Continuous coal mining machine paste filling mining method

A technology of paste filling and mining methods, which is applied in the direction of filling, ground mining, mining equipment, etc., which can solve the problems of difficult matching, synchronization, slow filling speed and large transportation engineering volume between transportation and filling, and achieve compact and continuous equipment layout , safe, stable and reliable, and the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

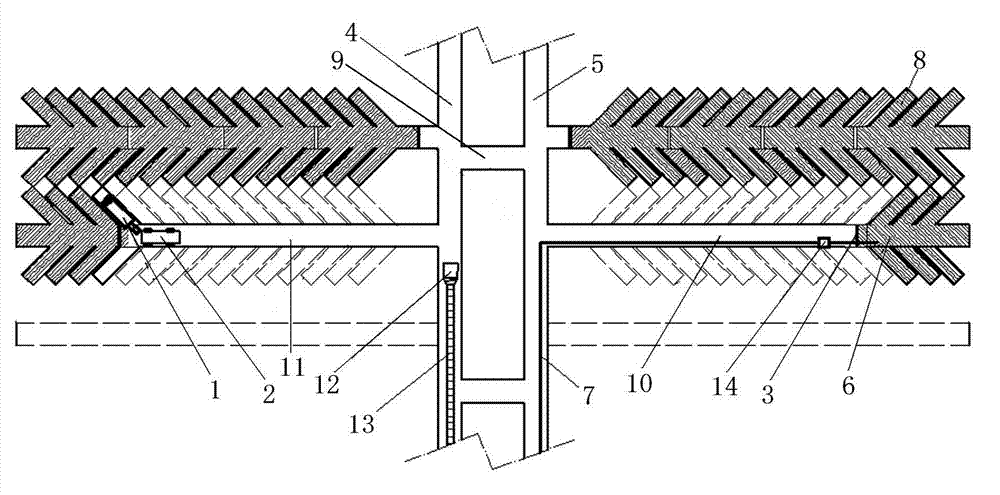

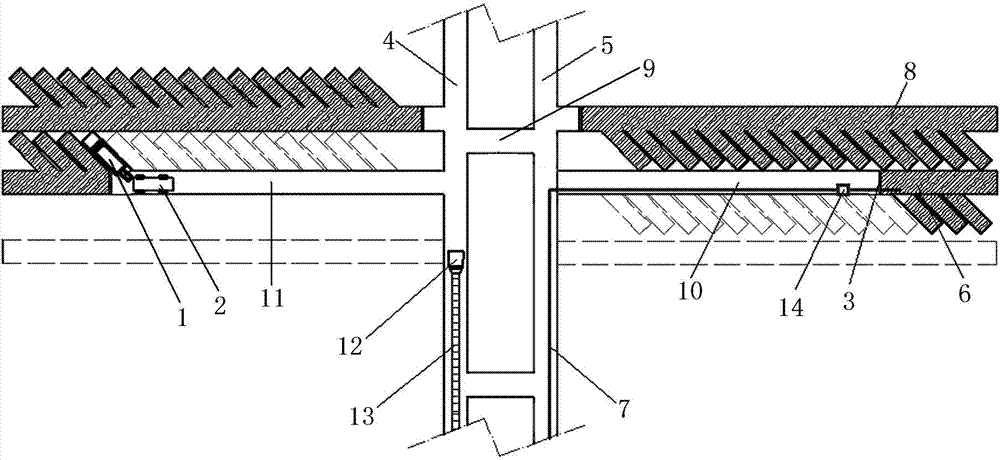

[0021] A continuous mining machine paste filling mining method, including arranging main and auxiliary transport roadways in the middle of the mining area, arranging branch roadways on both sides for simultaneous operation, one side of the branch roadway adopts a continuous coal mining machine for coal pillar recovery, and the other side branch roadway The roadway uses the filling pipeline system to fill the goaf with paste, forming a parallel operation system for mining and filling.

[0022] Specifically include the following steps;

[0023] (1) Roadway layout: the main roadway 4 and the auxiliary roadway 5 are arranged in parallel in the middle of the mining area, and the connecting roadway 9 is arranged at intervals between the main roadway 4 and the auxiliary roadway 5, which runs through the main roadway 4 and the auxiliary roadway 5; The outer side of the auxiliary roadway 5 is respectively arranged with a mining branch roadway 11, and the mining branch roadway 11 is fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com