Non-contact vancometer

A non-contact, glossy technology, applied to the measurement of scattering characteristics, etc., can solve the problems of undetectable, product scratches, affecting product testing results, etc., and achieve the effect of improving accuracy and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be further described in detail below.

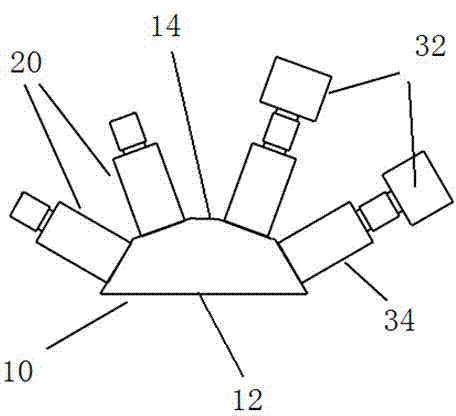

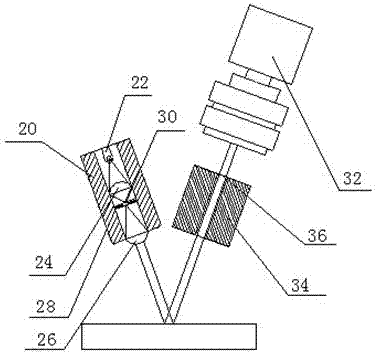

[0017] like figure 1 As shown, a non-contact gloss meter of the present invention includes a hollow casing 10 , which is a semi-cylindrical structure, including a flat surface 12 and an arc-shaped surface 14 . Wherein, a penetrating observation hole (not shown) is provided in the middle of the plane 12 . The observation hole is used to get close to the measured object to observe the measured object. Two parallel light generators 20 are disposed on the arc surface 14 . The parallel light generator 20 comprises a light source 22, a first convex lens 24 and a second convex lens 26 in turn, and a light shielding plate 28 which seals the cylinder 18 into two parts is also arranged between the first convex lens 24 and the second convex lens 26. A through circular hole 30 is set on the plate 28, and the circular hole 30 is just located on the focal point of the first convex lens 24, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com