DG feed line-containing current sequence component comparison mode fault section positioning method

A technology of current sequence component and fault section, applied in fault location, measurement of electrical variables, detection of faults by conductor type, etc., can solve problems such as failure, and achieve the effect of fast action, simple principle and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

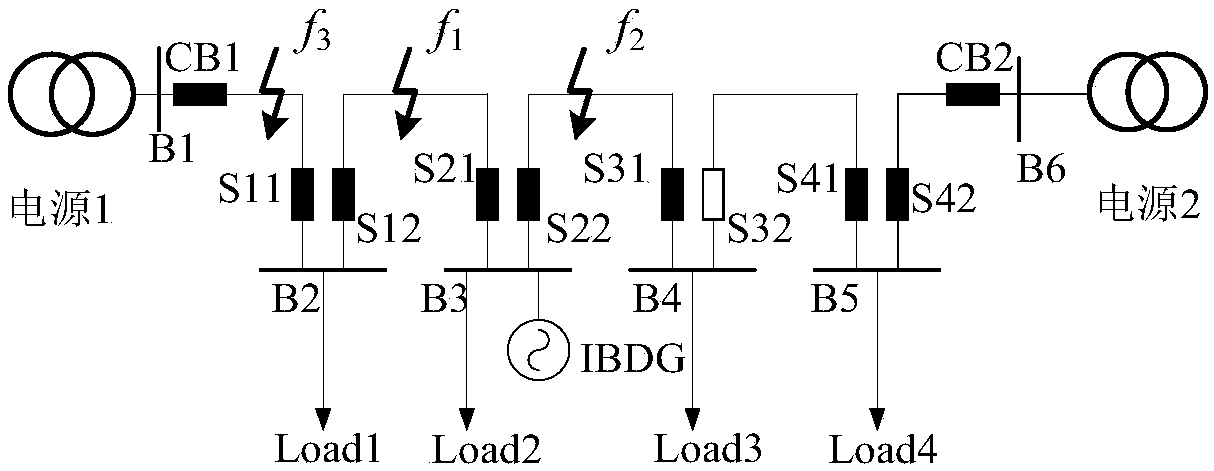

[0048] The present invention will be further described below in conjunction with accompanying drawing.

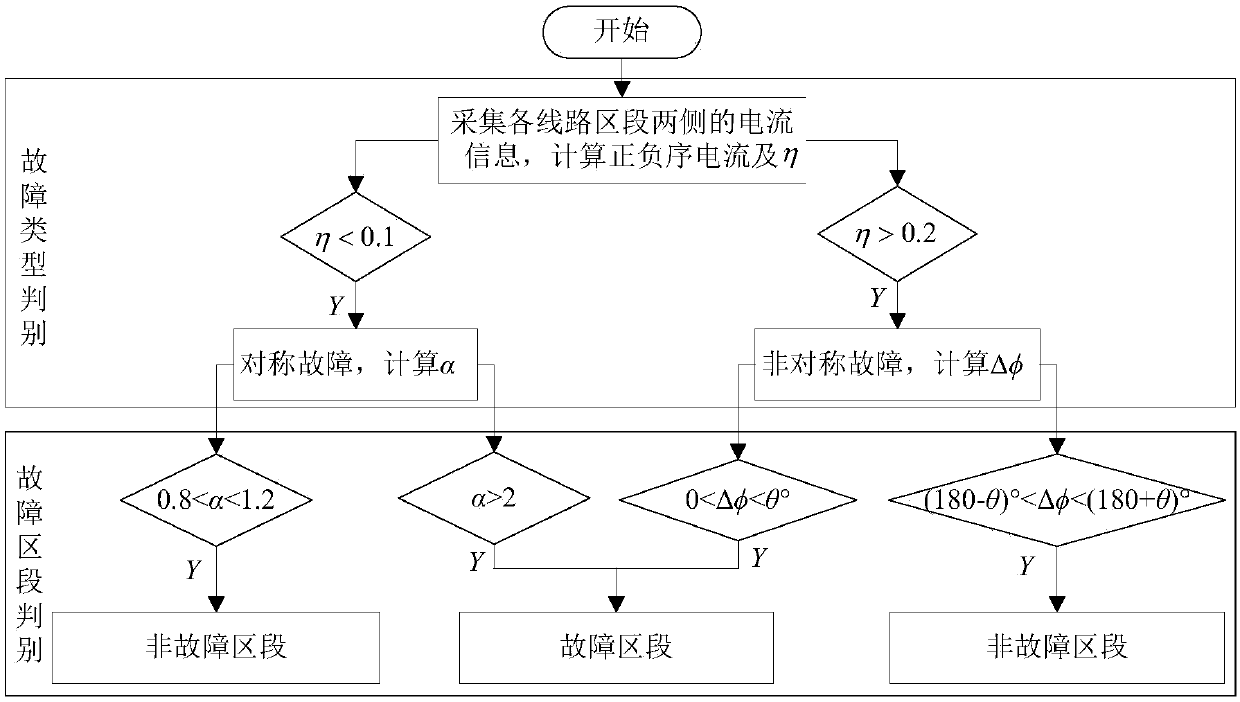

[0049] The present invention discloses a current sequence component comparison type fault section location method including DG feeder, as shown in Figure 1, including the following steps:

[0050] (1) Collect the current flowing through the switches on both sides of the feeder in real time;

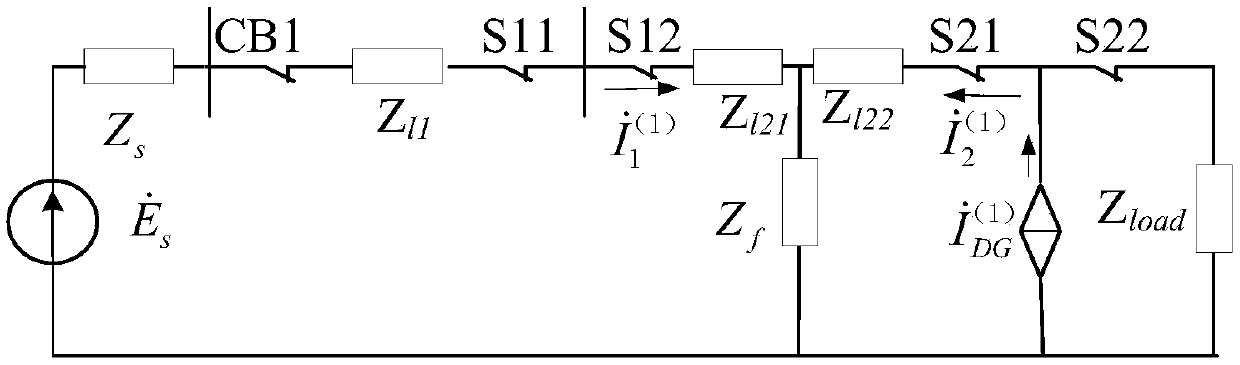

[0051] (2) After detecting a fault in the feeder, use the symmetrical component method to calculate the positive and negative sequence current components of the fault current for subsequent steps;

[0052] (3) Judging the symmetrical or asymmetrical fault according to the magnitude difference between the positive and negative sequence currents calculated in (2);

[0053] (4) When it is determined in step (3) that the fault is an asymmetrical fault, the negative sequence current phase comparison method is introduced to calculate the negative sequence current phase difference at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com