Fast responding control device of turbine leaf apex gap control system based on shape memory alloy

A technology of memory alloy and control system, which is applied in the direction of leakage prevention, engine components, machines/engines, etc. It can solve the problems of strain characteristics (unstable direction and size, weak theory and technology, complex structure, etc.) to improve engine turbine efficiency , fast action speed and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

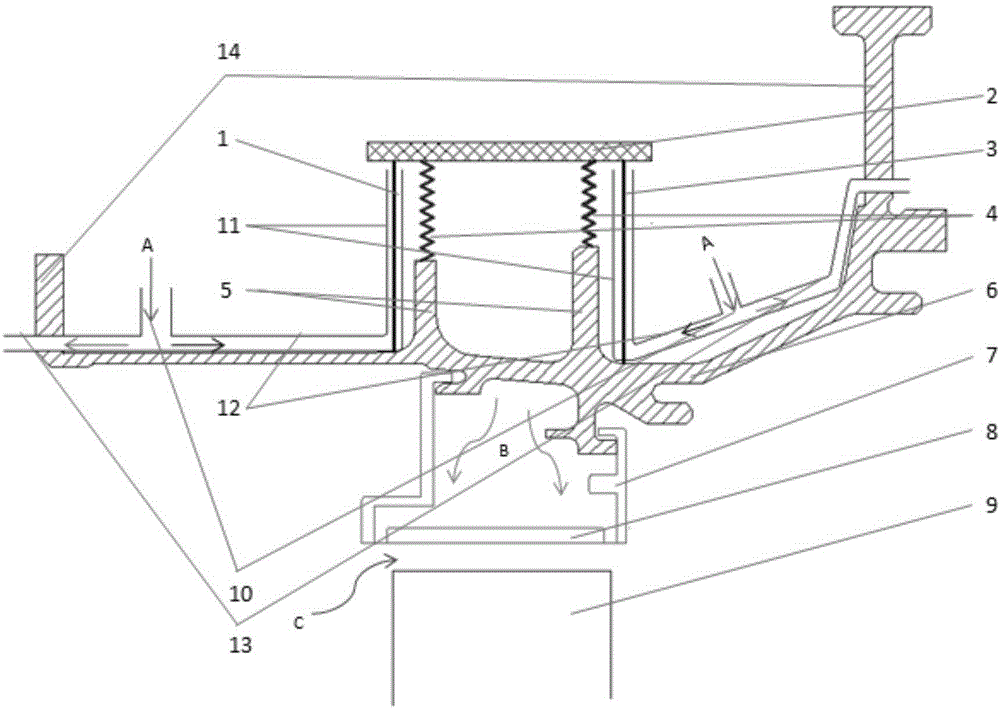

[0030] Please refer to figure 1 As shown, the present invention is based on the quick response control device of the memory alloy turbine blade tip clearance control system, acting on the casing 6, which includes a memory alloy drive system and a vortex tube cooling system, and the memory alloy drive system includes a first memory alloy wire 1. The second memory alloy wire 3 arranged in parallel with the first memory alloy wire 1, the movable plate 2 and the bias spring 4, the vortex tube cooling system includes the vortex tube 10 installed on the casing 6, the cold end of the vortex tube Cooling pipeline 11, vortex tube cold end outlet pipeline 12 and vortex tube hot end outlet pipeline 13, vortex tube 10 includes two spaced apart ones installed on the casing 6, vortex tube 10 and vortex tube cold end The cooling pipelines 11 are connected through the outlet pipeline 12 at the cold end of the vortex tube. The outlet pipeline 12 at the cold end of the vortex tube and the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com