Surface treatment method regulating and controlling transition interface structure of thermal barrier coating through laser shock

A laser shock and thermal barrier coating technology, applied in the field of laser applications, to achieve the effect of inhibiting the growth rate of TGO and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Plasma spraying thermal barrier coating was carried out on the sample before nanosecond laser shock treatment, and the industrial CoCrAlYTaSi composite powder was used as the bottom layer. Plasma spray transition layer

[0041] (CoCrAlYTaSi).

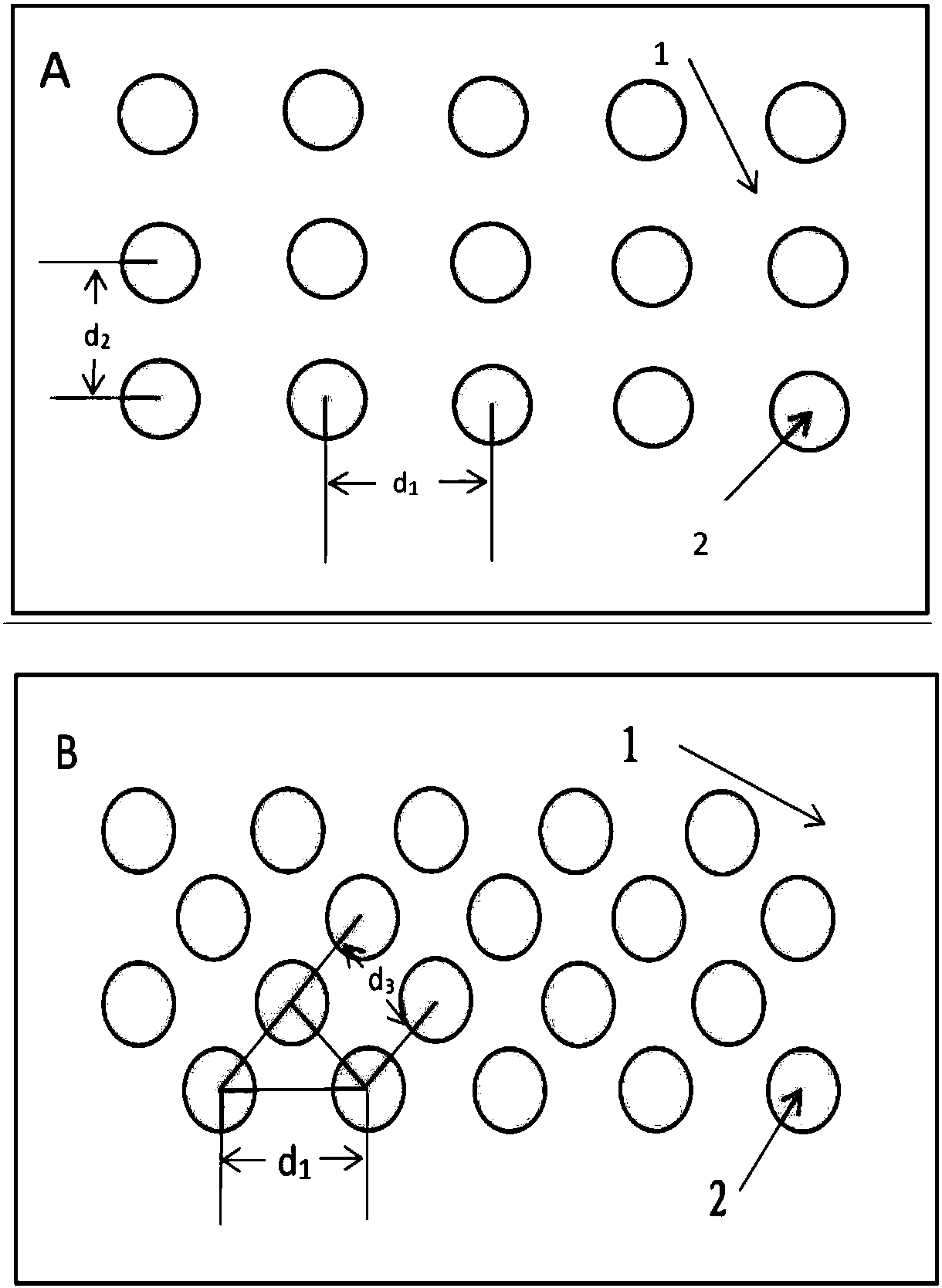

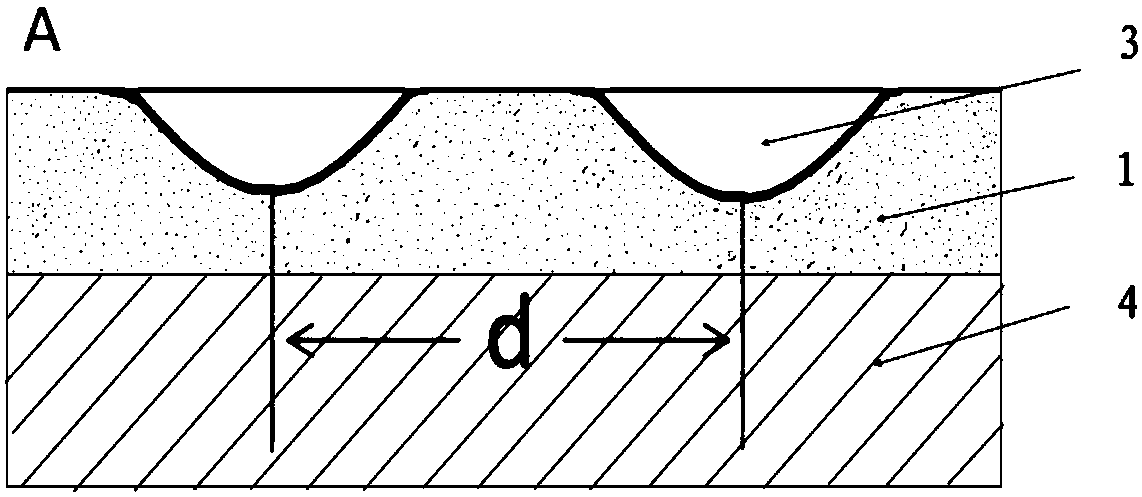

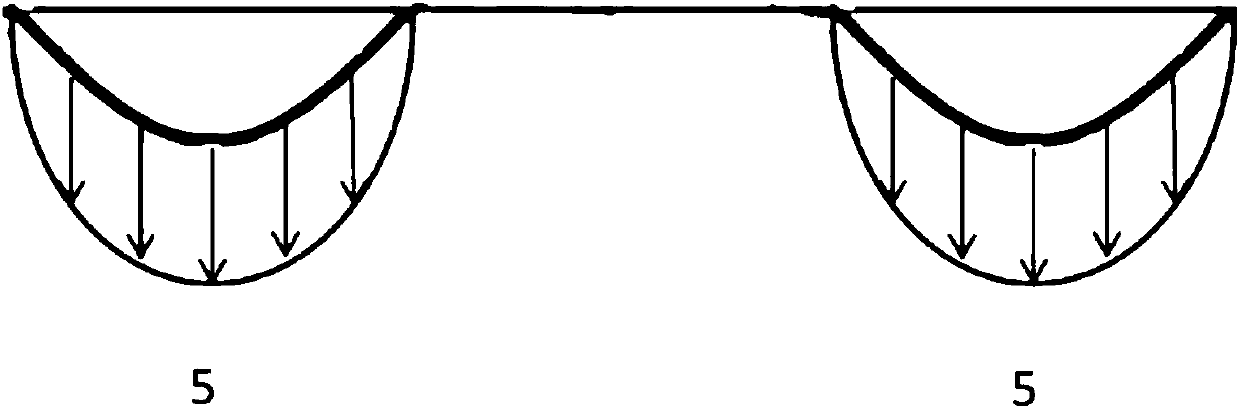

[0042] 2) Use nanosecond laser beams to perform impact strengthening treatment on the surface of the bonding layer of the thermal barrier coating, and construct the macroscopic geometric structure of the bonding layer surface. The test material is GH4202 alloy, and the size of the thermal shock sample is 40×40×3mm. Second laser shock parameters: wavelength 1064nm, pulse width 23ns, energy 14J, spot diameter on the surface of the adhesive layer is about 4mm; the confinement medium is water, and a single shock treatment is implemented. Laser shock treatment leaves 3mm on each side of the sample, the center distance of the spot is 8mm, the impact area accounts for about 19.6%, 25 impact pits, and the diameter of the spherical cr...

Embodiment 2

[0045] 1) Plasma spraying thermal barrier coating was carried out on the sample before nanosecond laser shock treatment, and the industrial CoCrAlYTaSi composite powder was used as the bottom layer.

[0046] 2) Use nanosecond laser beams to perform impact strengthening treatment on the surface of the bonding layer of the thermal barrier coating, and construct the macroscopic geometric structure of the bonding layer surface. The test material is GH4202 alloy, and the size of the thermal shock sample is 40×40×3mm. Second laser shock parameters: wavelength 1064nm, pulse width 23ns, energy 18J, diameter of focused spot on the surface of the bonding layer is 4mm; the confinement medium is water, and a single shock treatment is implemented. Laser shock treatment leaves 3mm on each side of the sample, the center distance of the spot is 6mm, the impact area accounts for about 28.26%, 36 impact pits, and the diameter of the spherical crown pit is about The average height is 20 μm.

...

Embodiment 3

[0049] 1) Plasma spraying thermal barrier coating was carried out on the sample before nanosecond laser shock treatment, and the industrial CoCrAlYTaSi composite powder was used as the bottom layer.

[0050] 2) Use nanosecond laser beams to perform impact strengthening treatment on the surface of the bonding layer of the thermal barrier coating, and construct the macroscopic geometric structure of the bonding layer surface. The test material is GH4202 alloy, and the size of the thermal shock sample is 40×40×3mm. Second laser shock parameters: wavelength 1064nm, pulse width 23ns, energy 20J, diameter of focused spot on the surface of the bonding layer is 4mm; the confinement medium is water, and a single shock treatment is implemented. Laser shock treatment leaves 3mm for each side of the sample, the center distance of the spot is 0mm, the impact area accounts for about 63.58%, 81 impact pits, and the diameter of the spherical crown pit is about The average height is 30 μm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com