Patents

Literature

239results about How to "Reduce reactive power loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

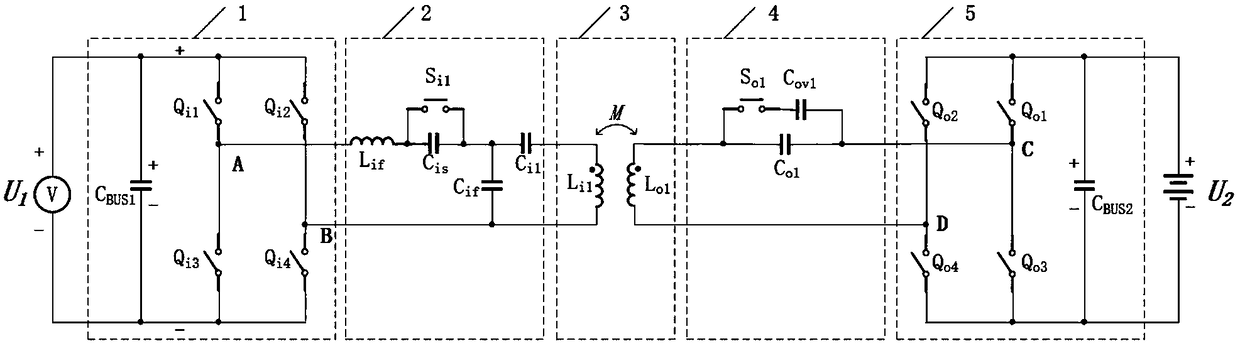

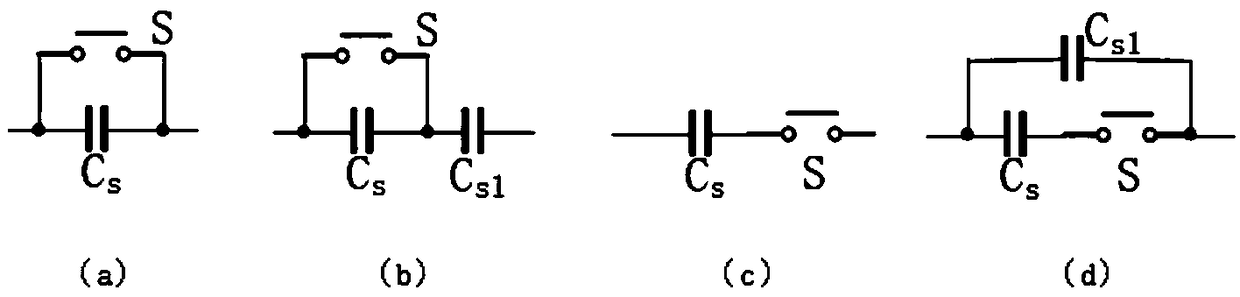

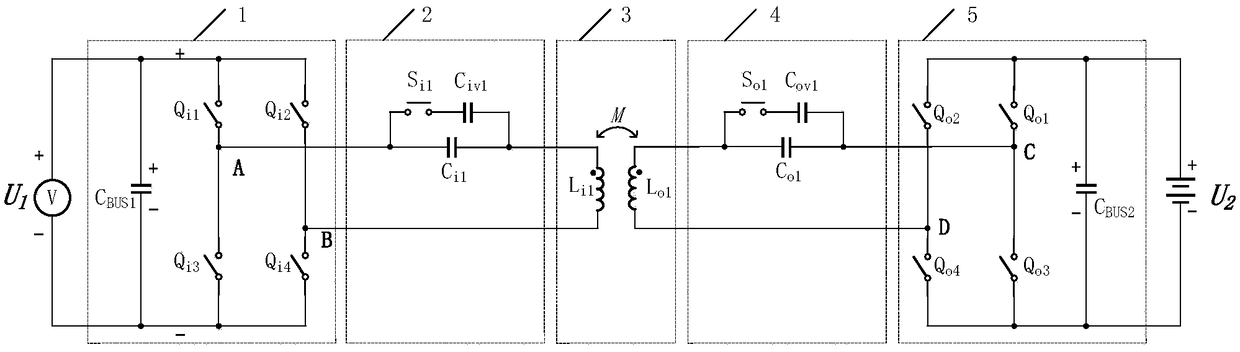

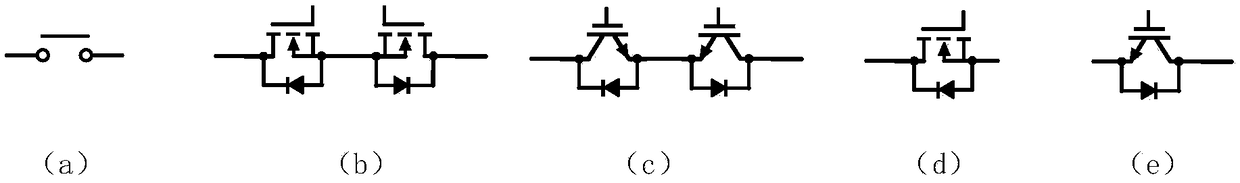

Electric converter circuit topological structure and control method thereof

PendingCN109302070ARealize two-way transmissionReduce the difficulty of design and manufactureEfficient power electronics conversionDc-dc conversionCapacitanceFull bridge

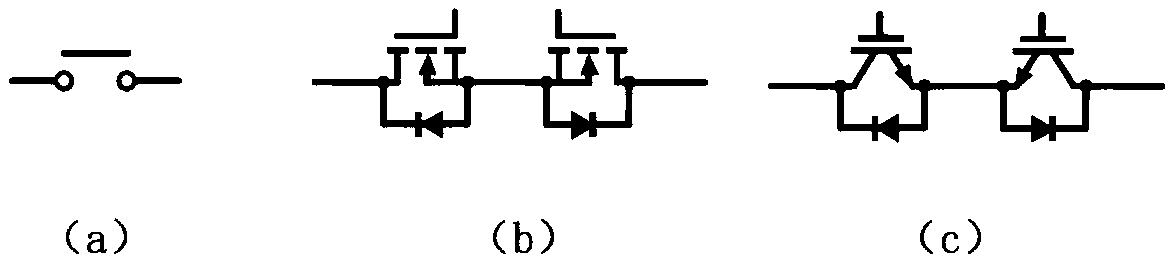

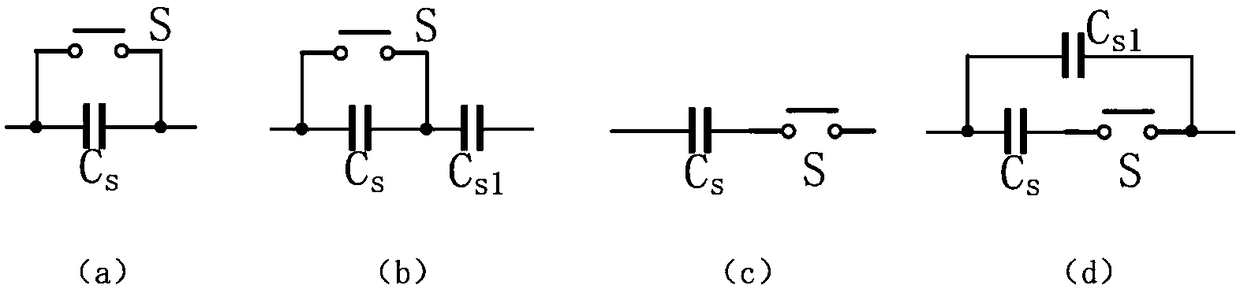

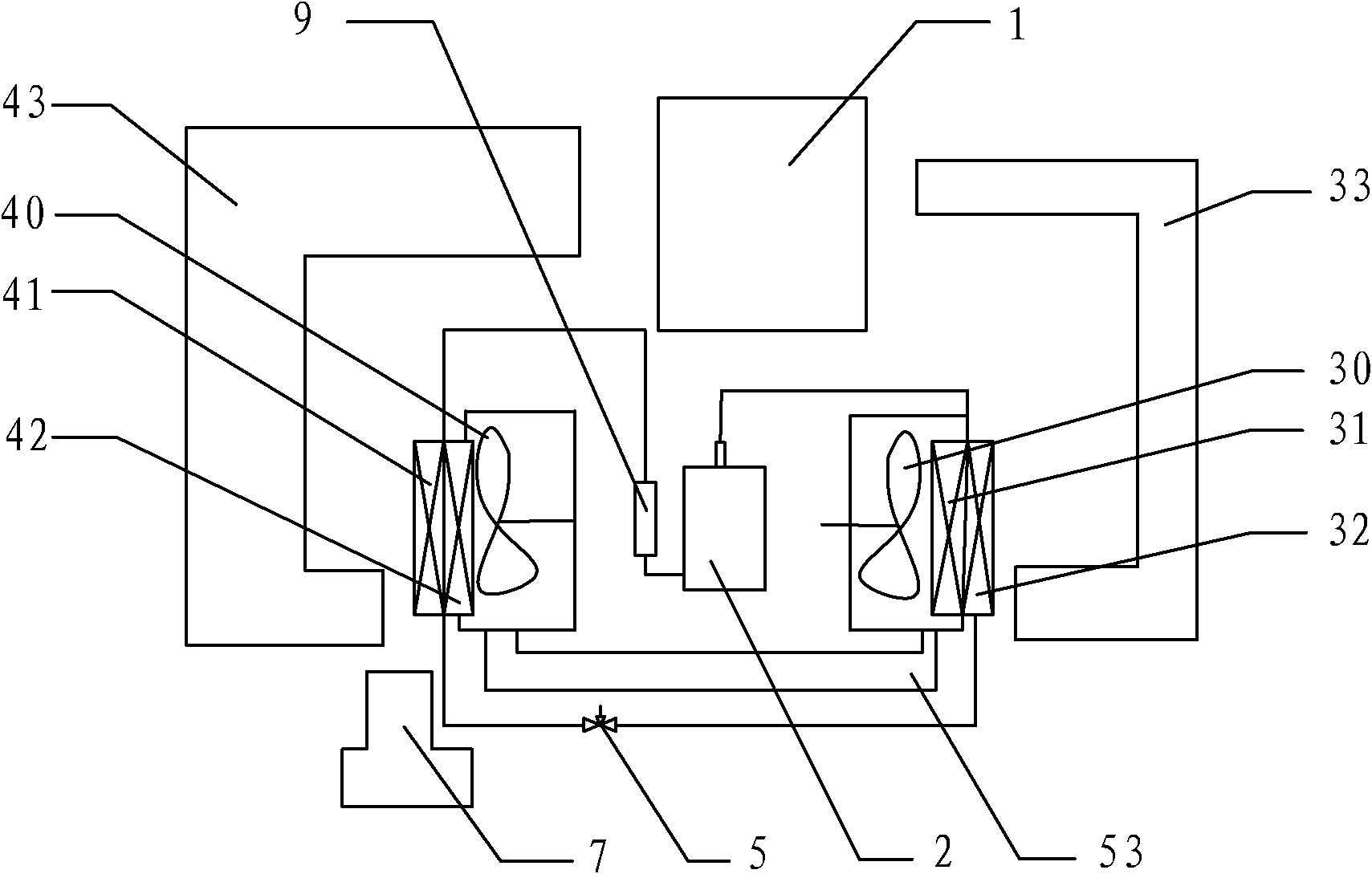

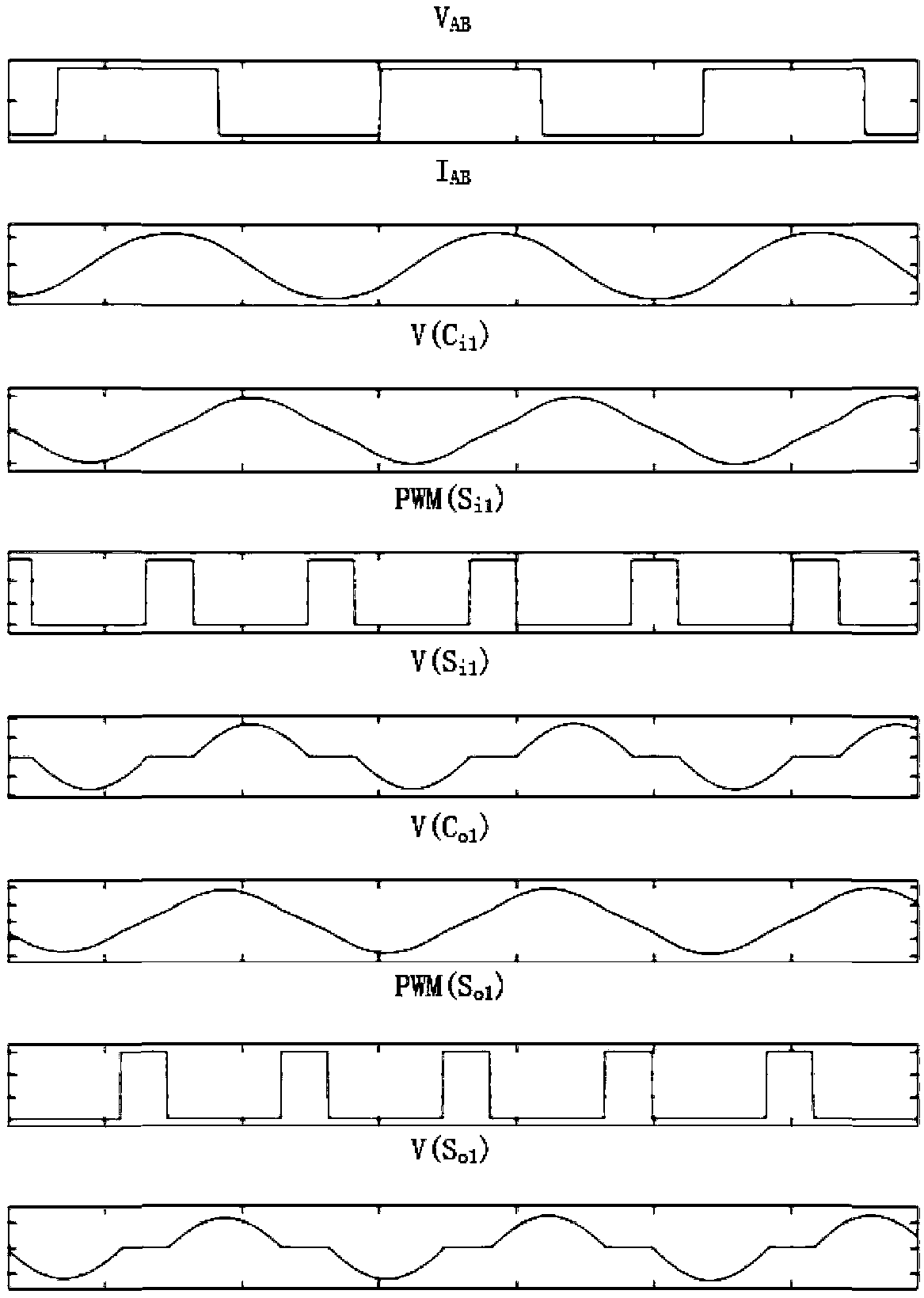

The present invention discloses an electric converter circuit topological structure and a control method thereof. The circuit topology comprises a full-bridge inverter, a primary side resonance dynamic compensation network, a primary side coil, a secondary coil, a secondary resonance dynamic compensation network, a full-bridge synchronous rectifier and a load. The primary side resonance dynamic compensation network employs a structure of connection in series of a compensation inductor and an adjustable resonance capacitor, the secondary resonance dynamic compensation network employs a structure of connection in series of a coil and the adjustable resonance capacitor, in the conditions that system parameters are changed caused by factors such as different coil coupling coefficients, different loads, the temperatures and device production manufacturing errors, the PWM duty ratio of a capacitive switching switch is regulated to generate continuously changed and adjustable equivalent resonant capacitance to perform dynamic compensation for the resonance network to achieve the soft switch of the full-bridge inverter and minimize the reactive power in the energy transmission of the system so as to maximum the electric energy transmission efficiency of the system and effectively enhance the regulation ability of the system output features in a condition of the constant working frequency of the system.

Owner:ARMY ENG UNIV OF PLA

A circuit topology structure suitable for bidirectional near-field power transmission

PendingCN109245536ARealize two-way transmissionReduce the difficulty of design and manufactureEfficient power electronics conversionCircuit arrangementsCapacitanceElectric power transmission

The invention discloses a circuit topology structure suitable for bidirectional near-field power transmission, which comprises a full-bridge inverter, a primary-side resonant dynamic compensation network, a primary-side coil, a secondary-side coil, a secondary-side resonant dynamic compensation network, a full-bridge synchronous rectification and a load. The invention can realize bidirectional near-field transmission of electric energy, and at different coil coupling coefficients, at different load size and due to temperature, under the condition of system parameter change caused by manufacturing error of device, by adjusting the PWM duty cycle of the capacitor switching switch, the equivalent capacitance of the capacitor switching switch can change continuously to compensate the resonantnetwork dynamically, so as to realize the soft switching of the full-bridge inverter, to minimize the reactive power in the energy transmission of the system, and to maximize the energy transmission efficiency of the system. In addition, due to the symmetry of the circuit structure, it can realize the bidirectional transmission of near-field electric energy, that is, the bidirectional energy flowbetween the power grid and the load, which improves the utilization rate of the system in the smart grid.

Owner:ARMY ENG UNIV OF PLA

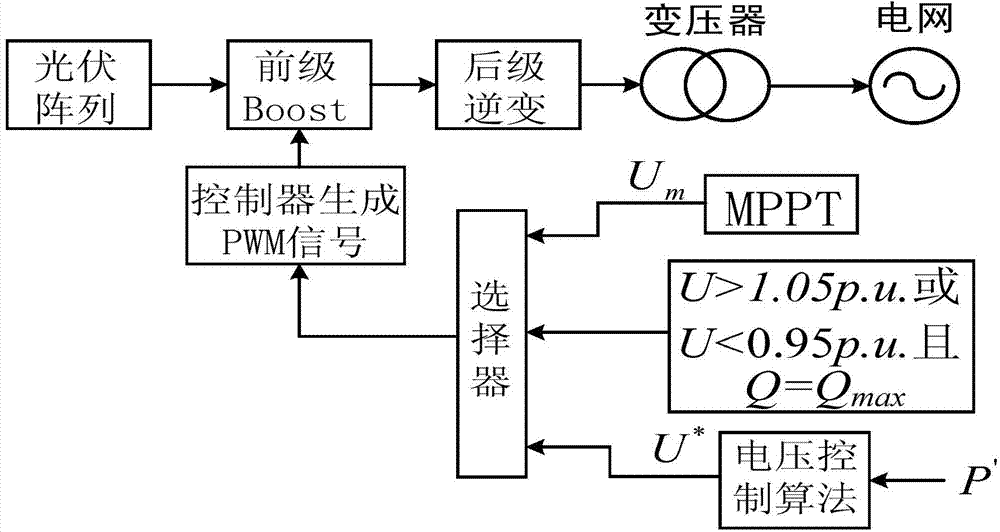

Reactive voltage control method and system for grid-connected photovoltaic power station

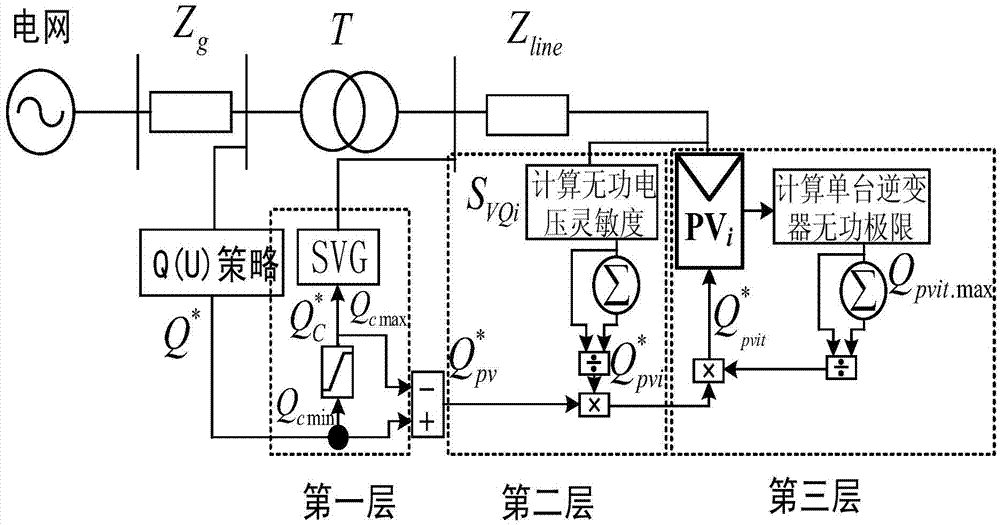

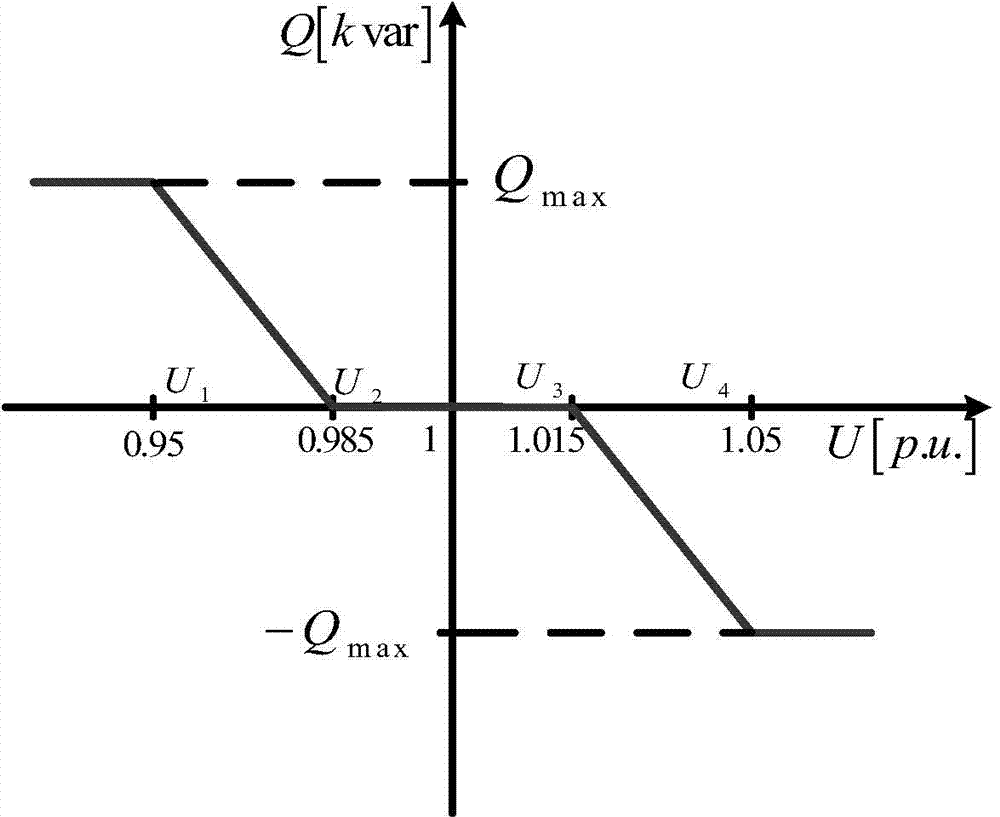

ActiveCN103580030AGuaranteed uptimeImprove permeabilitySingle network parallel feeding arrangementsAc network voltage adjustmentPower gridPhotovoltaic power station

The invention discloses a reactive voltage control method and system for a grid-connected photovoltaic power station. A three-layer reactive power control strategy is adopted to coordinate the reactive output between a reactive compensation device and a photovoltaic power generation unit and between inverters of a single photovoltaic power generation unit. Under the control strategy, the reactive voltage support is provided for the power grid; the photovoltaic power station can effectively regulate the power grid voltage; the active loss and the reactive loss of the power grid are minimal on the premise of keeping the power grid voltage within the required range. A photovoltaic array power reduction running strategy is further combined, the stable operation of the power grid is ensured on the premise of maintaining a certain reactive output capacity of the photovoltaic power station. The reactive voltage control method and the system solve the problem that the voltage at the grid-connected point is out of limit, which is caused by the fact that the large-scale photovoltaic power station is connected to the power grid, increase the permeability of the photovoltaic current in the power grid, and improve the stable running performance of the power grid voltage.

Owner:CHONGQING UNIV

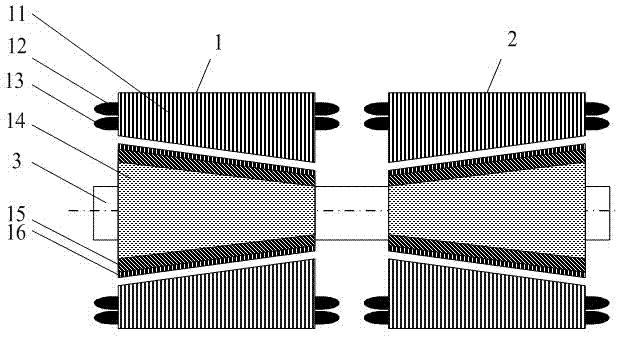

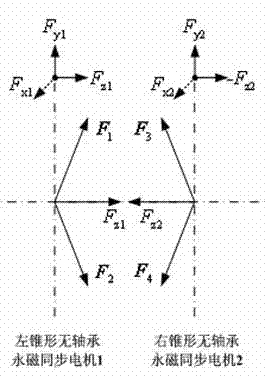

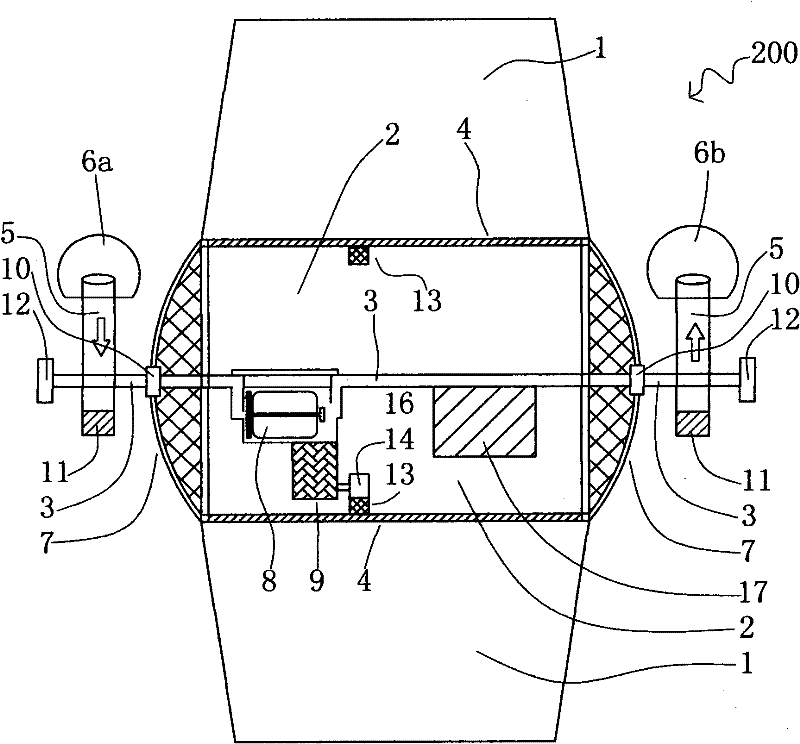

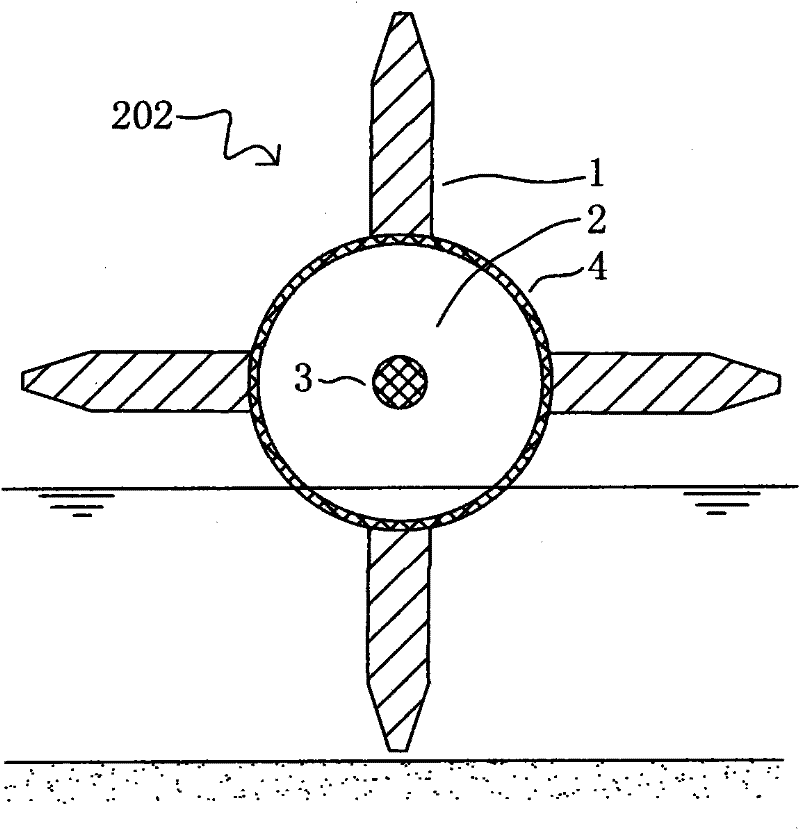

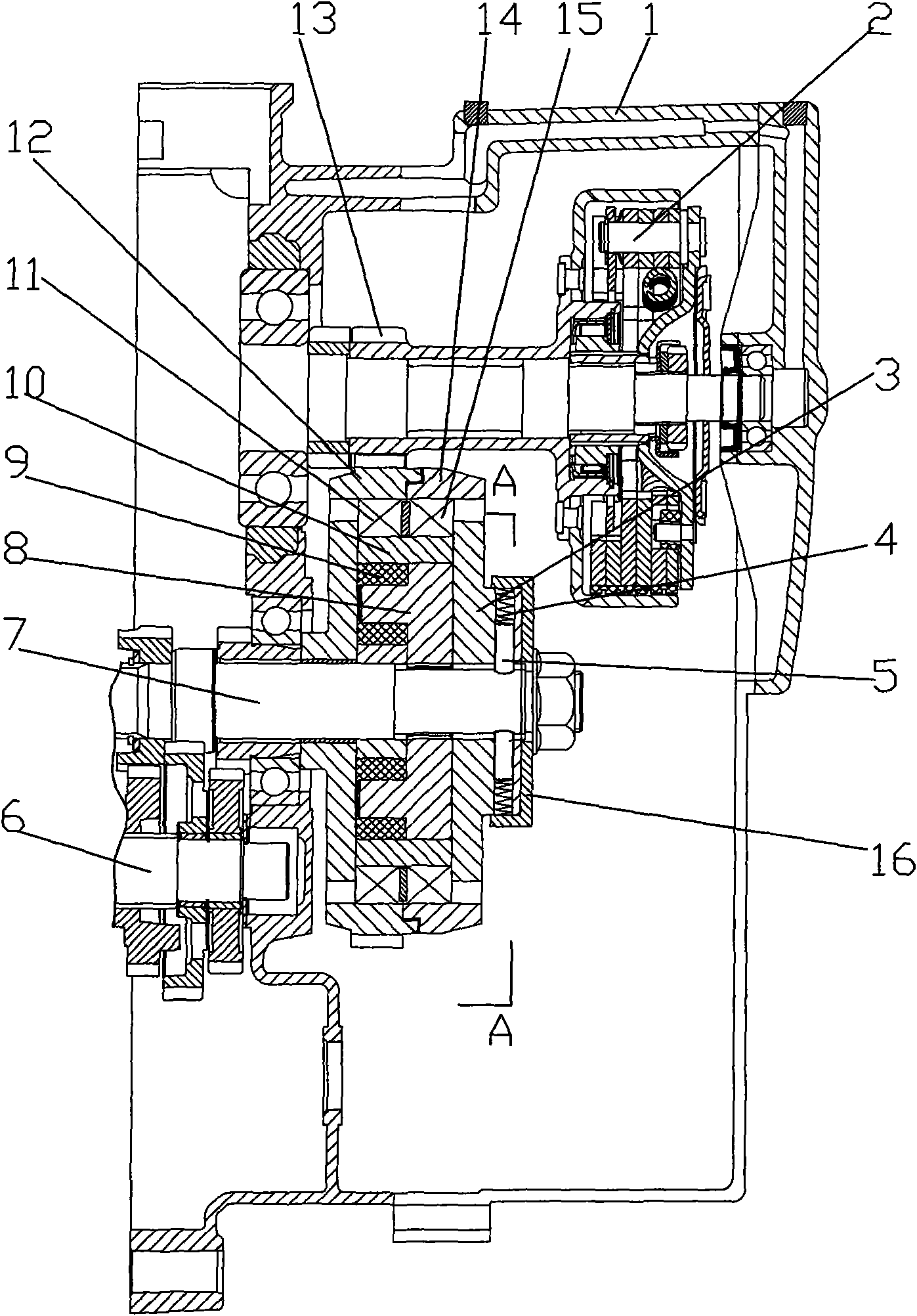

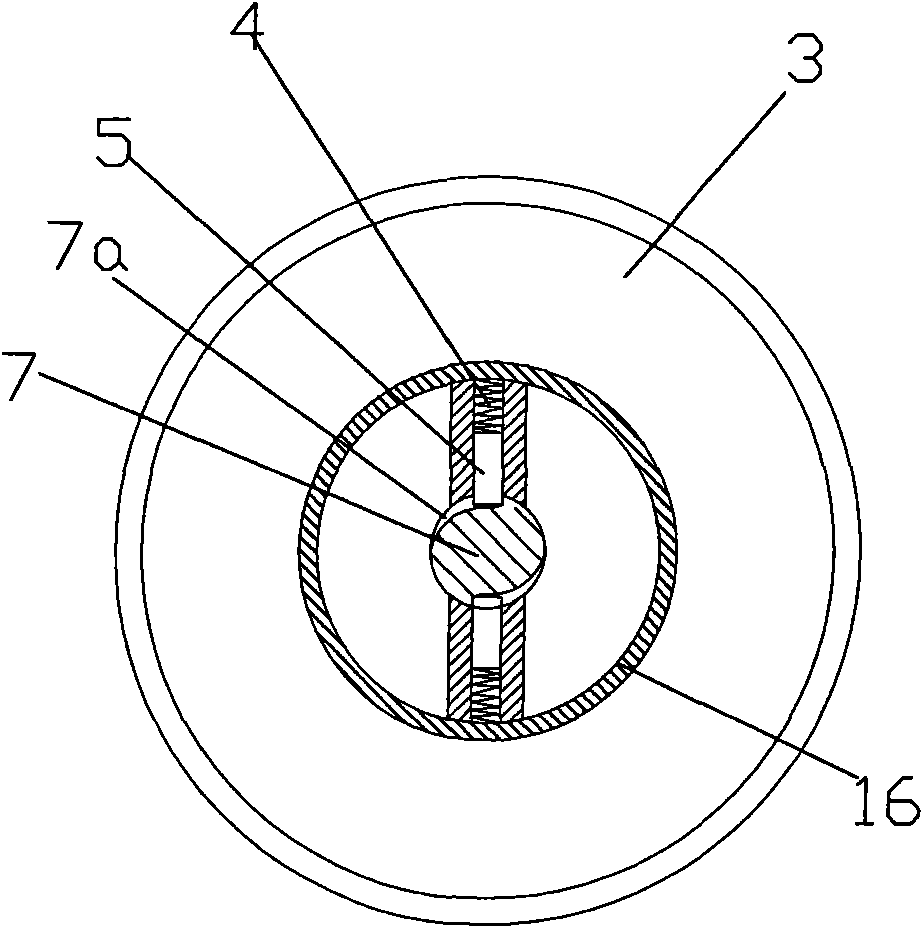

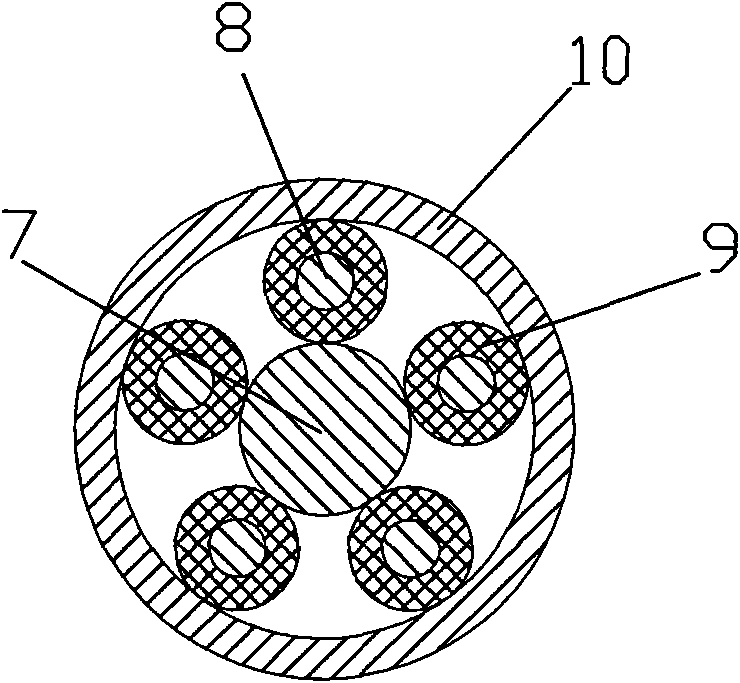

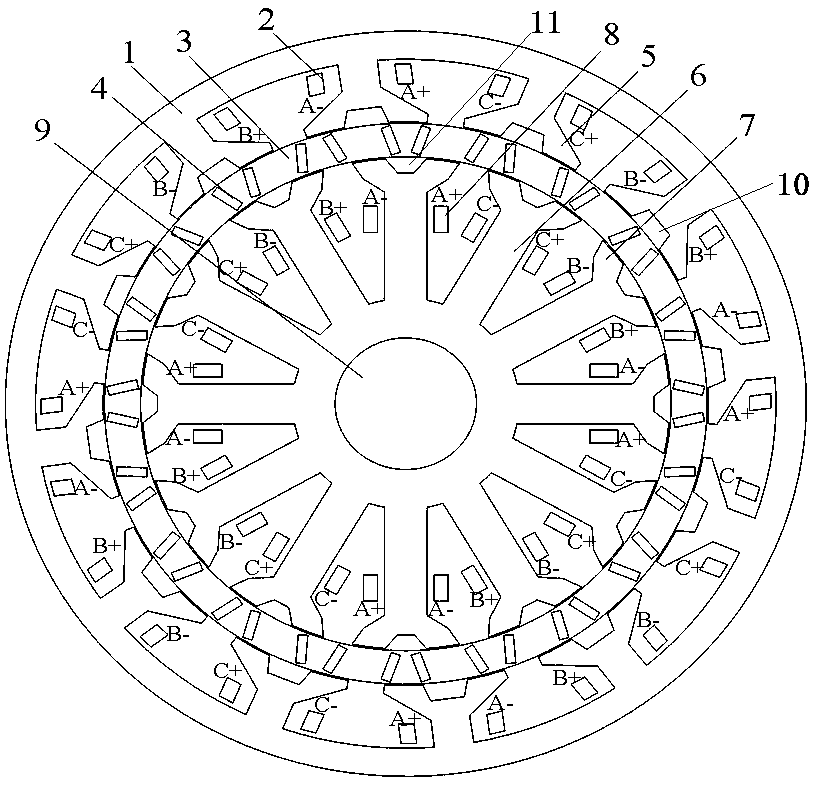

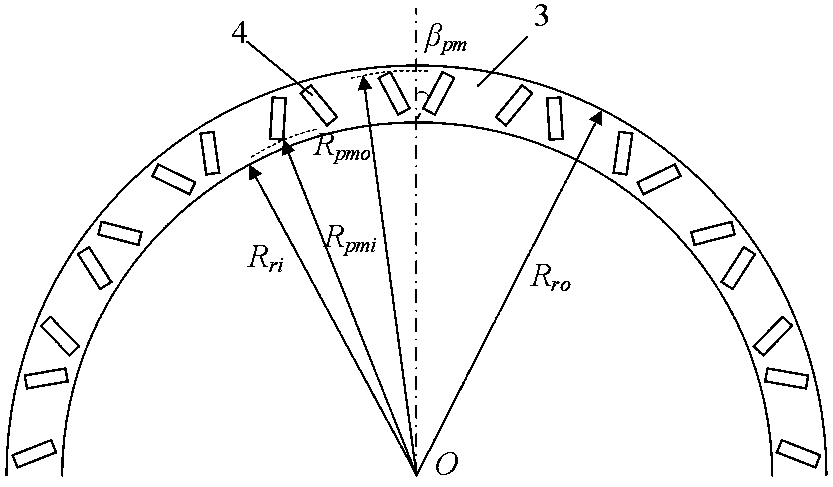

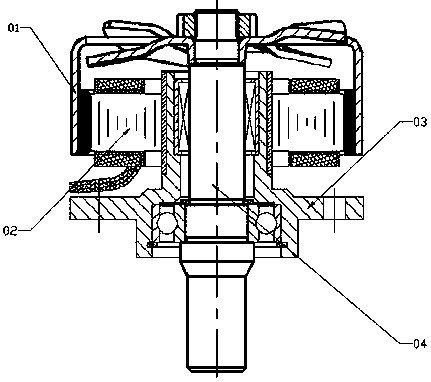

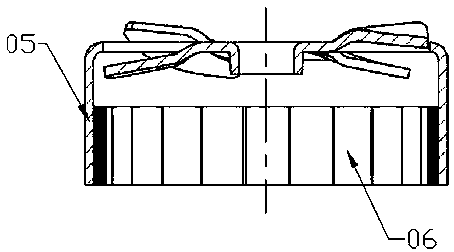

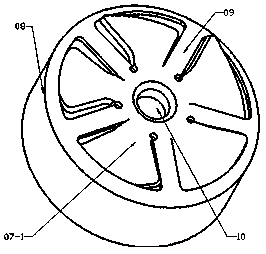

Five-degree-of-freedom (five-DOF) bearing-free permanent magnet synchronous motor

ActiveCN102377298AAchieve levitationSimple structureDynamo-electric machinesMagnetic holding devicesSynchronous motorMagnetic bearing

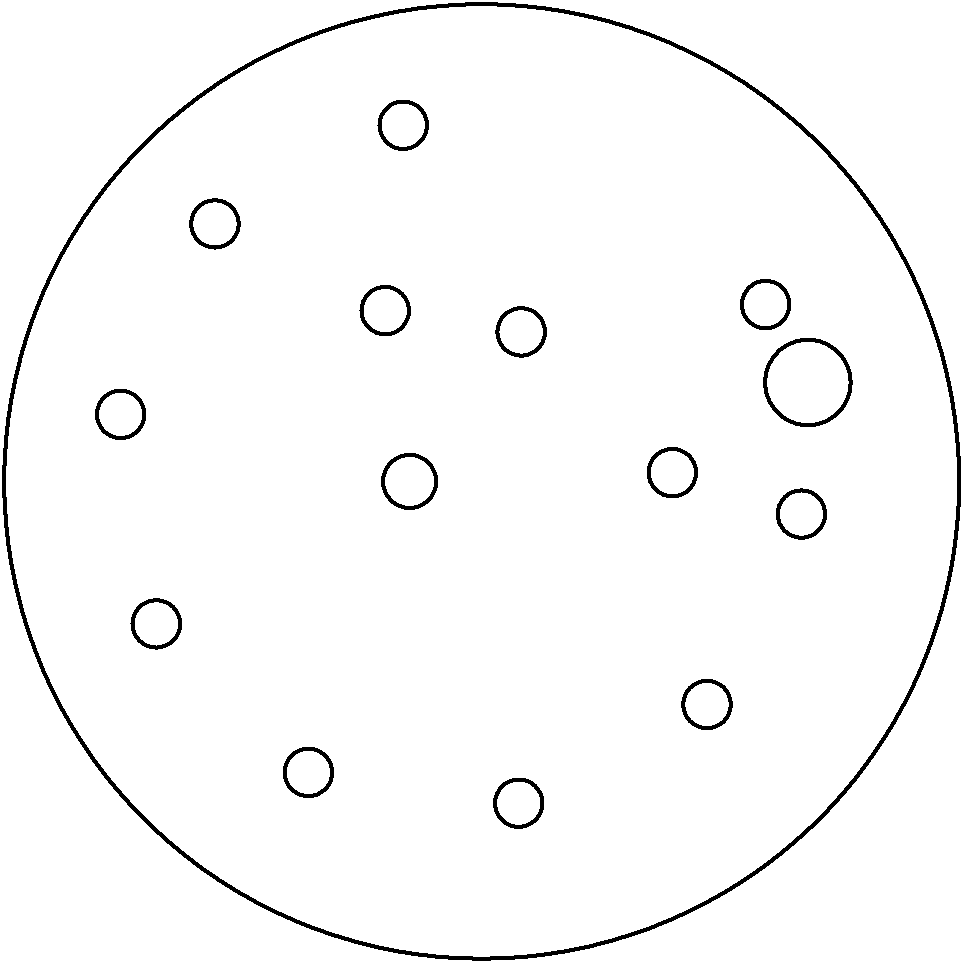

The invention discloses a five-degree-of-freedom (five-DOF) bearing-free permanent magnet synchronous motor. Left and right conical bearing-free permanent magnet synchronous motors respectively arranged at the left and right ends of a motor shell are symmetrically connected to a mechanical rotating shaft; each conical bearing-free permanent magnet synchronous motor consists of a conical stator, atorque winding, a suspension force winding and a conical rotor; and a permanent magnet is mounted on the outer surface of the conical rotor, a jacket is fixedly sleeved outside the permanent magnet, the conical rotor is fixedly arranged on the mechanical rotating shaft, the conical stator is provided with a plurality of through slots in the axial direction, each through slot is divided into an inner layer and an outer layer in the radial direction, the suspension force winding and the torque winding are respectively placed in the inner layer and the outer layer, the pole number of the torque winding is as same as that of the permanent magnet, and the difference between the pole number of the suspension force winding and the pole number of the torque winding is 2. The five-DOF bearing-freepermanent magnet synchronous motor can simultaneously realize radial and axial five-DOF suspension of the rotor without an additional magnetic bearing, has the advantages of high integration, reducedvolume and high critical rotating speed, and is easy to realize high-power ultrahigh-speed operation.

Owner:ZHENJIANG YUANDONG ELECTRIC MOTOR

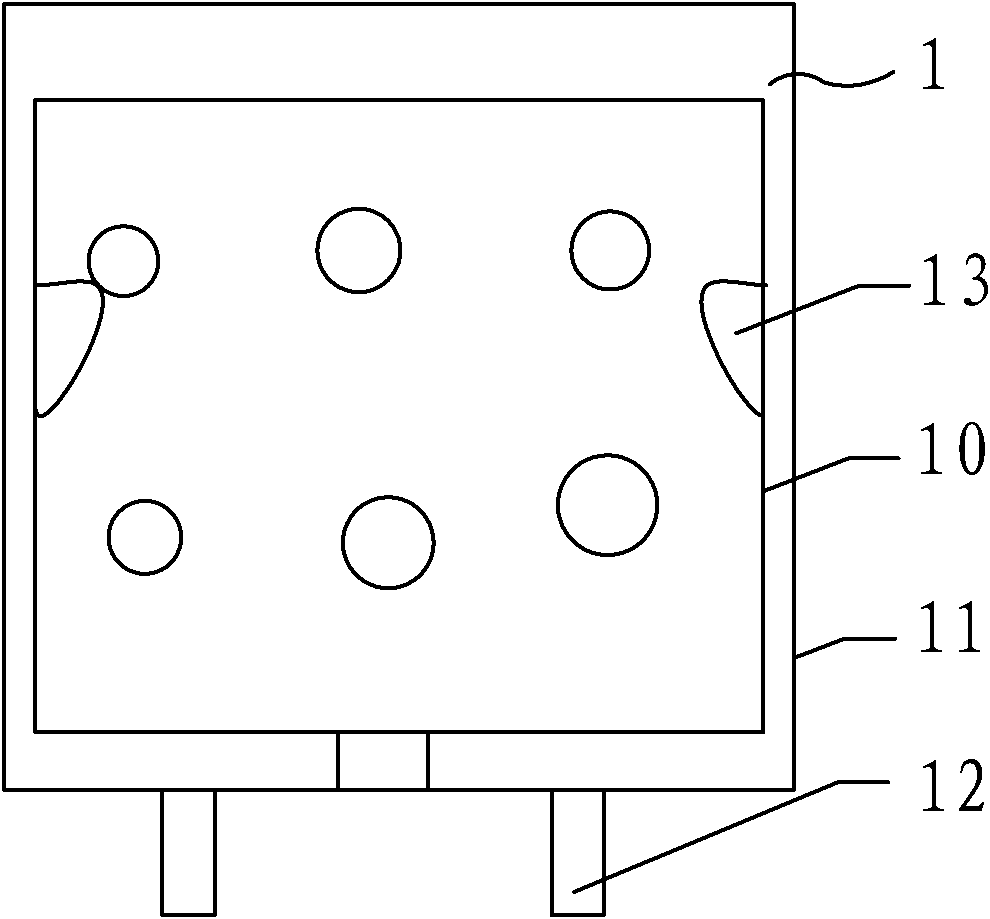

Heat pump type clothes dryer

ActiveCN102002843AReduce power consumptionAvoid scorchingTextiles and paperLaundry driersControl systemProcess engineering

The invention relates to a heat pump type clothes dryer which comprises a control system, a refrigeration system and an air circulation system, wherein the refrigeration system consists of a compressor, a condenser, an evaporator and a throttle valve, the air circulation system consists of a clothes drying barrel, an evaporator, an evaporator fan, a condenser, a condenser fan, a humid heat air flow passage, a low-temperature dry air flow passage and a dry air flow passage, the humid heat air flow passage is arranged between the clothes drying barrel and the evaporator, the low-temperature dry air flow passage is arranged between the evaporator and the condenser, the dry air flow passage is arranged between the condenser and the clothes drying barrel, the compressor is a variable-frequency compressor and comprise a first condenser and a second condenser group which are connected in series, and the output end of the first condenser is also provided with a by-pass pipeline so that refrigerants can selectively flow to the throttle valve through the by-pass pipeline. The heat pump type clothes dryer can be used for high temperature dehumidification in high moisture content, can be used for medium temperature dehumidification in low moisture content and has obvious energy saving effect.

Owner:TCL AIR CONDITIONER ZHONGSHAN CO LTD

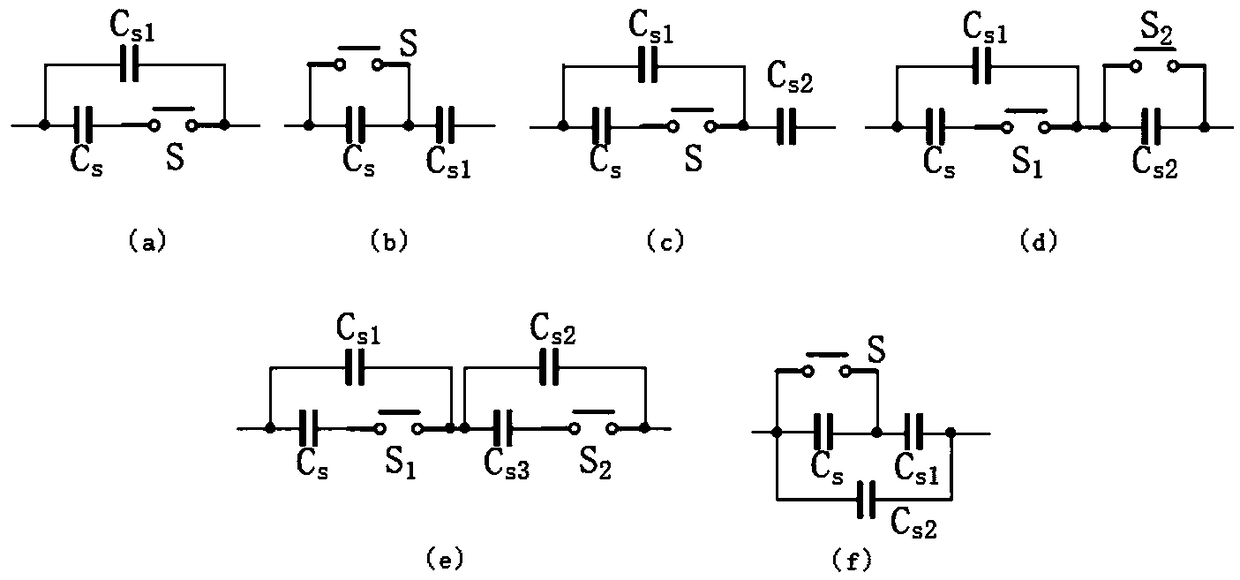

A symmetrical power converter circuit topology and control method thereof

PendingCN109245542AReduce conduction lossReduce lossEfficient power electronics conversionDc-dc conversionCapacitanceSoft switching

The invention discloses a circuit topology of a power converter suitable for bidirectional near-field electric energy transmission and a control method thereof. The circuit topology comprises a full-bridge inverter, a primary-side resonant dynamic compensation network, a primary-side coil, a secondary-side coil, a secondary-side resonant dynamic compensation network, a full-bridge synchronous rectification and a load. The invention adopts a structure that a coil is connected in series with an adjustable resonant capacitor, At different coil coupling coefficients, at different load size and dueto temperature, under the condition of system parameter change caused by manufacturing error of device, the resonant network can be dynamically compensated by adjusting the PWM duty cycle of the capacitor switching switch to produce a continuously variable equivalent series resonant capacitor, to achieve full-bridge inverter soft switching, minimize the reactive power in the system energy transfer, thereby maximizing the system power transfer efficiency, in the case of a constant operating frequency, effectively enhance the system output characteristics of the adjustment capability. In addition, because of the symmetry of the circuit structure, it can realize the bi-directional transmission of near-field electric energy, that is, the bi-directional energy flow between the power grid and the load, which improves the utilization rate of the system in the smart grid.

Owner:ARMY ENG UNIV OF PLA

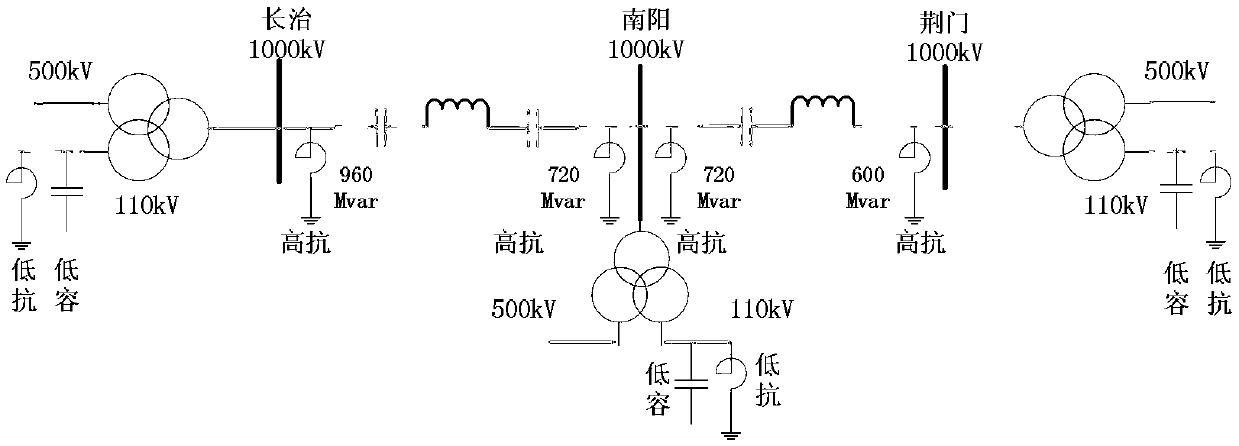

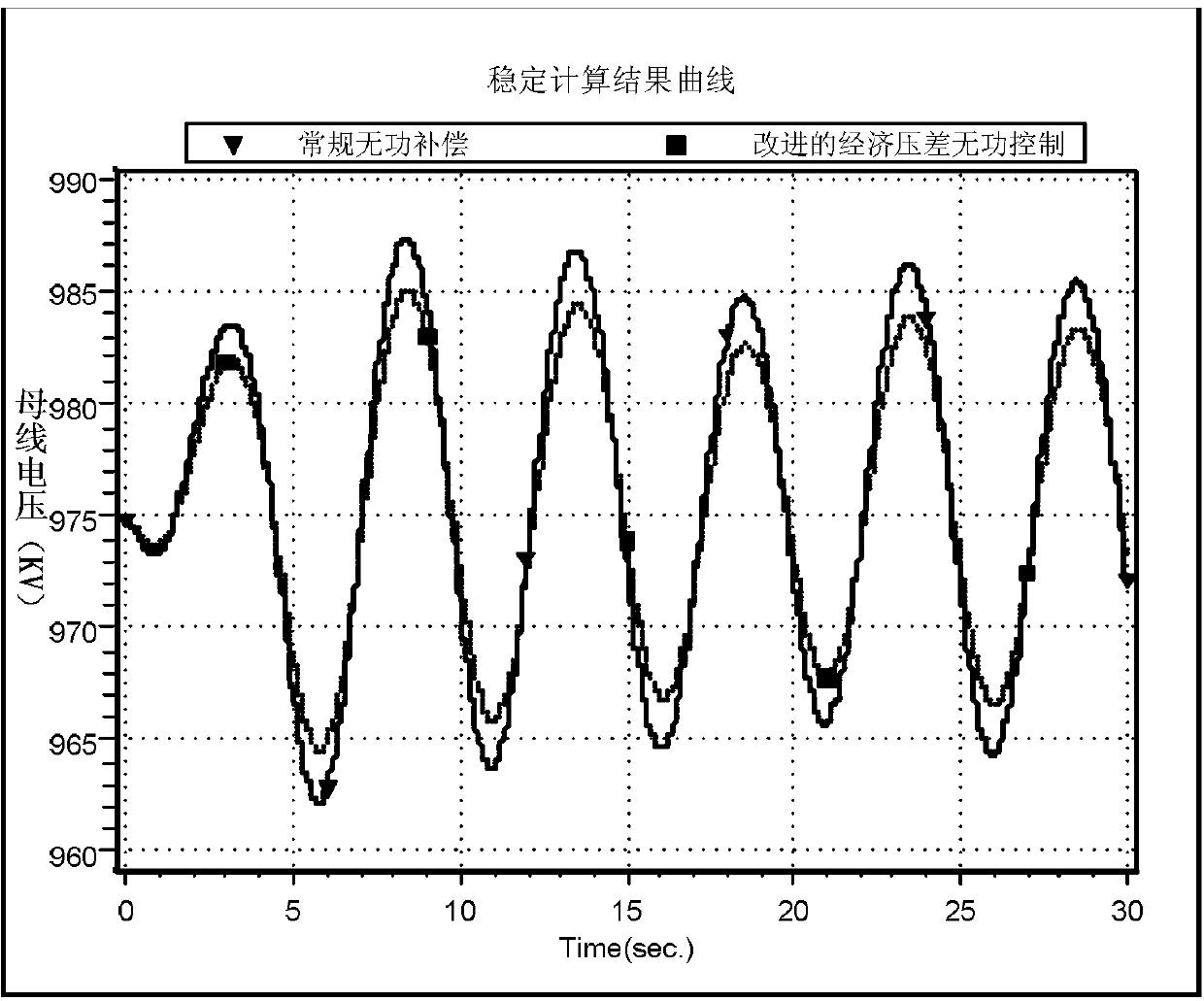

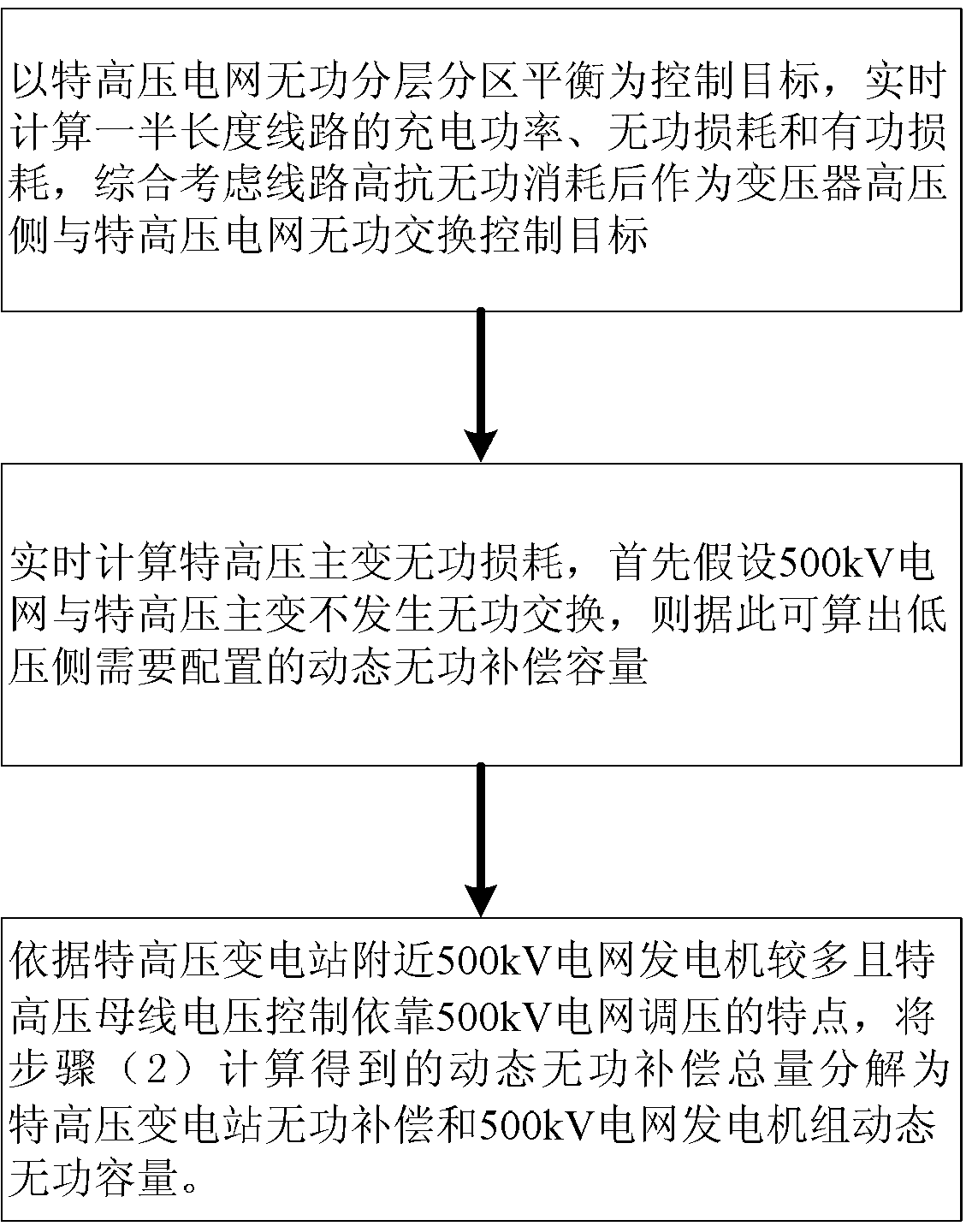

Method for controlling reactive voltage in ultra-high voltage grid on the basis of improved economic voltage difference

ActiveCN103001234ARealize reactive power real-time balanceReduce reactive power lossReactive power adjustment/elimination/compensationReactive power compensationPower gridEngineering

The invention provides a method for controlling reactive voltage in an ultra-high voltage grid on the basis of improved economic voltage difference. For current simulation and problems in controlling the reactive voltage in the ultra-high voltage grid, the reactive voltage in the ultra-high voltage grid is balanced in real time by real-time coordination of low voltage side conventional reactive compensation with 500kV grid dynamic reactive compensation. The method allows real-time coordinated control for the low voltage side reactive compensation and 500kV grid side dynamic reactive compensation, and ensures real-time reactive power and efficient and economic operation of the ultra-high voltage grid. In addition, by the use of the method, operating frequency in conventional compensation switching can be reduced greatly, reactive loss of transformers is lowered further, and busbar voltage fluctuation caused by power fluctuation of tie lines is suppressed to a certain degree.

Owner:CHINA ELECTRIC POWER RES INST +2

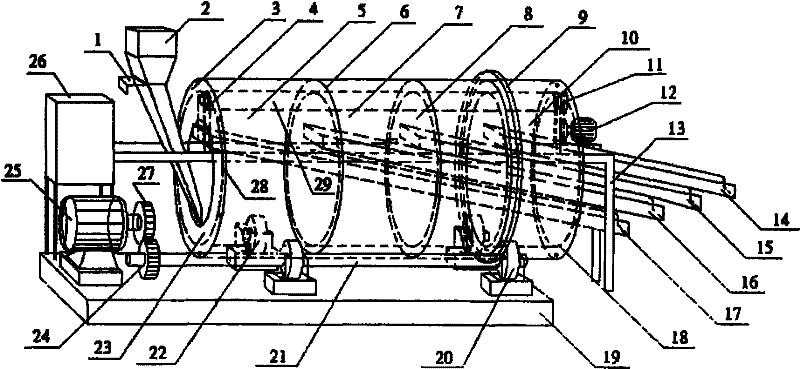

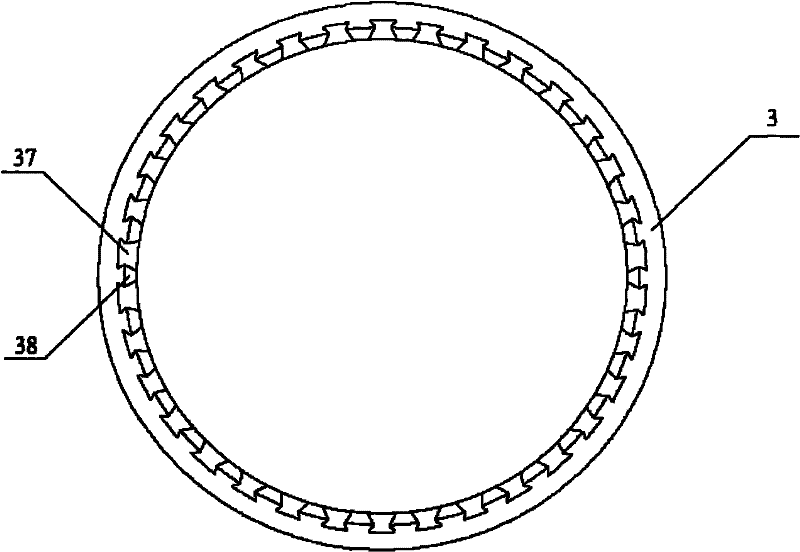

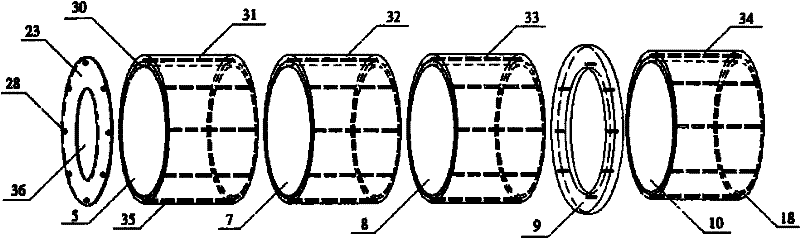

Permanent magnet inner cylinder type polymetallic synchronous magnetic separator

ActiveCN102179298AThe probability of getting rough is highReduce missed selectionMagnetic separationMagnetic separatorSeparation process

The invention relates to a permanent magnet inner cylinder type polymetallic synchronous magnetic separator and belongs to mineral machinery. The permanent inner cylinder type polymetallic synchronous magnetic separator consists of a power motor, a foundation, a permanent magnet roller, a support, a control cabinet, a feeding box, charging grooves, a charging brush roller and a transmission part;magnetic systems are distributed on the inner wall of a permanent magnet roller body from bottom to top sequentially; and when mineral powder to be separated passes through magnetic areas with different field intensities, different metal element powder particles are adsorbed by magnetic separation areas with different field intensities respectively according to respective specific susceptibility and then fall into the charging grooves which are distributed separately, so that the polymetallic single-machine same-roller synchronous classification separation is realized. The permanent magnet inner cylinder type polymetallic synchronous magnetic separator is suitable for the separation of complex polymetallic minerals and tailings and can also be applied to a dry separation process and a wetseparation process, and can also be applied to performing synchronous primary separation, precise separation and scavenging on one certain mine variety.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST

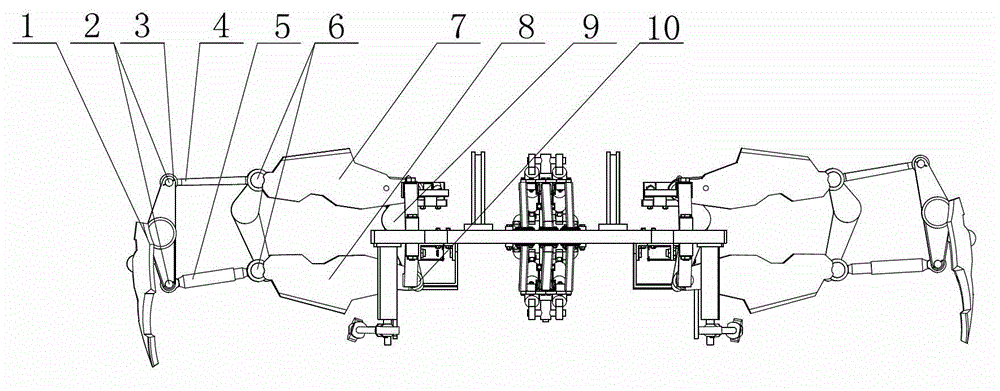

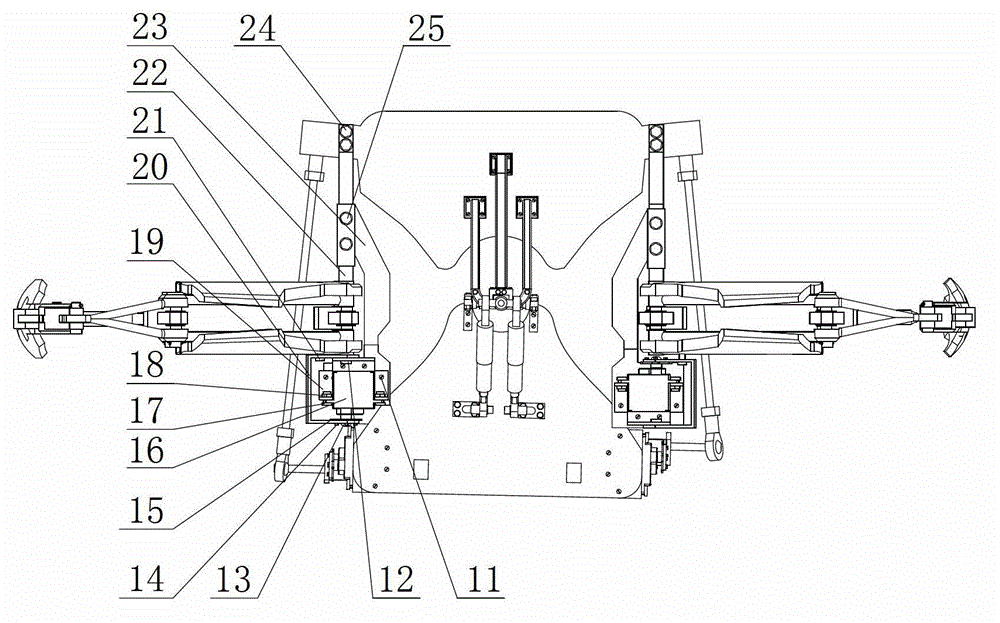

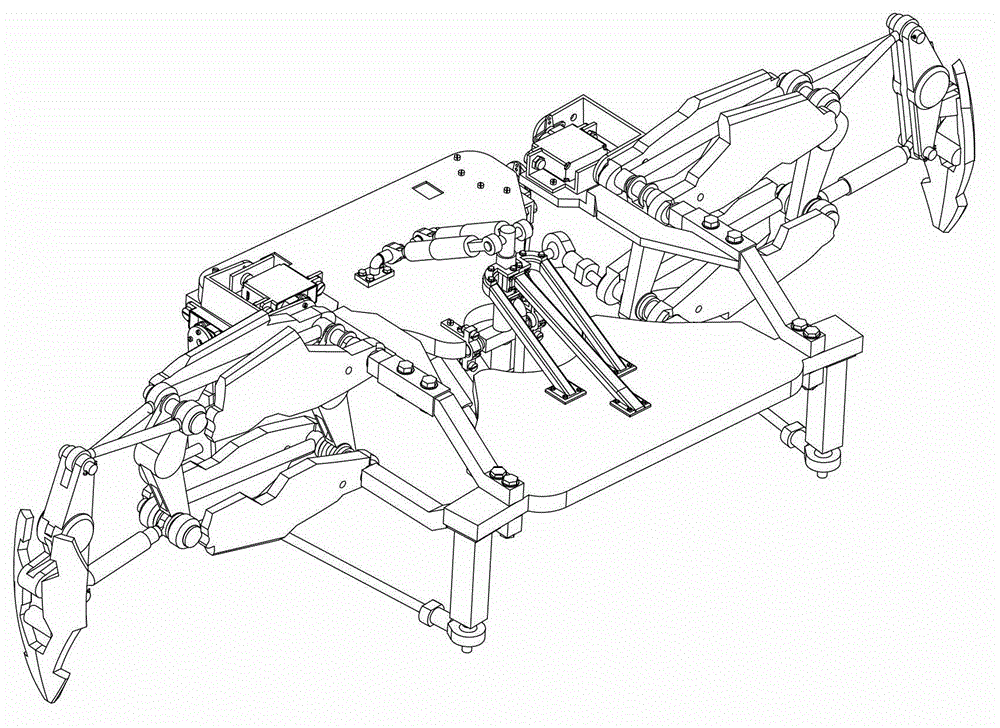

Modularized walking robot with flexible torso

The invention provides a modularized walking robot with a flexible torso. The walking robot comprises the flexible torso and two groups of walking legs, wherein the flexible torso comprises a front machine body plate, a rear machine body plate, and waist joints used for connecting the front machine body plate with the rear machine body plate; the two groups of walking legs are respectively mounted on the left sides and right sides of the front machine body plate and the rear machine body plate, and are connected with the front machine body plate and the rear machine body plate; first steering engines are used for driving the walking legs; a second steering engine is used for driving the flexible torso. The modularized walking robot abandons the traditional rigid body structure, and has three two-free-degree waist joints, so that the movement flexibility and stability of the robot are higher, and the obstacle crossing capability is stronger. The walking legs of the walking robot can be conveniently expanded into six legs, eight legs, ten legs or even more legs. As the walking leg structure is simplified in a better manner, reactive power loss due to gravity action in the walking process is reduced, and as a double-action damper is mounted between each thigh and each crus, the passive buffering effect is achieved, and the ground impact on the robot in the walking process is reduced.

Owner:HARBIN ENG UNIV

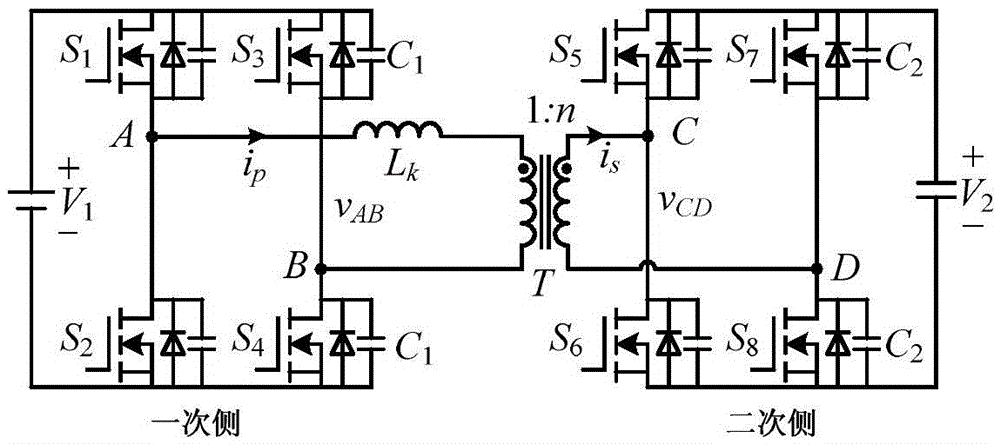

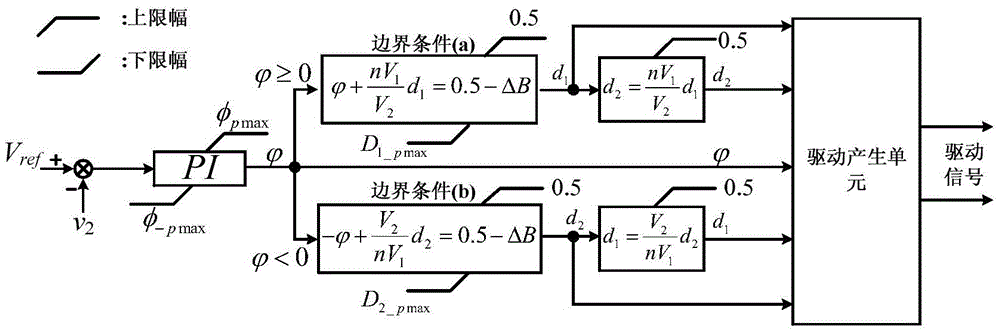

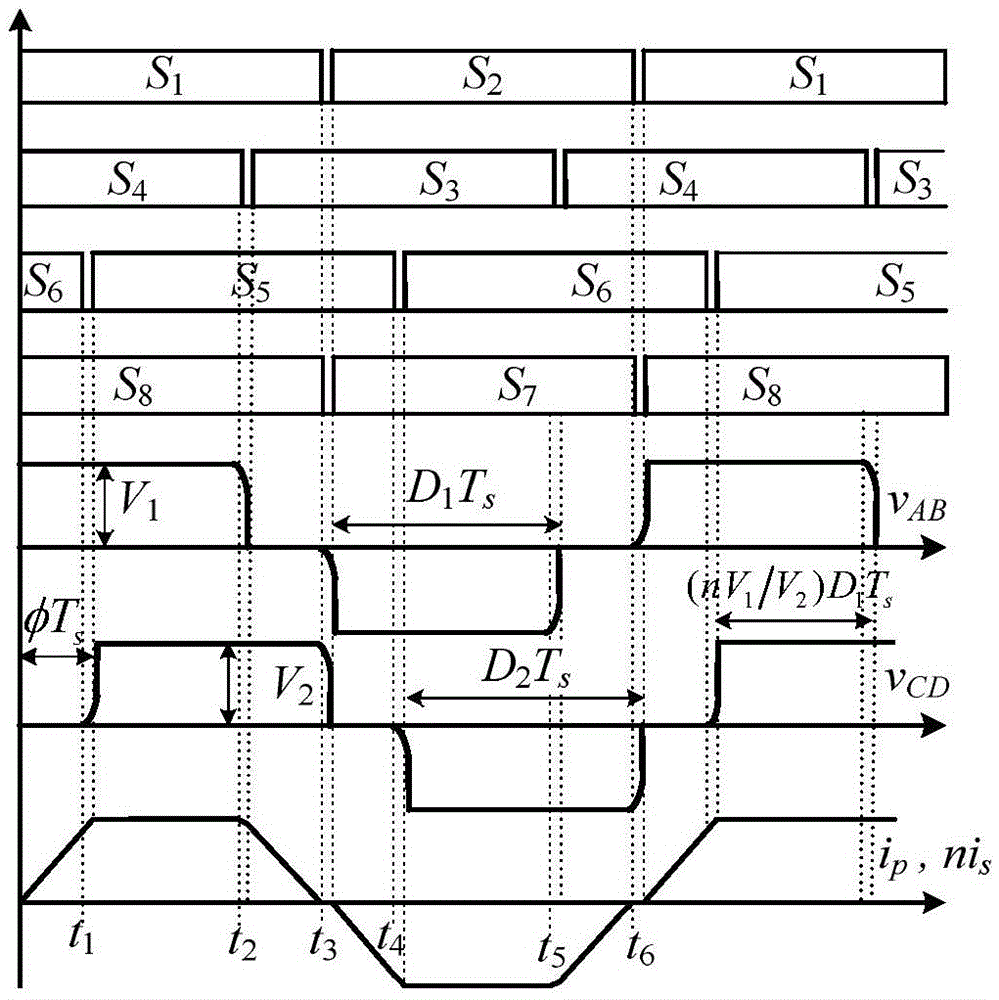

Current critical continuous unified control method for bidirectional DC-DC converter

ActiveCN105553274AReduce lossReduce conduction lossDc-dc conversionElectric variable regulationPhase differenceEngineering

The invention discloses a current critical continuous unified control method for a bidirectional DC-DC converter, relates to a current critical continuous unified control method for a dual-active bridge bidirectional DC-DC converter, and belongs to the field of power electronics. According to the control method disclosed by the invention, voltages on a primary side and a secondary side of a transformer and a phase difference between the voltages are controlled to make the converter work in a transformer current critical continuous mode and reduce the ring current and conduction loss of the converter. In addition, a transformer current can be enabled to be in a critical continuous mode through a boundary condition and a control condition, so that the reactive loss of a circuit is reduced, the current stress of a switching tube and the ring current loss of the converter are reduced, and the efficiency and reliability of the converter can be improved. The method further can greatly lower the complexity of a control unit and realize real-time control. The method can be applied to high-frequency isolation switching power supplies.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

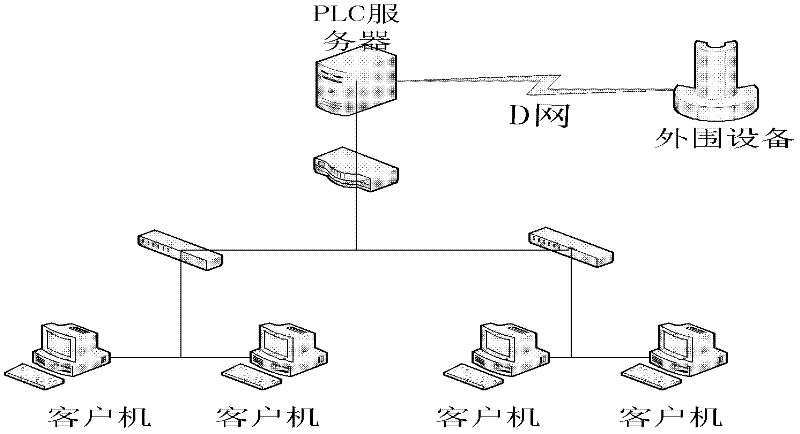

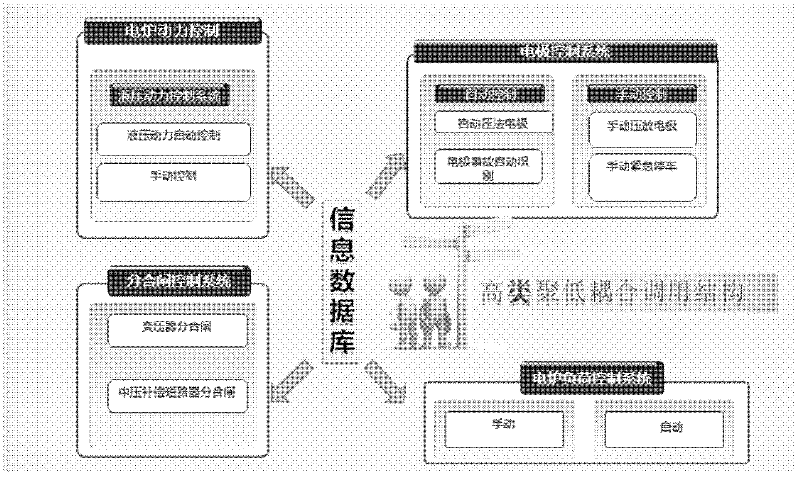

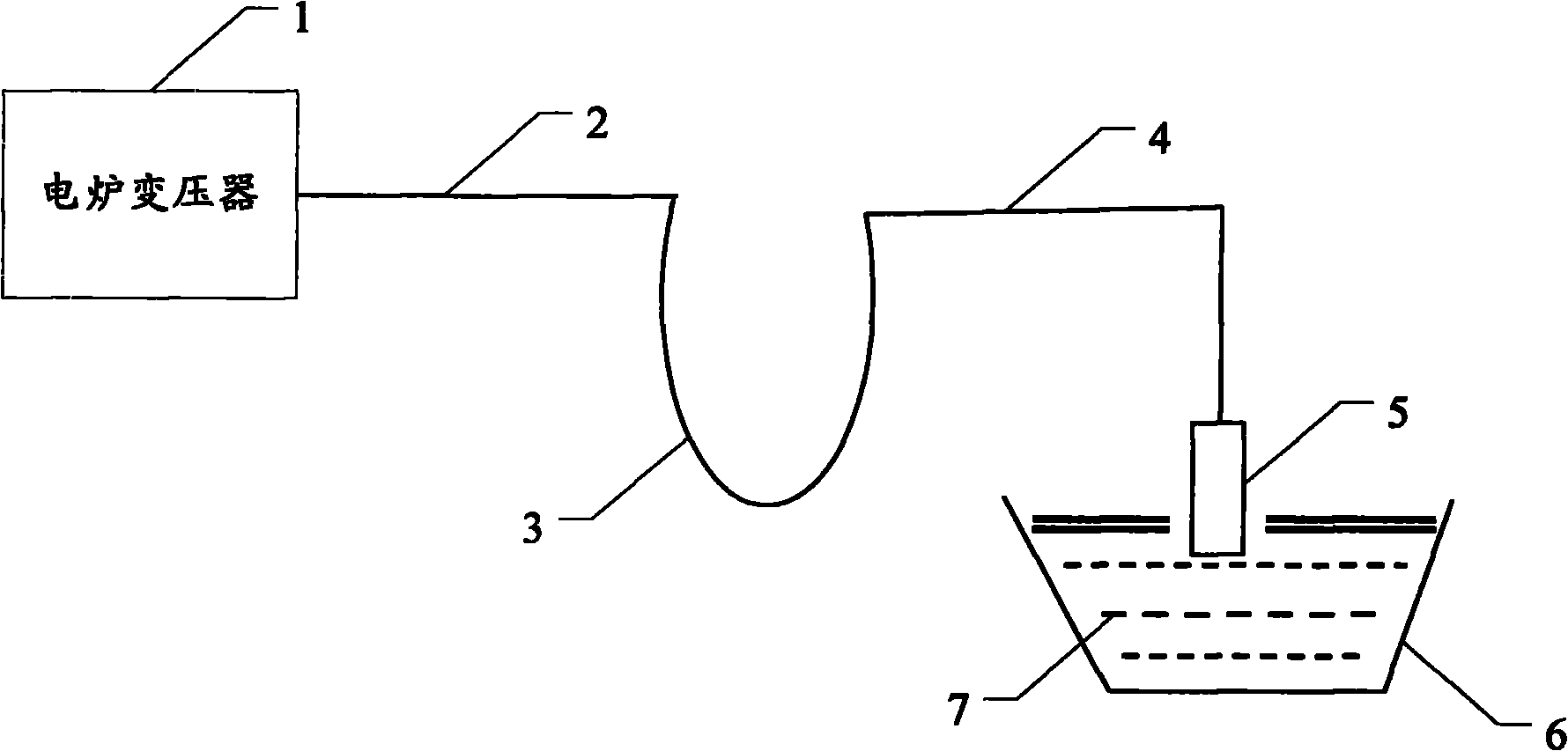

System and method for controlling electrode of ore-smelting electric furnace

InactiveCN102331193AImprove safe operationReduce reactive power lossIncreasing energy efficiencyControl devices for furnacesTransformerControl system

The invention provides a system for controlling an electrode of an ore-smelting electric furnace. The system comprises a current signal acquisition module, a setting module, a computation module, an electrode controller, a transformer controller and a control module, wherein when a current detection value obtained by the current signal acquisition module does not exceed the range of a current change comparison region computed by the computation module, the control module does not change the stroke of the electrode and / or the voltage class of a transformer. According to the embodiment of the invention, the electrode load of the ore-smelting electric furnace can be automatically adjusted so as to ensure balanced load control of the three-phase electrode of a large-sized ore-smelting circuit, thus reducing the reactive loss of the circuit, prolonging the service lives of the circuit transformer and a high-voltage circuit breaker, and achieving high precision and good real-time property; a primary current is taken as the most principal load control parameter, which is beneficial to improvement on the control precision; and by means of judgment of electrode faults, the safety operatingperformance of the ore-smelting electric furnace can be further improved.

Owner:云南文山斗南锰业股份有限公司

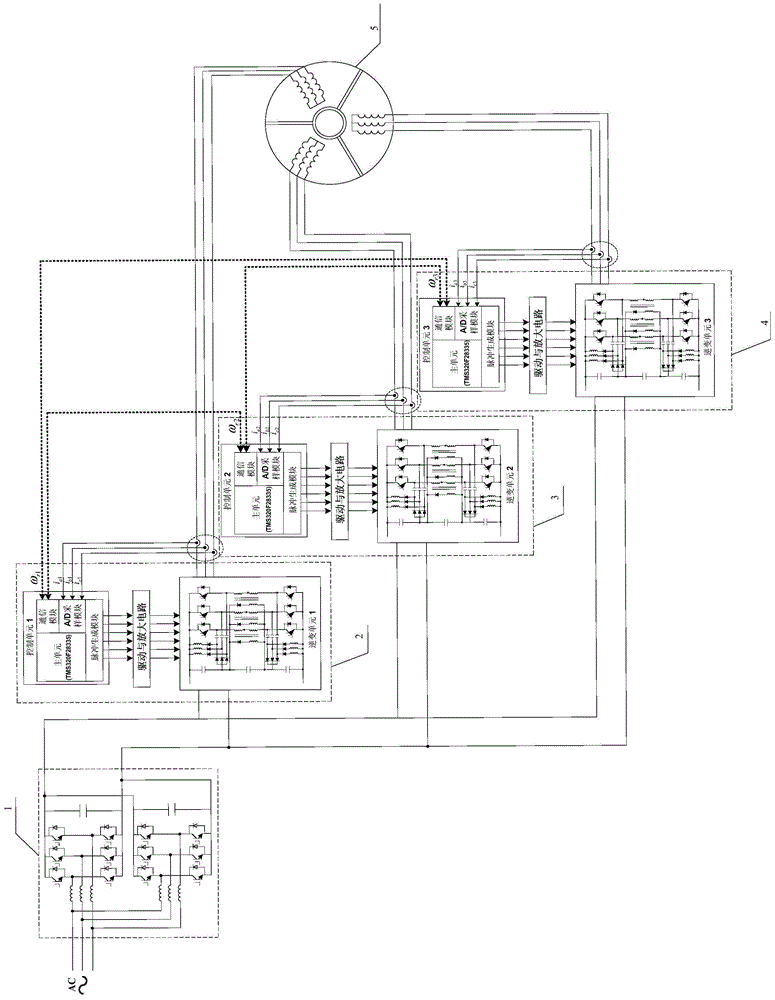

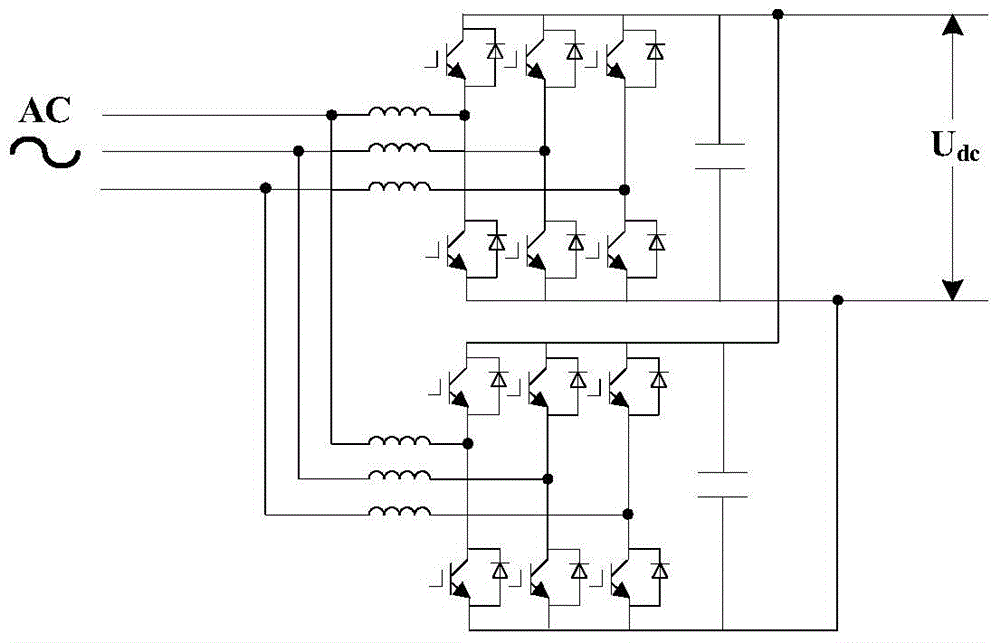

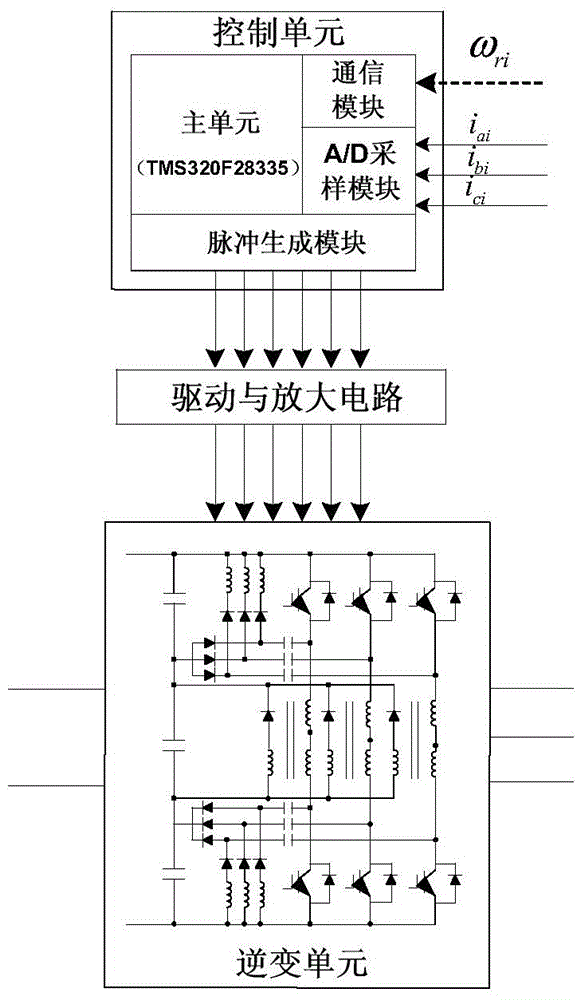

Intelligent cooperative control system of multi-unit permanent magnet synchronous motor and method thereof

InactiveCN105007014AReduce switching lossesIncrease profitAC motor controlAc-dc conversion without reversalLow speedLow voltage

The invention, which belongs to the technical field of the power electronics and electrical drives, provides an intelligent cooperative control system of a multi-unit permanent magnet synchronous motor and a method thereof. According to the invention, a structure of parallel connection of low-voltage multiple permanent magnet motor cooperative control units is employed to realize low-voltage, high-power, low-speed, large-torque control and system redundancy control. On the basis of the dual-parallel PWM rectification circuit structure, when the system is in an unbalanced power supply network environment, two groups of PWM rectifiers are respectively used for controlling positive-sequence and negative-sequence currents, thereby reducing the reactive loss and the harmonic loss. An inverter unit uses a resonance pole type three-phase soft switch inversion circuit, so that the utilization rate of the direct-current bus voltage is improved and the switching loss of the device in a high-frequency state can be substantially reduced. In terms of permanent magnet motor control, a current control and speed estimation unit is used for estimating velocity and phase angle information of a rotor accurately, and the cost is low and reliability is high. The controlled object is a multi-unit permanent magnet synchronous motor, so that problems of difficult motor installation, transport and maintenance for the high-power electrical transmission system can be solved.

Owner:NORTHEASTERN UNIV LIAONING +1

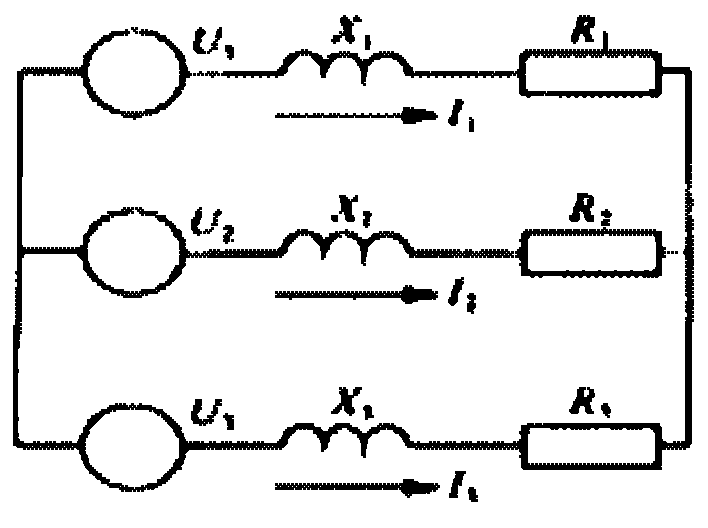

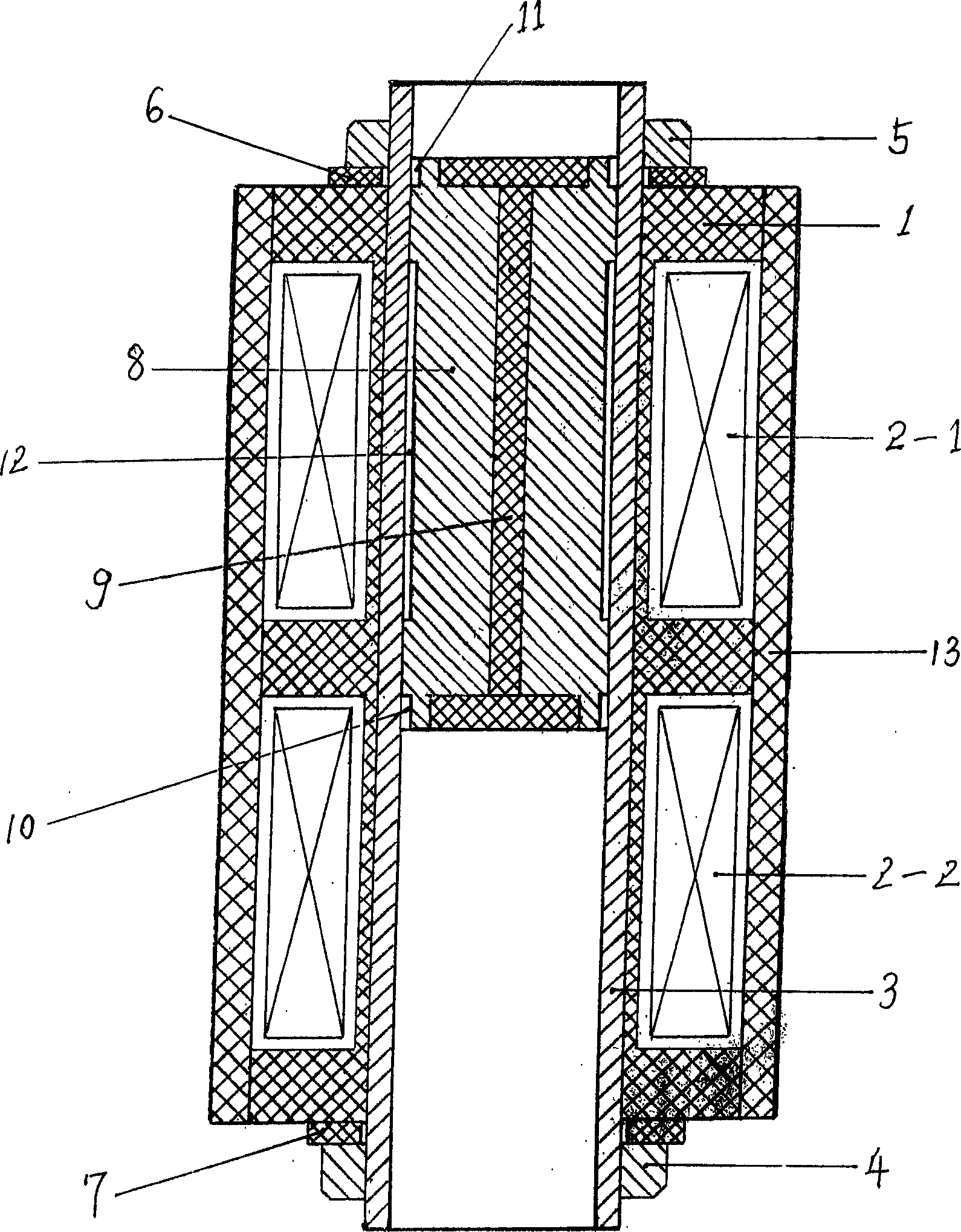

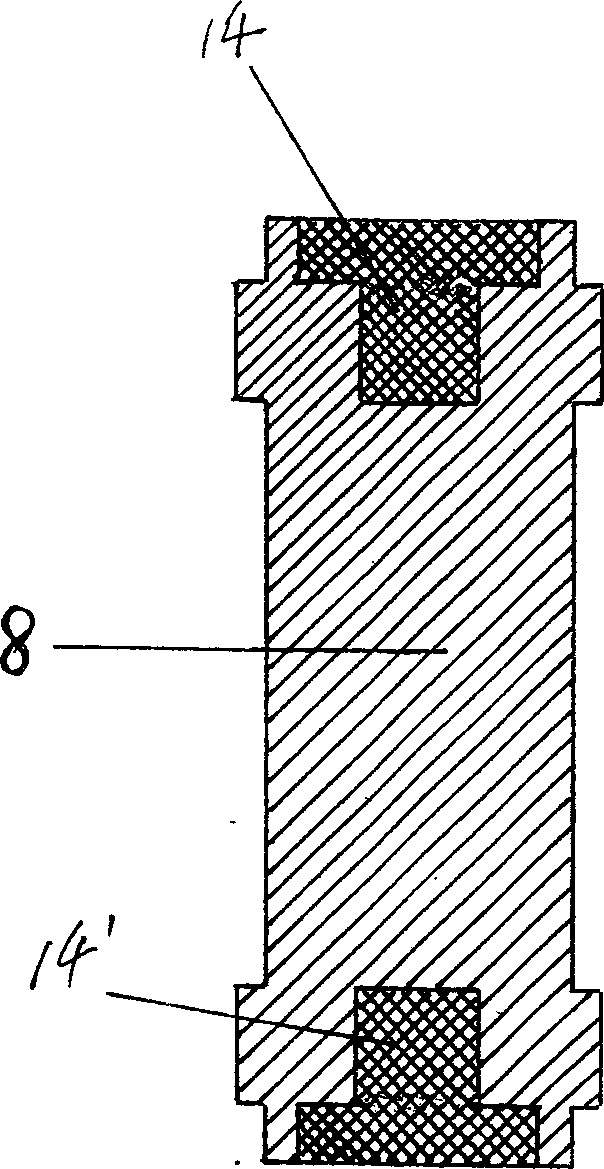

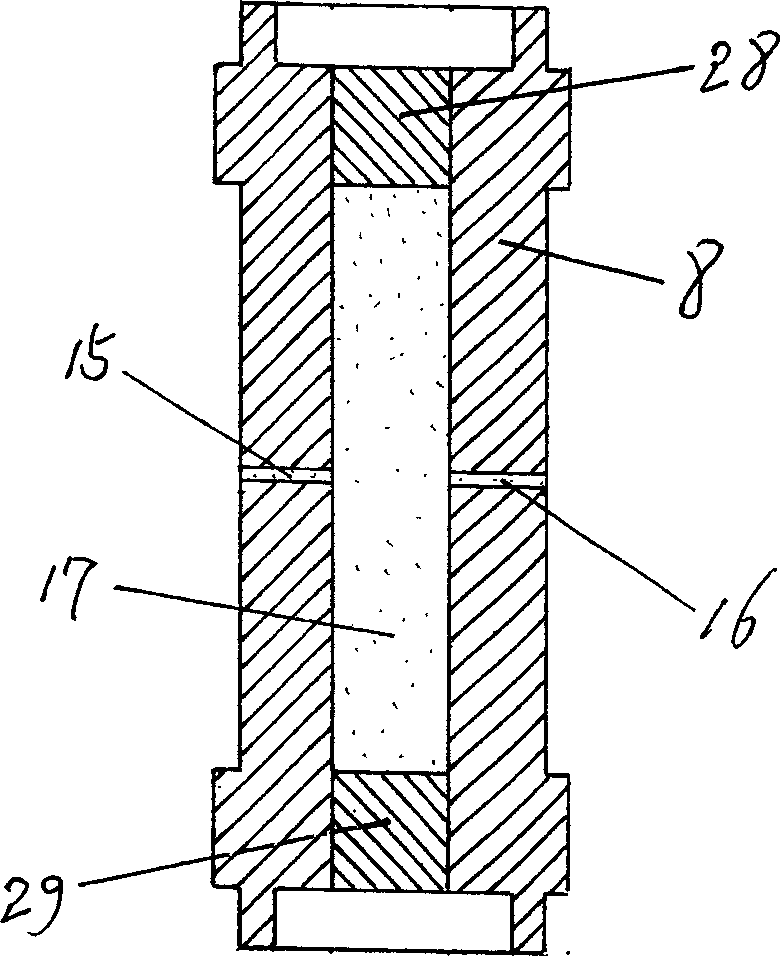

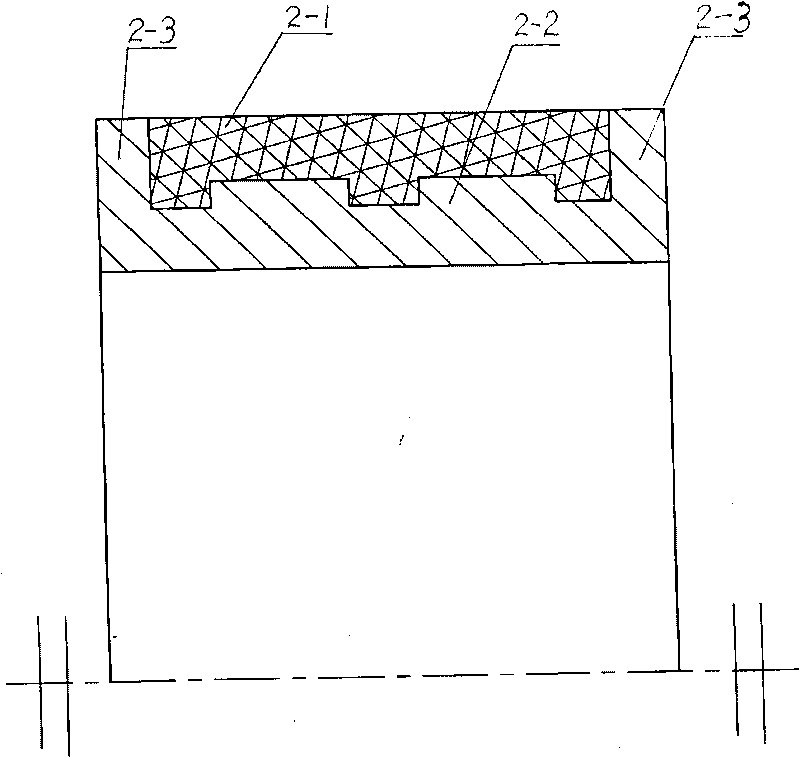

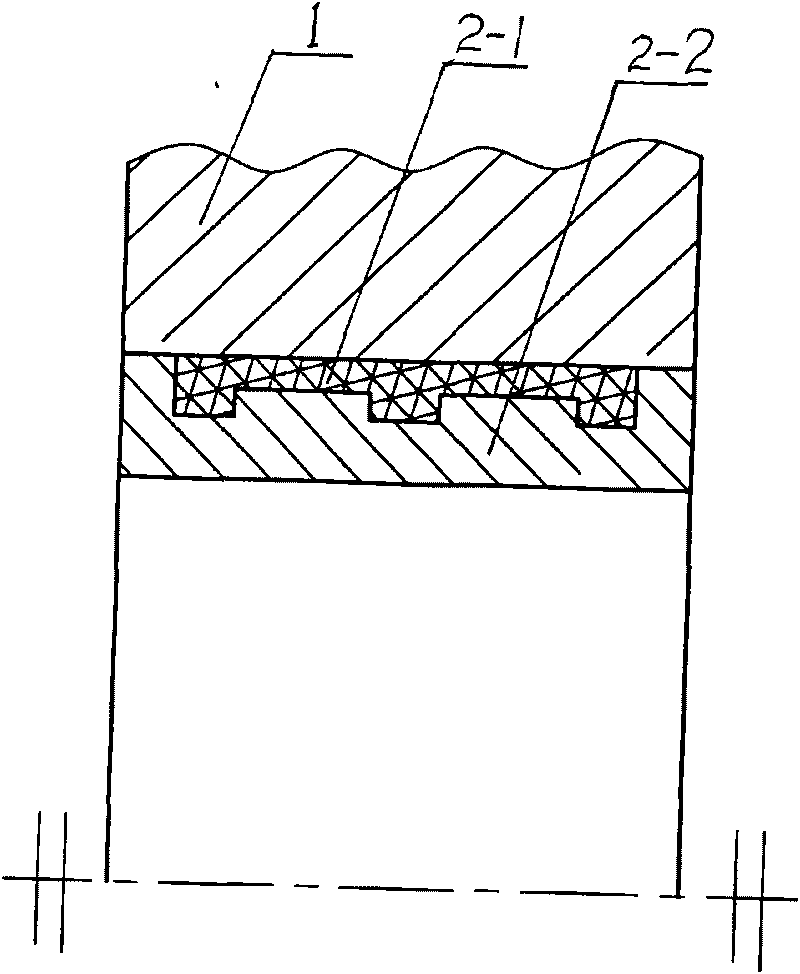

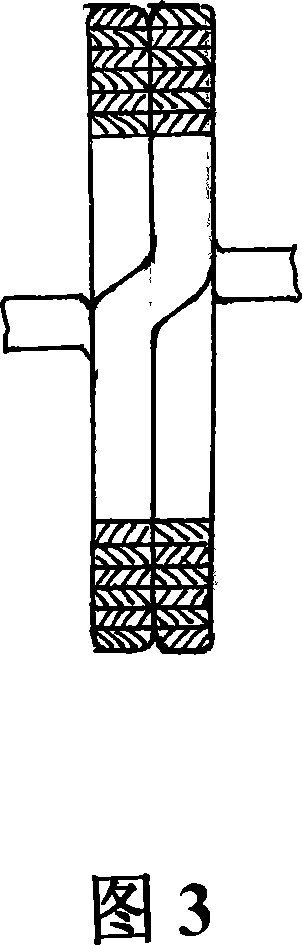

Reluctance type linear oscillating motor and its integrative application device and power supply method

InactiveCN1756053AIncrease profitReduce reactive power lossDynamo-electric machinesMagnetic reluctanceAir compressor

The invention discloses a reluctance linear oscillating motor which axially assembles two excitation coils (2-1 and 2-2) and utilizes the pulsating direct current excitation of positive and passive half-periods of single-phase alternating current to be flowed in the two excitation coils (2-1 and 2-2) on the two ends of motor to make the magnetic field back and forth reposition between two ends of motor, and the iron core (8) of cylinder mover inside the motor utilizes the magneto-resistive least principle to back and forth reposition following the magnetic reluctance, and straightly repeating moves inside the cylinder with two-way output function; and it has the characters of plunger piston and cylinder of compressor to realize the continuous output of liquid or gas via the bridge rectifying tube formed by four one-way control valves on the two ends of motor. And the motor uses the silicone lubricant to make the high pressure gas output by the air compressor without oil and the two-way output structure of said reluctance linear oscillating motor can be demounted to supply linear driving motor with independent power source for impacting and compressing to simplify the structure of these machines.

Owner:张玉宝

Floating wheel type water turbine

InactiveCN102345549AIncrease the water interception areaReduce load-bearing frictionBarrages/weirsWater-power plantsHigh energyEngineering

The invention relates to a water turbine used for operations such as hydroelectric power generation, water pumping and the like by using nature water flow and low water head. The water turbine is characterized in that a water wheel is composed of a floating barrel and blades provided with independent seal cavities, the water wheel rotates by absorbing water energy so as to provide power for the water turbine and generally provide buoyant force support for the water turbine simultaneously; and the water turbine is divided into a built-in type water turbine and an external type water turbine and the main difference between the two types of water turbine is that a generator, a gear case and the like are placed inside or outside the floating barrel. The water turbine provided by the invention has the advantages of low manufacturing cost and operating cost and high energy conversion rate, and is applicable to multiple occasions.

Owner:杨春义

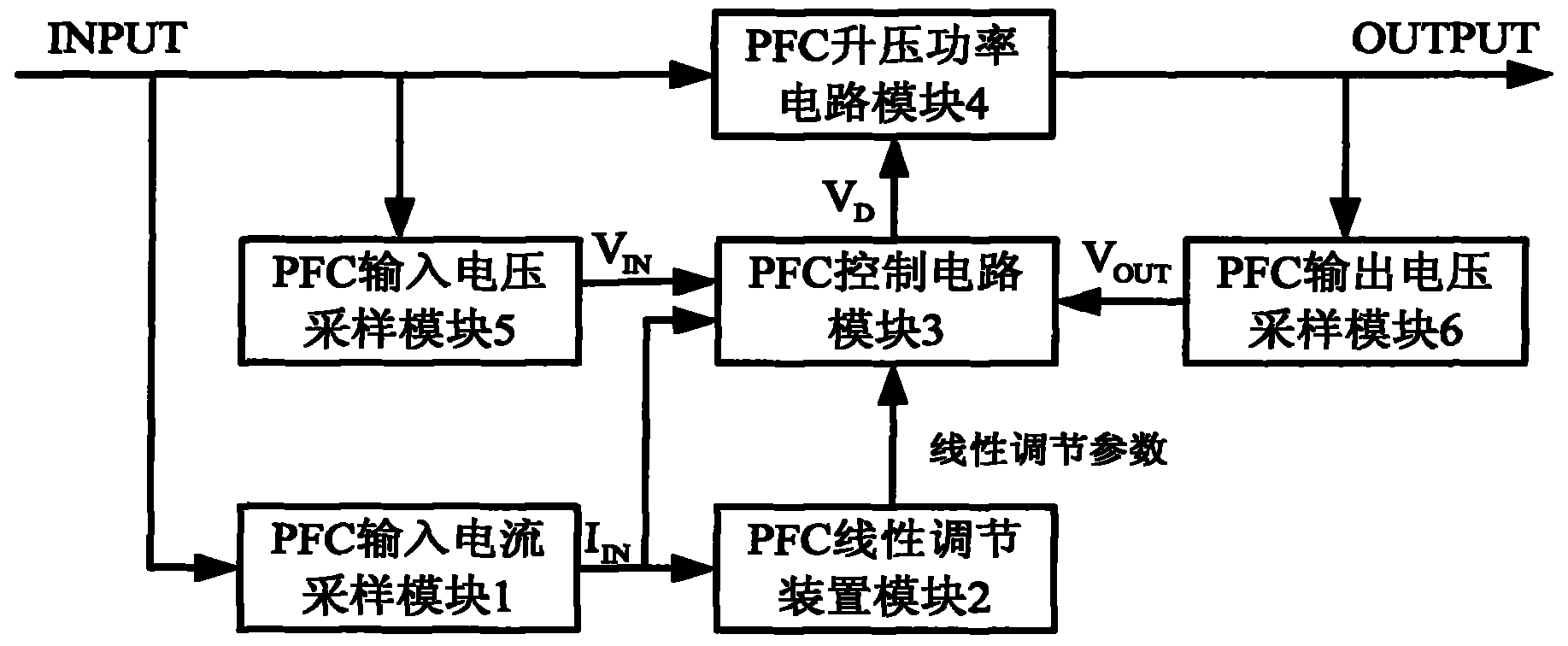

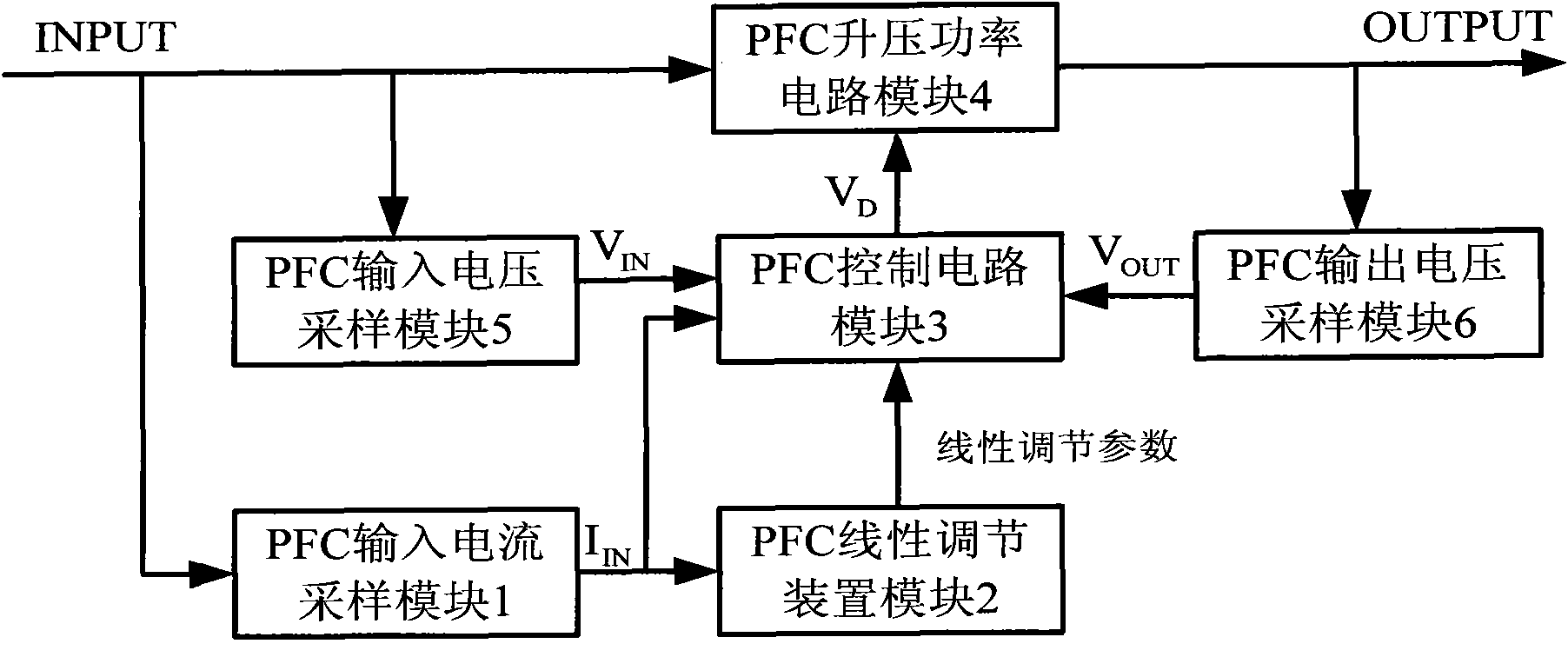

Linear-regulated PFC (Power Factor Correction) control circuit and control method

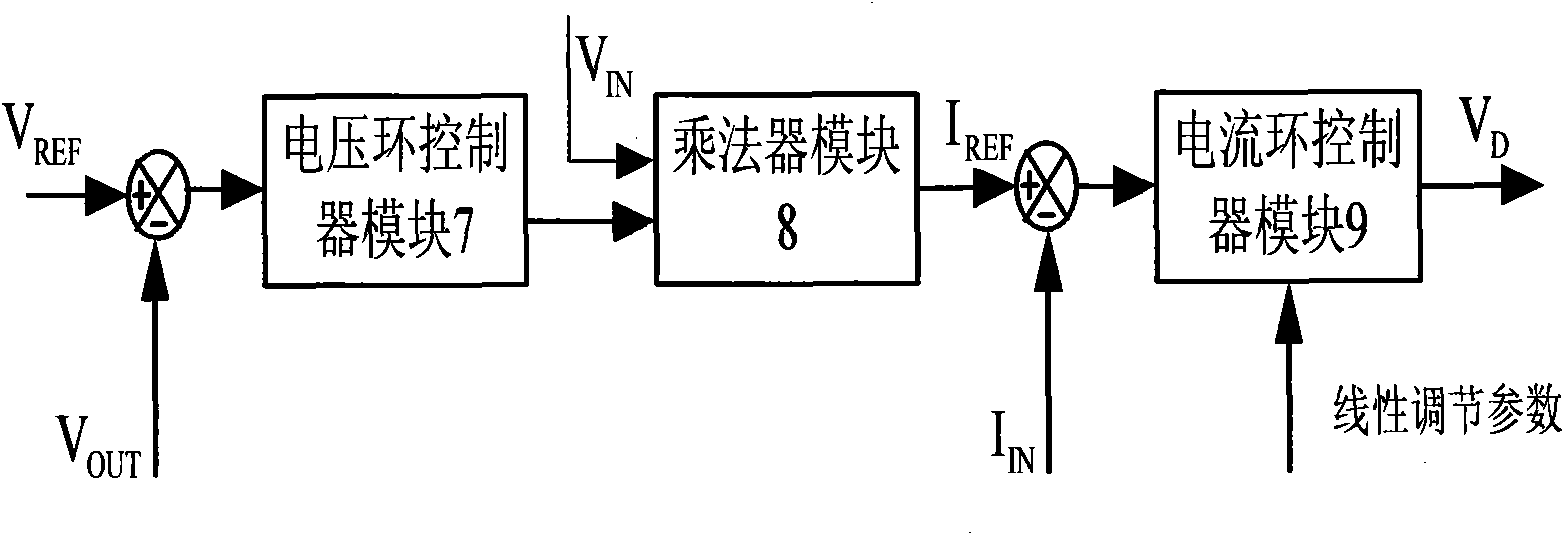

ActiveCN101814825AActive Waveform ControlImprove machine efficiencyEfficient power electronics conversionEnergy industryPower factorHeavy load

The invention discloses a linear-regulated PFC control circuit which comprises a PFC input voltage sampling module, a PFC input current sampling module, a PFC output voltage sampling module, a PFC control circuit module, a PFC output voltage-boosting power circuit module and a PFC linear regulation module, wherein the PFC linear regulation module is used for generating a linear regulation parameter of the linear regulation for the current loop control executed by the PFC control circuit module within the range from a heavy load to a light load according to the input current sampled by the PFC input current sampling module, and the PFC control circuit module is used for generating a wave generating signal of the linear regulation control for the PFC output voltage-boosting power circuit module according to the linear regulation parameter. An inner loop parameter is linearly regulated by utilizing the size of the load or the input current to finish effective wave shape control and obtain index optimization within a full-load range, and meanwhile, the overall efficiency within the light-load range is improved and the reactive power loss is reduced.

Owner:NANJING ZHONGXING SOFTWARE

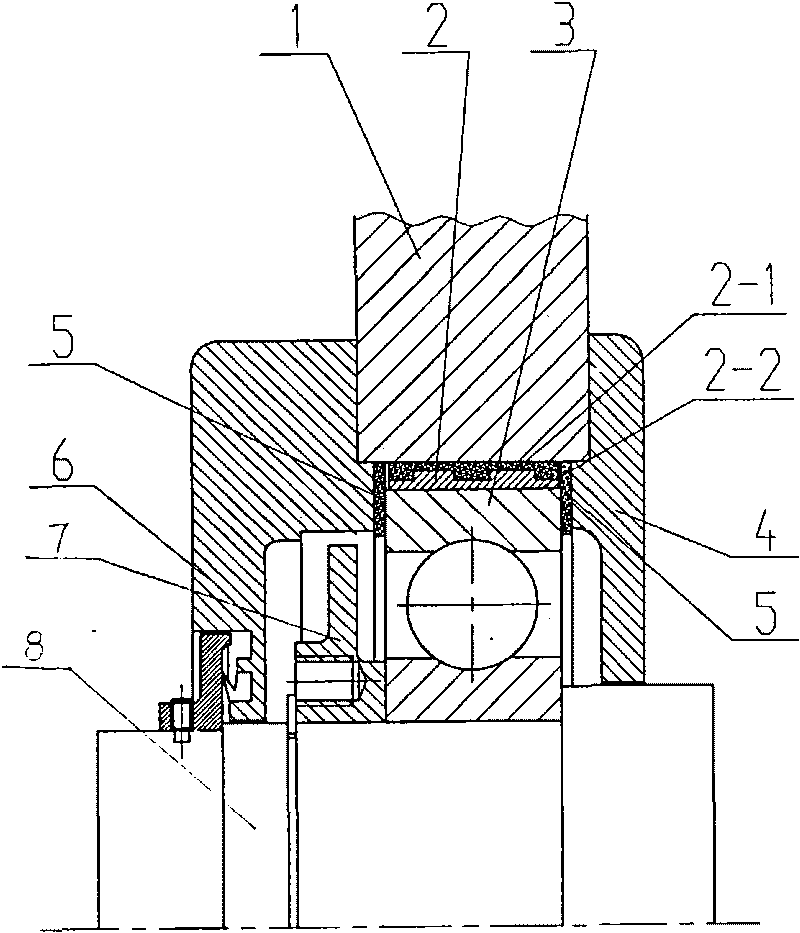

Motor insulating bearing device and manufacturing method thereof

InactiveCN101692590AGuaranteed uptimeExtended service lifeSupports/enclosures/casingsMotor insulationEngineering

The invention relates to a motor insulating bearing device and a manufacturing method thereof. The bearing device is characterized in that an insulating bushing is positioned at a circumference part between a bearing pedestal and a motor bearing, insulating space rings are arranged between the end of the insulating bushing and the motor bearing and an outer bearing cover and between the end thereof and an inner bearing cover, and a gap is left between the insulating space ring and the insulating bushing. The motor insulating bearing device is manufactured by a unique method, the formation of rotor axial current loop is prevented effectively and the electric corrosion damage of the motor bearing is avoided, thereby ensuring the reliable operation of the motor, prolonging the service life of the motor and decreasing the reactive power loss of the electric energy at the same time; the motor insulating bearing device has the advantages of reasonable structure design, reliable operational performance and convenient installation and maintenance, etc.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

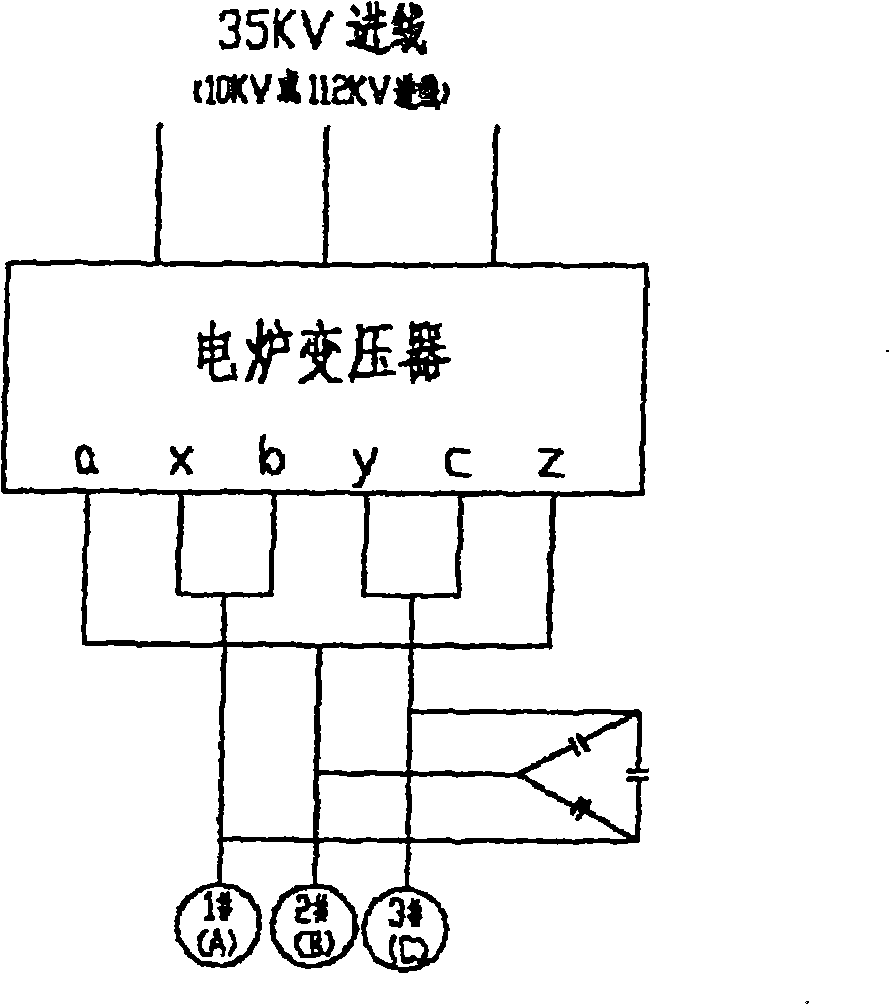

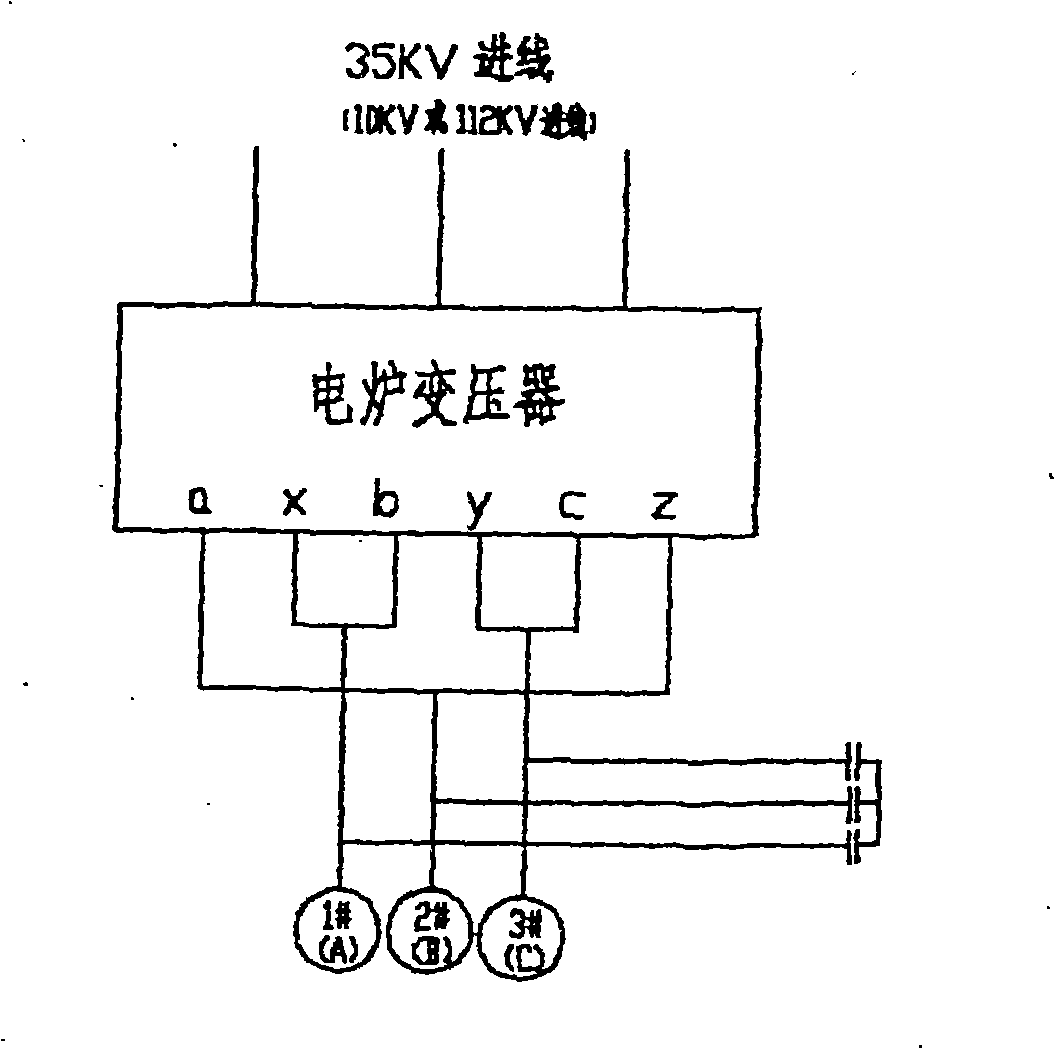

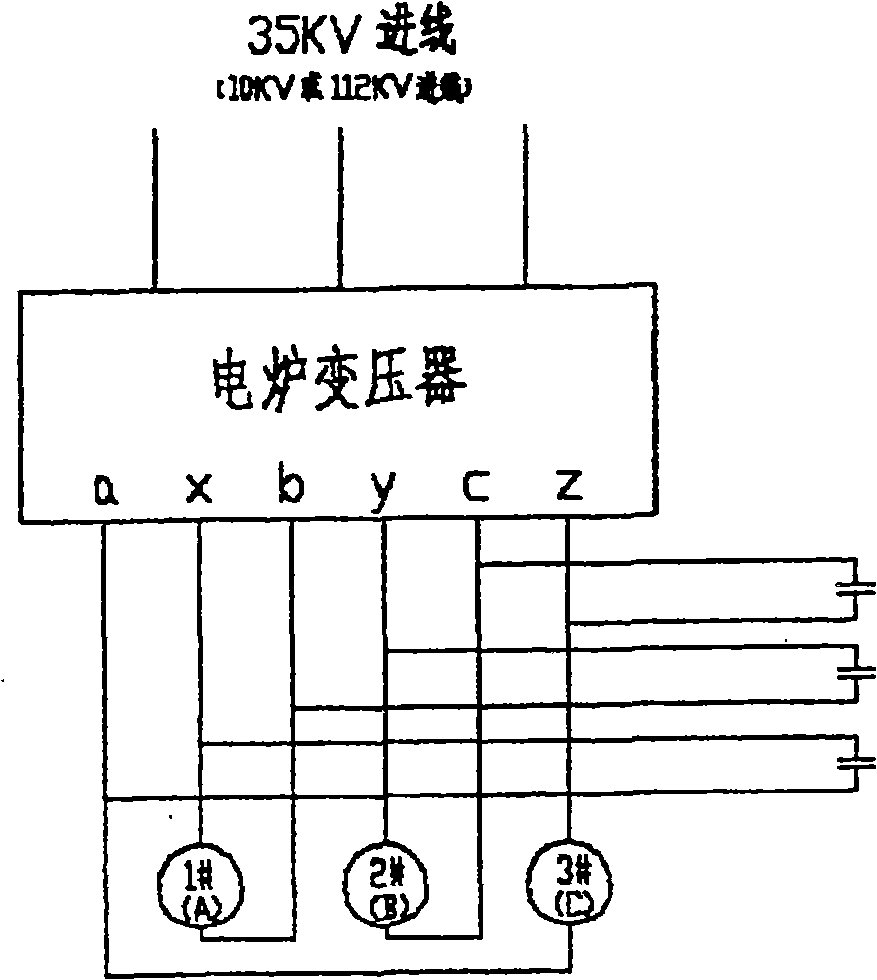

Low-voltage reactive compensator capable of saving energy of electric arc furnace

InactiveCN101330217AIncrease productionReduce reactive power lossLighting and heating apparatusReactive power adjustment/elimination/compensationElectric arc furnacePower factor

The invention discloses a low-voltage reactive power compensating device used for saving the energy of an electric arc furnace. The device comprises a three-phase compensating circuit which is respectively connected with the secondary side of a furnace transformer through the short network of a compensating system, the short network of the compensating system is connected with a fast acting fuse and a reactance in series, each phase of the three-phase compensating circuit comprises a capacitor, and a static compensator is composed by connecting the capacitor with the short network of the compensating system through a connecting wire. The device can greatly improve the power factor, and have high production efficiency and low production cost.

Owner:西安瑞驰电力设备有限公司

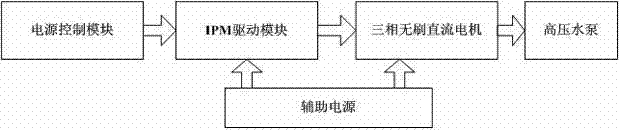

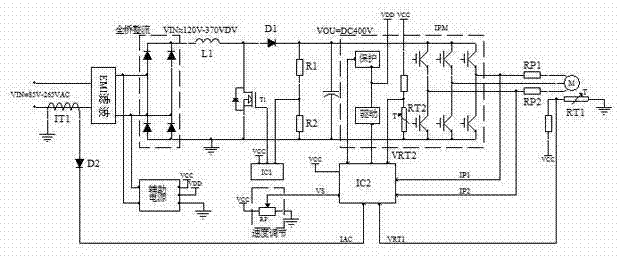

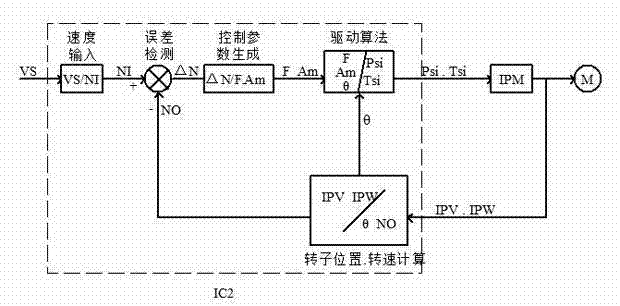

High-pressure washer driving system and method based on brushless direct current motor

ActiveCN104289489AImprove energy conversion efficiencyReduce lossCleaning using liquidsPower factorHigh-voltage direct current

The invention discloses a high-pressure washer driving system and method based on a brushless direct current motor. The system comprises a power supply control module, an IPM driving module and the three-phase brushless direct current motor, wherein the power supply control module is used for being externally connected with an alternating current power supply and outputting direct voltage through EMI filtering, rectification and power factor compensation; the IPM driving module is used for controlling the rotating speed of the three-phase brushless direct current motor; the three-phase brushless direct current motor is used for outputting power to a high-pressure water pump; the power supply control module outputs and supplies the high direct voltage to the IPM driving module, the IPM driving module controls the three-phase brushless direct current motor to output the power to the high-pressure water pump, energy conversion efficiency of a high-pressure washer is improved, under limits of low input currents, high power output is achieved, energy consumption is effectively reduced, a free gear speed regulation function is achieved, the high-pressure washer outputs different types of pressure and flow values, and the system and method have good application prospects.

Owner:SUMEC HARDWARE & TOOLS

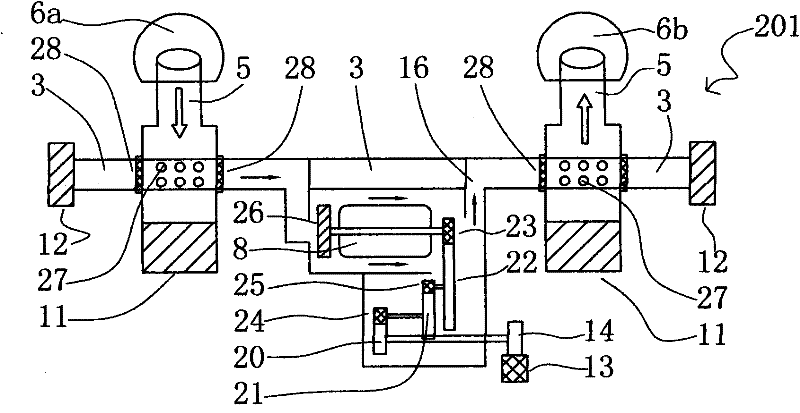

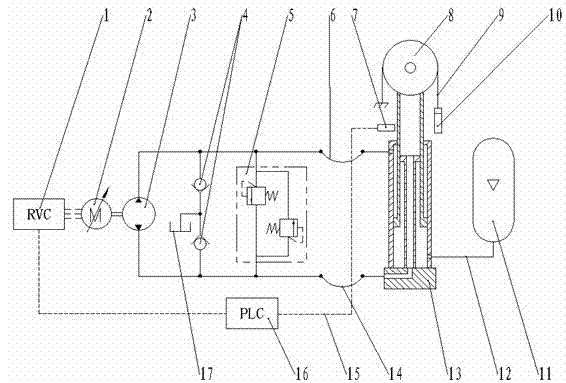

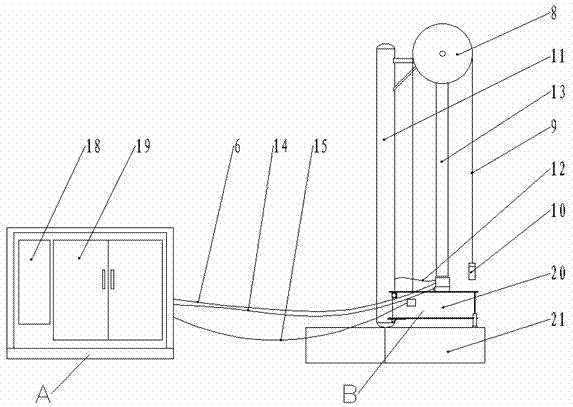

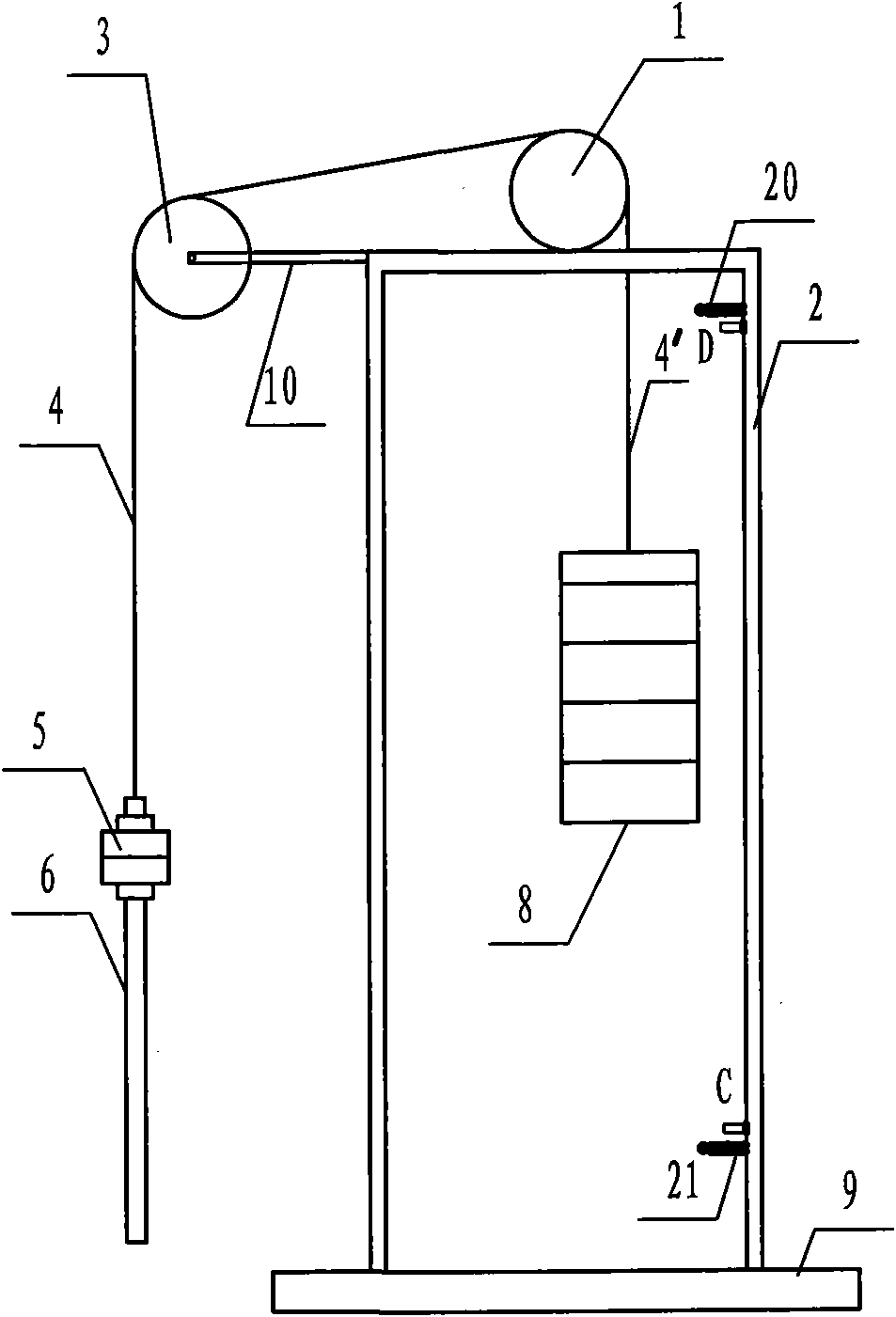

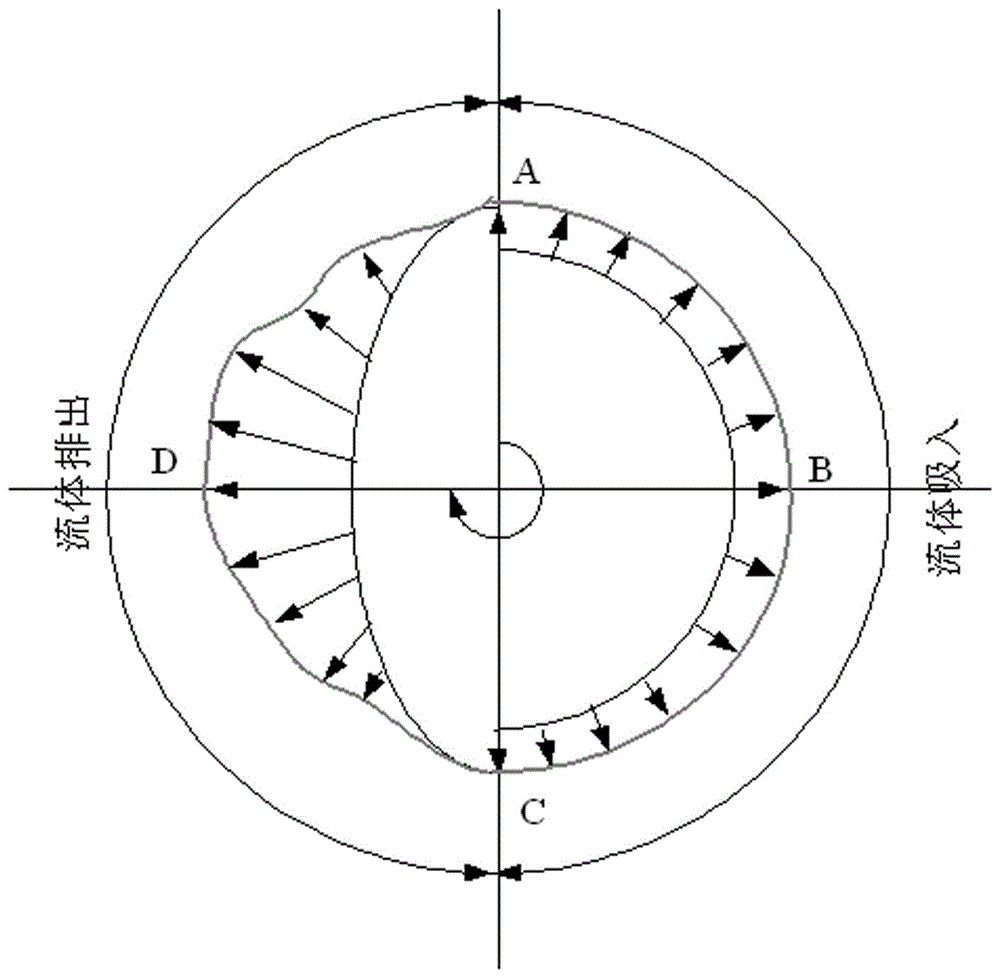

Compact hydraulic oil pumping machine adopting composited pneumatic-hydraulic cylinder

ActiveCN102900400AReduce reactive power lossIncrease loading capacityFluid removalHydraulic cylinderHydraulic circuit

The invention discloses a compact hydraulic oil pumping machine adopting a composited pneumatic-hydraulic cylinder, which comprises a power unit and an oil pumping unit, wherein the oil pumping unit is an executing part of the hydraulic oil pumping machine, directly placed at a wellhead and used for driving a polish rod; and the power unit is connected with the oil pumping unit through an oil pipe and a control cable, and used for controlling and driving the oil pumping unit to move. A closed hydraulic circuit of a three-cavity composited pneumatic-hydraulic cylinder is controlled by using a variable-rotational-speed pump, the up-and-down motion of a piston rod of the composited pneumatic-hydraulic cylinder drives a movable block, and the movable block lifts a beam hanger at the tail end of a steel wire rope wound around the movable block so as to realize an oil pumping process of a sucker-rod pump. A balance weight cavity of the composited pneumatic-hydraulic cylinder is connected with a nitrogen tank so as to realize pneumatic balance. The three-cavity composited pneumatic-hydraulic cylinder and the nitrogen tank both are functional parts and brackets of the oil pumping machine, and a walking beam and a truss are not required. An effect of pneumatic balance and an effect of variable-frequency valveless direct drive are simultaneously achieved by using the three-cavity composited pneumatic-hydraulic cylinder; and the compact hydraulic oil pumping machine is large in load capacity, compact in structure, steplessly regulated in stroke and jig frequency, small in reactive loss of motors, and high in oil pumping efficiency.

Owner:ZHEJIANG UNIV

Overrunning type clutch transmission mechanism of motorcycle

InactiveCN101648587AAvoid separationExtended service lifeVehicle transmissionFreewheel clutchesEmbedded systemEnergy conservation

The invention discloses an overrunning type clutch transmission mechanism of a motorcycle, comprising a casing, a main clutch and a variable-speed device, wherein a power output shaft of the main clutch is matched with a power input shaft of the variable-speed device in a transmission way by an overrunning clutch. In the parking operation process, the invention can eliminate the influence of the experience of a driver, does not depend on the operation of the main clutch, can automatically cut off a transmission chain before parking, enables a vehicle to glide, thereby avoiding the long-time separation running of the main clutch and prolonging the service life of the main clutch; moreover, the gliding transmission chain is shorter, reactive loss is reduced and the invention is beneficial to energy saving; and the transmission mechanism enables the driver to successfully carry out the parking operation, ensures safe driving, is beneficial to protecting the variable-speed device and the clutch and lowers the operation and maintenance cost.

Owner:CHONGQING LONCIN MOTOR

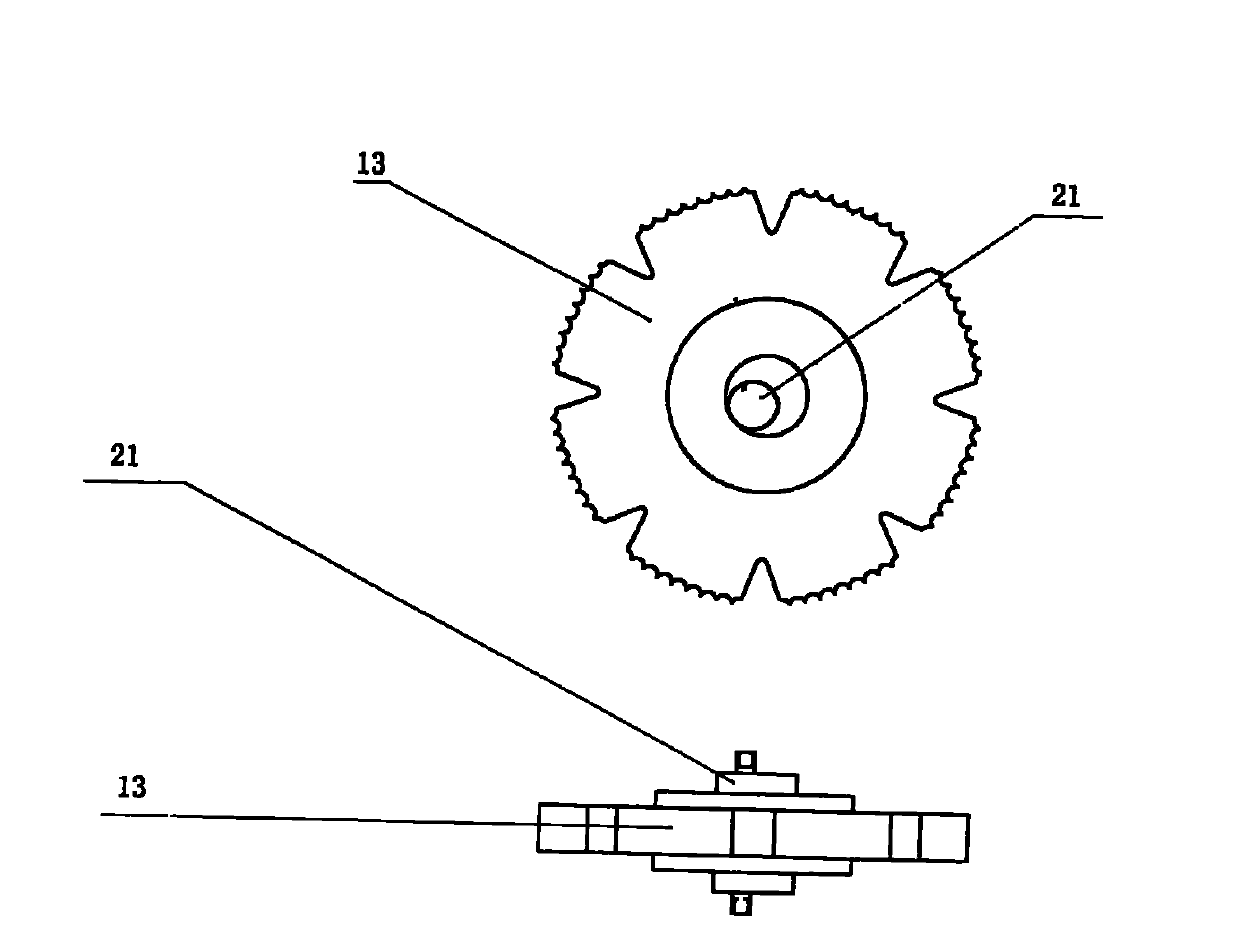

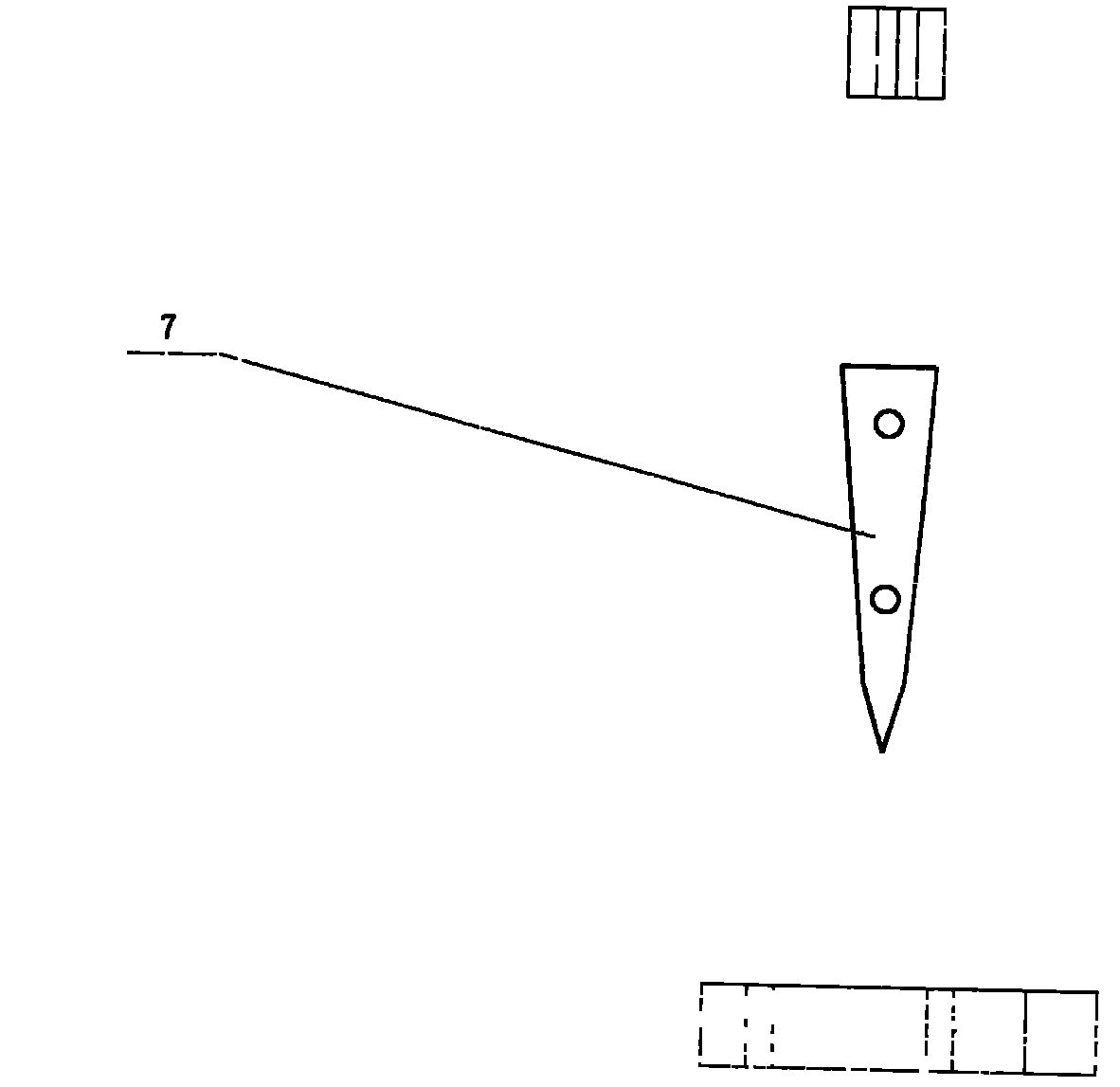

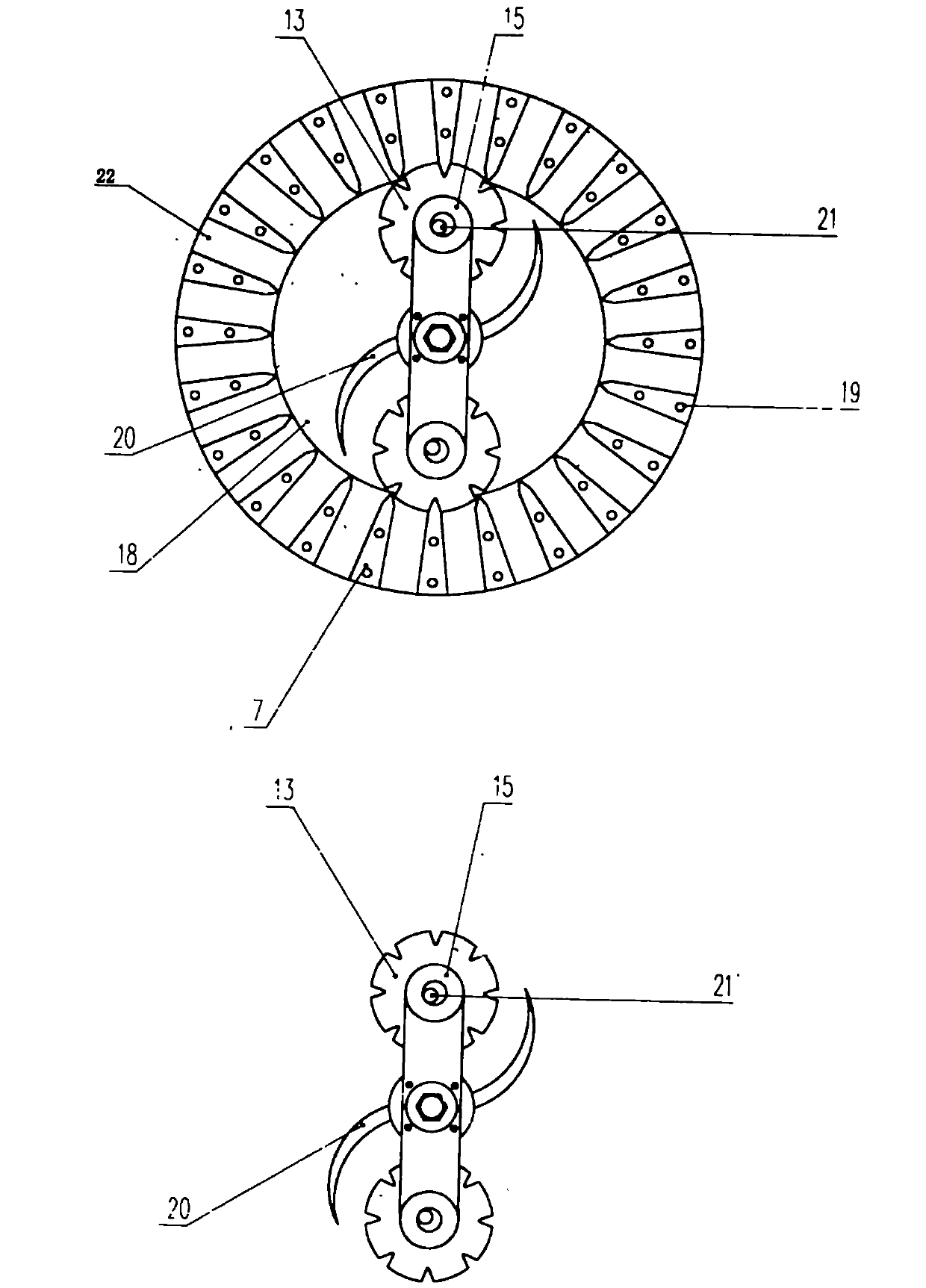

Biomass molding machine with annular tooth-shaped mold

InactiveCN102310578AImprove performanceReduce sensitivityShaping pressMolding machineInjection molding machine

The invention discloses a biomass molding machine with an annular tooth-shaped mold. When a biomass raw material enters a molding cavity, a tooth-shaped pressure roller and the annular tooth-shaped mold synchronously and relatively rotate, so that the raw material entering the molding cavity is fed into a molding mold hole under the mutual clamping action of the tooth-shaped pressure roller and the annular tooth-shaped mold instead of being extruded freely into the molding mold hole; a tooth-shaped pressure roller point is used for further pushing the raw material into the molding mold hole; the discharging speed of the raw material entering a molding mold under the forced pushing action of the pressure roller tooth point is not decreased, and hole blocking and machine halt are avoided; and the idle rotating time of the raw material which rotates along with the tooth-shaped pressure roller is reduced. The raw materials are pressed into the molding mold hole at any time, so that the characteristics of various raw materials and the sensitivity of the molding machine to the raw materials are lowered relatively, reactive loss is reduced, the abrasive degree is lowered, the suitability of the molding machine with the annular tooth-shaped mold for various raw materials is enhanced, the overall performance of the molding machine is enhanced greatly, and the technical defects of the conventional molding machine are overcome remarkably.

Owner:萧钠 +1

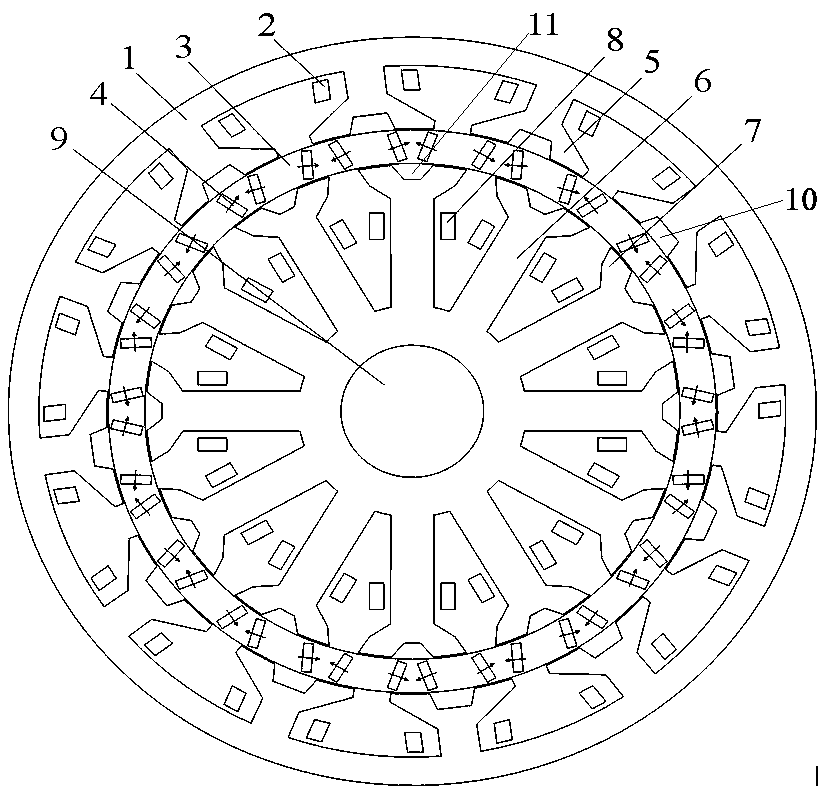

Split-slot magnetic field modulation permanent magnet motor suitable for hybrid electric vehicle

ActiveCN109617267AGood conditionReduce Flux LeakageMagnetic circuit rotating partsMagnetic circuit stationary partsHarmonicPermanent magnet motor

The invention discloses a split-slot magnetic field modulation permanent magnet motor suitable for a hybrid electric vehicle. A plurality of permanent magnets having a rectangular radial section are embedded in the inner part of an intermediate rotor in the circumferential direction, every two permanent magnets form a permanent magnet module, two permanent magnets in one permanent magnet module are arranged in a V-shape and the two permanent magnets are not in contact, one V-shape opening direction of two permanent magnets in two adjacent permanent magnet modules is radially inward and the other V-shape opening direction is radially outward when the two permanent magnets are arranged in a V-shape; at the middle of each tooth end of an inner stator, an inner stator imaginary slot is arranged to form two inner stator core salient poles, and at the tooth end of the outer stator of each outer stator, an outer stator imaginary slot is arranged to form two outer stator core salient poles. Based on the principle of magnetic field modulation, the unnecessary harmonics in the air gap magnetic field are reduced and the torque output capability of the motor is enhanced by the cooperation of the split-slot structure of internal and external stators and the V-shaped permanent magnet topology structure of the intermediate rotor.

Owner:JIANGSU UNIV

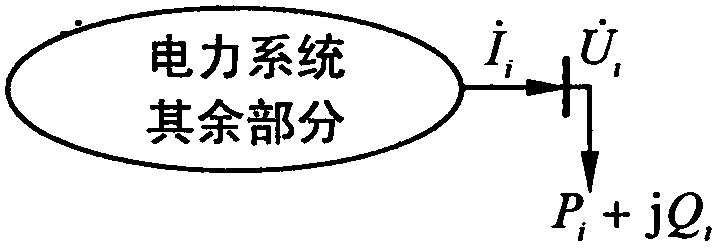

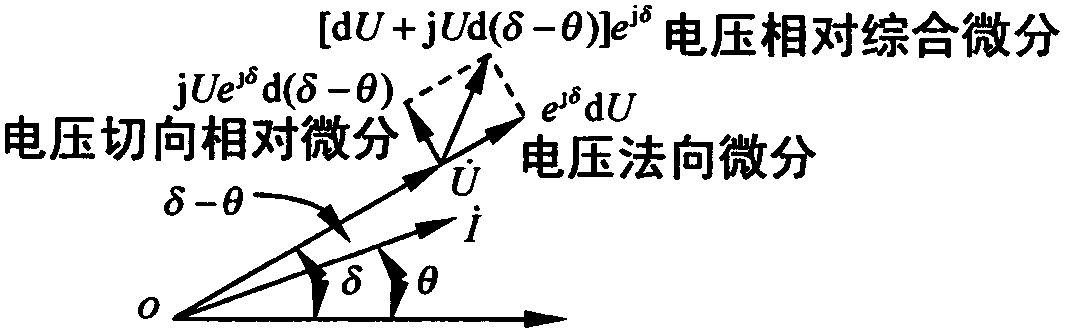

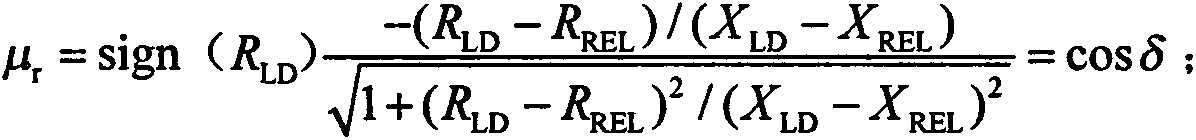

Method for comprehensive evaluation of quiescent voltage stability and power angle stability by using resistance margin

InactiveCN104135008AReduce active powerReduce reactive power lossAc network voltage adjustmentElectrical resistance and conductancePower flow

The invention provides a method for comprehensive evaluation of quiescent voltage stability and power angle stability by using resistance margin, belonging to the field of a power system. Based on a power flow quotation, the dynamic characteristic of system power is considered to be injected, relatively comprehensive dynamic equivalence is carried out on the system, from a view of a PV node, the relatively comprehensive dynamic equivalence impedance of the system and the resistance margin index of the node are calculated, and according to the resistance margin index of the node, whether the quiescent voltage and the power angle of the system are subjected to instability is rapidly judged, or the stability degree of the power angle of the PV node is judged. During online application, the calculation of the resistance margin index is independent of the prior knowledge of a load mode in the system. The method can be applicable for online analysis control and offline simulation analysis of the power system, system running and scheduling persons can conveniently take effective measures, the stability level of the system is improved, system planning is facilitated, the scheduling persons can conveniently adopt a reasonable design and running scheme, and the comprehensive static stability level and the economy of system running are improved.

Owner:刘光晔

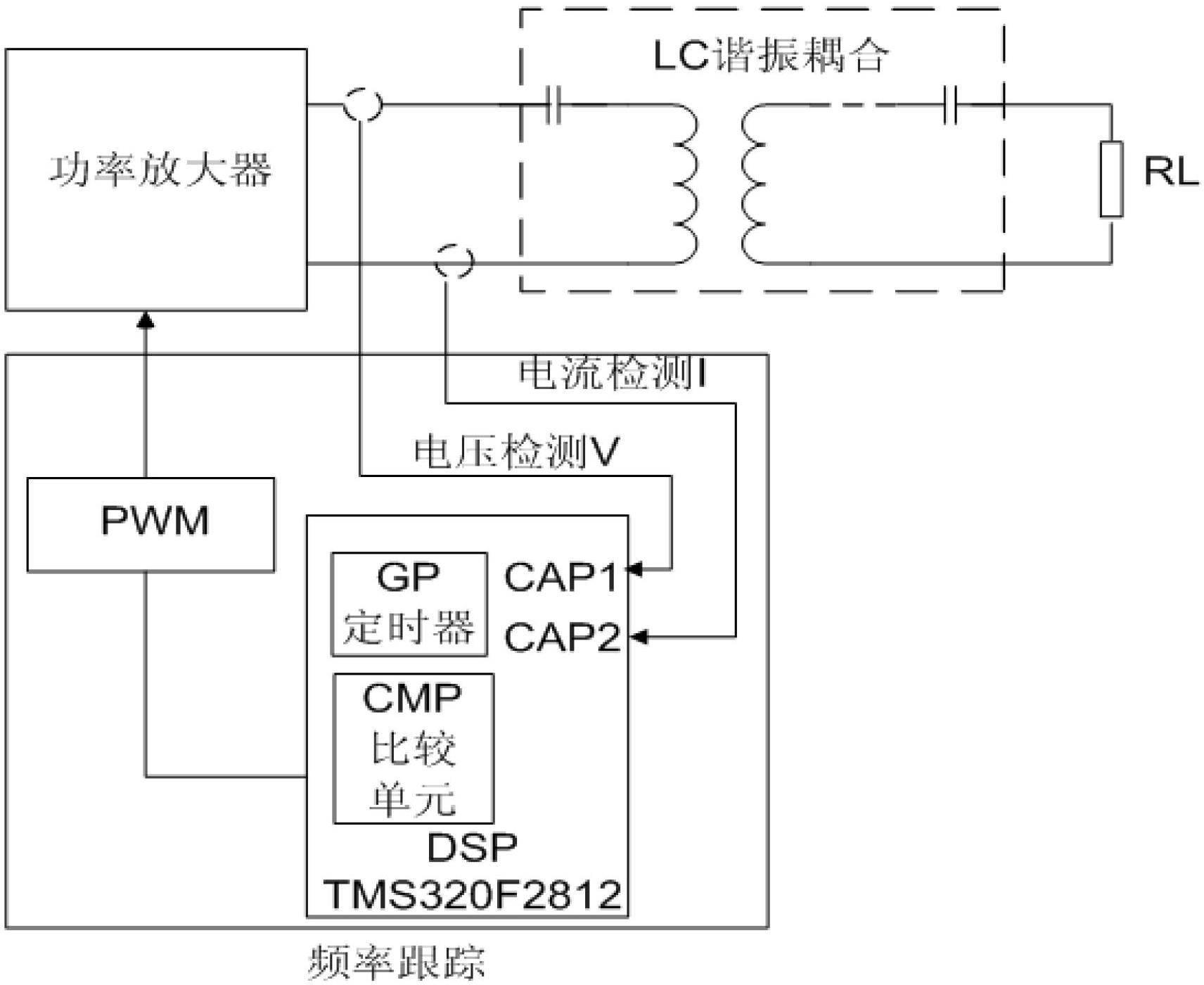

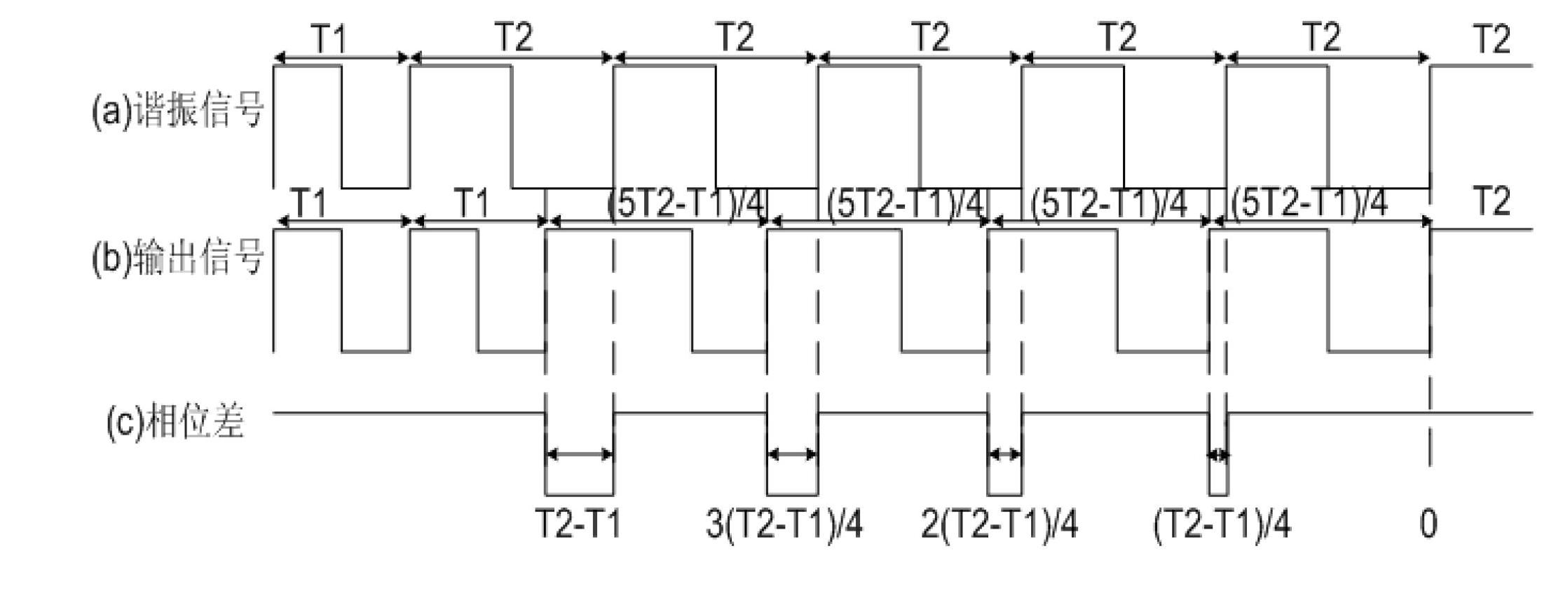

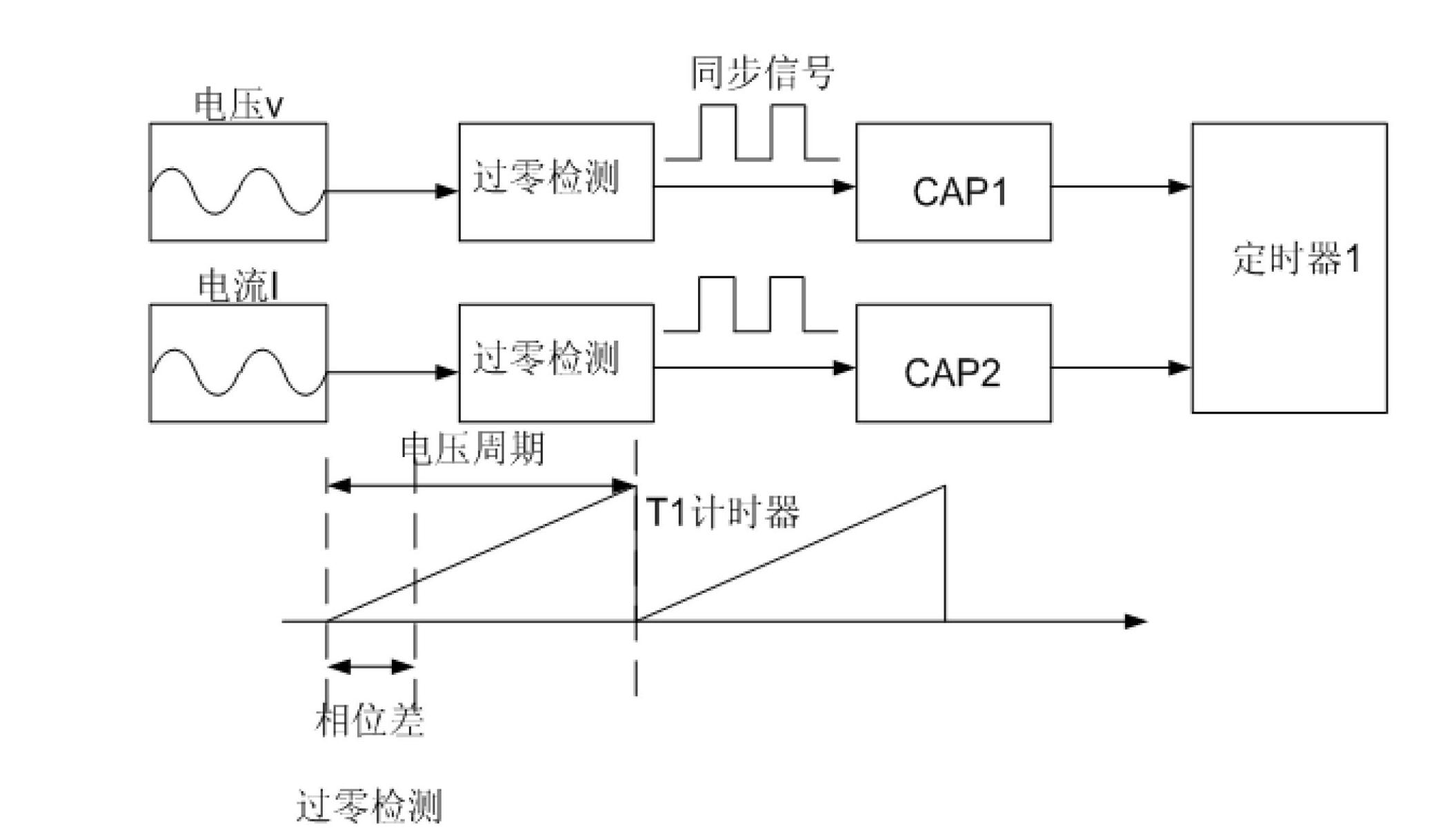

Contactless power transmission (CPT) resonance frequency device based on digital signal processor (DSP) phase lock technique

InactiveCN102647183ASolve the problem that the efficiency will drop sharplyHigh precisionPulse automatic controlDigital signal processingCapacitance

The invention discloses a CPT resonance frequency device based on a DSP phase lock technique. The CPT resonance frequency device based on the DSP phase lock technique mainly comprises a power supply unit, an LC resonance coupler and a frequency tracking unit, wherein the frequency tracking unit comprises a digital signal processor (DSP), the pulse width modulation (PWM) input end of the DSP is connected with a power amplifier connected with the LC resonance coupler, inductors and capacitors of a primary coil and a secondary coil of the LC resonance coupler are arranged symmetrically, PWM waves produced by the DSP are converted to sinusoidal waves through second order filtering, input into the power amplifier, and outputs sinusoidal signals with certain power to the LC resonance coupler. According to the CPT resonance frequency device based on the DSP phase lock technique, signal output power of the power amplifier is controlled by PWM waves produced by the DSP, phase lock is achieved by utilizing the DSP, not only hardware circuits are simplified and cost is reduced, but also problems of burn-in, temperature drift and the like of devices in analog circuits are solved, and accuracy and speed of the phase lock are improved.

Owner:SHANGHAI MARITIME UNIVERSITY

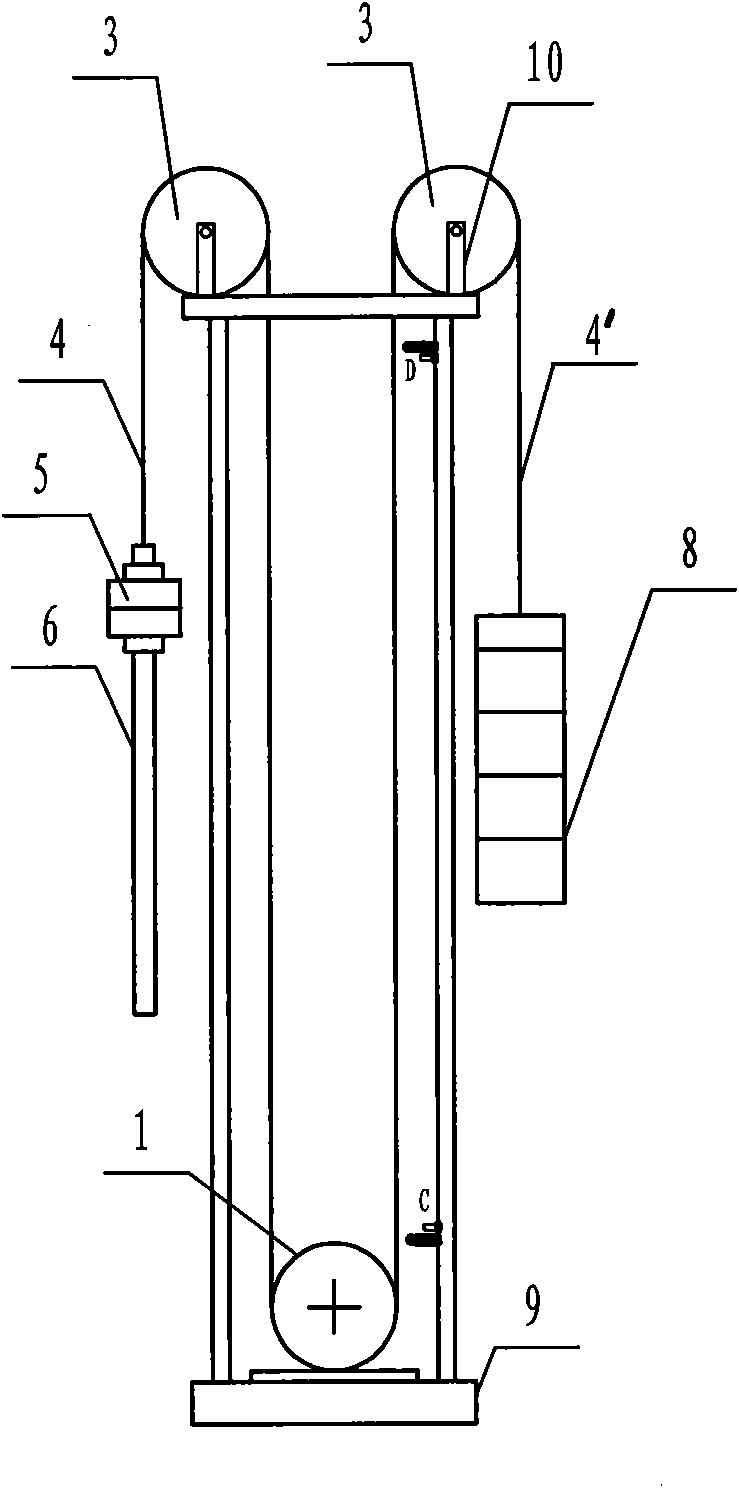

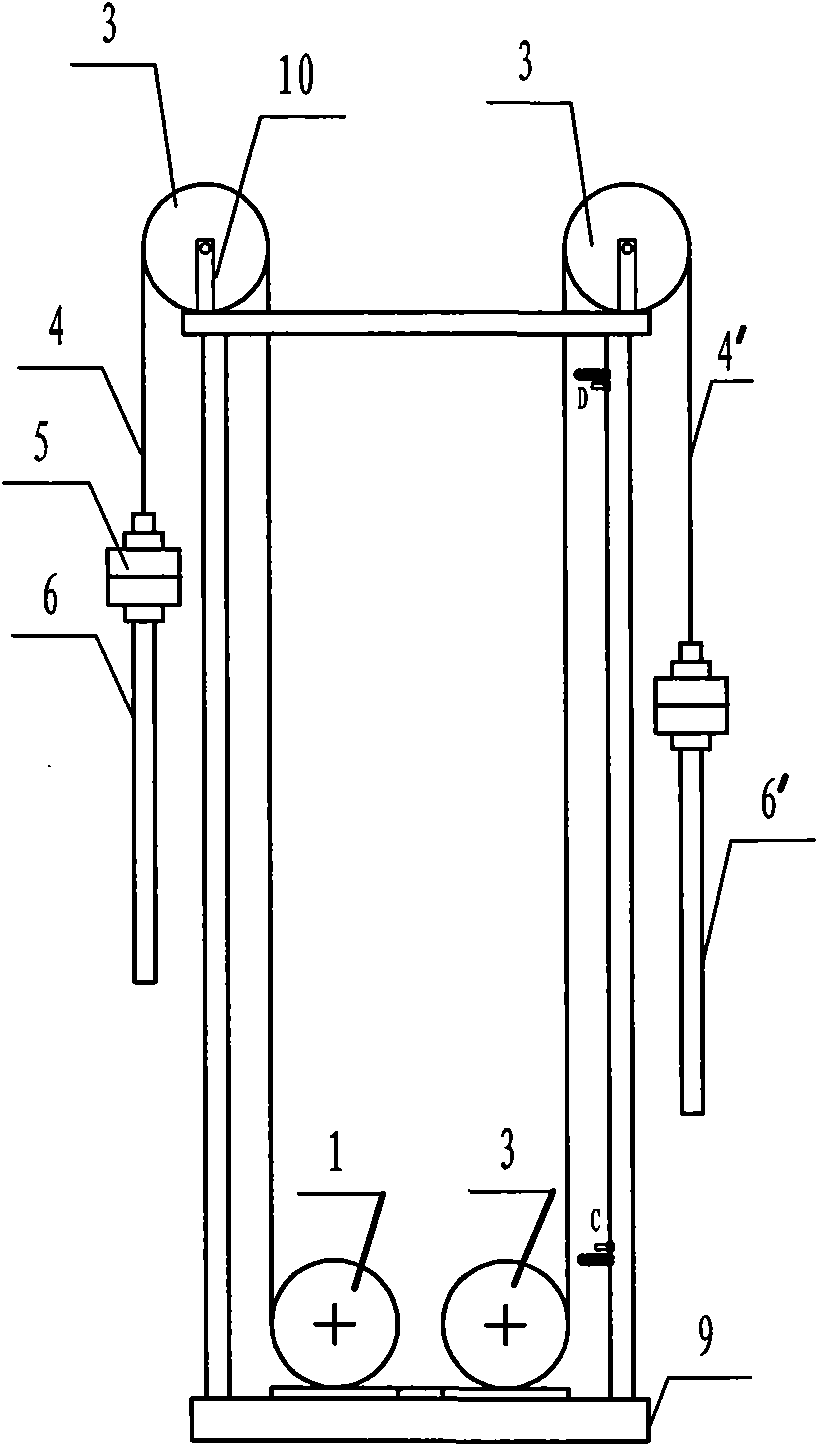

Oil pumping machine

ActiveCN101775970AReduce energy consumptionReduce reactive power lossDrilling rodsFluid removalPetroleumMagnet

The invention discloses an oil pumping machine which comprises a fixedly arranged driving host of a permanent magnet synchronous speed reducer, a pylon fixed on a foundation and a first oil pumping rod driven by the driving host, wherein a steel wire cable drum which is driven by an output shaft of the driving host and wound with two steel wire cables is arranged on the driving host; one end of one steel wire cable is fixed on the drum, while the other end is fixed and articulated to a guide wheel on the pylon through a wheel shaft and then connected with the first oil pumping rod; one end of the other steel wire cable is fixed on the drum, while the other end passes through the guide wheel and then is connected with a counterweight or directly connected with the counterweight without passing through the guide wheel; and the wheel shaft of the guide wheel and the axis of the steel cable drum are horizontally arranged in parallel. The invention has reduced energy consumption, simple structure and convenient maintenance, can conveniently adjust the stroke and the jig frequency of an oil well, has the functions of diagnosing and detecting the working state of the oil well at any time and can further realize digital control and remote network control. The oil pumping machine is used as a petroleum exploitation machine.

Owner:SHIJIAZHUANG TONGAN MACHINERY CO LTD

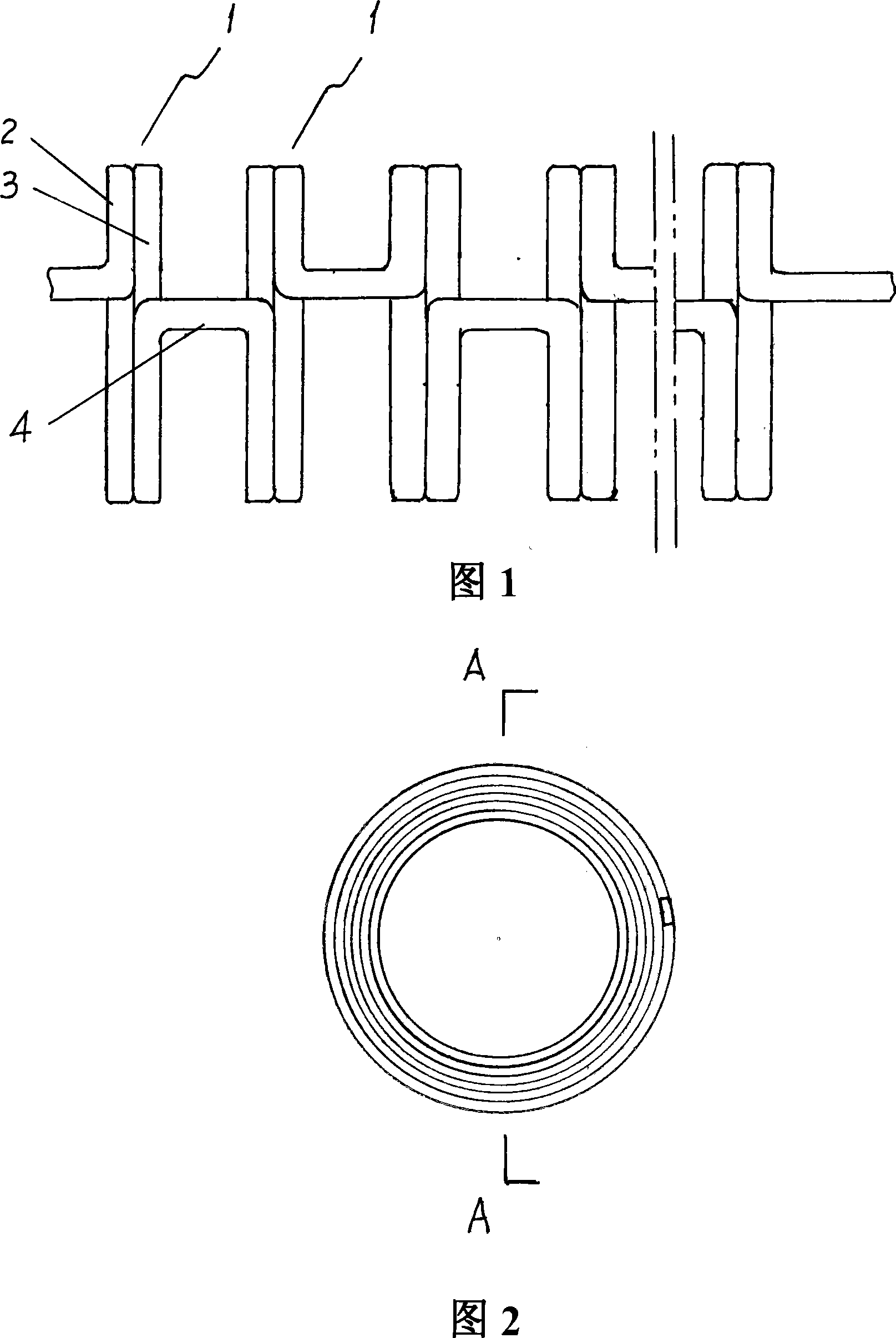

Stator winding of cylinder submersible linear electric machine with oil and its winding method

ActiveCN101090214AIncrease the cross-sectional areaReduce reactive power lossManufacturing dynamo-electric machinesWindings conductor shape/form/constructionElectric machineStator coil

This invention relates to a stator winding of a cylinder-submersible oil linear motor and its winding method characterizing that the stator coil winding is composed of multiple serial single-coke coils and each one is a double-layer structure, one layer is winded clockwise and the other is winded anticlockwise, which is advantaged that the winding structure of the coil is special, and the lead out wires at the two ends are set outside of the coil increasing the power of a linear motor to the utmost and the coil is winded with flat electromagnetic wires so the space of a disk core is fully utilized and the filling rate of the motor groove and section area of the wire are increased greatly and powerless loss of the motor is reduced.

Owner:SHENYANG XINCHENG PETROLEUM MACHINERY MFG

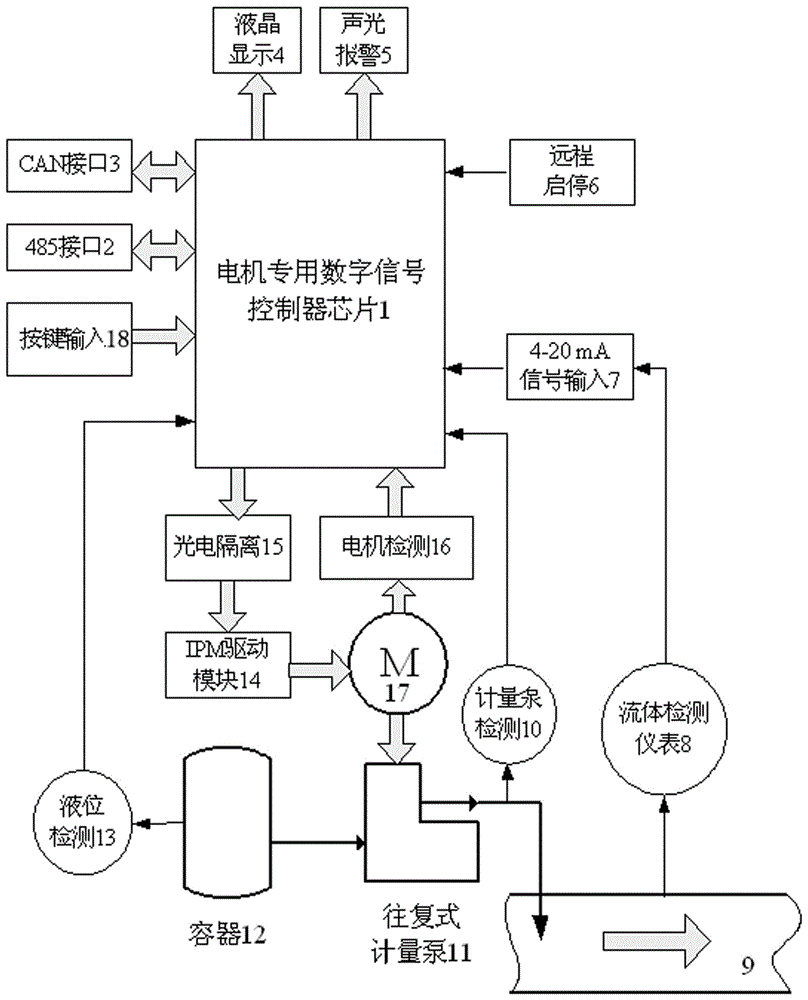

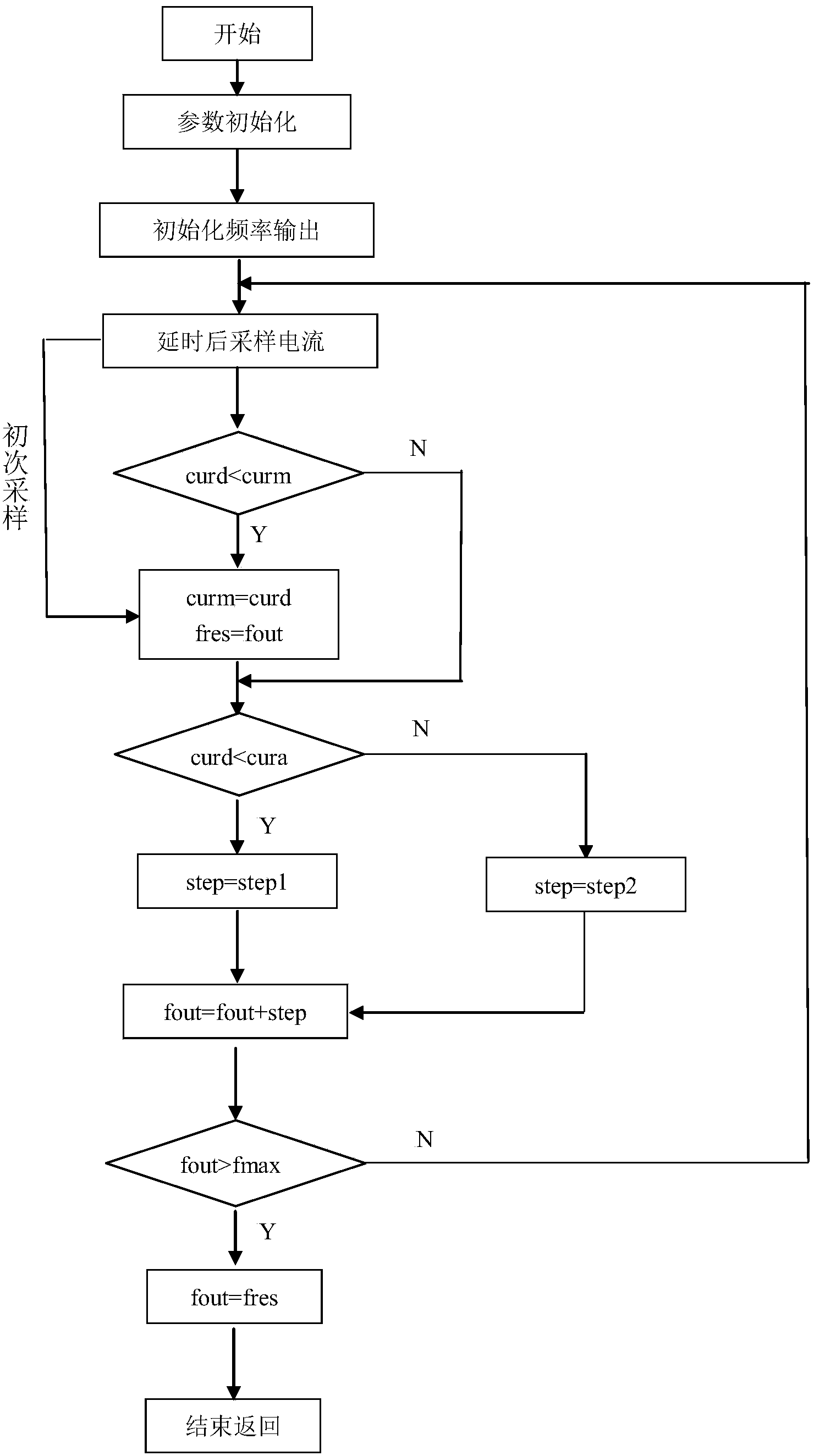

The dynamic compensation method of digital frequency conversion controller specially for industrial metering pump

ActiveCN106685300AReduce impact damageImprove the accuracy of fixed ratio dosingElectronic commutation motor controlAC motor controlMotor speedChemical industry

The invention relates to a dynamic compensation method of a digital frequency conversion controller specially for an industrial metering pump. A quantitative dosing and a proportion dosing of the fluid which are called a quantitative and proportion dosing for short, based on the industrial metering pump, are widely used in the fields such as a petroleum, a chemical industry, a water treatment, a food, a pharmacy, an environmental protection, a liquid fertilization. The dynamic compensation method of the digital frequency conversion controller specially for the industrial metering pump, based on a Hall magnetic steel and a Hall sensor, makes an real-time observation of an rotation speed fluctuation of a metering pump driving motor, transforms the rotation speed fluctuation of the motor into a time fluctuation, and then transforms a rotation speed ring into a time ring in the standard vector control. The dynamic compensation method of the digital frequency conversion controller specially for the industrial metering pump, through a closed-loop control, takes a dynamic compensation to the motor speed and makes the motor running smoothly under a pulsating load for reducing the impact and the damage on the mechanical transmission system, reducing an reactive power loss, driving a module heating and improving the accuracy of the quantitative and proportion dosing of the fluid.

Owner:ZHEJIANG UNIV OF TECH

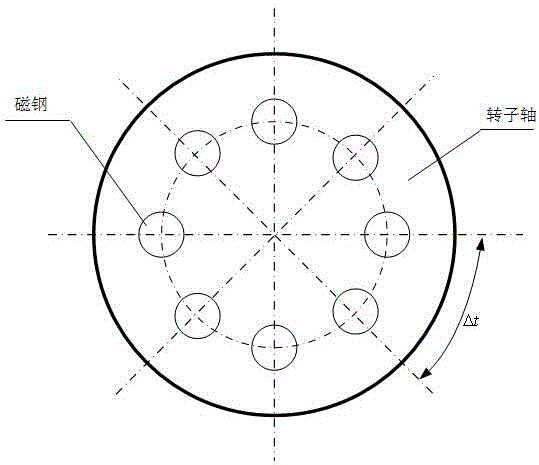

Self-cooling outer rotor motor

PendingCN108155758ALow costReduce noiseMagnetic circuit rotating partsPump componentsCold airEngineering

The invention relates to a self-cooling outer rotor motor. A rotor bracket assembly comprises a rotor bracket and permanent magnetic steel, the magnetic steel is bonded to the inner wall of a cavity of the rotor bracket and is in fit clearance connection with a stator assembly, the rotor bracket comprises an outer cylinder body and an end cover, the end cover is arranged at one end of the outer cylinder body, and a rotating shaft hole is formed in the middle of the end cover. The end cover is provided with a plurality of hollow blades, the blades are evenly distributed on the outer circumference of the rotating shaft hole, and the hollow end cover and the outer cylinder body together constitute an axial flow fan. A gap is reserved between the rotor bracket and a fixing frame assembly; thegap between the rotor bracket and the fixing frame assembly, a gap between the stator assembly and the magnetic steel and a gap between an inner cavity of the outer cylinder body and the end cover constitute a cold air and hot air circulation passage. By using stamping or precision casting, the blades are directly hollowed out on the rotor bracket to form the axial flow fan, so that the purpose ofrapid cooling of the motor without increasing the size of the motor is achieved.

Owner:SHANGHAI HUISHEN TOOL TECH

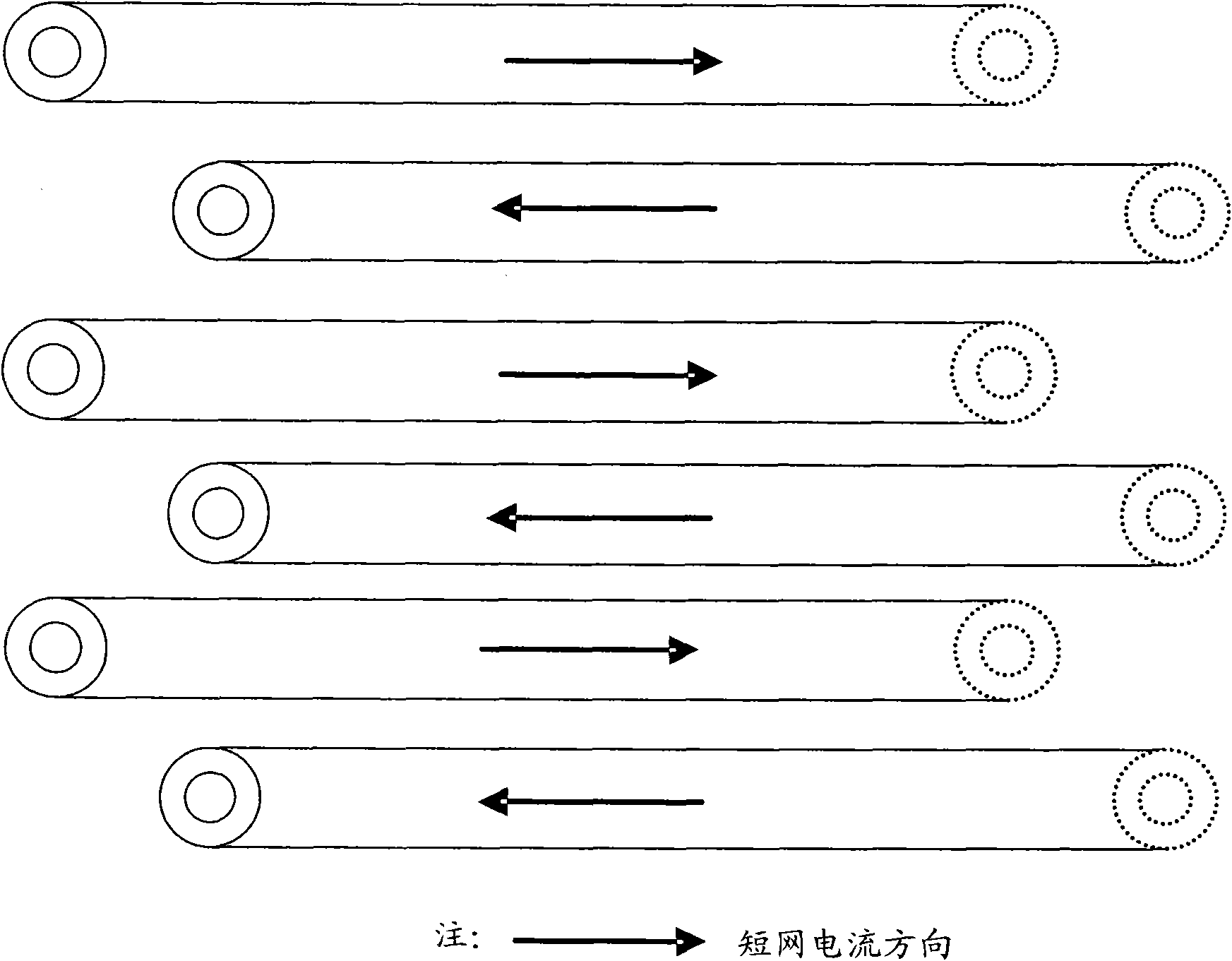

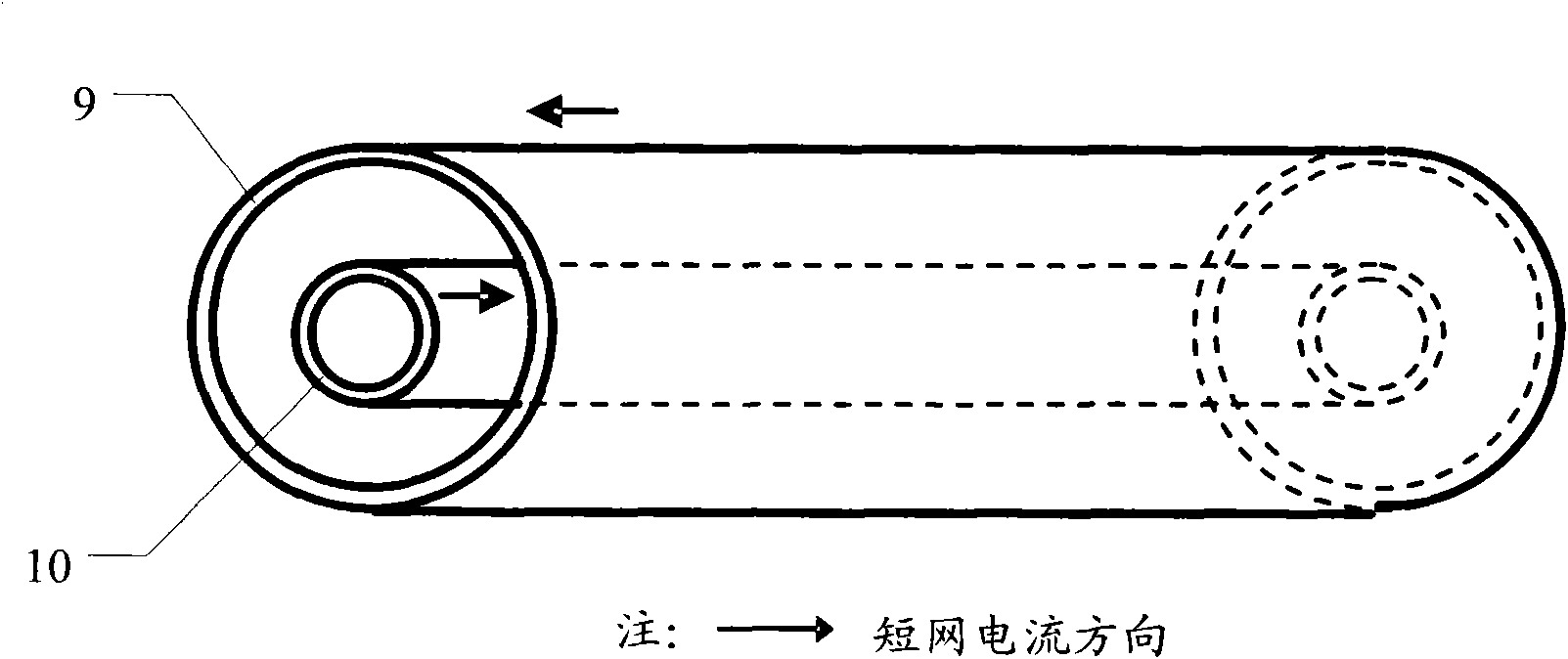

Copper tube and electric furnace energy-saving noninductive short net

InactiveCN102097155ALower overall pressure dropReduce lossNon-insulated conductorsElectric discharge heatingHigh impedanceElectrical conductor

The invention discloses a copper tube and an electric furnace energy-saving noninductive short net, wherein the copper tube comprises a first conductor and a second conductor axially sleeved on the periphery of the first conductor; a first insulation layer is filled between the first conductor and the second conductor; and the electric furnace energy-saving noninductive short net comprises a plurality of parallel conductive pipe fittings, each conductive pipe fitting comprises the first conductor and the second conductor axially sleeved on the periphery of the first conductor; and the first insulation layer is filled between each first conductor and the corresponding second conductor. By means of the electric furnace energy-saving noninductive short net provided by the invention, the defects of high inductive reactance, high impedance, low natural power factor, high unit power consumption and the like in the prior art are overcome, and the advantages of low inductive reactance, low impedance, high natural power factor and low unit power consumption are realized.

Owner:郭延武 +2

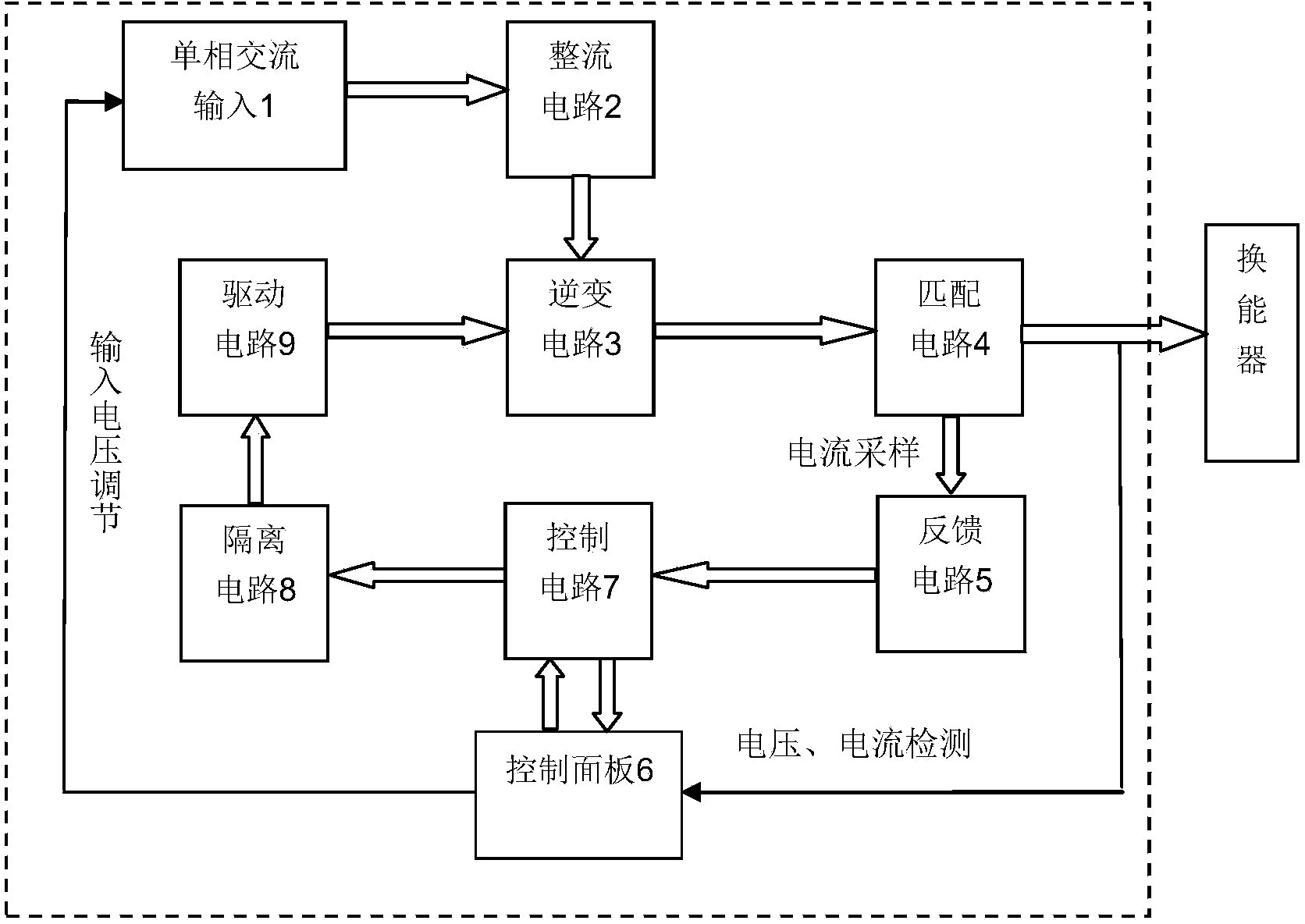

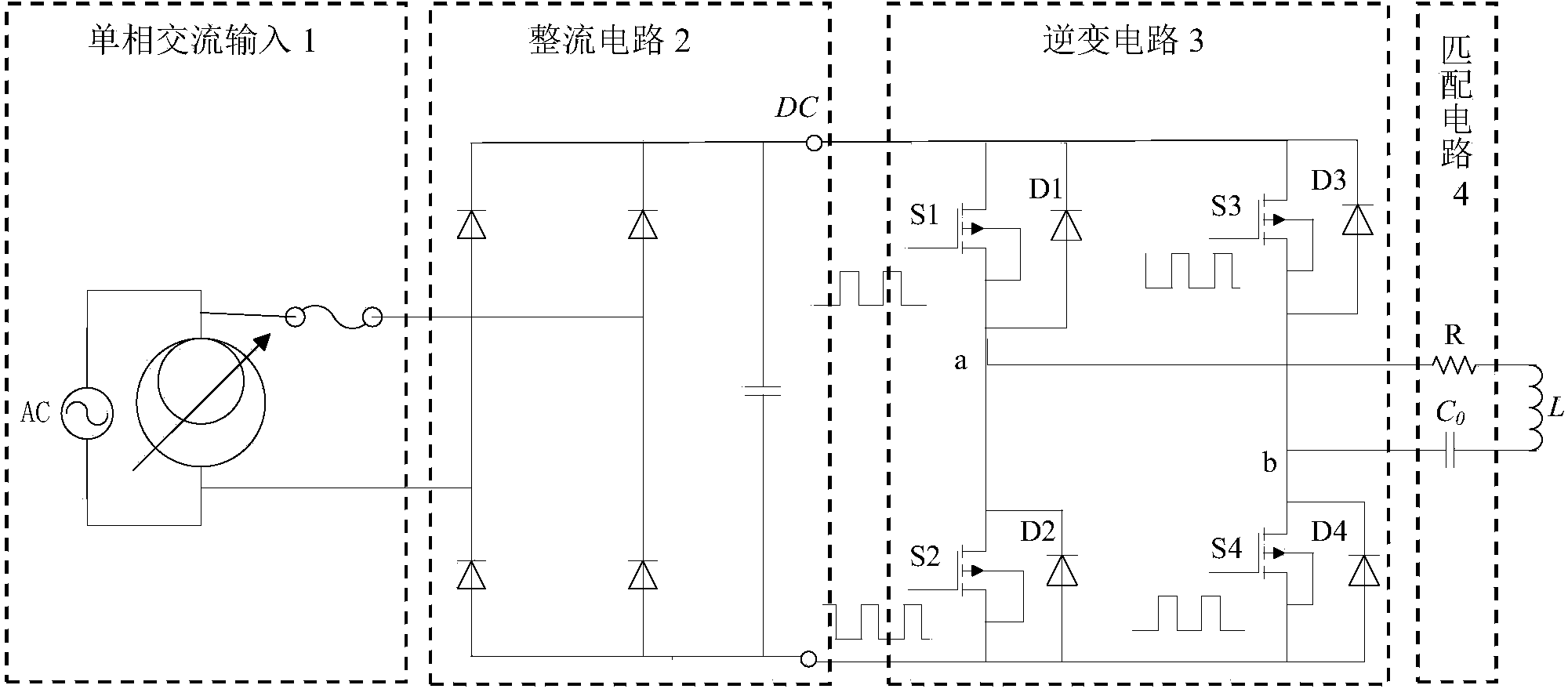

Frequency-variable power source for driving small or medium-sized magnetostrictive transducer

InactiveCN103825471AImprove work efficiencyReduce reactive power lossAc-ac conversionEngineeringFeedback circuits

The invention relates to a frequency-variable power source for driving a small or medium-sized magnetostrictive transducer. The frequency-variable power source comprises a single-phase alternating current (AC) input, a rectifying circuit, an inverter circuit, a matching circuit, a feedback circuit, a control panel, a control circuit, an isolating circuit and a driving circuit. The frequency-variable power source is used for driving the small or medium-sized magnetostrictive transducer which has the frequency range of ultrasonic frequency (20-30KHz), medium high frequency (1-20KHz) or lower frequency (500-1000Hz) and different power requirements (maximum output power is 2KW); the frequency can be set by keys arranged on the control panel; the control circuit can be used for rapidly locking the resonant frequency of the transducer when being assisted by the feedback circuit, so that the demand of sine wave current drive of the transducer can be met; and the frequency-variable power source has the advantage of being wide in frequency adjustment range.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com