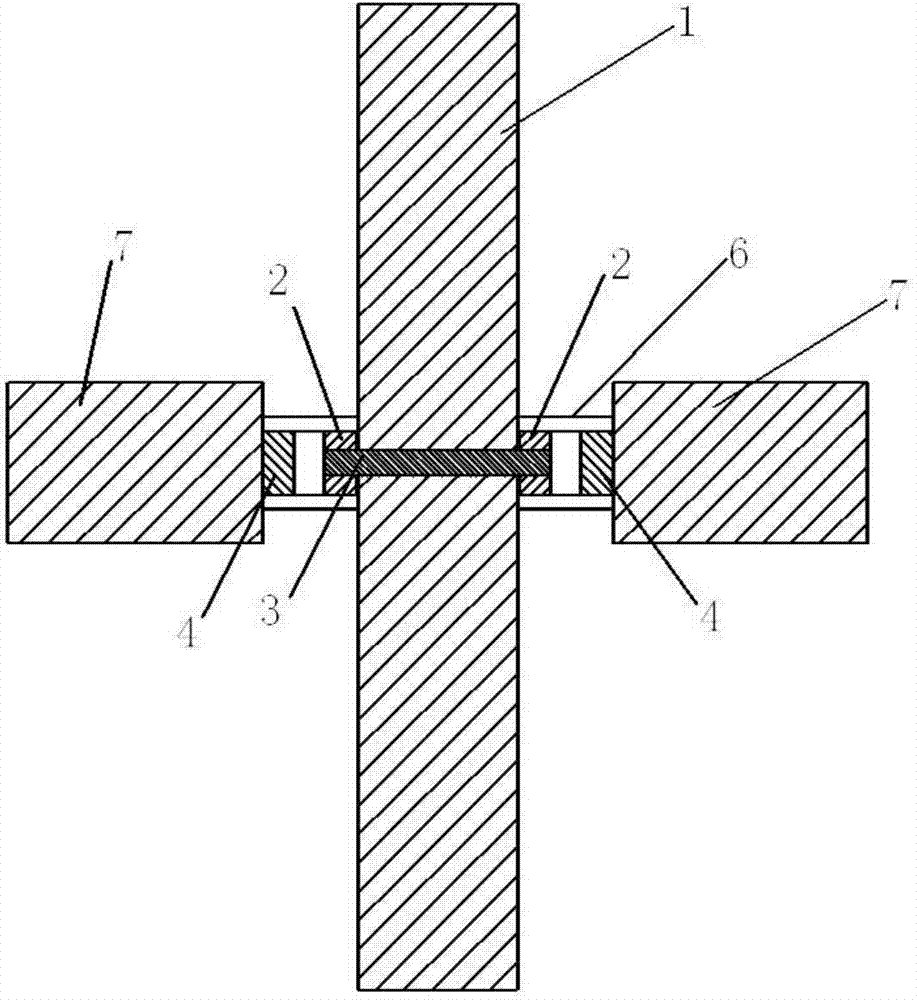

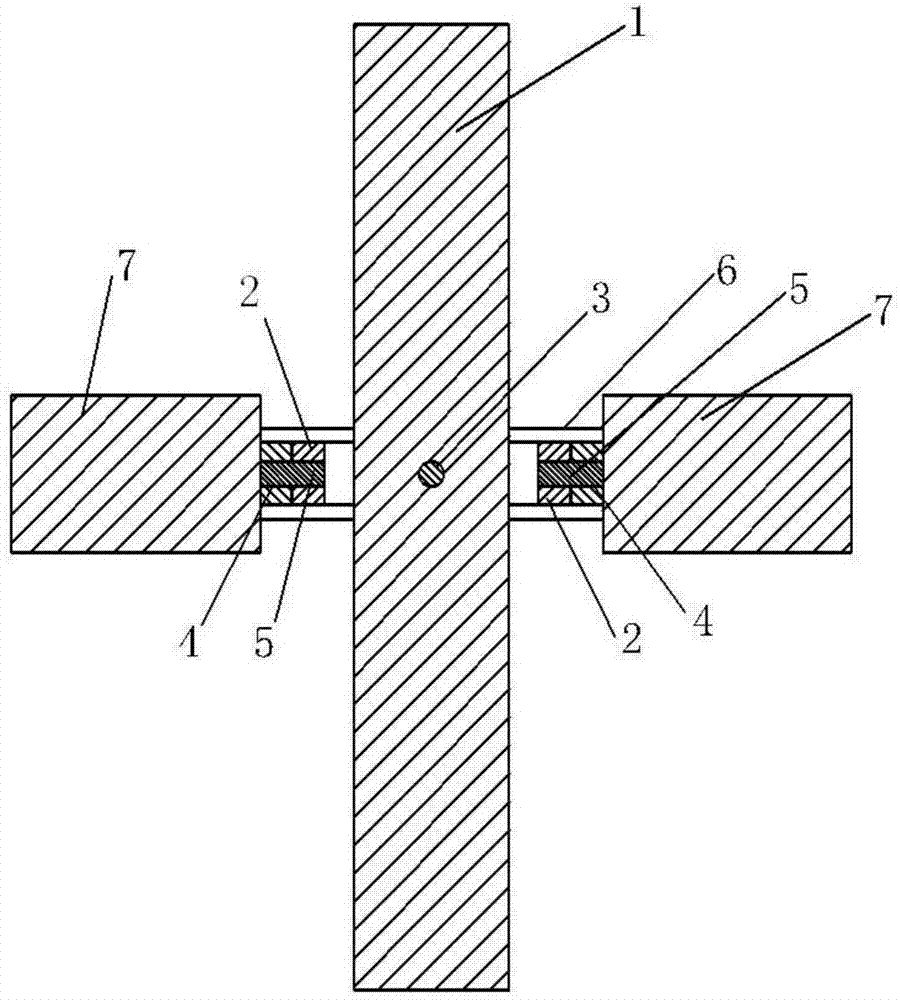

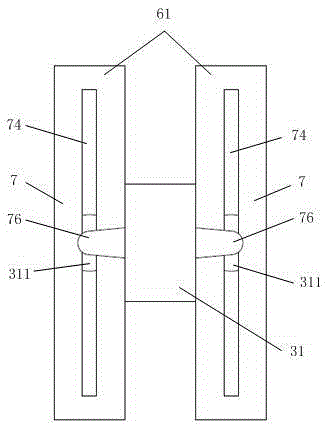

Beam post steel ring hinging section point

The invention provides a beam post steel ring hinging section point, which comprises an upright post, a plurality of cross beams, an inner steel ring, an outer steel ring, a post steel ring plug pin and an inter-steel-ring plug pin, wherein the inner steel ring is sheathed on the upright post, the outer steel ring is sheathed on the inner steel ring, the post steel ring plug pin connects the inner steel ring onto the upright post, the inter-steel-ring plug pin connects the outer steel ring onto the inner steel ring, the inner steel ring rotates by using the post steel ring plug pin as a rotating shaft, the outer steel ring rotates by using the inter-steel-ring plug pin as a rotating shaft, a long shaft of the post steel ring plug pin and a long shaft of the inter-steel-ring plug pin are positioned in the orthogonal direction, and during the earthquake, the inner steel ring does limited rotation relative to the upright post and the outer steel ring, so the upright post generates relative movement with the cross beams and a floor slab, further, the mutual traction effect is not generated by each composition component of a building structure, the earthquake effect can be favorably reduced, in addition, the upright post and the cross beams are connected through rigid bonding-pre-stress-free steel bars, the building structure can be enabled to return to the initial position after the earthquake through the elastic recovery force generated by the bonding-pre-stress-free steel bars during the earthquake, and the structural damage caused by earthquakes can also be reduced.

Owner:TONGJI UNIV

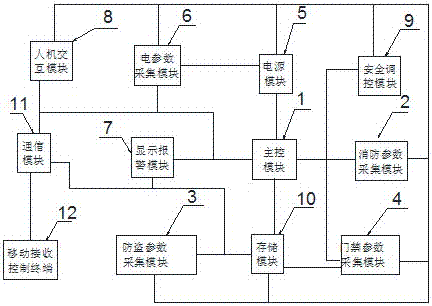

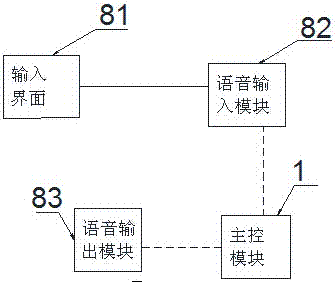

Multifunctional intelligent household security control system

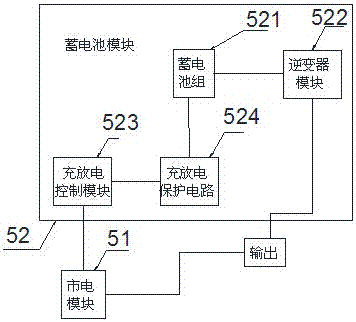

InactiveCN107132826ADamage reductionIncrease risk resistanceMeasurement devicesComputer controlExternal connectionStandby power

The invention discloses a multifunctional intelligent household security control system. The system comprises a master control module, a firefighting parameter collection module, an antitheft parameter collection module, a gate inhibition parameter collection module, a power supply module, an electric parameter collection module, a display alarming module, a man-machine interaction module, a safety regulation and control module, a storage module, a communication module and a mobile reception control terminal. According to the invention, different household indoor parameter information can be detected automatically, related environment data and security monitoring data is back fed in real time, the collected parameter information can be processed, regulation and control is implemented automatically when the data exceeds the thresholds, damage is reduced to the largest extent, the man-machine interaction system provides external connection channels in emergency and provides instant messaging for people via a bidirectional voice transmission system, a storage battery arranged in the power supply module can provide standby power supply after power failure, the anti-risk performance of the system is improved, and the system has wider application prospects and higher practical values.

Owner:合肥佳洋电子科技有限公司

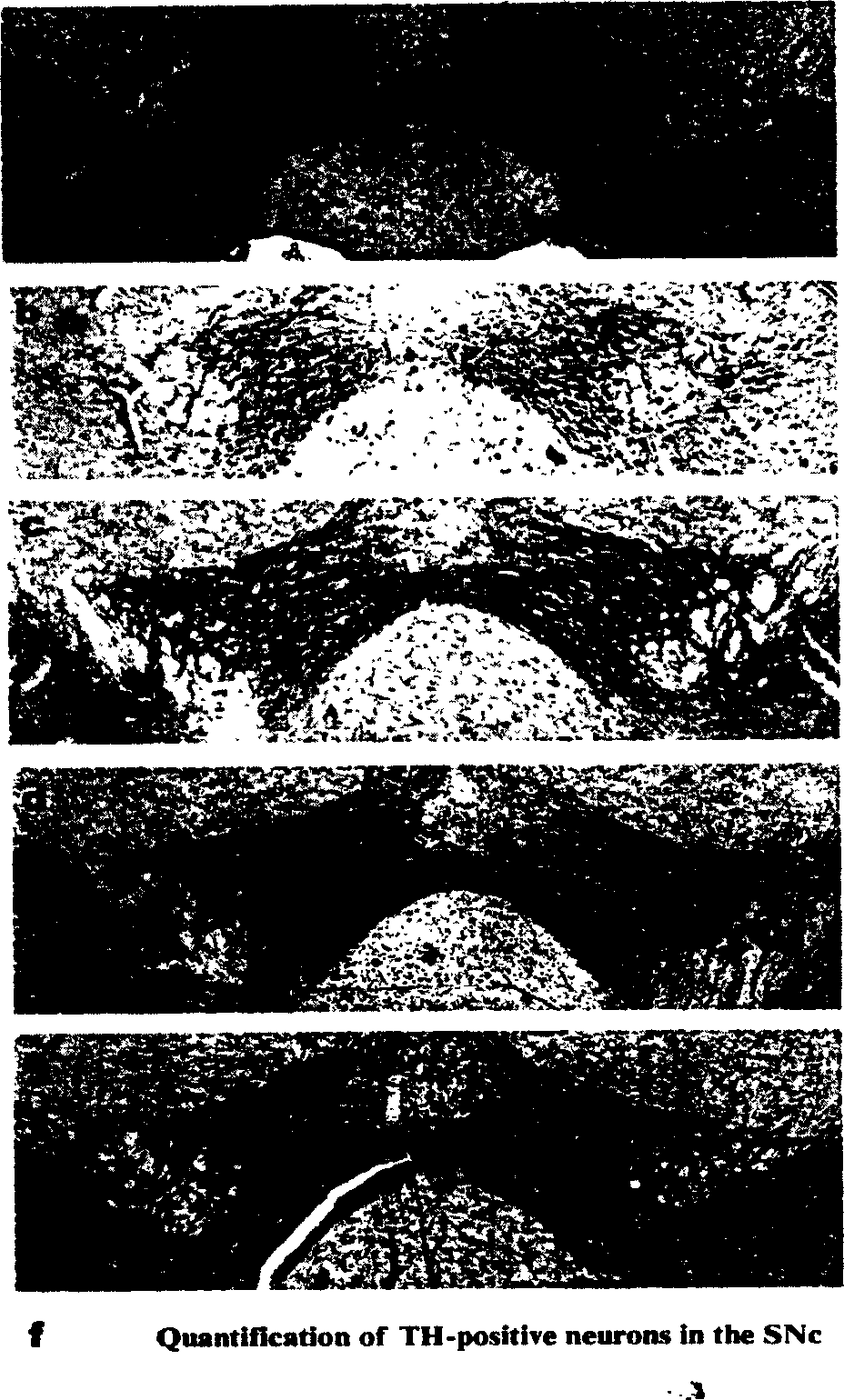

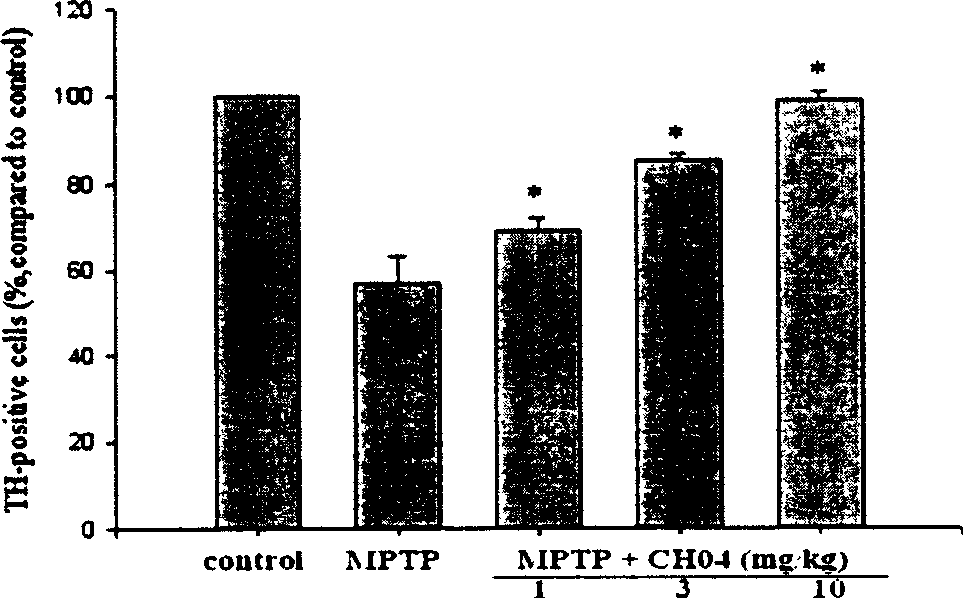

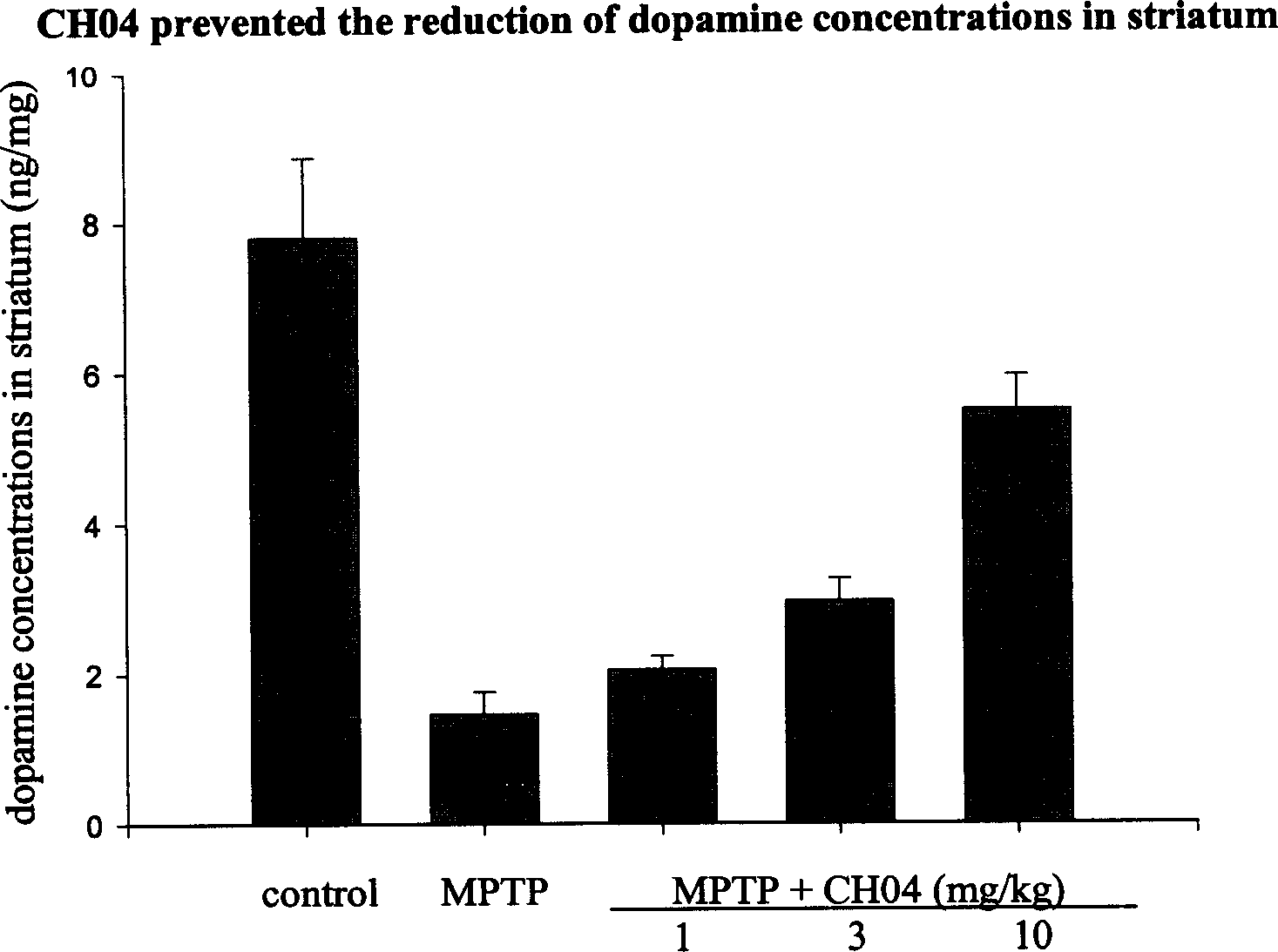

Application of stevioside R1 and its derivative as medicine for preventing and treating neurodegeneration disease

InactiveCN1608628ADamage reductionOrganic active ingredientsNervous disorderNeurodegenerationTherapeutic index

Japanese raspberry herb, Stevioside R1 and its derivative are used in preparing medicine for preventing and treating neurodegeneration disease. Animal and human body experiments show that the medicine has excellent treating effect on neurodegeneration diseases, including Parkinson's disease, senile dementia, etc. with high treating index and high safety.

Owner:SUN YAT SEN UNIV

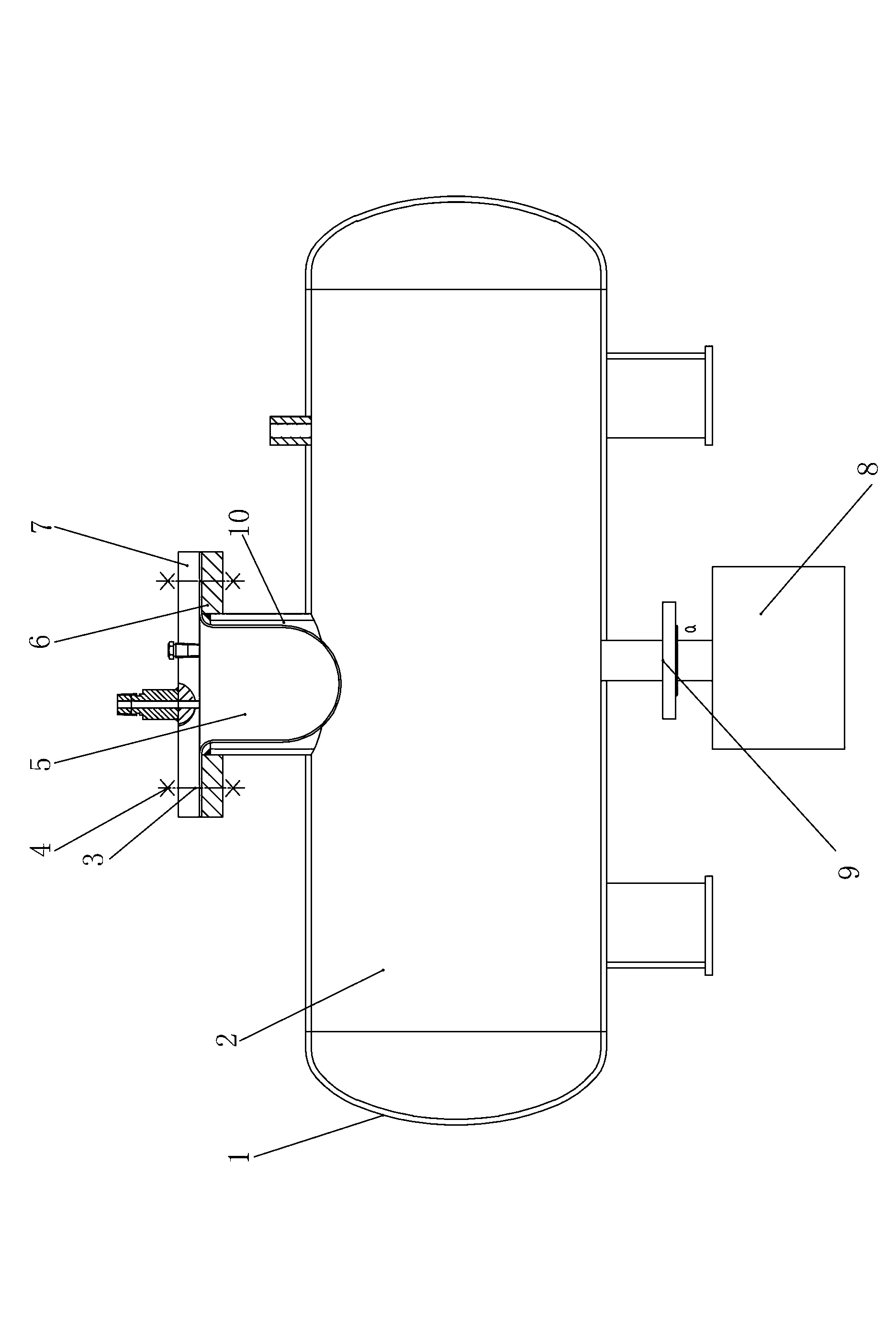

Pressure container pressure resistance test process and auxiliary tools thereof

InactiveCN102798571AEnsure safetyDamage reductionDetection of fluid at leakage pointMaterial strength using tensile/compressive forcesForeign matterPressure resistance

The invention discloses a pressure container pressure resistance test process and auxiliary tools thereof, belonging to the technical field of manufacturing of pressure containers. According to the invention, pressurization cavities and storage containers, which serve as the auxiliary tools, are additionally arranged and matched with an original test tool; in the process, a pressurization cavity mounting step is added; and different pressure test mediums are filled in the different cavities. The test process comprises the specific steps of foreign matter cleaning, pressure test medium filling, emptying, pressurization cavity mounting, water injection, pressure testing, decompression, dichlorofluoroethane recovery and ending. According to the invention, after the pressurization cavities are added in the test process, the synchronous application of a plurality of liquids can be realized; and when the dichlorofluoroethane (R141b) is taken as the pressure test medium, the production efficiency can be effectively improved and the manufacturing cost can be reduced.

Owner:RUIDONG GRP

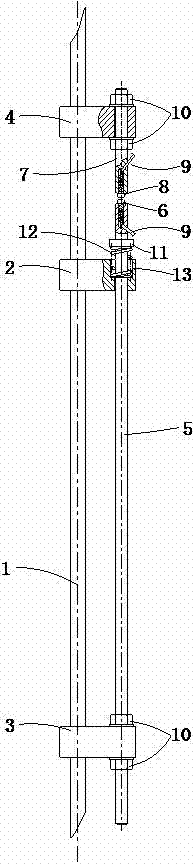

Steel wire rope looseness and breakage alarming device

The invention relates to a steel wire rope looseness and breakage alarming device. The steel wire rope looseness and breakage alarming device comprises a first fixing device and a second fixing device both fixed on a vertically arranged steel wire rope, wherein a long threaded rod is also arranged between the first fixing device and the second fixing device; a movable contact is arranged on the top end of the long threaded rod; a third fixing device is also arranged above the long threaded rod; a short threaded rod is arranged on the third fixing device; a fixed contact is arranged on the tail end of the short threaded rod; the fixed contact is arranged on the upper part of a movable contact; a gap is formed between the fixed contact and the movable contact; the fixed contact and the movable contact are connected to a console respectively through control lines. When a steel wire rope is loosened or broken accidentally, the fixed contact and the movable contact are in contact to trigger safety protection devices of crane equipment such as an elevator and a stereoscopic parking garage to lighten damage caused by accidents. The steel wire rope looseness and breakage alarming device has the characteristics of simple installation, a capability of discovering looseness and breakage of the steel wire rope as early as possible, high sensitivity and the like.

Owner:SUZHOU INDAL TECH RES INST OF ZHEJIANG UNIV +2

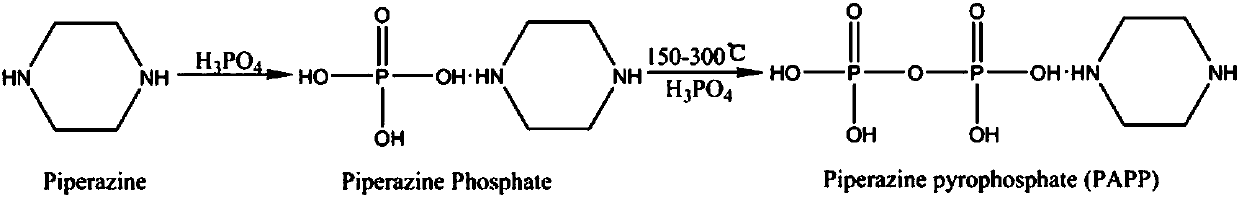

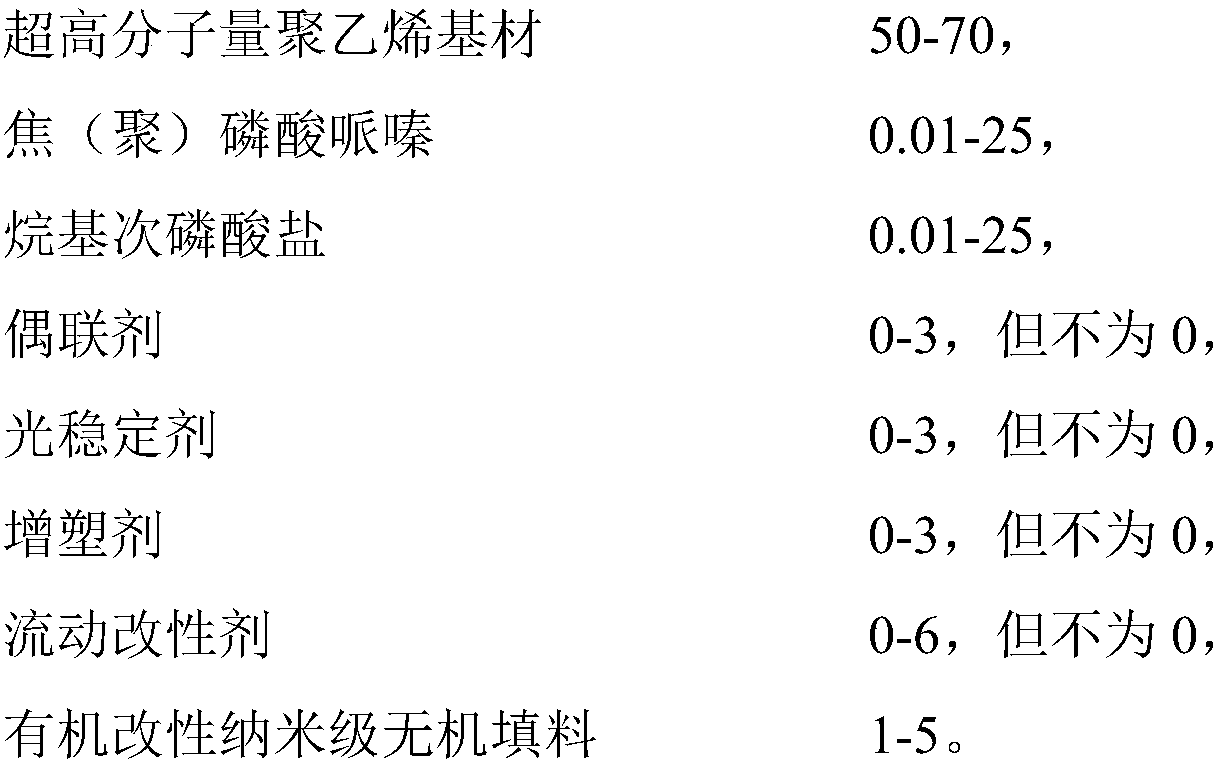

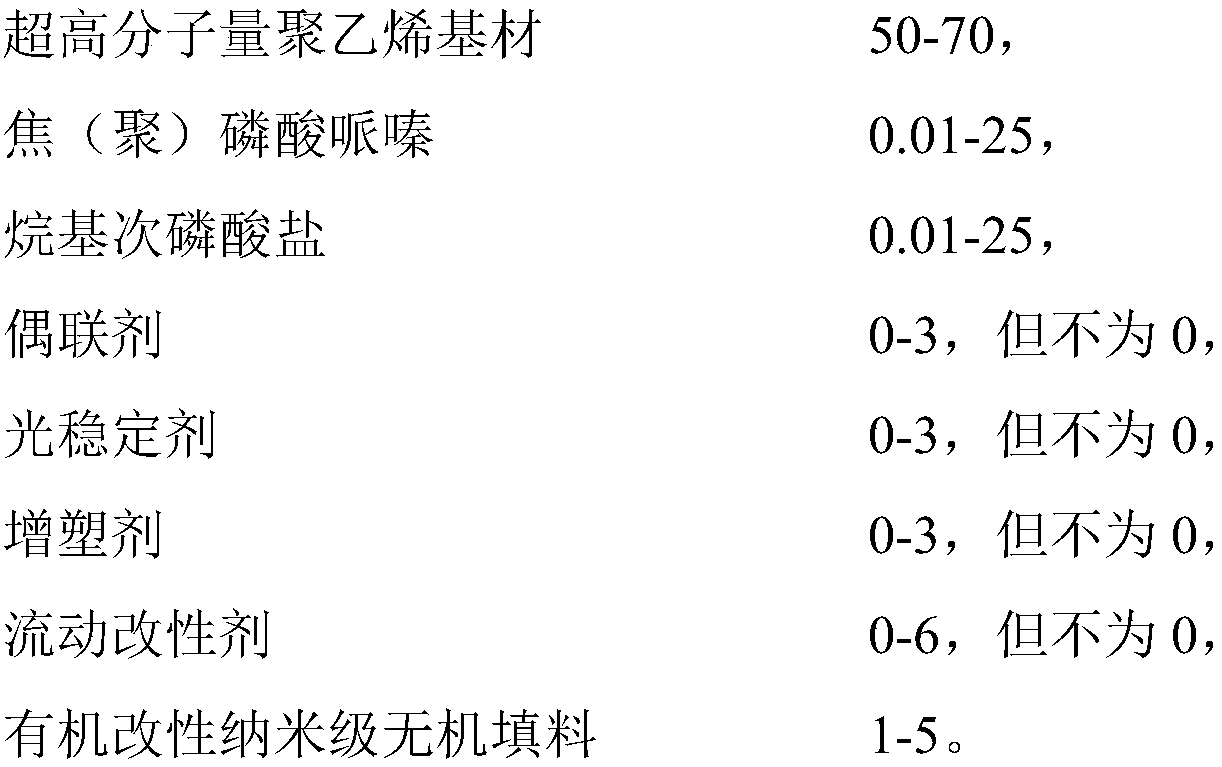

Halogen-free flame-retarding ultrahigh-molecular weight polyethylene material and preparation method of same

The invention relates to a halogen-free flame-retarding ultrahigh-molecular weight polyethylene material and a preparation method of same. The material is prepared from: 50-70 parts of a ultrahigh-molecular weight polyethylene base material, 0.01-25 parts of piperazine (poly) pyrophosphate, 0.01-25 parts of alkyl hypophosphite, 0-3 (not equal to 0) parts of a coupling agent, 0-3 (not equal to 0) parts of a photo-stabilizer, 0-3 (not equal to 0) parts of a plasticizer, 0-6 (not equal to 0) parts of a flow modifier, and 1-5 parts of an organically modified nano inorganic filler. The flame-retarding ultrahigh-molecular weight polyethylene material is free of halogens and has good flame-retarding effect reaching UL94 V-0 grade, and also has excellent mechanical performance.

Owner:SHANGHAI RES INST OF CHEM IND

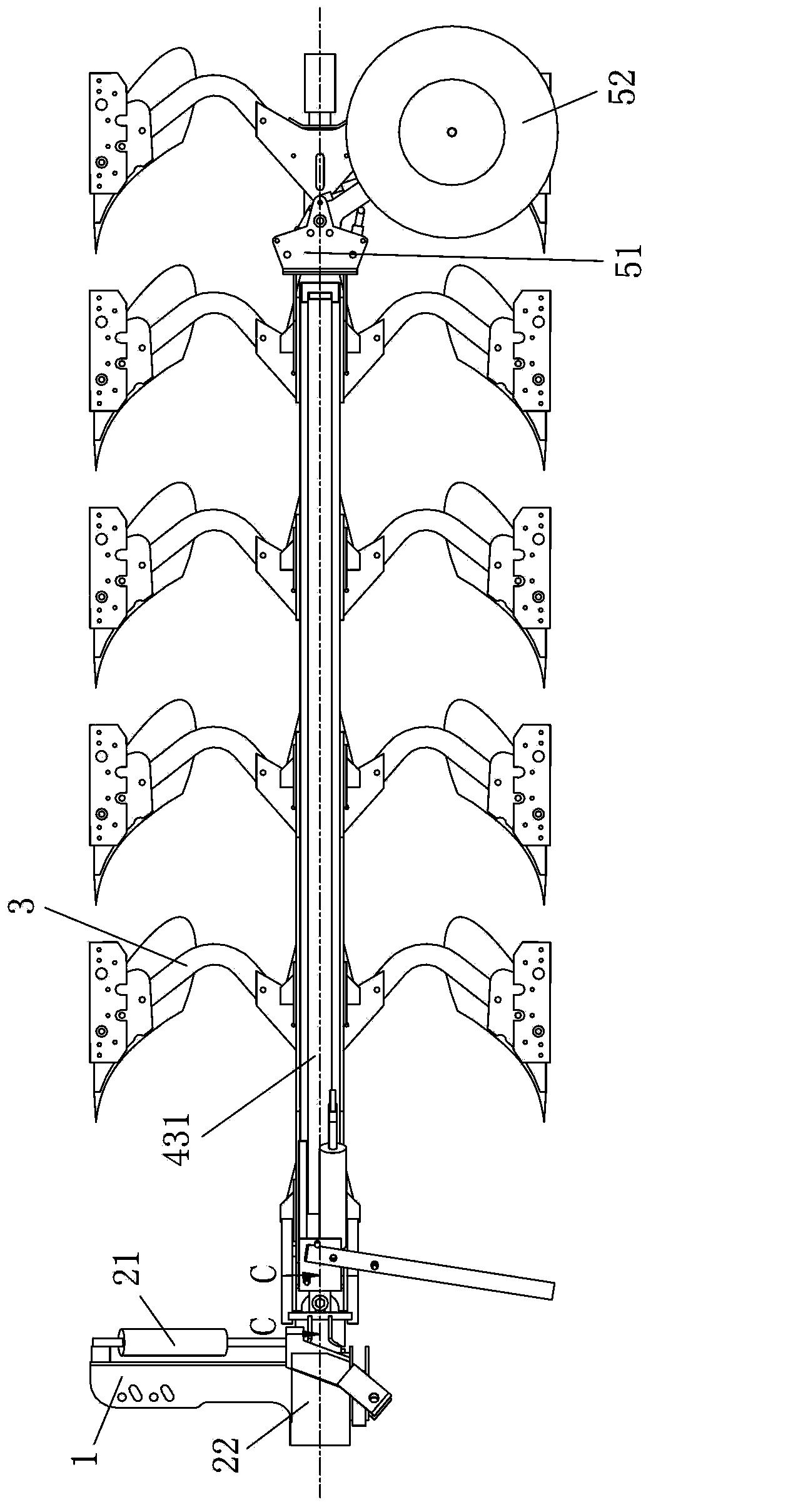

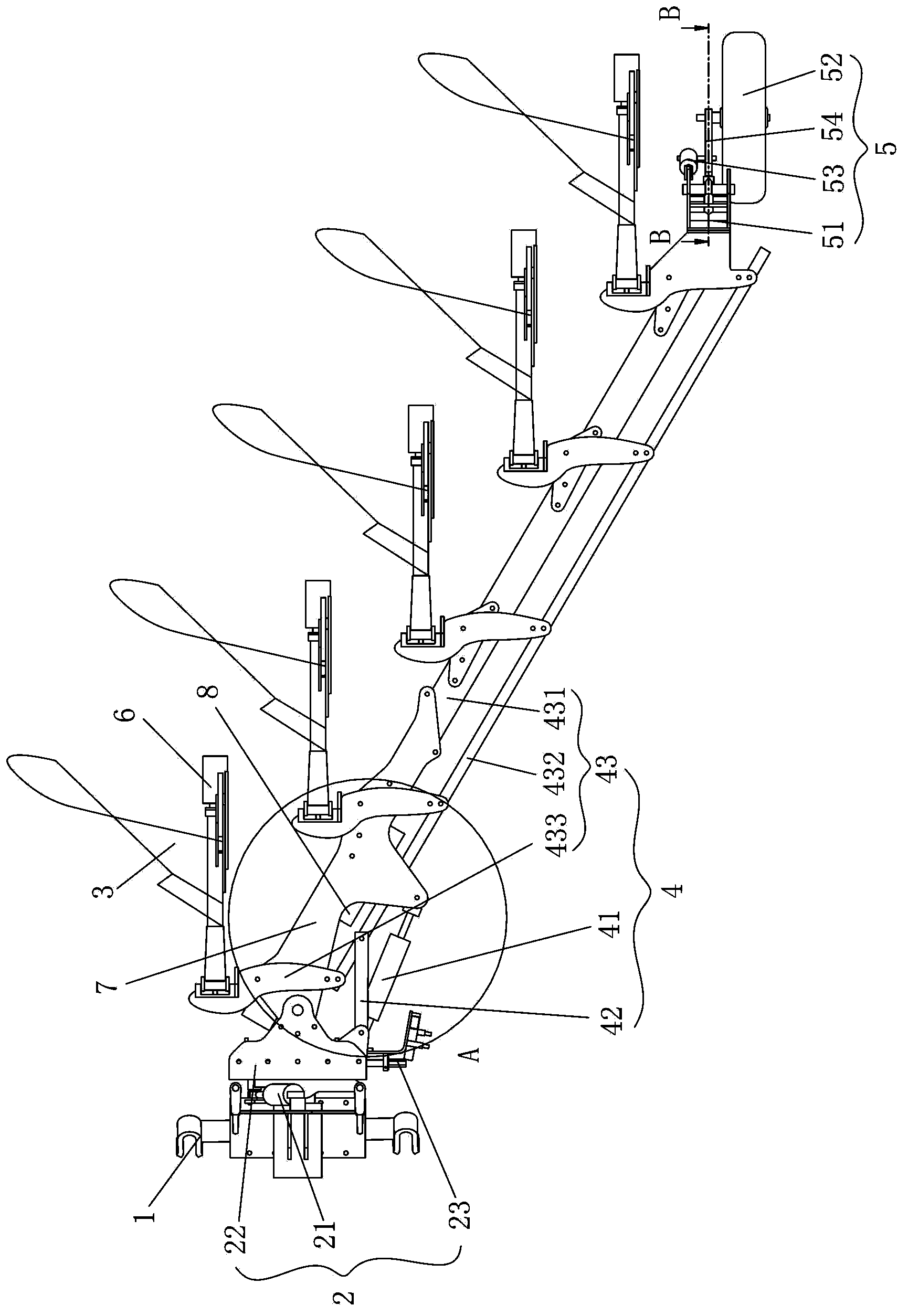

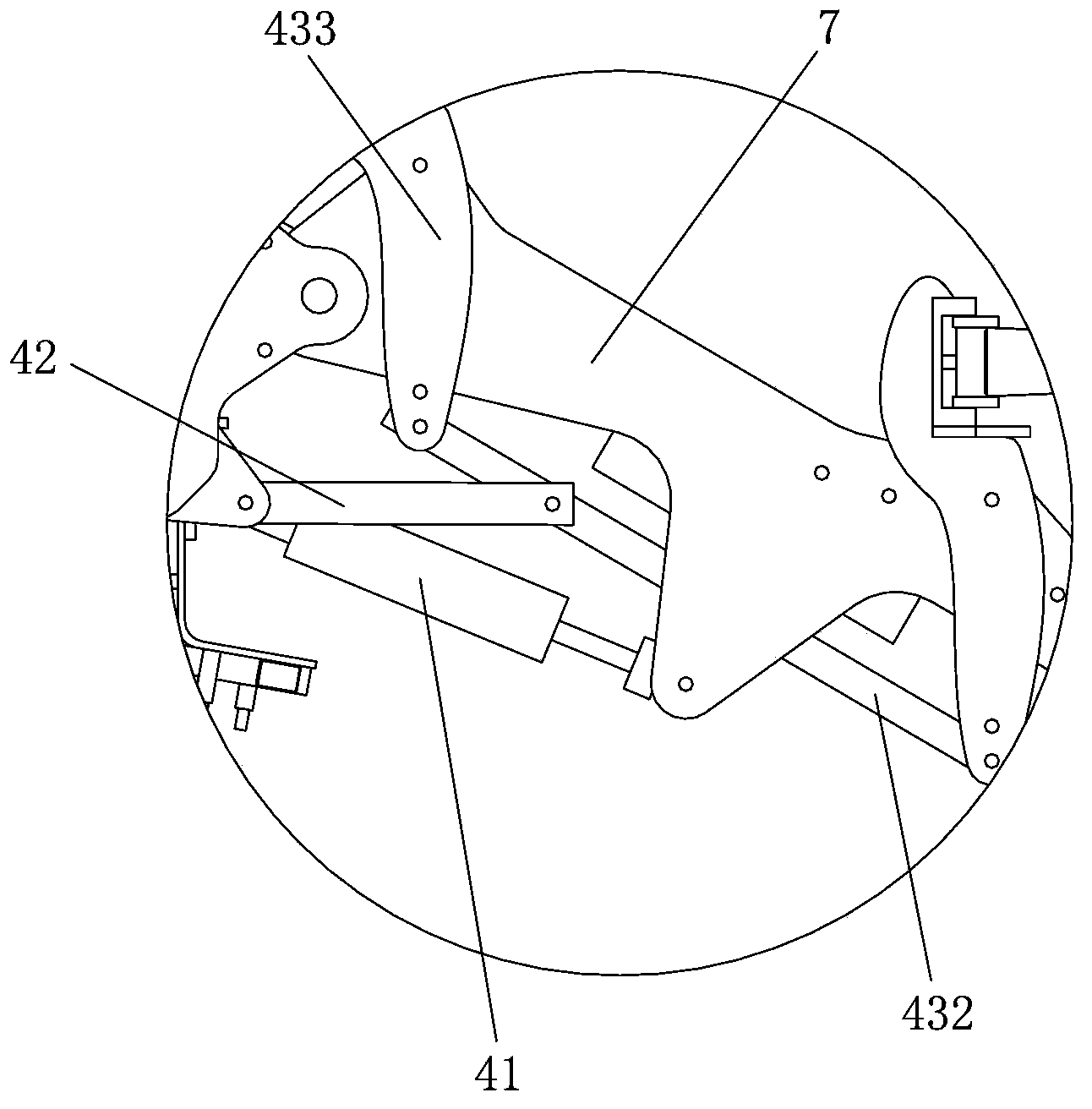

Suspension-type high-speed width-regulation hydraulic turnover plow and stepless width regulation device thereof

Owner:CHINESE ACAD OF AGRI MECHANIZATION SCI +1

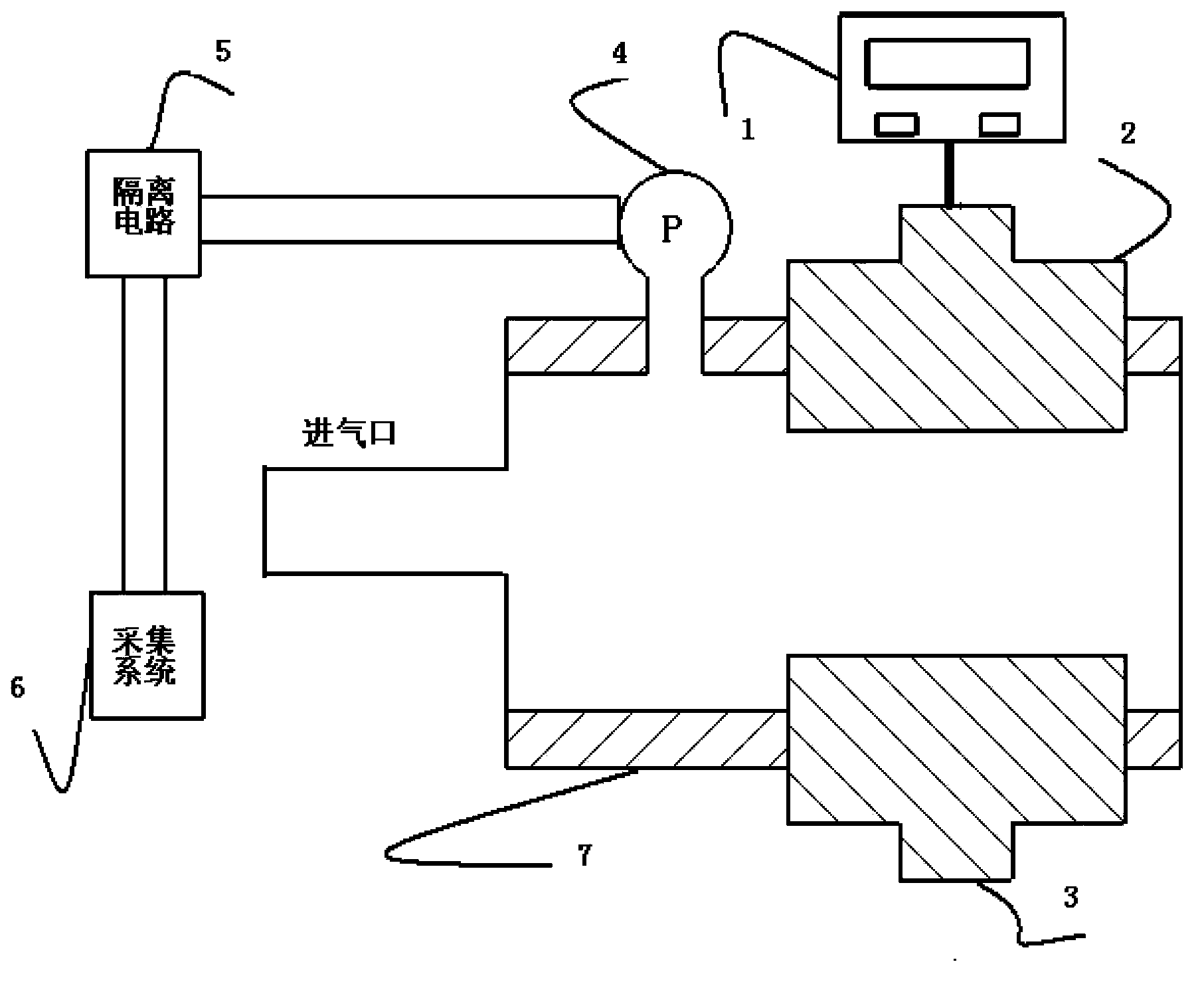

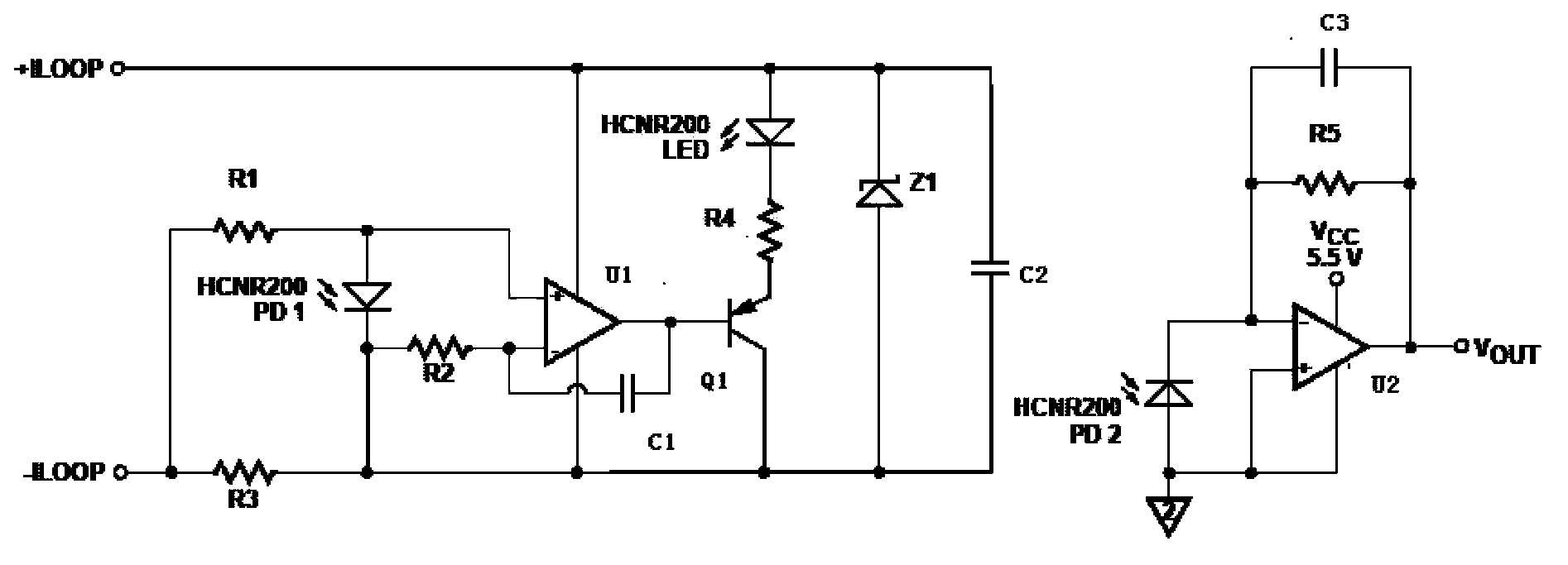

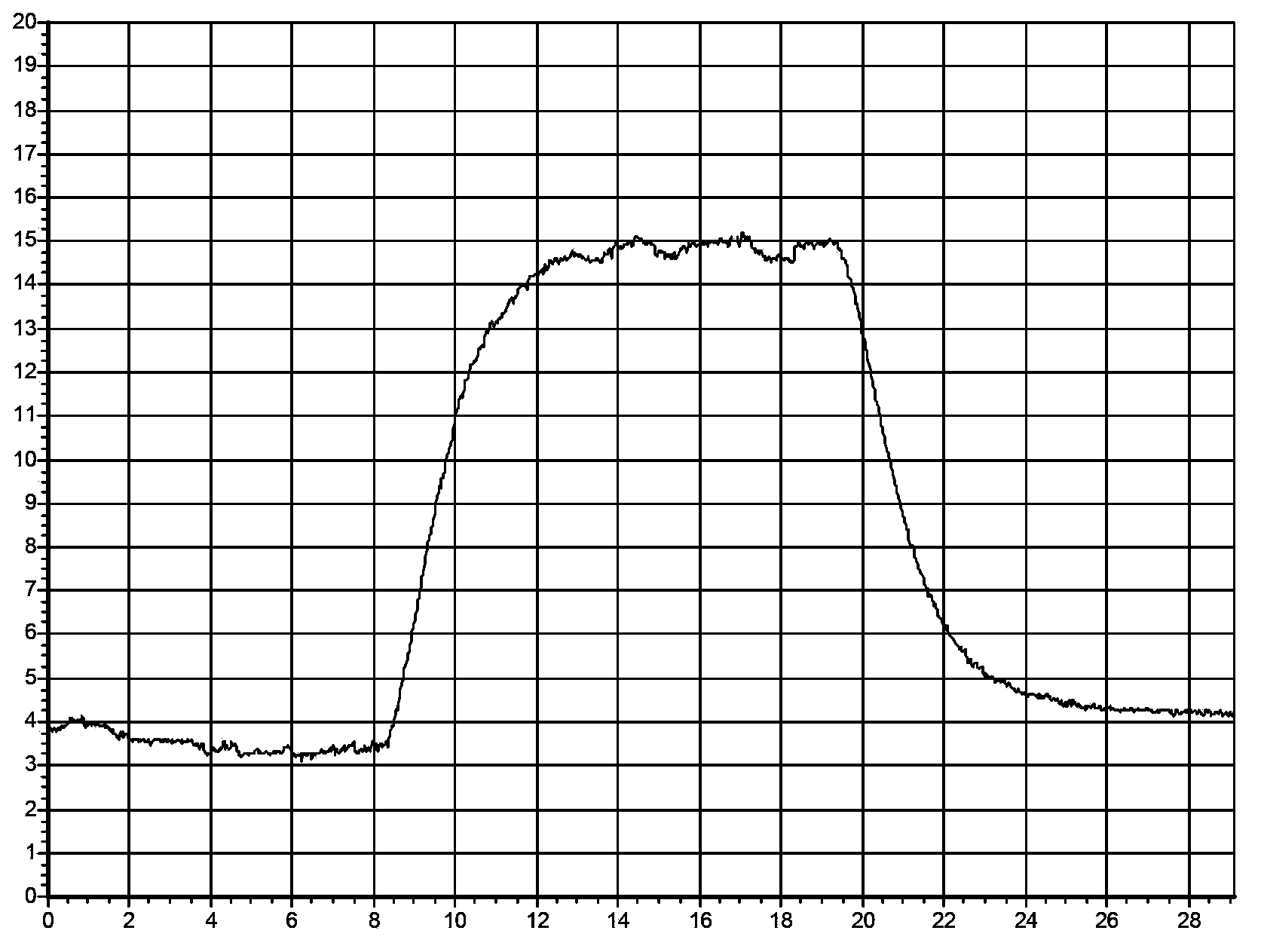

Measurement and control system capable of isolating strong impulse interference

The invention discloses a measurement and control system capable of isolating strong impulse interference. The measurement and control system comprises a pressure transmitter, an isolating circuit and a collecting system. The pressure transmitter is connected with a discharging cavity, and is used for measuring the pressure of the gas inside the discharging cavity when a discharging circuit discharges for the gas inside the cavity. The isolating circuit is connected with the output end of the pressure transmitter, and is used for sampling output electrical signals to electrically isolate input signals from the output signals and to achieve linear conversion between the input signals and the output signals. The collecting system is connected with the output end of the isolating circuit, and is used for collecting clear signals output by the isolating circuit to a computer system, and the clear signals are displayed through measurement and control software. According to the measurement and control system, interference signals coupled to a testing signal transmission line are isolated in the period of discharging to high-power impulses, and therefore the amplitude of the interference of strong impulses is effectively reduced, the damage to a testing system from the strong impulse interference signals is prevented, and the signals cannot lose. The measurement and control system has the advantages of being compact and ingenious in structure, safe, reliable, convenient and fast to use and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel double-counterweight elevator

ActiveCN105253755AThe car moves smoothlyDamage reductionBuilding liftsMine liftsEngineeringMechanical engineering

The invention discloses a novel double-counterweight elevator. The novel double-counterweight elevator comprises a vertically-arranged hoistway, a car moving up and down in the hoistway, a counterweight device, a driving device and a control device, wherein the driving device comprises a first driving device and a second driving device; the first driving device comprises a first steel wire rope, and a first motor, a first speed reduction box and a first dragging wheel which are in driving connection with one another in sequence; the second driving device comprises a second steel wire rope, and a second motor, a second speed reduction box and a second dragging wheel which are in driving connection with one another in sequence; the counterweight device comprises a first counterweight device and a second counterweight device; the first steel wire rope is wound on the first dragging wheel; two ends of the first steel wire rope are connected with the first counterweight device and the top of the car respectively; the second steel wire rope is wound on the second dragging wheel; two ends of the second steel wire rope are connected with the second counterweight device and the top of the car respectively; the first counterweight device and the second counterweight device are symmetrically arranged on the outer side opposite to the car; the first dragging wheel and the second dragging wheel are same in rotation speed and opposite in rotation direction.

Owner:HOMEFRIEND & FUJI ELEVATOR CO LTD

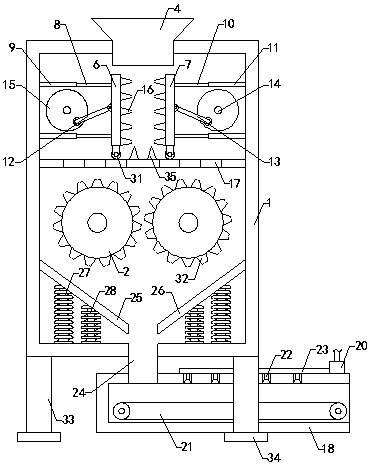

Road waste disposal area waste residue treatment device

PendingCN109847830ADamage reductionImprove practicalityUsing liquid separation agentGrain treatmentsSlagScrap

The invention relates to the technical field of solid waste treatment accessory devices, in particular to a road waste disposal area waste residue treatment device. The road waste disposal area wasteresidue treatment device can break large waste, damage to a smashing roller can be reduced, raised dust caused during waste slag guide-out operation can be treated, the pollution to the construction environment and nearby air environment can be avoided, practicability reliability is improved, meanwhile, blockage generated by waste slag in a work cavity can be effectively avoided, construction proceed is ensured, the device comprises a smashing box, two sets of smashing rollers, two driving motors, a loading hopper, a discharging opening, two first motors, a left breaking plate, a right breaking plate, four sets of left guide columns, four sets of left guide sleeves, four sets of right guide columns, four sets of right guide sleeves, a left driving rod, a right driving rod, a driving shaftand a rotating disc; the right end of the left breaking plate and the left end of the right breaking plate are provided with multiple sets of breaking teeth, and a grid plate, a conveying box, a conveying motor, an atomizing pump, a conveying device, an atomizing head, a communication pipe, a discharging pipe, a left guide conveying plate and a right guide conveying plate are further included.

Owner:山西省交通环境保护中心站(有限公司)

Golden jujube dry red fruit wine and production method thereof

ActiveCN101845381AGuarantee normal fermentationDamage reductionAlcoholic beverage preparationMicroorganism based processesZiziphus jujubaBiology

The invention discloses golden jujube dry red fruit wine and a preparation method thereof. The golden jujube dry red fruit wine is prepared from 60 to 70 percent of dry golden jujube, 20 to 30 percent of fresh wild jujube and 10 to 20 percent of fresh winter jujube by pulping, temperature controlled fermentation, coagulation treatment of added agar, filter, freezing treatment, fine filter at the low temperature and pasteurization treatment. The preparation method ensures fresh fruit aroma of the dry red fruit wine, improves the quality of the fruit wine, ensures that the fruit wine does not produce sediment in normal storage period of 6 months, and meets the requirement of industrialized production.

Owner:苏州盛泽科技创业园发展有限公司

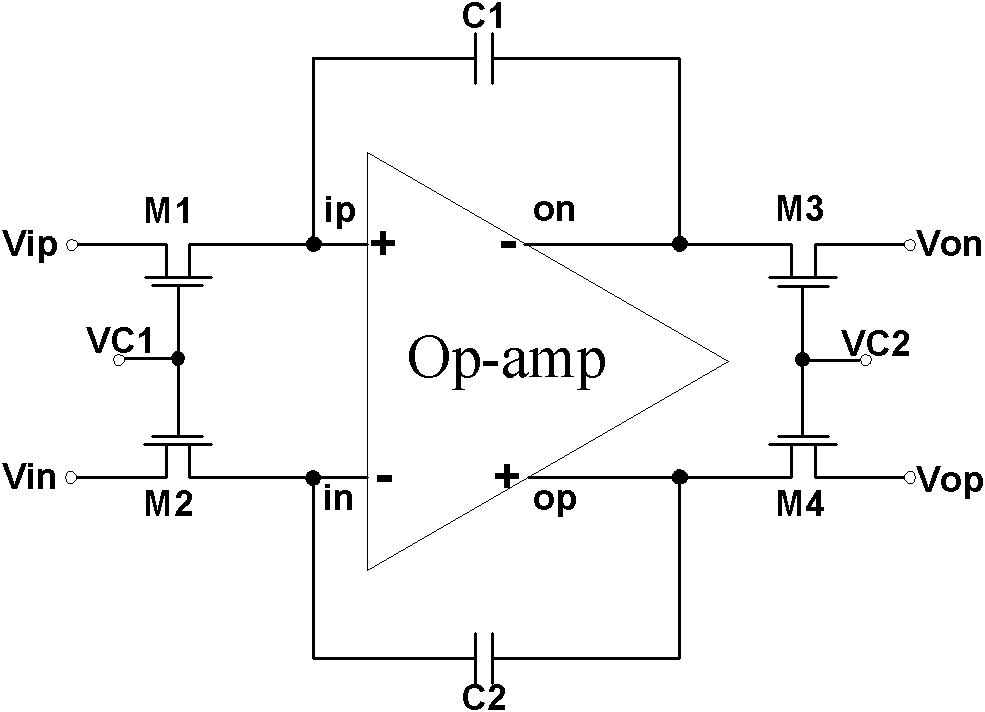

DC offset cancellation circuit

InactiveCN102130867AEliminate DC OffsetDamage reductionDc level restoring means or bias distort correctionCapacitanceEngineering

The invention discloses a DC offset cancellation circuit, which comprises a first transistor, a second transistor, a third transistor, a fourth transistor, a first feedback capacitor, a second feedback capacitor, a first voltage control signal port, a second voltage control signal port, a signal input positive end, a signal input negative end, a signal output positive end, a signal output negative end and an operational amplifier. A first voltage control signal controls the resistance of equivalent resistors of the first and second transistors, and a second voltage control signal controls the resistance of the equivalent resistors of the third and fourth transistors to fulfill the aim of adjusting equivalent high pass off frequency; therefore, the DC offset cancellation circuit can reduce damages to useful low frequency components in the signals as much as possible at the same time of suppressing or canceling DC offset. The DC offset cancellation circuit adopts active resistors instead of passive resistors, so the area of a circuit layout is reduced, and the level of integration of the circuit is improved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

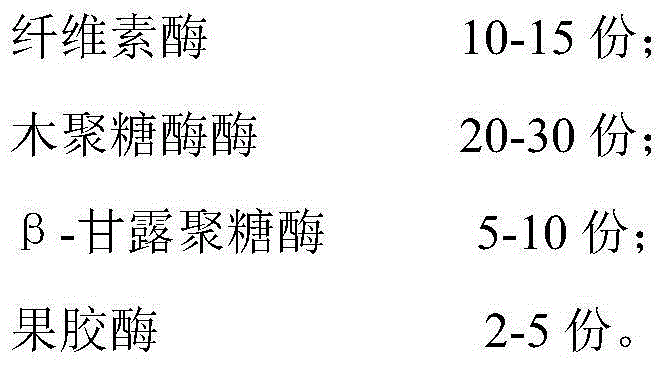

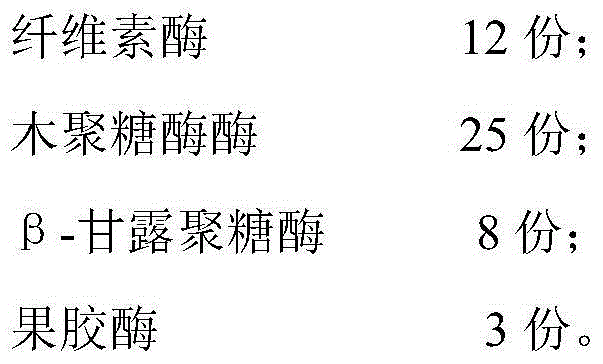

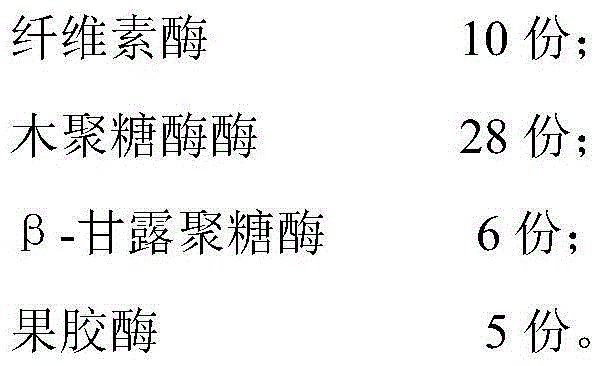

Composite enzyme for soaking corn starch and applications thereof

The invention discloses a composite enzyme for soaking corn starch and applications thereof. In the prior art, the sulfurous acid concentration of a soaking solution is high, the sulfurous acid water solution with a high concentration can corrode the equipment, and moreover can cause underground water pollution and trace residues of sulfurous acid in products, and thus the using effect of starch is affected. The composite enzyme comprises cellulase, xylanase, beta-mannose, and pectase. The provided composite enzyme can be used during the hydrolysis process of corns, is capable of effectively shortening the soaking time and production period and reducing the energy consumption, can reduce the soaking time of corn starch in sulfurous acid during the wet process corn starch production process, thus effectively reduces the sulfurous acid content in starch, and guarantees the starch quality. The composite enzyme has the advantages of low cost, good effect, and vast application prospect.

Owner:SICHUAN HENGYI TECH

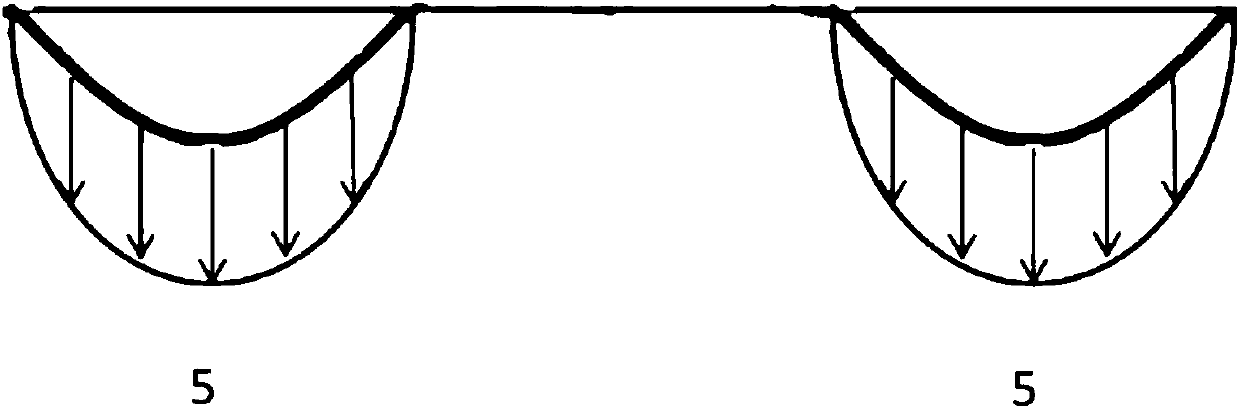

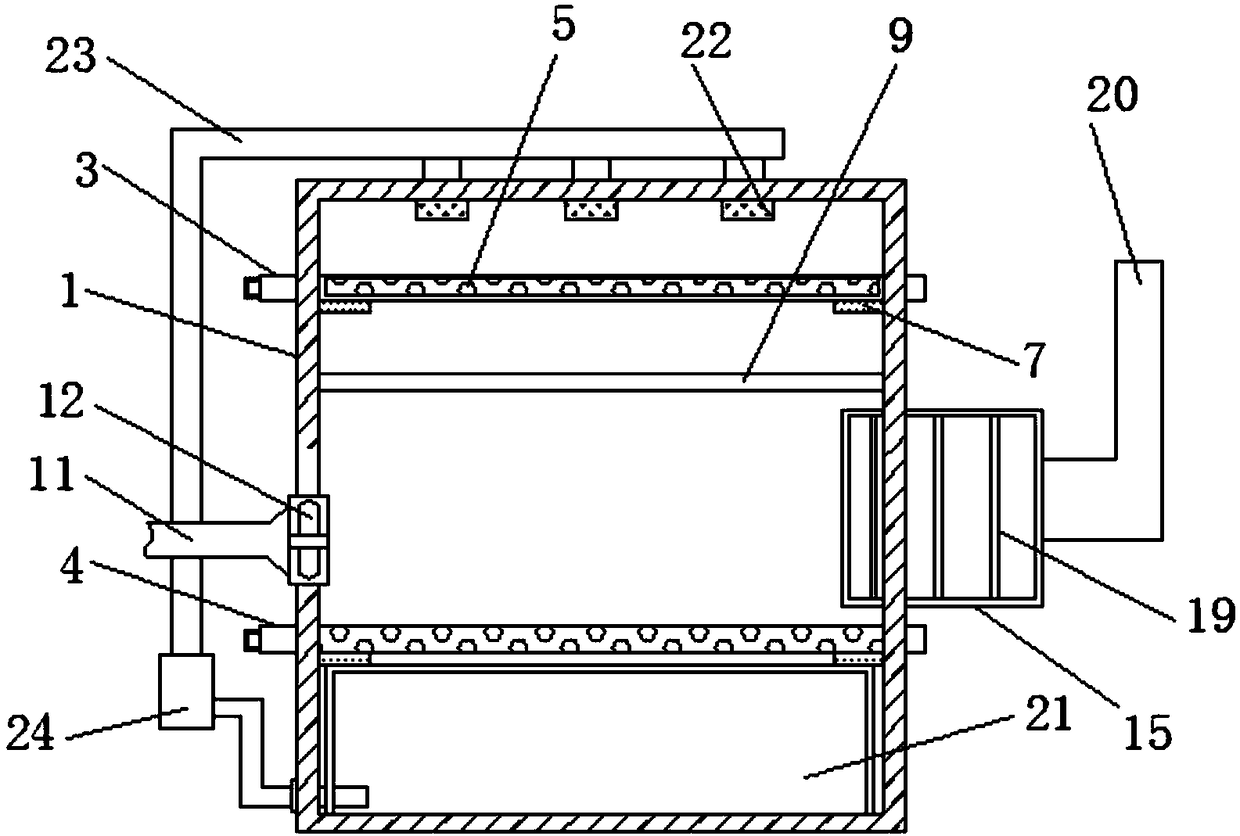

Power generation device utilizing ocean wave energy

ActiveCN107061121ADamage reductionExtend your lifePiezoelectric/electrostriction/magnetostriction machinesMachines/enginesEnergy harvestingSupply energy

The invention provides a power generation device utilizing ocean wave energy. The power generation device comprises a piezoelectric energy harvesting device arranged on a levee. The piezoelectric energy harvesting device comprises piezoelectric structure units. Each piezoelectric structure unit comprises an arched copper plate. A plurality of piezoelectric films are mounted inside each piezoelectric structure unit. The two ends of the piezoelectric energy harvesting device are fixed on a sliding rail through connecting rods. The piezoelectric energy harvesting device is connected to a power source control device through a wire so as to output power energy. By utilizing the power generation device, damage of waves to the levee can be relieved, the life is prolonged, spontaneous power energy supply can be also obtained, energy resource waste is reduced, and great economic benefits are obtained.

Owner:ZHEJIANG UNIV

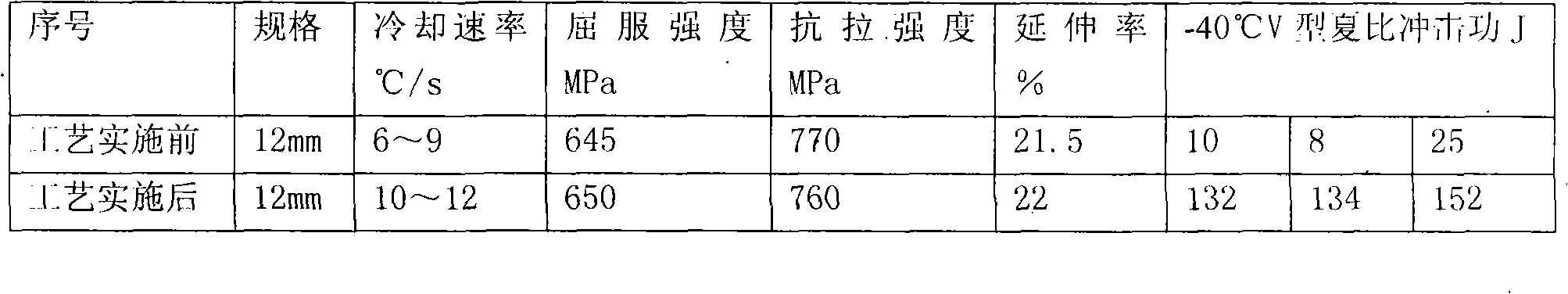

Method for improving low-temperature impact toughness of high-strength steel hot rolled plate coil for engineering machines

The invention provides a method for improving the low-temperature impact toughness of a high-strength steel hot rolled plate coil for engineering machines, which belongs to the technical field of steel for engineering machines. The method adopts a hot feeding and hot loading process, and the control technical parameters in the process include a hot loading temperature, a pouring superheat degree and a drawing speed, wherein the hot loading temperature is 500 to 600 DEG C, the pouring superheat degree is 18 to 20 DEG C, and the drawing speed is controlled to be 1.2 to 1.4m / min. Production is carried out in a mode of coarsely rolling by two machine frames and finely rolling by six machine frames, six-pass rolling is adopted in a coarse rolling phase, six-pass fine rolling is adopted in a fine rolling phase, and the rolling reduction in a non-recrystallized areas of austenite is 65 to 70 percent. A front-end laminar flow cooling mode is adopted for quickly cooling to a target temperature after fine rolling, and the cooling speed is improved to 10 to 15DEG C / s. After being removed from the production line, the plate coil is cooled by wind to 100 DEG C and then by air to room temperature. The method has the advantages of ensuring high strength and high toughness at the same time, saving consumption and improving production efficiency.

Owner:HEBEI SHOUGANG QIAN AN IRON & STEEL CO LTD +1

Chip sucking and impurity removing device for timber processing

InactiveCN106985230ADamage reductionEasy to recycleBark-zones/chip/dust/waste removalImpurityPulp and paper industry

The invention discloses a chip sucking and impurity removing device for timber processing. The device comprises a timber processing machine table; a dust removal device is fixed on the upper part of the timber processing machine table through a support; an exhaust fan is welded to the top of the outer side of the dust removal device; a wood chip discharging hole is formed in the timber processing machine table; a receiving hopper is welded in the wood chip discharging hole; the discharging end of the receiving hopper is connected to one end of a guiding pipe in a welded mode; the other end of the guiding pipe is connected to the side wall of a box body in a welded mode; an inner cavity of the guiding pipe communicates with an inner cavity of the box body; an impurity filter plate is placed in the inner cavity of the box body; a connecting rod is welded on the impurity filter plate; and a drainage pipe is welded on the side wall of the box body. The chip sucking and impurity removing device for timber processing is simple in structure, low in manufacturing cost and easy to popularize widely, dust generated during timber processing can be removed in time, damage to the body of a worker can be reduced, and wood chips can be conveniently recycled.

Owner:剑河县荣昌木业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com