Mechanical model device for rotor of motor

A technology of mechanical models and rotors, applied in the direction of measuring devices, testing of mechanical parts, testing of machine/structural parts, etc., can solve problems such as troublesome end fixing, waste, consuming a lot of manpower, material resources and time, saving manpower and material resources, simple installation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

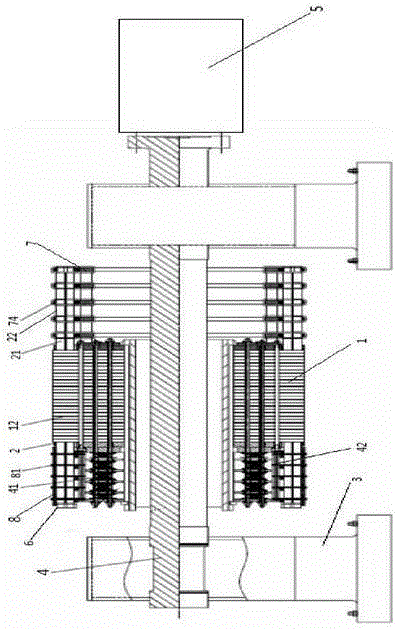

[0052] As a preferred embodiment of the present invention, with reference to the attached figure 1 , this example discloses

[0053] A rotor mechanical model device of a motor, comprising a support frame 3, a support shaft 4 and a drive mechanism 5, one end of the support shaft 4 is connected to the drive mechanism 5, and rotates under the drive of the drive mechanism 5; the support frame 3 supports Below the supporting shaft 4, the supporting shaft 4 and the supporting frame 3 are relatively rotated; the supporting shaft 4 is provided with a rotor 1 matched with the end fixing device 6, and the rotor 1 rotates with the rotation of the supporting shaft 4 .

Embodiment 2

[0055] As another preferred embodiment of the present invention, with reference to the attached figure 1 , this example includes

[0056] A rotor mechanical model device of a motor, comprising a support frame 3, a support shaft 4 and a drive mechanism 5, one end of the support shaft 4 is connected to the drive mechanism 5, and rotates under the drive of the drive mechanism 5; the support frame 3 supports Below the supporting shaft 4, the supporting shaft 4 and the supporting frame 3 are relatively rotated; the supporting shaft 4 is provided with a rotor 1 matched with the end fixing device 6, and the rotor 1 rotates with the rotation of the supporting shaft 4 . The rotor 1 is formed by laminating a number of silicon steel sheets, and the rotor 1 is provided with a number of radial ventilation grooves 12; the rotor is provided with a rotor winding 2, and the rotor 1 is provided with an axial winding Slots 11 , into which axial winding bars 21 of the rotor winding 2 are insert...

Embodiment 3

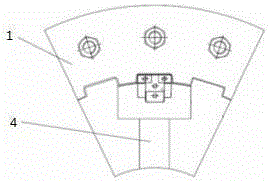

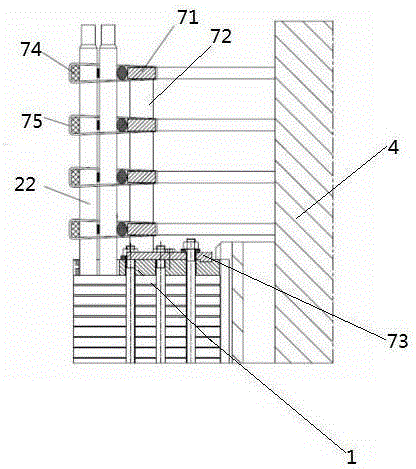

[0058] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses

[0059] A rotor mechanical model device of a motor, comprising a support frame 3, a support shaft 4 and a drive mechanism 5, one end of the support shaft 4 is connected to the drive mechanism 5, and rotates under the drive of the drive mechanism 5; the support frame 3 supports Below the supporting shaft 4, the supporting shaft 4 and the supporting frame 3 are relatively rotated; the supporting shaft 4 is provided with a rotor 1 matched with the end fixing device 6, and the rotor 1 rotates with the rotation of the supporting shaft 4 . The rotor 1 is formed by laminating a number of silicon steel sheets, and the rotor 1 is provided with a number of radial ventilation grooves 12; the rotor is provided with a rotor winding 2, and the rotor 1 is provided with an axial winding Slots 11 , into which axial winding bars 21 of the rotor winding 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com