Patents

Literature

646results about How to "Fast action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

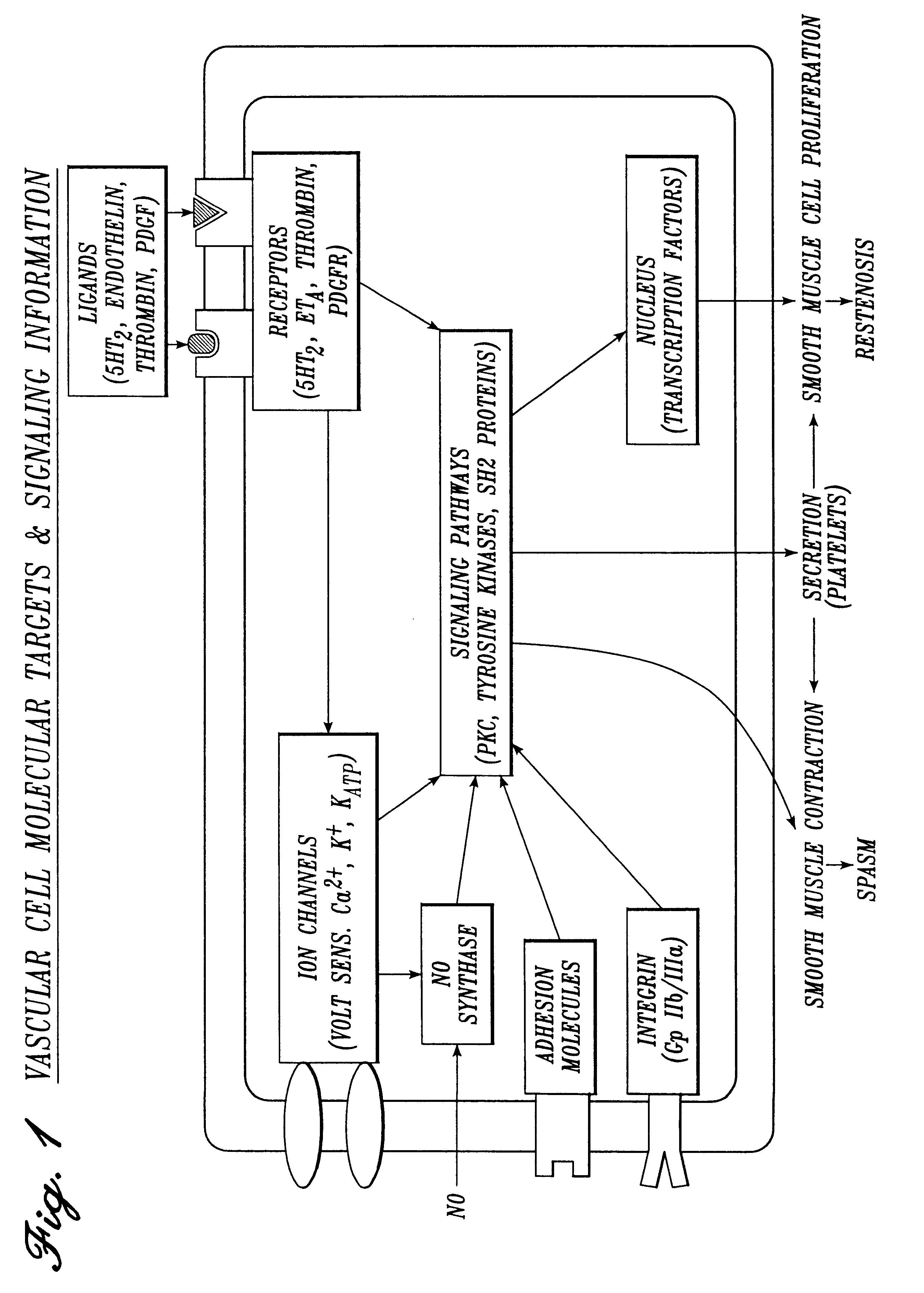

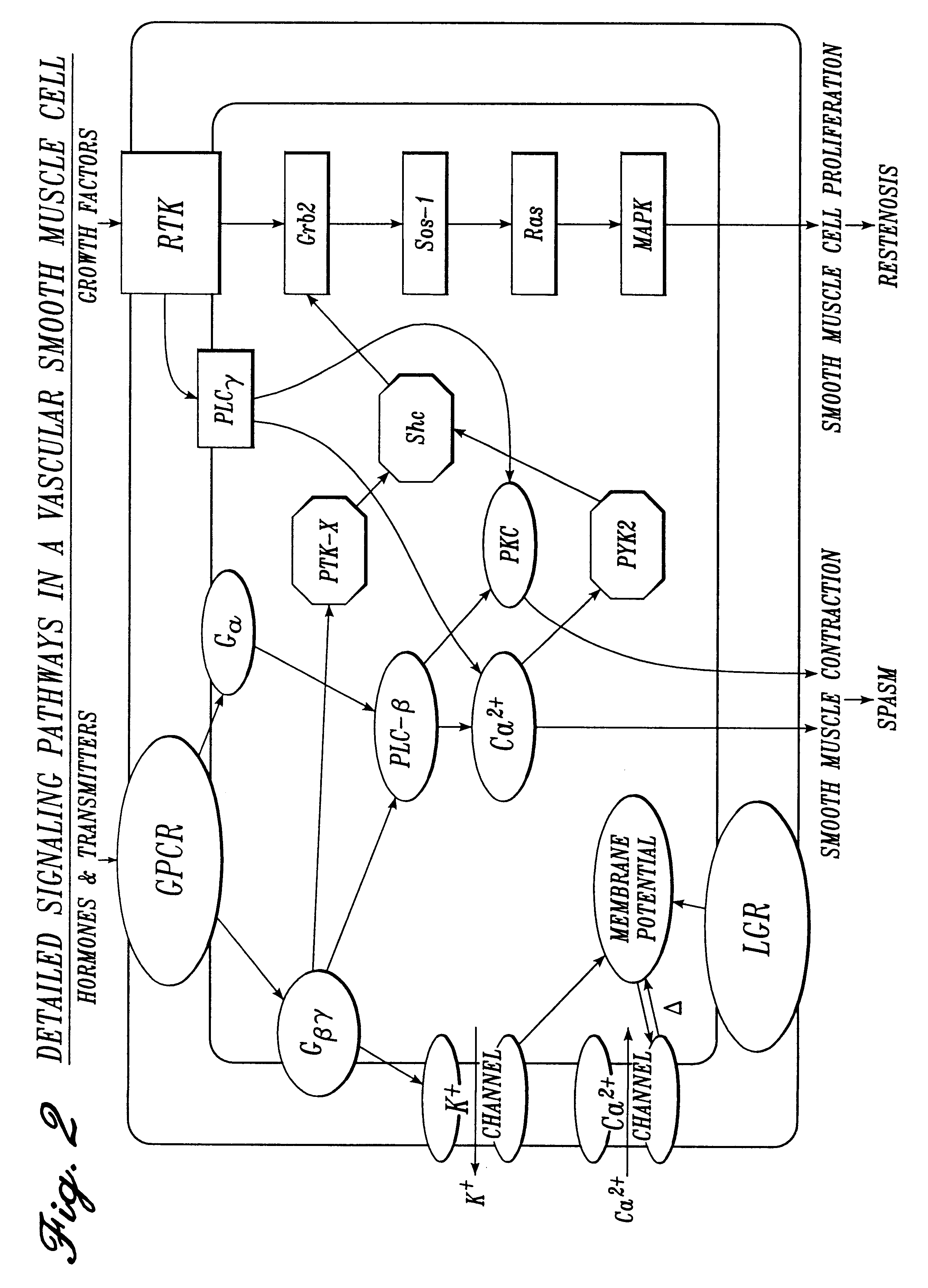

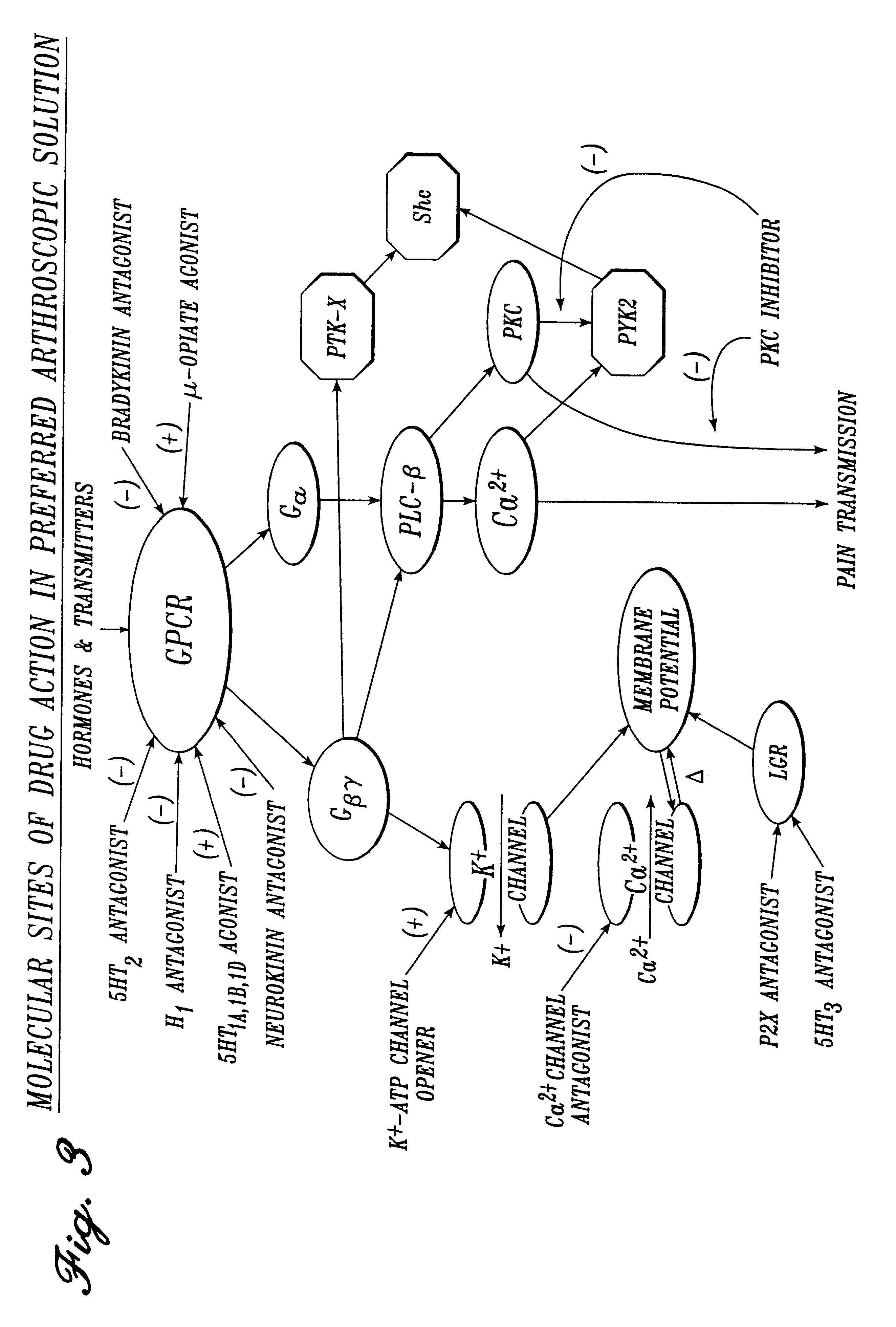

Irrigation solution and methods for inhibition of tumor cell adhesion, pain and inflammation

InactiveUS6492332B1Rapid onsetIncrease chanceBiocideNervous disorderLymphatic SpreadTumor cell adhesion

This invention relates to a method of inhibiting tumor cell adhesion, pain, and inflammation at a wound during a surgical procedure by delivering an irrigation solution containing a tumor cell anti-adhesion agent and a plurality of additional agents to an operative site during the surgical procedure. In addition, methods of inhibiting tumor cell attachment and implantation during a surgical procedure as well as inhibiting tumor metastasis during a surgical procedure are also provided.

Owner:OMEROS CORP

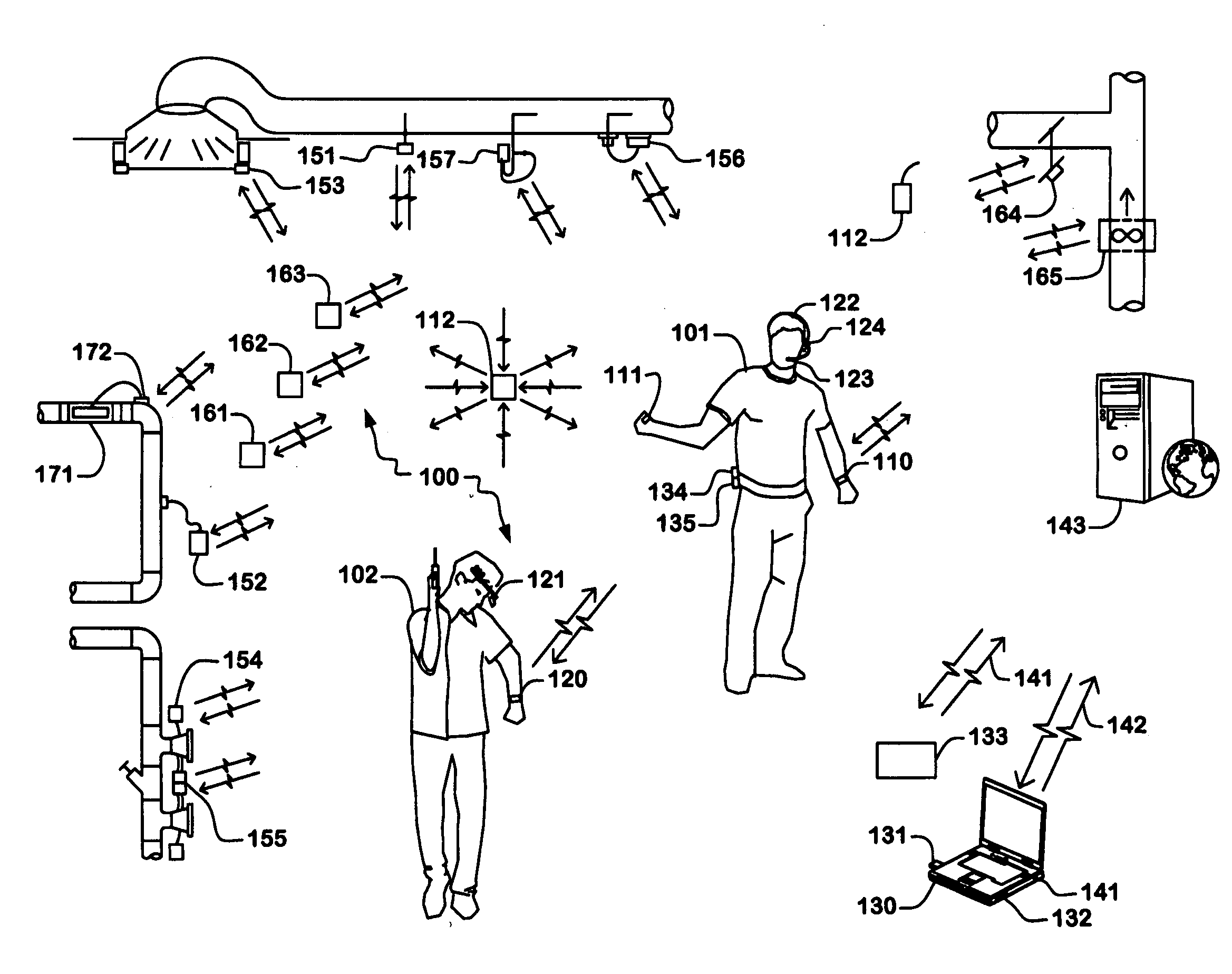

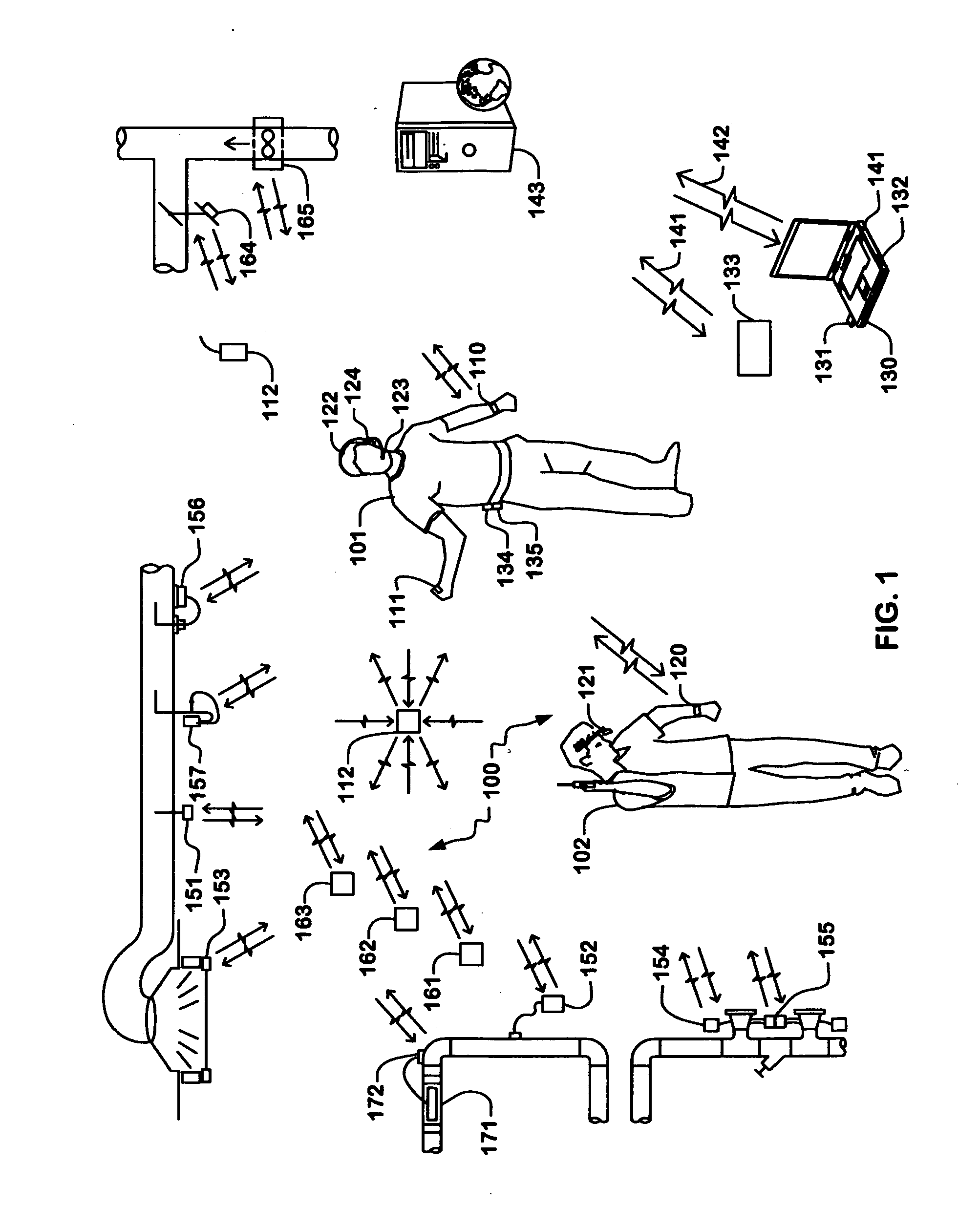

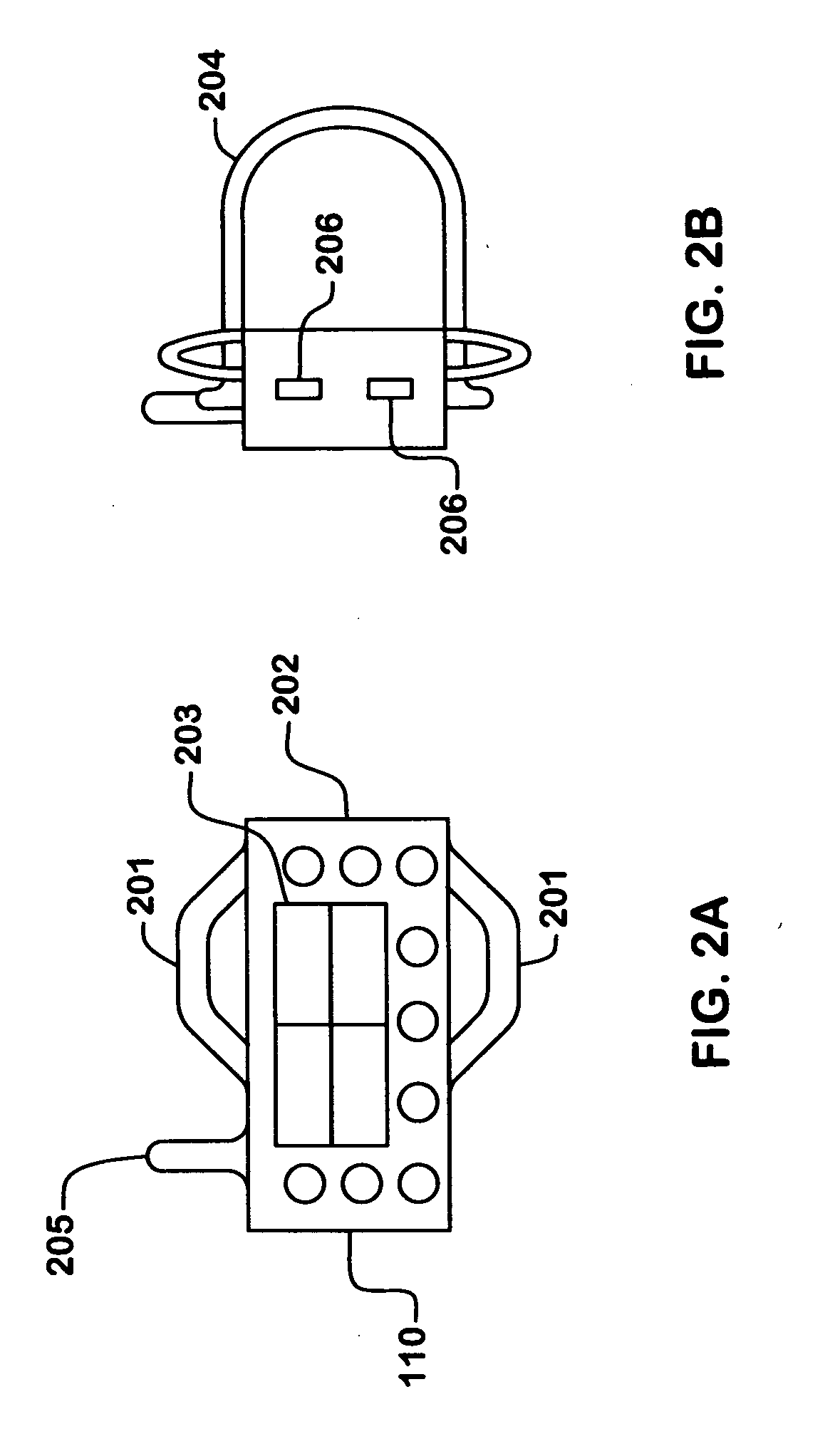

Wireless sensors system and method of using same

ActiveUS20120046792A1Improve understandingAct quicklySpace heating and ventilationTemperatue controlEngineeringWater temperature

An apparatus, system, and methods for measuring environmental parameters are disclosed. The apparatus, system, and methods can be used for a variety of applications, including HVAC air balancing and building commissioning. The system includes a variety of wireless sensing modules and wearable modules for control, display, and storage. Parameters measured include air and water temperature, pressure, velocity, and flow. Also included are sensors for light intensity, CO concentrations, and CO2 concentrations.

Owner:EVERGREEN TELEMETRY LLC

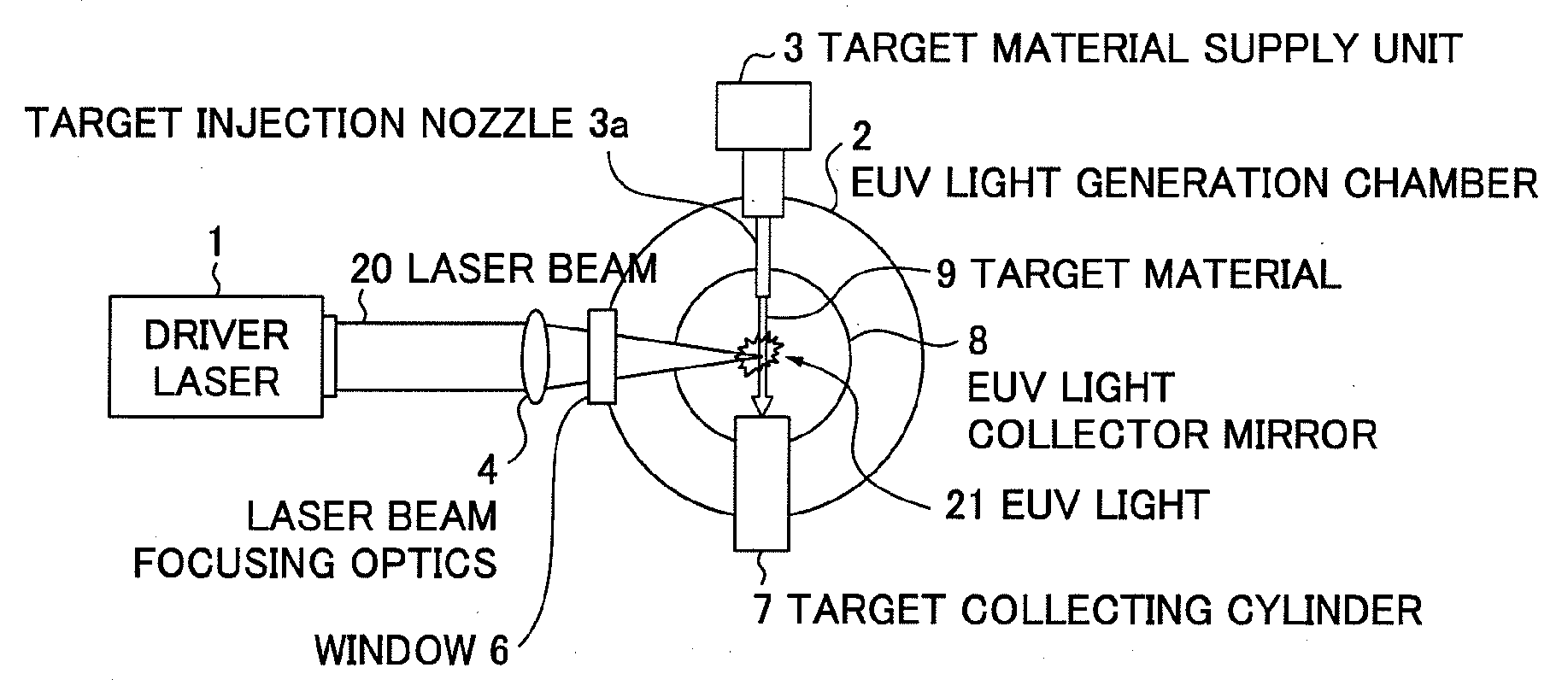

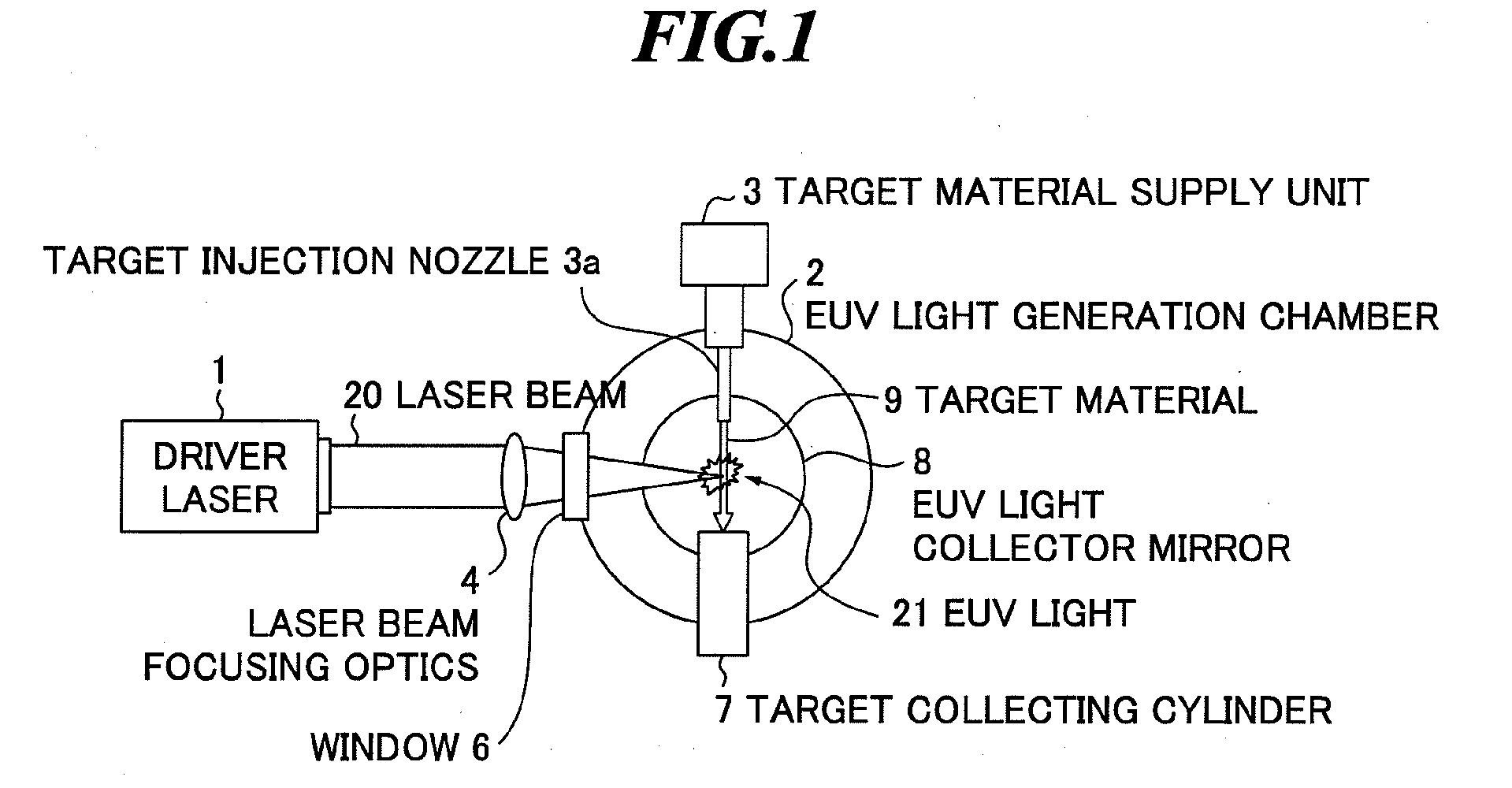

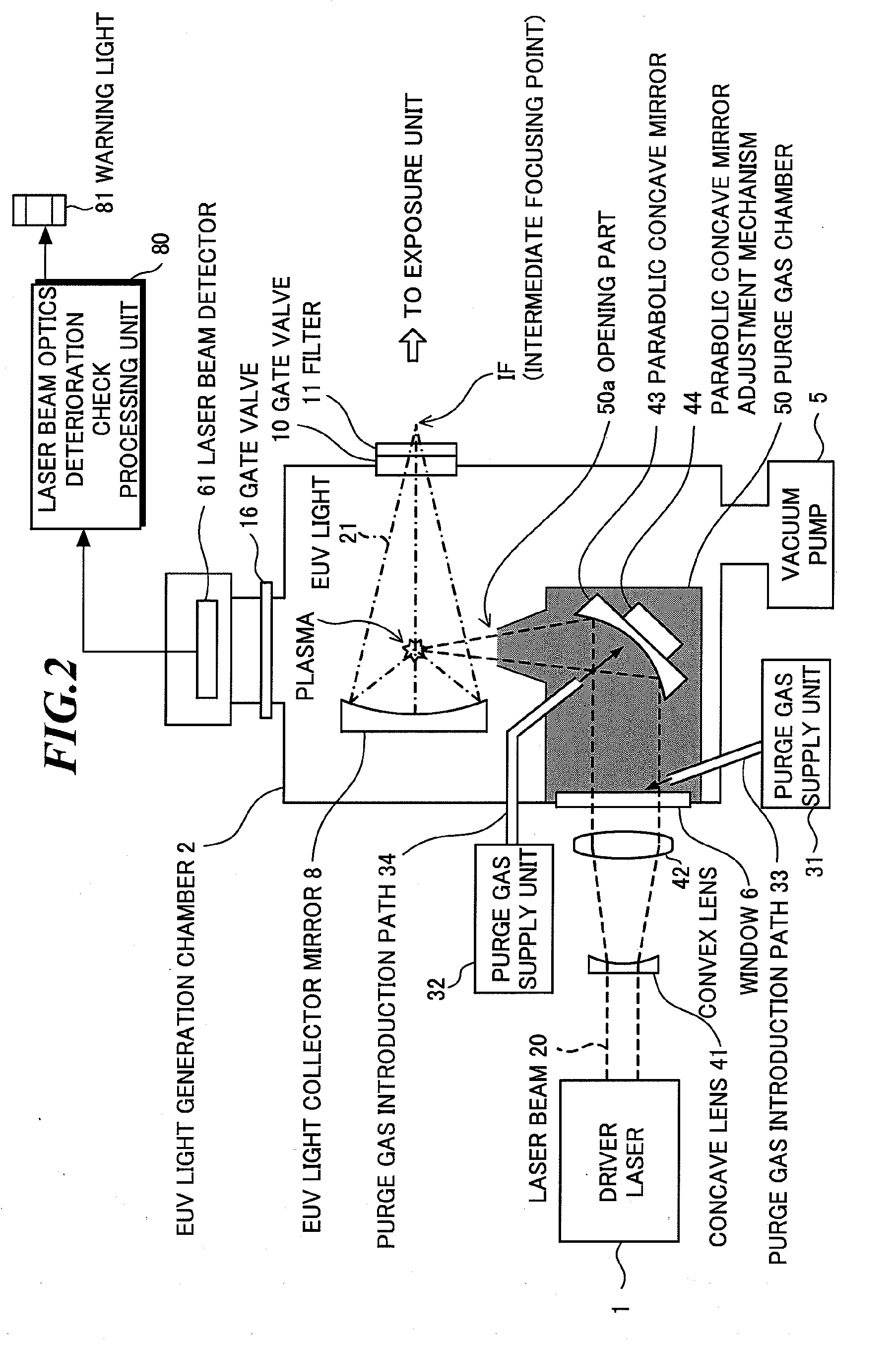

Extreme ultraviolet light source apparatus

ActiveUS20100171049A1Fast actionRapid variationRadiation pyrometryMaterial analysis by optical meansLight beamOptoelectronics

An EUV light source apparatus can reliably detect and accurately judge deterioration of an optical element in a laser beam focusing optics disposed within an EUV light generation chamber. This EUV light source apparatus includes: the EUV light generation chamber; a target material supply unit; an EUV light collector mirror; a driver laser; a window; a parabolic mirror which focuses collimated laser beam by reflection and is disposed within the EUV light generation chamber; an energy detector detecting energy of the laser beam diffused without being applied to a target material after being focused by the laser beam focusing optics when the EUV light is not generated; and a processing unit for judging the deterioration of the window and the parabolic mirror according to the laser beam energy detected by the energy detector.

Owner:GIGAPHOTON

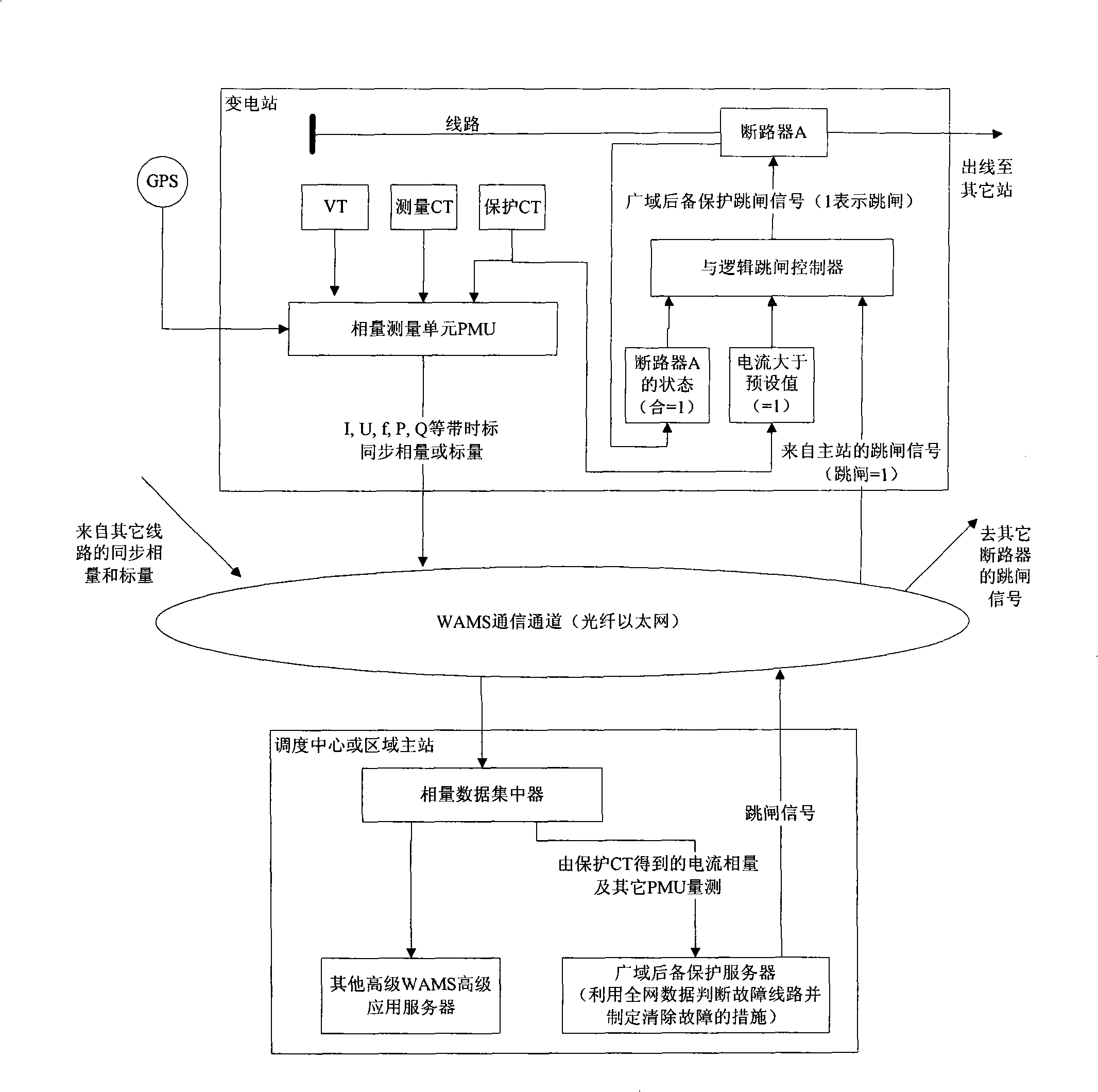

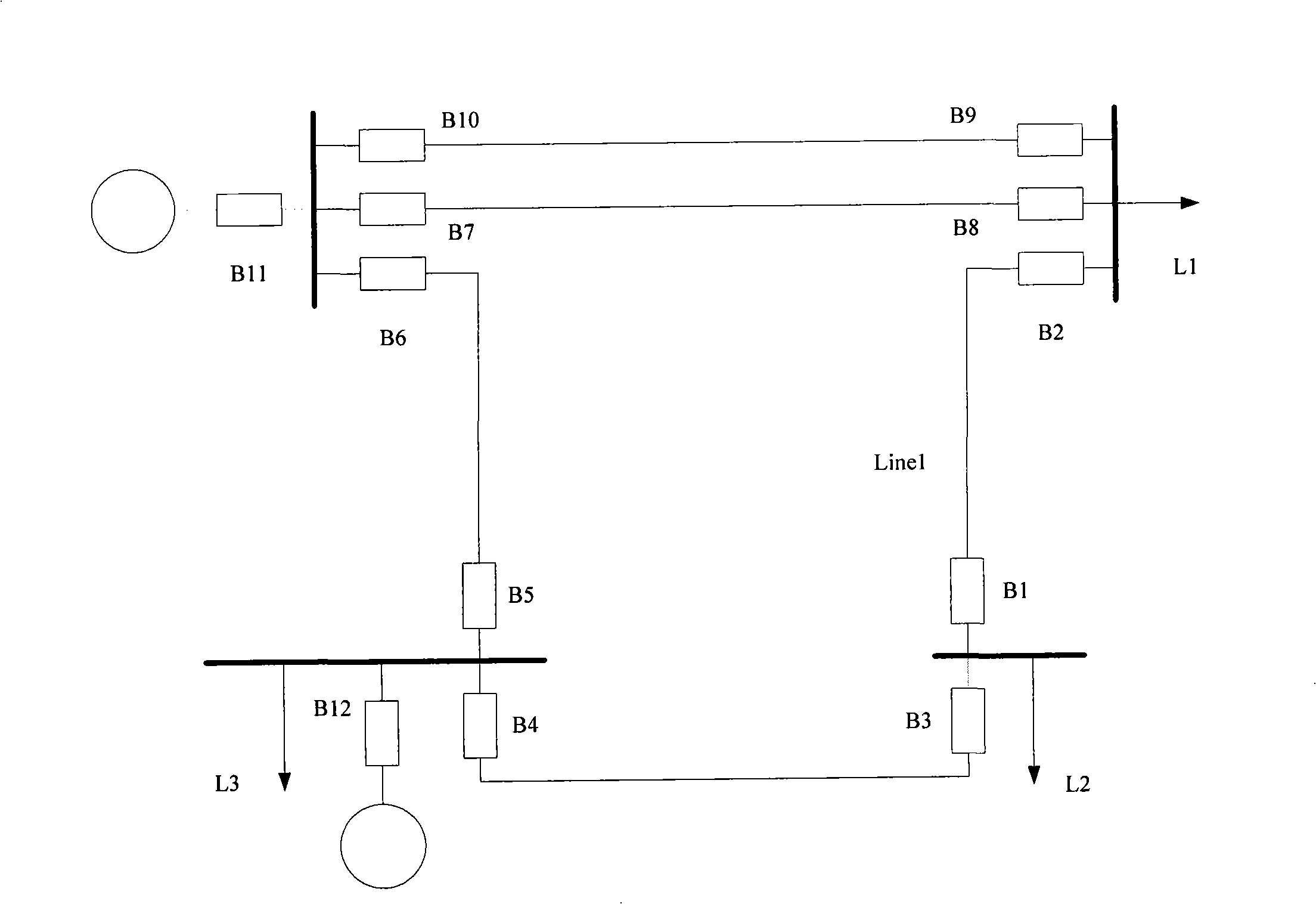

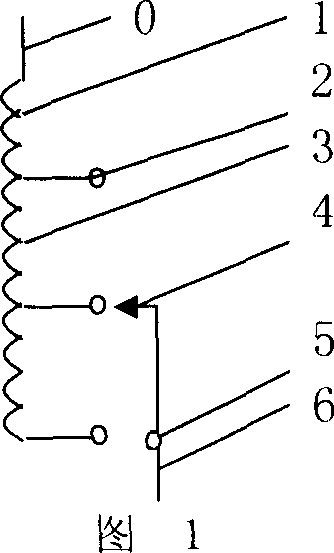

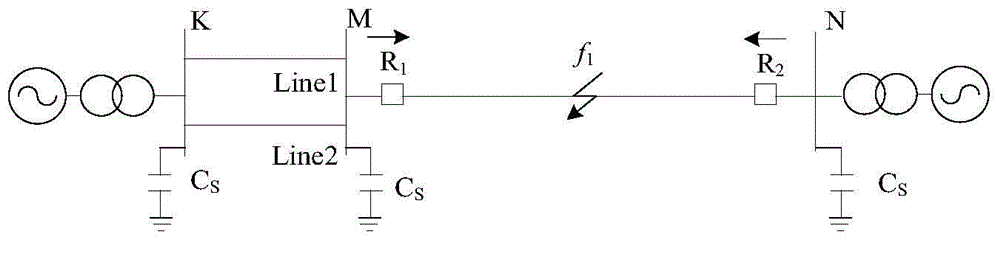

Rapid line backup protection method with reliable selection based on wide area measuring system

ActiveCN101409442AImplement fallback protectionFast actionEmergency protective circuit arrangementsWide areaEngineering

The invention discloses a line backup protection method. The method realizes simultaneous real-time measurement of voltages and current phasors on head ends and tail ends of all lines arranged with PMU in a network-wide area by the existing wide area measurement system; and accurately judges the specific line in which a fault occurs by a distinguishing method of the phase separated element current differential protection in a main station of the wide area measurement system on the basis of the data, then a faulty line tripping signal is instantaneously sent to a line tripping execution unit of a transformer substation by a control server added in a WAMS main station. The time coordination of the main protection and the backup protection is realized by the inherent delay of a communication system and a main station judgment and decision system, thus realizing quick action of the backup protection and the reliable selectivity under the condition that the main protection of the line fails. Under the condition of switch malfunction, all adjacent lines are selected to be cut off by topological analysis.

Owner:CHINA SOUTHERN POWER GRID COMPANY +1

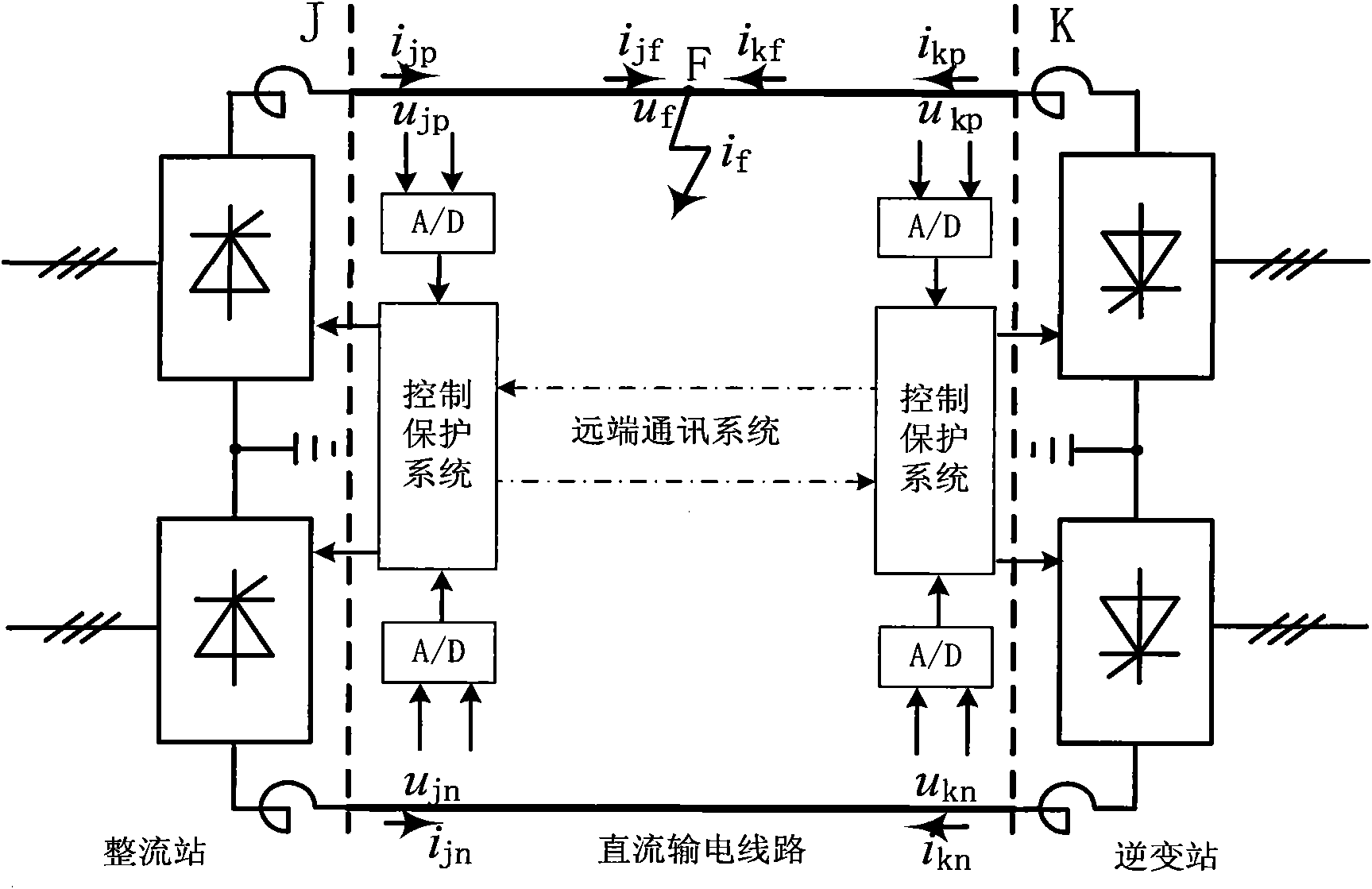

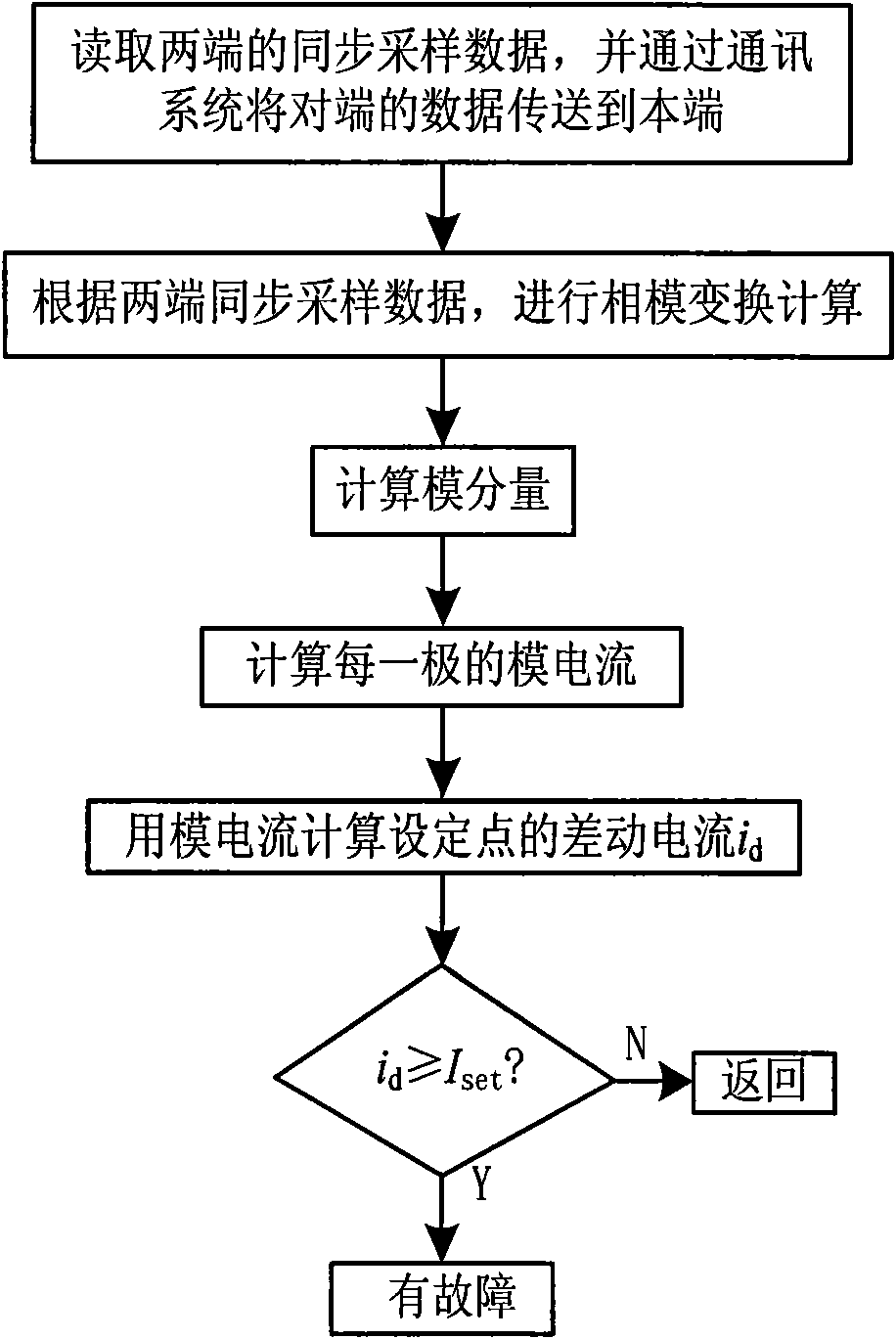

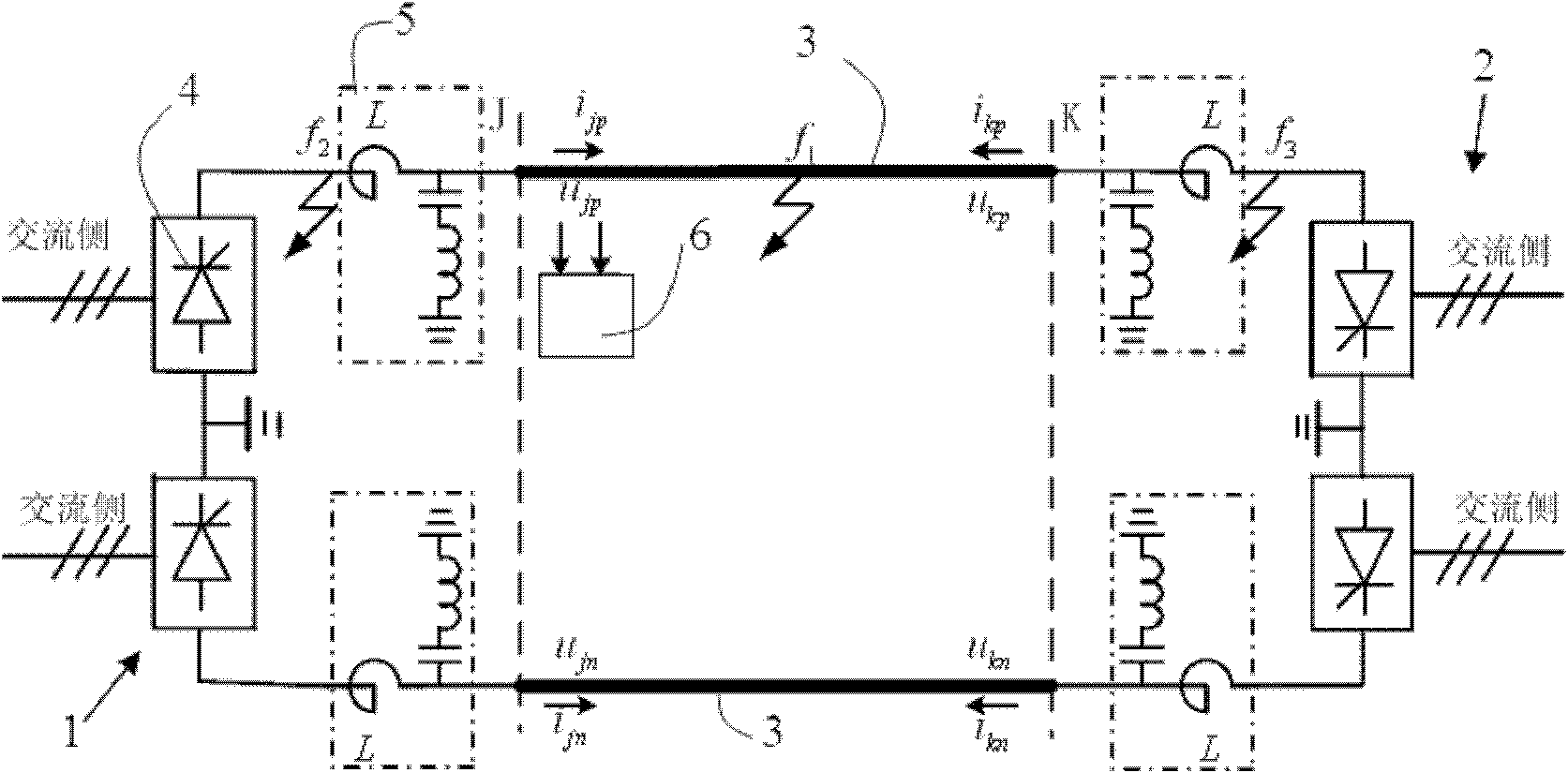

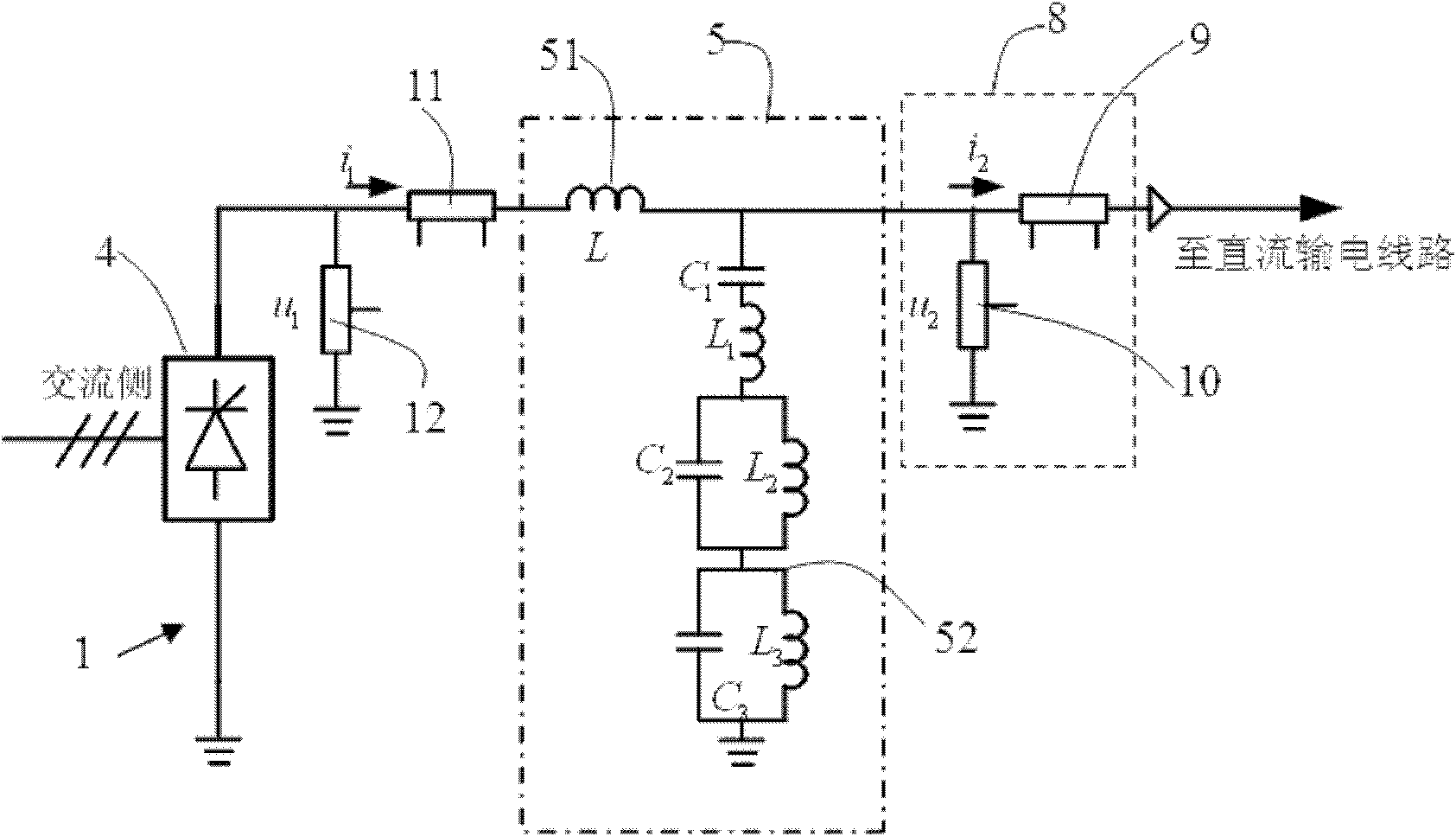

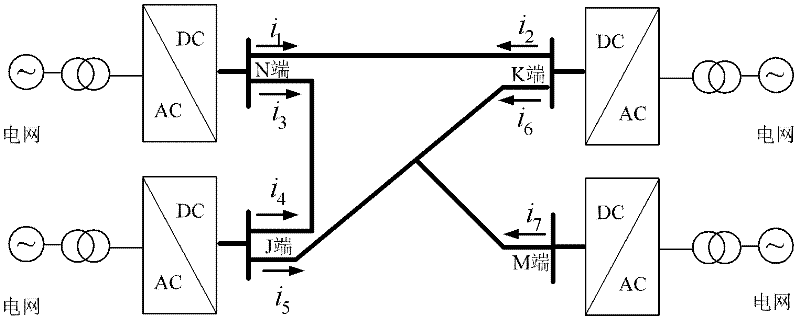

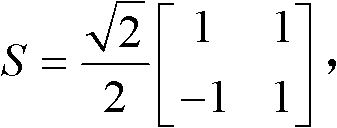

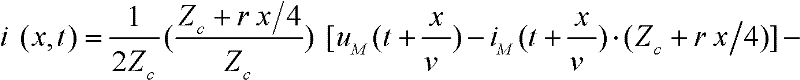

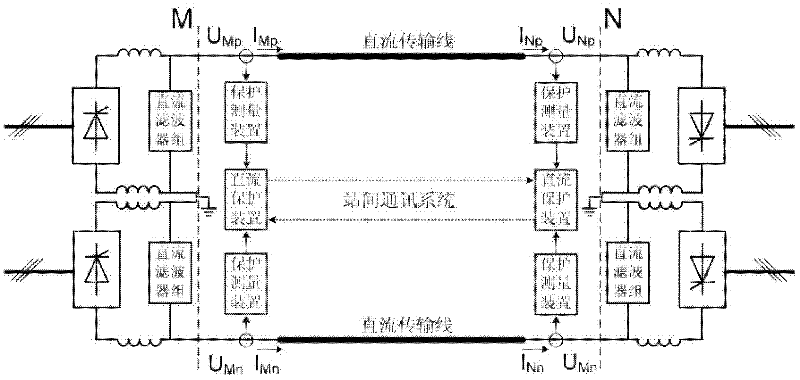

Method for current differential protection of direct current electric transmission line

InactiveCN101577417AImprove reliabilityFast actionEmergency protective circuit arrangementsDc currentElectric power system

The invention discloses a method for current differential protection of a direct current electric transmission line, which comprises the following steps: according to a distributed parameter model of the electric transmission line, using mode transformation in a time domain to transform sampling values of direct current and direct current voltage into a modulus; then using the mode voltage and the current of two ends from two ends of a line respectively to calculate mode current of certain point of the line at each moment; and using the mode current to directly construct a current differential protection criterion, or synthesizing electrode current through electrode mode inverse transformation, and then constructing the current differential protection criterion according to the electrode current. The method can improve the sensitivity and the reliability of direct current line protection, has good controllability and high security, has a complete setting theory, overcomes the defects of the conventional traveling-wave protection as the main protection of a high-voltage direct current line, and requires no recognition of a traveling-wave wave head; besides, the calculation is simple. The method is mainly used for the current differential protection of the direct current electric transmission line in an electric power system, in particular for the protection of an ultra / extra high-voltage direct current electric transmission line.

Owner:XI AN JIAOTONG UNIV

Single-ended electrical quantity full-line quick-action protection method for recognizing faults inside and outside high-voltage direct-current transmission line region

ActiveCN102255293AImprove reliabilityFast actionEmergency protective circuit arrangementsFault locationElectric power systemEngineering

The invention relates to the field of relay protection of direct-current transmission lines of power systems, in particular to a single-ended electrical quantity full-time quick-action protection method for recognizing faults inside and outside a high-voltage direct-current transmission line region. The faults inside and outside the high-voltage direct-current transmission line region are recognized by using an amplitude of a special frequency component of electrical quantity of the direct-current line side of a single-ended convertor station. The invention is mainly used in single-ended electrical quantity full-line quick-action protection of the direct-current transmission line in the power system, only needs to adopt the singe-ended electrical quantity, has low requirement on the sampling frequency and a simple algorithm, is easy to realize on the engineering, has the advantages of high action speed, good selectivity and high reliability, and is complete in theory and easy to integrate. The protection method in the invention can be used as the main protection of the direct-current transmission line instead of the traditional traveling wave protection, and is especially suitable for full-line quick-action protection of extra / super high-voltage direct-current transmission lines by using single-ended electrical quantity.

Owner:XI AN JIAOTONG UNIV

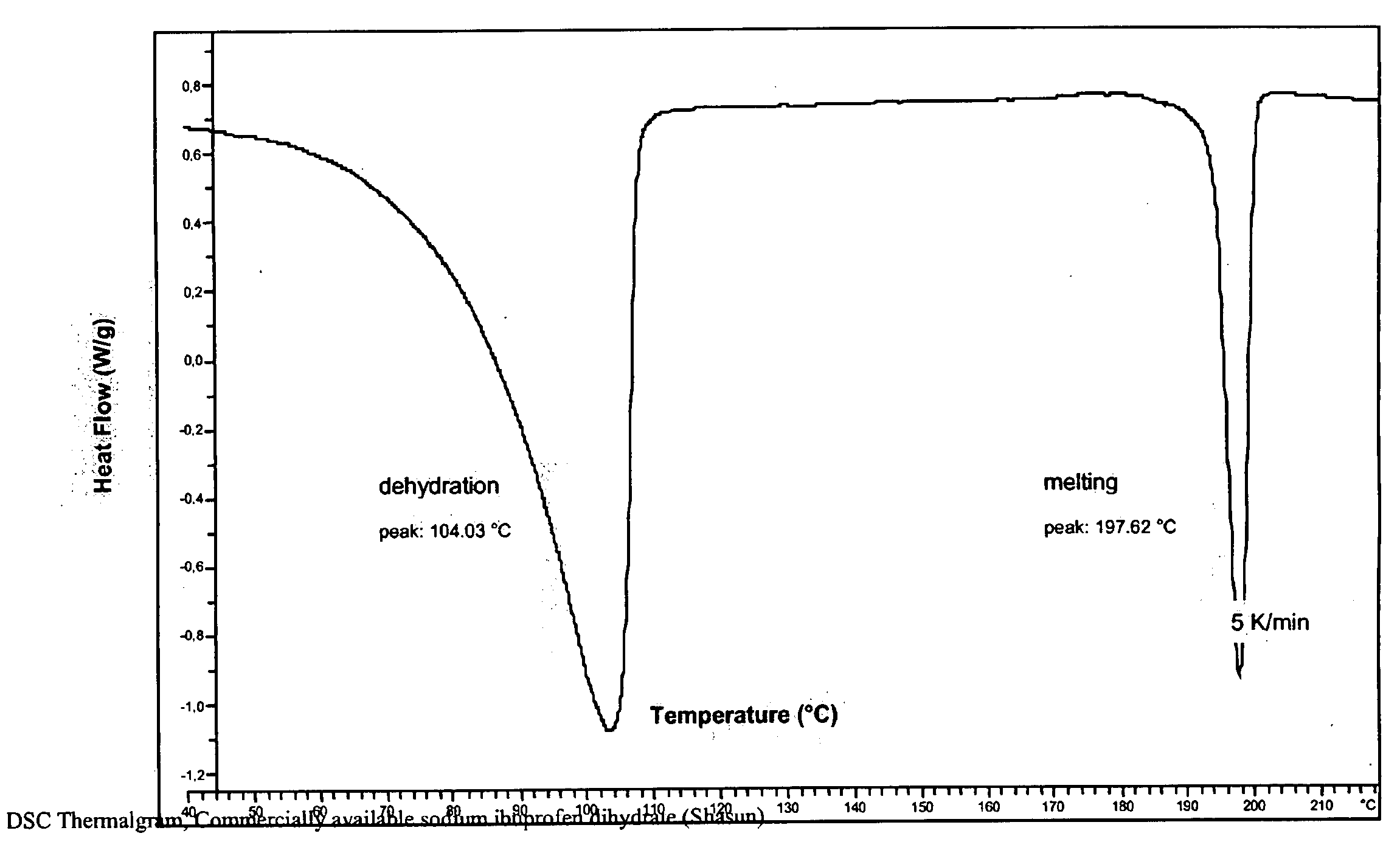

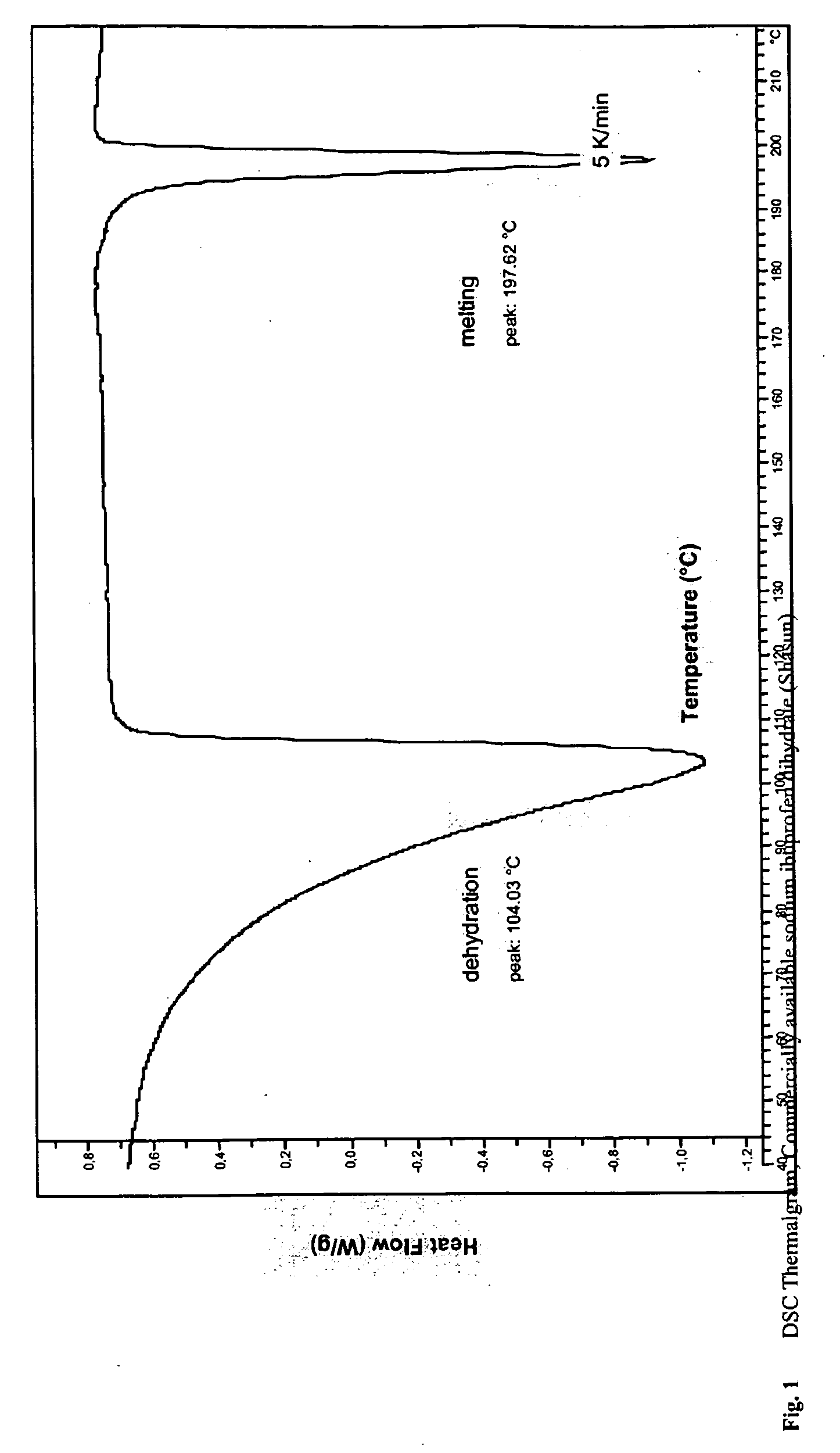

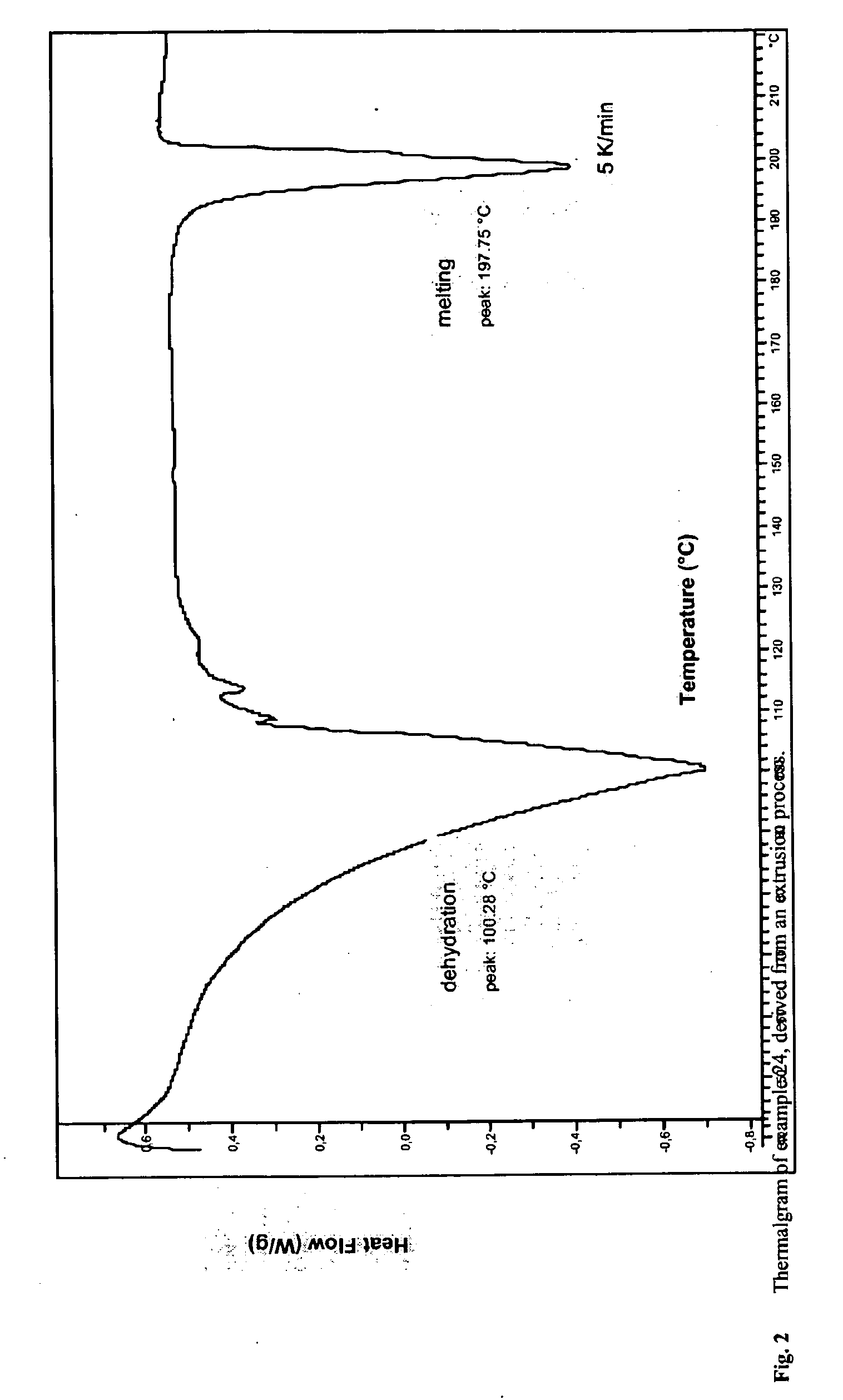

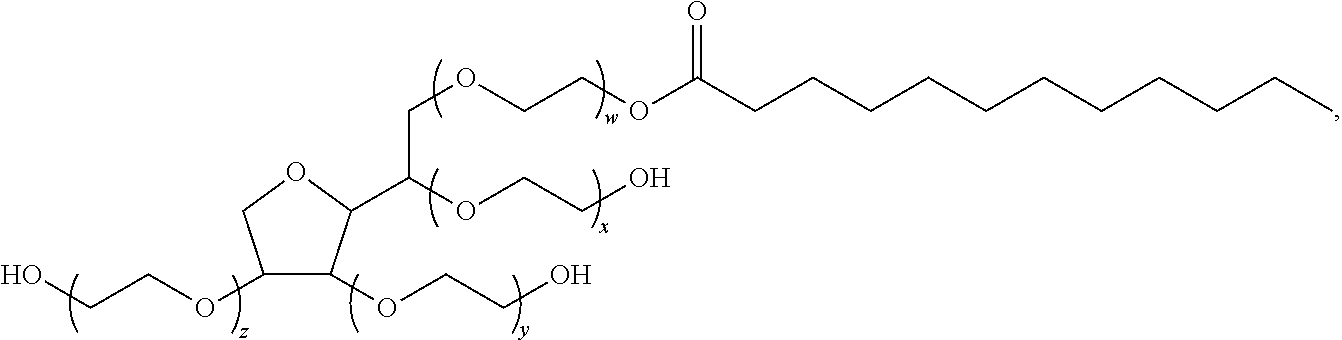

Solubilized ibuprofen

ActiveUS20090175940A1Easy to produceIncreased blood levelsBiocideOrganic compound preparationSolubilityPotassium hydroxide

A process for producing a solubilized ibuprofen, preferably in the form of a granulate, the process comprising the steps of: providing a mixture comprising solid ibuprofen and a first base selected from the group consisting of sodium hydroxide, potassium hydroxide, sodium carbonate, potassium carbonate, sodium glycinate, potassium glycinate and tribasic sodium and potassium phosphates and mixtures thereof, and reacting the ibuprofen and the first base in essentially dry state. The obtainable granulate and the pharmaceutical compositions and dosage forms that may be produced therefrom are distinguished by their high solubility and rapid disintegration and dissolution in aqueous media, by their good flow properties and compressibility, by rapidly achieving onset of analgesic effect.

Owner:LOSAN PHARMA GMBH

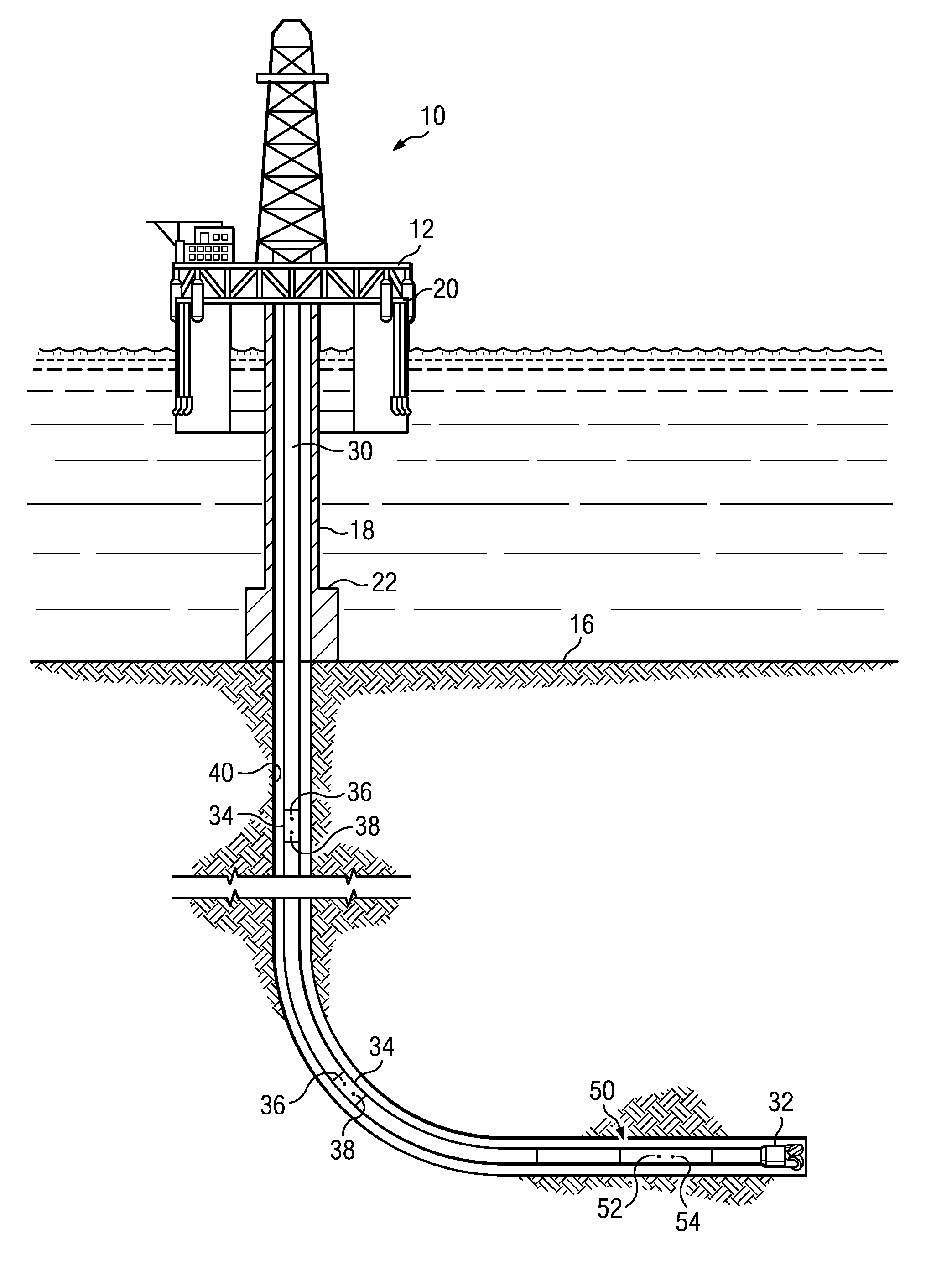

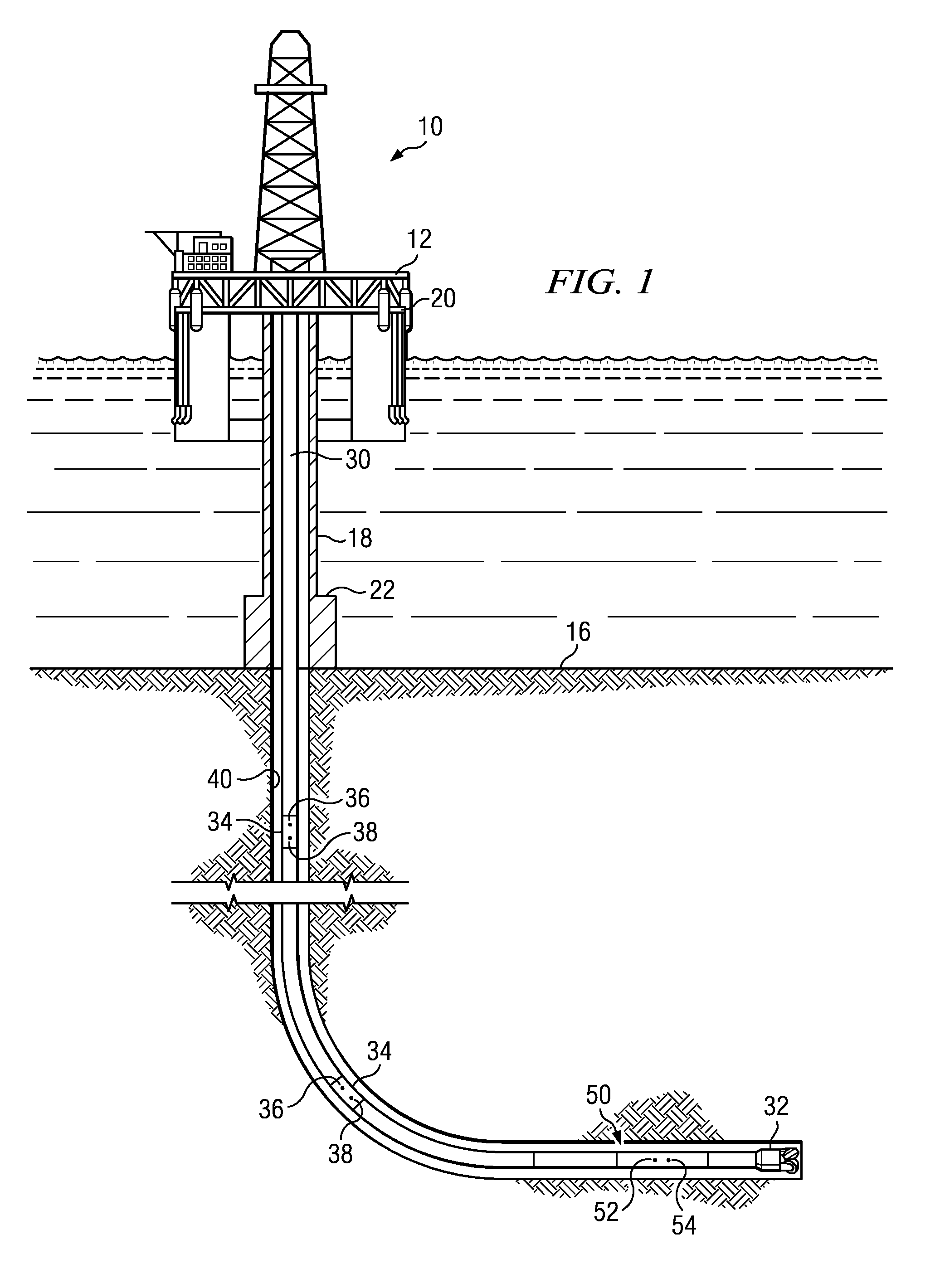

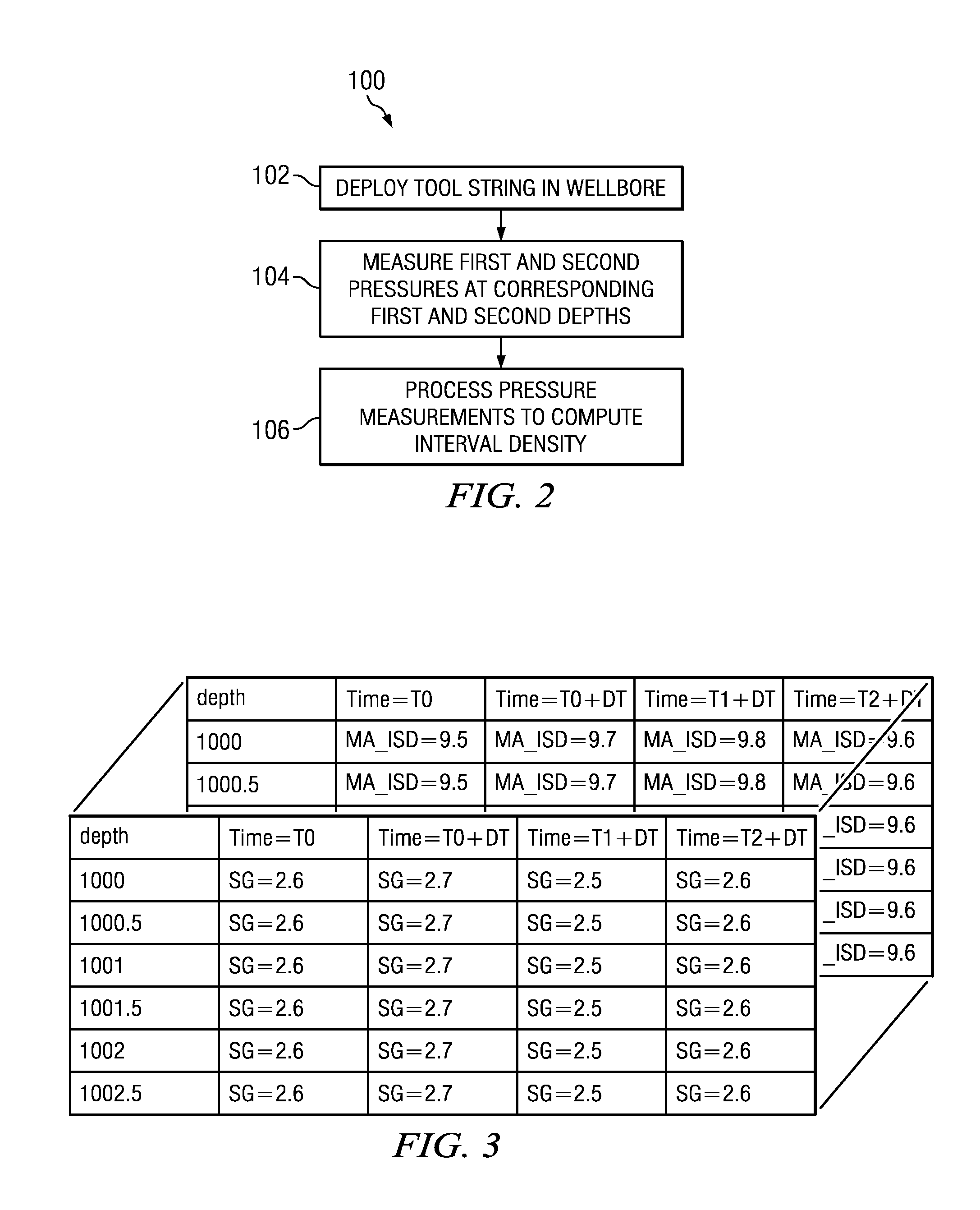

Methods for evaluating cuttings density while drilling

ActiveUS20130054146A1Save considerable rig timeMitigating action can be quicklyElectric/magnetic detection for well-loggingSurveyWell drillingPressure measurement

A method evaluating a cuttings density while drilling a subterranean wellbore includes acquiring first and second axially spaced pressure measurements in the wellbore. The pressure measurements may then be processed to obtain an interval density of drilling fluid between the measurement locations. A tool string including a large number of axially spaced pressure sensors (e.g., four or more or even six or more) electronically coupled with a surface processor via wired drill pipe may be used to obtain a plurality of interval densities corresponding to various wellbore intervals. The interval density may be measured while drilling and may be further processed to compute a cuttings density in the annulus. Moreover, changes in the computed interval density with time while drilling may be used as an indicator of a change in cuttings density.

Owner:SCHLUMBERGER TECH CORP

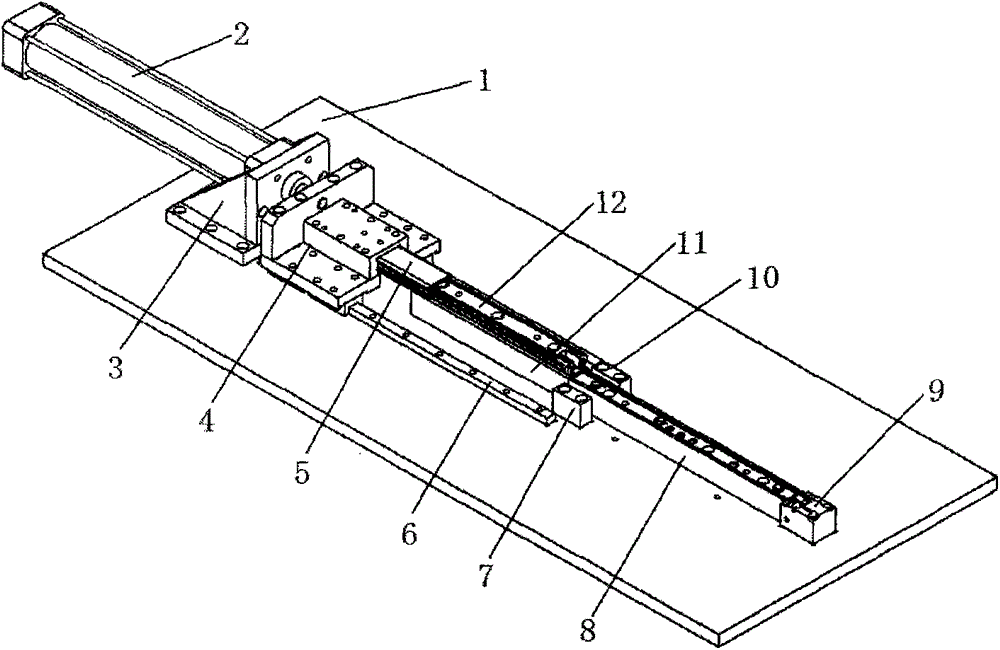

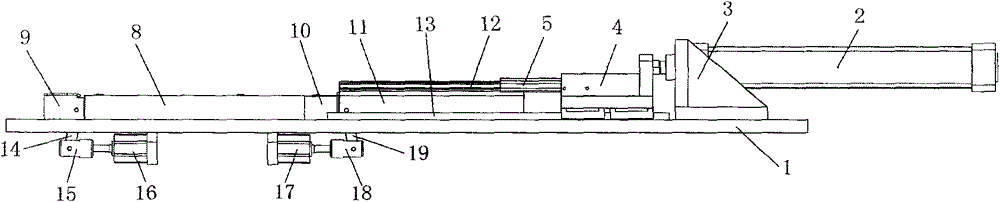

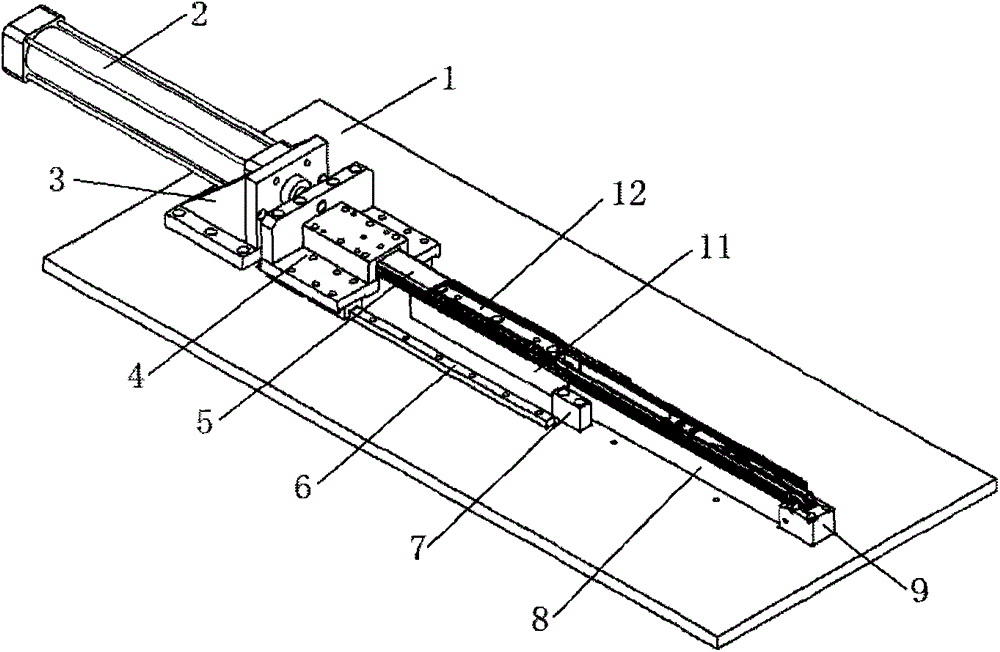

Automobile seat sliding track assembling machine and assembling method for same

ActiveCN103551834AImprove assembly efficiencyEfficient assembly workMetal working apparatusCar seatEngineering

The invention discloses an automobile seat sliding track assembling machine and an assembling method for same. The automobile seat sliding track assembling machine comprises a base, an assembling cylinder, a cylinder rack, an outer ejector block, an inner ejector block, a right guide track, a right limiting block, an inner sliding track rack, an end stopping block, a left limiting block, a supporting block, a side sliding track rack, a left guide track, a front clamping jaw, a front connecting rod, a front clamping cylinder, a rear clamping cylinder, a rear connecting rod and a rear clamping jaw. The automobile seat sliding track assembling machine is suitable for assembling automobile seat slide tracks. By the automobile seat sliding track assembling machine, assembly operation can be finished instead of manual work, and slide track components are clamped and assembled by the different cylinders. The automobile seat sliding track assembling machine has the advantages of large output force, high assembling speed, high efficiency, high quality and the like; the labor intensity of workers is effectively reduced; and the quality uniformity of products of assembly parts is ensured. In addition, the automobile seat sliding track assembling machine is compact in structure, high in reliability, stable in operation and low in cost.

Owner:ZHEJIANG LONGSHENG AUTO PARTS TECH CO LTD

Bactericidal Formulations

InactiveUS20080118591A1Fast actionHigh antibacterial activityAntibacterial agentsHalogenated hydrocarbon active ingredientsSkin surfaceAdditive ingredient

The invention relates to bactericidal formulations that come into contact with human body, particularly wash formulations including liquid soaps, comprising perfume ingredients active against gram-negative bacteria. Such compositions contact the target site, for example the skin surface, only for a short time, usually not longer than 30 seconds. Therefore the antibacterial action has to be of the bactericidal type and rapid. Furthermore, the bactericidal activity has to be sufficiently high to ensure an effect even when applied to wet substrates that will dilute the bactericidal formulation.

Owner:GIVAUDAN SA

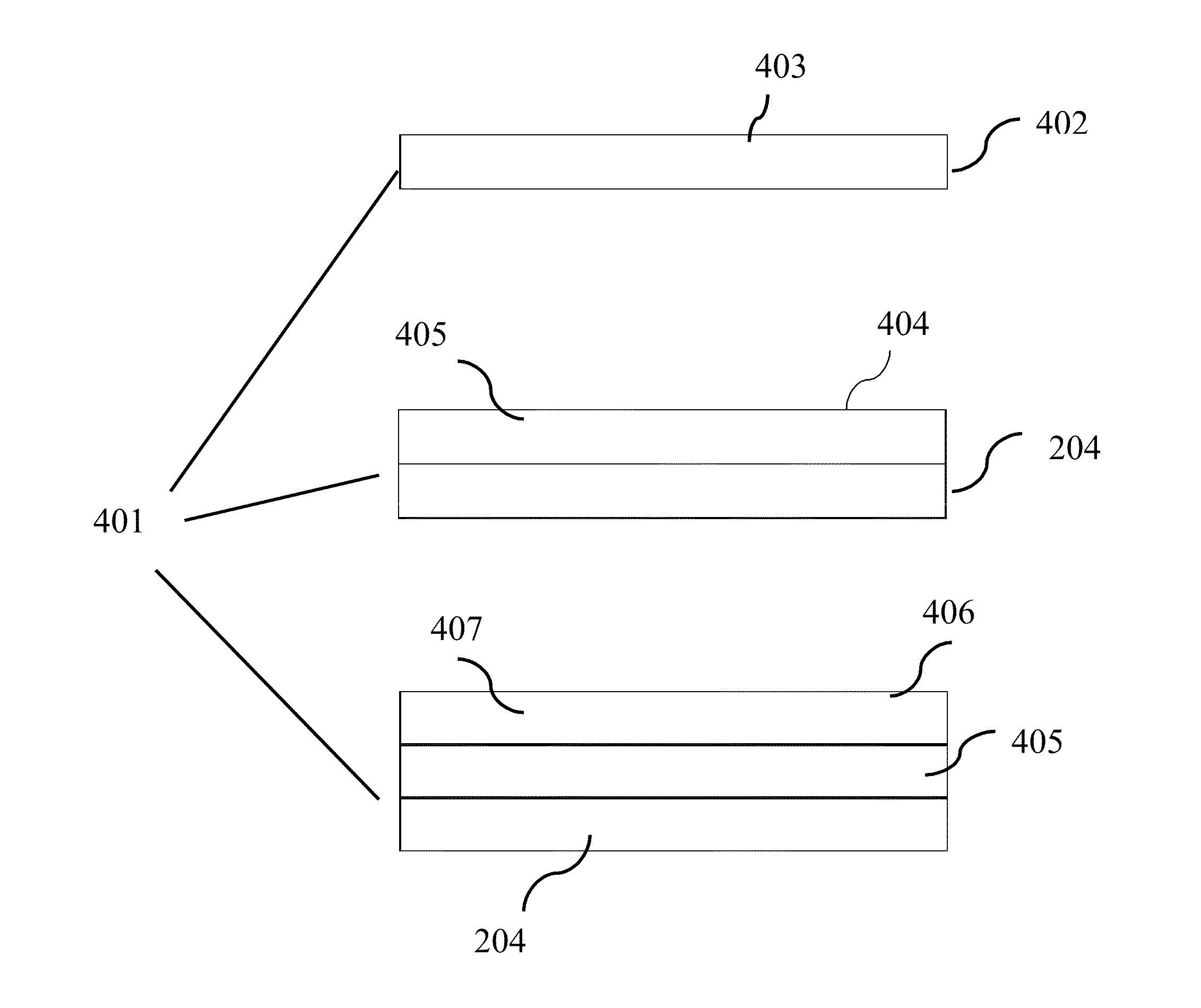

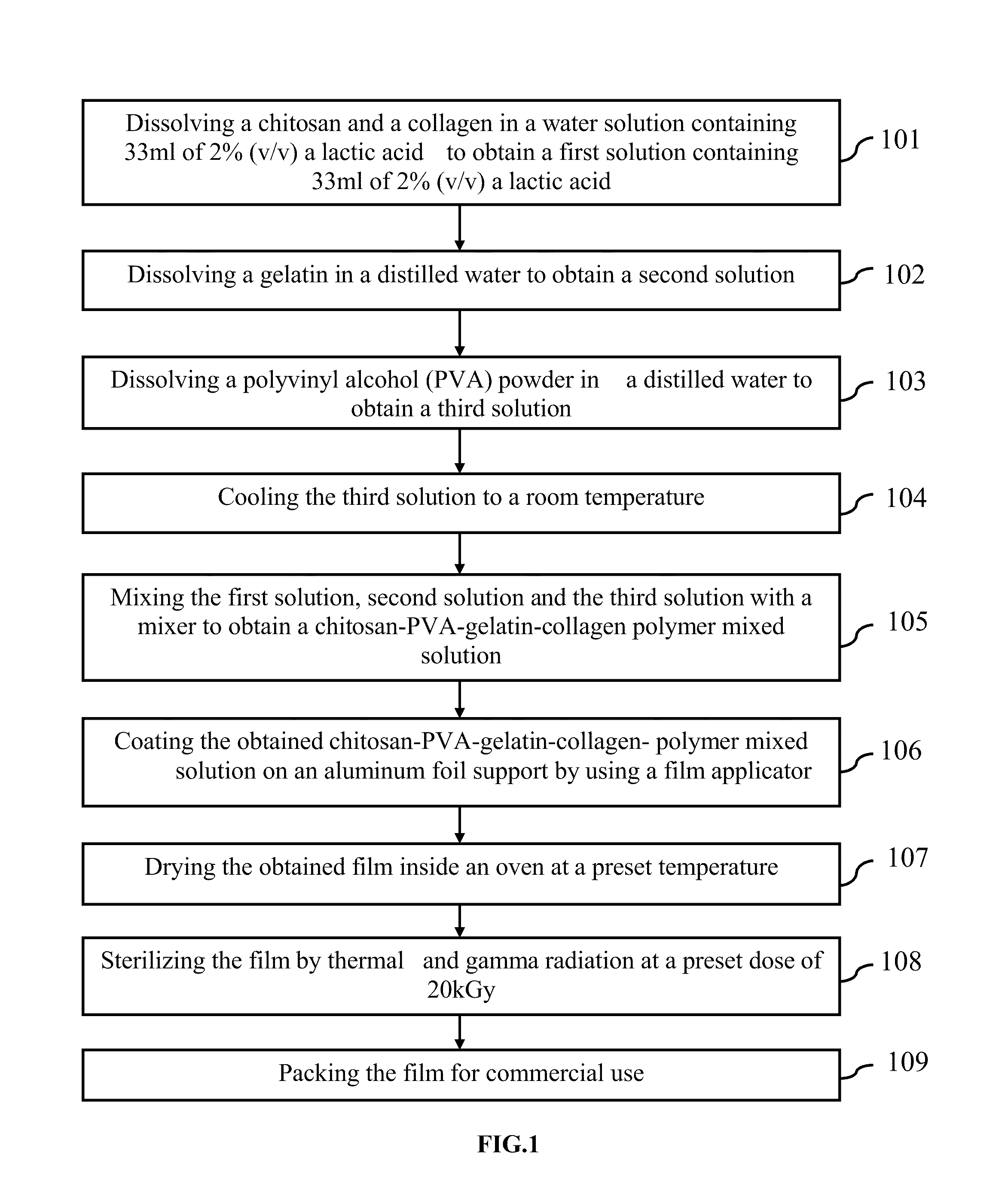

Non drug based wound dressing polymer film and a method of producing the same

InactiveUS20110218472A1Separating woundEasy to separatePretreated surfacesAdhesive dressingsWound dressingBiopolymer

The various embodiments herein provide a polymer wound dresser in which no drug is used and a method of producing the same. According to an embodiment, a wound dressing film comprises a base polymer film and a laminated backing layer on the base polymer film. The base polymer film includes a natural polymer, a biopolymer and an artificial water absorber polymer. The natural polymer is a chitosan having a preset weight percentage. The biopolymer comprises one or more element selected from a group comprising of a gelatin having a preset weight percentage and a collagen having a preset weight percentage or a combination thereof. The artificial water absorber polymer is selected from a group comprising of a hydrophilic material having a preset weight percentage. The wound dressing film is a single film or a double layered film or a three layered film.

Owner:IRAN POLYMER & PETROCHEM INST IPPI

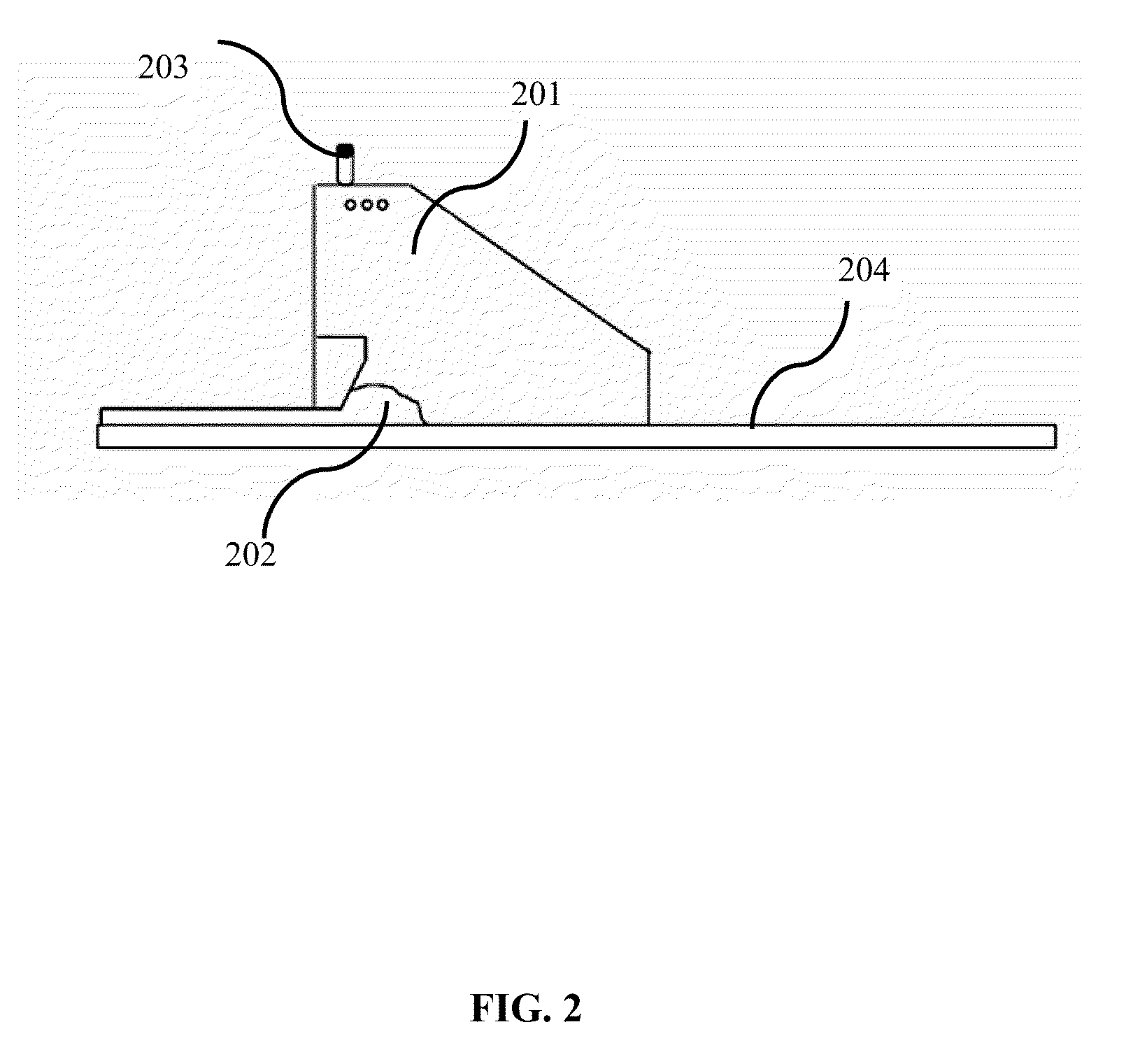

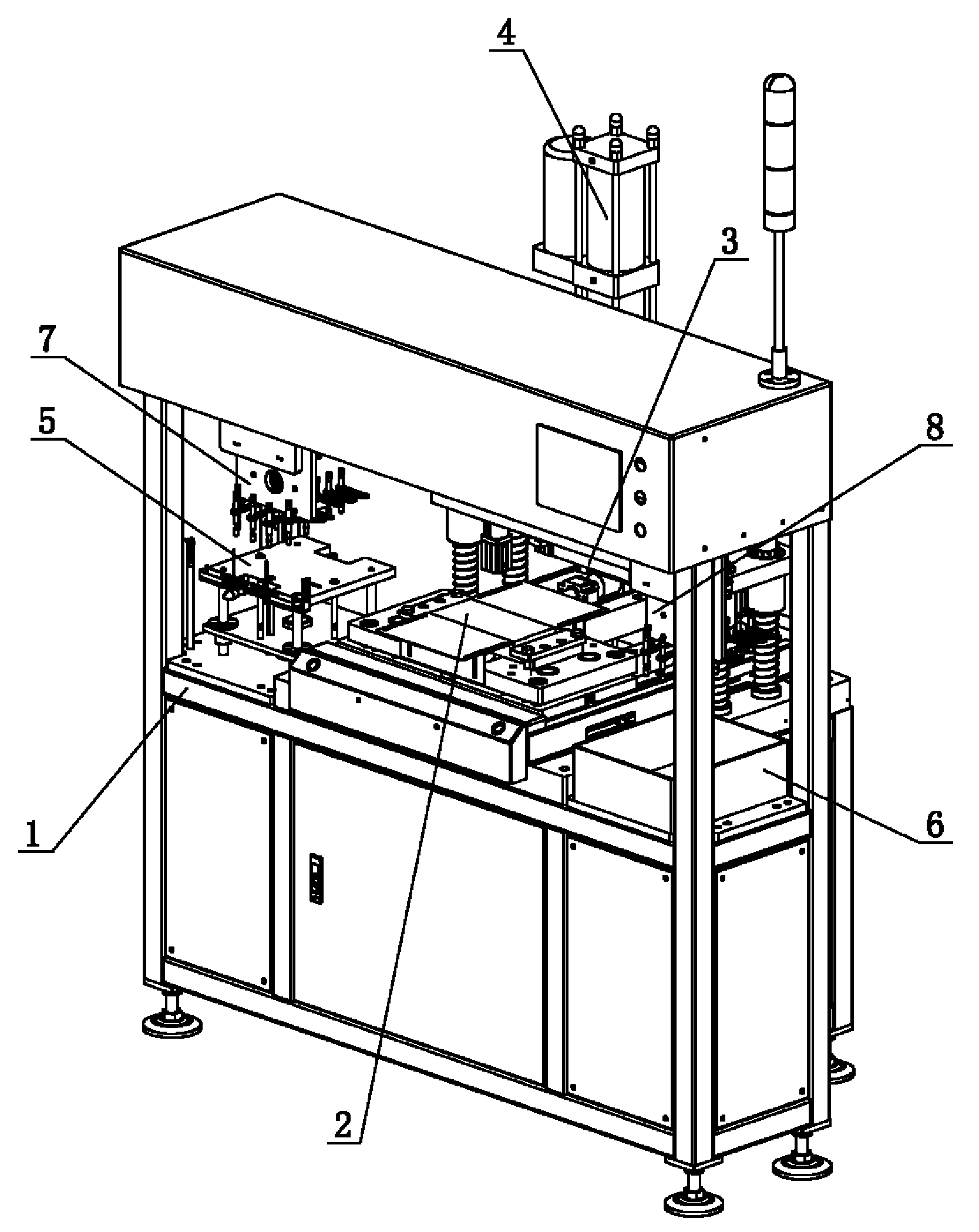

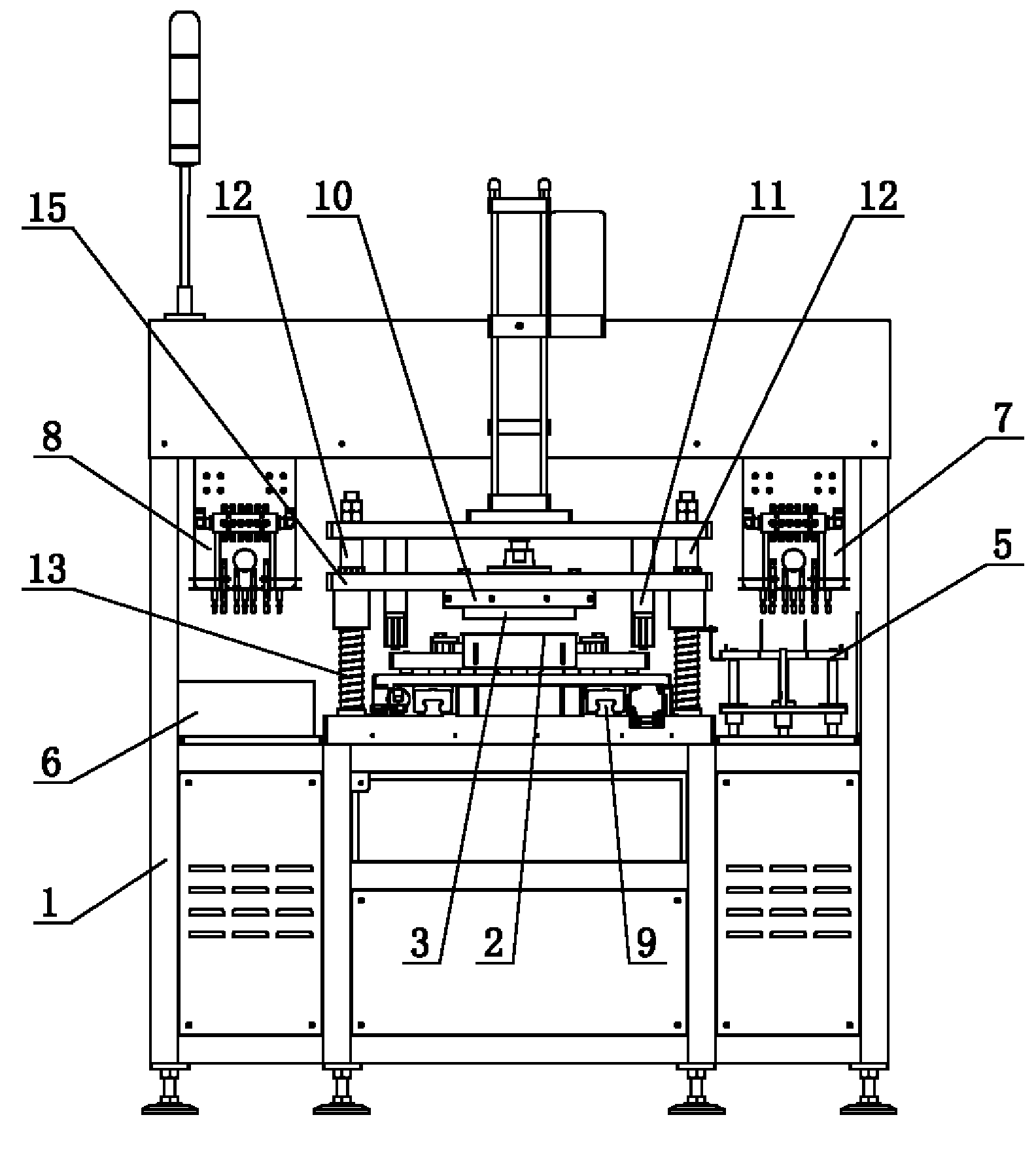

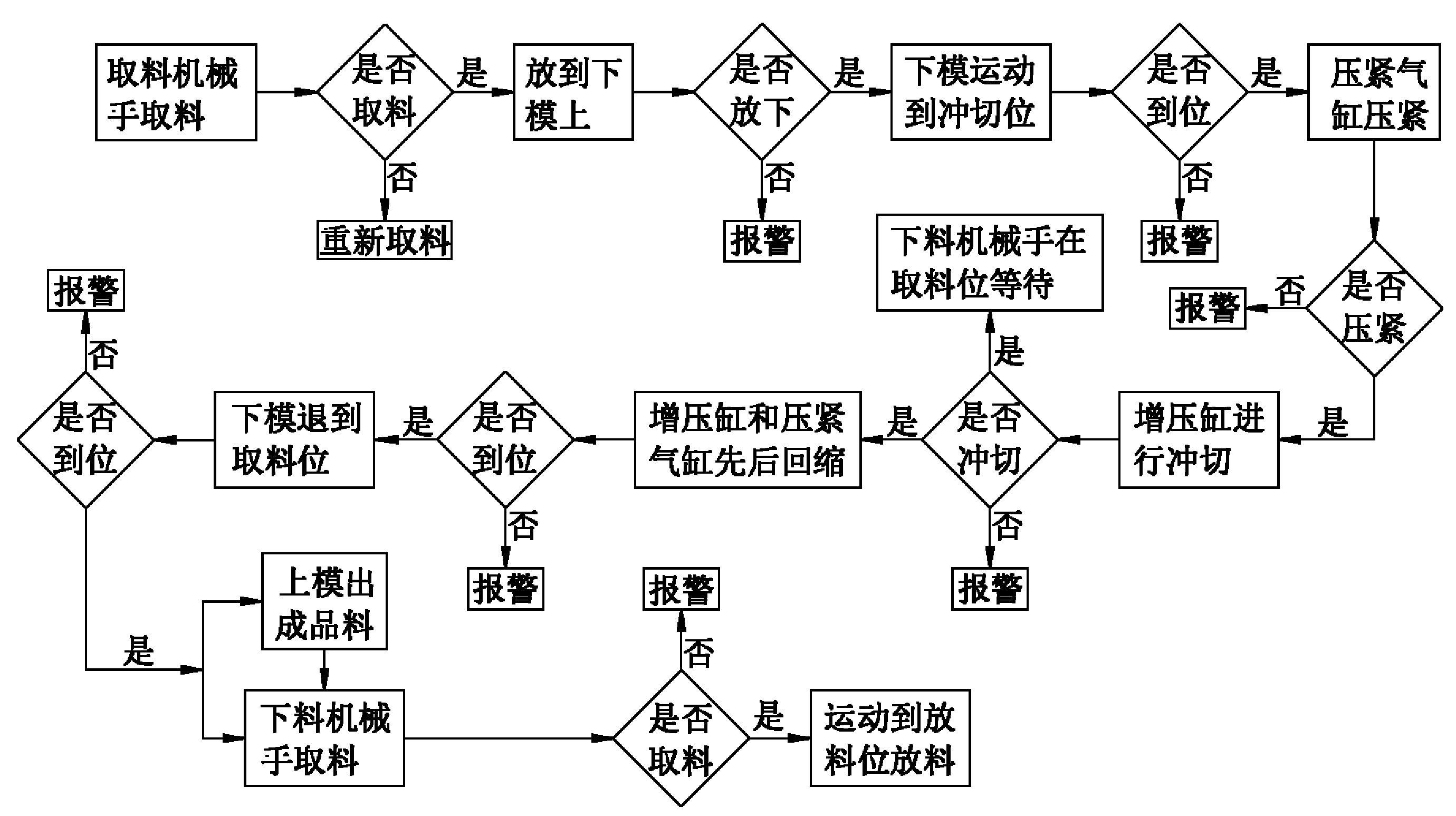

Automatic punch equipment and processing method thereof

ActiveCN104227781AImprove processing qualityRealize automatic processingMetal working apparatusConveyor partsAutomatic test equipmentPunch press

The invention relates to the technical field of FPC (flexible printed circuit) processing equipment, in particular to automatic punch equipment. The automatic punch equipment comprises a lower die, an upper die and a pressure cylinder, wherein the lower die is arranged on a rack, the upper die is located right above the lower die, and the pressure cylinder is used for driving the upper die to vertically move; the pressure cylinder is fixedly arranged on the rack; the rack is also provided with a feeding tray and a discharging tray; a feeding manipulator is arranged above the feeding tray; a discharging manipulator is arranged above the discharging tray; the processing method for the automatic punch equipment comprises the following steps: clamping an FPC material from the feeding tray by the feeding manipulator and transferring the FPC material to the lower die, and backwards moving the lower die to a punching position from a material fetching position; downwards moving the upper die to perform punching processing and then, returning to an original position; forwards moving the lower die to return to the material fetching position; transferring an FPC finished product into the discharging tray from the material fetching position by the discharging manipulator. Automatic processing of FPC punching is realized; manual feeding and discharging actions are not needed; a feeding position and a discharging position are more accurate; the processing quality of the punch equipment is greatly improved.

Owner:GUANGDONG HUAHENG INTELLIGENT TECH CO LTD

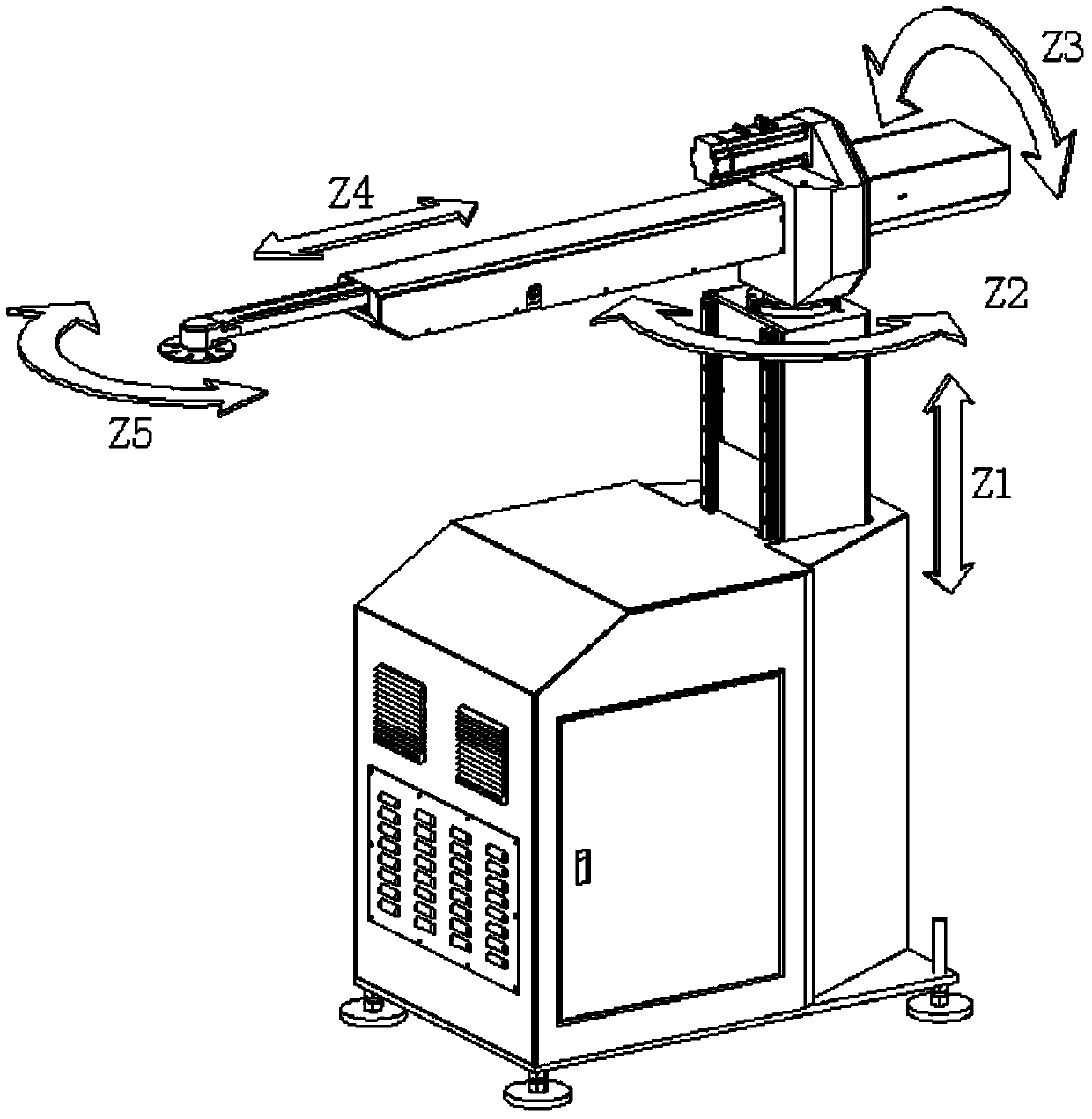

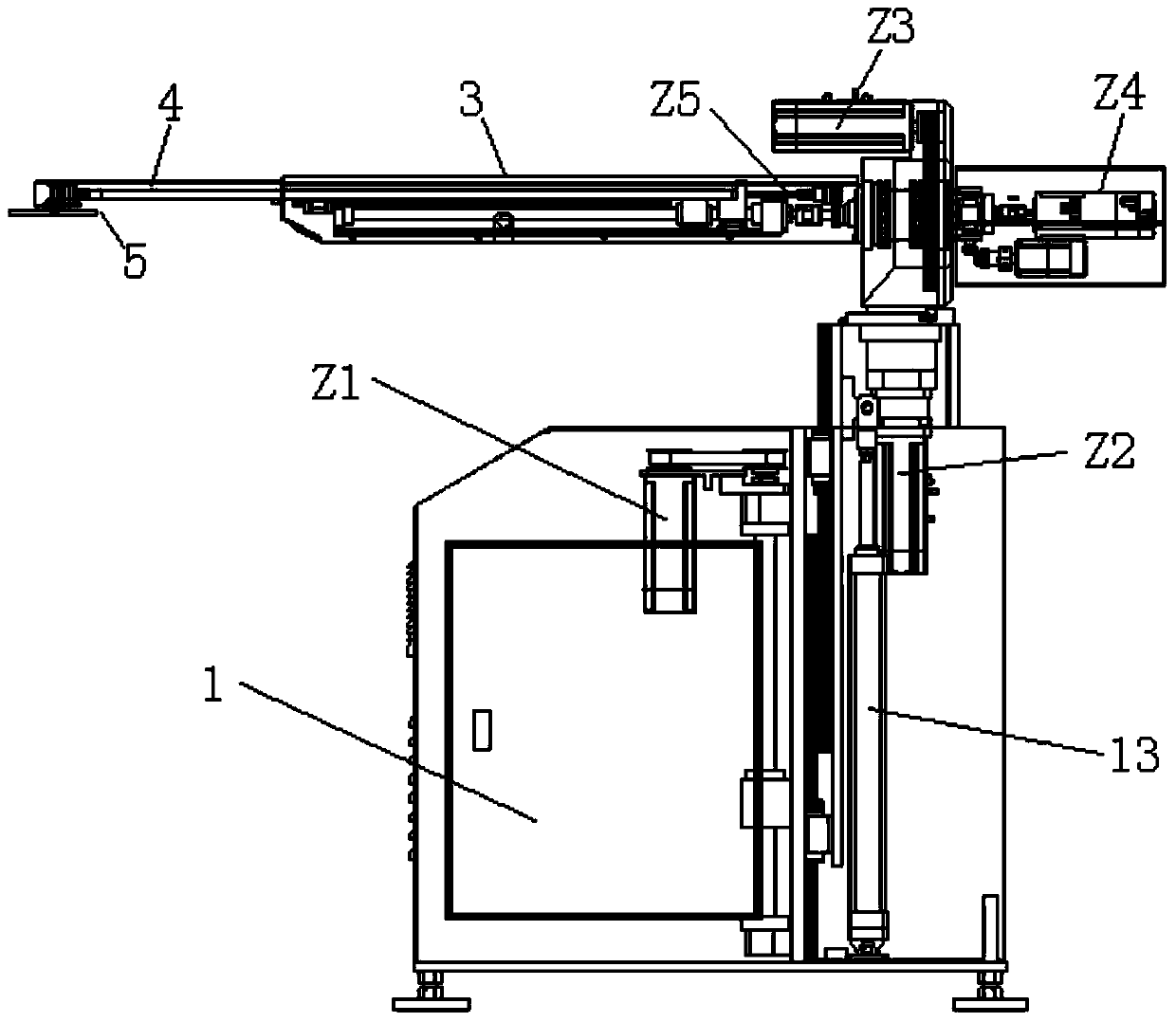

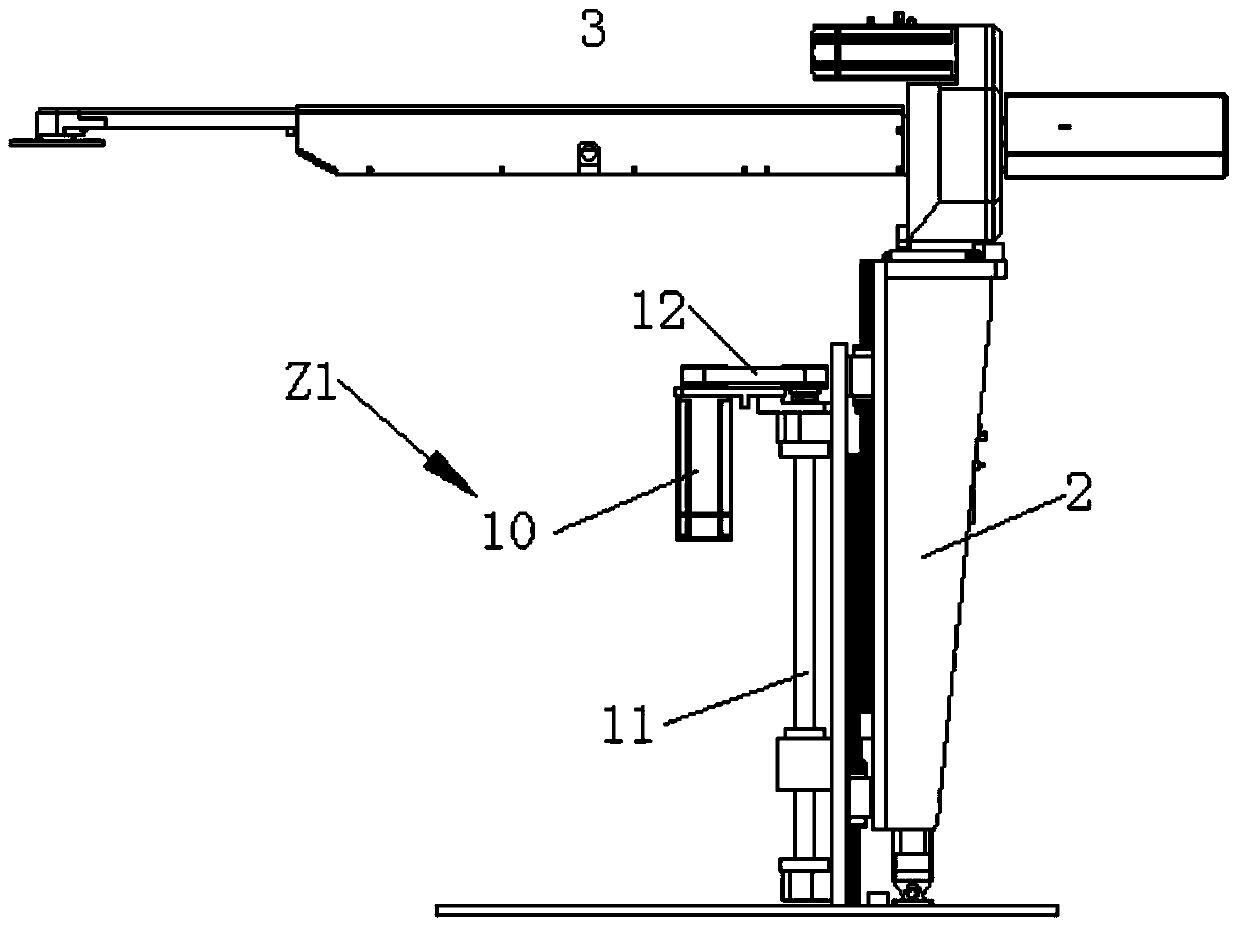

Intelligent five-shaft manipulator

The invention discloses an intelligent five-shaft manipulator. The manipulator comprises a manipulator body and five movement mechanisms, wherein a swing arm movement mechanism is supported on a vertical movement mechanism, and can be driven to realize upper and lower mobile positioning through the vertical movement mechanism; an overturning movement mechanism is supported on the swing arm movement mechanism, and can be driven to rotate by the swing arm movement mechanism; a horizontal movement mechanism and an actuating station rotary movement mechanism are supported on the overturning movement mechanism, and can be driven to rotate together by the overturning movement mechanism, and the horizontal movement mechanism can drive a telescopic arm to move to and fro in the length direction of a main arm; and a flange plate can be driven to revolve around the center of the actuating station rotary movement mechanism through the actuating station rotary movement mechanism; and the mounting positions of the five movement mechanisms are reasonably configured to reduce the bearing capacities of the swing arm movement mechanism and the horizontal movement mechanism, so that the intelligent five-shaft manipulator is not only fast in movement speed, small in inertia and flexible to operate, but is also high in positioning precision, high in stability and good in safety.

Owner:昆山威创自动化科技有限公司

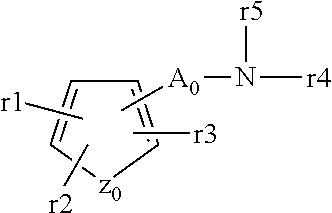

Aryl- or heteroaryl-sulfonyl compounds as acid secretion inhibitors

ActiveUS20110288040A1Low toxicityHigh expressionAntibacterial agentsBiocideAcyl groupProton-pump inhibitor

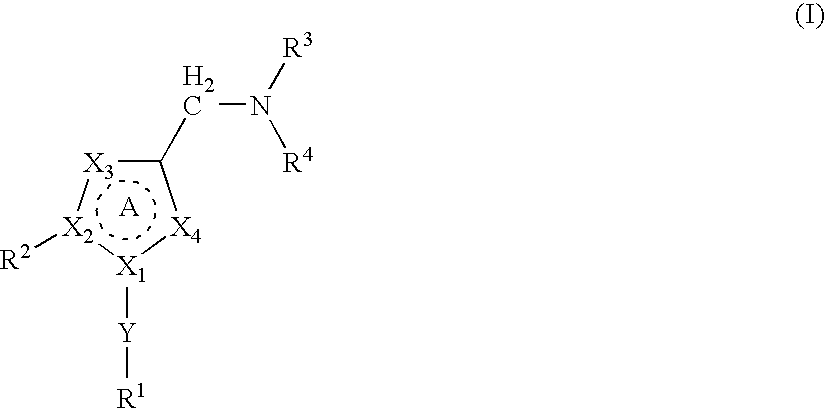

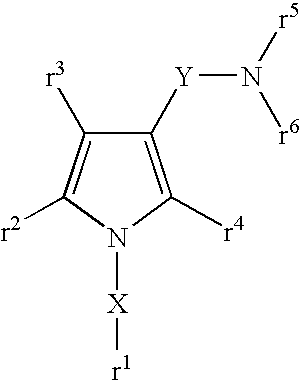

The present invention provides a compound having a superior acid secretion inhibitory action, an antiulcer activity and the like.A proton pump inhibitor containing a compound represented by the formula (I)wherein ring A is a saturated or unsaturated 5- or 6-membered ring group optionally having, as a ring-constituting atom besides carbon atom, 1 to 4 hetero atoms selected from a nitrogen atom, an oxygen atom and a sulfur atom, ring-constituting atoms X1 and X2 are each a carbon atom or a nitrogen atom, a ring-constituting atom X3 is a carbon atom, a nitrogen atom, an oxygen atom or a sulfur atom, R1 is an optionally substituted aryl group or an optionally substituted heteroaryl group, R2 is an optionally substituted alkyl group, an optionally substituted aryl group or an optionally substituted heteroaryl group, R3 is an aminomethyl group optionally substituted by 1 or 2 lower alkyl groups, which is a substituent on a ring-constituting atom other than X1, X2 and X3, and ring A optionally further has substituent(s) selected from a lower alkyl group, a halogen atom, a cyano group and an oxo group, or a salt thereof or a prodrug thereof.

Owner:TAKEDA PHARMA CO LTD

Salts of benzimidazole compound and use thereof

InactiveUS20030181487A1Improve stabilityExcellent antiulcer actionAntibacterial agentsBiocideBarium saltMagnesium salt

Owner:TAKEDA PHARMA CO LTD

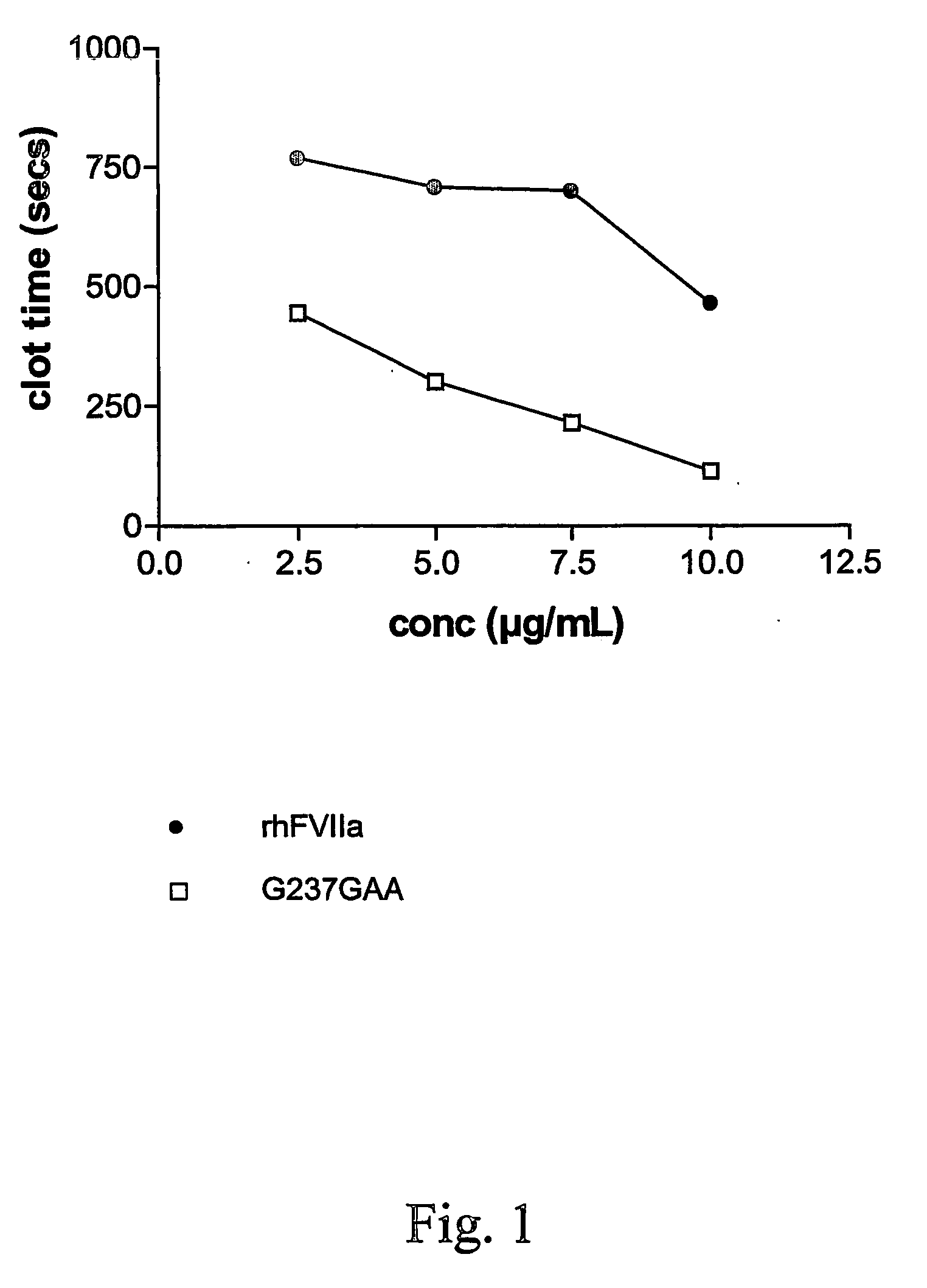

Fvii or fviia variants

InactiveUS20070054366A1Easy to handleFast actionPeptide/protein ingredientsMammal material medical ingredientsClotting timeBiology

Variants of FVII or FVIIa comprising at least one amino acid modification in position 196, 237 or 341 relative to hFVII or hFVIIa. The variants exhibit an increased clotting activity, i.e. reduced clotting time, compared to rhFVIIa.

Owner:BAYER HEALTHCARE LLC

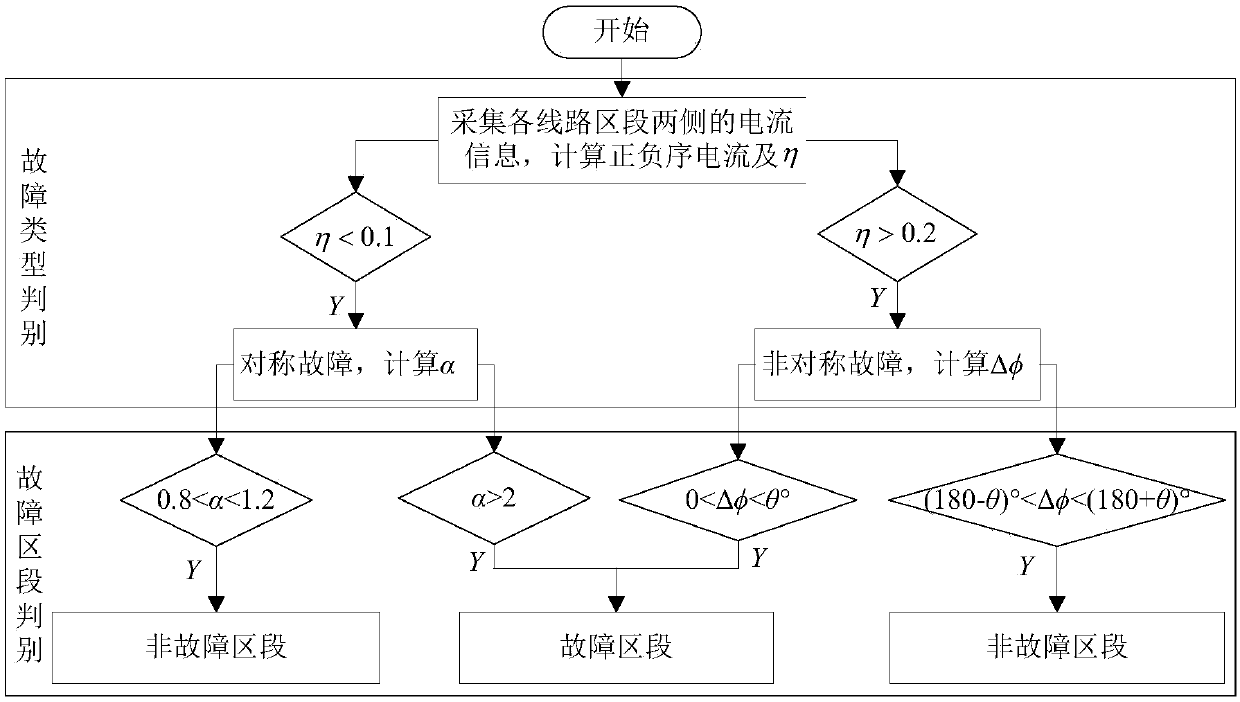

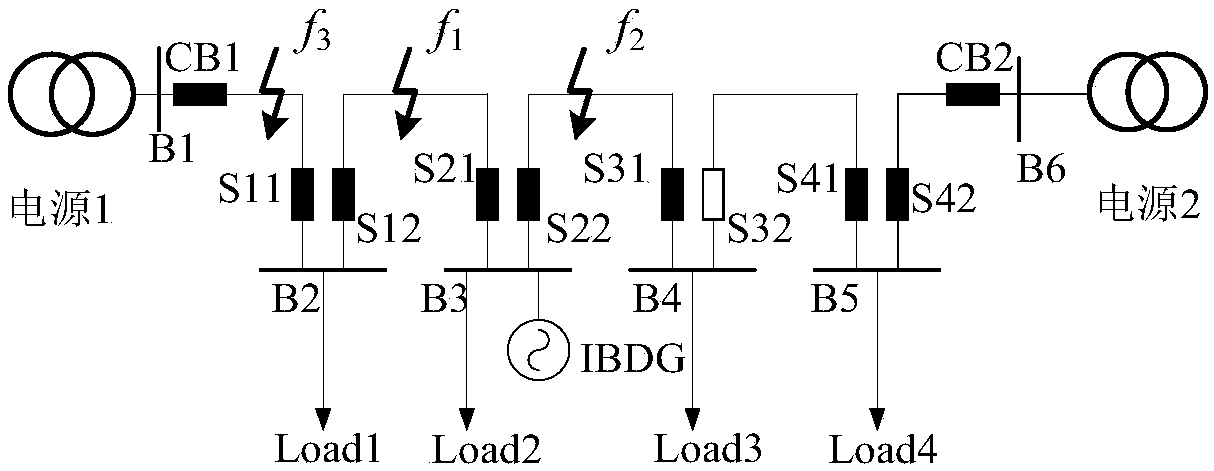

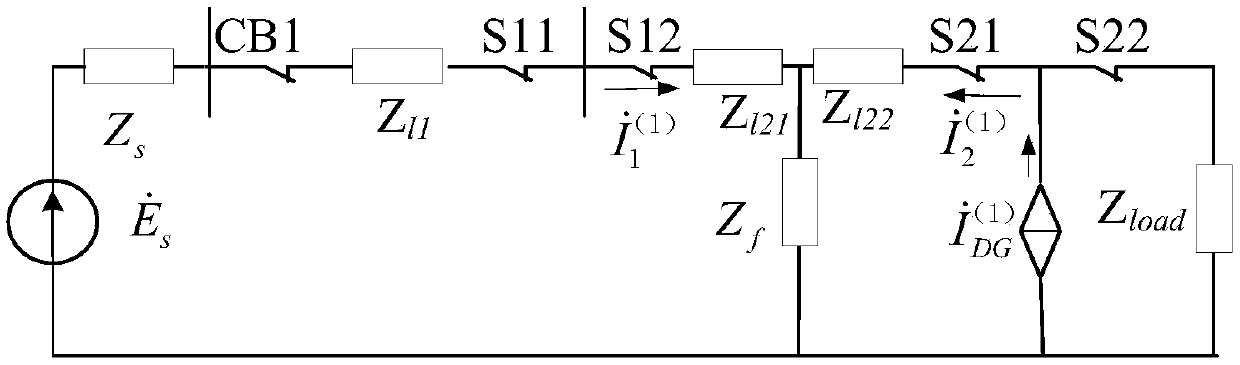

DG feed line-containing current sequence component comparison mode fault section positioning method

InactiveCN108445349AFast actionHigh sensitivityEmergency protective circuit arrangementsSingle network parallel feeding arrangementsElectrical resistance and conductanceDynamic models

The invention discloses a DG feed line-containing current sequence component comparison mode fault section positioning method comprising the following steps: gathering a current passing switches on two sides of a feed line in real time; detecting the feed line to have a fault, and calculating positive and negative sequence current components of the fault current; using an amplitude relation of thepositive and negative sequence current components to determine a fault type; determining the fault type as an asymmetry fault, comparing the negative sequence current phases on two ends of the feed line, and determining whether the section is the fault section or not according to the phase difference; determining the fault type as a symmetry fault, comparing the amplitudes of the positive sequence current on two ends of the feed line, and determining the fault section according to the ratio relation of said two. According to simulation, analysis and dynamic model tests, when different positions of the DG feed line have different types of faults, the method can correctly identify the fault sections with a high sensitivity and strong reliability; in addition, the method cannot be affected by DG types and capacities, transition resistance and crossing current factors.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +2

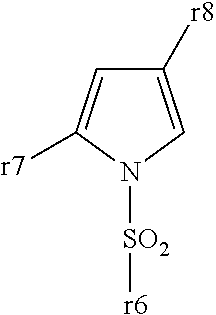

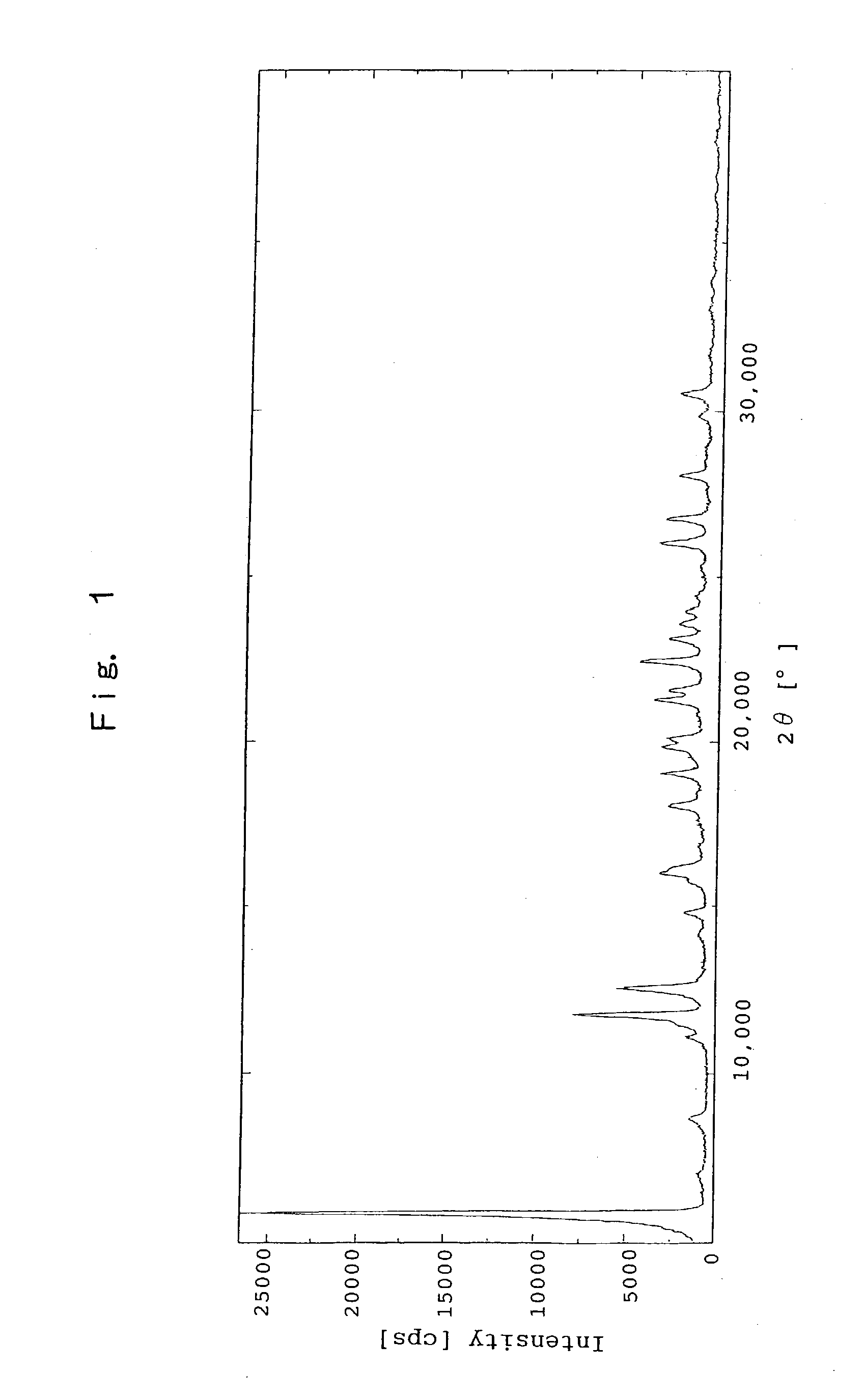

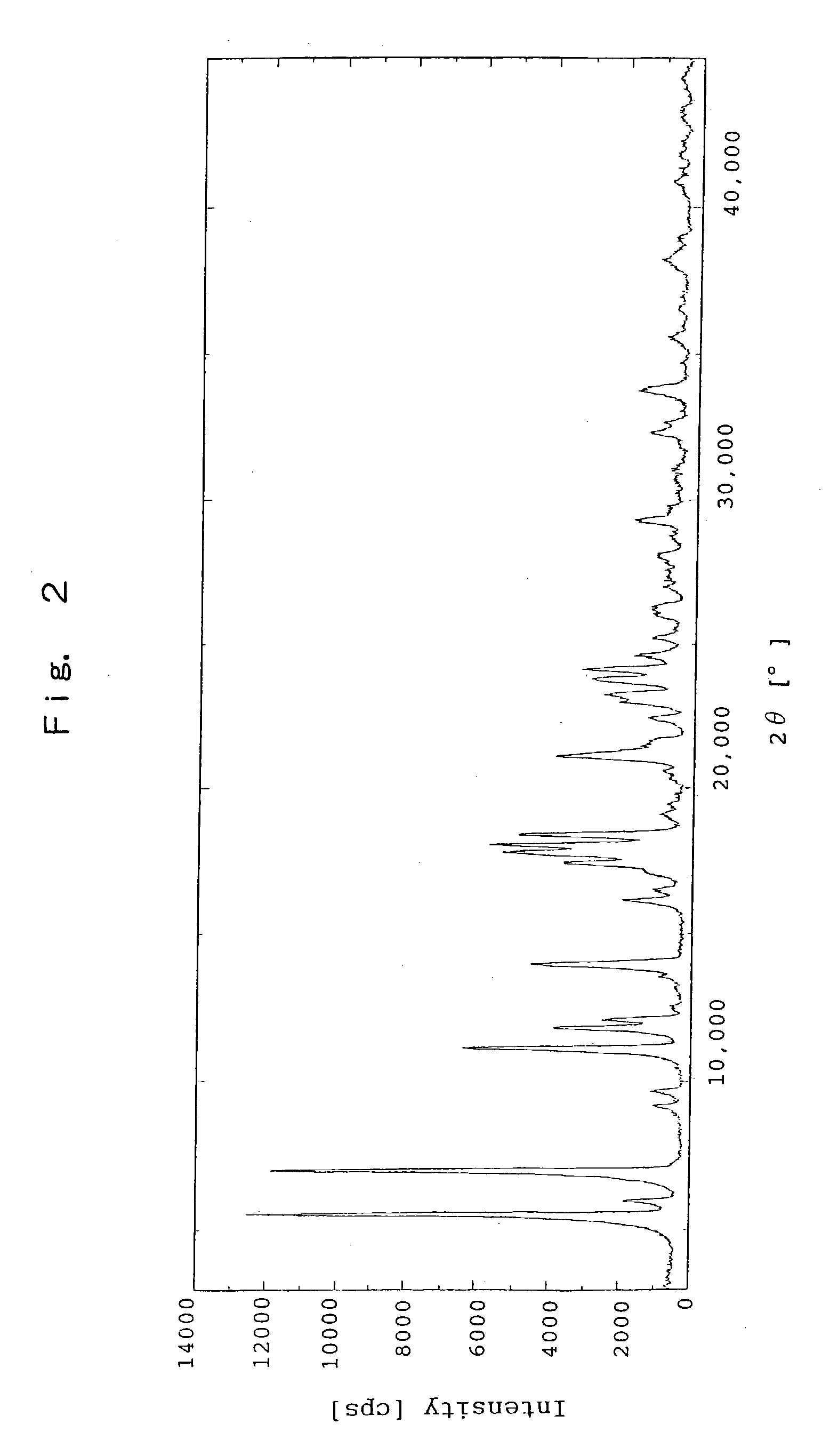

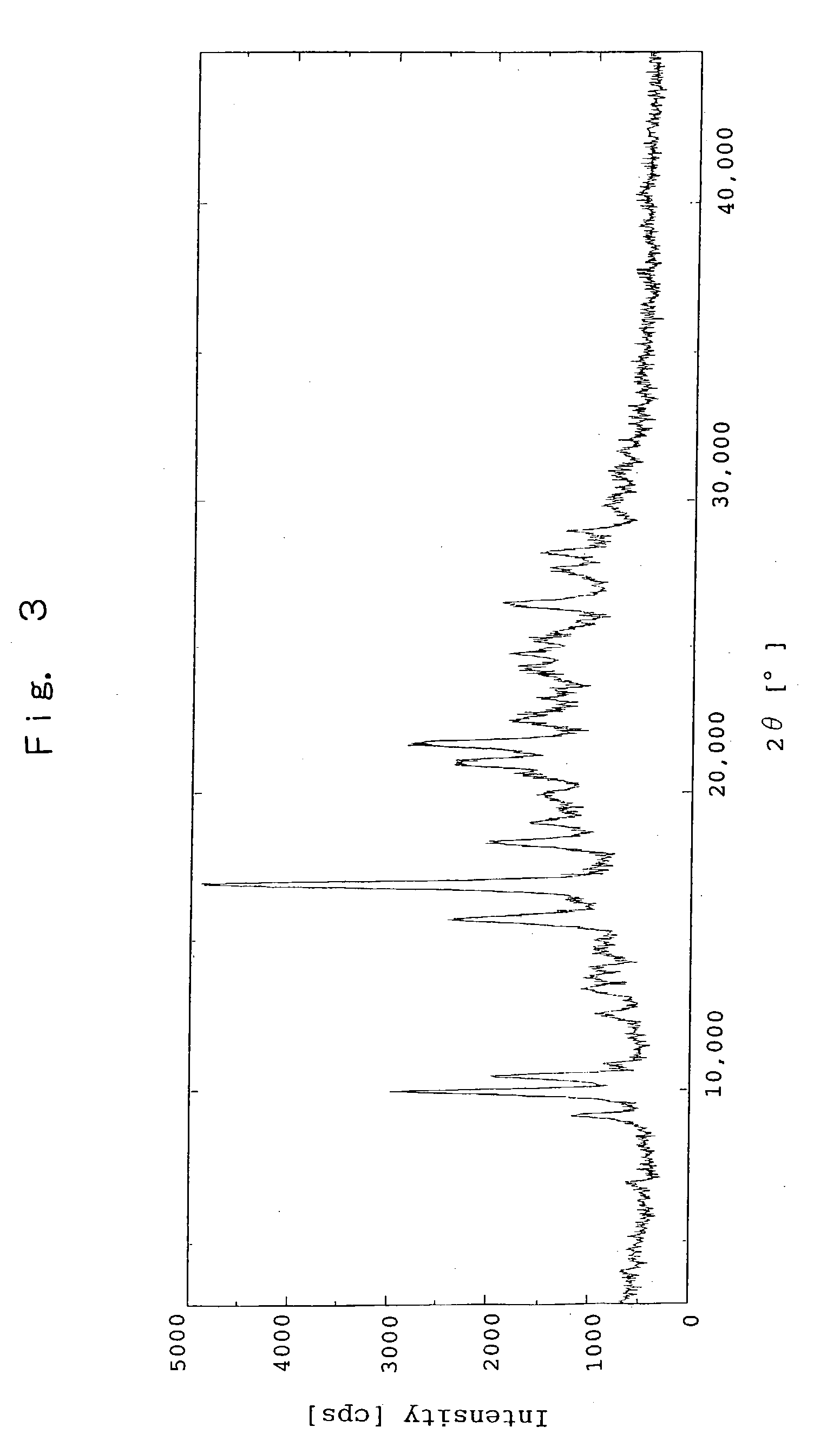

5-membered heterocyclic compound

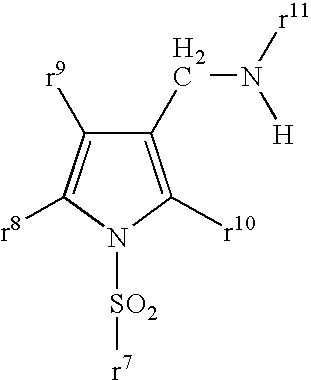

Provided is a compound having a superior acid secretion suppressive action, which shows an antiulcer activity and the like.A compound represented by the formula (I) or a salt thereof:wherein ring A is a saturated or unsaturated 5-membered heterocycle containing, as a ring-constituting atom besides carbon atoms, at least one heteroatom selected from a nitrogen atom, an oxygen atom and a sulfur atom, the ring-constituting atoms X1 and X2 are the same or different and each is C or N, the ring-constituting atoms X3 and X4 are the same or different and each is C, N, 0 or S (provided that a pyrrole ring wherein X1 is N is excluded from ring A), and when the ring-constituting atom X3 or X4 is C or N, each ring-constituting atom optionally has substituent(s) selected from an optionally substituted alkyl, an acyl, an optionally substituted hydroxy, an optionally substituted mercapto, an optionally substituted amino, a halogen, a cyano and a nitro;R1 and R2 are each a cyclic group optionally having substituent(s); R3 and R4 are each H or alkyl, or R3 and R4 form, together with the adjacent N, an nitrogen-containing heterocycle; and Y is a spacer.

Owner:TAKEDA PHARMA CO LTD

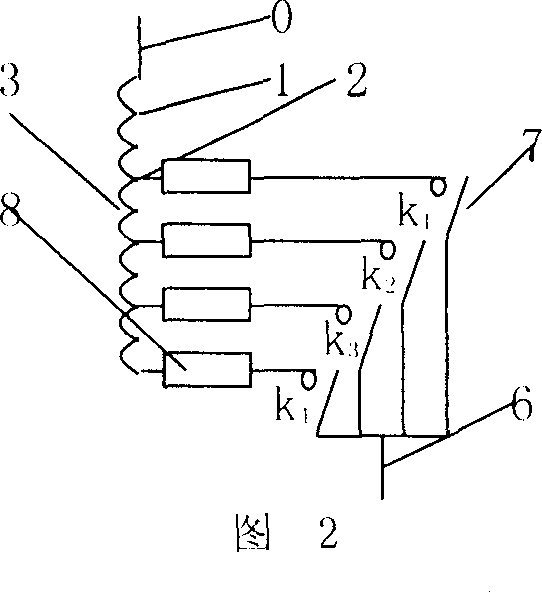

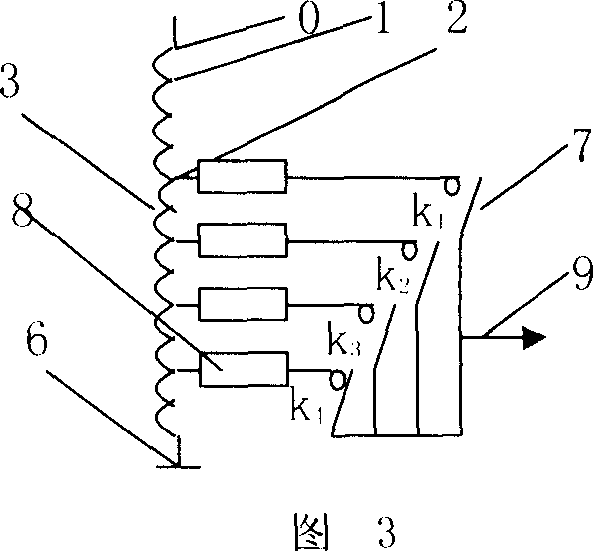

Method and apparatus for realizing load voltage regulation with a plurality of switching elements

InactiveCN101039091AExtended service lifeReduce tap-to-tap voltageConversion without intermediate conversion to dcVariable inductancesElectrical resistance and conductanceCurrent limiting

Provided is a method and device realizing load voltage regulation by a plurality of switch elements used by the regulating transformer and the reactor, each tap endpoint of the loading regulating transformer or the reactor voltage regulation winding is connected with the switch elements, a thermic element is connected between the tap changer and the switch element; or each tap endpoint of the regulating winding is connected with a current limiting branch composed of switch elements connected serially with the current limiting resistor or other current limiting elements and a direct passing branch composed of switch elements, the current limiting branch is paralleled with the direct passing branch; the switch element or the other end of the parallel circuit connected with the tap endpoint of the same phase voltage regulation winding are paralleled and educed; the device regulates the output voltage by controlling the make and break of different switch elements according to the detection of the voltage detection circuit.

Owner:魏明

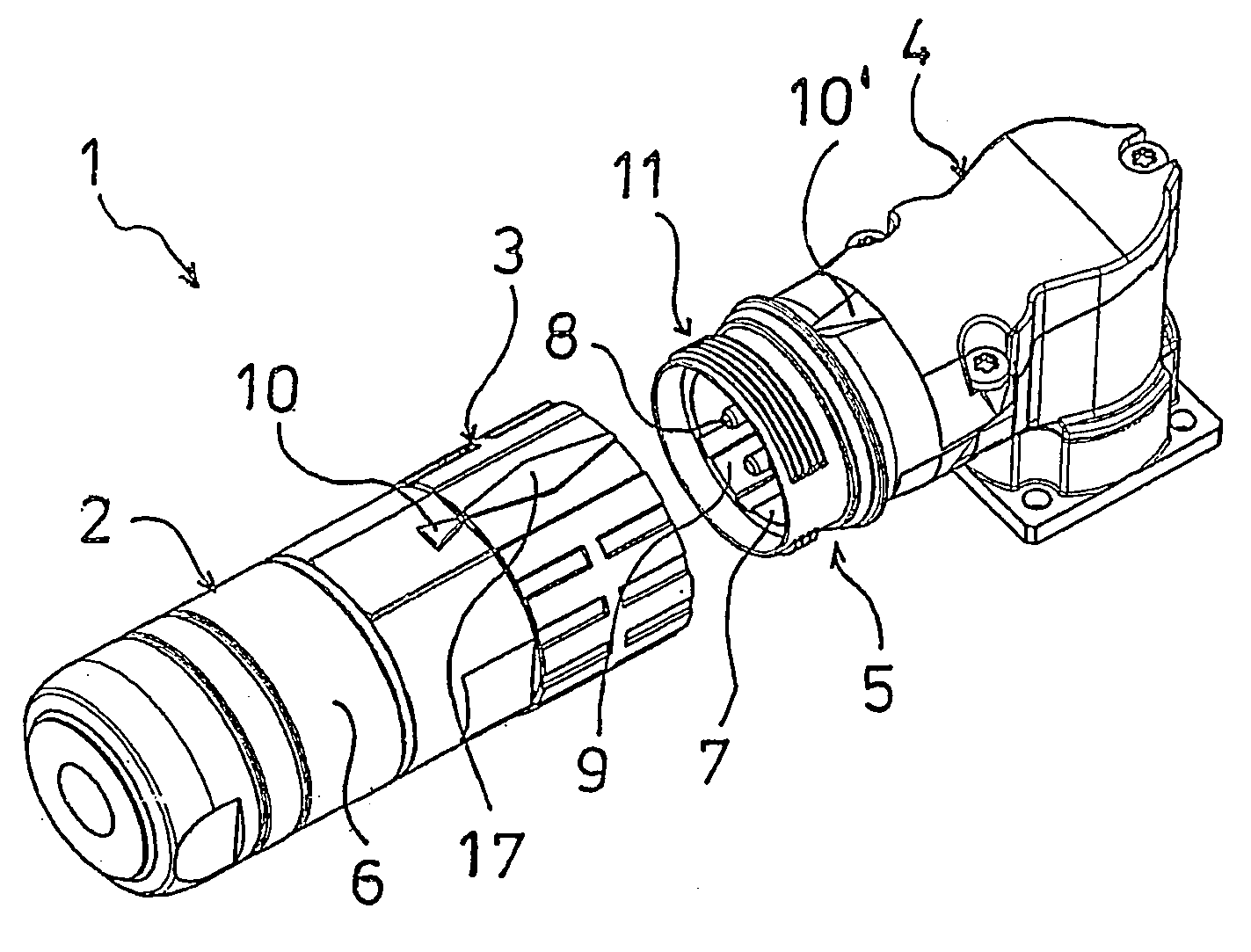

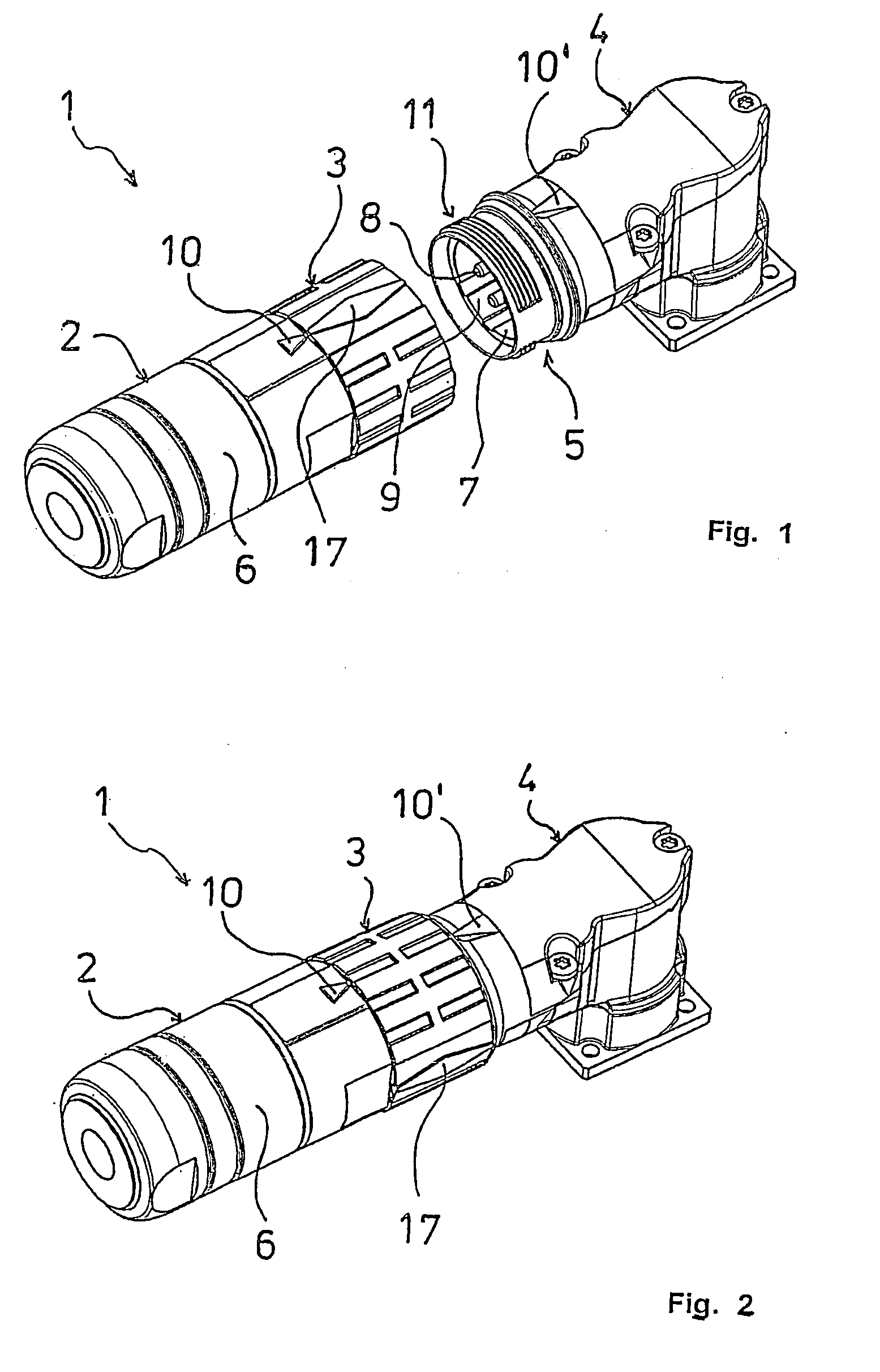

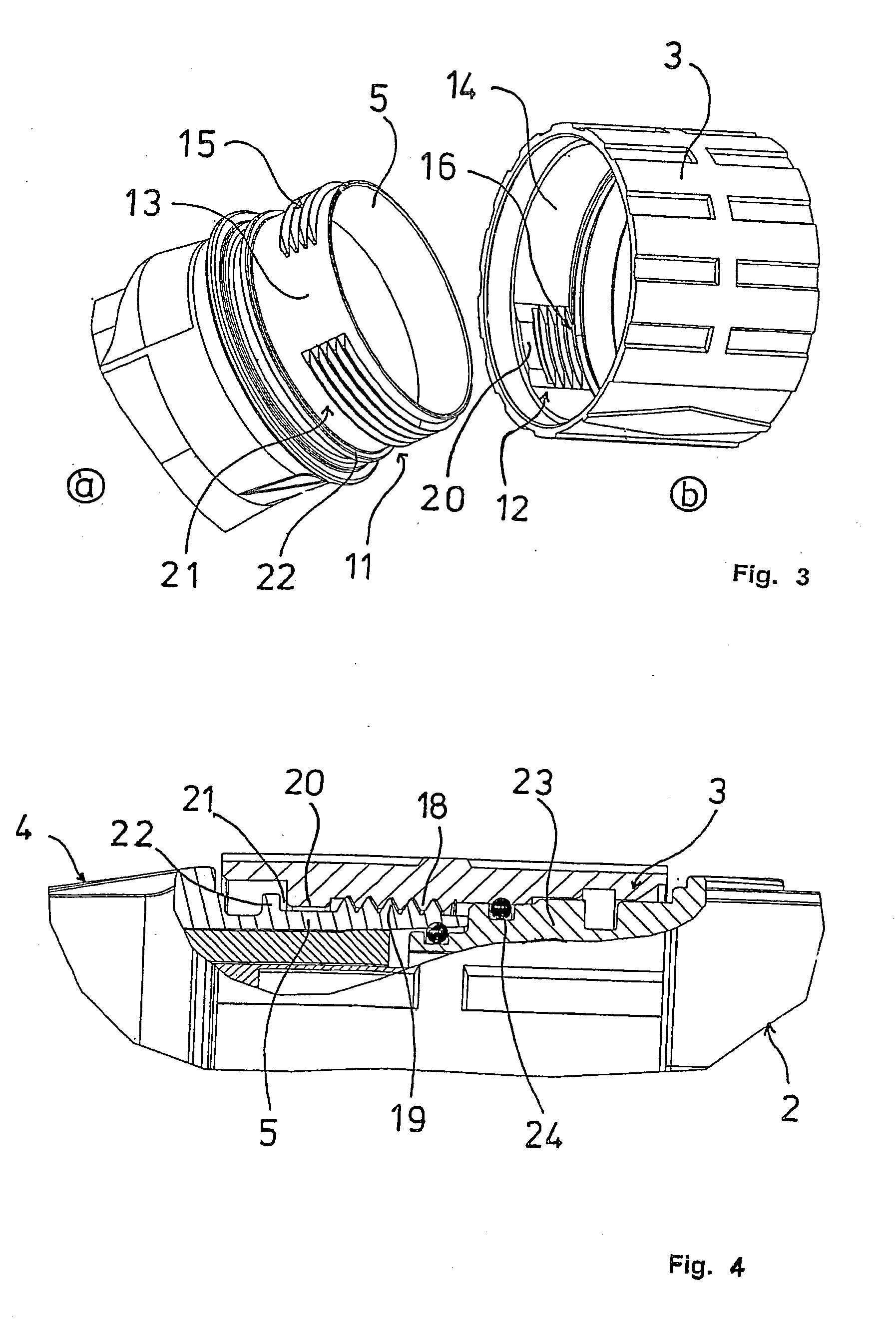

Electrical connector

InactiveUS20090170364A1Avoid turningFast actionEngagement/disengagement of coupling partsMating connectionCoupling

The invention relates to an electrical connector, comprising a connector part and a mating connector part which can be plugged together, and a coupling ring, carried by the connector part, for screwing the connector part with a threaded sleeve of the mating connector part. An outer thread of the threaded sleeve and a correspondingly configured inner thread of the coupling ring have at least one unthreaded section each in the direction of insertion. The respective unthreaded and threaded sections are configured and arranged in such a manner that the threaded sections of the coupling ring and the threaded sleeve can be inserted into the respective unthreaded section of the other connector part in order to plug the connector and mating connector together. The connector according to the invention is characterized by at least one raised annular collar section in front of at least one unthreaded section of the coupling ring in the direction of insertion, said annular collar section allowing the coupling ring to be rotated, when the connector is plugged together, once the annular collar section has passed the unthreaded section of the thread of the threaded sleeve.

Owner:CONINVERS

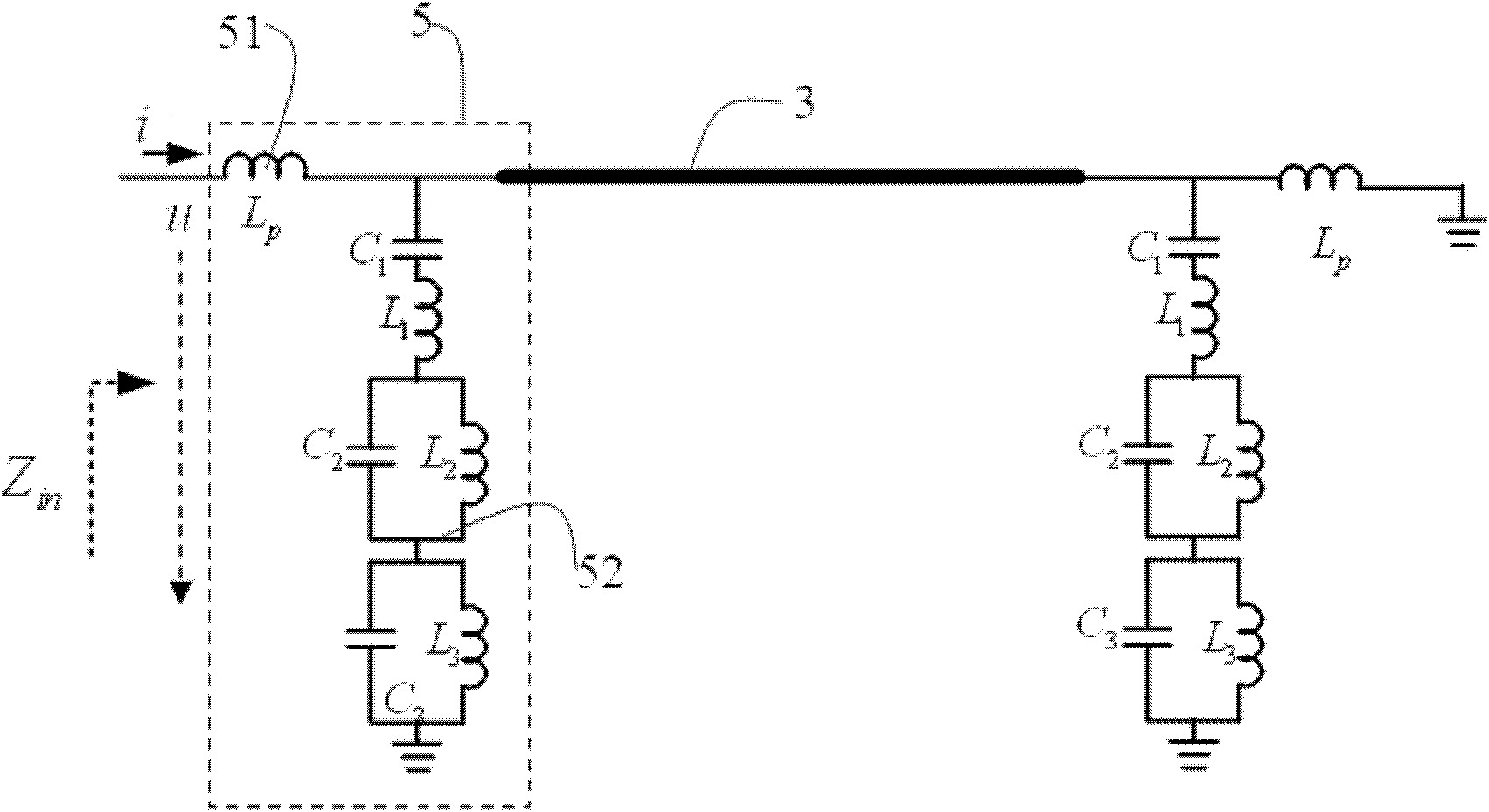

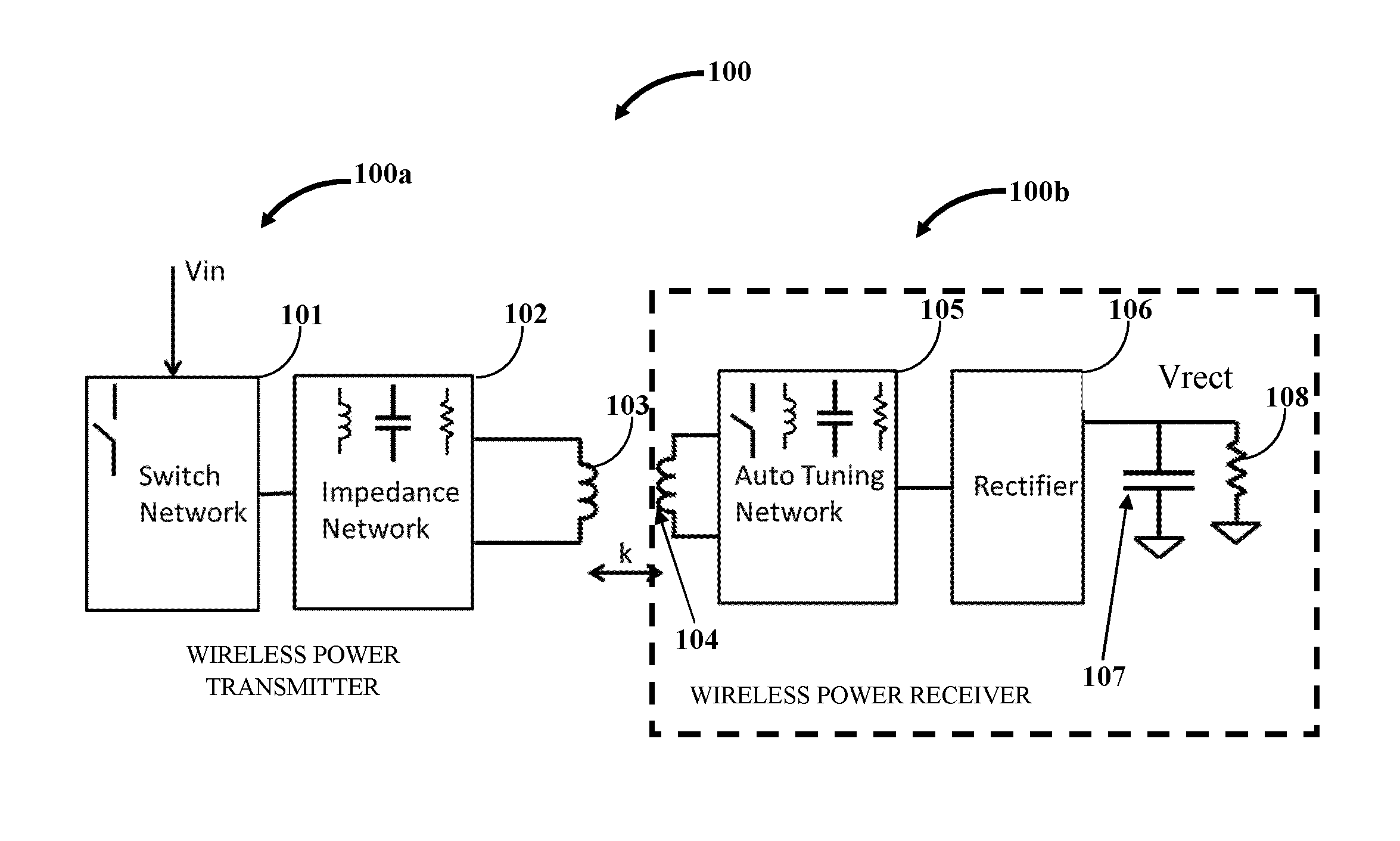

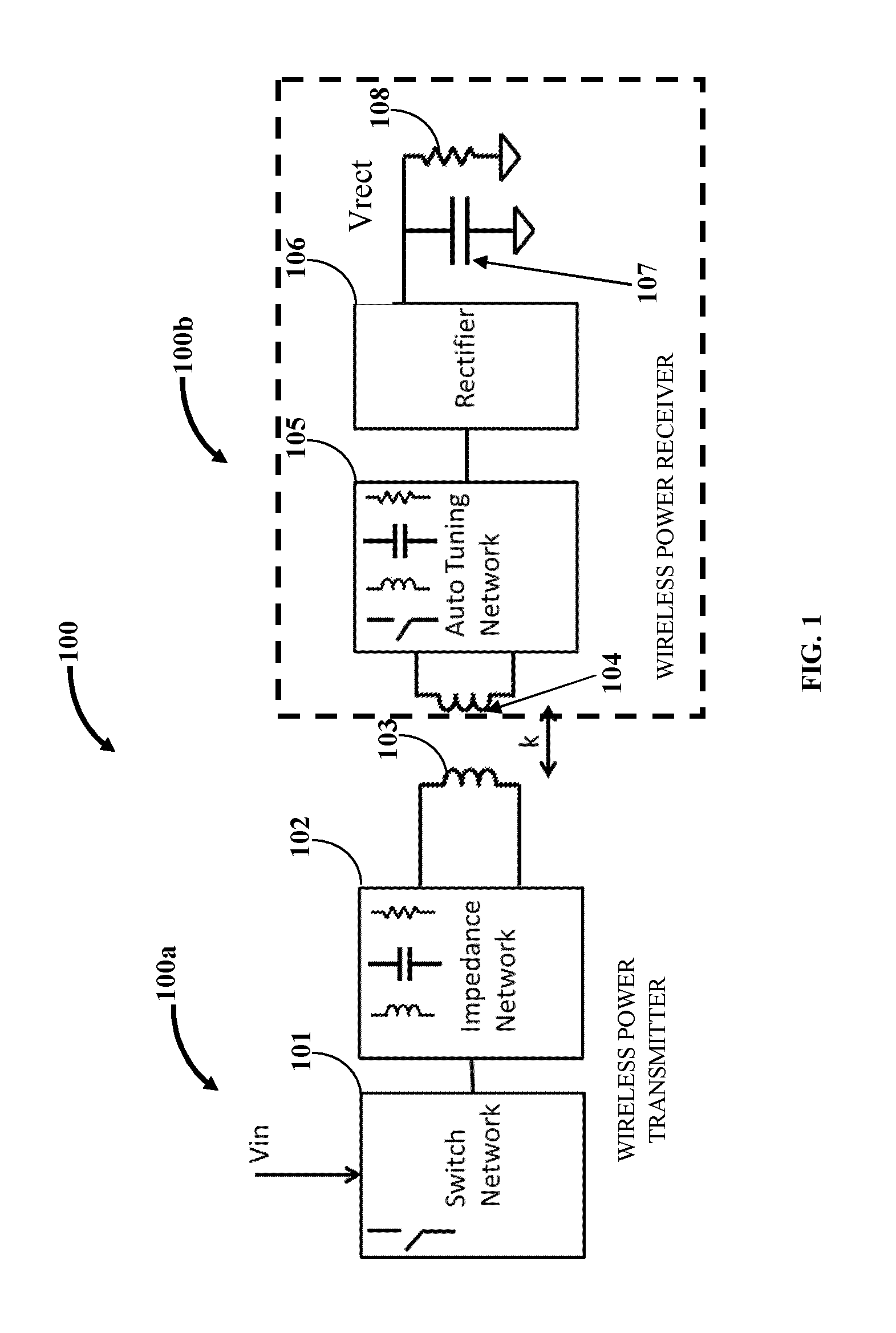

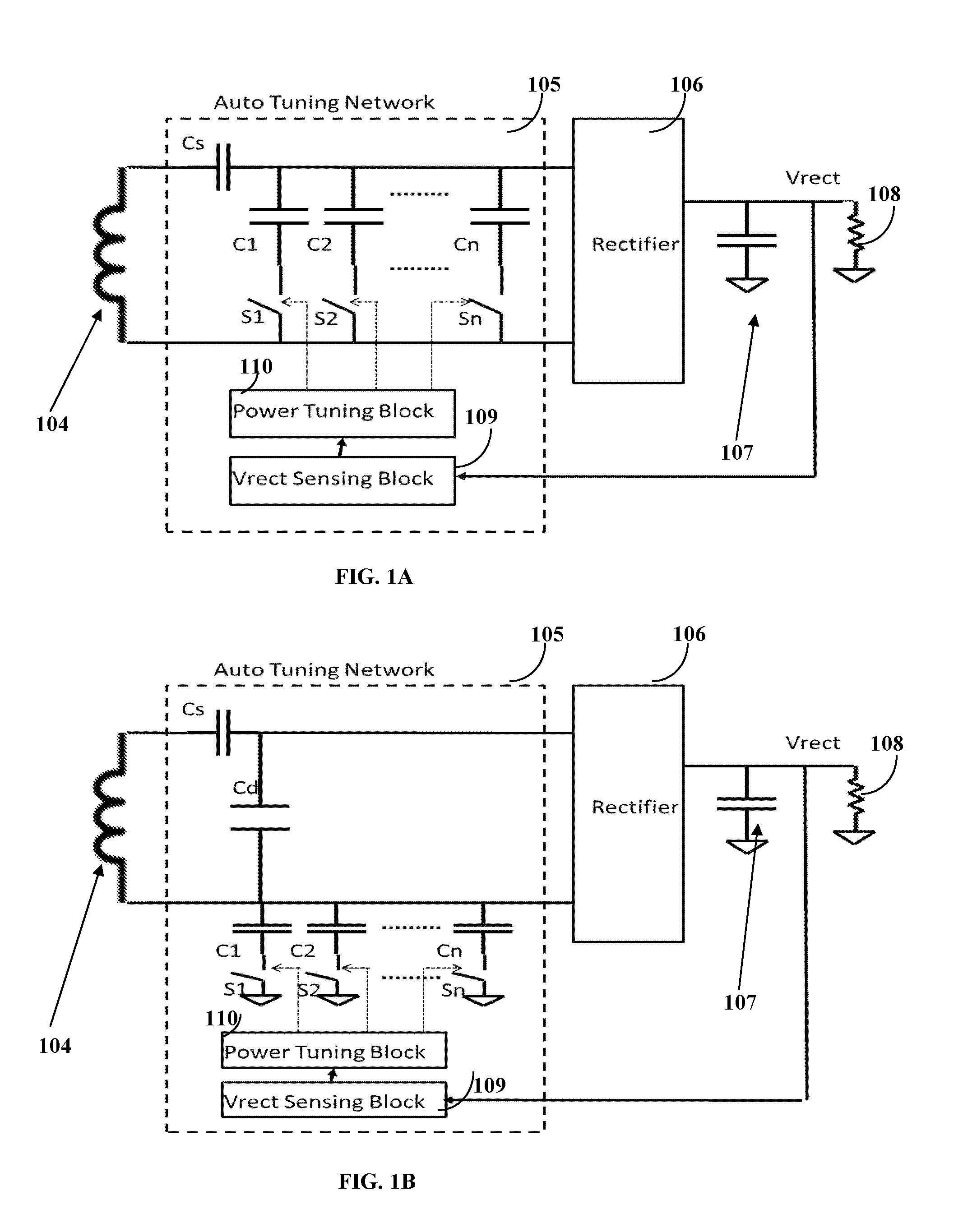

Wireless power system with a self-regulating wireless power receiver

ActiveUS20170040846A1Quick remedial actionEffective and faster over voltage protectionCircuit authenticationNear-field transmissionElectric power transmissionOperating point

A method and system for self-regulating wireless power transmitted to a wireless power receiver (WPR) is provided. An auto-tuning network is operably coupled within the WPR. The auto-tuning network comprises an impedance network that dynamically increases, decreases, or maintains amount of the received wirelessly transmitted power by detecting changes in a rectifier load disposed in the WPR and / or in an output voltage of the rectifier in the WPR. The auto-tuning network self-regulates the wireless power received from a wireless power transmitter (WPT) obviating the need for conventional communication messages. The WPT is hence free from a modulator / demodulator block and an out-of-band communication block and can operate over a limited operating range to enable simpler design for passing EMC regulation. Additionally, the WPR implements a receiver-maximum power-signature algorithm for enabling the WPT to detect unsupported receivers, configure its operating point and range, and terminate power transmission when not needed by WPR.

Owner:WIPQTUS

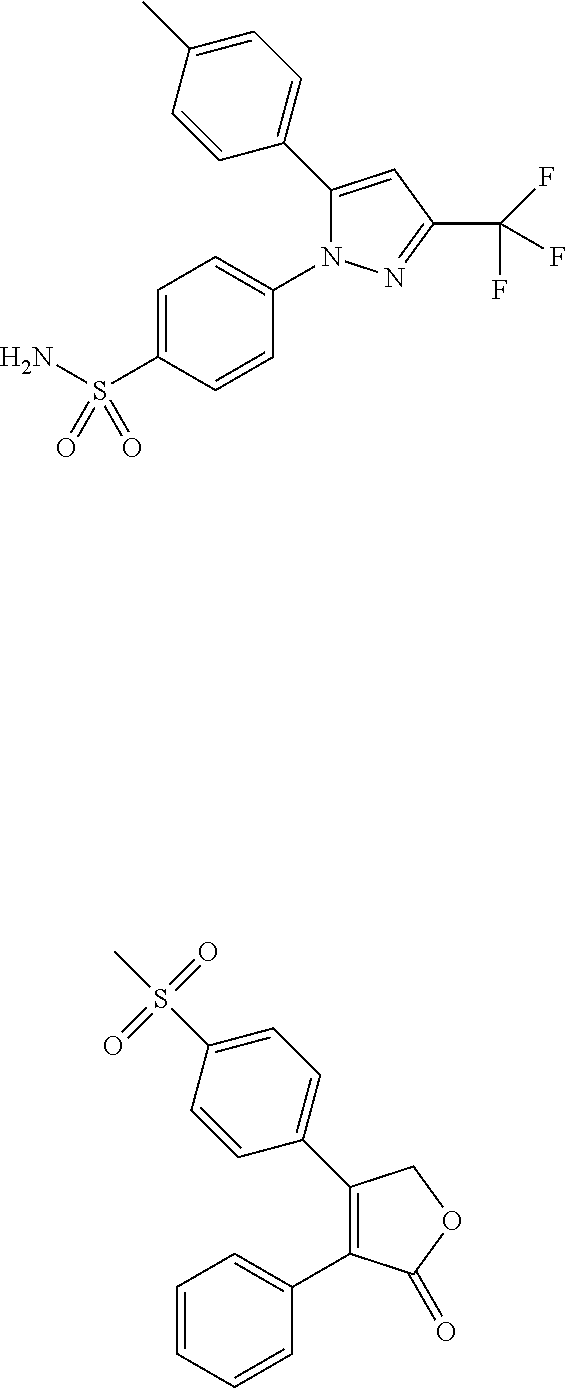

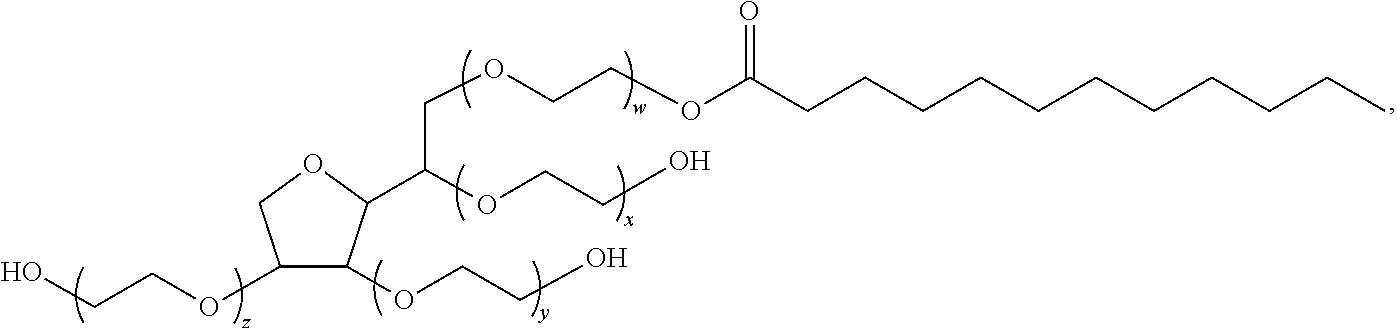

Cox-2 inhibitors and related compounds, and systems and methods for delivery thereof

InactiveUS20140004177A1Improve efficiencyReduce riskBiocideNervous disorderMedicineCompound (substance)

The present invention generally relates to the transdermal delivery of various compounds. In some aspects, transdermal delivery may be facilitated by the use of a hostile biophysical environment. One set of embodiments provides a composition for topical delivery comprising a COX-2 inhibitor and / or a salt thereof, and optionally, a hostile biophysical environment and / or a nitric oxide donor. In some cases, the composition may be stabilized using a combination of a stabilization polymer (such as xanthan gum, KELTROL® BT and / or KELTROL® RD), propylene glycol, and a polysorbate surfactant such as Polysorbate 20, which combination unexpectedly provides temperature stability to the composition, e.g., at elevated temperatures such as at least 40° C. (at least about 104° F.), as compared to compositions lacking one or more of these.

Owner:STRATEGIC SCI & TECH

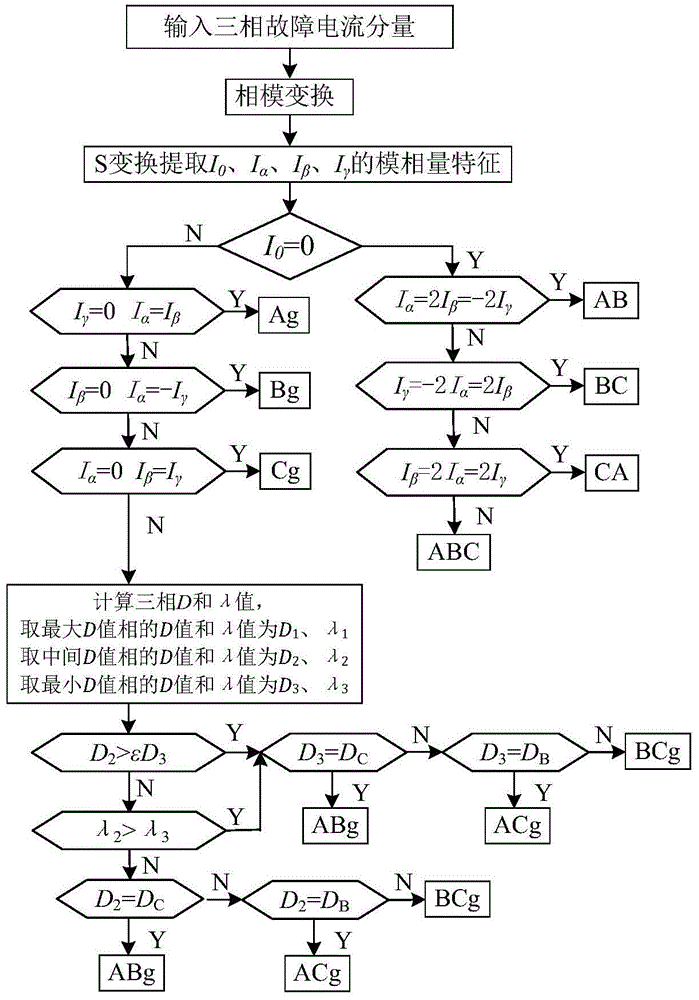

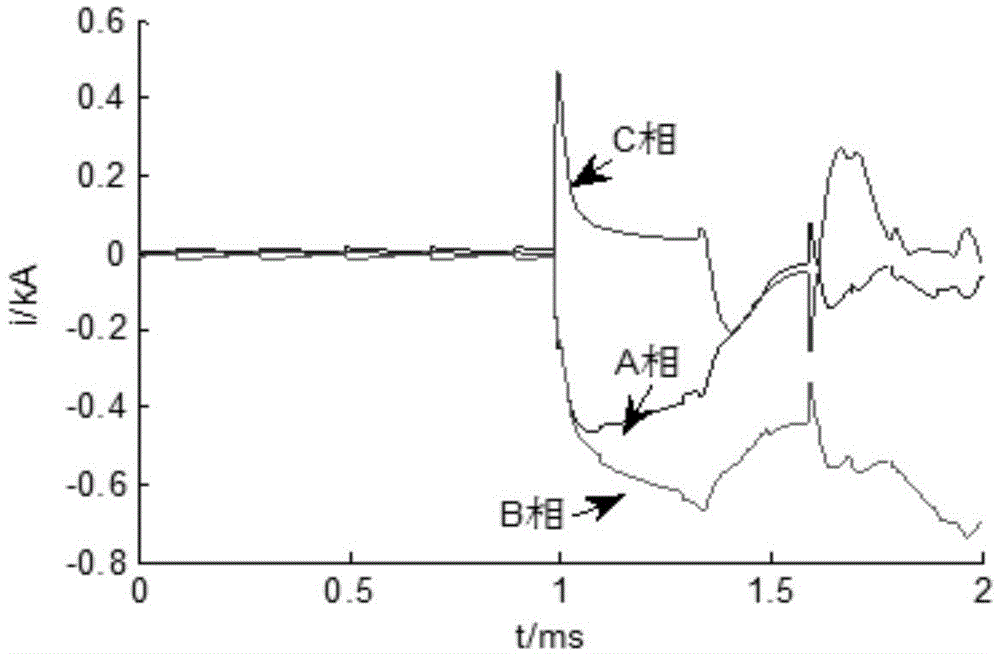

Transmission line fault fast phase selection method based on S conversion

ActiveCN104391229AFast photo selectionReliable identificationFault locationPhase currentsEngineering

The invention discloses a transmission line fault fast phase selection method based on S conversion. The transmission line fault fast phase selection method based on S conversion includes following steps: (1) collecting the current of the protection element at the line side at real time; (2) executing phase-mode transformation on the fault component current and extracting the model component of the fault component current after filtering the power frequency component for the corrected current; (3) executing S conversion on the model component current signal to obtain complex time-frequency matrix of each model, obtaining the model and phase angle, judging the ground fault or non-ground fault according to the characteristic of the zero model phasor, using the relationship among the line model phasors for having fast phase selection operation; (4) respectively integrating for the wave form of the phase current at two sides of the time axis, describing the wave form characteristic and recognizing the fault phase while the fault is dual-phase ground fault. The method adopts the S conversion for extracting the single frequency model component of each model component at special time, the fault type is determined according to the relationship among the model phasors, the method has the advantages of high sensitivity, fast action speed and exact recognition.

Owner:SHANDONG UNIV

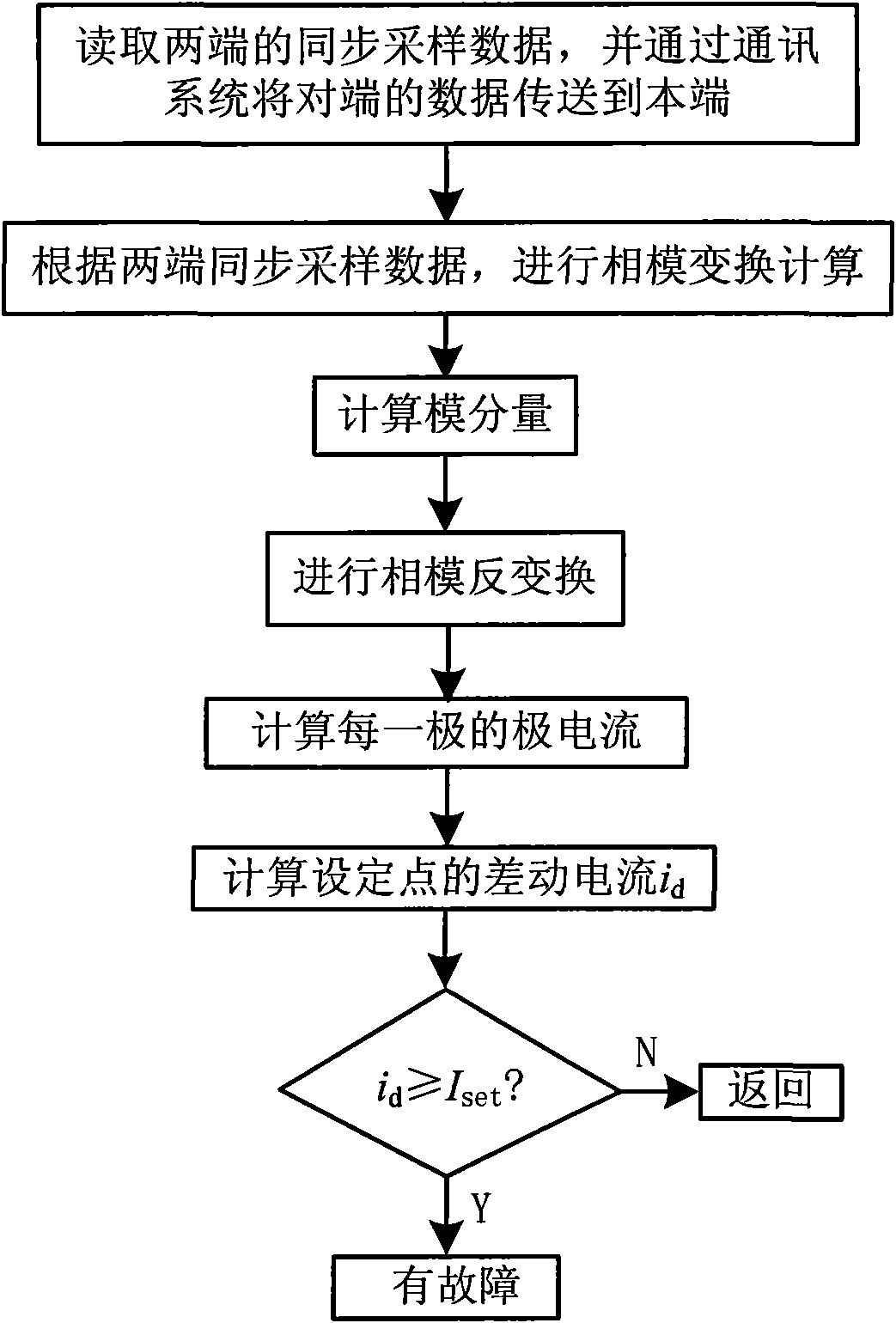

Self-adaptive current differential protection method for direct-current lines

ActiveCN102403699ARapidity is not affectedHigh sensitivityEmergency protective arrangements for automatic disconnectionFault severityVoltage source

The invention provides a self-adaptive current differential motion protection method for direct-current lines. The method is suitable for direct-current power transmission lines in two-end and multi-end direct-current power transmission systems. To the two-end system, setting-point currents are respectively calculated through electric quantities at two ends so as to realize the current differential protection; and to the multi-end system, branch-point currents are respectively calculated through the voltage and the current of a converter station line end so as to realize the current differential protection. A self-adaptive fault severity setting method is brought forward, and the self-adaptive adjustment of a differential current threshold is realized through the change of the voltage, so that the rapidity and the sensitivity of the protection are taken into account. The self-adaptive current differential protection method for the direct-current lines can improve the sensitivity and the reliability of the protection of direct-current lines and is suitable for the two-end and multi-end direct-current power transmission systems and a voltage source converter type direct-current power transmission system.

Owner:XI AN JIAOTONG UNIV

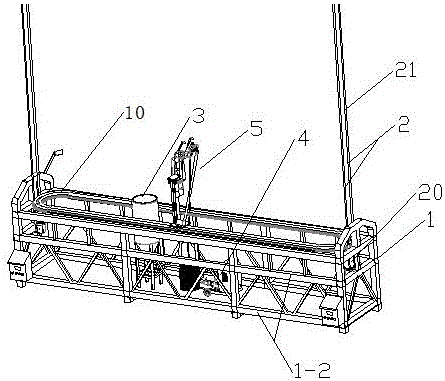

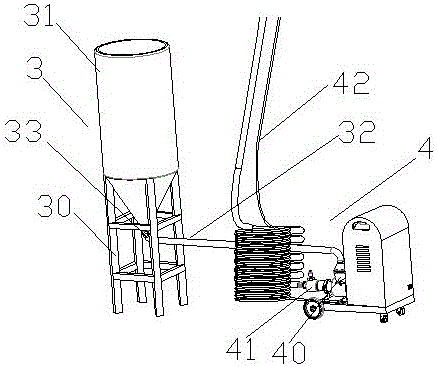

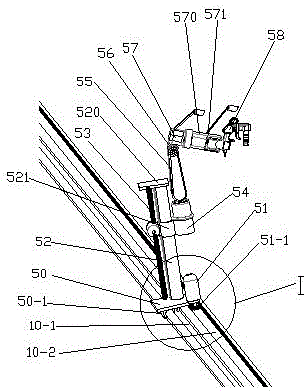

Intelligent robot for spraying outer wall of high-rise building

ActiveCN106695830ARealize intelligent controlEasy to controlProgramme-controlled manipulatorBuilding constructionsElectric machineHigh rise

The invention provides an intelligent robot for spraying the outer wall of a high-rise building and belongs to the technical field of high-rise building outer wall spraying equipment. The intelligent robot has the beneficial effects that the perpendicular movement of an automatic spraying mechanical arm can be adjusted; a supporting rod is inlaid in a fixing sleeve A; a rotating shaft A is hinged to the top of the supporting rod; one end portion of the rotating shaft A is connected with an output shaft of a servo motor A; the other end of the rotating shaft A is connected with a rotating seat; a fixing sleeve B of the rotating seat is connected with an output shaft of a servo motor B; an aerial fog spray gun is arranged at the tail end of the fixing sleeve B; the servo motor A and the servo motor B drive the rotating shaft A to rotate; and the rotating seat rotates so that the aerial fog spray gun can rotate by 360 degrees for spraying; The whole device is reasonable in layout, fast in action speed, capable of conducting continuous work and capable of achieving the effects that spraying is conducted in an all-dimensional manner without dead corners, and flatness and evenness are achieved.

Owner:JUYE QICAI SHELL E COMMERCE CO LTD

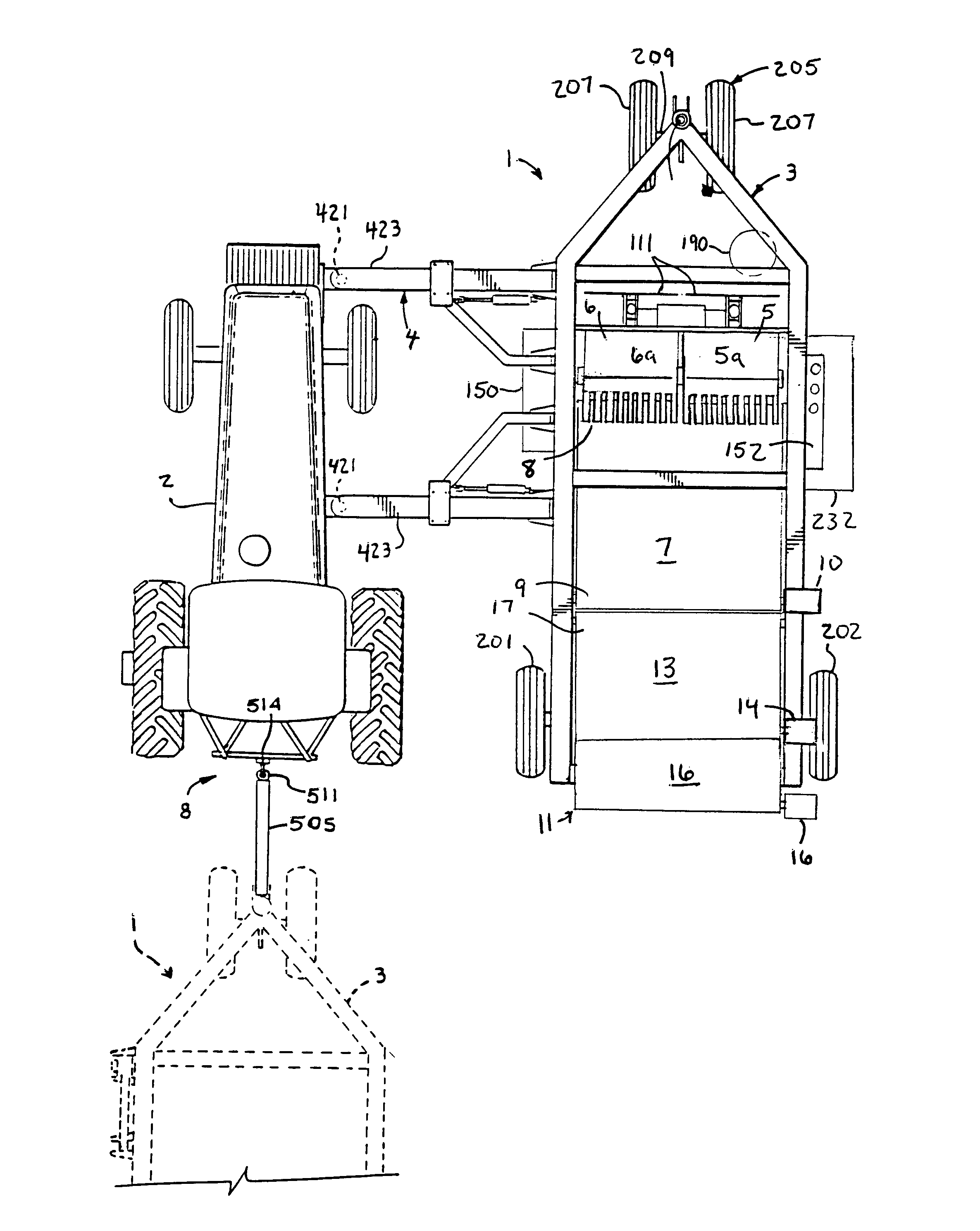

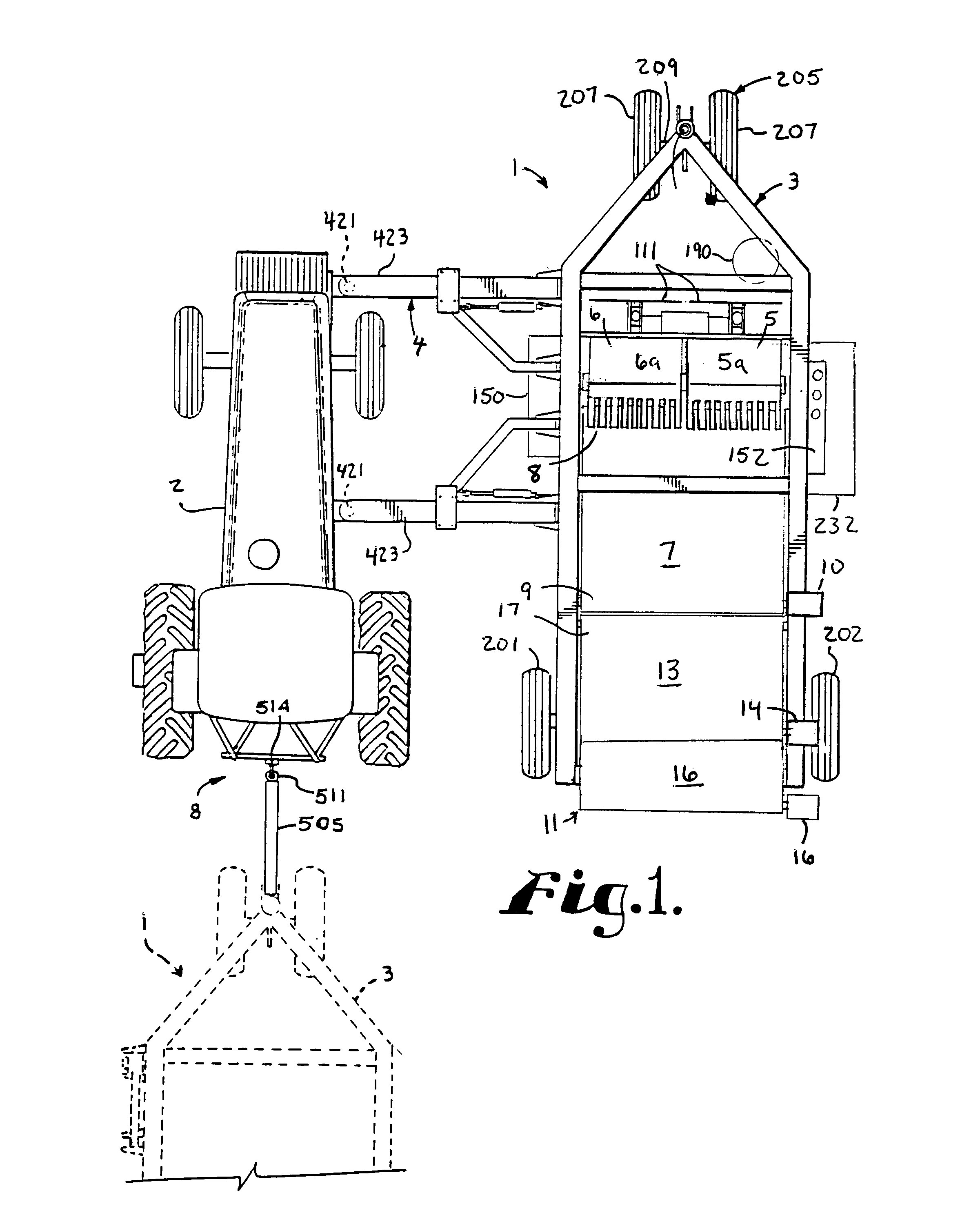

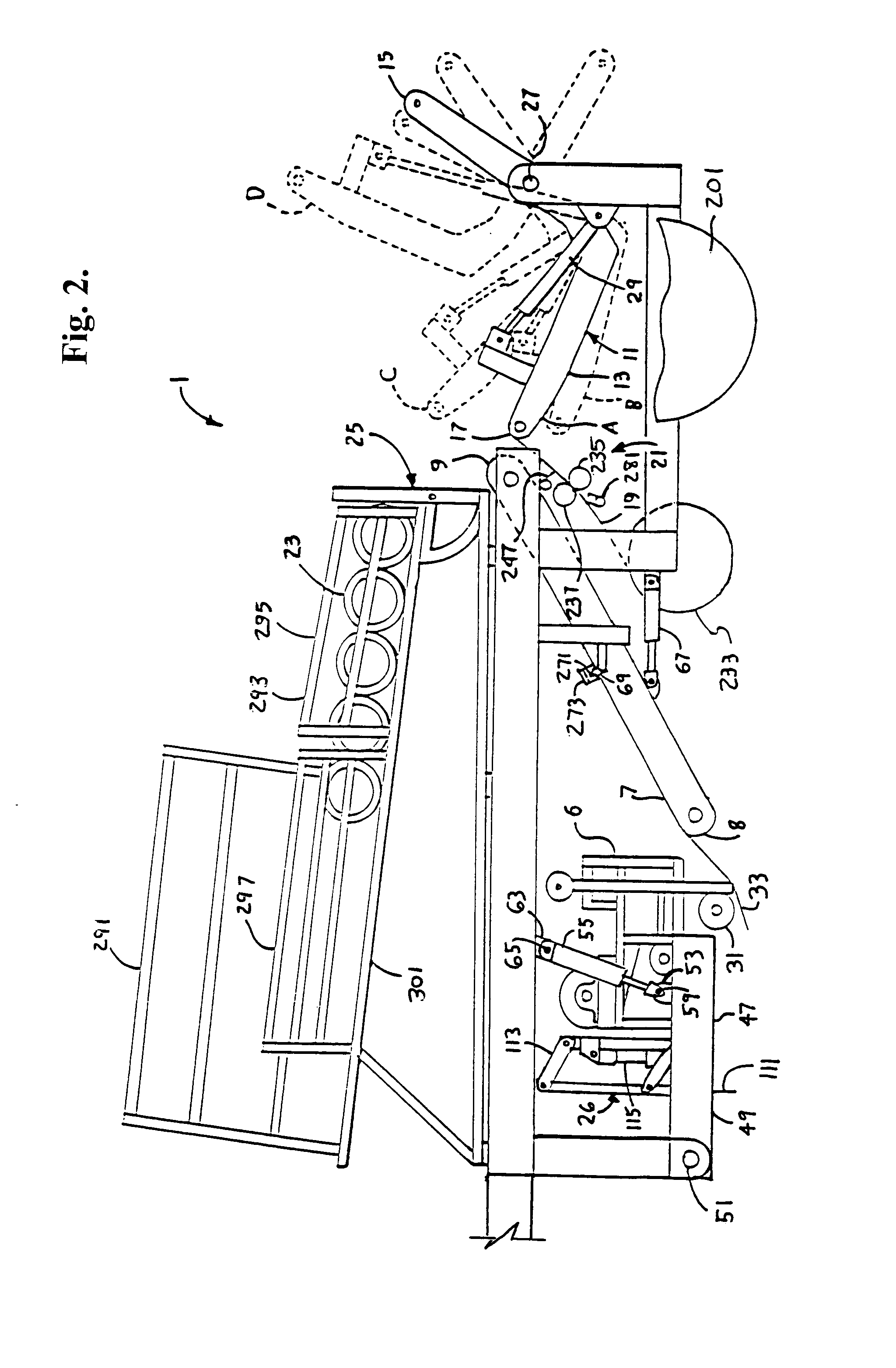

Sod harvester with controlled sod cut-off and conveying system

ActiveUS7264063B1Reduce cutting actionFast actionHops/wine cultivationTurf growingHydraulic motorControl valves

A sod harvester includes a sod cut-off system driven by a hydraulic actuator controlled by a processor in response to signals from a ground speed sensor to cut a strip of sod to a desired length. The controller also operating to control the speed of conveyors used to roll the sod into a roll. The sensor measures the rotations of a ground wheel and produces a signal which is used by a processor on the harvester to determine the distance traveled by the harvester. A control valve assembly and a high pressure hydraulic fluid accumulator provide for rapid extension of the actuators to produce a rapid downward cutting action of the cutting blades. A hydraulic motor connected in driving relationship to an outer rear wheel of the harvester provides power thereto to overcome the tendency of the tractor to drift to that side.

Owner:BUCYRUS EQUIP

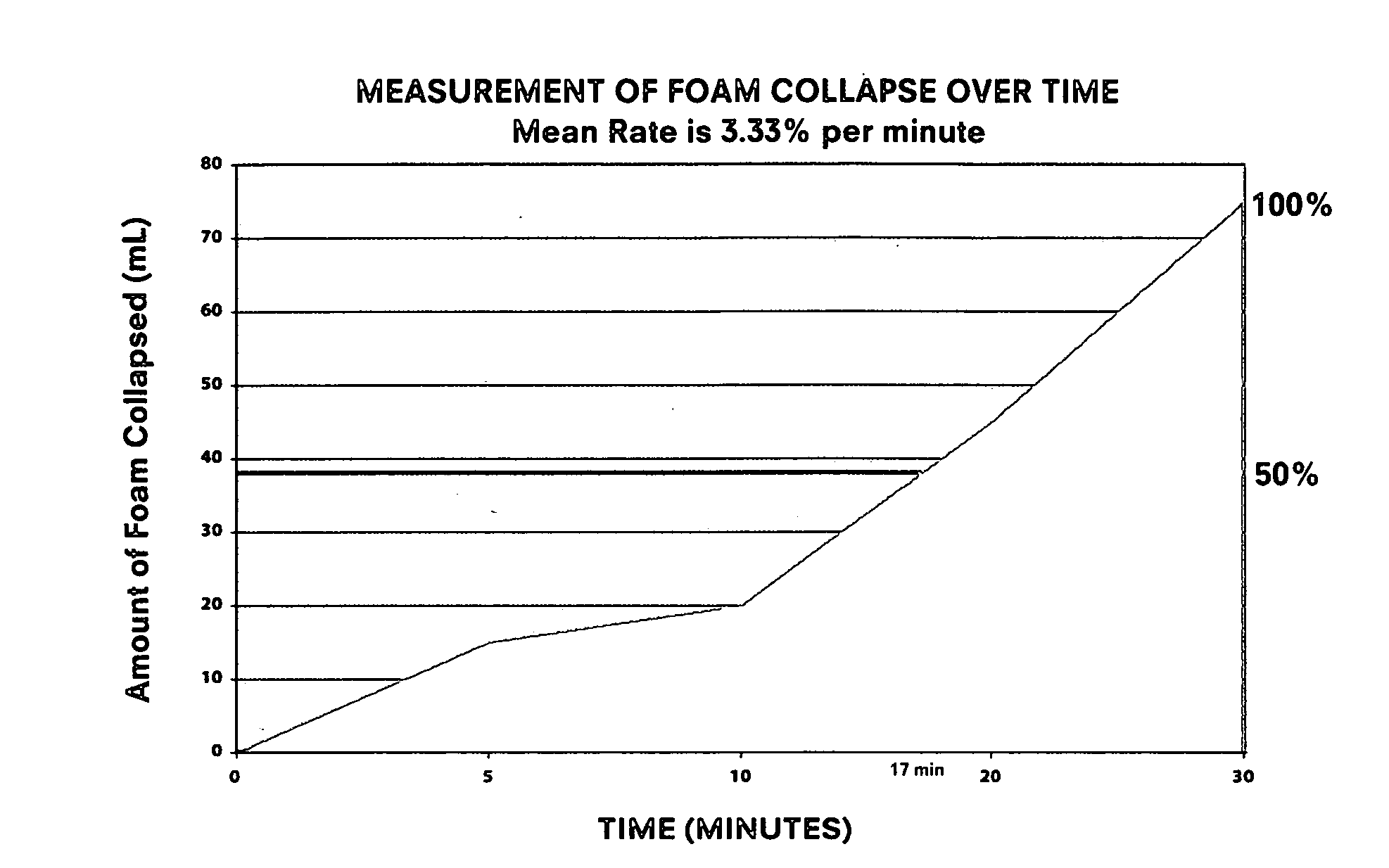

Whitening system capable of delivering effective whitening action

InactiveUS20060198803A1Faster whitening actionFast actionCosmetic preparationsHair cosmeticsFoaming agentPhosphate

The invention provides a foamable composition for tooth bleaching which can be a one- or two-component system. The system has at least one peroxide compound, and at least one foaming agent. The composition can also contain at least one source of calcium, strontium and mixtures thereof, at least one de-sensitizing agent and at least one source of phosphate. The composition can produce a longer-lasting, collapsible foam structure with enhanced whitening action. The foamable composition can also be a one-component multi-phase system. A two-component composition can be packed in a two-compartment syringe. The syringe can also be fitted with a dispensing tip which may or may not have a static mixer.

Owner:GRINRX

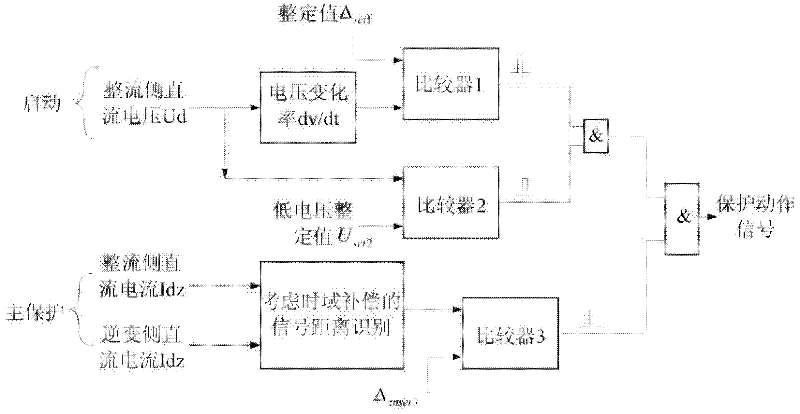

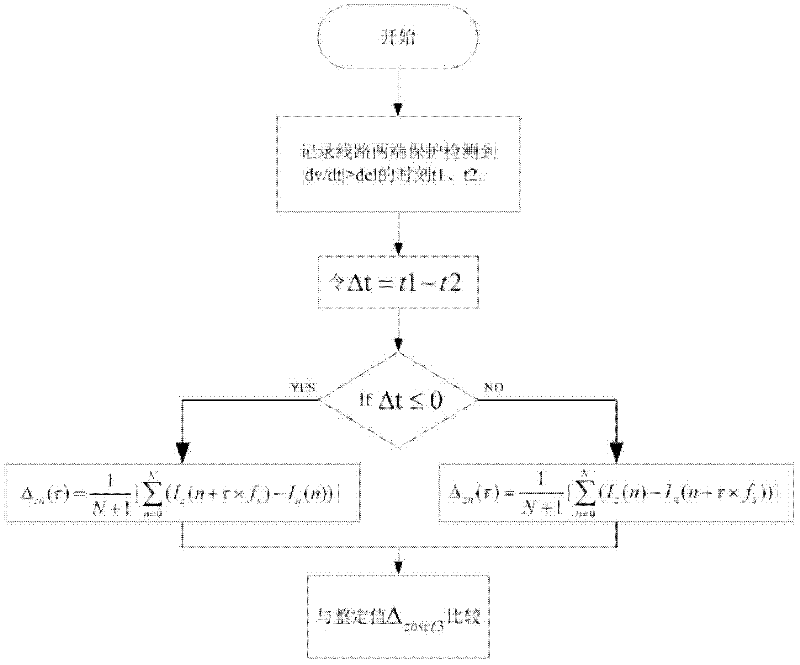

Signal distance protection method of direct current power transmission line

InactiveCN102237676AOvercome the shortcomings of poor reliability and easy misoperationOvercoming the incomplete defect of judging the faultEmergency protective circuit arrangementsElectrical resistance and conductanceCapacitance

The invention discloses a signal distance protection method of a direct current power transmission line. The fault type of the direct current power transmission line is determined by computing current signals of current transformers at two ends of the direct current power transmission line as discrete sample signals to obtain a distance degree Delta zn (tau) between the discrete sample signals. The signal distance protection method of the direct current power transmission line is applicable to the direct current power transmission line, is not influenced by distributed capacitance currents, overcomes the defects of the conventional high-voltage direct-current line differential protection, has high tolerance capacity of transition resistance, does not have special requirements on a sampling frequency, and is simple in operation, easy to implement, high in motion speed and high in reliability.

Owner:SHANGHAI JIAO TONG UNIV

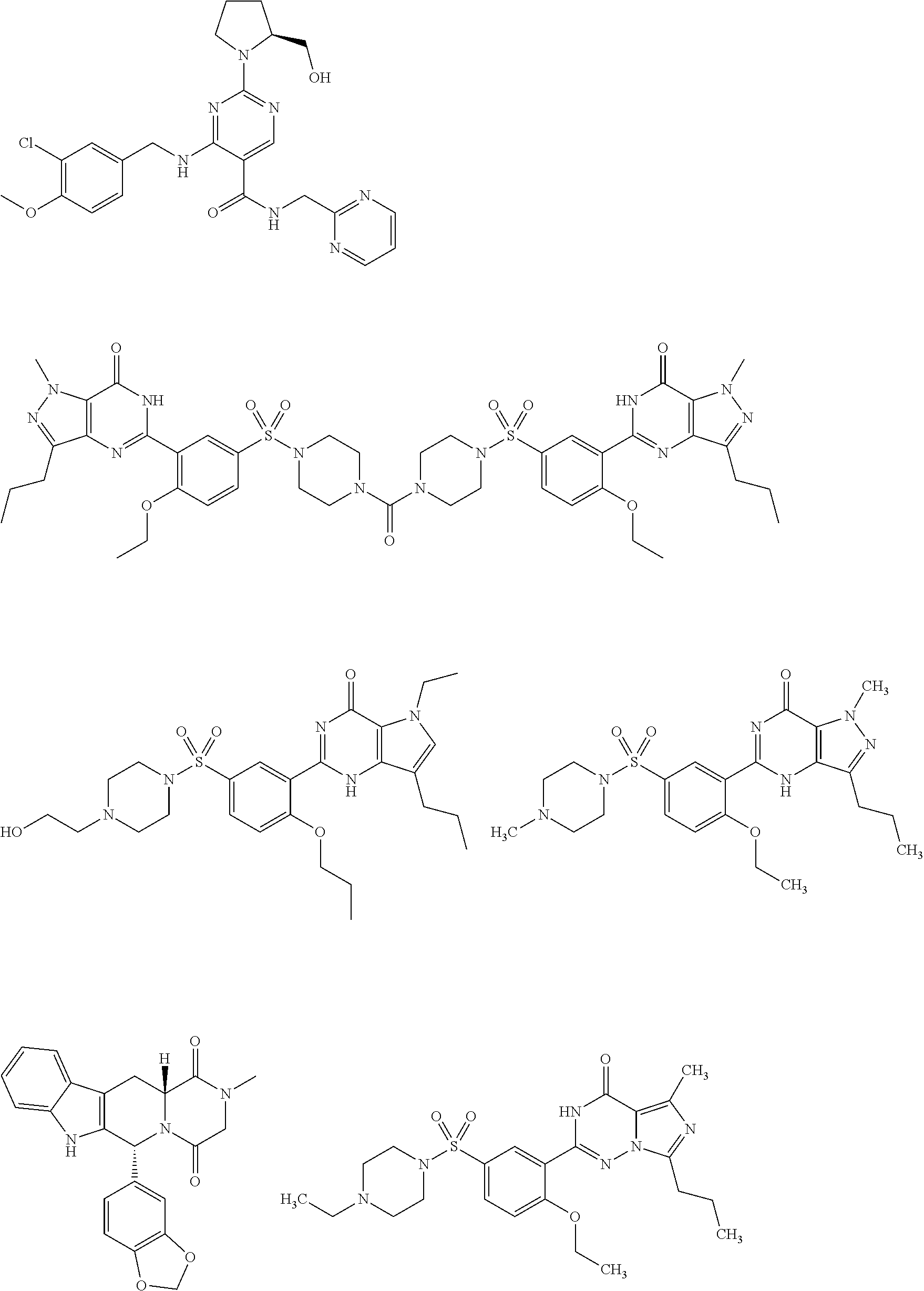

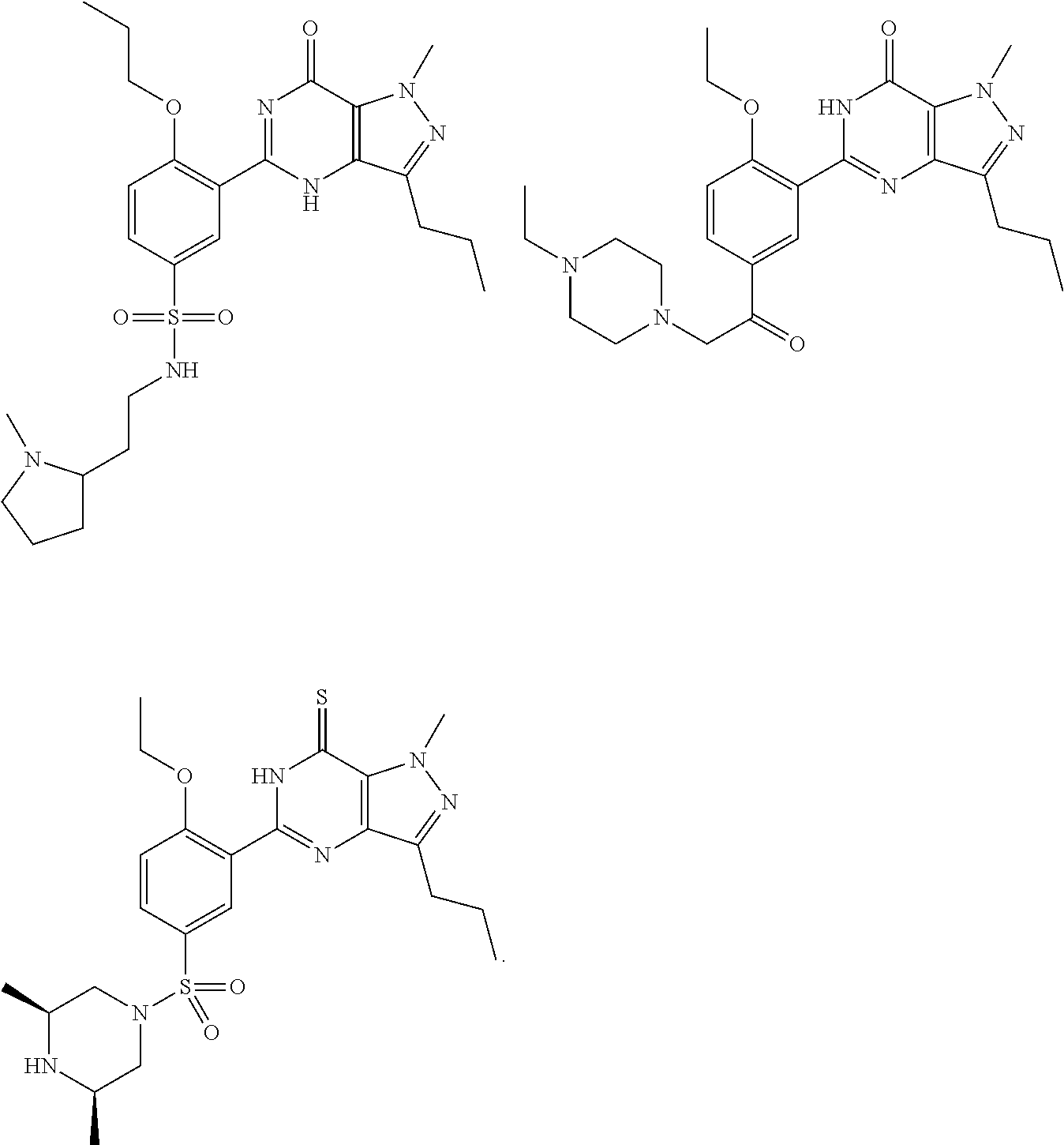

Treatment of erectile dysfunction and other indications

ActiveUS20140086980A1Improve efficiencyFast actionBiocideInorganic non-active ingredientsNitric oxidePhosphodiesterase Type 5 Inhibitors

The present invention generally relates to the transdermal delivery of various compounds. In some aspects, transdermal delivery may be facilitated by the use of a hostile biophysical environment. One set of embodiments provides a composition for topical delivery comprising a phosphodiesterase type 5 inhibitor and / or a salt thereof, and optionally, a hostile biophysical environment and / or a nitric oxide donor. In some cases, the composition may be stabilized using a combination of a stabilization polymer (such as xanthan gum, KELTROL® BT and / or KELTROL® RD), propylene glycol, and a polysorbate surfactant such as Polysorbate 20, which combination unexpectedly provides temperature stability to the composition, e.g., at elevated temperatures such as at least 40° C. (at least about 104° F.), as compared to compositions lacking one or more of these.

Owner:STRATEGIC SCI & TECH

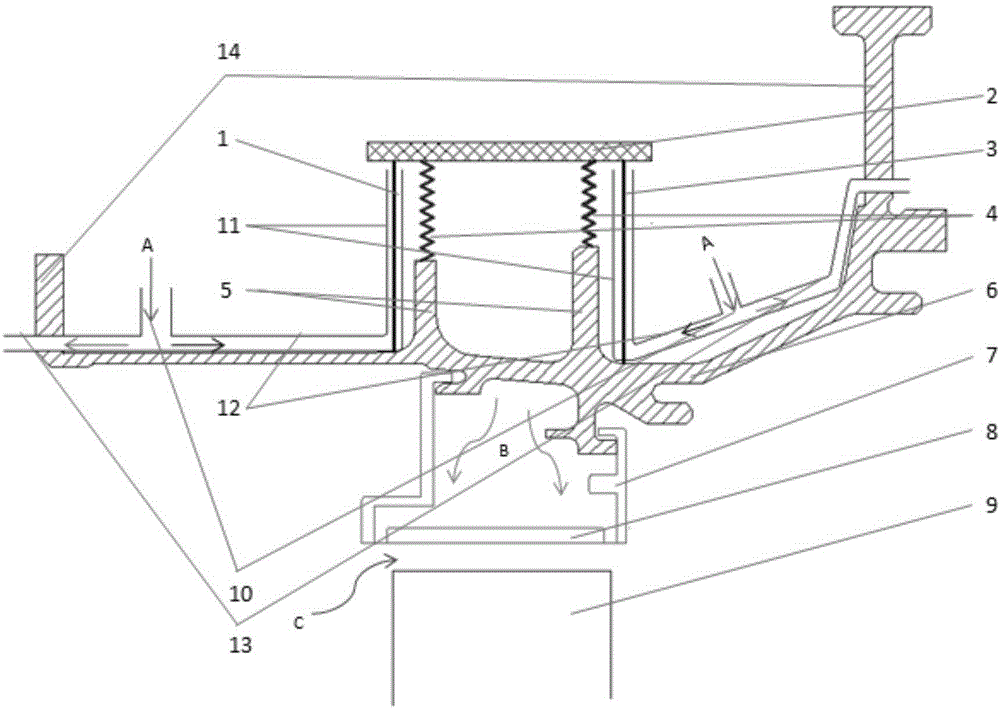

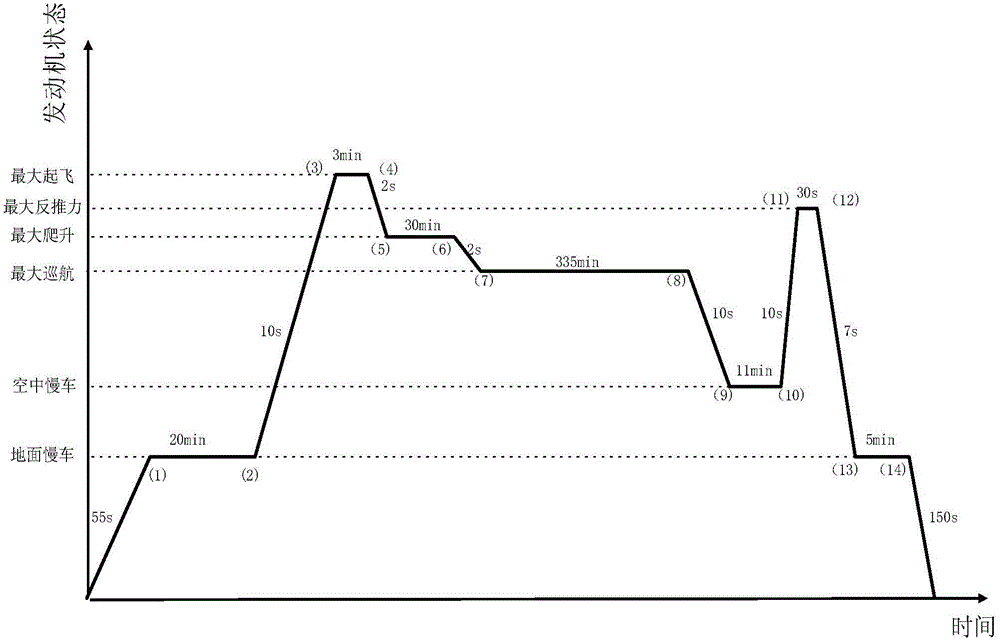

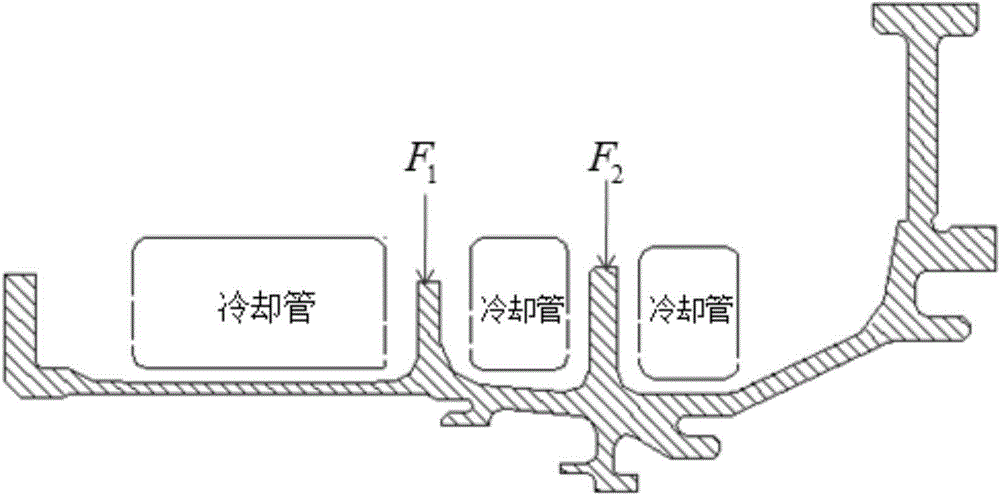

Fast responding control device of turbine leaf apex gap control system based on shape memory alloy

The invention discloses a fast responding control device of a turbine leaf apex gap control system based on a shape memory alloy (SMA). The fast responding control device of the turbine leaf apex gap control system based on the SMA comprises an SMA driving system and a vortex tube cooling system, wherein the SMA driving system comprises an SMA wire, a biasing spring and a movable board, the vortex tube cooling system comprises a vortex tube and a vortex tube cooling end cooling pipeline, one end of the SMA wire is fixed on a vortex tube cooling end outlet pipeline, the other end of the SMA wire is connected to the movable board, and the two ends of biasing spring are respectively connected to a power brake reinforcing rib and the movable board. The excellent memory recovering performance of the SMA under different temperature conditions and the immediate refrigeration and heating characteristic of the vortex tube are used, the fan outer flow of a corresponding working condition in different flying states is guided and cooled through the vortex tube and conducts the cooling treatment on the SMA, the recovering displacement and the recovering stress of the SMA under different temperatures are reasonably controlled, the adjusting and the control of realizing the power brake deformation of the biasing spring are combined, the leaf apex gap is changed, and the self-adaption active control on the leaf apex gap is expected to be realized.

Owner:南京长江工业技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com