Coconut oil extraction method

An extraction method, coconut oil technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of high moisture content of coconut oil, low extraction rate of coconut oil, unfavorable coconut oil preservation, etc., and achieve good application prospects, extraction method Simple, safe, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

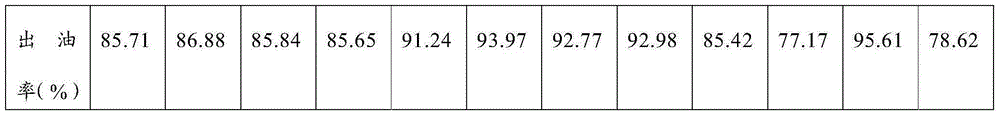

Embodiment 1

[0027] A kind of extraction method of coconut oil, comprises the following steps:

[0028] 1) Refining 100g of coconut meat and 300g of water to obtain coconut milk I

[0029] 2) Put the coconut milk I into an ultrasonic and microwave co-extractor for processing for 10 minutes, then cool to 25°C to obtain coconut milk II;

[0030] 3) Add 1 g of compound enzyme to the coconut milk II, enzymatically hydrolyze it in a water bath for 24 hours, the temperature of the enzymolysis in the water bath is 40° C., and carry out an enzymatic treatment for 30 minutes after the enzymolysis in a water bath to obtain coconut milk III;

[0031] The compound enzyme is prepared from 1g of cellulase, 3g of papain and 1g of beta-glucanase;

[0032] 4) The coconut milk III is centrifuged, the centrifugal speed is 3000r / min, and the centrifugation time is 10min, and the upper layer of clear oil is absorbed to obtain the coconut oil.

Embodiment 2

[0034] A kind of extraction method of coconut oil, comprises the following steps:

[0035] 1) Refining 100g of coconut meat and 400g of water to obtain coconut milk I

[0036] 2) Put the coconut milk I into an ultrasonic microwave synergistic extractor for processing for 5 minutes, then cool to 40°C to obtain coconut milk II;

[0037] 3) Add 2g of compound enzyme to the coconut milk II, enzymatically hydrolyze it in a water bath for 36 hours, and the temperature of the enzymolysis in the water bath is 55° C. After enzymolysis in a water bath, carry out an enzymatic treatment for 30 minutes to obtain coconut milk III;

[0038] The compound enzyme is prepared from 1g of cellulase, 1g of papain and 1g of beta-glucanase;

[0039] 4) The coconut milk III is centrifuged, the centrifugal speed is 5000r / min, and the centrifugation time is 20min, and the upper layer of clear oil is absorbed to obtain the coconut oil.

Embodiment 3

[0041] A kind of extraction method of coconut oil, comprises the following steps:

[0042] 1) Refining 100g of coconut meat and 500g of water to obtain coconut milk I

[0043] 2) Put the coconut milk I into an ultrasonic and microwave synergistic extractor for processing for 15 minutes, then cool to 50°C to obtain coconut milk II;

[0044] 3) Add 3g of compound enzyme to the coconut milk II, enzymatically hydrolyze it in a water bath for 36 hours, the temperature of the enzymolysis in the water bath is 60°C, and carry out an enzymatic treatment for 30 minutes after the enzymolysis in a water bath to obtain coconut milk III;

[0045] The compound enzyme is prepared from 3g cellulase, 2g papain and 2g beta-glucanase;

[0046] 4) The coconut milk III is centrifuged, the centrifugal speed is 8000r / min, and the centrifugation time is 30min, and the upper layer of clear oil is absorbed to obtain the coconut oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com