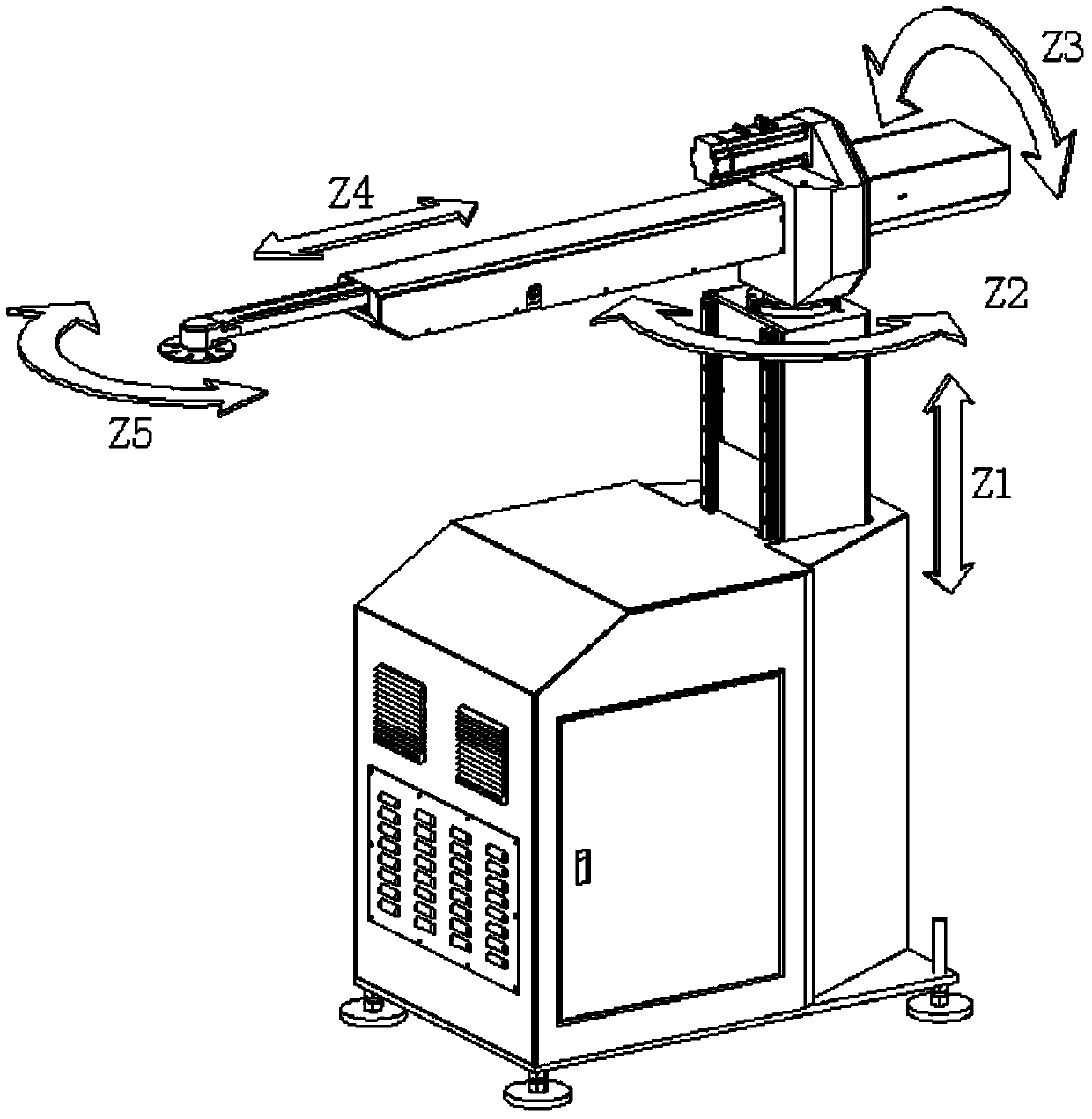

Intelligent five-shaft manipulator

A manipulator and intelligent technology, applied in the field of manipulators, can solve the problems of poor positioning accuracy, large moment of inertia of the swing arm movement mechanism, which affects the accuracy of manipulator equipment, etc., and achieve the effect of fast action speed, small inertia and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

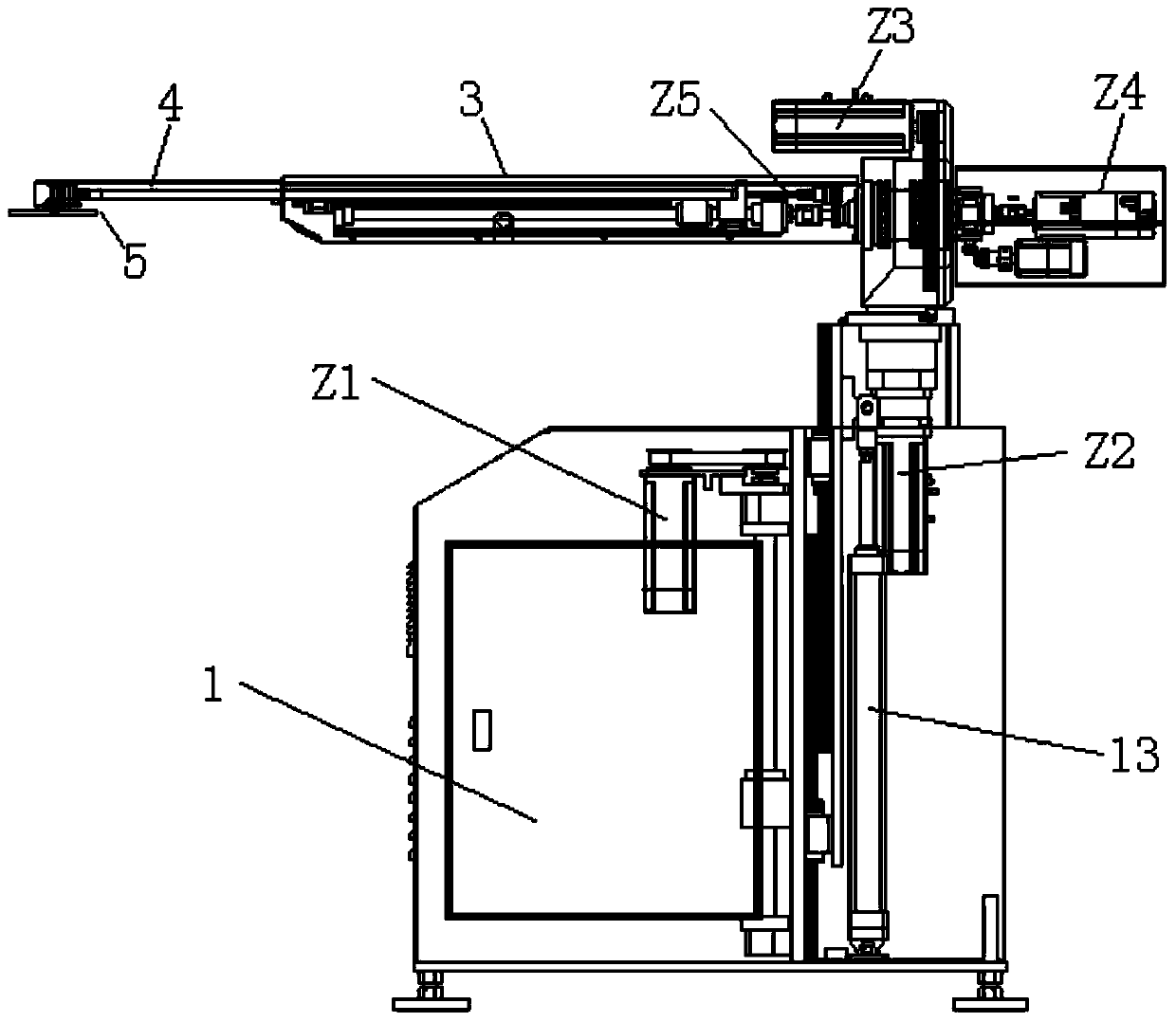

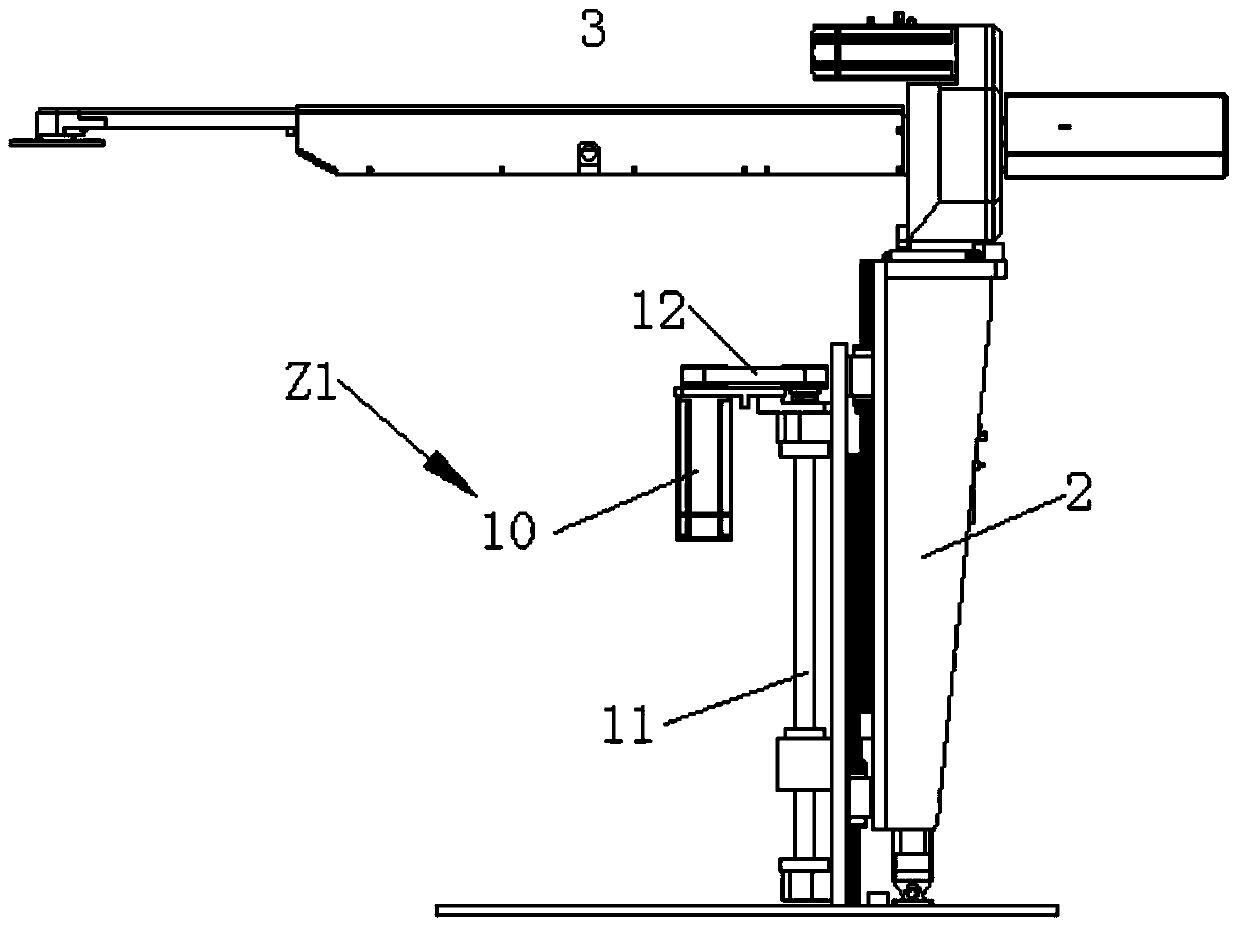

[0029] An intelligent five-axis manipulator according to the present invention includes a machine platform 1, a mechanical arm positioned on the machine platform 1, a vertical movement mechanism Z1, a swing arm movement mechanism Z2, an overturning movement mechanism Z3, and a horizontal movement mechanism Z4 and the rotary motion mechanism Z5 at the execution end, the mechanical arm includes the main arm 3 and the telescopic arm 4 carried on the main arm, and one end of the telescopic arm 4 is also movably provided with a suction cup or a clamping jaw. Flange 5; the swing arm movement mechanism Z2 is carried on the vertical movement mechanism Z1, and can be moved up and down relative to the machine table 1 under the drive of the vertical movement mechanism Z1; the turning movement mechanism Z3 is carried on the swing arm movement mechanism Z2, and can rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com