Impurity removing device and method for separating and extracting corncobs through water pressure

A technology of corn cob and hydraulic pressure, which is applied in the direction of chemical instruments and methods, solid separation, wet separation, etc., can solve the problem that grain removal machinery cannot extract corn cob alone, and achieve resource saving, cost energy saving, emission reduction, manufacturing low difficulty effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

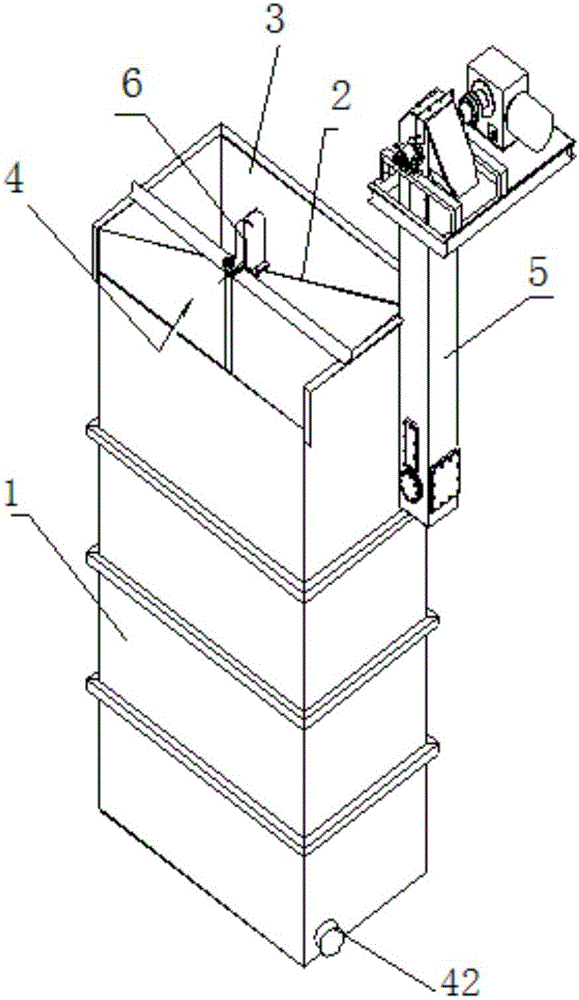

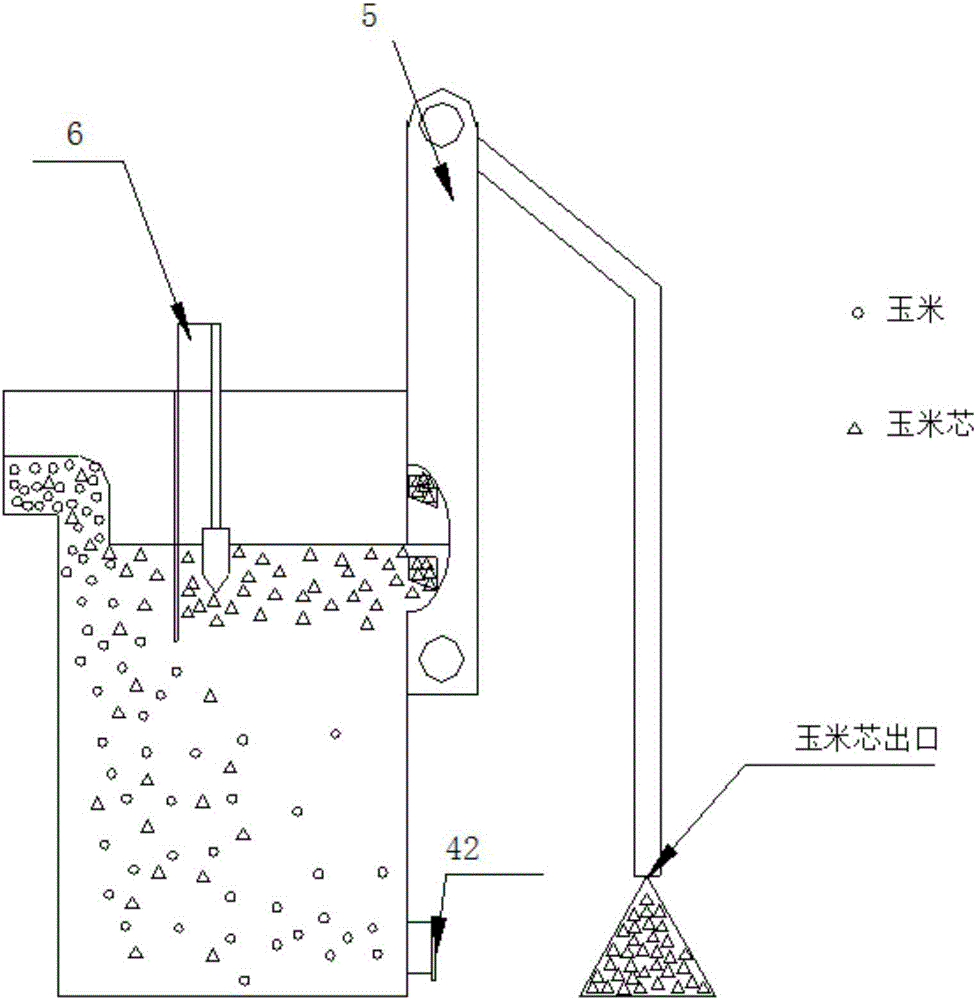

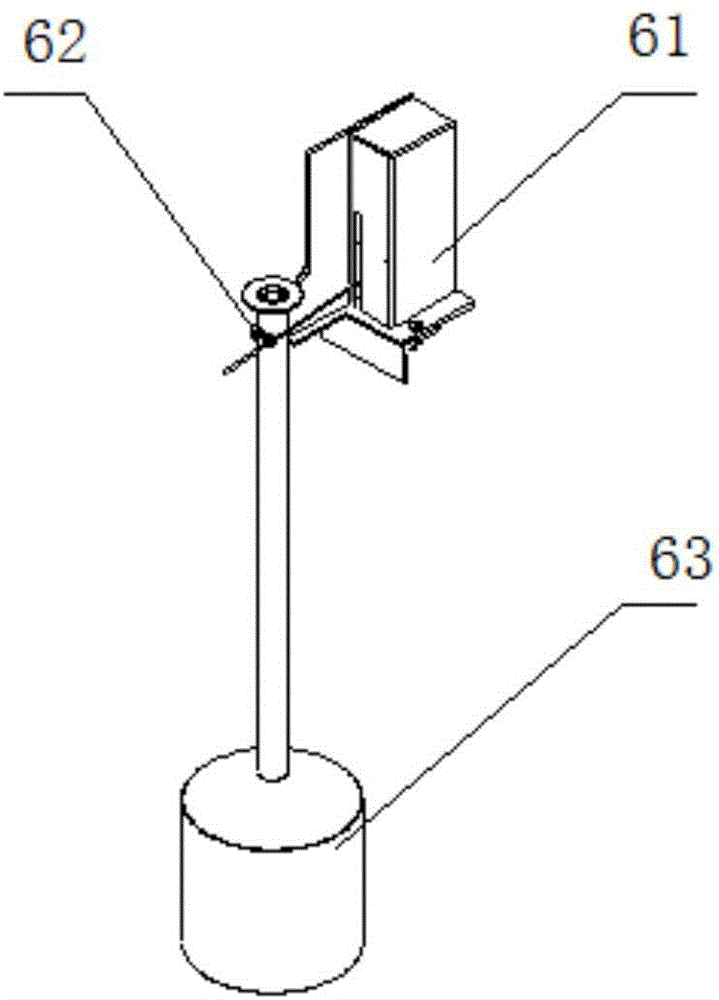

[0036] Such as figure 1 , 2 As shown, a kind of impurity removal device utilizing hydraulic separation and extraction of corncobs, comprising: a rectangular or square impurity removal tank 1; The material inlet area 3 is formed, and the material outlet area 4 is formed between the other side and the impurity removal tank 1. The inlet of the material inlet area 3 is connected with the outlet of the corn desander; the bucket elevator 5 is arranged outside the impurity removal tank 1 , and the feed port of the bucket elevator 5 is connected to the first discharge port of the discharge area 4; the liquid level sensor 6 is inserted in the impurity removal tank 1; the feed liquid composed of corn, corncobs and water Along the partition 2, it is discharged into the feed area 3 of the impurity removal tank 1, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com