Axial flow compressor serially connected by multiple single-stage axial flow fans in L-shaped arrangement

A technology of axial flow compressors and axial flow fans, applied in the field of axial flow compressors, can solve problems such as the inability to arrange axial flow compressors, and achieve the effects of reducing design and manufacturing difficulty, ensuring reliability, and reducing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

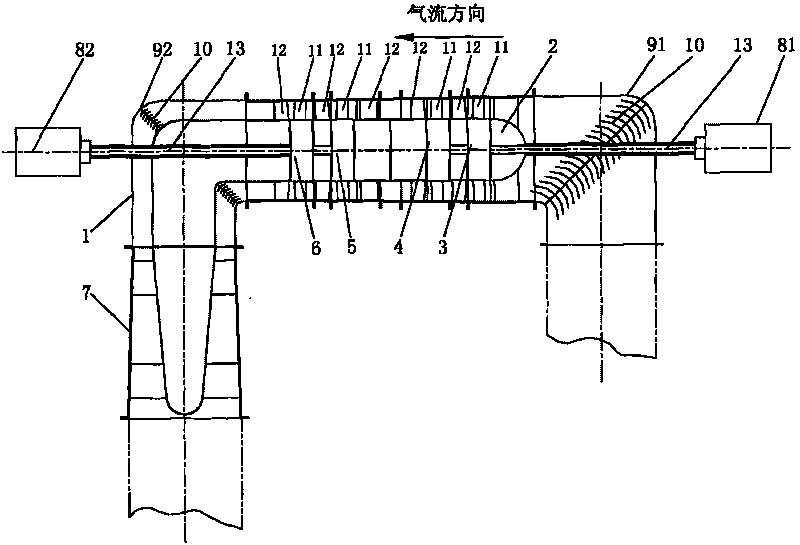

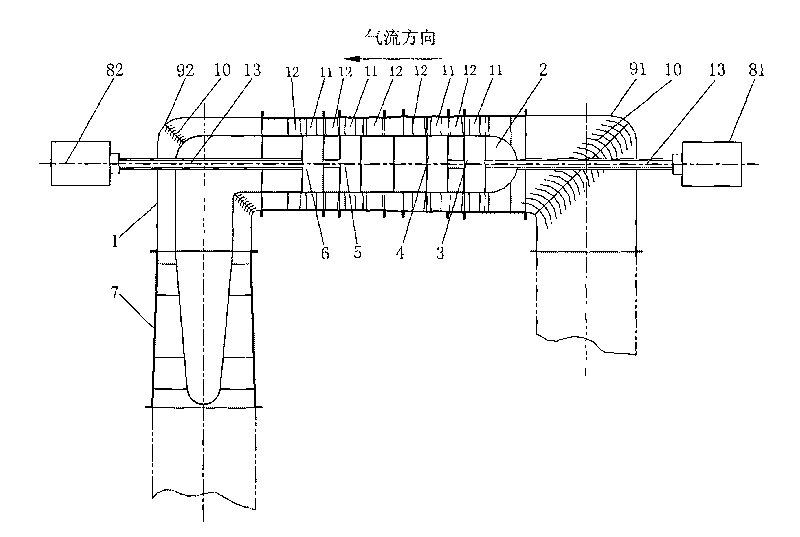

[0016] like figure 1 As shown, an axial flow compressor in which multiple single-stage axial flow fans arranged in an L shape are connected in series, including a casing 1, a fairing 2, an I-stage impeller 3, a II-stage impeller 4, a III-stage impeller 5, and an IV stage impeller 6 and diffuser 7, the casing 1 is an elongated pipe with two right-angled corners arranged along the airflow direction of the wind tunnel, the first corner 91 and the second corner 92 of the casing 1 are all installed There are turning guide vanes 10; the entire axial flow compressor is arranged in an L shape, the fairing 2 is installed behind the first corner 91, and the diffuser 7 is installed behind the second corner 92, and is located at the tail end of the casing 1; each stage The impellers respectively include a moving blade 11 and a guide vane 12. Along the direction of air flow, the guide vane 12 is arranged behind the moving blade 11. The inner diameter and blade installation angle of each mo...

Embodiment 2

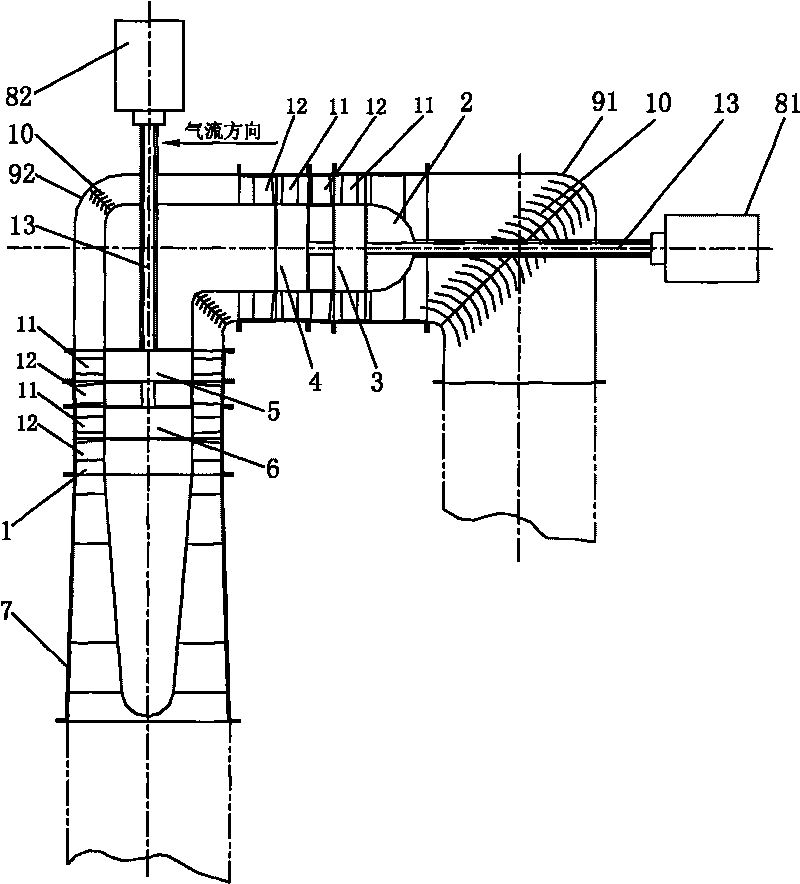

[0019] like figure 2 As shown, an axial flow compressor in which a plurality of single-stage axial flow fans arranged in an L shape are connected in series. The difference between embodiment 2 and embodiment 1 is that along the direction of air flow, the first-stage impeller 3 and the second-stage The impellers 4 are arranged coaxially in series between the first corner 91 and the second corner 92. The I and II stage impellers and the fairing 2 together form one side of the L shape. The III stage impeller 5 and the IV stage impeller 6 are connected in series. Arranged coaxially after the second corner 92 in sequence, the III and IV stage impellers and the diffuser 7 together form the other side of the L-shape; where the I-stage impeller 3 and the II-stage impeller 4 form a group and are connected to the first stage through the intermediate shaft 13 The main motor 81, the first main motor 81 is installed on the axial head of the I-stage impeller 3; the III-stage impeller 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com