Improved manipulator clamping jaw on component arranging equipment

A manipulator and equipment technology, applied in the field of manipulator jaws, can solve the problems of scratches left on the material, damage to the material, affecting the quality of the material, etc., to achieve the effect of simple structure and reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

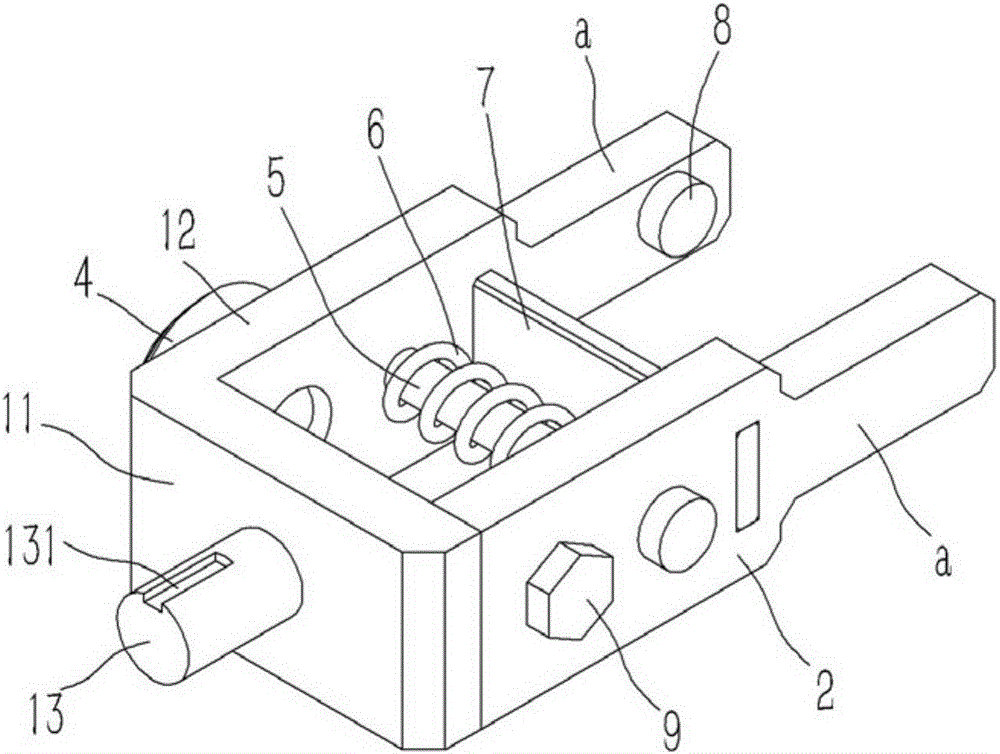

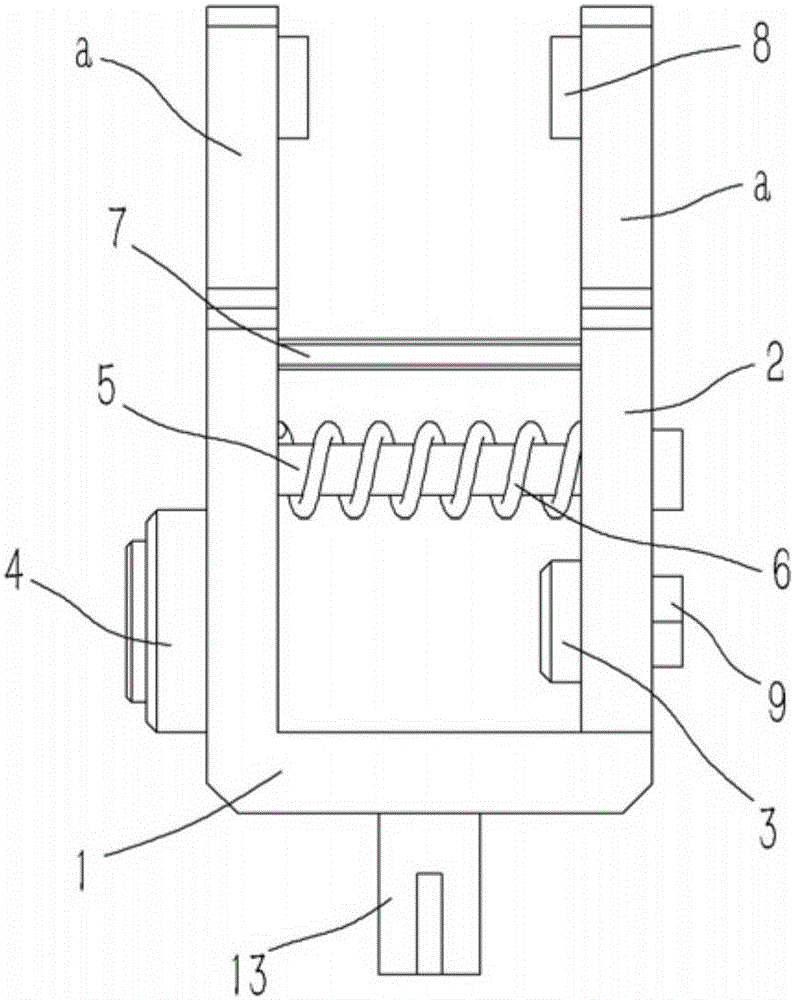

[0018] Example: see figure 1 , 2 As shown, an improved manipulator gripper on the part placement equipment includes an L-shaped positioning seat 1 and a splint 2. The positioning seat 1 is composed of a transverse part 11 and a longitudinal part 12. The rear end of the splint 2 is against the positioning seat 1. On the inner wall of the transverse portion 11, an iron block 3 is fixed on the inner side wall of the splint 2 rear end, an electromagnet 4 opposite to the iron block 3 is fixed on the longitudinal portion 12 of the positioning seat 1, and the splint 2 on the front side of the iron block 3 is inserted. A T-shaped guide rod 5 is connected, and the guide rod 5 is fixed on the longitudinal part 12 of the positioning seat 1. The guide rod 5 is inserted with a compression spring 6, and the two ends of the compression spring 6 are respectively pressed against the positioning seat 1. And on the splint 2, the splint 2 on the front side of the guide rod 5 is inserted with a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com