Patents

Literature

70results about How to "Reduce the difficulty of design and manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

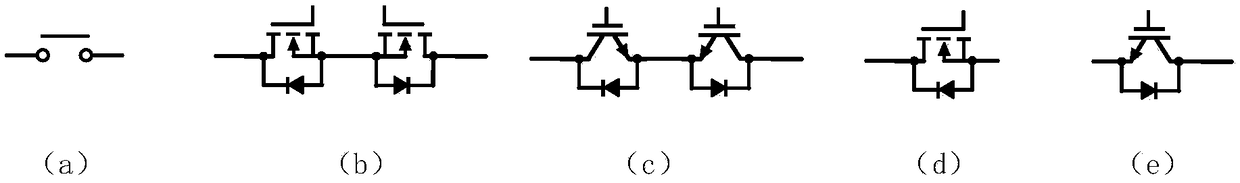

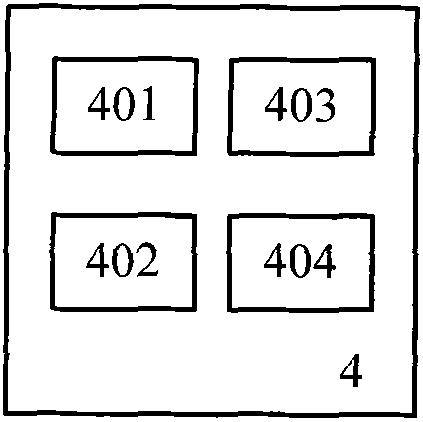

Electric converter circuit topological structure and control method thereof

PendingCN109302070ARealize two-way transmissionReduce the difficulty of design and manufactureEfficient power electronics conversionDc-dc conversionCapacitanceFull bridge

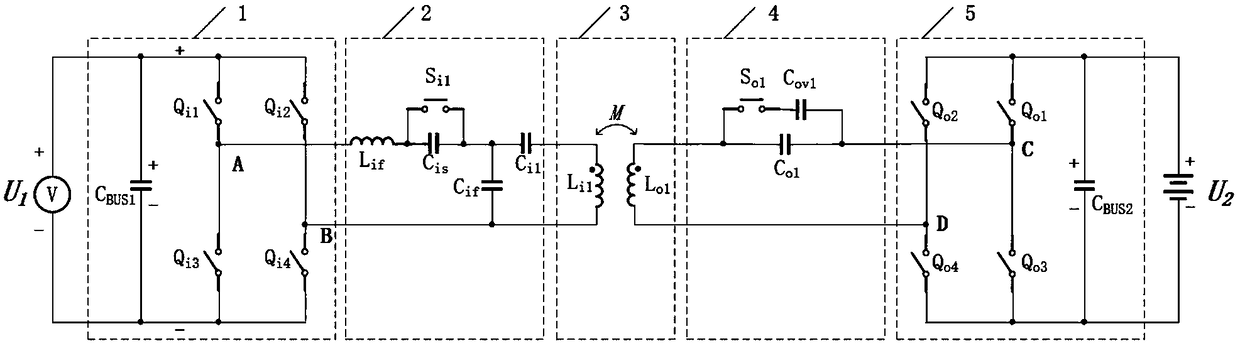

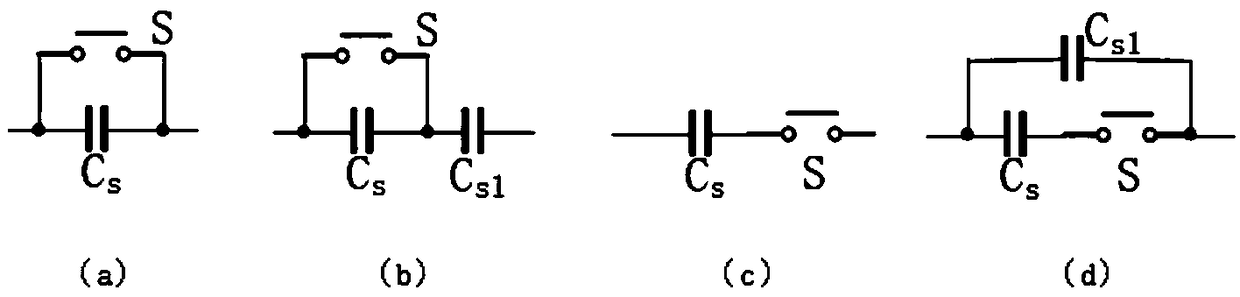

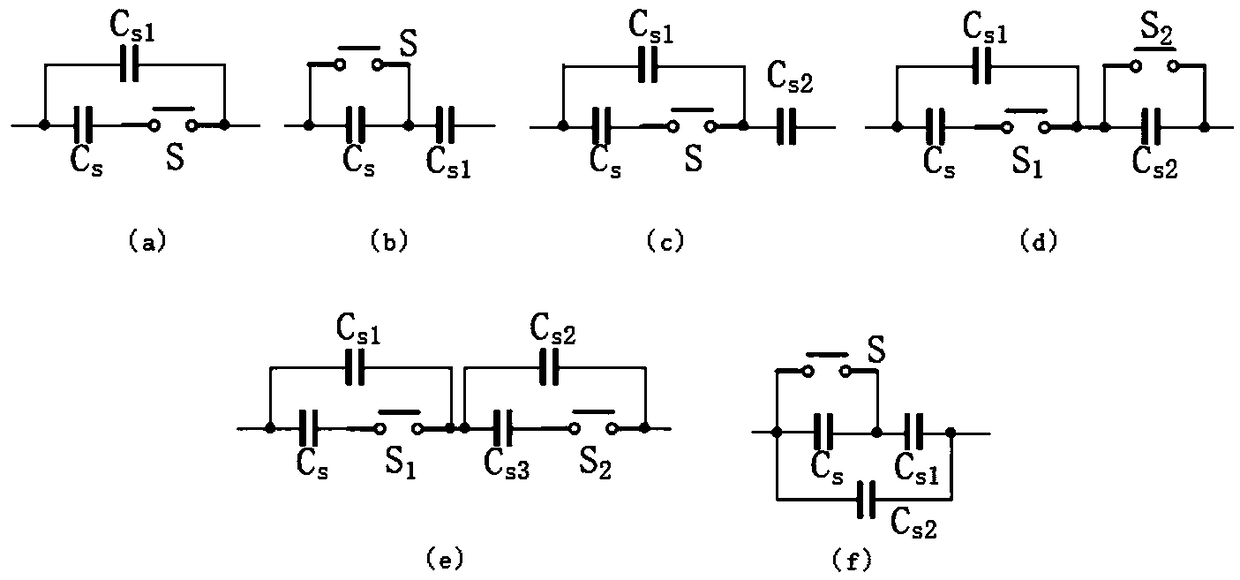

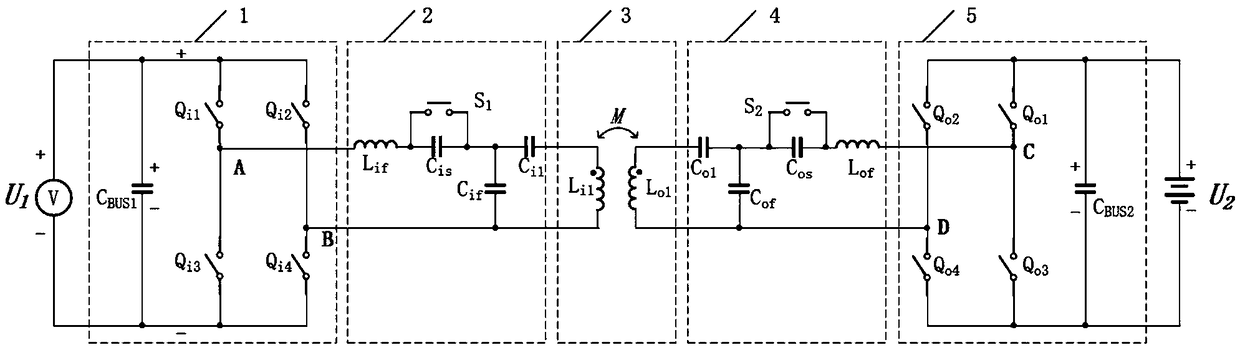

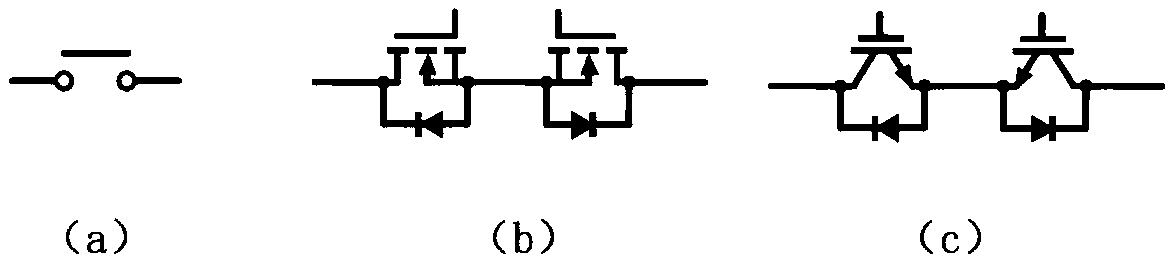

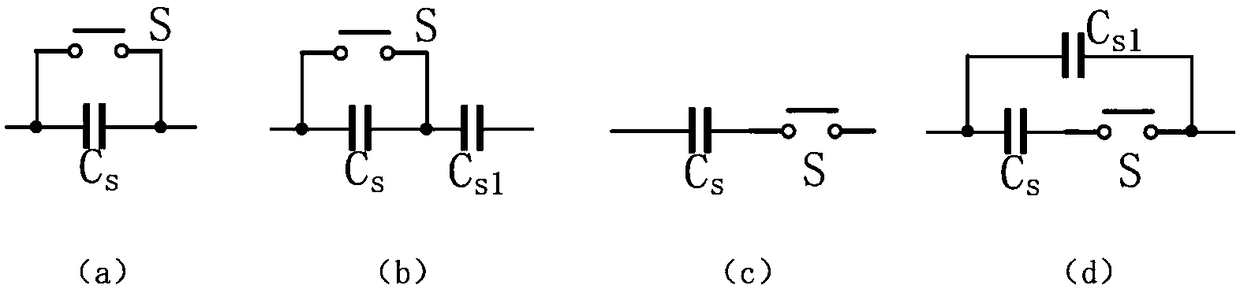

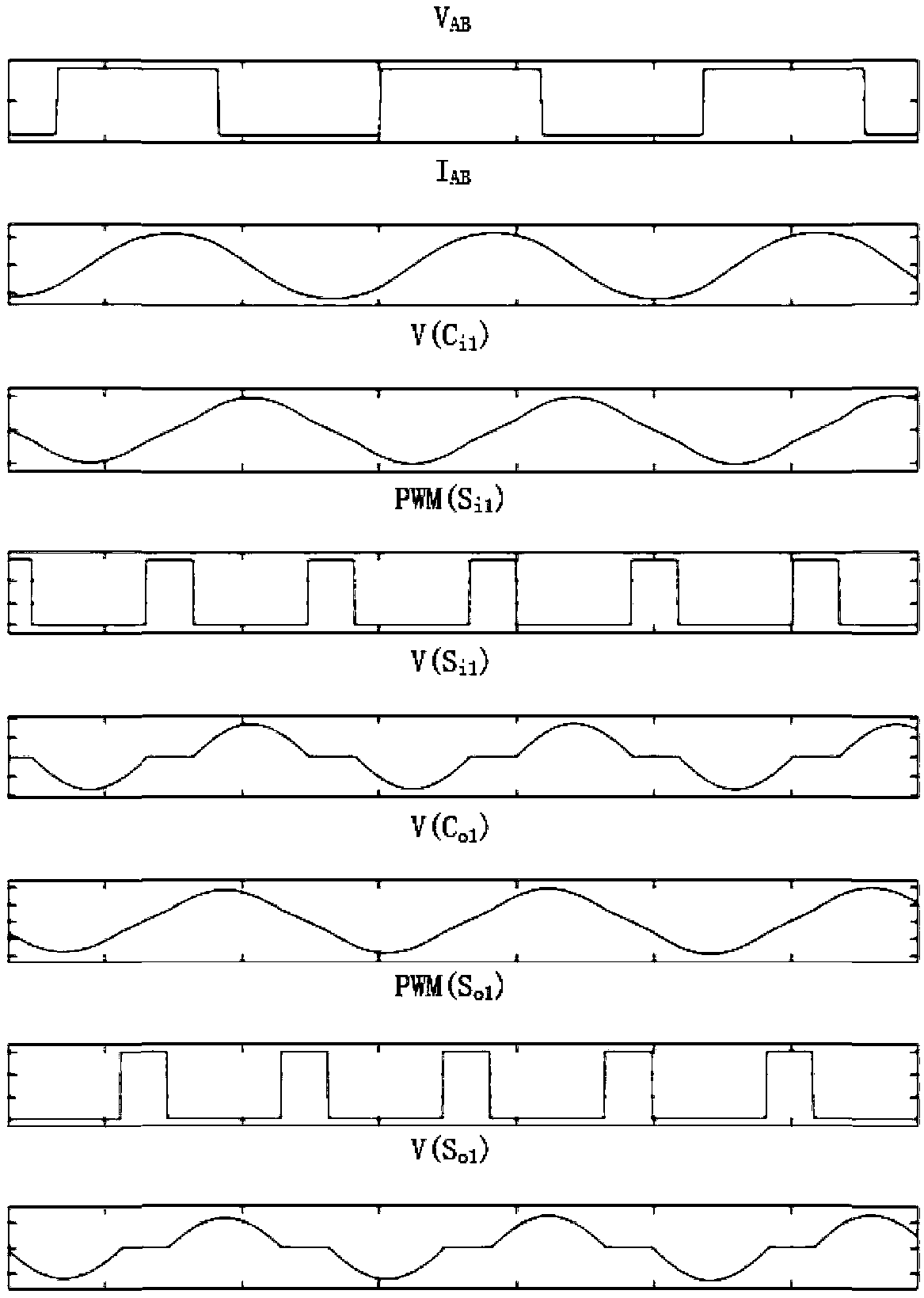

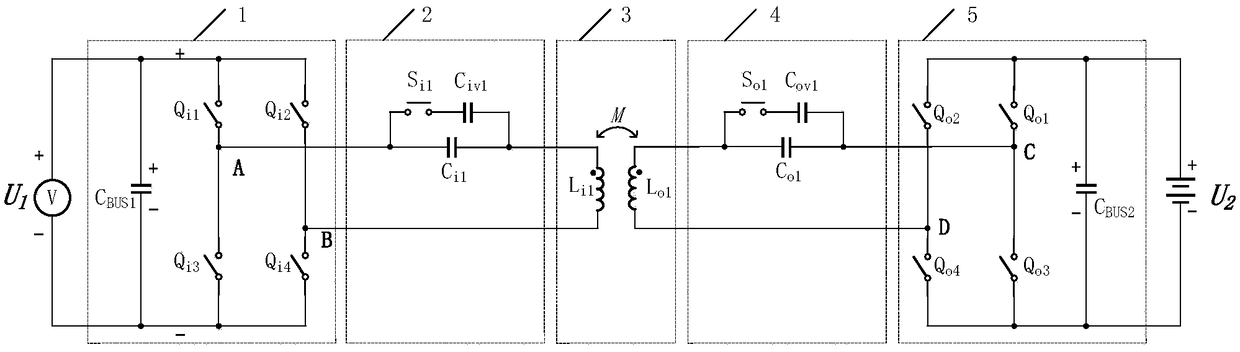

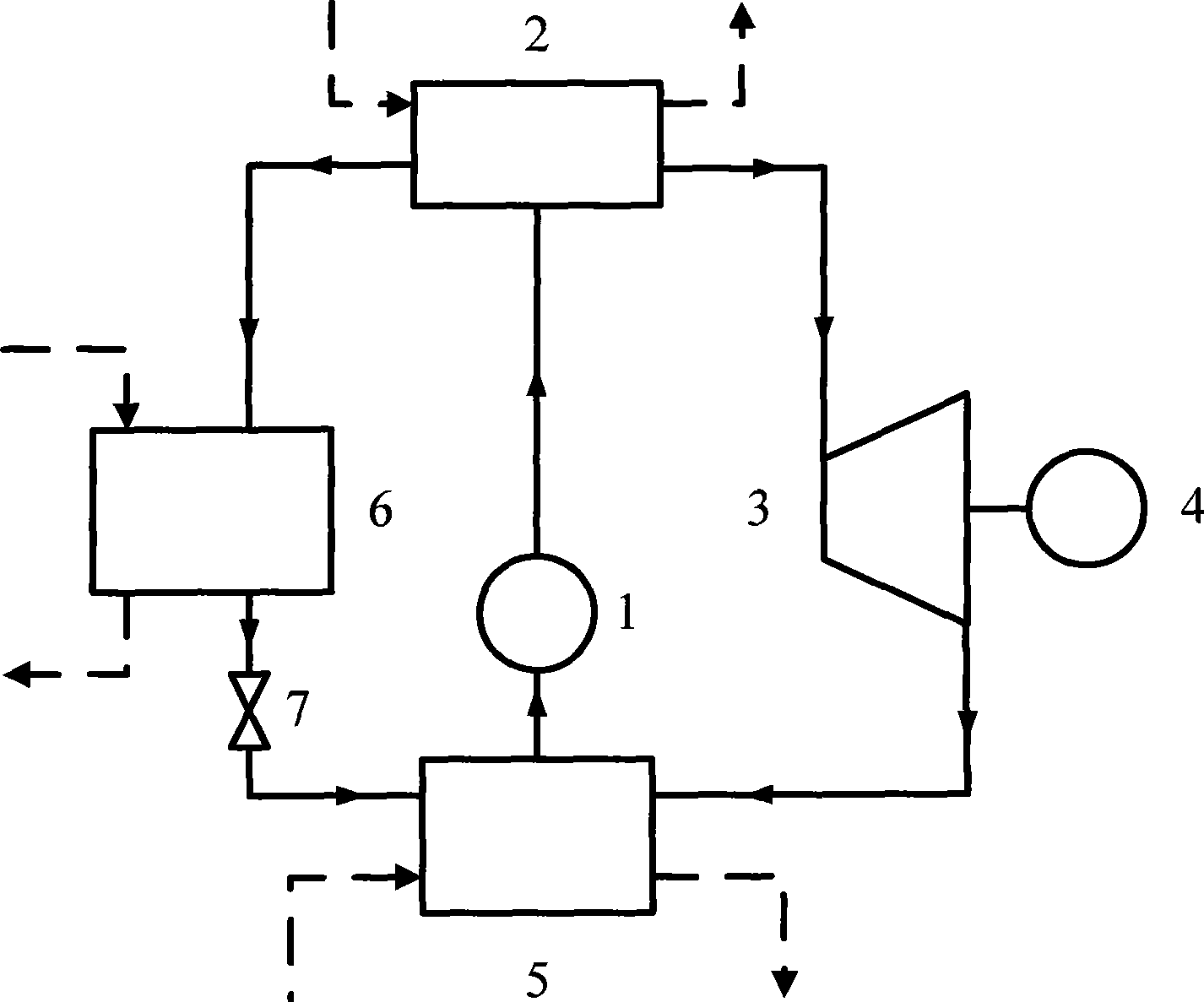

The present invention discloses an electric converter circuit topological structure and a control method thereof. The circuit topology comprises a full-bridge inverter, a primary side resonance dynamic compensation network, a primary side coil, a secondary coil, a secondary resonance dynamic compensation network, a full-bridge synchronous rectifier and a load. The primary side resonance dynamic compensation network employs a structure of connection in series of a compensation inductor and an adjustable resonance capacitor, the secondary resonance dynamic compensation network employs a structure of connection in series of a coil and the adjustable resonance capacitor, in the conditions that system parameters are changed caused by factors such as different coil coupling coefficients, different loads, the temperatures and device production manufacturing errors, the PWM duty ratio of a capacitive switching switch is regulated to generate continuously changed and adjustable equivalent resonant capacitance to perform dynamic compensation for the resonance network to achieve the soft switch of the full-bridge inverter and minimize the reactive power in the energy transmission of the system so as to maximum the electric energy transmission efficiency of the system and effectively enhance the regulation ability of the system output features in a condition of the constant working frequency of the system.

Owner:ARMY ENG UNIV OF PLA

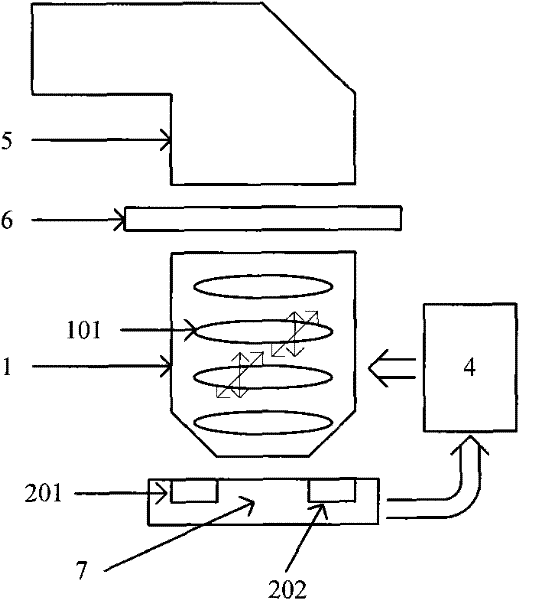

A circuit topology structure suitable for bidirectional near-field power transmission

PendingCN109245536ARealize two-way transmissionReduce the difficulty of design and manufactureEfficient power electronics conversionCircuit arrangementsCapacitanceElectric power transmission

The invention discloses a circuit topology structure suitable for bidirectional near-field power transmission, which comprises a full-bridge inverter, a primary-side resonant dynamic compensation network, a primary-side coil, a secondary-side coil, a secondary-side resonant dynamic compensation network, a full-bridge synchronous rectification and a load. The invention can realize bidirectional near-field transmission of electric energy, and at different coil coupling coefficients, at different load size and due to temperature, under the condition of system parameter change caused by manufacturing error of device, by adjusting the PWM duty cycle of the capacitor switching switch, the equivalent capacitance of the capacitor switching switch can change continuously to compensate the resonantnetwork dynamically, so as to realize the soft switching of the full-bridge inverter, to minimize the reactive power in the energy transmission of the system, and to maximize the energy transmission efficiency of the system. In addition, due to the symmetry of the circuit structure, it can realize the bidirectional transmission of near-field electric energy, that is, the bidirectional energy flowbetween the power grid and the load, which improves the utilization rate of the system in the smart grid.

Owner:ARMY ENG UNIV OF PLA

A symmetrical power converter circuit topology and control method thereof

PendingCN109245542AReduce conduction lossReduce lossEfficient power electronics conversionDc-dc conversionCapacitanceSoft switching

The invention discloses a circuit topology of a power converter suitable for bidirectional near-field electric energy transmission and a control method thereof. The circuit topology comprises a full-bridge inverter, a primary-side resonant dynamic compensation network, a primary-side coil, a secondary-side coil, a secondary-side resonant dynamic compensation network, a full-bridge synchronous rectification and a load. The invention adopts a structure that a coil is connected in series with an adjustable resonant capacitor, At different coil coupling coefficients, at different load size and dueto temperature, under the condition of system parameter change caused by manufacturing error of device, the resonant network can be dynamically compensated by adjusting the PWM duty cycle of the capacitor switching switch to produce a continuously variable equivalent series resonant capacitor, to achieve full-bridge inverter soft switching, minimize the reactive power in the system energy transfer, thereby maximizing the system power transfer efficiency, in the case of a constant operating frequency, effectively enhance the system output characteristics of the adjustment capability. In addition, because of the symmetry of the circuit structure, it can realize the bi-directional transmission of near-field electric energy, that is, the bi-directional energy flow between the power grid and the load, which improves the utilization rate of the system in the smart grid.

Owner:ARMY ENG UNIV OF PLA

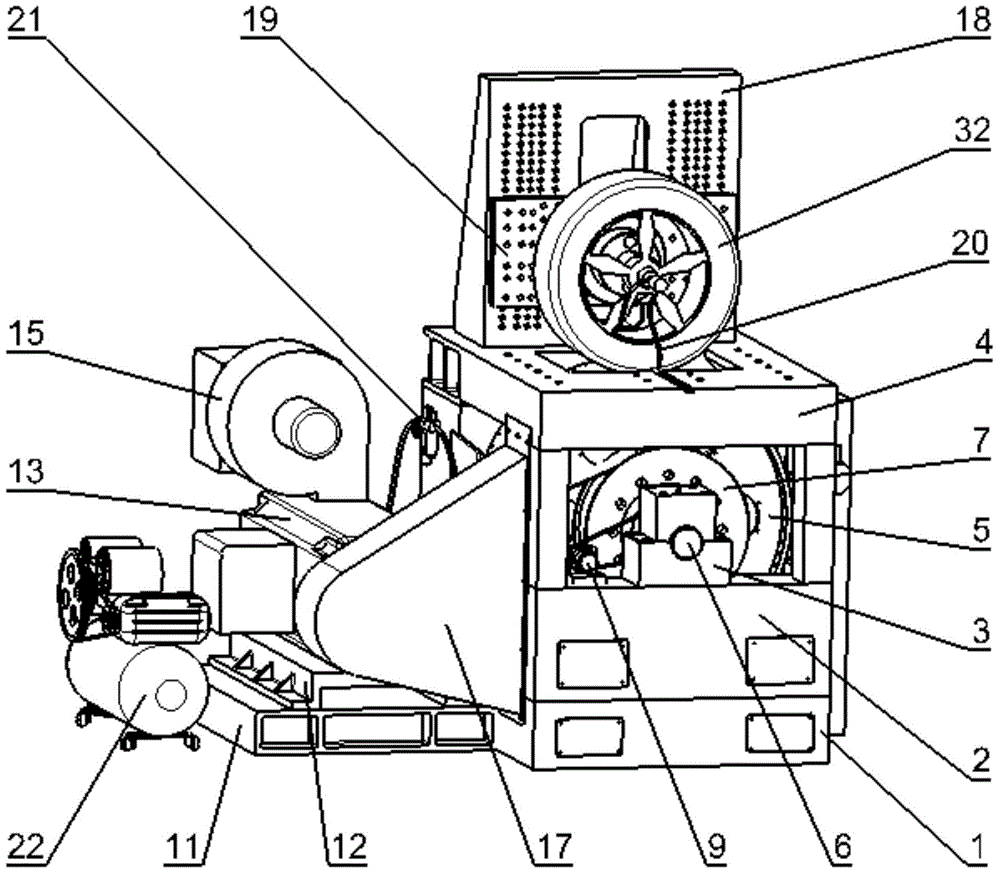

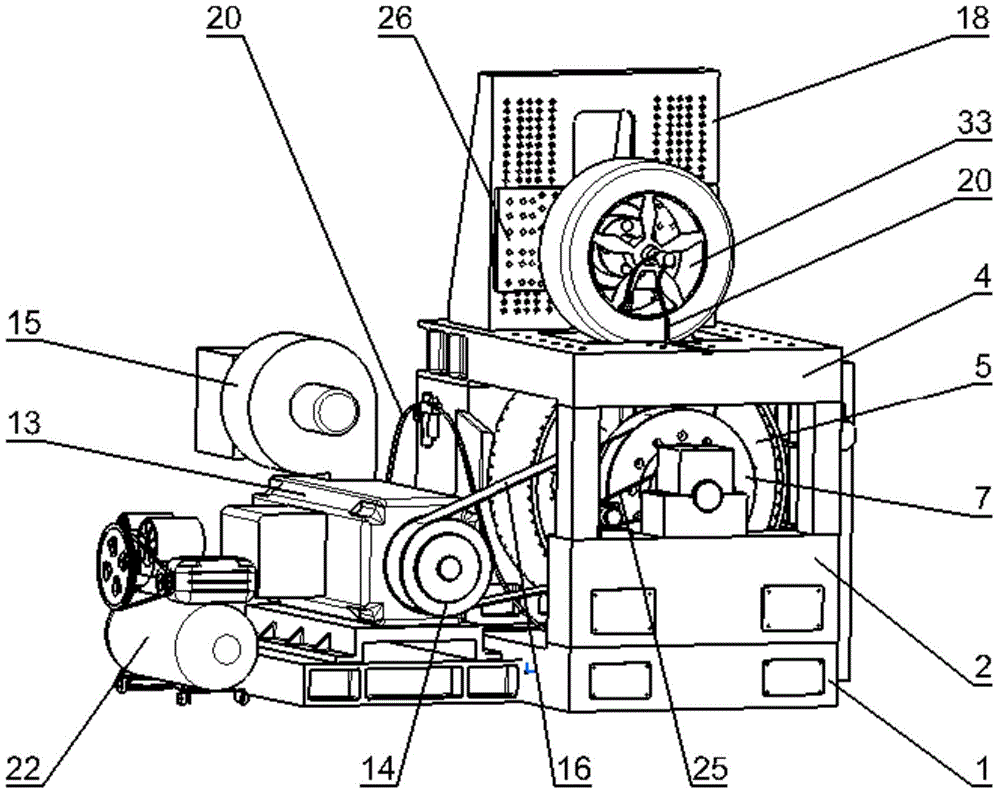

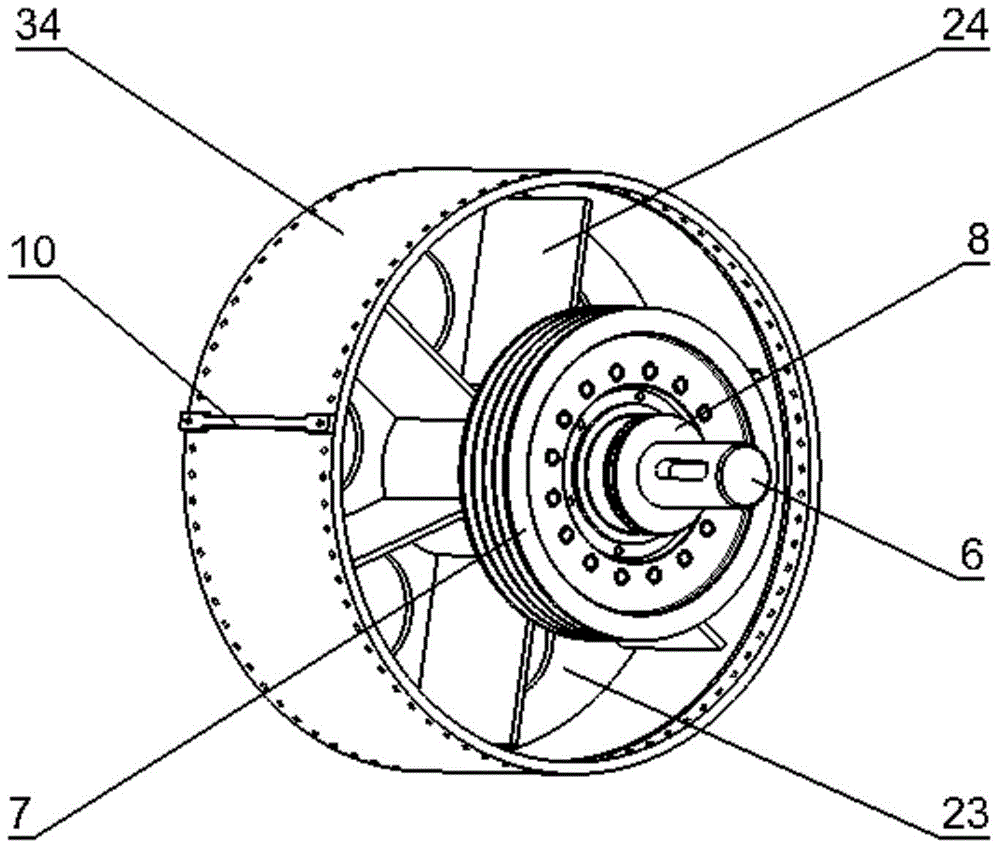

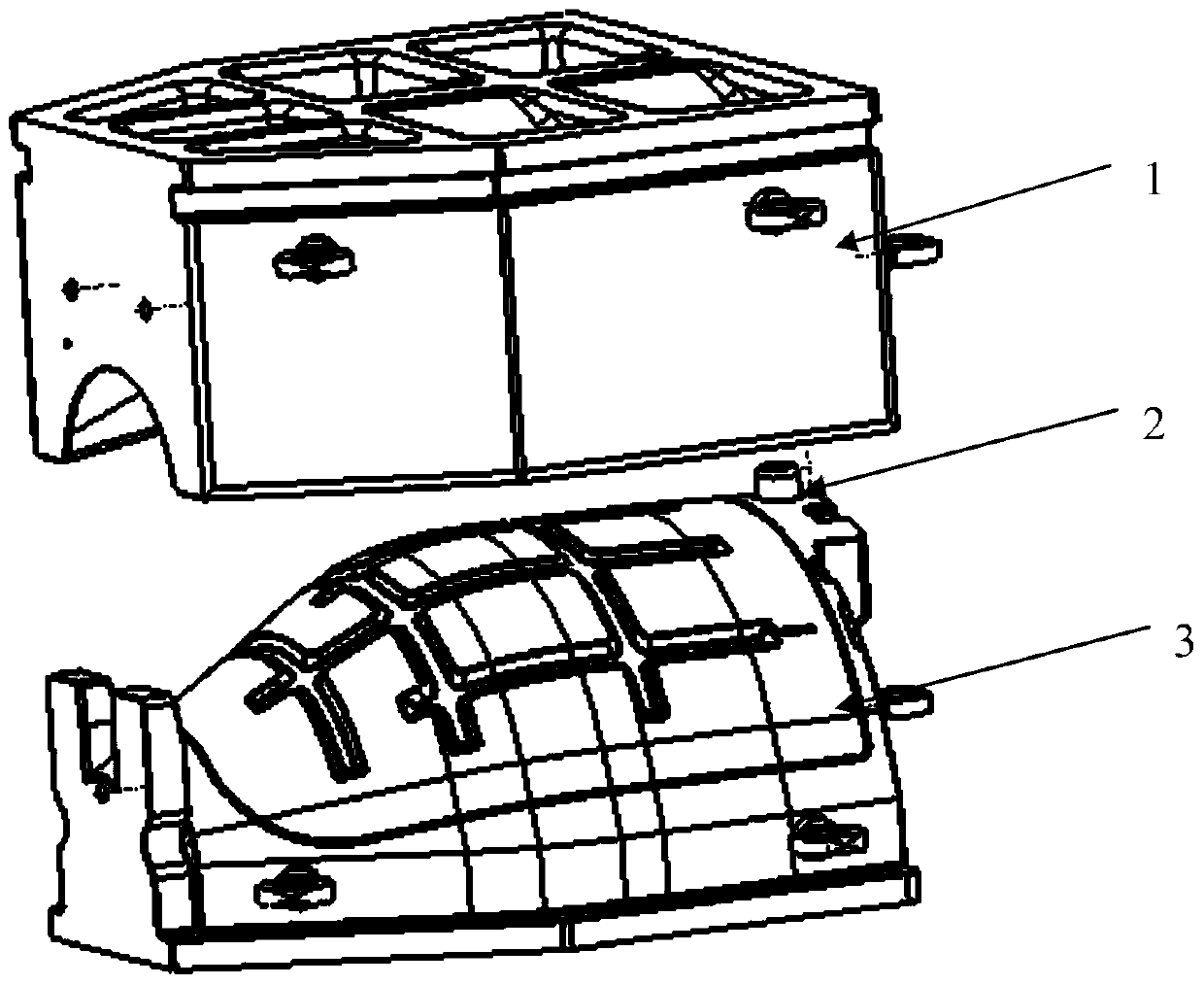

Test bed and method for testing high-frequency mechanical characteristic of tire

InactiveCN104458286AAchieve stiffnessAchieve uniformityVehicle tyre testingRoad surfaceControl valves

The invention relates to a test bed and a method for testing the high-frequency mechanical characteristic of a tire. The test bed comprises a simulation road surface rack assembly composed of a bottom plate, a lower box body, a shaft base and an upper box body, a simulation road surface assembly composed of a high-rigidity drum, a main shaft, a driven belt pulley, a synchronous belt pulley, a speed measuring assembly and road surface protruding blocks, a drive mechanism assembly composed of a motor base, a motor plate, a servo motor, a drive belt pulley and an air blower, a transmission toothed belt, a wheel cover, a tire positioning assembly composed of a positioning support and an installing plate assembly, and a tire inflating and deflating mechanism assembly composed of an air pipe, a tire pressure control valve and an air pump, and the transmission toothed belt and the wheel cover are arranged between the drive belt pulley and the driven belt pulley. The test method comprises the steps that a deflated tire is installed on the positioning support and pressed on the outer surface of the high-rigidity drum, the tire is inflated to be vertically loaded, and the different road surface protruding blocks are installed on the high-rigidity drum to carry out the test and collect data. The test bed and the method are suitable for testing and modeling of the high-frequency mechanical characteristic of the tire.

Owner:JILIN UNIV

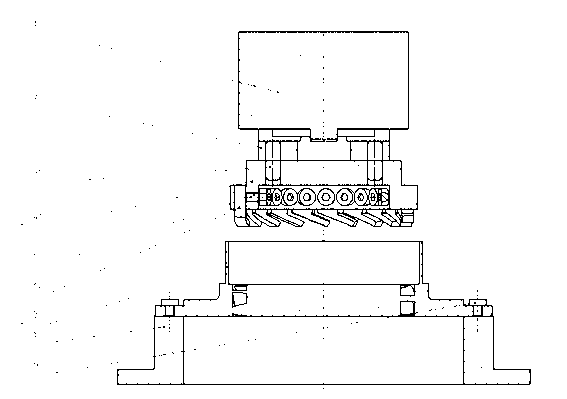

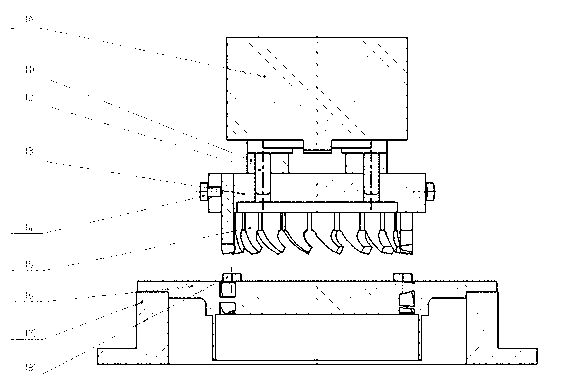

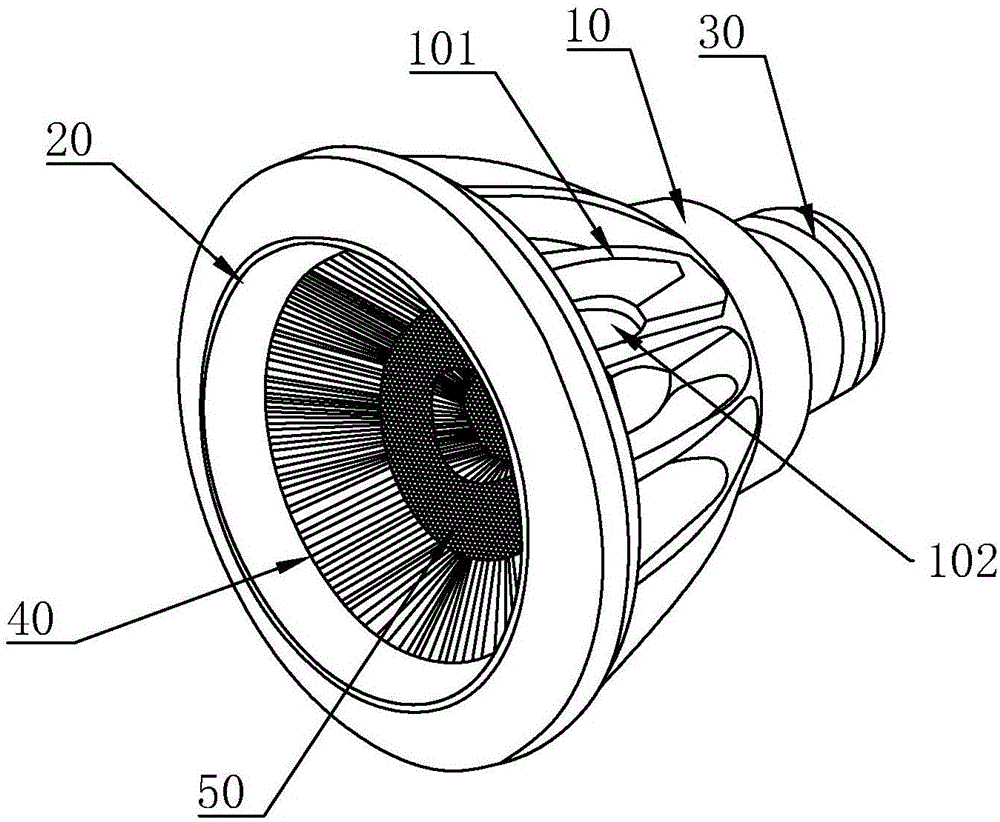

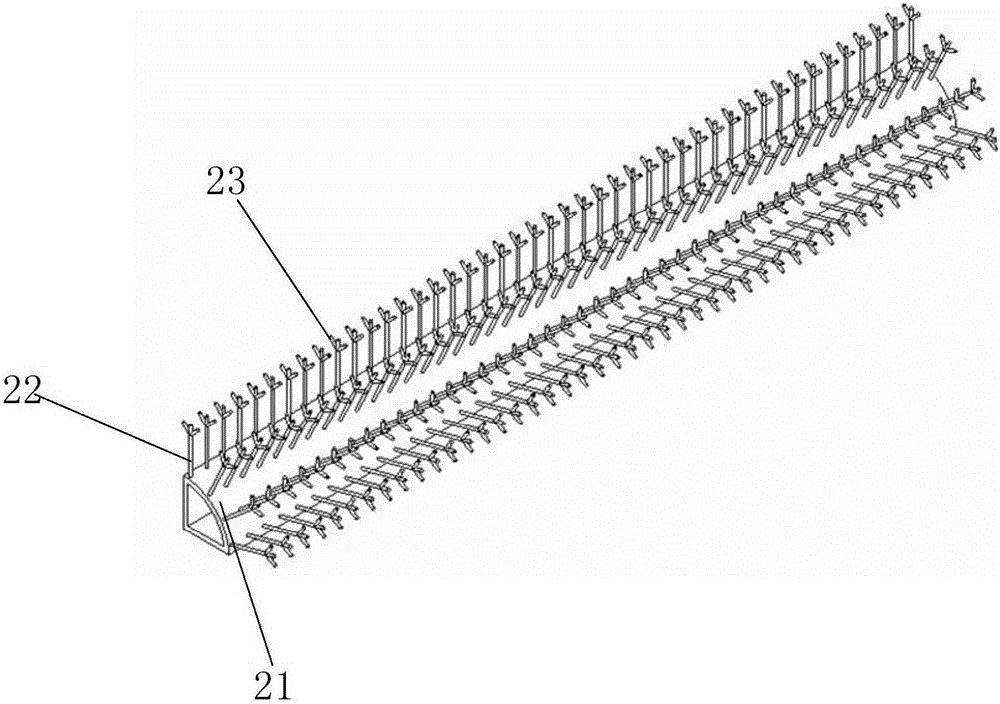

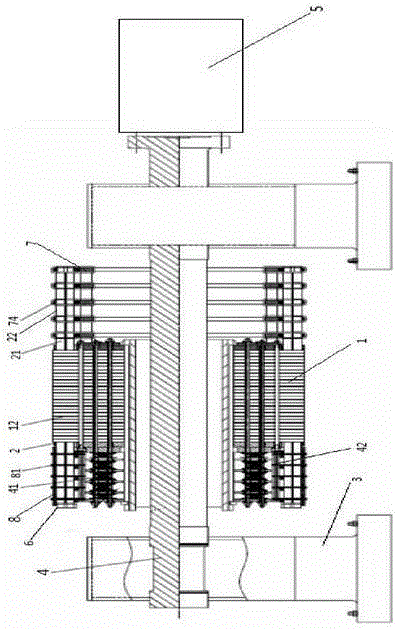

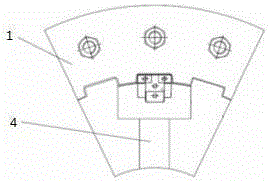

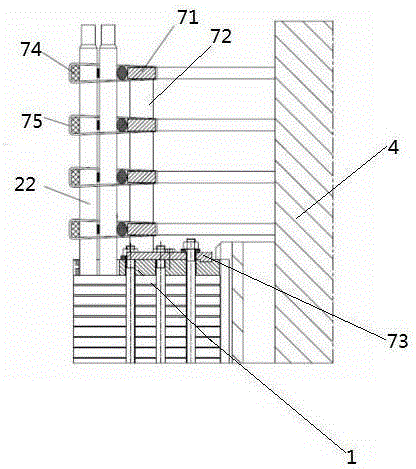

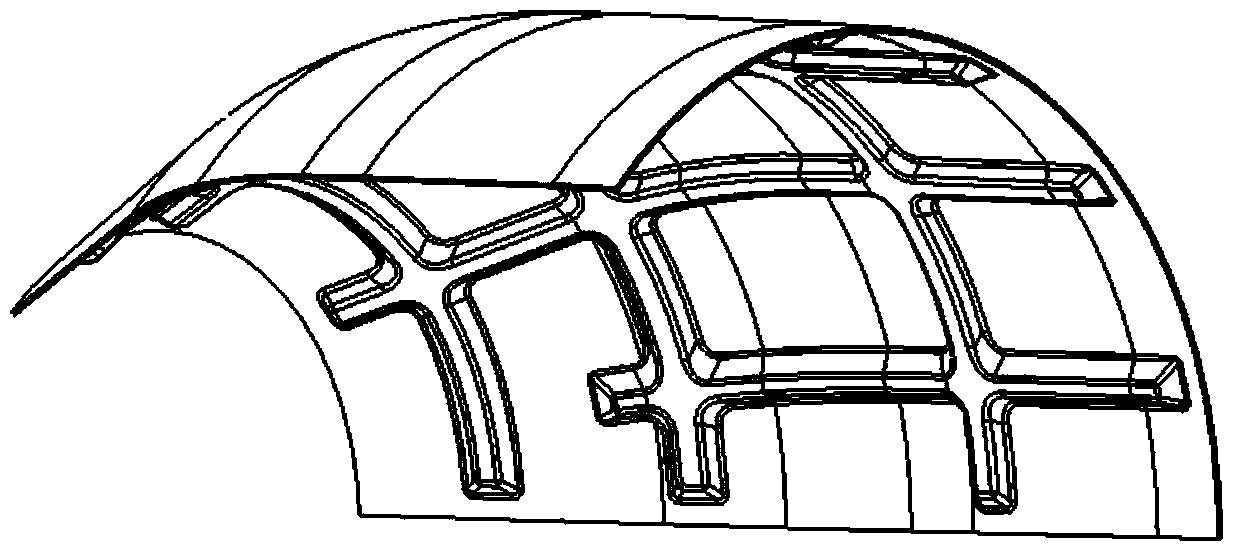

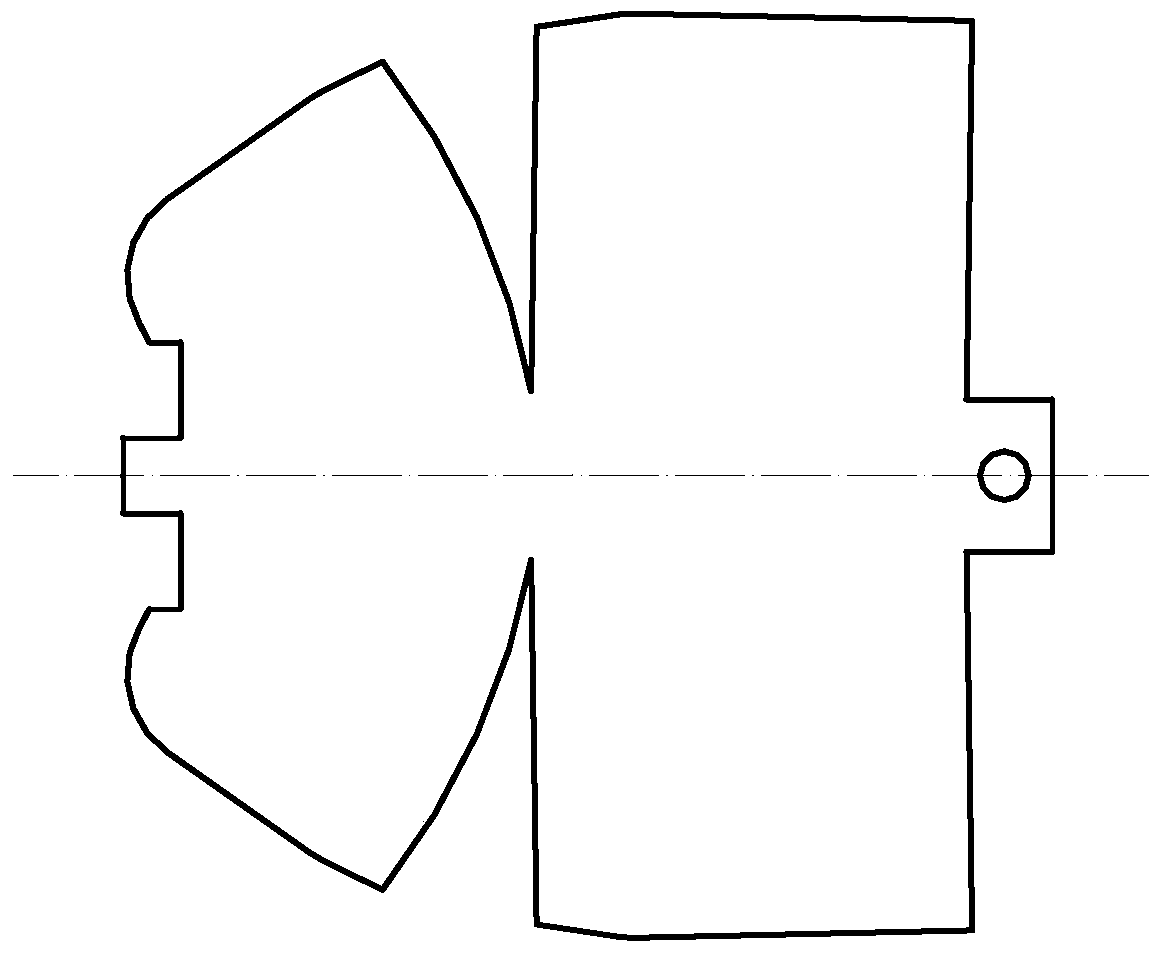

Machining method and device for vane channels of uniform-cross section profile cowled integral impeller

InactiveCN103212760AIncreased processing accessibilityReduce the difficulty of design and manufactureImpellerMachining process

The invention discloses a machining method and device for vane channels of a uniform-cross section profile cowled integral impeller. The machining method comprises the following steps of firstly designing near shaped electrodes of entry machining areas and exit machining areas of the channels by applying the numerical control electric spark technology; respectively starting machining from entries and exits of the channels by using a set of entry machining area electrodes and a set of exit machining area electrodes of which the number is equal to that of the vane channels of the impeller to finish rough machining of all channels; finishing semi finish machining and finish machining on all the channels in sequence by applying a numerical control compensating motion; and processing channels with special surface requirements by adopting other finishing machining processes, such as an abrasive flow machining process and the like to achieve corresponding surface quality requirements. The machining device comprises a reference seat, a reference element, an electrode holder, electrodes and a base. Compared with a traditional machining method for the vane channels of the uniform-cross section profile cowled integral impeller, the machining method for the vane channels of the uniform-cross section profile cowled integral impeller disclosed by the invention has the technical economic characteristics that the efficiency is high and the precision is high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

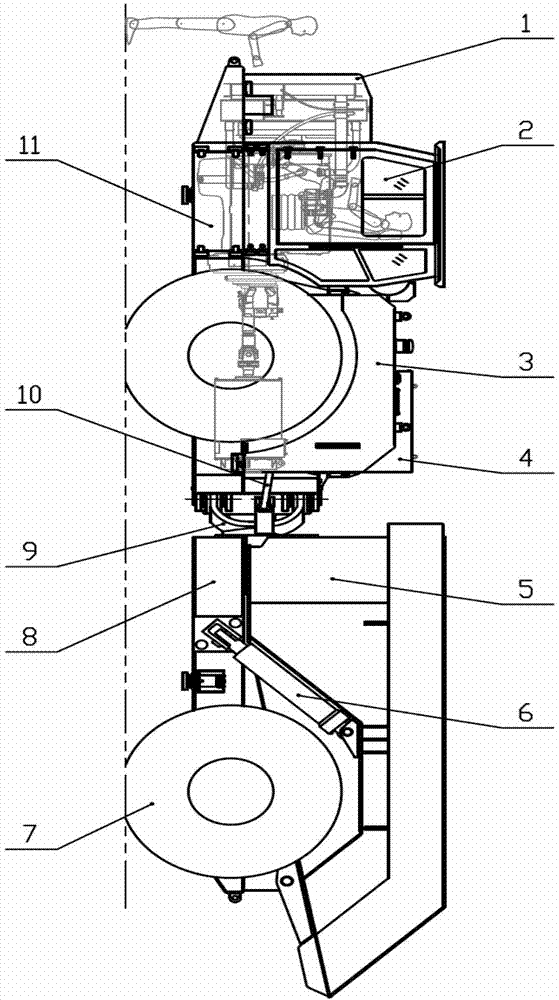

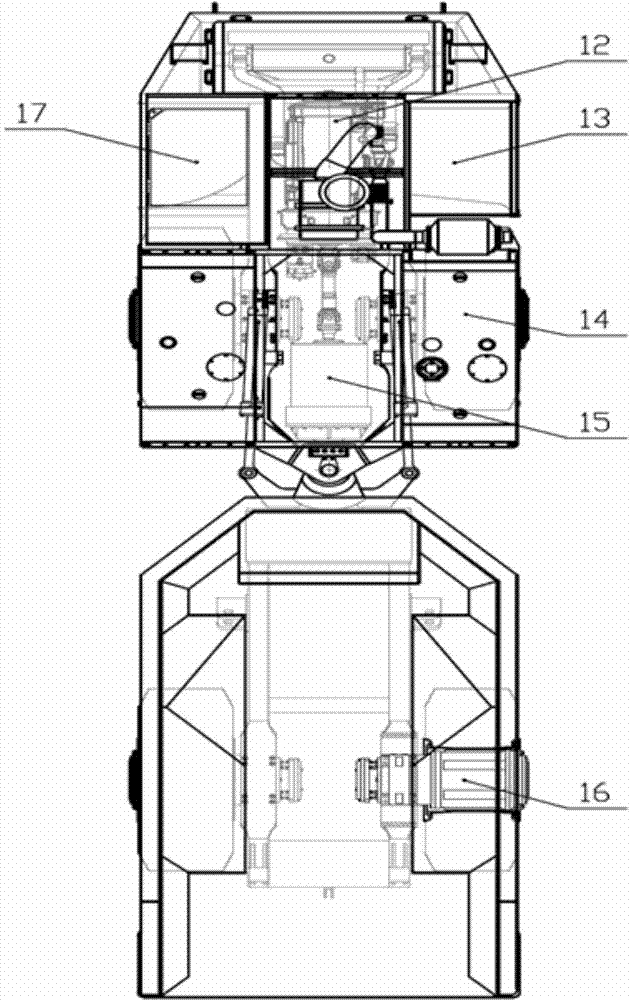

Hybrid electric drive underground mining car

InactiveCN103863103ASimple structureReduce the difficulty of design and manufactureUnderstructuresControl devicesElectricityVehicle frame

The invention discloses a hybrid electric drive underground mining car which comprises two front electric wheel units and two rear electric wheel units, wherein the four electric wheel units respectively and independently drive four wheels of a dumper and have complete interchangeability; the hybrid electric drive underground mining car comprises a front frame, a rear frame and a hinging body; the front frame is hinged to the rear frame through the hinge body; steering cylinders are respectively arranged on two sides of the hinge body and are used for hinging and steering of the car. The hybrid electric drive underground mining car disclosed by the invention has the advantages that by adopting wiring power, the operation speed of the equipment can be greatly increased and the production efficiency is increased; diesel-electric power is used for auxiliary standby power and the power of the diesel-electric power is one third of normal power, and thus the underground pollution can be greatly reduced; the finished car structure is simplified and the design and manufacture difficulties of driving parts are reduced; due to the adoption of a maintenance-free wheel-side driving motor, the reliability of the car is improved and the maintenance cost of the system is effectively reduced; the four electric wheel units can be freely interchanged, and thus a good interchangeability is obtained.

Owner:UNIV OF SCI & TECH BEIJING

Additive and subtractive combined machining method based on electron beam fusing

InactiveCN106891167AFast preparationHigh precisionOther manufacturing equipments/toolsElectron beam welding apparatusNumerical controlMachine control

The invention discloses an increasing and decreasing composite processing method based on an electron beam fuse, which is used to solve the technical problem of low precision of the existing metal increasing and decreasing material processing methods. The technical solution is to use the three-dimensional contour geometric information of the processed part, and the layer geometric information to generate numerical control codes that fuse the electron beam fuse deposition parameters and machining parameters through the computer. The additive molding system scans the accumulated materials layer by layer according to the contour trajectory. Material processing control, finally forming three-dimensional solid parts. The present invention combines electron beam fuse additive manufacturing and traditional mechanical processing subtractive manufacturing at the same time. The advantages of the two processes are complementary, and realizes the high-efficiency, high-precision, and high-fatigue strength personalized customized fast and precise manufacturing of complex parts. The invention can not only be used in the manufacture of the whole parts, but also can be used in the processing of parts with complicated structure and difficult processing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

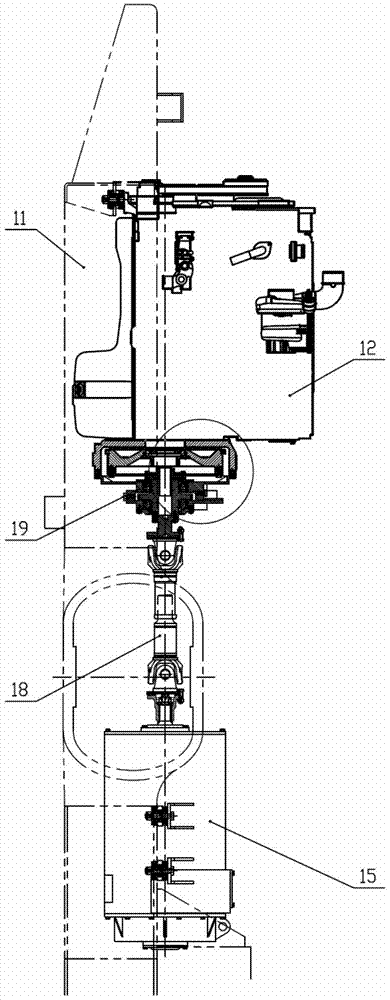

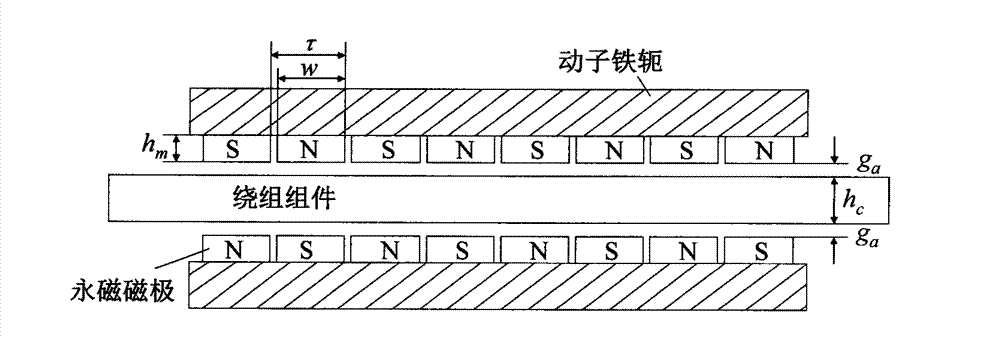

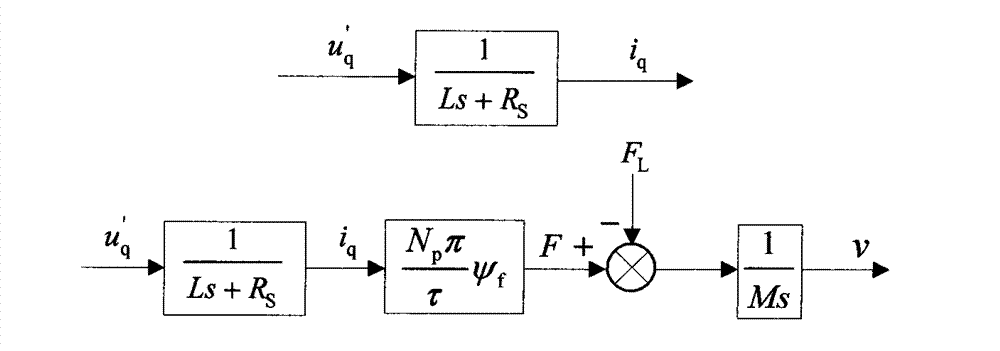

Control method based on linear servo motor

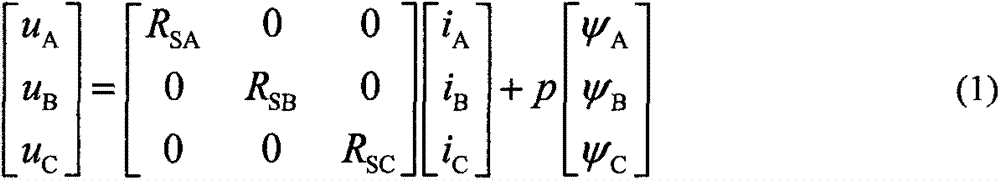

InactiveCN103248312AReduce volumeReduce the difficulty of design and manufactureAC motor controlAnalytic modelSynchronous motor

A control method based on a linear servo motor comprises the following steps: 1, according to the requirement of an electromagnetic catapult for a driving linear motor, performing design on an overall structure of the linear motor; 2, establishing an air-gap field analytic model and a thrust model of an iron core-free permanent magnetic linear synchronous motor; 3, establishing a mathematical model of the linear motor under autonomous decentralized control; and 4, performing autonomous decentralization on controlled magnetic-motive force. The control method has the advantages that the efficiency of the linear motor is improved and the design and manufacture difficulty of the motor is lowered.

Owner:杭州中科赛思伺服电机有限公司

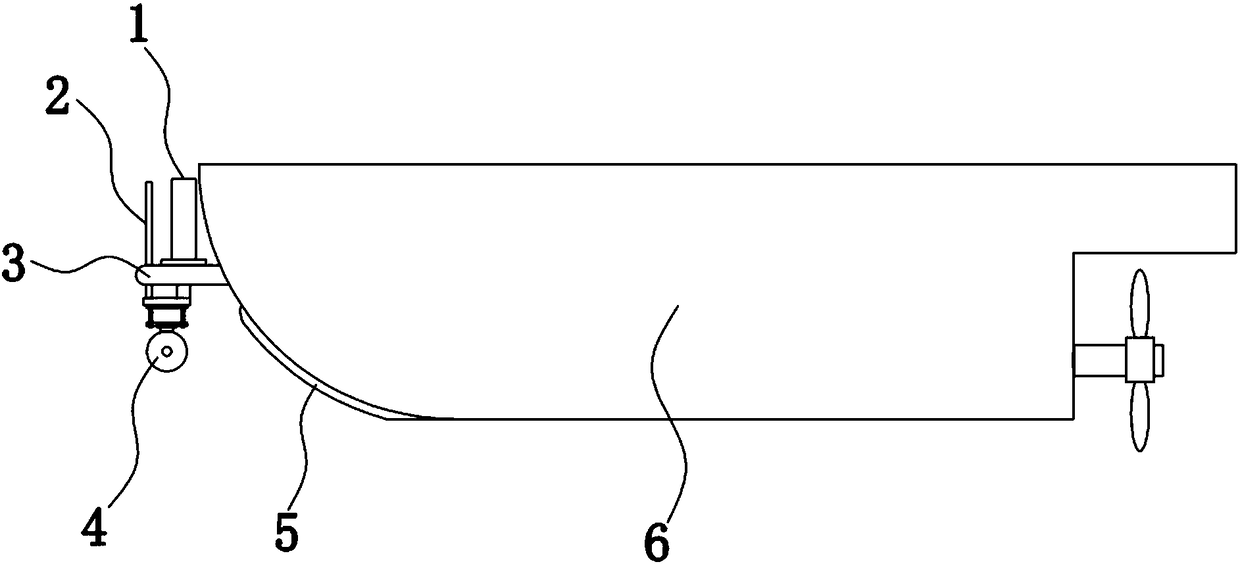

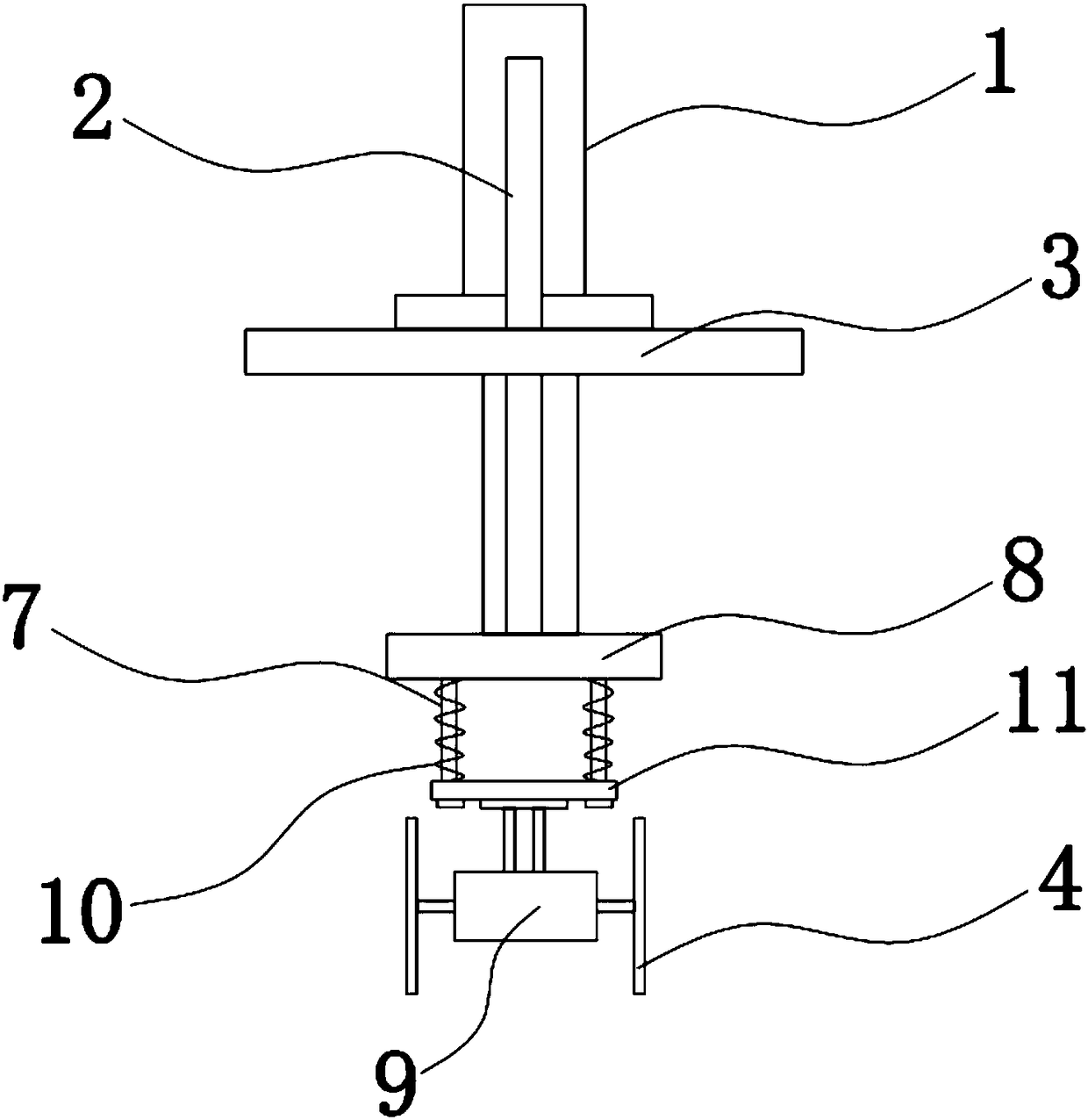

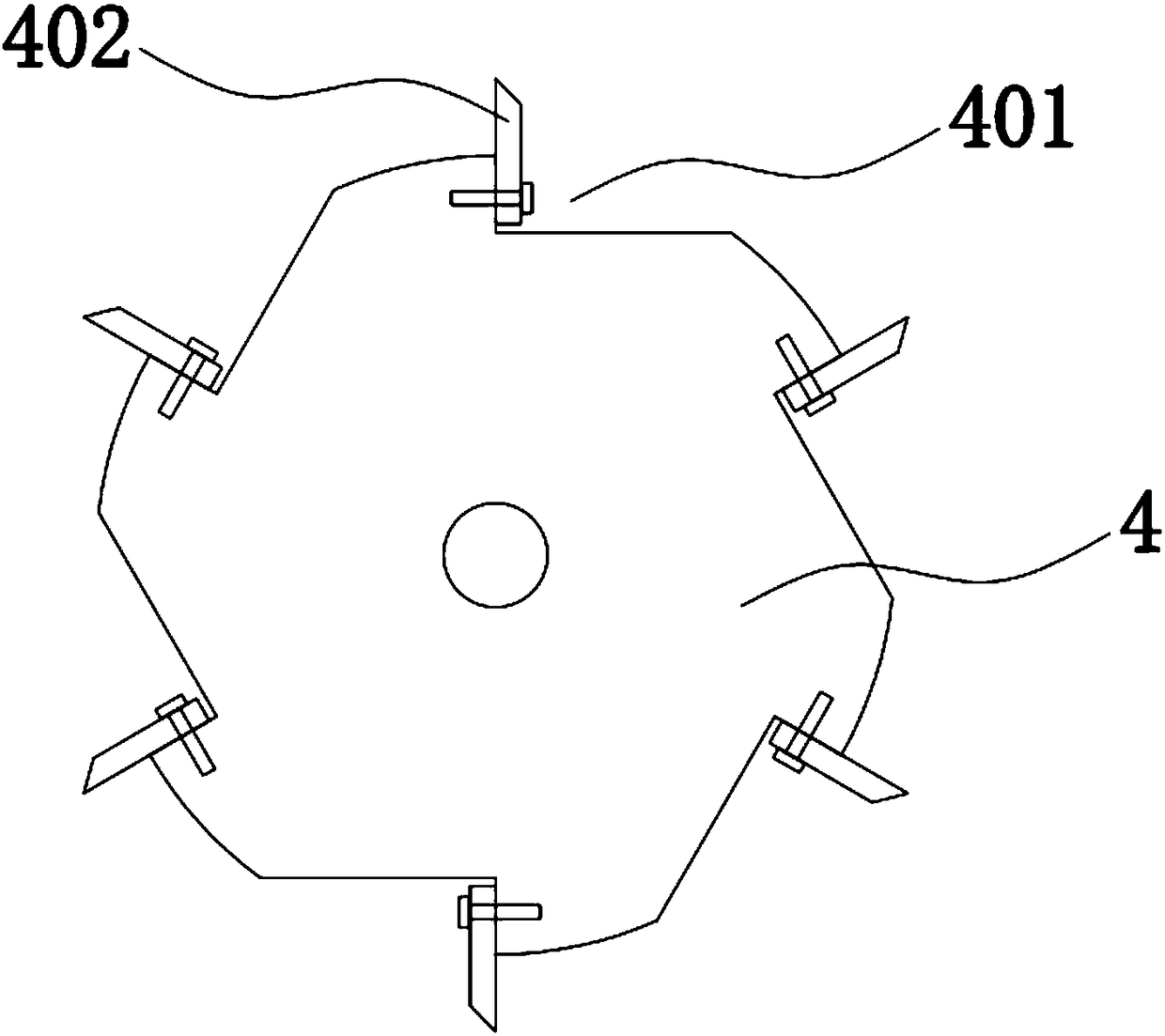

Icebreaking device for navigation and using method thereof

InactiveCN108466678AAvoid getting stuckReduced Power RequirementsWaterborne vesselsIce breakersHydraulic cylinderEngineering

The invention discloses an icebreaking device for navigation and a using method thereof. The icebreaking device comprises a supporting plate and an icebreaking cutter plate; the supporting plate is fixedly welded to the front end of an icebreaking hull, the supporting plate is fixedly provided with a hydraulic cylinder by bolts, a first mounting plate is installed at the telescopic end of the hydraulic cylinder by bolts, ejector rods are fixedly welded to the first mounting plate, and a second mounting plate is movably connected to the ejector rods in a sleeving mode; and cutter heads are fixed at the edge of the icebreaking cutter plate, the icebreaking cutter plate is fixed on an output shaft of a motor in a pin joint mode, and the motor is mounted at the bottom of the second mounting plate through a motor bracket. The icebreaking cutter plate is driven by the double-shaft motor to cut the ice surface and destroy the ice surface structure when the icebreaking hull advances, then thecut ice surface is hit by a reinforcing plate, and crushing of the whole ice surface is facilitated; and the second mounting plate can be moved up and down through springs, a certain cushioning property is obtained, the icebreaking cuter plate is prevented from getting stuck, and improvement of the icebreaking efficiency is facilitated.

Owner:WUHAN UNIV OF TECH

Ultrahigh pressure cylinder

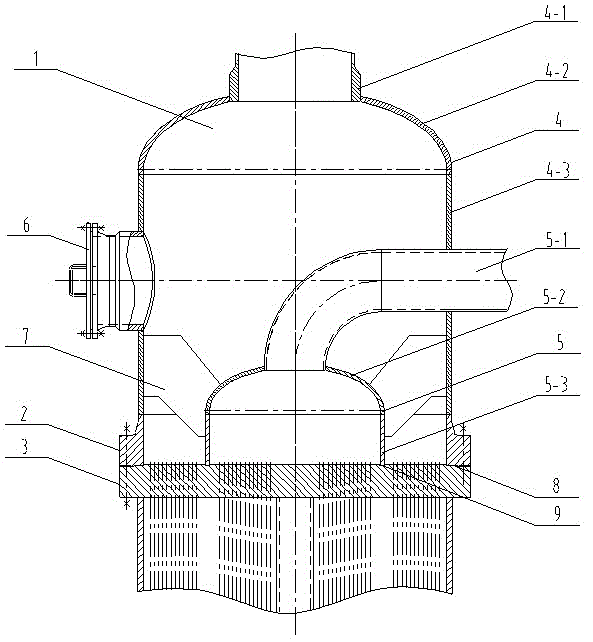

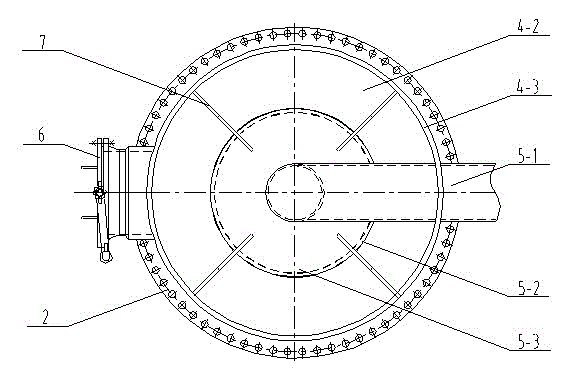

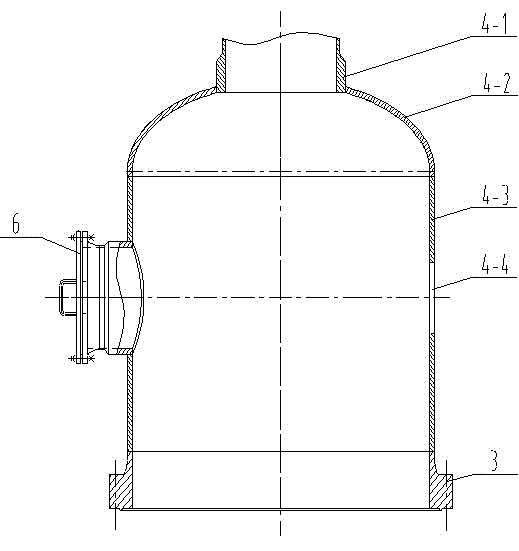

InactiveCN102518488AReduce internal and external pressure differenceReasonable wall thickness designMachines/enginesEngine componentsSteam pressureEngineering

The invention discloses an ultrahigh pressure cylinder, which comprises an internal cylinder and an external cylinder. The rear part of the internal cylinder is sealed with the external cylinder. A steam inlet pipe and a steam exhaust pipe are connected on the external cylinder. The steam inlet pipe passes through the external cylinder and extends into the internal cylinder. Steam enters the internal cylinder through the steam inlet pipe. The front end of the internal cylinder is of a sealed structure. A communication pipe is hermetically connected on the internal cylinder. The other end of the communication pipe is hermetically connected on a steam exhaust opening of the external cylinder. Steam in the internal cylinder is directly discharged to the steam exhaust pipe through the communication pipe. A sealed interlayer space is formed between the internal and external cylinders. A high pressure heater that conveys relatively stable steam to the interlayer space is connected on the external cylinder. When the ultrahigh pressure cylinder operates normally, the steam pressure in the internal cylinder, the steam pressure in the interlayer space and the atmospheric pressure outside the external cylinder decrease progressively. The ultrahigh pressure cylinder reduces the internal and external pressure difference of the external cylinder and maintains the reasonable wall thickness of the external cylinder when through-flow is not changed and steam exhaust pressure is increased so as to alleviate the difficulty in design and manufacturing. The ultrahigh pressure cylinder has strong practicality and high safety.

Owner:DONGFANG TURBINE CO LTD

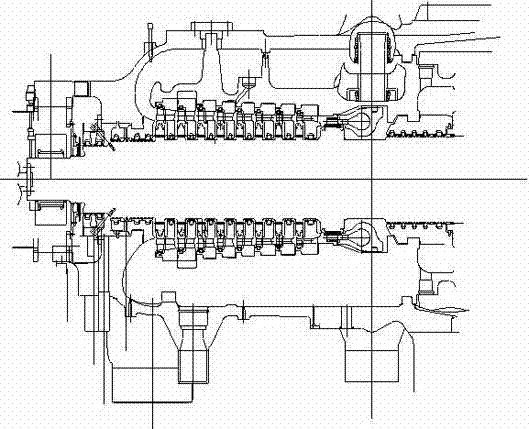

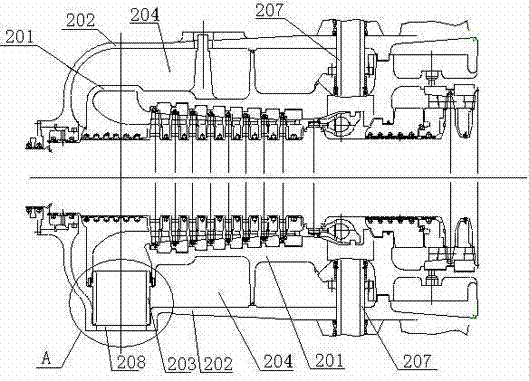

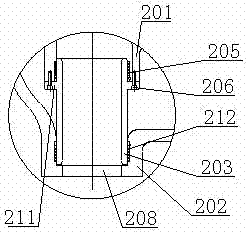

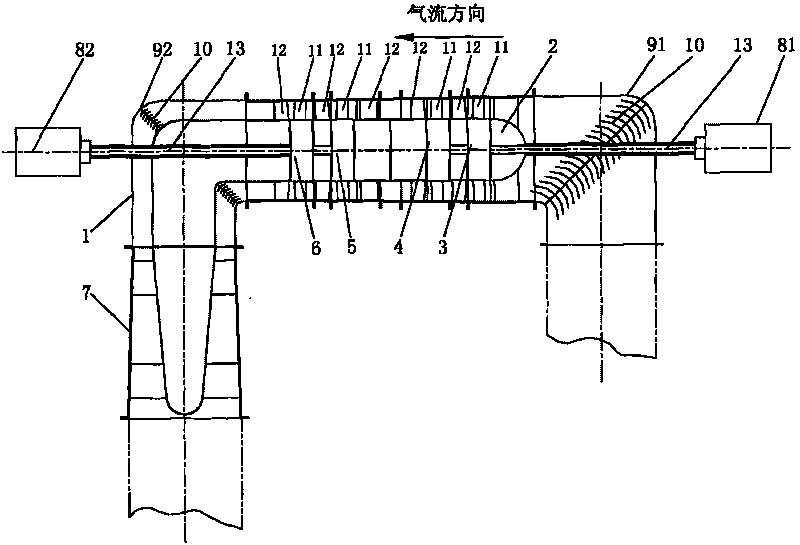

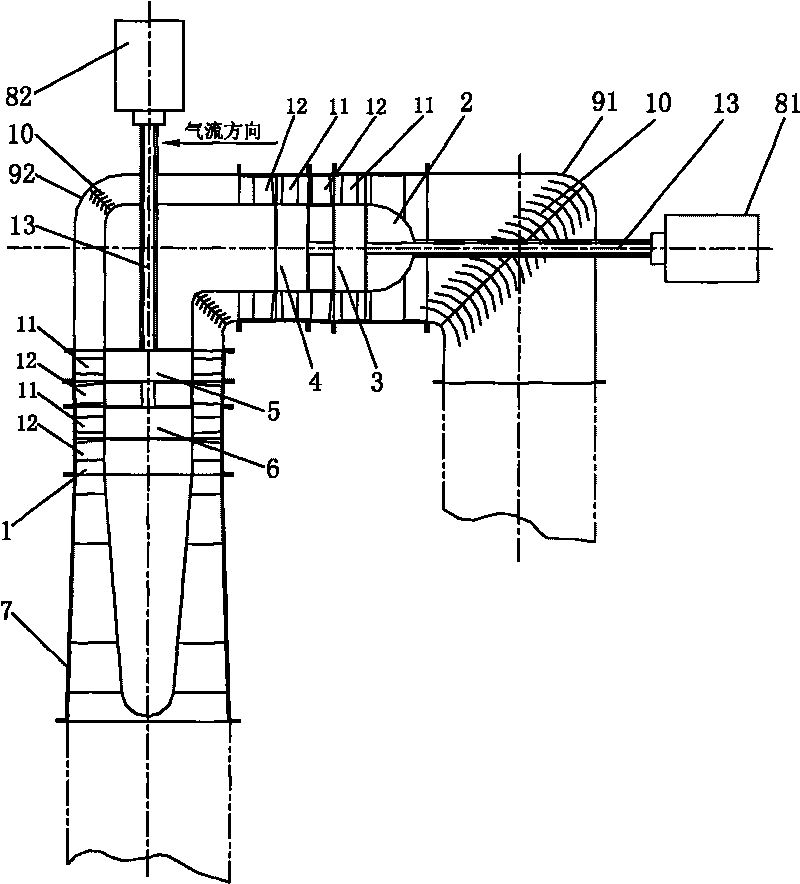

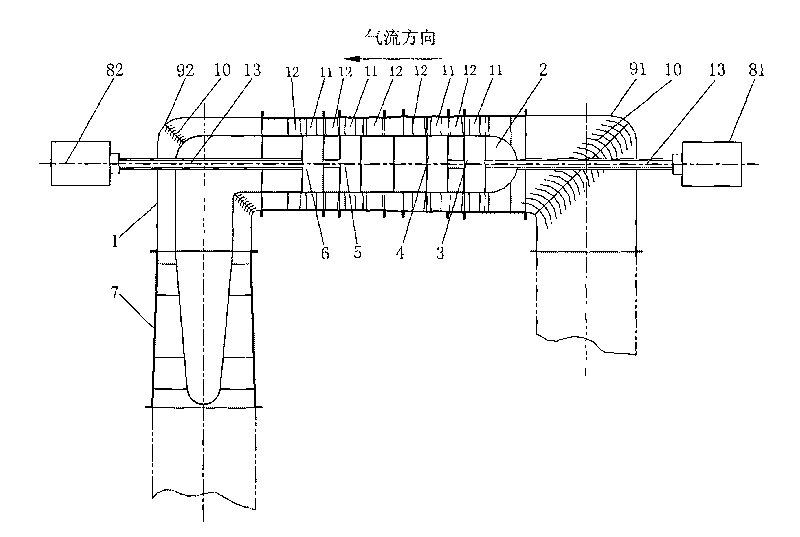

Axial flow compressor serially connected by multiple single-stage axial flow fans in L-shaped arrangement

InactiveCN101696695AImprove unityShorten the lengthPump componentsRadial flow pumpsImpellerSingle stage

The invention relates to the field of fans used for closed type circular wind tunnels, in particular to an axial flow compressor formed by serially connecting by multiple fans, i.e. an axial flow compressor formed by serially connecting by multiple single-stage axial flow fans in L-shaped arrangement, comprising a casing, a fairing, an I-stage impeller, an II-stage impeller, an III-stage impeller, an IV-stage impeller and a diffuser, wherein the casing is a long pipeline with two orthogonal corners, which is arranged along the air flow direction of the wind tunnel; the whole axial flow compressor is arranged in an L shape, the diffuser is arranged behind the second corner after the fairing is arranged at the first corner; all the impellers are serially connected between the faring and the diffuser, the I-stage impeller and the II-stage impeller form a group to be connected with a first main motor through an intermediate shaft, and the III-stage impeller and the IV-stage impeller form a group to be connected with a second main motor through an intermediate shaft. The whole axial flow compressor is in L-shaped arrangement, is easy to arrange in the closed type circular wind tunnel and has low design and manufacture difficulty of the motors, consistent impeller pumping points and reliable working performance, thereby meeting the requirements on both mass flow and higher pressure ratio.

Owner:SHANGHAI BLOWER WORKS

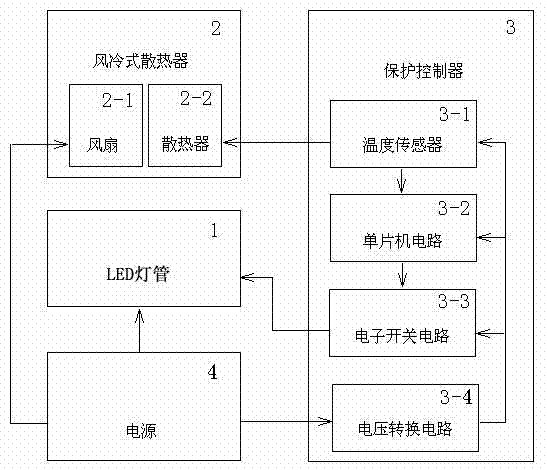

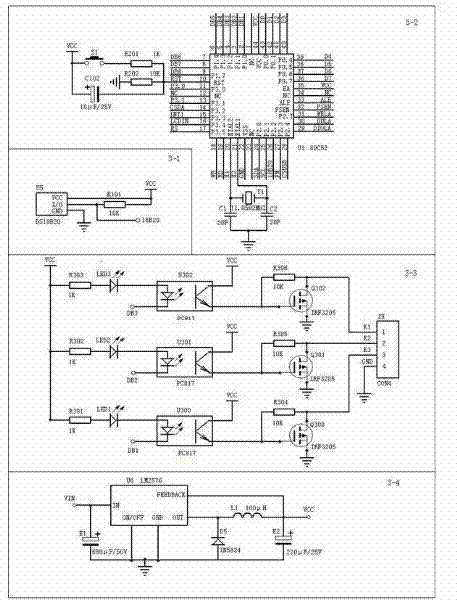

Air-cooling radiation LED (light emitting diode) lamp

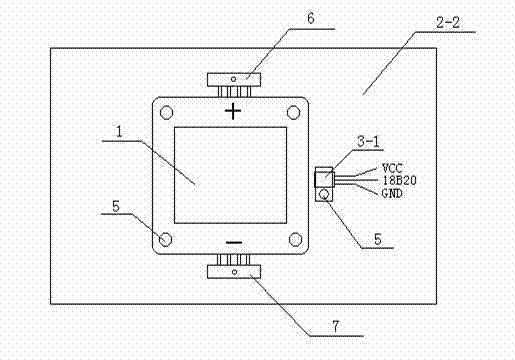

InactiveCN102413619AAutomatic temperature monitoringWith automatic overheating protection functionPoint-like light sourceLighting heating/cooling arrangementsElectronic switchRadiation mode

The invention discloses an air-cooling radiation LED (light emitting diode) lamp, which comprises an LED lamp tube and a power supply. The lamp is characterized by comprising a protective controller and an air-cooling radiator, wherein the protective controller consists of a singlechip circuit, a temperature sensor, an electronic switching circuit and a voltage conversion circuit, and the temperature sensor and the electronic switching circuit are respectively connected with the singlechip circuit; the voltage conversion circuit is connected with the power supply, and respectively connected with the singlechip circuit, the temperature sensor and the electronic switching circuit; the air-cooling radiator consists of a fan and a radiator, and the fan is connected with the power supply; and the LED lamp tube is fixedly connected to the radiator, and is connected with the electronic switching circuit of the protective controller and the power supply. In the use process, the air-cooling radiation LED lamp can automatically detect the temperature of the radiator, and performs an automatic overheat protecting function to the LED lamp tube, so that the problems that the lamp has a large radiator and high cost by adopting a natural radiation mode, and poor wind and shaking resistance caused by overweight dead weight of the lamp can be solved.

Owner:CHONGQING DONGLING NETWORK INFORMATION TECHCO

Two-flow tube header structure of wound-tube-type heat exchanger

InactiveCN103148730AHigh strengthImprove sealingHeat exchanger casingsPlate heat exchangerEngineering

The invention discloses a two-flow tube header structure of a wound-tube-type heat exchanger. The two-flow tube header structure comprises a tube header assembly, a flange base and a tube sheet. The tube header assembly comprises an outer tube header and an inner tube header, wherein the inner tube header and the outer tube heater respectively comprise a nozzle and a head and a cylindrical shell which are sequentially connected, the inner tube header is arranged in the outer tube header and is connected with the outer tube header through rib plates, the nozzle of the inner tube header is led out from the cylindrical shell of the outer tube header, the lower end of the cylindrical shell of the outer tube header is fixedly arranged on the flange base, two annular sealing surfaces which are arranged in the same plane are arranged on the upper end surface of the tube sheet and are respectively connected with the bottom end surface of the cylindrical shell of the inner tube header and the bottom end surface of the flange base which is connected with the bottom end of the cylindrical shell of the outer tube header, gaskets are arranged between the connected end surfaces, and the flange base is connected with the tube sheet through bolts to tightly fasten the integral inner and outer tube headers on the tube sheet. The two-flow tube header structure has the advantages that the design and manufacturing difficulty and the production cost are reduced, the unreasonable design structure with a bypass tube header on a shell side is avoided, the design calculation and the manufacturing difficulty are reduced, the overall performance is excellent, the structure is convenient to assemble and the operation for maintenance, inspection, repair and the like is easy to conduct.

Owner:四川川润动力设备有限公司

Adsorption type low temperature heat resource power generation and refrigeration device

InactiveCN101520254AReduce the difficulty of design and manufactureImprove cooling effectClimate change adaptationEnergy efficient heating/coolingThermal energyAdsorption refrigeration

The invention relates to an adsorption type low temperature heat resource power generation and refrigeration device in the technical field of energy, which comprises a working medium pump, a vapor generator, a turbine, a generator, an adsorption refrigerator, a throttle valve, and an absorber which are connected in turn. Solar energy, geothermal energy, biomass energy or various industrial exhaust heat is taken as a system heat source; a binary working medium is selected as a system working medium; in the process of heating the heat source, a low boiling point volatile component of the binary working medium is changed into a gaseous state to push the turbine to do work and generate electricity, and the liquid part of the binary working medium releases heat in the adsorption refrigerator to realize refrigeration; and a gas working medium flowing out of an outlet of the turbine is re-absorbed by the liquid working medium flowing out of the adsorption refrigerator in the absorber so as to finish a working cycle. The device combines a low temperature Rankine cycle and an adsorption refrigeration cycle, and continuously outputs electric energy and cold energy when low-grade heat energy is continuously recycled, thereby realizing the power generation and the refrigeration by utilizing low temperature exhaust heat.

Owner:SHANGHAI JIAO TONG UNIV

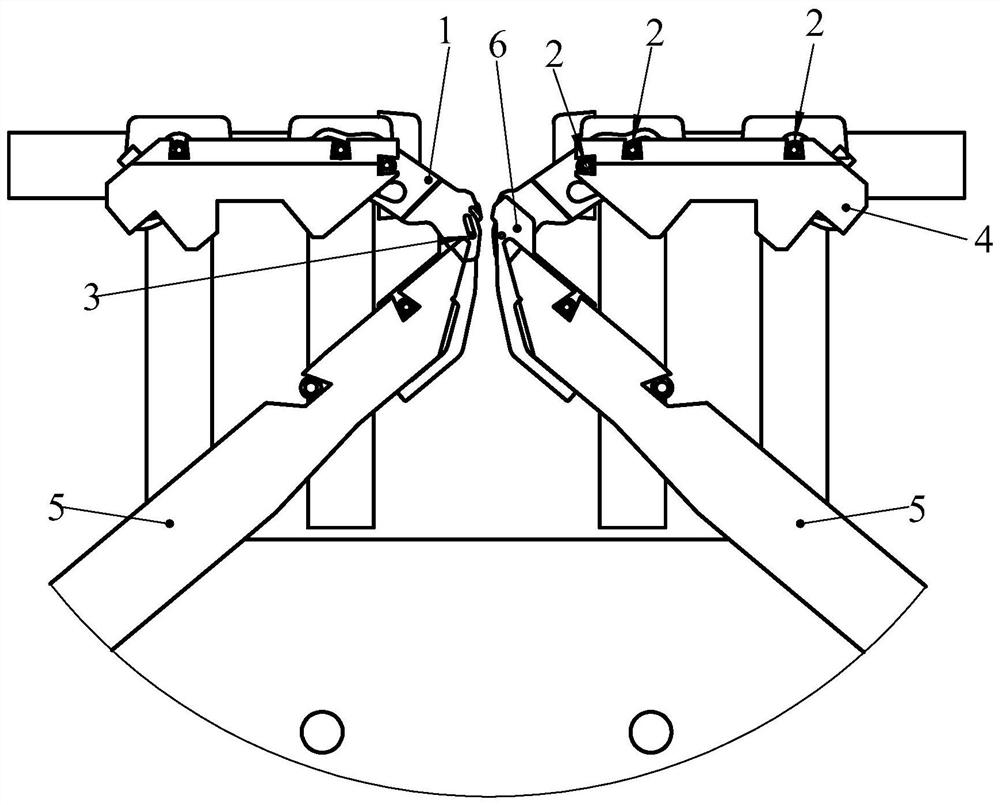

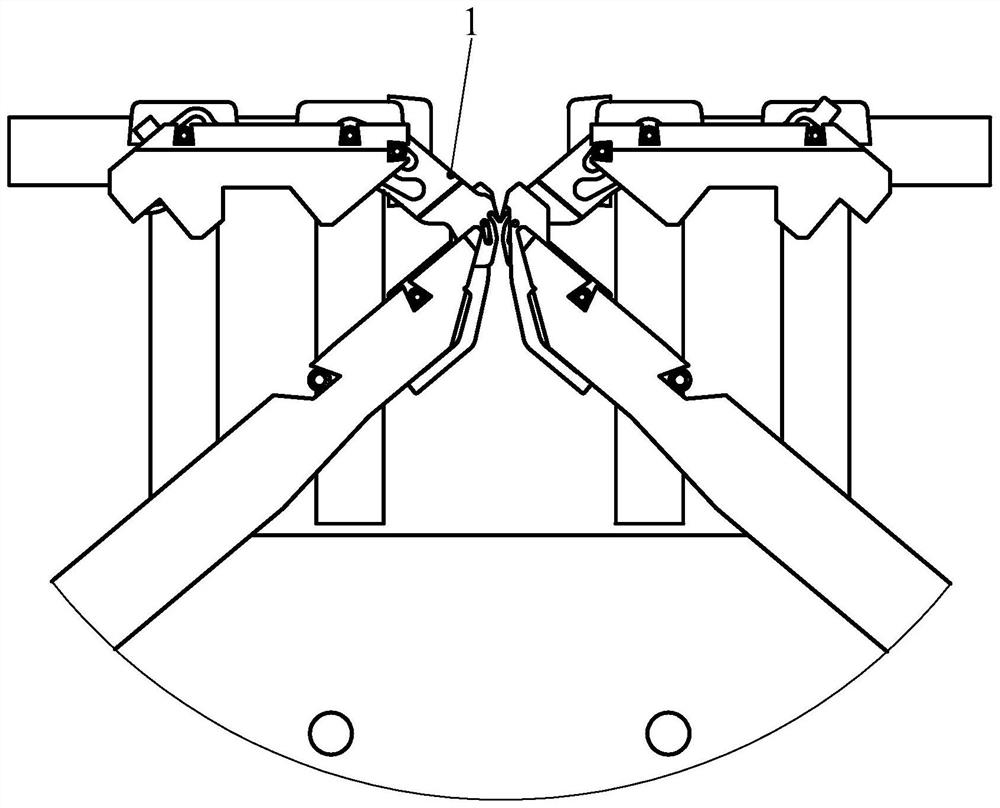

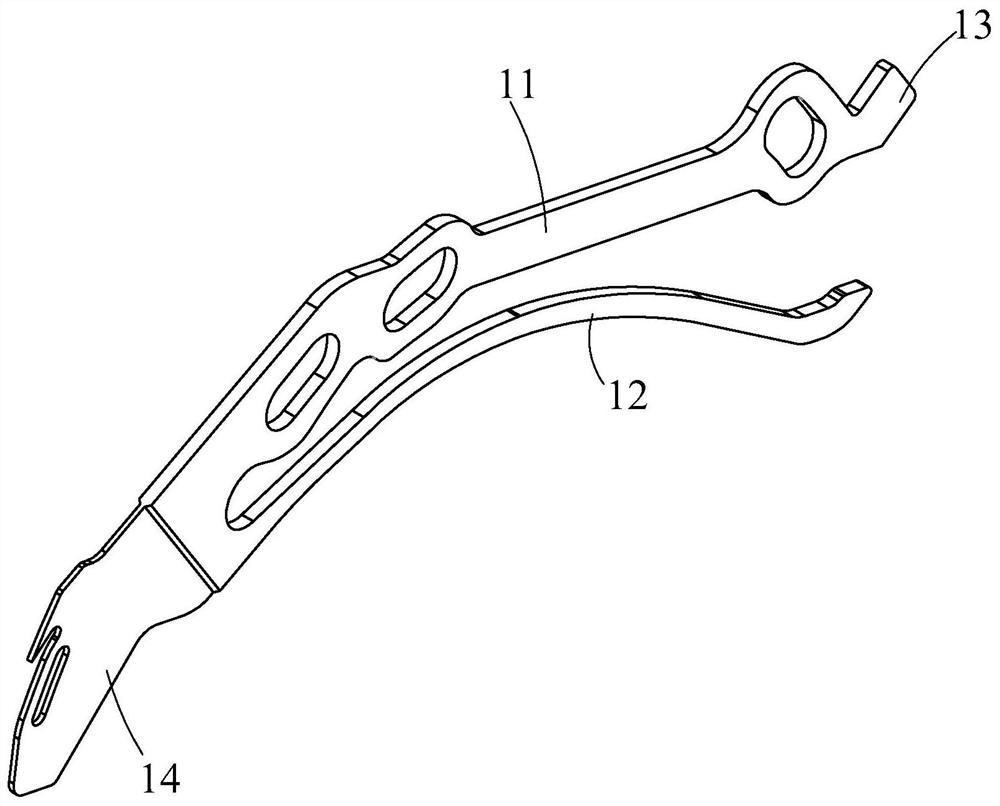

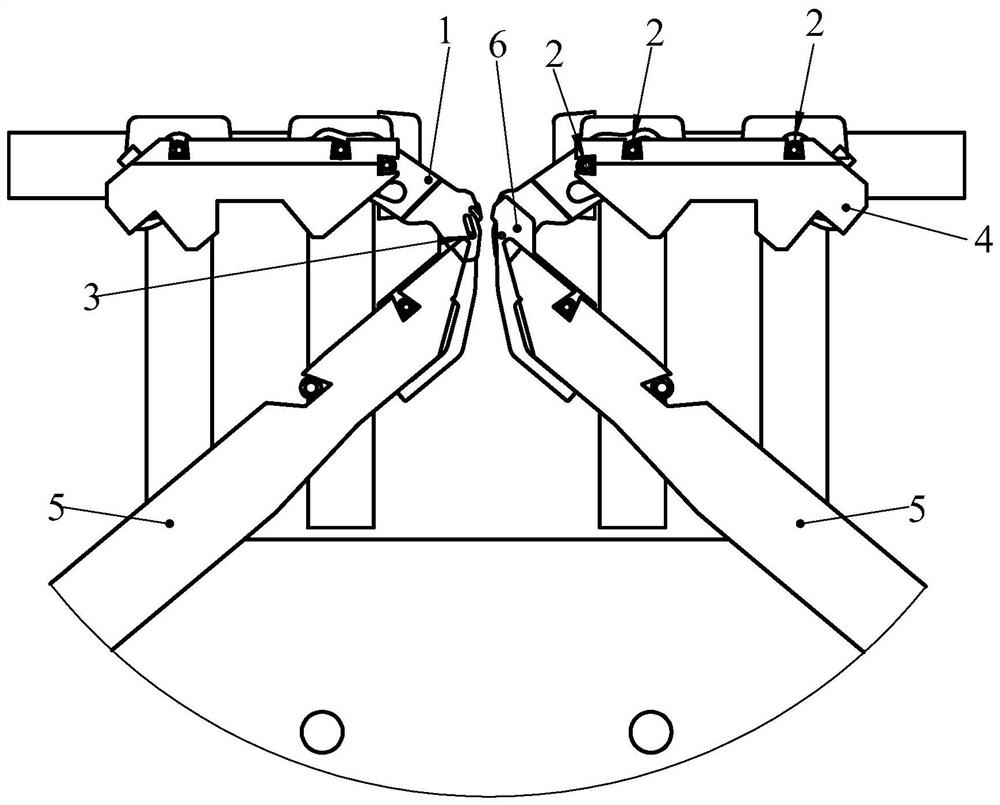

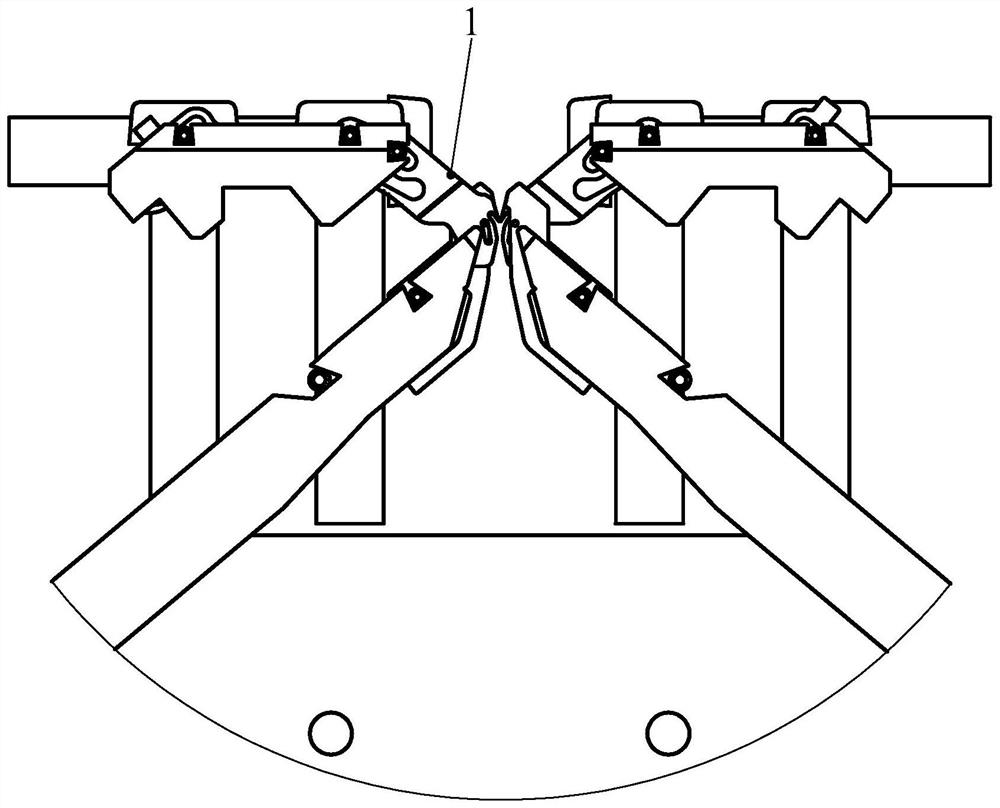

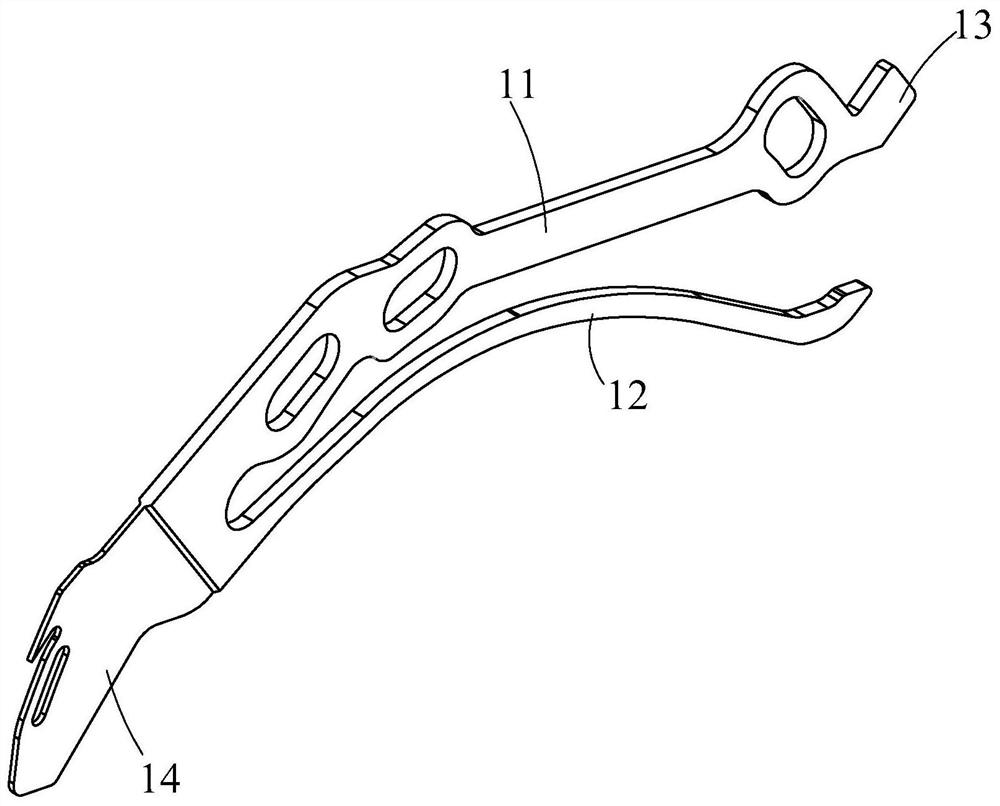

Yarn pressing device of flat knitting machine and working method of yarn pressing device

The invention relates to a yarn pressing device of a flat knitting machine and a working method of the yarn pressing device. A sinker is installed in a sinker containing groove; the sinker comprises a sinker body, an elastic presser foot part, a power piece heel part and a yarn pressing part; three rotary positioning holes are formed in the sinker body; a through hole for limiting is formed in the yarn pressing part; three through grooves are formed in a sinker needle plate; a first positioning steel wire is installed in each through groove, and the three first positioning steel wires penetrate through three rotary positioning holes respectively; three intersection points generated by the axial leads of the three first positioning steel wires and the same cross section are not on the same straight line, a virtual circle is determined by the three intersection points, and the circle centers of all the virtual circles form a virtual axial lead; and the power piece heel part enables the sinker to rotate back and forth around the virtual axial lead under the action of power. According to the yarn pressing device, the use requirements on rollers, presser feet and other flat knitting machine mechanisms during knitting are reduced, the structural design optimization of an integrated garment making machine is facilitated, and the overall production cost is favorably controlled.

Owner:桐乡市强隆机械有限公司

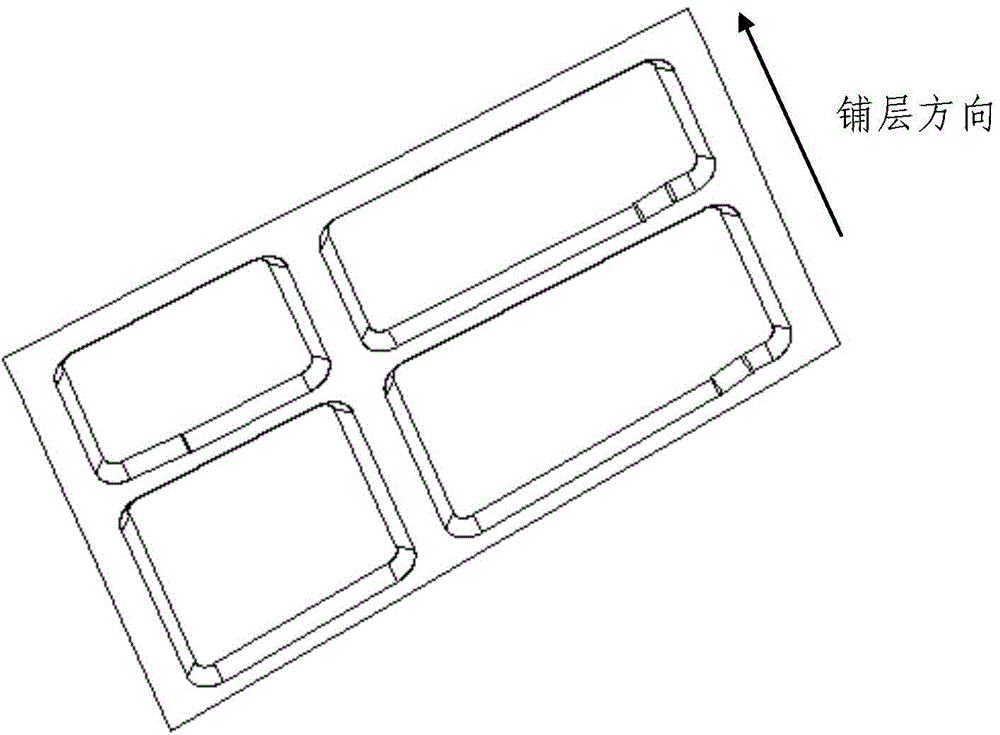

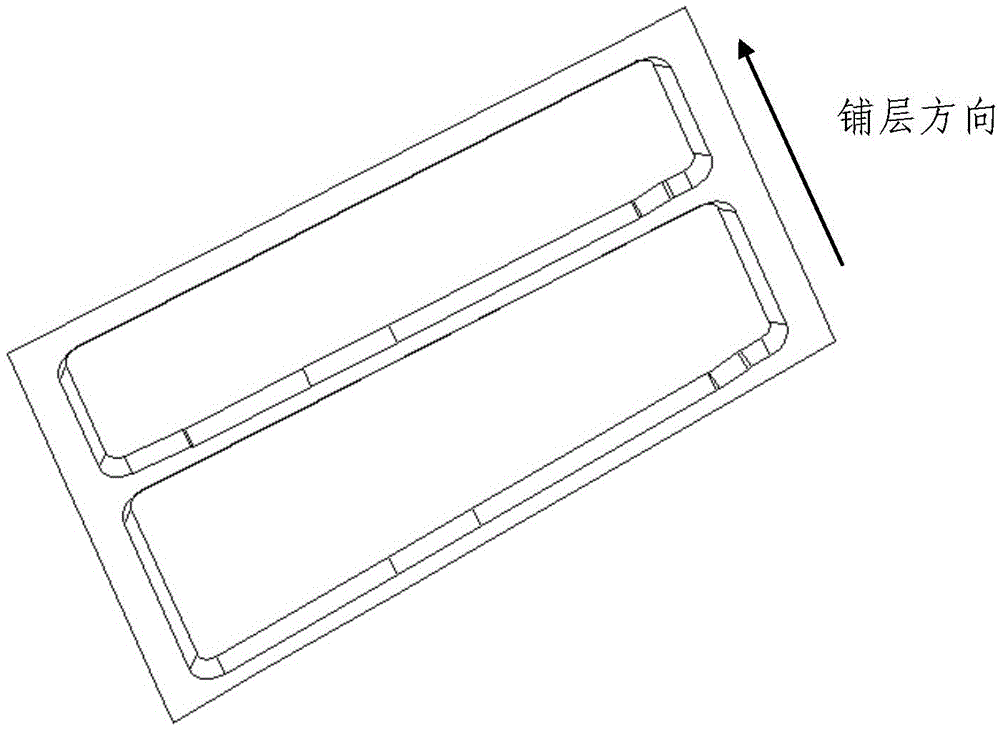

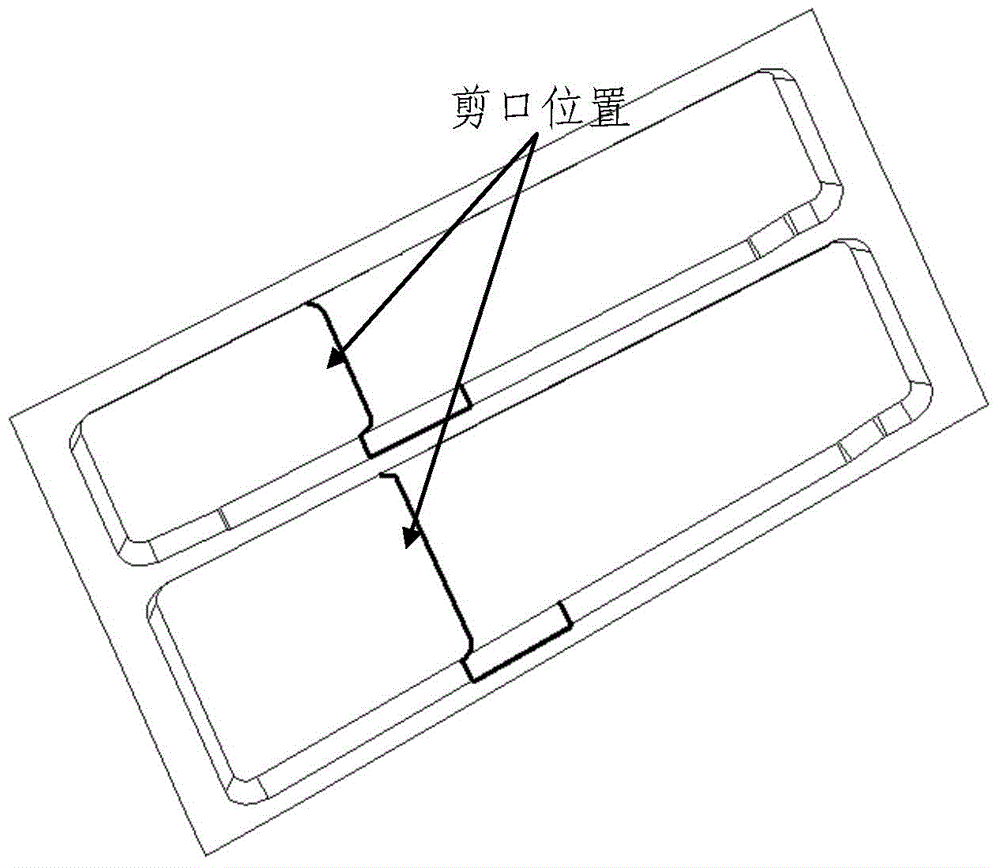

Method for unfolding multi-honeycomb sandwich structure member upper skin paving layer

InactiveCN105653749AIncrease profitReduce the difficulty of design and manufactureSpecial data processing applicationsNumerical controlFree zone

The invention provides a method for unfolding a multi-honeycomb sandwich structure member upper skin layer. The method includes the following steps: a first step, making a paving surface of a multi-honeycomb sandwich structure member upper skin in a human-computer interaction interface; a second step, filling up honeycomb-free zones parallel to a paving layer direction in the paving layer direction in the human-computer interaction interface to obtain a simulation surface of the multi-honeycomb sandwich structure member upper skin; a third step, using software to perform paving property analysis on the simulation surface of a composite material member, and then unfolding the paving layer on the simulation surface to form upper skin paving layer unfolding data; a forth step, using software to perform reasonable shearing on the paving layer on the paving surface and to make an outline of a patch cutting piece to form shearing position data and patch plane unfolding data; and a fifth step, inputting the upper skin paving layer unfolding data and the patch plane unfolding data into numerical control blanking data, inputting the shearing position data into laser projection data to complete unfolding of the multi-honeycomb sandwich structure member upper skin.

Owner:JIANGXI CHANGHE AVIATION IND

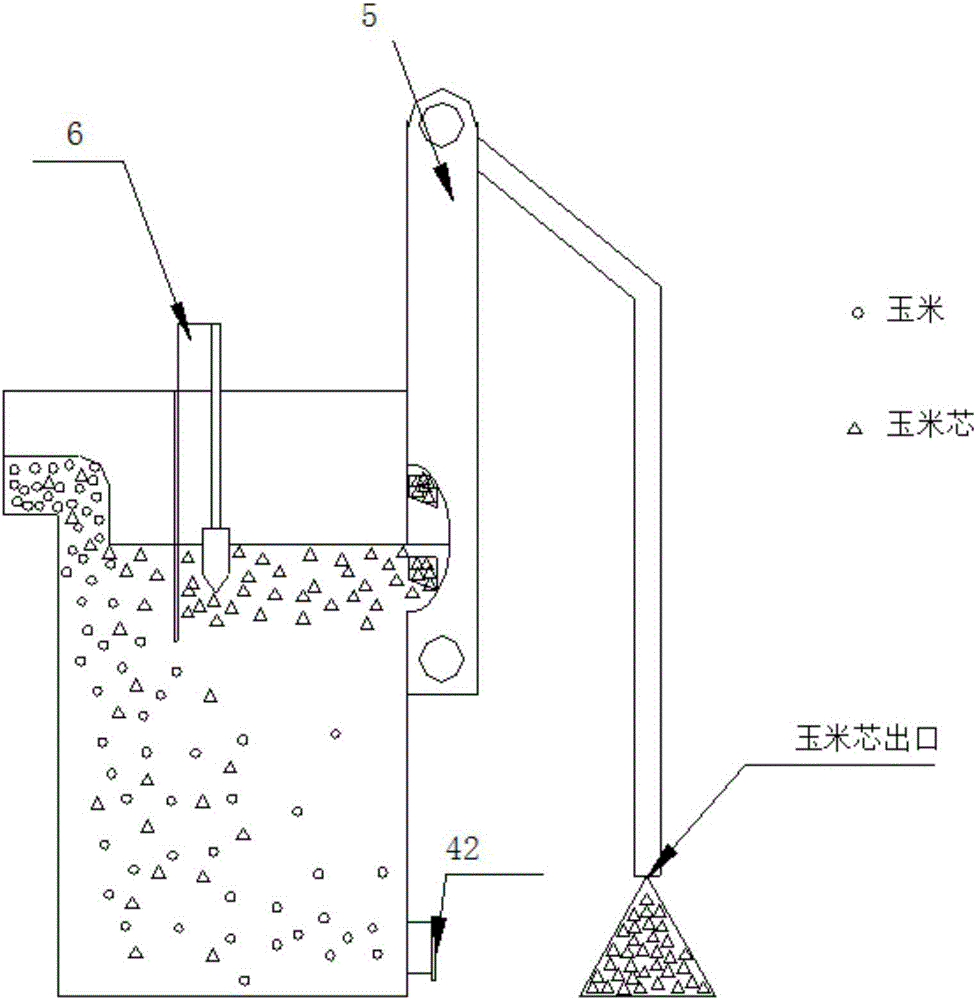

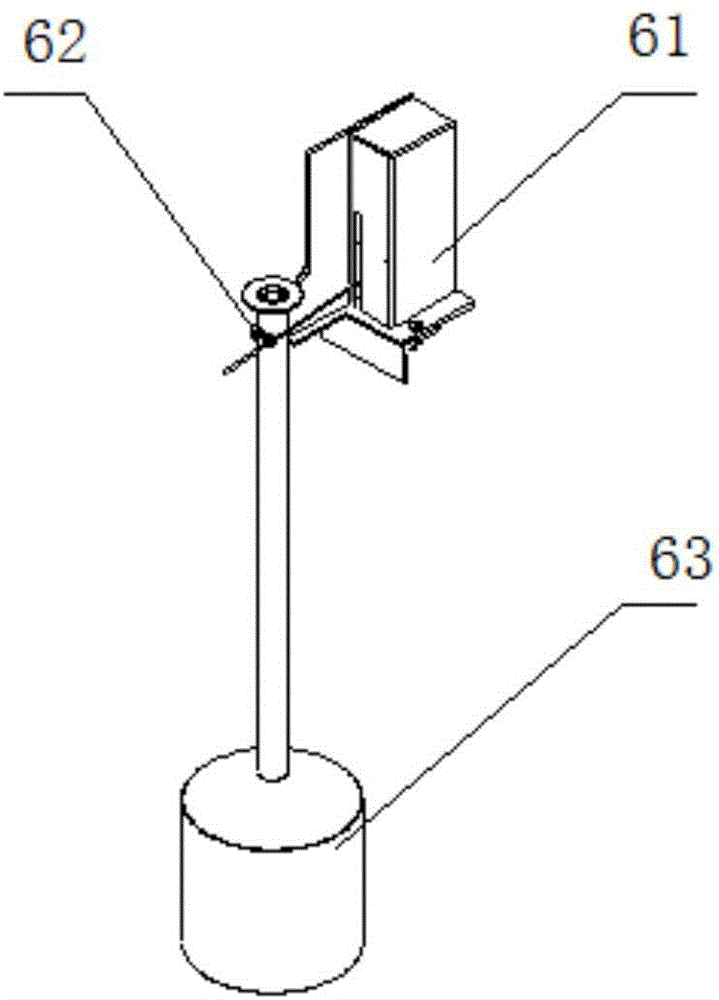

Impurity removing device and method for separating and extracting corncobs through water pressure

InactiveCN106111311ASimple structureReduce the difficulty of design and manufactureWet separationPore water pressureWorking environment

The invention discloses an impurity removing device and method for separating and extracting corncobs through water pressure. The impurity removing device comprises an impurity removing tank, a partition plate, a bucket elevator and a liquid level sensor. The partition plate is arranged in the impurity removing tank, a material inlet area is formed between one side of the partition plate and the impurity removing tank, and a material outlet area is formed between the other side of the partition plate and the impurity removing tank. The bucket elevator is arranged on the outer side of the impurity removing tank. A feeding port of the bucket elevator is connected with a first discharging port of the material outlet area, and the liquid level sensor is arranged in the impurity removing tank. Material liquid composed of corns, the corncobs and water is discharged into the material inlet area of the impurity removing tank along the partition plate, the corns and the corncobs mutually move and are separated under the action of the water pressure, the corns are gathered at the bottom of the impurity removing tank, and the corncobs float on the water level of the material outlet area and enter the feeding port of the bucket elevator. The impurity removing device and method solve the problem that the corncobs cannot be independently extracted through a grain impurity removing machine; and meanwhile, environment pollution is reduced, the mechanical degree is improved, the work environment is improved, and a foundation is laid for maximization of grain machines.

Owner:姚劲 +1

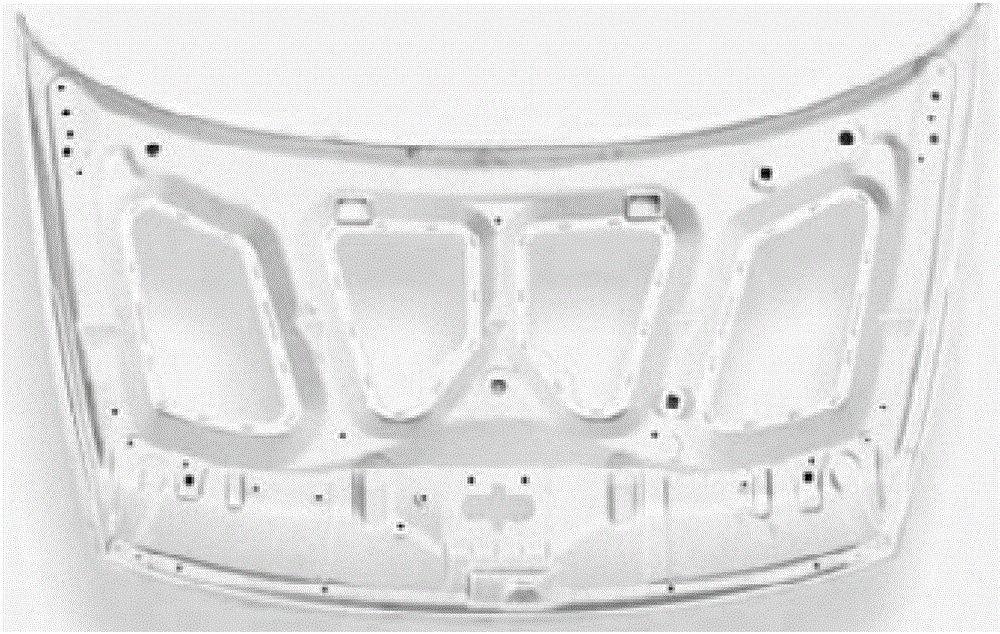

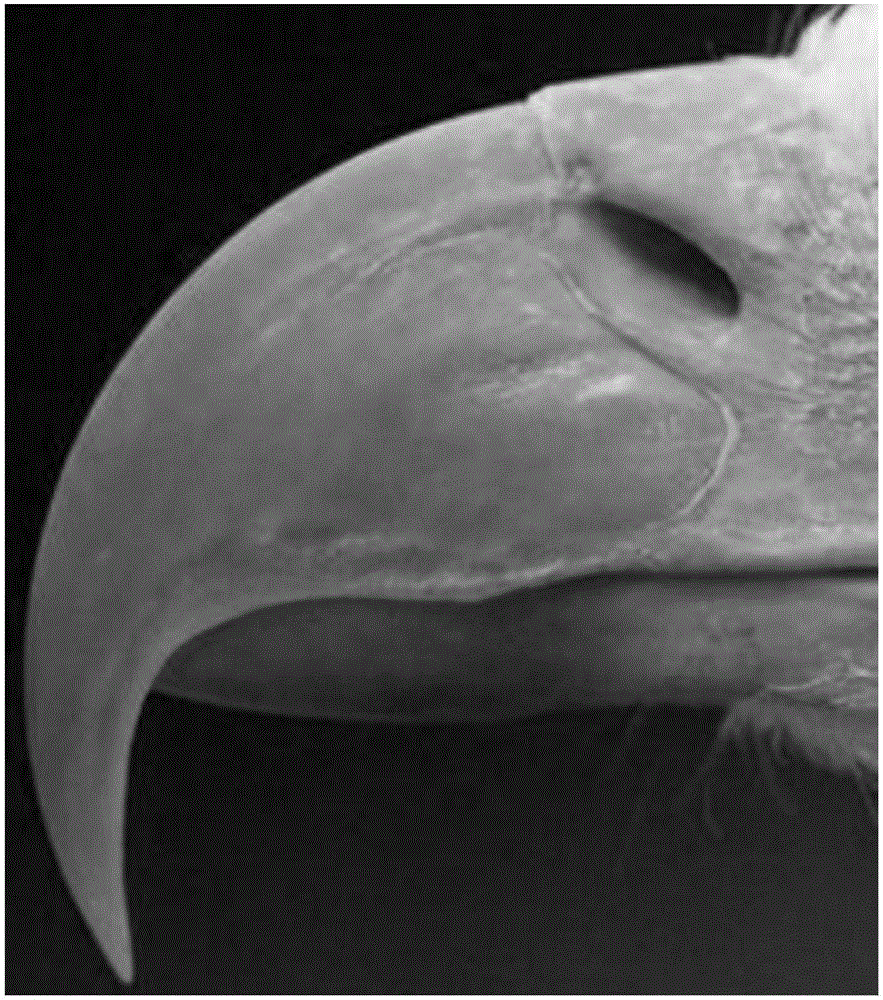

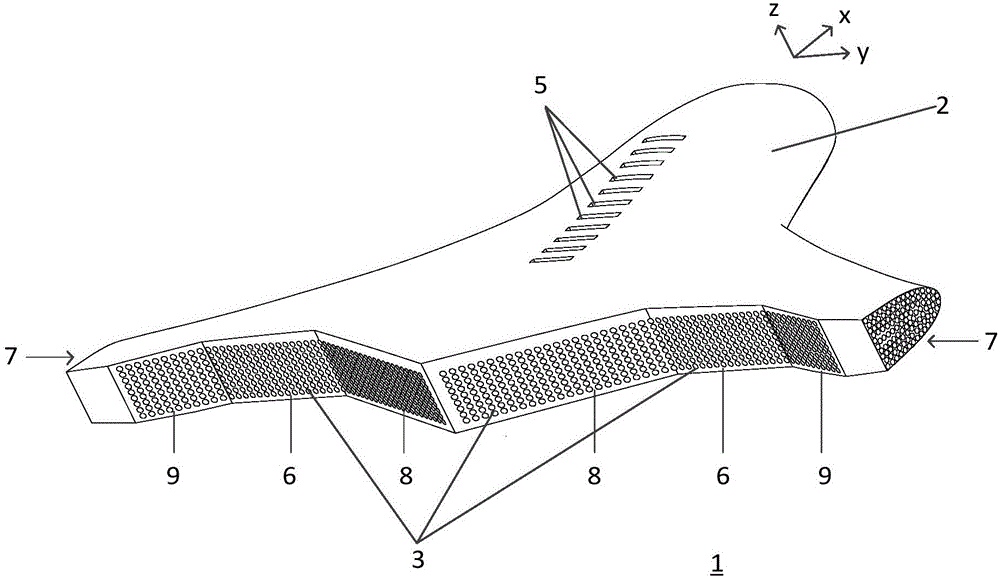

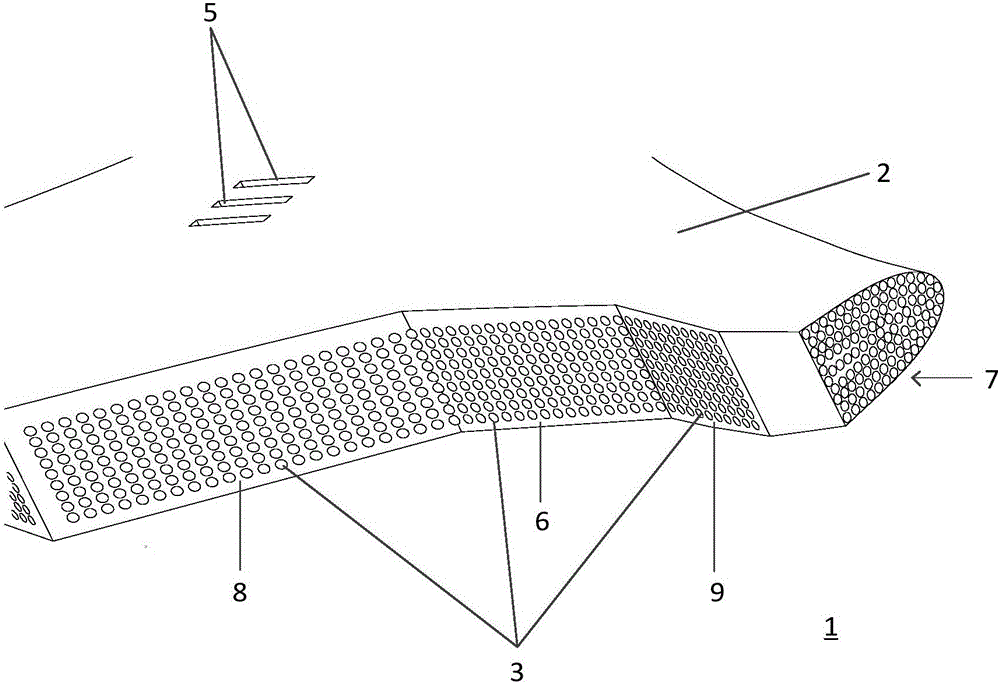

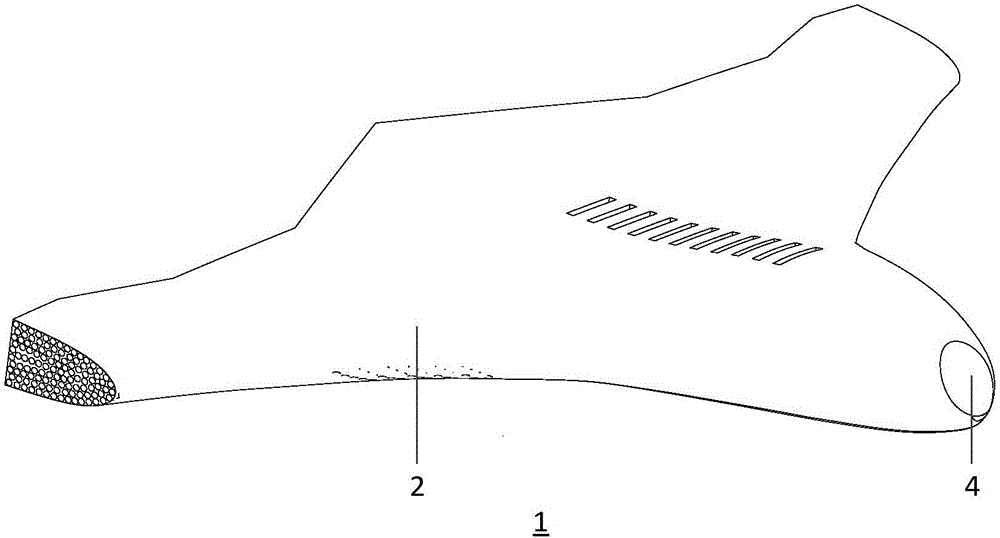

Bionic partition-type engine cover outer plate for sportscar

InactiveCN106335555AReduce the difficulty of design and manufactureReduce maintenance costsSuperstructure subunitsVehiclesCurve shapeEngineering

The invention relates to a partition-type engine cover outer plate, in particular to a bionic partition-type engine cover outer plate with an olecranon characteristic for a sportscar. The engine cover outer plate adopts a bionic design idea; an olecranon with favorable air adhesion decreasing and resistance reducing characteristic is used for a sportscar engine cover design, i.e., the outline curve of the engine cover outer plate is of a longitudinal-section outline bionic characteristic curve shape of the olecranon. The partition-type engine cover outer plate is capable of better achieving an enveloping effect on an engine and other parts in an engine compartment, is relatively good in heat insulation and sound insulation effects, and is simple in structure, streamline in modeling, beautiful in appearance and low in wind resistance coefficient.

Owner:JILIN UNIV

Thrust matrix

ActiveCN106005441ASimple structureHigh freedom of movementPower plant typeMaintainabilityControl system

The invention provides a thrust matrix. The thrust matrix comprises a machine body, and a plurality of power units and a control system which are arranged on the machine body; and the control system is used for controlling the plurality of power units to provide a three-dimensional all-directional time-varying propelling capability to the machine body. The plurality of power units are arranged in a one-dimensional or two-dimensional or three-dimensional direction of a space of the machine body and are used for providing the three-dimensional all-directional time-varying propelling capability to the machine body. The thrust matrix can realize the effects that the machine body is simple in structure, high in degree of freedom of motion, strong in maneuverability, high in flexibility, wide in power range, low in design and manufacturing difficulty of the power units, low in production and manufacturing cost, high in reliability, good in maintainability and high in health safety.

Owner:TSINGHUA UNIV

Current transformer

InactiveCN105006358AReasonable designPrevent low load dead zoneTransformersTransformers/inductances coils/windings/connectionsLow loadElectric power system

The invention relates to the field of electric power system automation, and specifically relates to a current transformer. The current transformer comprises mutual inductance coils composed of closed iron cores and windings. The mutual inductance coils comprise two groups, namely a first mutual inductance coil and a second mutual inductance coil. The ratio of the number of turns of the secondary winding of the first mutual inductance coil to the number of the primary winding of the first mutual inductance coil is larger than the ration of the number of turns of the secondary winding of the second mutual inductance coil to the number of the primary winding of the second mutual inductance coil. The first mutual inductance coil is connected to a comparison circuit, the second mutual inductance coil is connected to an amplification circuit, and the amplification circuit is connected to the comparison circuit. According to the invention, an output distortion problem of the current transformer under a low load condition is solved, the metering accuracy is improved, and the economic loss for the power grid is reduced.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

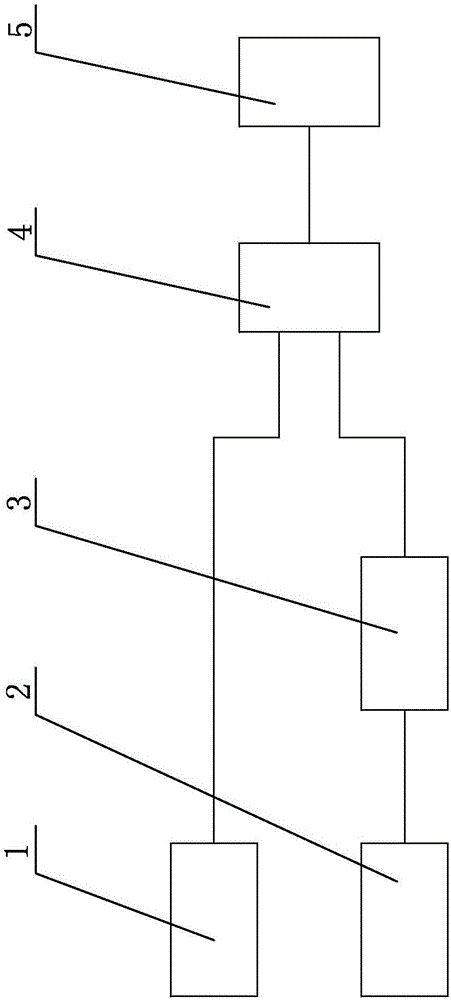

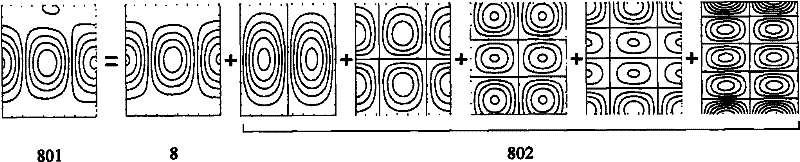

Exposure system based on control of principal component of space image

ActiveCN102540745AControlling the Spatial Light Intensity Distribution CharacteristicsReduce the difficulty of design and manufacturePhotomechanical exposure apparatusMicrolithography exposure apparatusPrincipal component analysisLight propagation

The invention relates to an exposure system based on the control of the principal component of a space image, sequentially comprising an illuminator, a masking plate, a projection objective lens and a silicon wafer table along the light propagation direction. A measuring unit used for measuring the space image information is arranged on the silicon wafer table. At least one movable lens of which the position can be adjusted is arranged in the projection objective lens. The exposure system based on the control of the principal component of the space image further comprises a control module. The control module is used for establishing a matrix of conversion from the position of the movable lens in the projection objective lens to the principal component of the space image according to the space image information measured by the measuring unit and calculating the position adjustment quantity of the movable lens according to the matrix of conversion so as to control the displacement of movable lens.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Controllable brake parachute free of heat proof

InactiveCN102658872AGet rid of troubleSignificant improvementSystems for re-entry to earthCosmonautic landing devicesAtmosphereSpacecraft

A controllable brake parachute free of heat proof for a reentry of a recoverable spacecraft into the atmosphere relates to a returning process of the recoverable spacecraft. The controllable brake parachute free of the heat proof is composed of a brake parachute, a parachute opening mechanism and a launch and recovery mouth mechanism. The controllable brake parachute free of the heat proof is installed on the tail portion of the recoverable spacecraft, a reentry velocity and a reentry temperature can be reduced by substantially increasing drag areas of the recoverable spacecraft, and thereby an aim of the reentry free of the heat proof is achieved.

Owner:高荣江

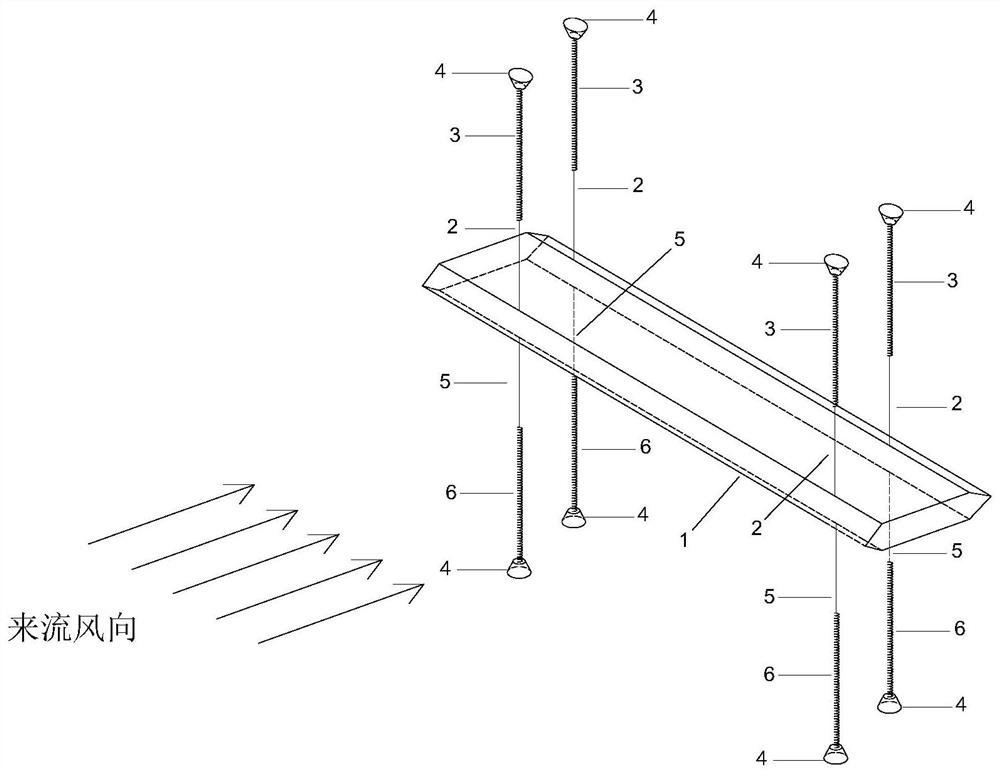

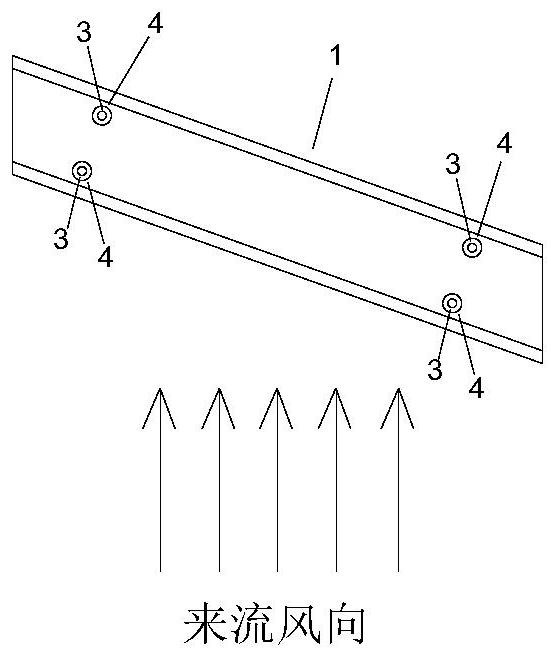

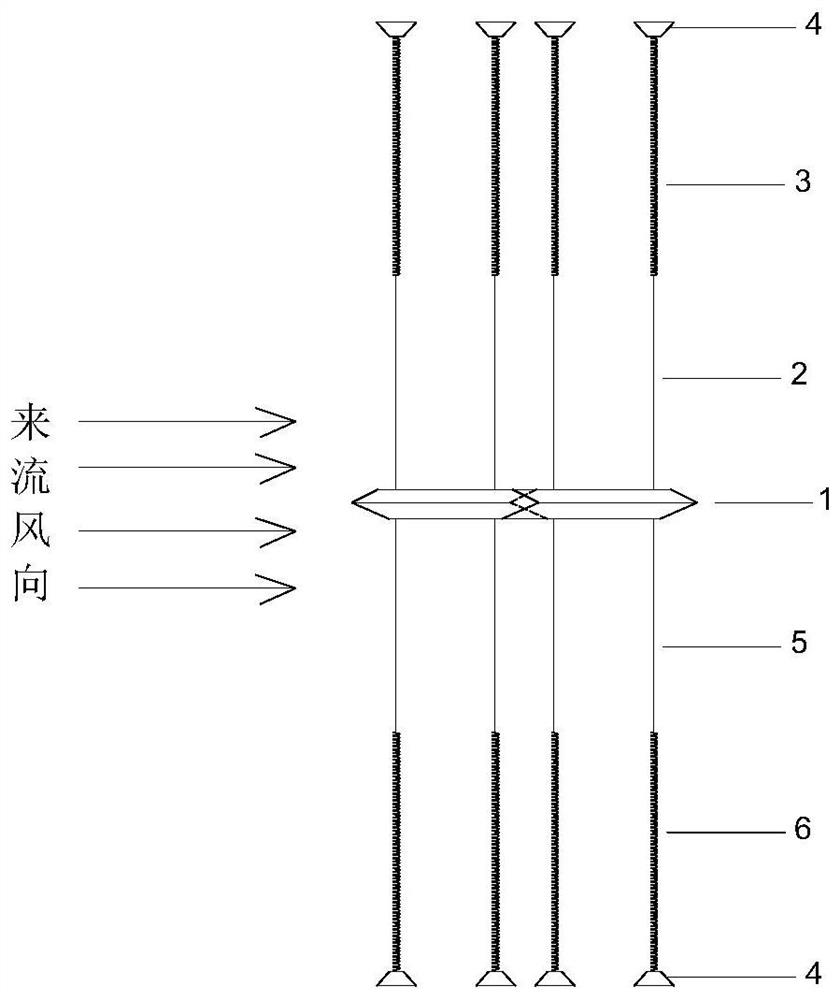

Bridge rigid segment model vibration measurement device for simulating oblique wind test condition in wind tunnel

PendingCN112051025AEasy to assemble and disassembleEasy to adjust wind angleAerodynamic testingVibration measurementAerodynamic load

A bridge rigid segment model vibration measurement device for simulating inclined wind test conditions in a wind tunnel adopts an upper spring suspension system and a lower spring suspension system, and the positions of spring suspension points need to be adjusted along with wind deflection angles; upper and lower spring lifting points are fixed on a wind tunnel top plate and a wind tunnel bottomplate by strong suckers. And the spring is connected with the model through a light high-strength string. Under the condition that the normal incoming flow direction is kept in the wind tunnel, different wind deflection angles are achieved by adjusting the included angle between the longitudinal axis of the bridge model and the wind direction, and the two end faces are parallel to the wind direction and the wind tunnel side wall when the model is static. The device has the advantages that the windage yaw angle adjustment is simpler, more convenient and easier; no special bracket needs to be manufactured; no damage is caused to the wind tunnel; transverse lazy arms at the end parts of the model and connecting devices between the lazy arms and the model are canceled, so that the influence ofthe lazy arms on the aerodynamic load of the model is eliminated, and the model manufacturing difficulty is reduced; the suspension position of the model can be randomly selected as required withoutbeing limited at the end part, so that the rigidity requirement and the design difficulty of the model are reduced; and the device is lower in overall manufacturing cost and more practical.

Owner:DALIAN UNIV OF TECH

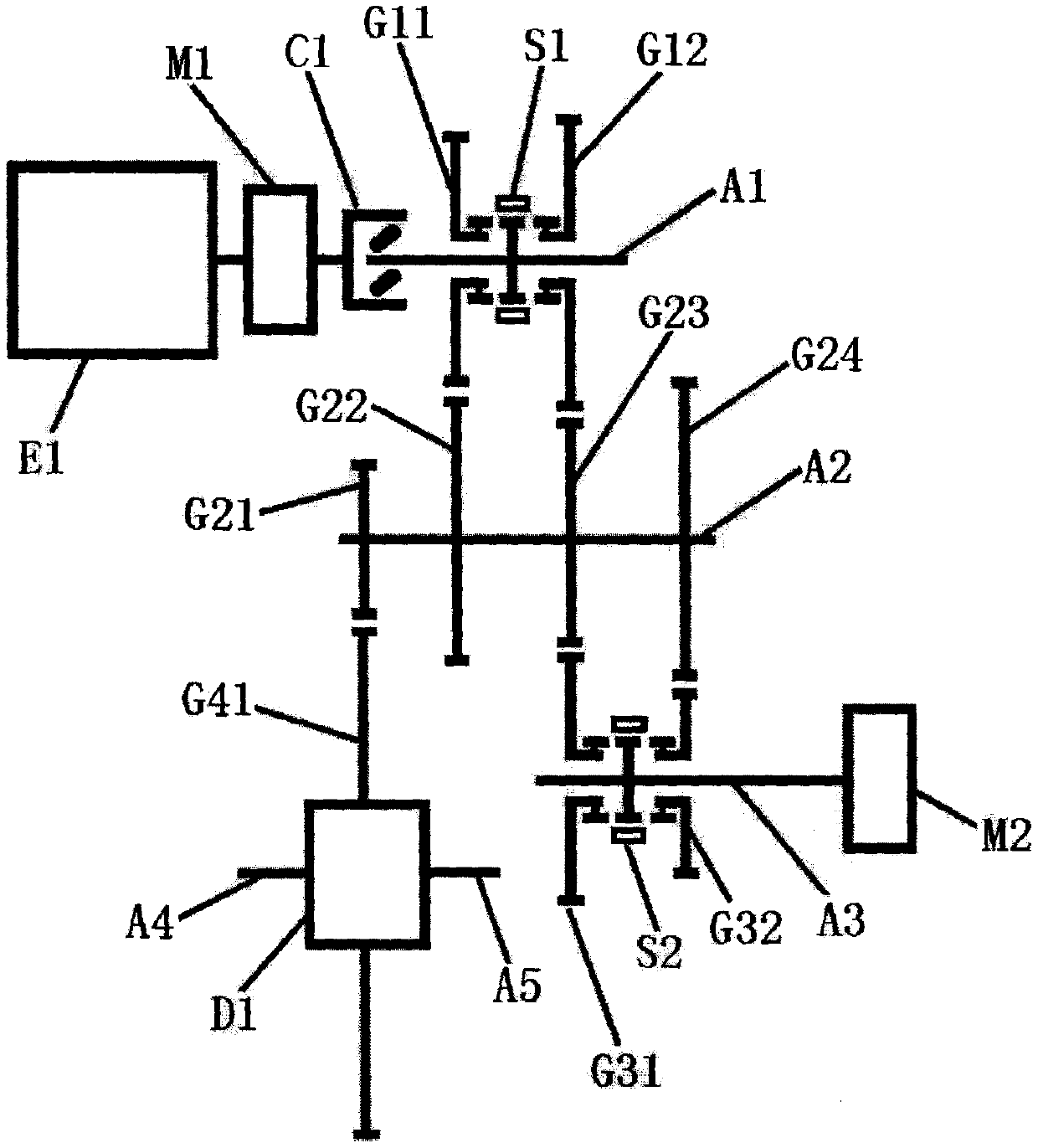

Hybrid electric vehicle system based on one-way clutch

InactiveCN111497593AGood energy saving effectImprove economyHybrid vehiclesGas pressure propulsion mountingAutomotive systemsGear drive

The invention provides a hybrid electric vehicle system based on a one-way clutch, belongs to the technical field of transportation machinery. The hybrid electric vehicle system is a shifting fork synchronizer gear shifting and speed changing mechanism based on the one-way clutch. The system is composed of an engine E1, a motor M1, a one-way clutch C1, a transmission shaft A1, a gear G11, a synchronizer S1, a gear G12, a transmission shaft A2, a gear G21, a gear G22, a gear G23, a gear G24, a motor M2, a transmission shaft A3, a gear G31, a synchronizer S2, a gear G32, a gear G41, a differential D1, a half shaft A4 and a half shaft A5. The one-way clutch C1 is used for achieving power decoupling of the gear shifting action of the transmission shaft A1. The vehicle system has nine working modes, can adapt to all working conditions required by vehicle running, can enable the engine to always work in the optimal fuel consumption rate interval, has independently designed climbing performance, low-speed acceleration performance and high-speed driving performance, supports unpowered interruption gear shifting and supports energy recovery.

Owner:江苏常州绿创新能源动力科技有限公司

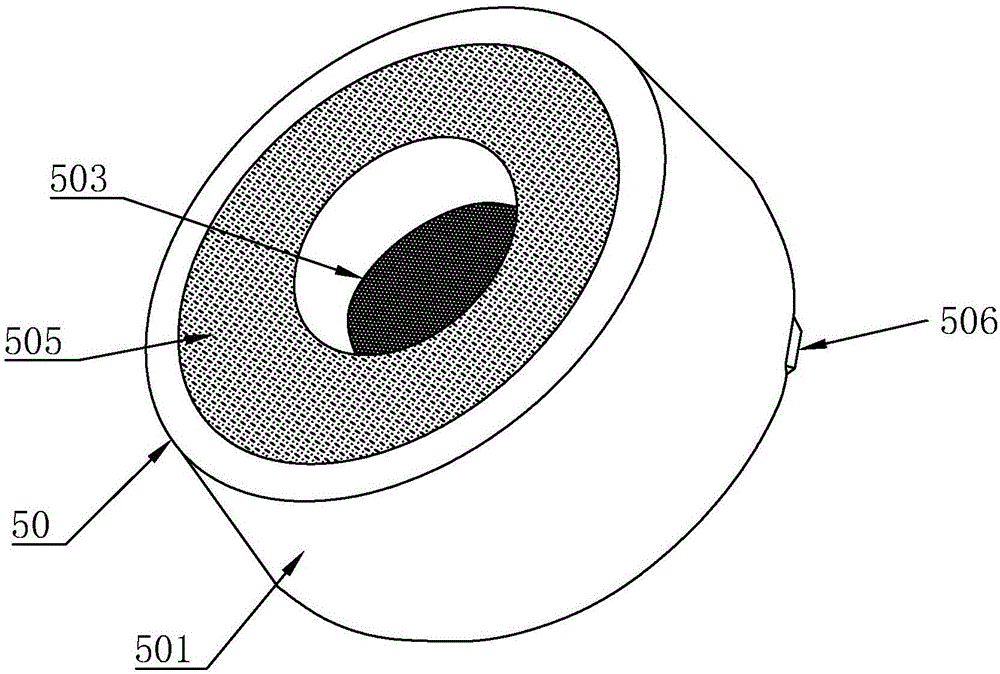

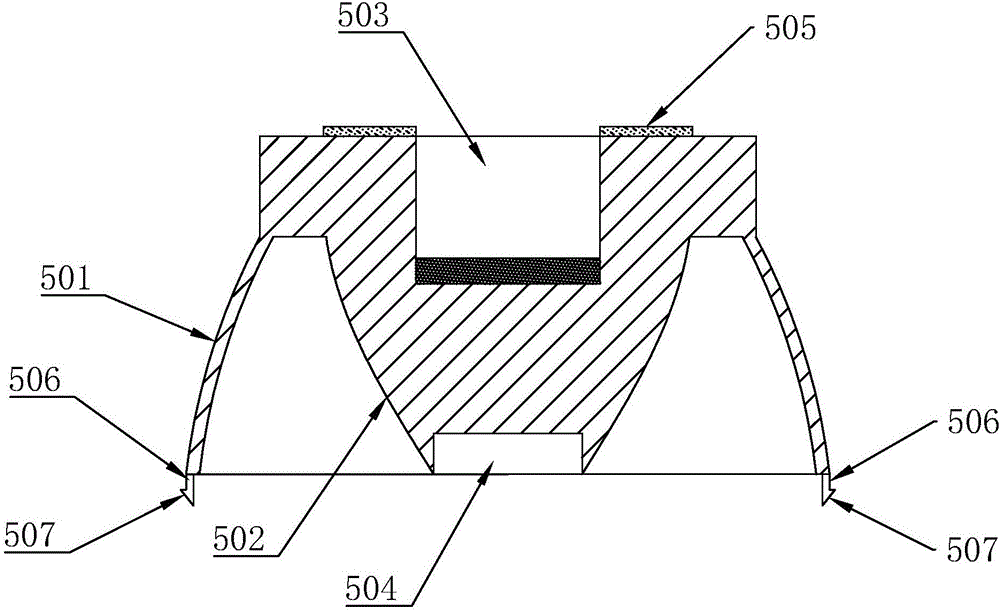

Combined-type lamp based on fisheye light distribution structure

InactiveCN106764515AGood light intensityUniform lightLighting heating/cooling arrangementsLight fasteningsDesign technologyLight source

The invention discloses a combined-type lamp based on a fisheye light distribution structure. The combined-type lamp comprises a radiator, a surface ring, a lamp holder, an LED light source, a reflection cup and a lens; the lamp holder is fixed to the tail portion of the radiator and used for being installed on a socket, an inner cavity is formed in the radiator and used for assembling of the LED light source, the reflection cup and the lens, and the LED light source is installed on the illuminated face of the lens, the lens is installed at a light inlet of the reflection cup; and an optic is clamped at an end opening of the top of the reflection cup through the surface ring. According to the combined-type lamp based on the fisheye light distribution structure, a concave-convex treatment technology is suppressed on the optical mirror surface or the lens surface of an LED lamp, by presetting a design technology of a series of tiny concave-convex points, the surface of the reflection cup is composed of countless ridge surfaces, the outer surface of the lens is composed of many tiny convex points, and thus an ideal optical system is jointly formed; and through design, emergent light of the lamp is good in light intensity and even and soft in light ray within a controllable range.

Owner:中山市华艺灯饰照明股份有限公司

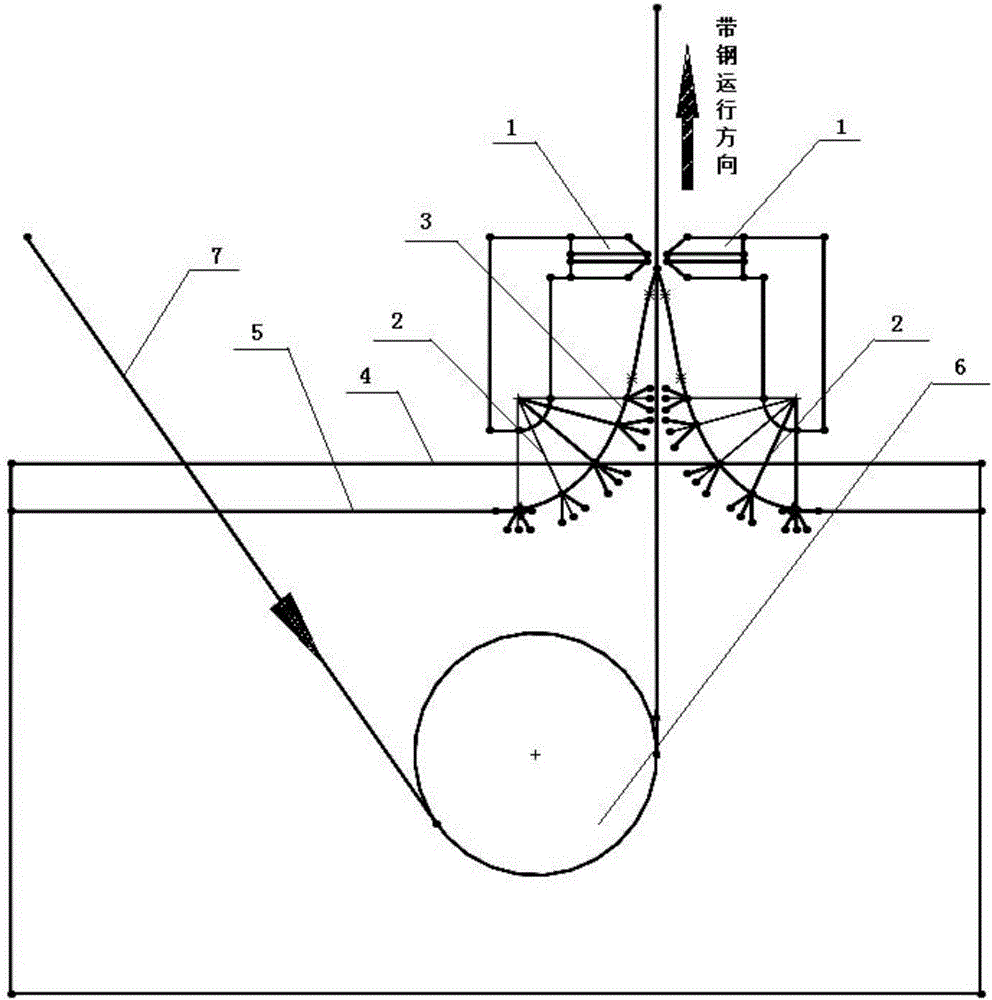

Plating control method and application thereof

ActiveCN105349930AReduce design and manufacturing difficultyLow costHot-dipping/immersion processesSlagAir knife

The invention discloses a plating control method. In the process that strip steel is separated from the solution surface of a plating solution, plating solution brought out of the solution surface by the strip steel is subjected to ultrasonic vibrating treatment through ultrasonic waves at first, and then jetting treatment is conducted through an air knife device. A curved surface of the plating solution brought out of the solution surface by the strip steel is formed between the strip steel and the solution surface, and the ultrasonic wave acts on plating solution within the range of the curved surface. The viscosity of nonferrous liquid metal is lowered through an ultrasonic device, and the splatter effect of liquid metal adhered to the strip steel surface is produced through the vibration produced by the ultrasonic wave in the liquid metal, so that a part of liquid metal is automatically stripped from the strip steel surface and the weight of nonferrous liquid metal brought out by the strip steel in operation is lowered. The accurate control over the thickness of plating can be achieved through the air knife scraping device with low gas pressure and flow. The slag production amount is greatly reduced; the pollution of noise and dust is also reduced; the design and manufacturing cost of an air knife is reduced; the problem of plating of thin plating in high speed condition is solved.

Owner:CISDI ENG CO LTD

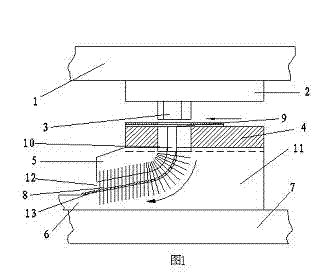

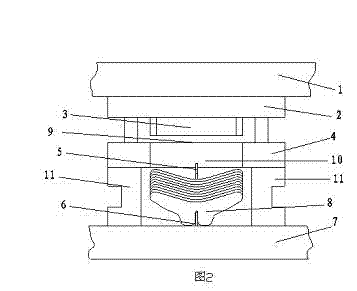

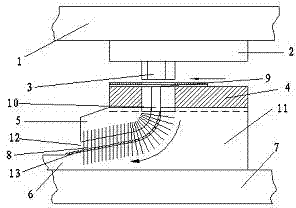

Stamping die

InactiveCN102476469ANo cloggingReduce the difficulty of design and manufactureShaping toolsPressesEngineeringMechanical engineering

The invention relates to a stamping die, which comprises an upper template, an upper die, a stamping head, a lower die, an upper guide plate, a lower guide plate, a bracket and a working platform, wherein the upper die is fixed below the upper template; the stamping head is fixed below the upper die; the lower die is fixed on the working platform through the bracket; the upper die and the lower die are flush in parallel; the lower die is provided with a blanking port; the stamping head is aligned with the blanking port; the upper guide plate and the lower guide plate are fixed below the lower die; the upper guide plate and the lower guide plate are provided with transmission devices; and a guide rail is arranged between the upper guide plate and the lower guide plate. In the invention, a simplest and most convenient guide plate guide device is adopted, the guide plate is provided with the transmission device, workpieces are stamped discontinuously, and extruded products pass through the smooth guide rail smoothly and are laminated effectively and orderly, so that the designing and manufacturing difficulty of the stamping die is lowered greatly, the products are not required to be sorted after guiding, packaging procedures are reduced, an appearance is not damaged, and cost is reduced.

Owner:秦赤球

Mechanical model device for rotor of motor

ActiveCN105181325AEasy to operateSimple and fast operationMachine part testingTesting dielectric strengthExperimental researchElectric machine

The invention discloses a mechanical model device for a rotor of a motor and relates to the technical field of test machinery. The mechanical model device comprises a rotor and a rotor winding, wherein an axial winding slot is arranged along an axial direction of the rotor; a winding bar of the rotor winding is inserted into the axial winding slot; a winding tail end of the winding bar exposed from the axial direction of the rotor is formed into an end winding; end fixing devices are fixedly arranged at the two ends of the rotor; the end fixing devices are used for fixing the end winding. The mechanical model device is fit for high-capacity winding type rotor machinery, especially for the experimental research for the fixing mode of the rotor winding end and the detection and test analysis for the safe reliability of the fixing of the winding bar end of the rotor and the electric insulating property of the rotor winding.

Owner:DONGFANG ELECTRIC MACHINERY

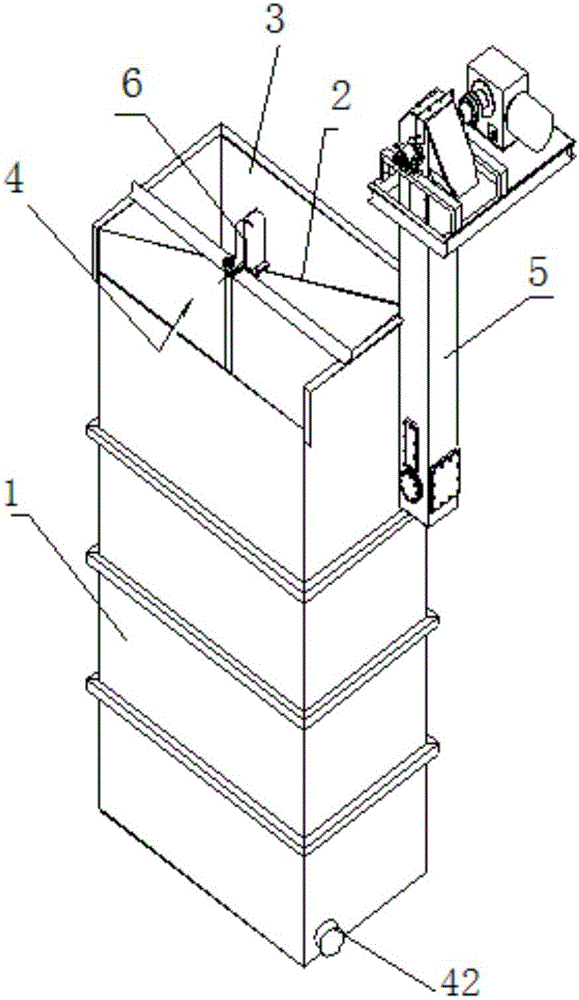

Superplastic forming/diffusion bonding forming method of titanium alloy parts with large curvature and complex profile

ActiveCN104588982BReduce structural complexityOvercome wrinkling and instabilityShaping toolsNon-electric welding apparatusHot workingTitanium alloy

The invention relates to a super-plastic forming / diffusion bonding forming method for a large-curvature complex surface titanium alloy part and belongs to the field of metal plates and hot working. Through reasonably and accurately calculating the unfold size of a part, residual materials on the wrinkled region of the part are removed through cutting in advance, after pre-forming is completed, overall welding and hot shape correction are performed, and the pre-formed and welded part is placed in the same tool so that super-plastic forming / diffusion bonding forming can be performed on the part. Without the help of blank holder force, pre-forming and super-plastic forming / diffusion bonding forming are completed through the same tool, one-time hot forming of the large-curvature complex surface part is completed, the defect that the part is wrinkled and loses stability is overcome, and technology difficulty and tool structure complexity are lowered. The part formed through the method has advantages.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Yarn pressing device and working method of flat knitting machine

The invention relates to a yarn pressing device for a flat knitting machine and a working method thereof. A sinker is installed in a sinker receiving groove; the sinker includes a sinker body, an elastic presser foot part, a power plate heel and a yarn pressing part; the sinker There are three rotation positioning holes on the body, and a limiting through hole on the yarn pressing part; there are three through grooves on the sinker needle plate, and a No. 1 positioning steel wire is installed in each through groove. No. 1 positioning steel wires are respectively passed through three rotation positioning holes; the axis center lines of the three No. 1 positioning steel wires are not on the same straight line as the three intersection points generated by the same cross section. The three intersection points determine a virtual circle, and the center of all virtual circles A virtual axis is formed; the heel of the power plate causes the sinker to rotate forward and backward around the virtual axis under the action of power. This yarn pressing device reduces the requirements for the use of rollers, presser feet and other flat knitting machines during knitting, facilitates the optimization of the structural design of the integrated garment machine, and is conducive to controlling the overall production cost.

Owner:桐乡市强隆机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com