Seamless line locking rail temperature pretreatment system

A technology for seamless track rails and rail temperature locking, which is applied in the directions of roads, tracks, laying tracks, etc., can solve the problems of uneven stress distribution inside the track, large damage to the rail surface, and complicated operation, and achieves efficient and uniform heat transfer. The effect of reducing damage and reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

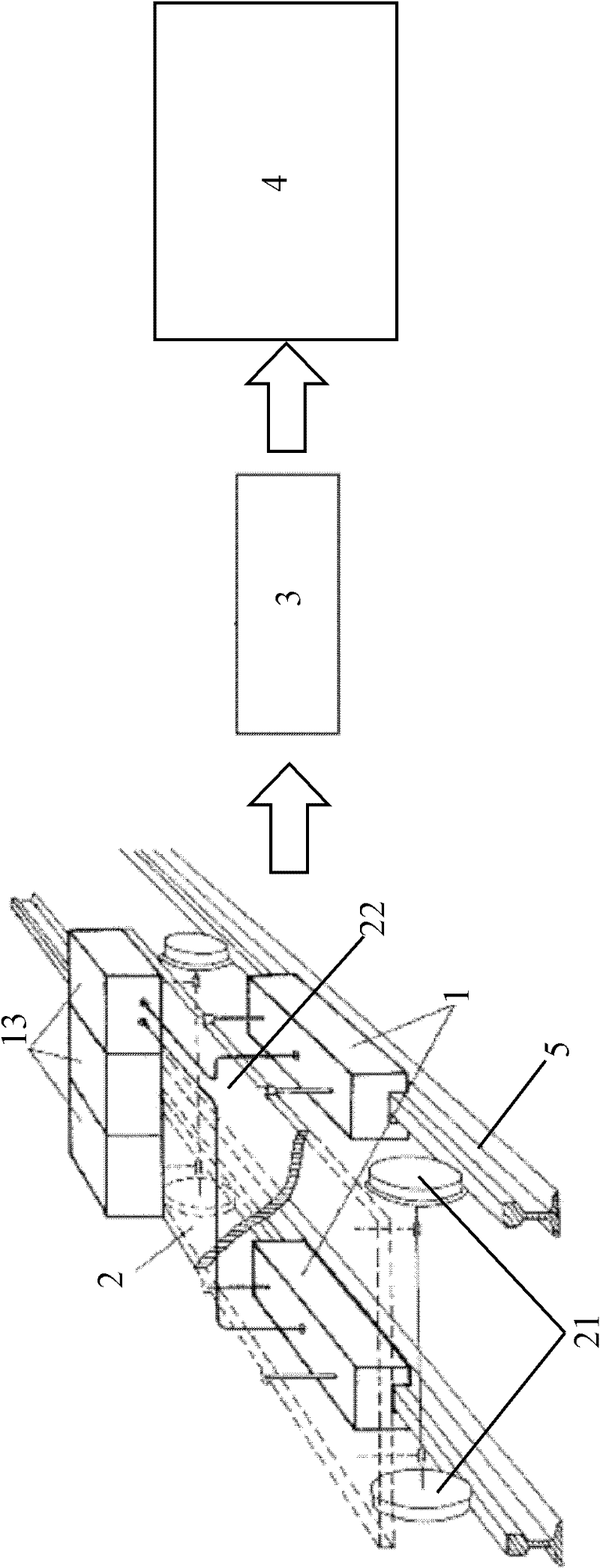

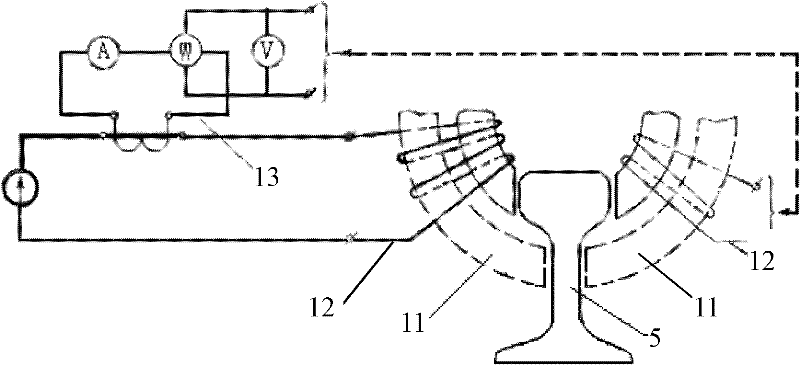

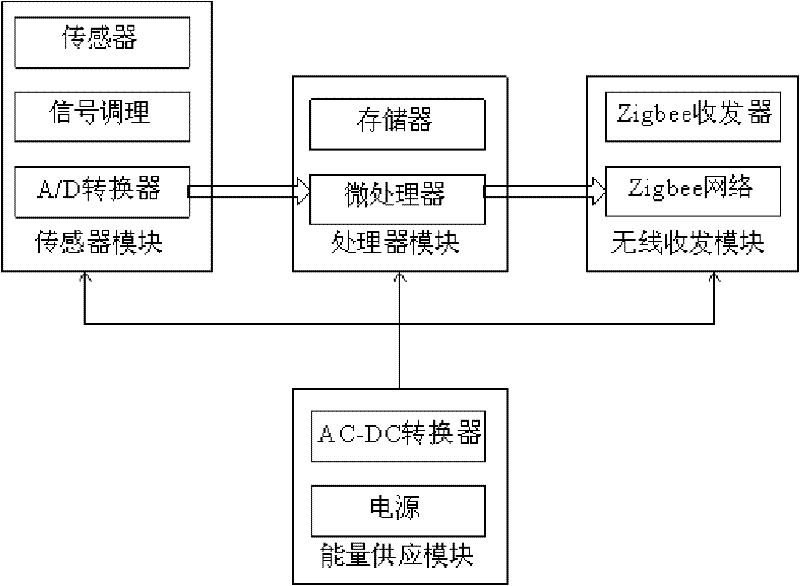

[0035] figure 1 It is a structural schematic diagram of the seamless line locked rail temperature pretreatment system according to the embodiment of the present invention. like figure 1 As shown, the seamless line locking rail temperature pretreatment system includes an electromagnetic induction heating device 1 , a travel control system 2 , a transmission system 3 and a host computer data processing system 4 . The main body of the electromagnetic induction heating device 1 and the transmission system 3 is installed on the travel control system 2; the travel control system 2 is movably arranged on the seamless line rail 5. The electromagnetic induction heating device 1 is used to generate magnetic flux to the rail 5 to heat the rail 5 to ensure that the rail temperature range is locked when the rail is laid; the transmission system 3 is used to coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com