Patents

Literature

41results about How to "Meet the needs of large flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

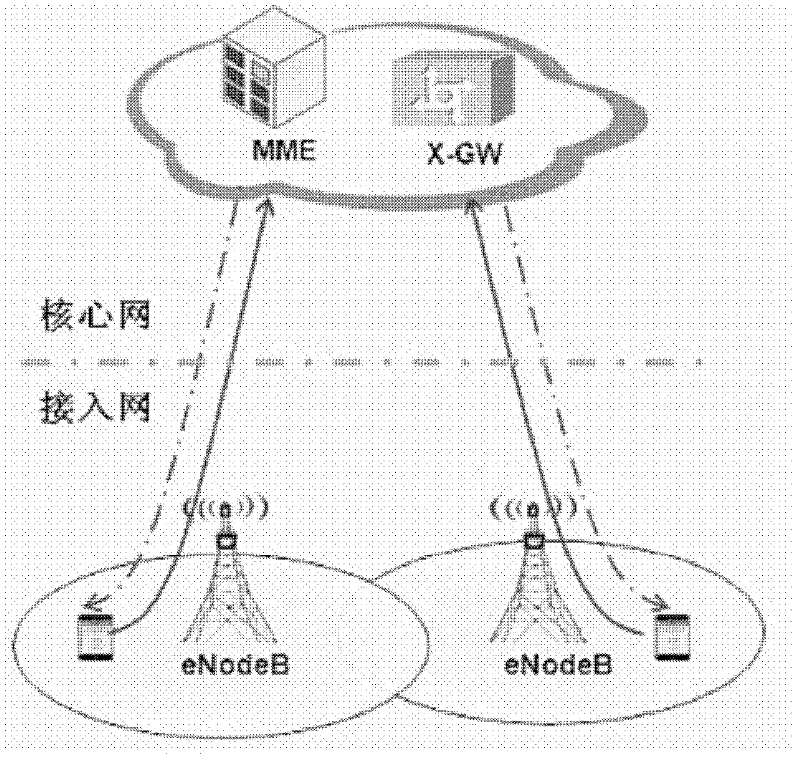

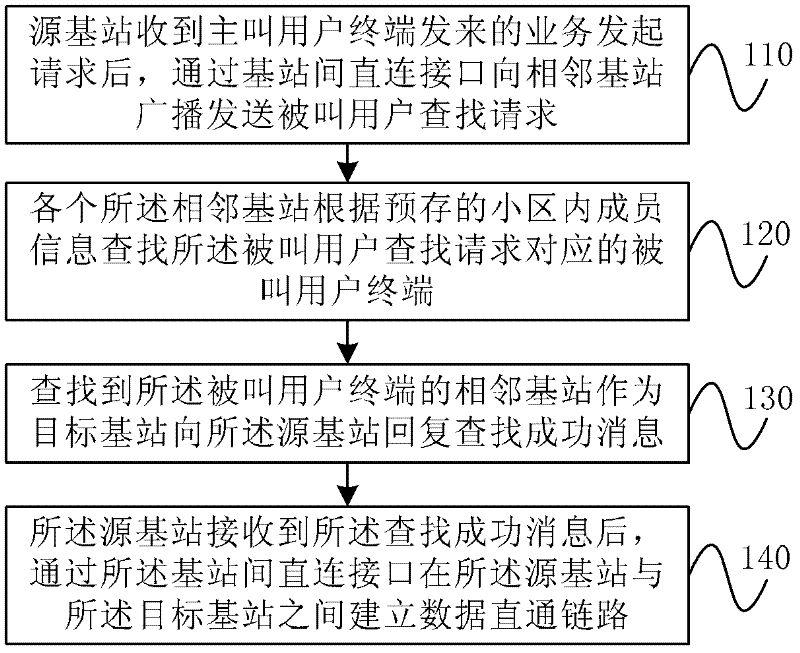

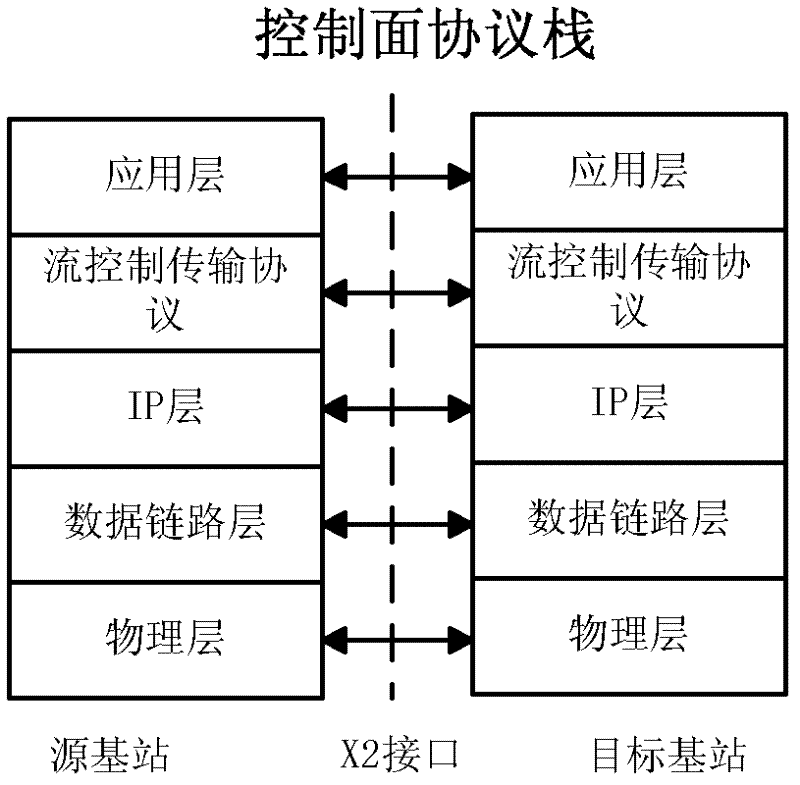

Method and system for carrying out direct communication of data among base stations

ActiveCN102421145ARealize data offloadReduce the burden onNetwork traffic/resource managementTraffic capacityAccess network

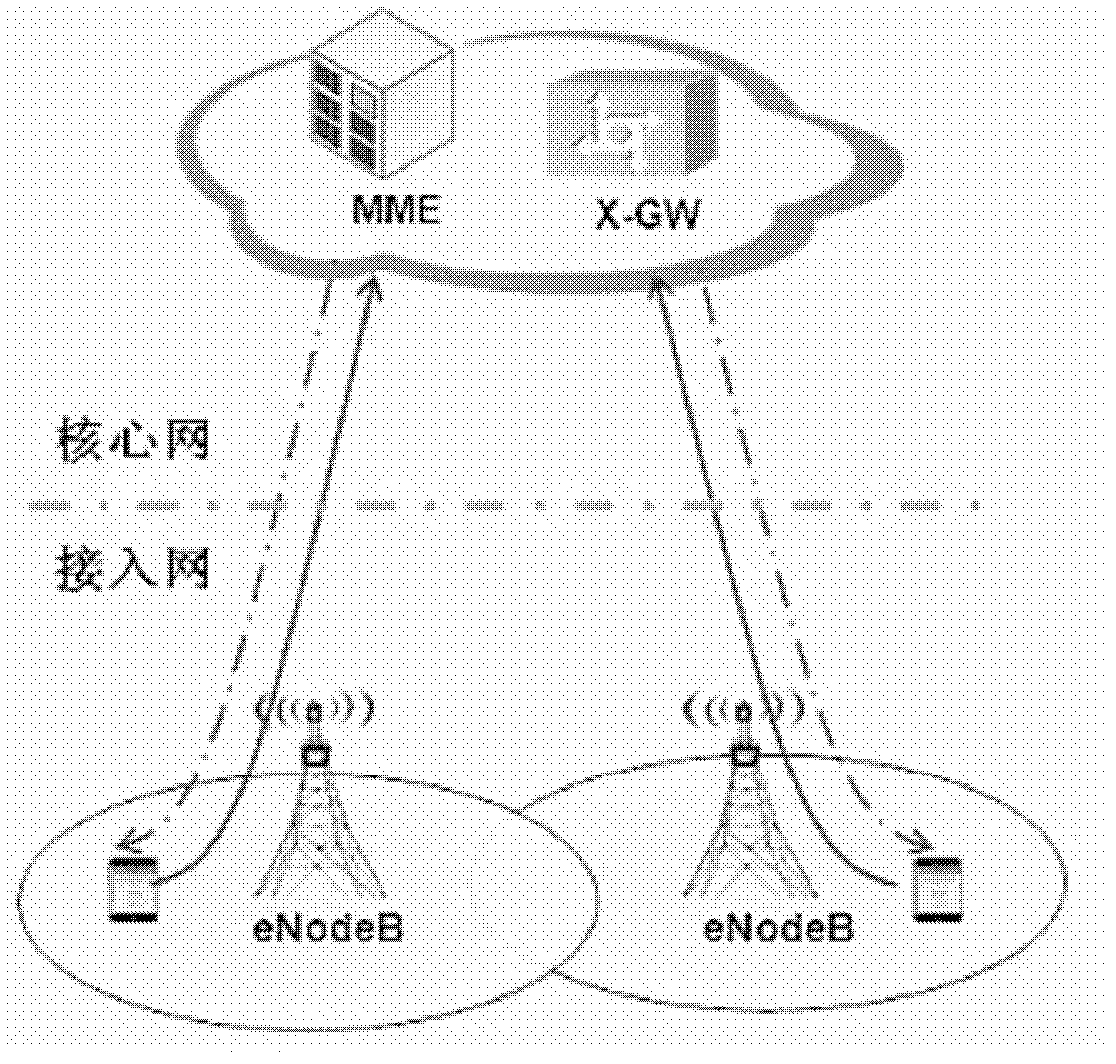

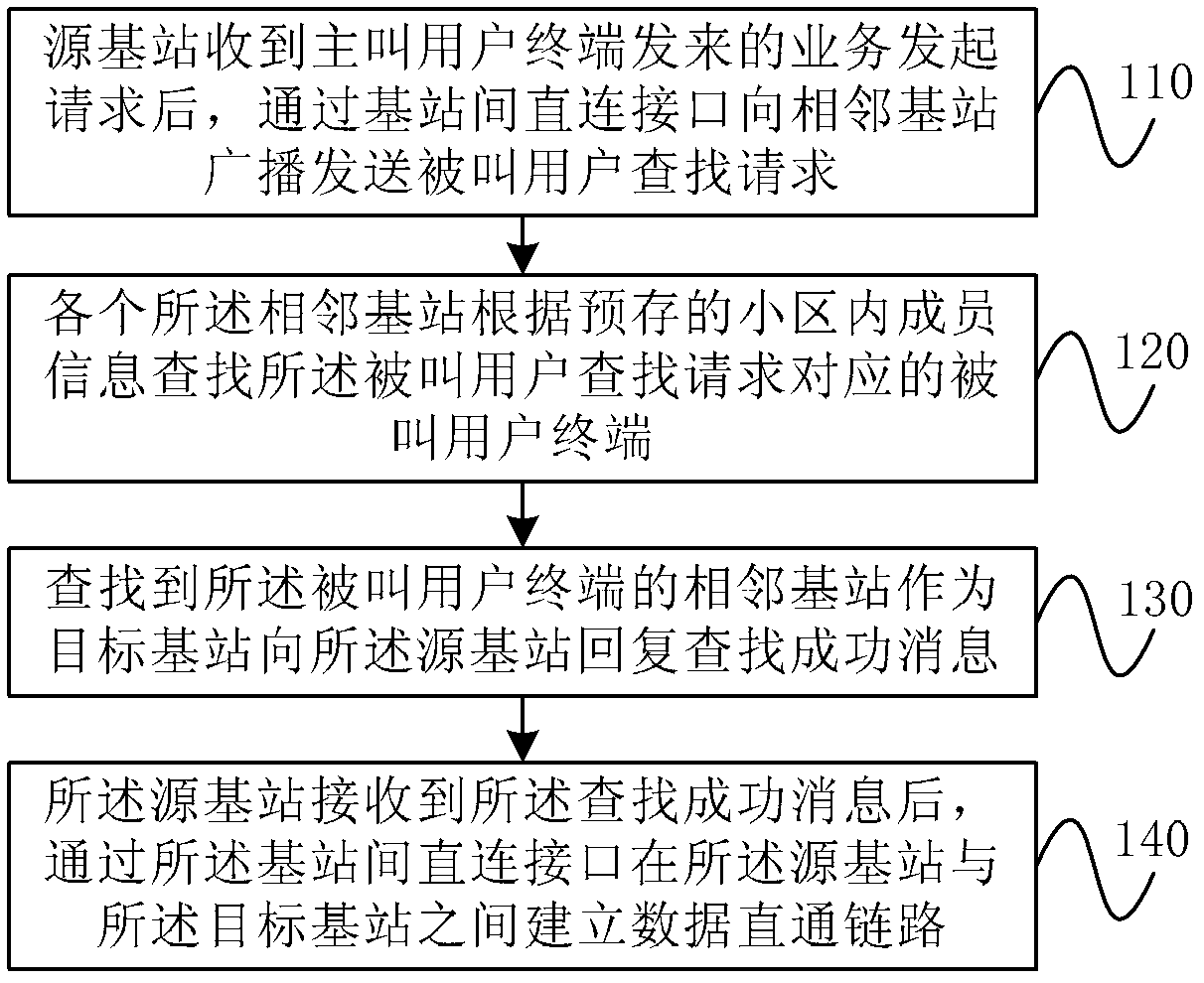

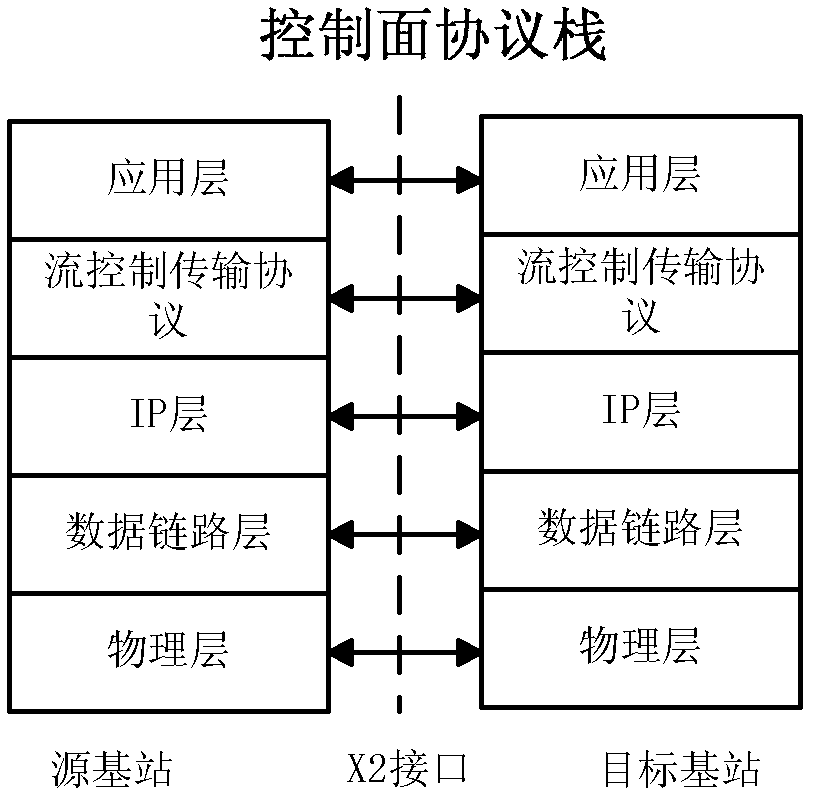

The invention provides a method and a system for carrying out direct communication of data among base stations. The method comprises the following steps that: after receiving a service initiating request sent by a calling subscriber terminal, a source base station broadcasts and sends a called subscriber searching request to adjacent base station through direct connection interface between the base stations; each adjacent base station searches a called subscriber terminal corresponding to the called subscriber searching request according to prestored in-cell member information; the adjacent base station which searches the called subscriber terminal replies a search success message to the source base station as a target base station; and after the source base station receives the search success message, a data direct communication link is established between the source base station and the target base station through the direct connection interface between the base stations. A great amount of data services are borne through the direct connection interfaces among the base stations, so that the direct communication of the data is realized, the load of a core network is reduced and the requirement of an access network on high flow is met.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

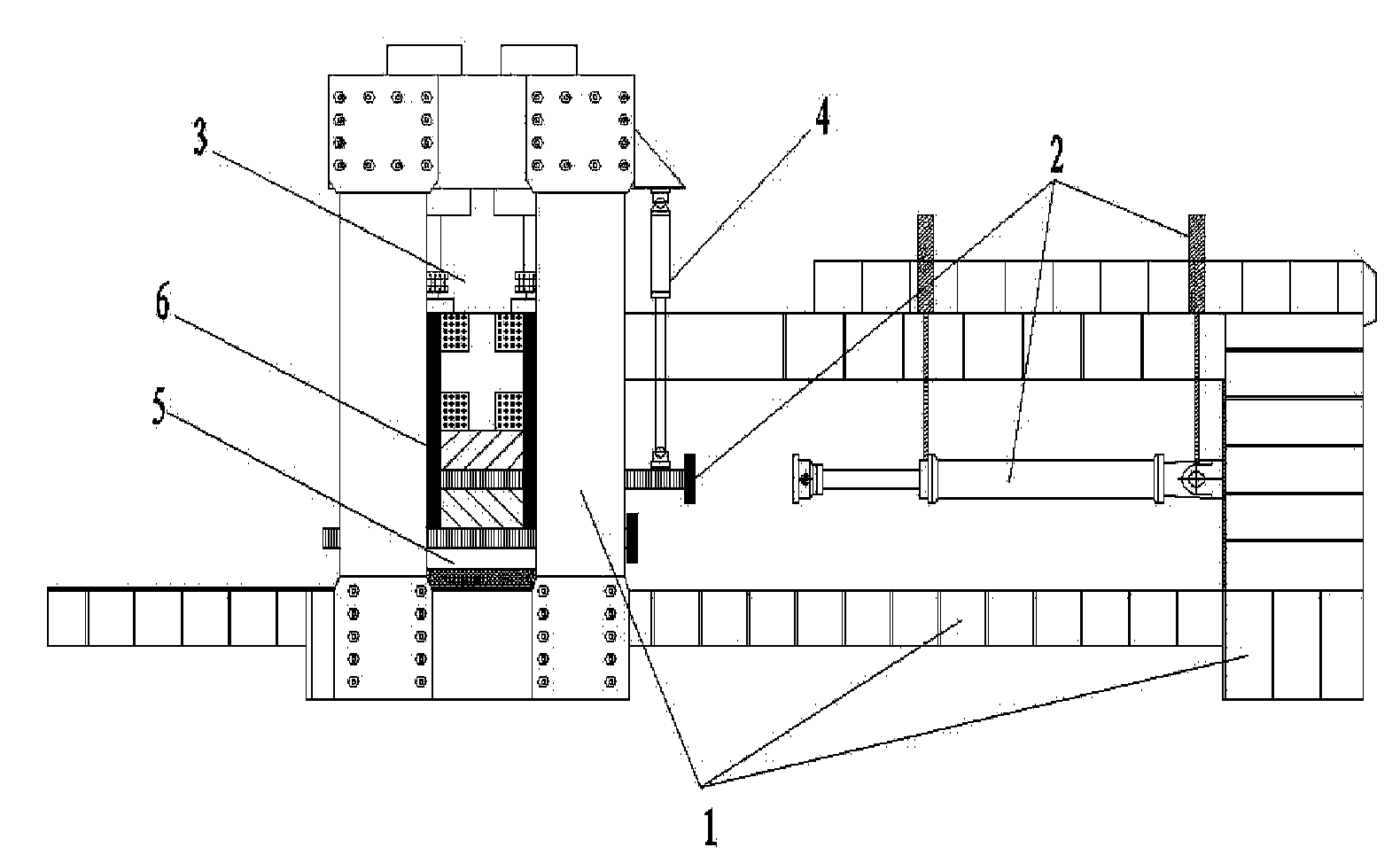

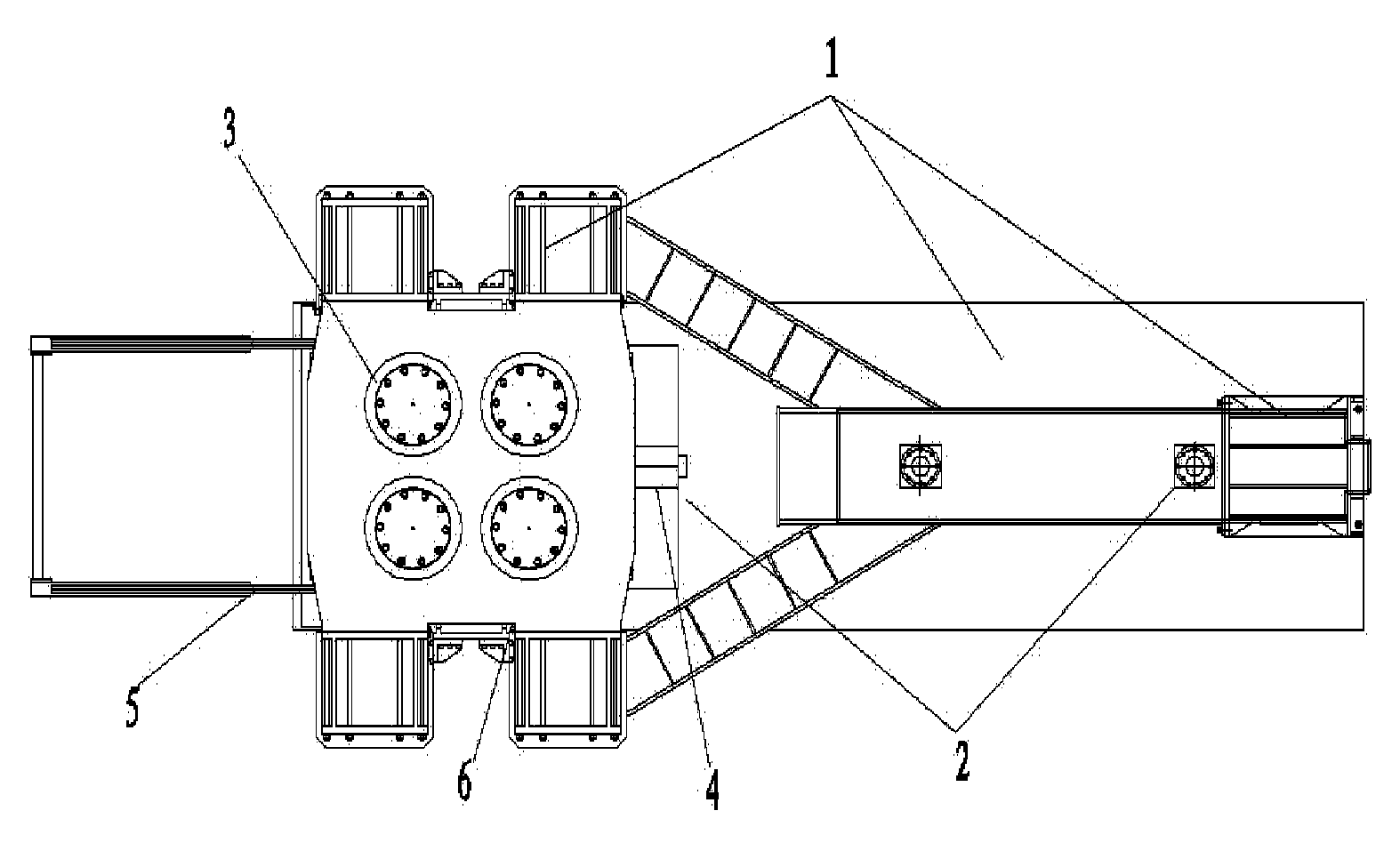

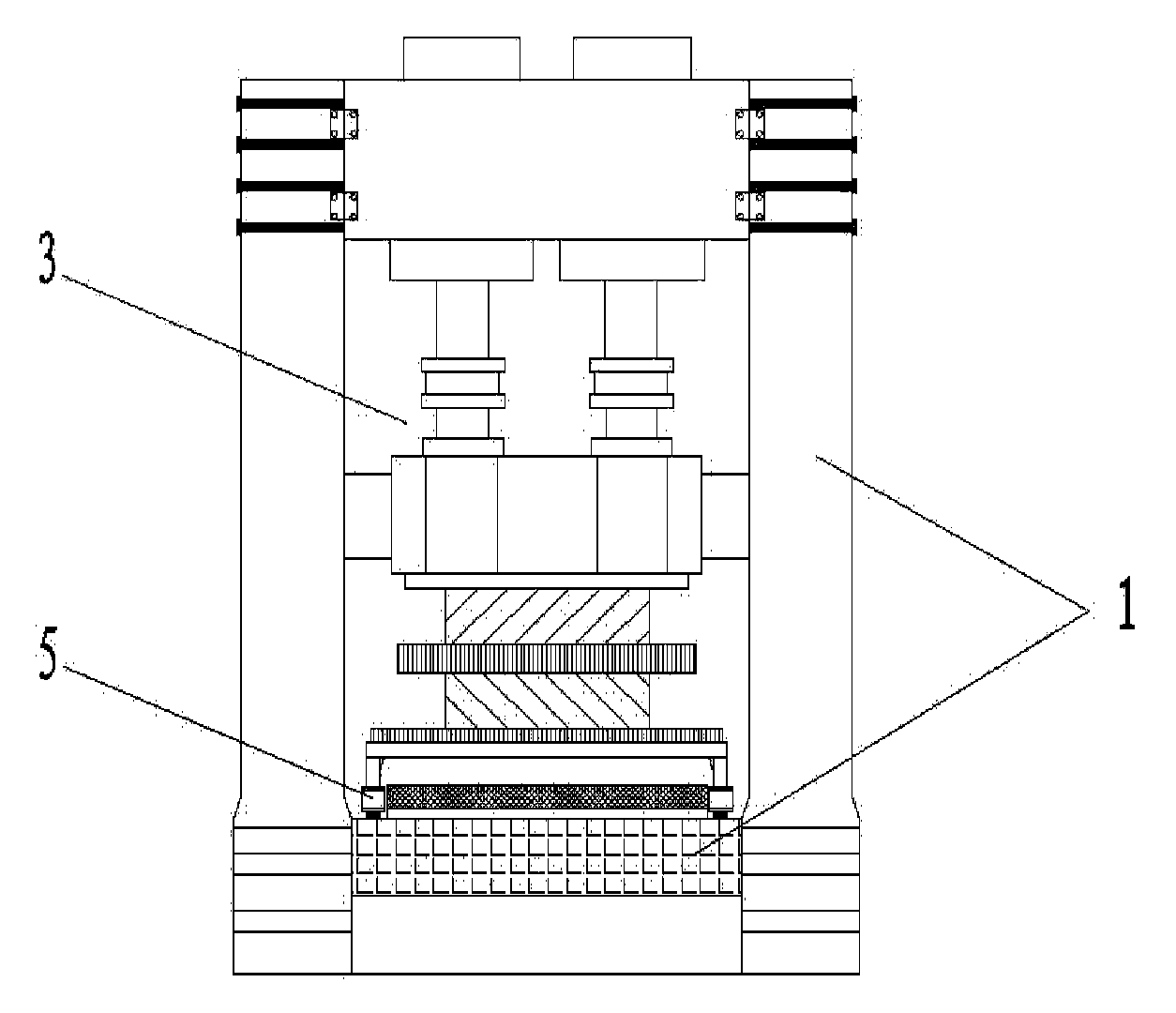

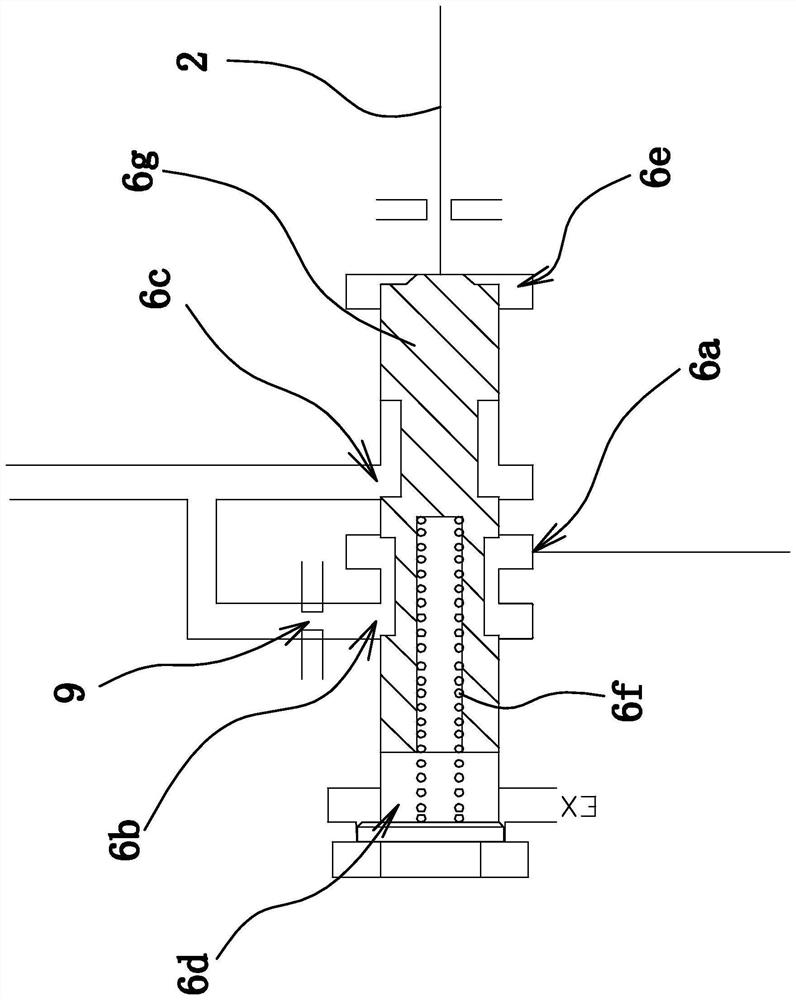

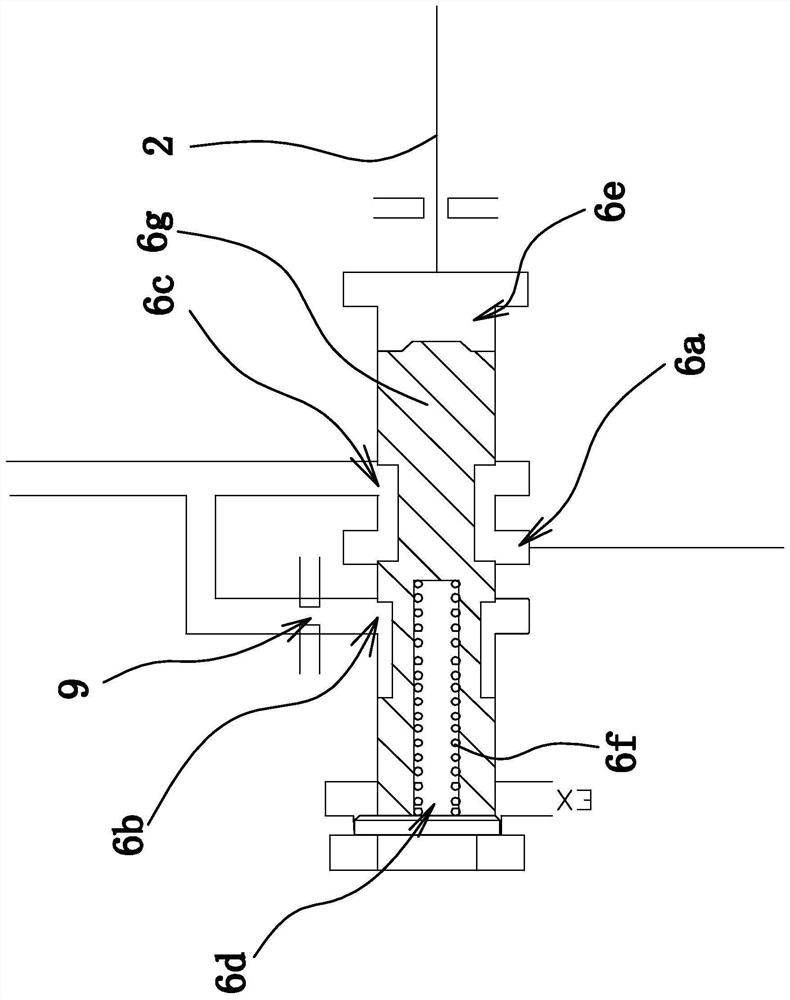

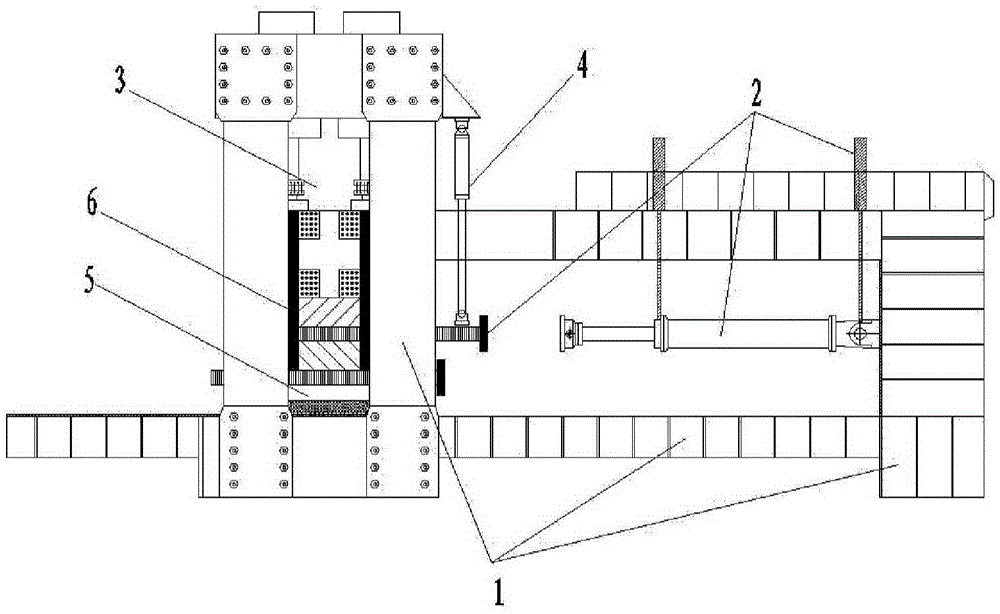

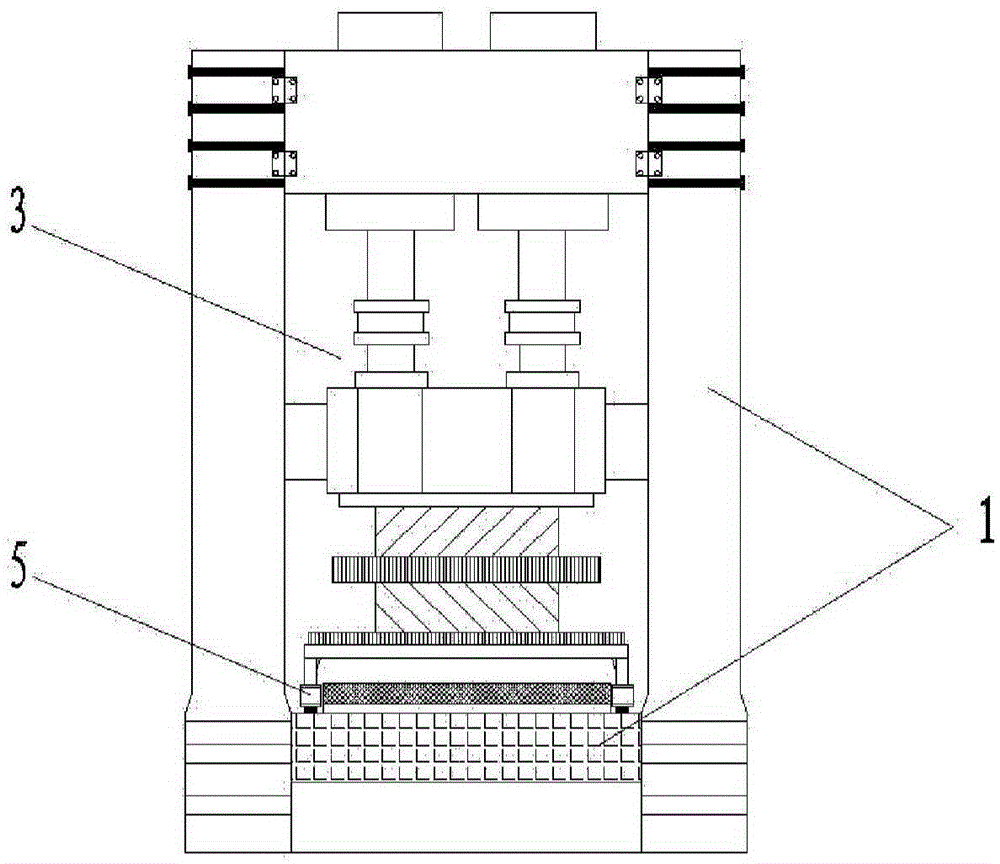

Device for carrying out static-dynamic force multifunction testing on support

ActiveCN103512740AReduce processingReduce the risk of leakageMachine part testingServo actuatorMultiple function

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

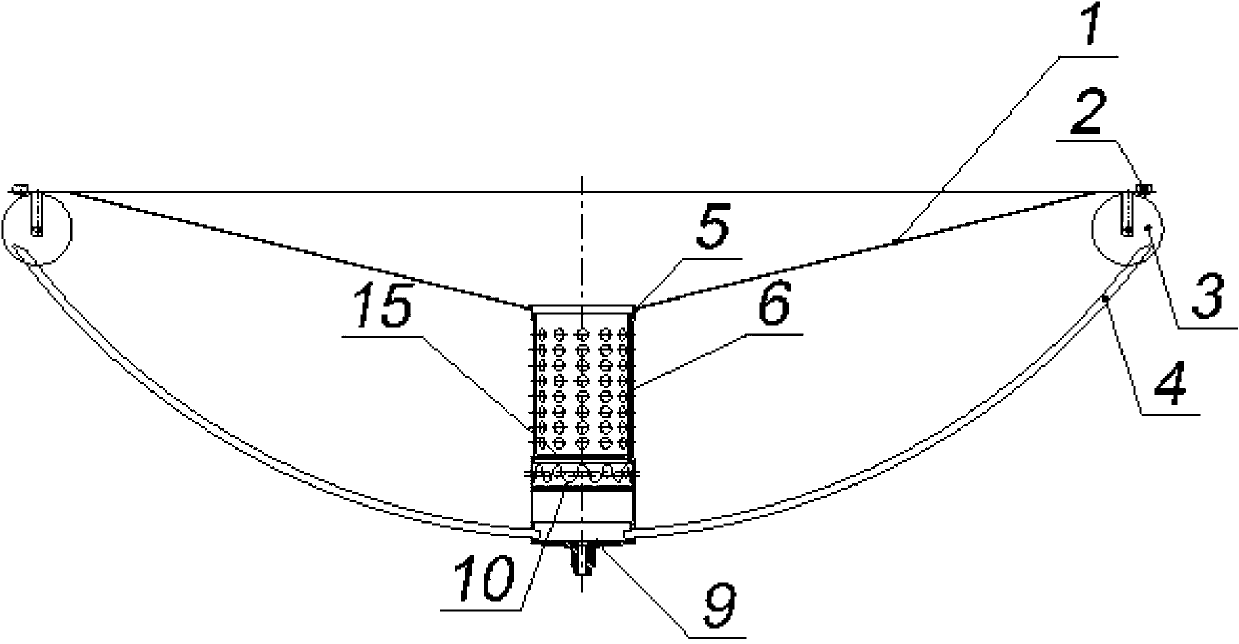

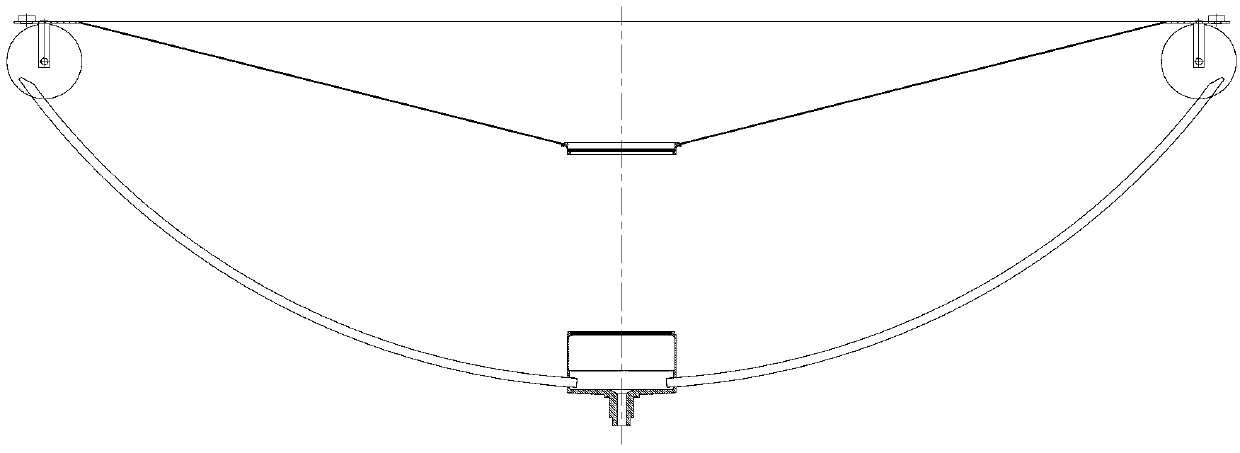

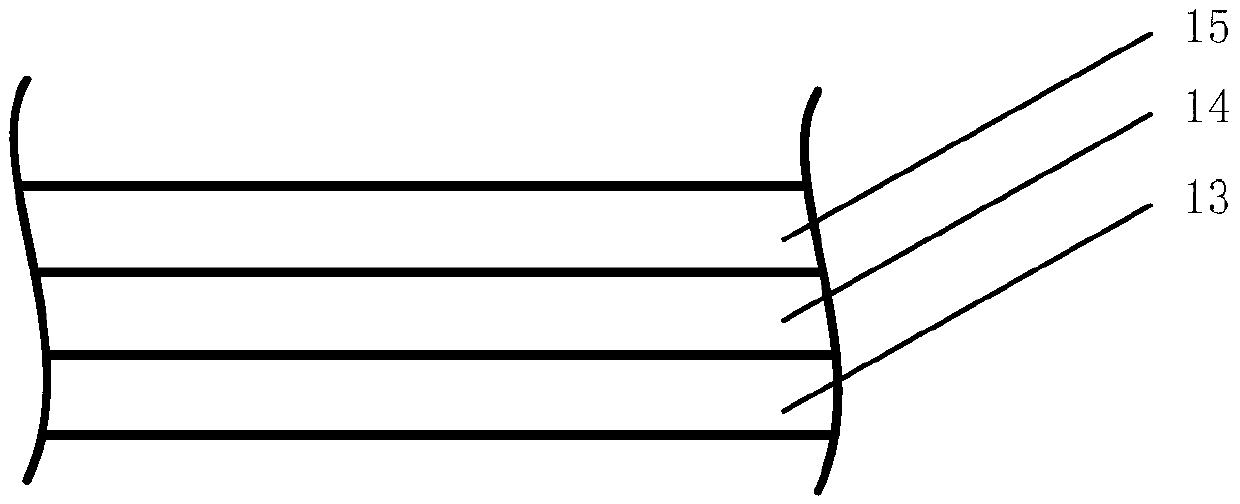

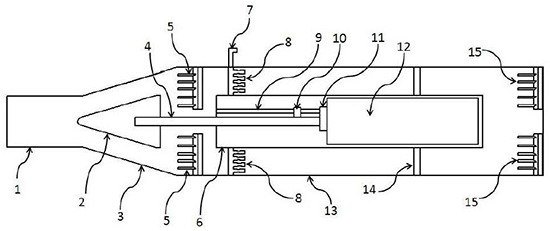

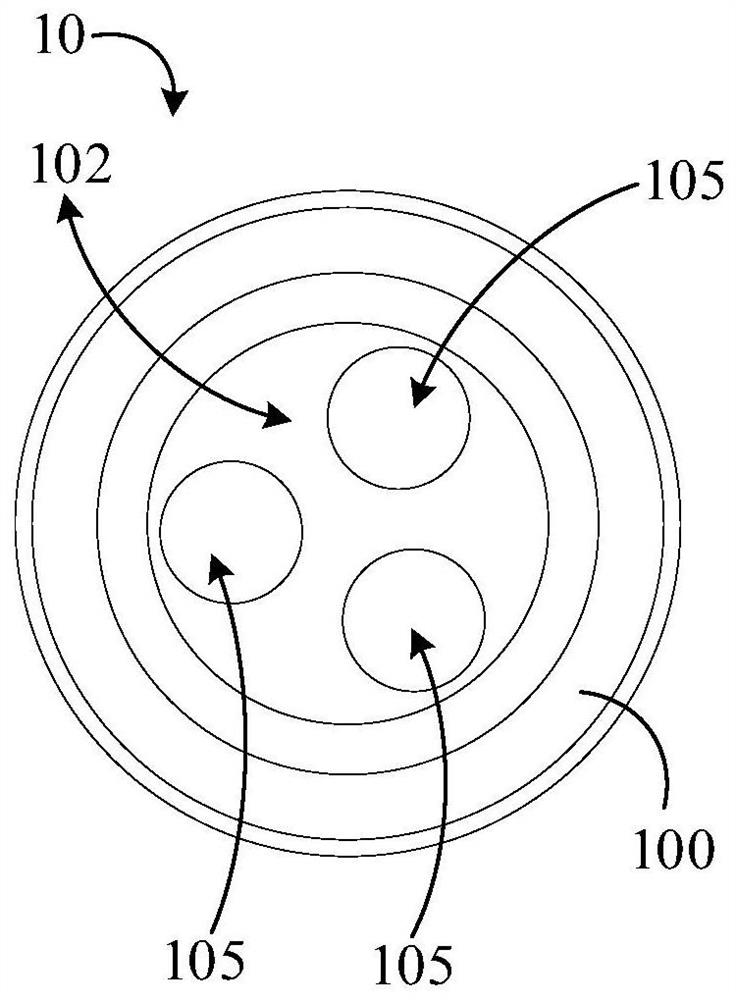

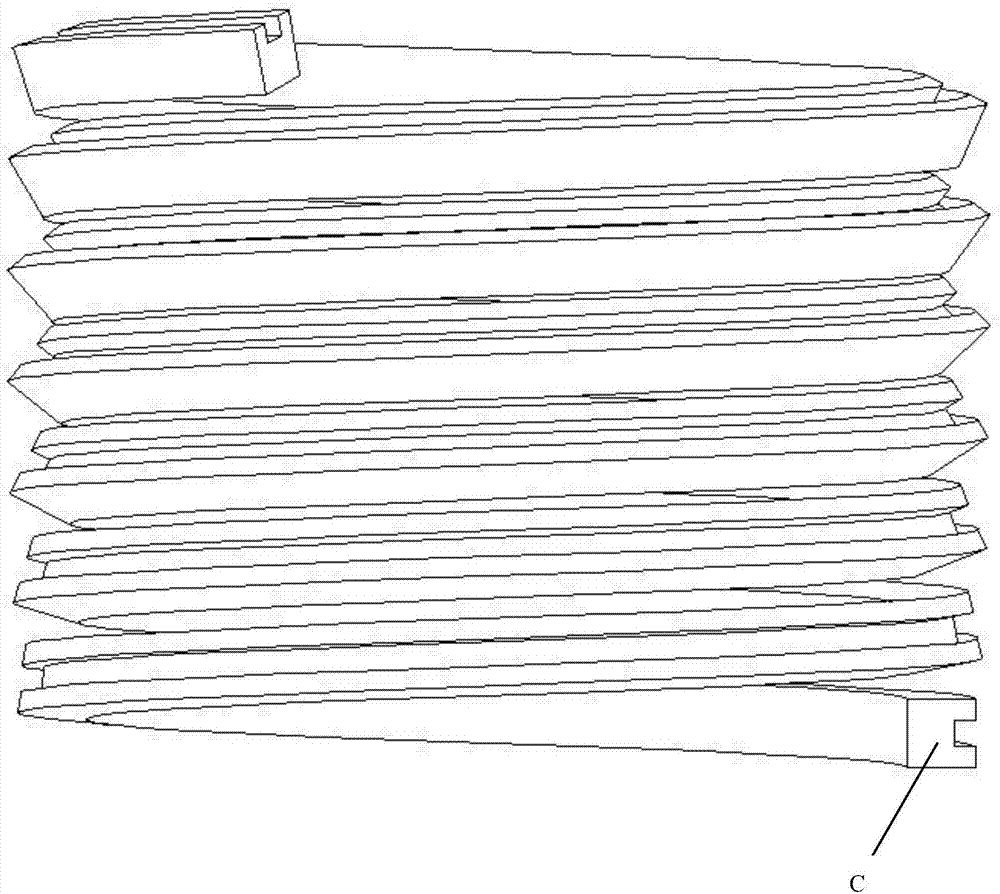

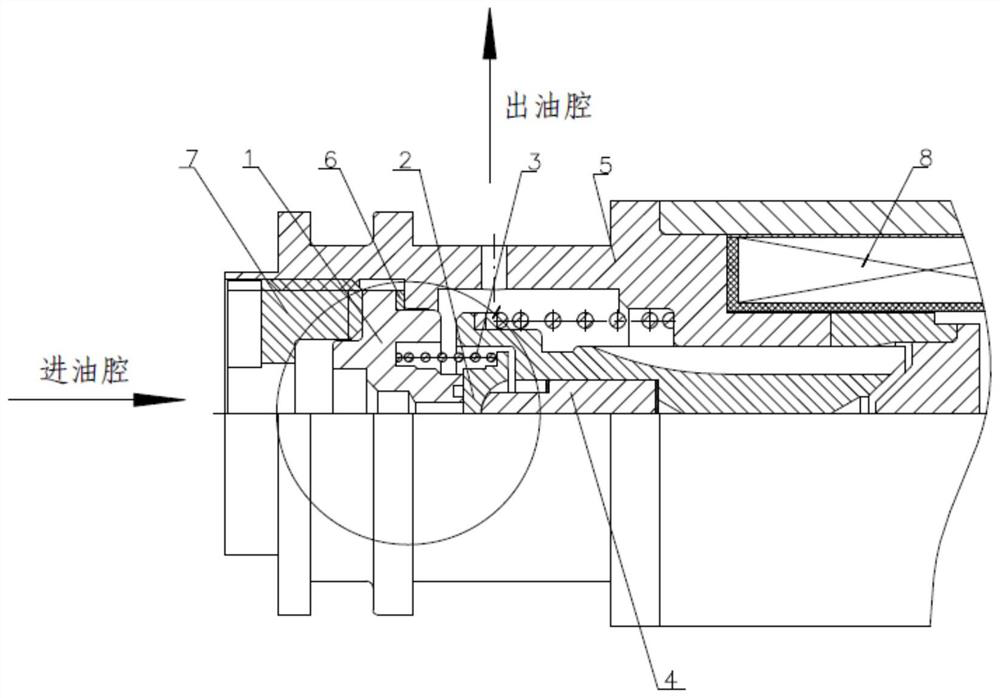

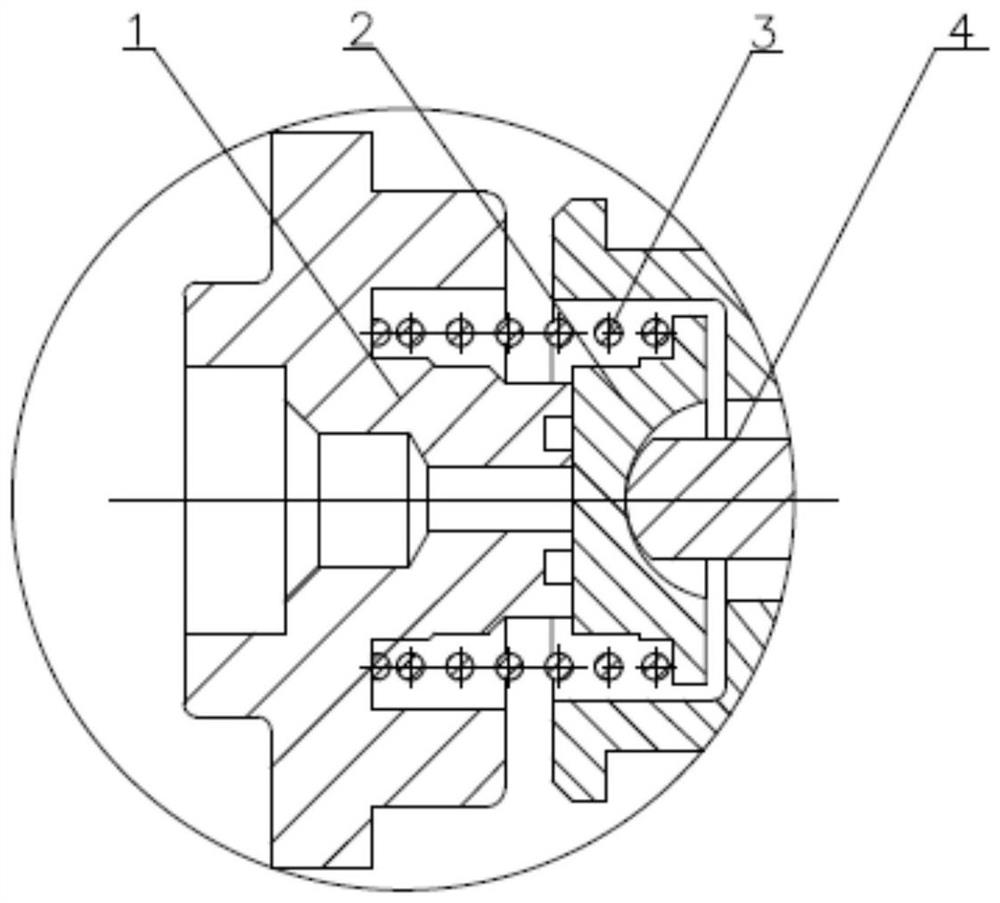

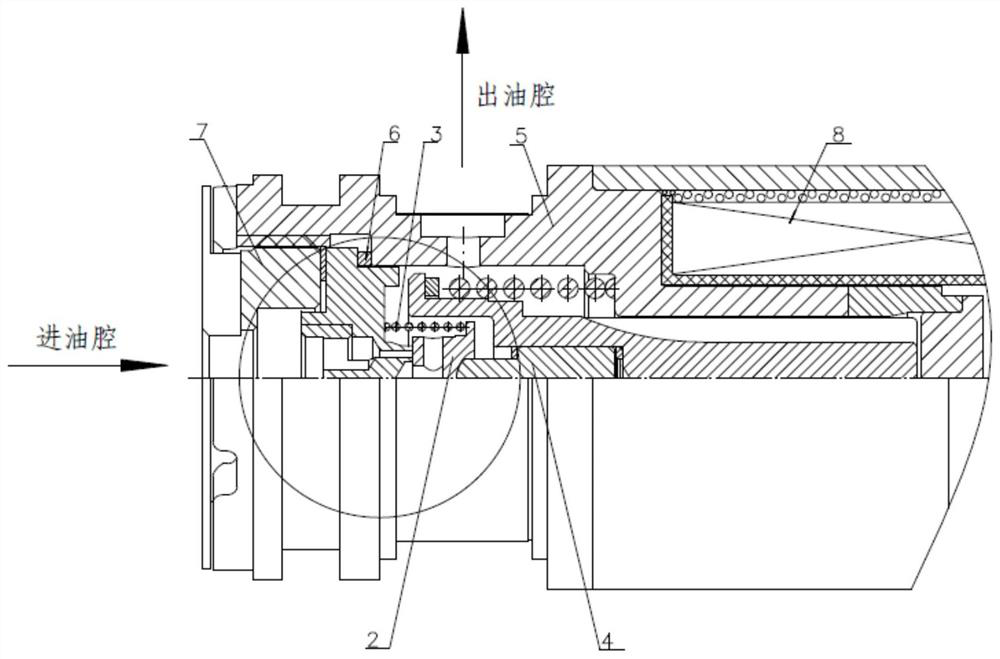

Vibration-proof liquid management inner core

InactiveCN103121515AIncrease the screening areaSimplify the core structureCosmonautic propulsion system apparatusEngineeringCoarse particle

The invention discloses a vibration-proof liquid management inner core. The vibration-proof liquid management inner core comprises a clapboard 1, an angle coarse particle collector 2, a coarse particle collector, a corner collector 3, and a bottom collector, wherein the coarse collector is connected between the clapboard 1 and the bottom collector, the angle coarse particle collector 2, the corner collector 3 are connected with the clapboard 1, the coarse particle collector comprises a force bearing barrel, a first thick mesh 7, a third supporting and pressing board 13, a second thick mesh 14, and a fourth supporting and pressing board 15, wherein the force bearing barrel comprises an adapter ring 5, an outer barrel 6, and an inner barrel 8, the bottom collector comprises a third collecting shell 9, a first supporting and pressing board 10, a thin mesh 11, and a second supporting and pressing board 12, wherein the bottom collecting shell is provided with a liquid outlet, and a thick collecting mesh structure is assembled by the third supporting and pressing board 13, the second thick mesh 14, and the fourth supporting and pressing board 15 from top to bottom. The vibration-proof liquid management inner core has the advantages of being simple in structure, and capable of effectively improving mechanical environmental adaptation of a storage tank, enhancing reliability of a system, and meanwhile meeting a mass flow requirement of the system.

Owner:SHANGHAI INST OF SPACE PROPULSION

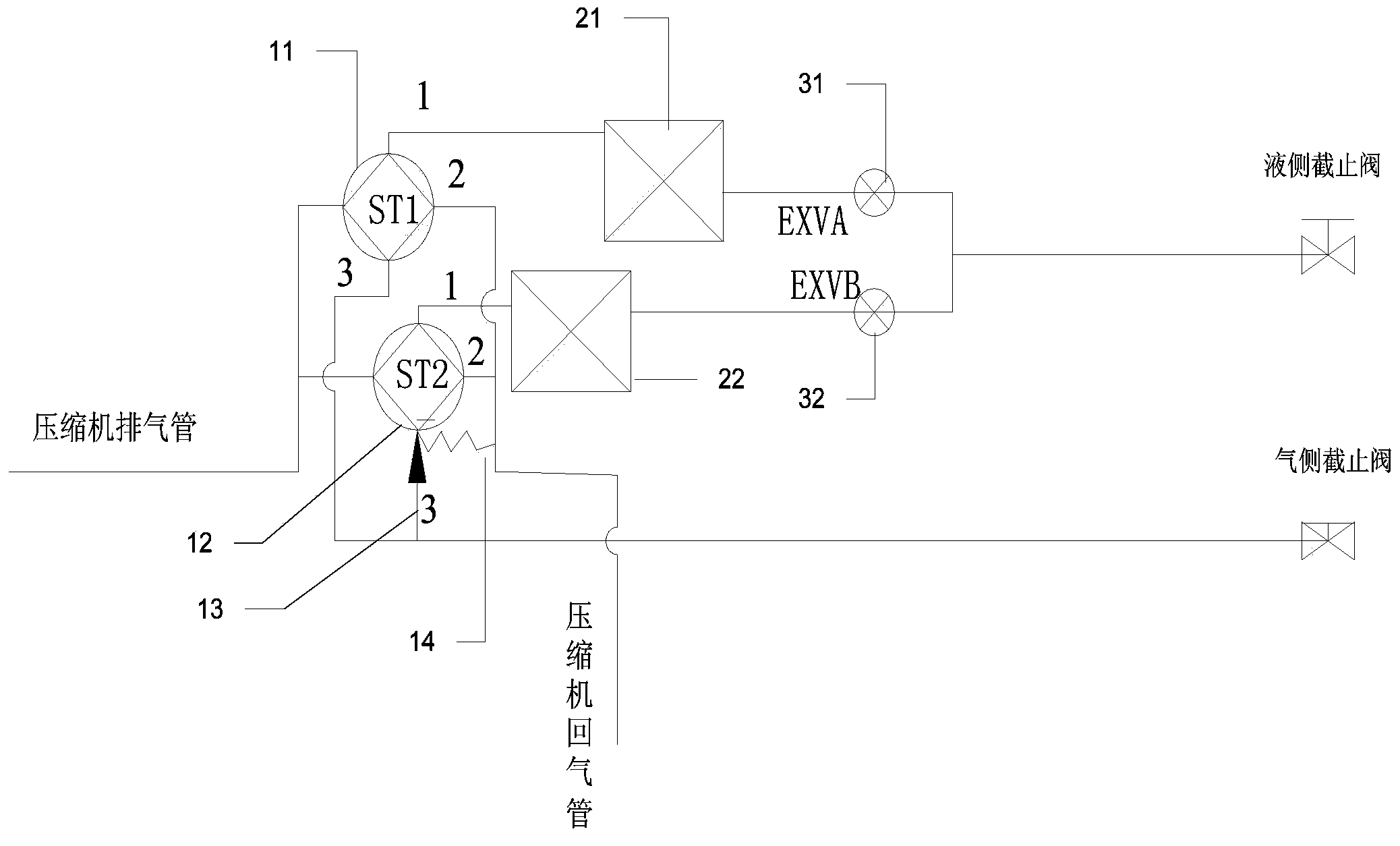

Control system and control method of parallel-connection four-way valve for multi-line machine

InactiveCN103851841AMeet the demand of large flowSimple structureMechanical apparatusFluid circulation arrangementElectricityFour-way valve

The invention discloses a control system and a control method of a parallel-connection four-way valve for a multi-line machine. The control system comprises a first condenser, a first electronic expansion valve, a second condenser, a second electronic expansion valve, a compressor exhaust pipe, a compressor air return pipe, an air side stop valve, a liquid side stop valve, a first four-way valve, a second four-way valve and a one-way valve; two our-way valves and two condensers are connected in parallel to meet the high-flow refrigerant requirement in full load; when the second four-way valve is electrified, as the one-way valve is conducted uni-directionally and is cut off in a reverse direction, the purpose of switching off half of condensers is achieved; the system adopts the small four-way valve without the large four-way valve, has the simple structure and the low cost, meets the high-flow refrigerant requirements in full load, and also can switch off half of the condensers in low load. The invention also provides the control method based on the control system.

Owner:GUANGDONG CHIGO HEATING & VENTILATION EQUIP CO LTD

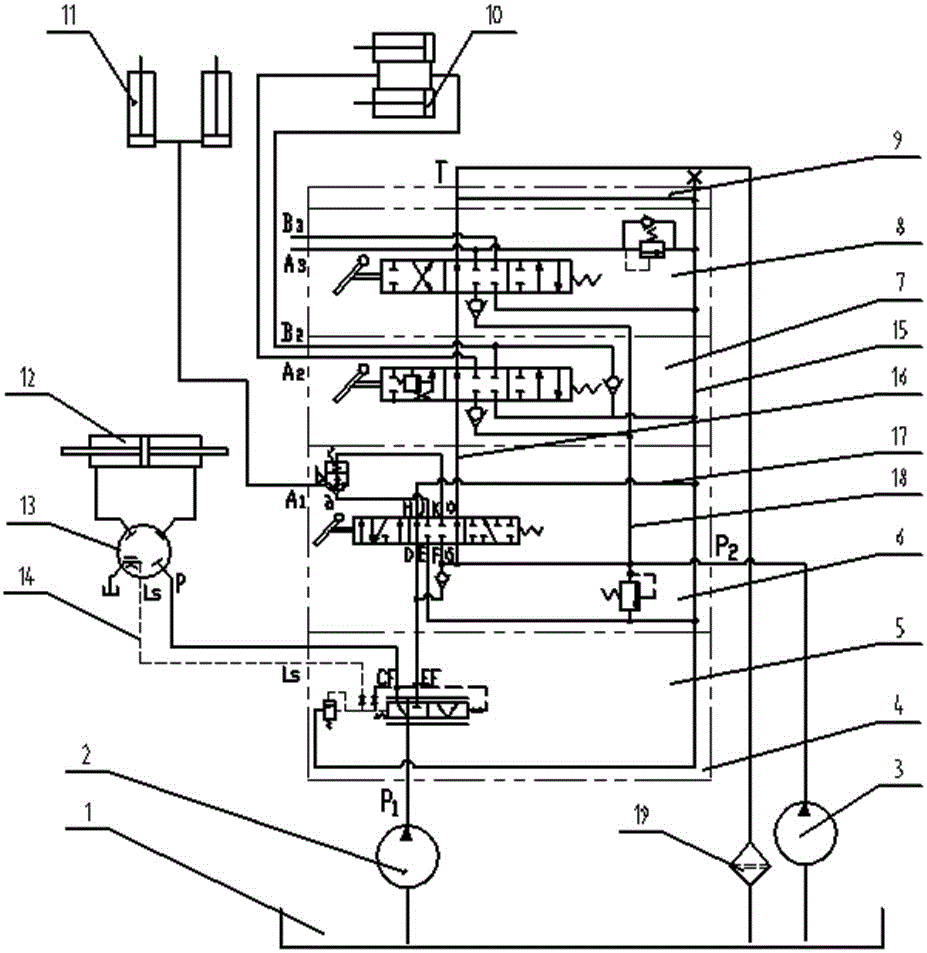

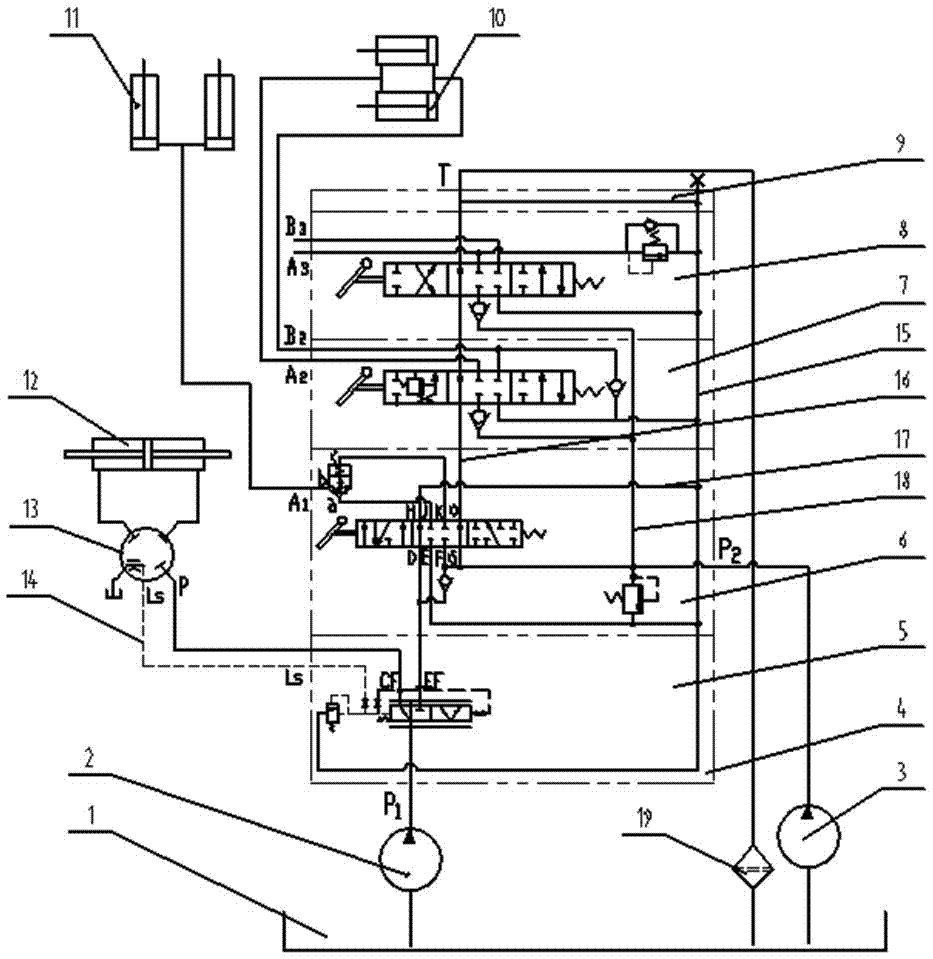

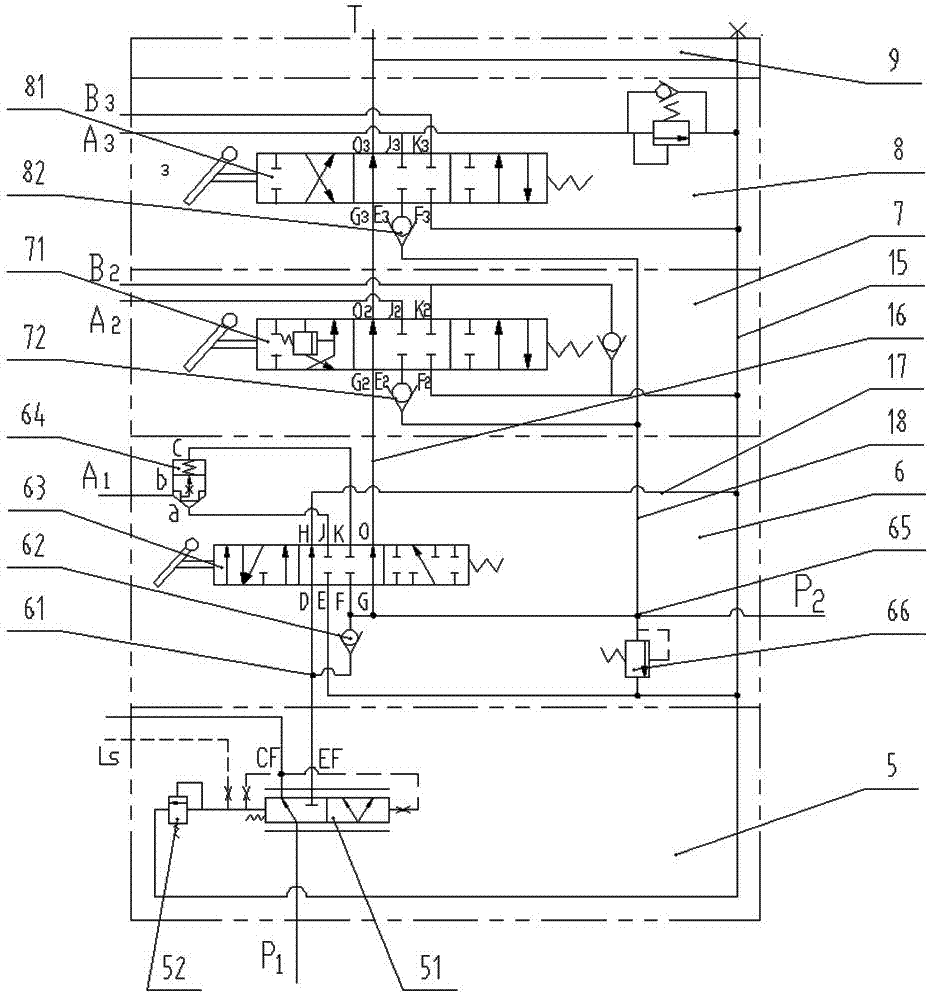

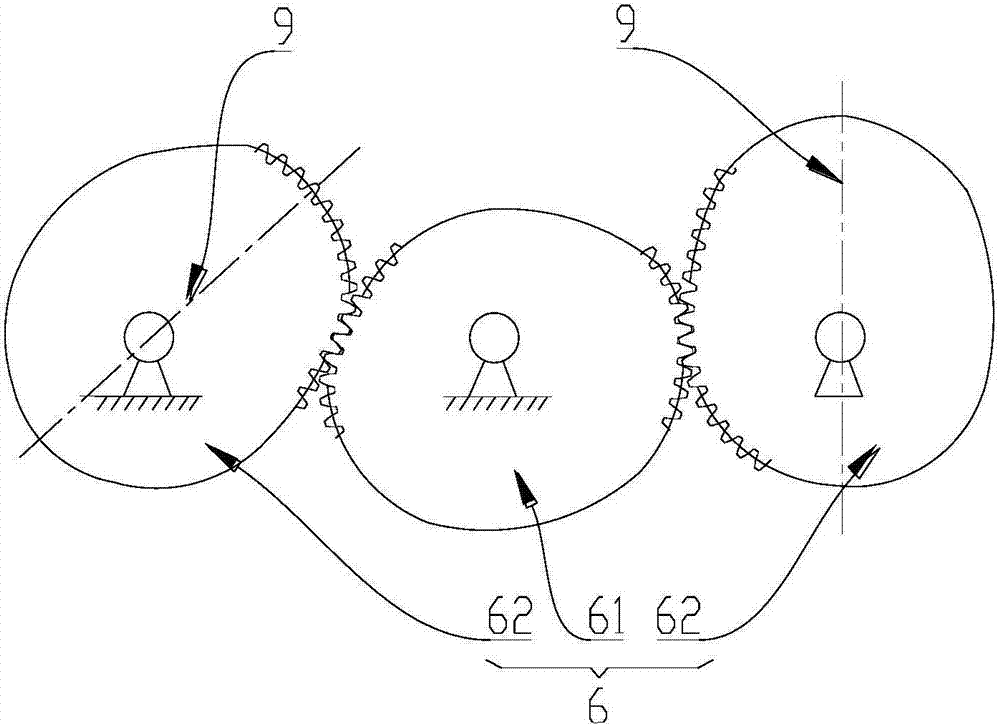

Dual-pump confluent energy-saving type forklift hydraulic system

ActiveCN105084261AMeet the needs of large flowReduce lossesServomotor componentsServomotorsMarine engineeringInlet valve

The invention relates to a dual-pump confluent energy-saving type forklift hydraulic system. The dual-pump confluent energy-saving type forklift hydraulic system comprises an oil tank, a first oil pump, a second oil pump, a multiway valve, tilting oil cylinders, lifting oil cylinders and a steering oil cylinder. The multiway valve is composed of an oil inlet valve plate, a lifting reversing valve plate, a tilting reversing valve plate, a fitting reversing valve plate and an oil return valve plate. The multiway valve is internally provided with an annular oil return passage and a center oil passage, wherein the center oil passage is communicated with the lifting reversing valve plate, the tilting reversing valve plate, the fitting reversing valve plate and the oil return valve plate. The oil inlet valve plate is composed of a priority valve and a steering safety valve. The lifting reversing valve plate is composed of a one-way valve, a lifting reversing valve, a hydraulic control one-way valve and a main safety valve. The tilting reversing valve plate comprises a tilting reversing valve and a tilting one-way valve. The fitting reversing valve plate comprises a fitting reversing valve and a fitting one-way valve. The lifting reversing valve adopts a three-position eight-way reversing valve, dual-pump oil supplying only during lifting is achieved, and the large flow demand is met; portal-frame tilting and fitting acting which need smaller flow can be achieved through one-pump oil supplying, the pressure loss of the system is low, and the energy loss is low.

Owner:ANHUI HELI CO LTD

Gearbox hydraulic control system and vehicle

InactiveCN110966400AHigh control precisionShort response timeClutchesGearing controlClutchOil pressure

The invention provides a gearbox hydraulic control system and a vehicle, and relates to the field of the vehicle. The gearbox hydraulic control system comprises a high-pressure main oil way formed bysequentially connecting an oil tank, a suction filter, an electronic double pump, a high-pressure press filter and an energy accumulator, a first high-pressure branch oil way and a second high-pressure branch oil way which are formed by connecting a first pressure proportional electromagnetic valve and a second pressure proportional electromagnetic valve with the energy accumulator respectively, alow-pressure oil way formed by connecting an oil cooler with the electronic double pump, and a control unit, wherein the first high-pressure branch oil way is connected with a parking system, the second high-pressure branch oil path is connected with a clutch, the control unit is used for controlling the oil outlet amount of the first pressure proportional electromagnetic valve so as to adjust the oil pressure of the first high-pressure branch oil way to achieve parking in or parking out of a parking system and controlling the oil outlet amount of the second pressure proportional electromagnetic valve so as to adjust the oil pressure of the second high-pressure branch oil way to achieve engagement or disengagement of the clutch. The hydraulic system has the advantages that high-precisioncontrol can be achieved, and overall working efficiency of the hydraulic system is improved.

Owner:YIWU GEELY AUTOMATIC TRANSMISSION CO LTD +1

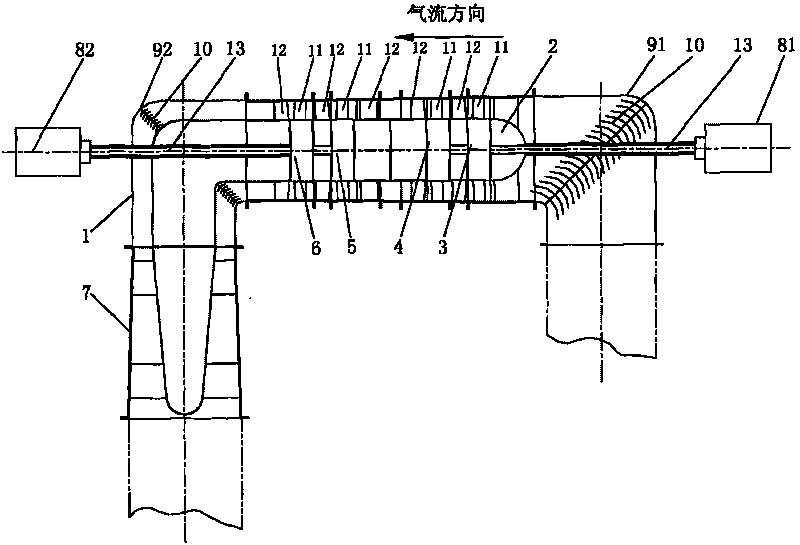

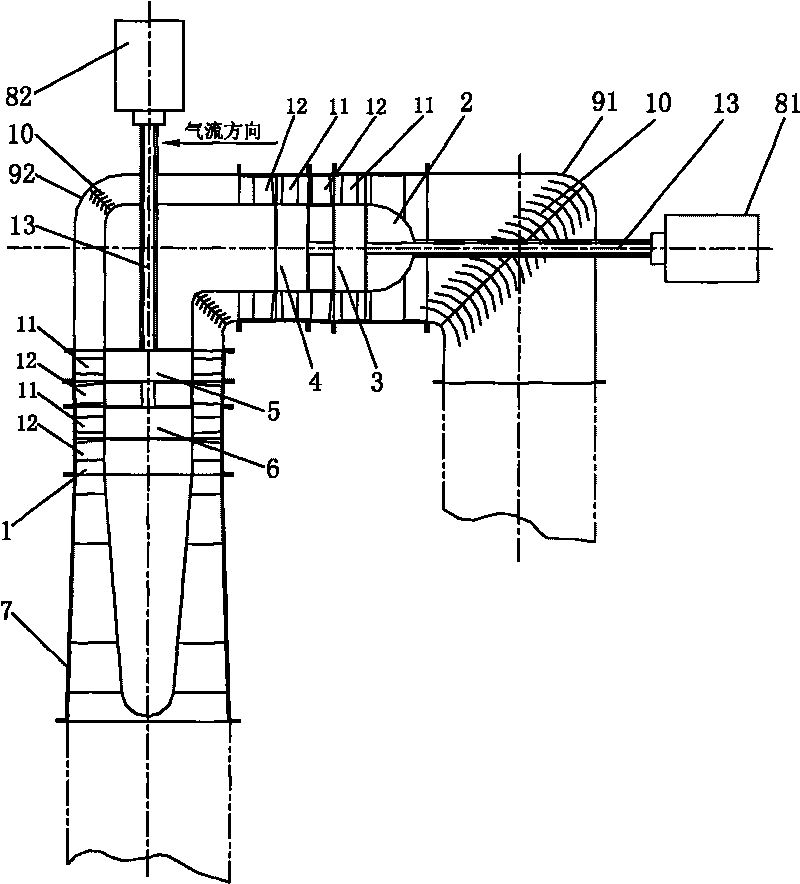

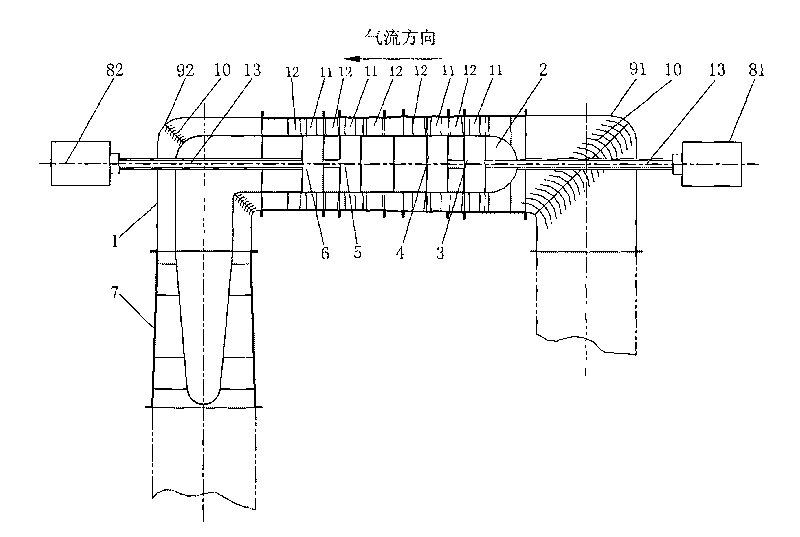

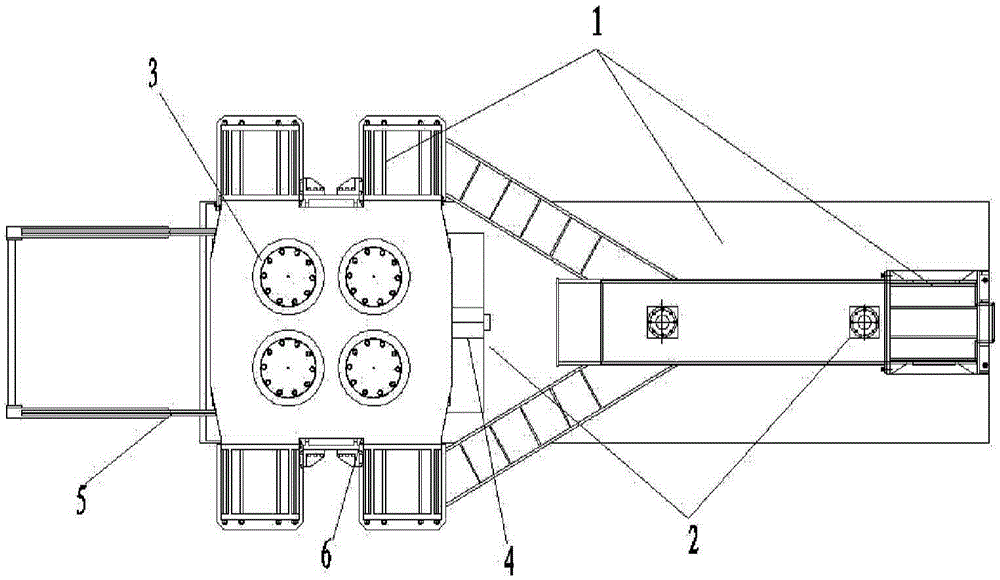

Axial flow compressor serially connected by multiple single-stage axial flow fans in L-shaped arrangement

InactiveCN101696695AImprove unityShorten the lengthPump componentsRadial flow pumpsImpellerSingle stage

The invention relates to the field of fans used for closed type circular wind tunnels, in particular to an axial flow compressor formed by serially connecting by multiple fans, i.e. an axial flow compressor formed by serially connecting by multiple single-stage axial flow fans in L-shaped arrangement, comprising a casing, a fairing, an I-stage impeller, an II-stage impeller, an III-stage impeller, an IV-stage impeller and a diffuser, wherein the casing is a long pipeline with two orthogonal corners, which is arranged along the air flow direction of the wind tunnel; the whole axial flow compressor is arranged in an L shape, the diffuser is arranged behind the second corner after the fairing is arranged at the first corner; all the impellers are serially connected between the faring and the diffuser, the I-stage impeller and the II-stage impeller form a group to be connected with a first main motor through an intermediate shaft, and the III-stage impeller and the IV-stage impeller form a group to be connected with a second main motor through an intermediate shaft. The whole axial flow compressor is in L-shaped arrangement, is easy to arrange in the closed type circular wind tunnel and has low design and manufacture difficulty of the motors, consistent impeller pumping points and reliable working performance, thereby meeting the requirements on both mass flow and higher pressure ratio.

Owner:SHANGHAI BLOWER WORKS

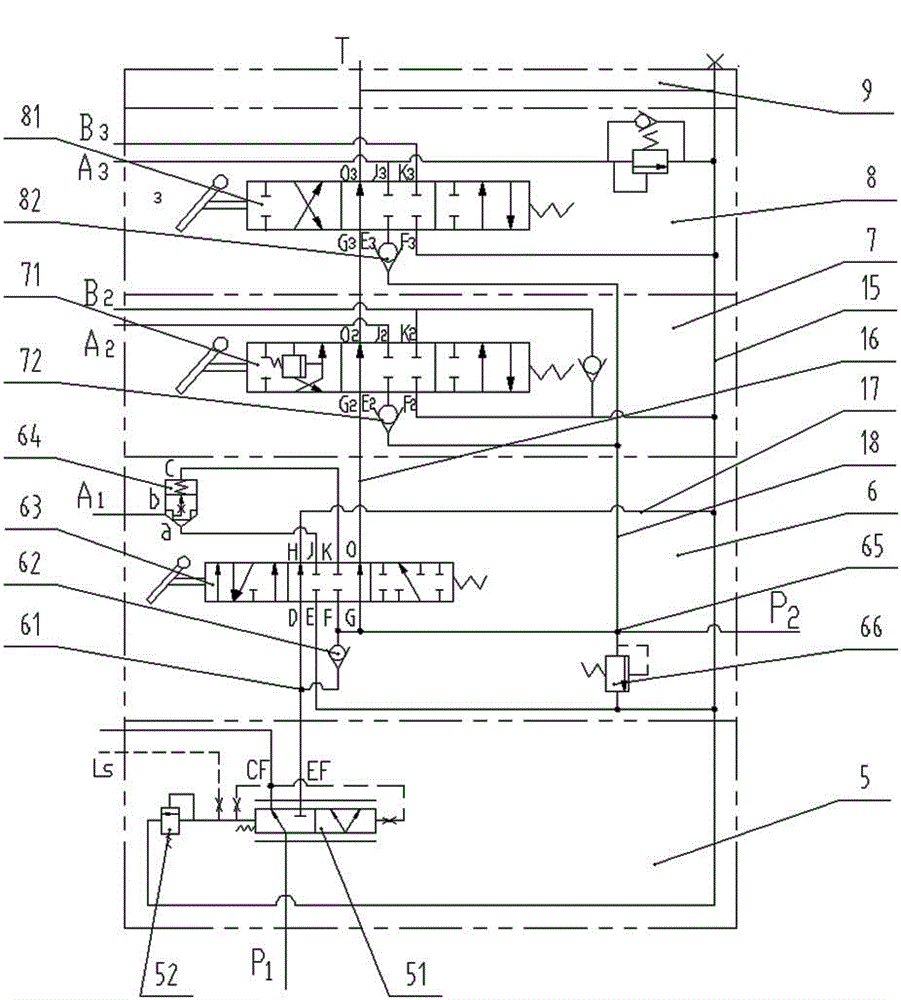

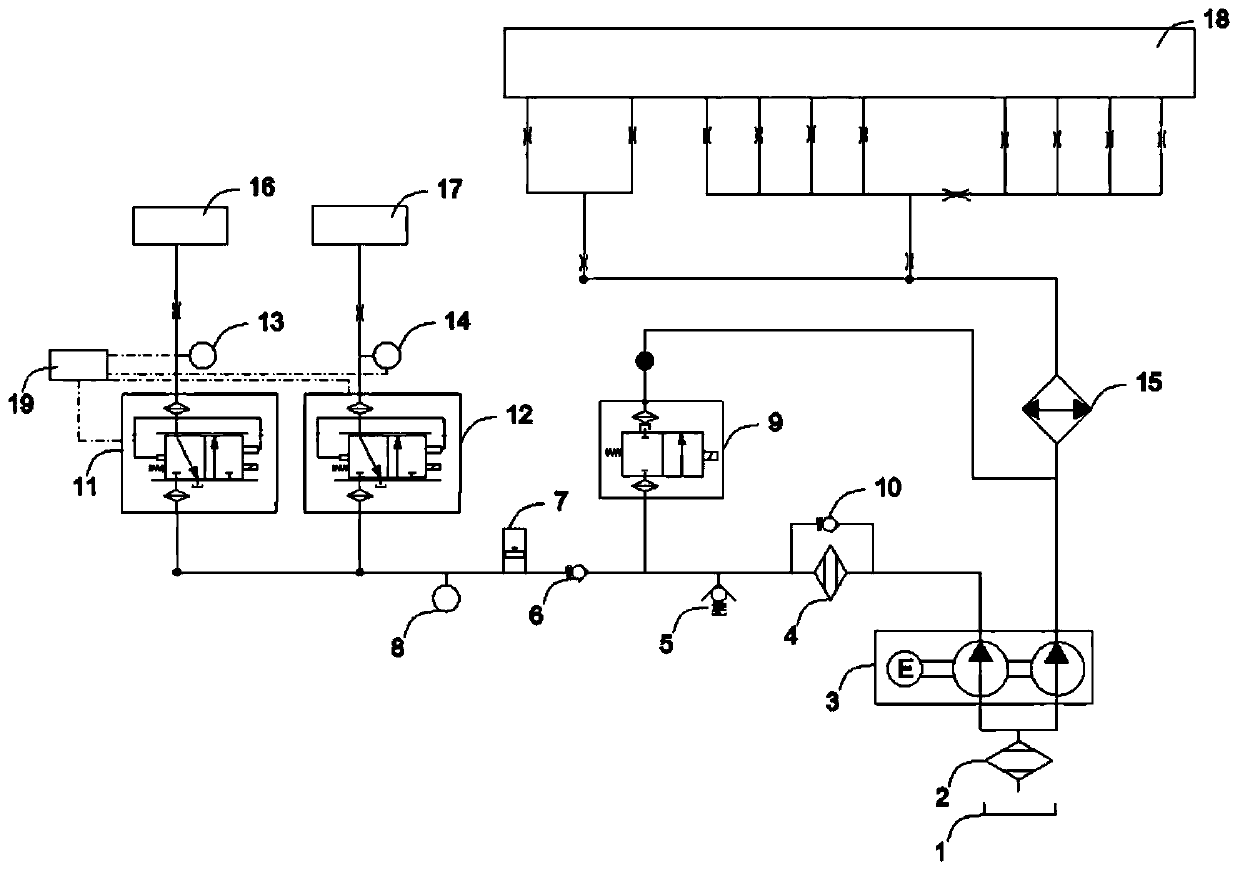

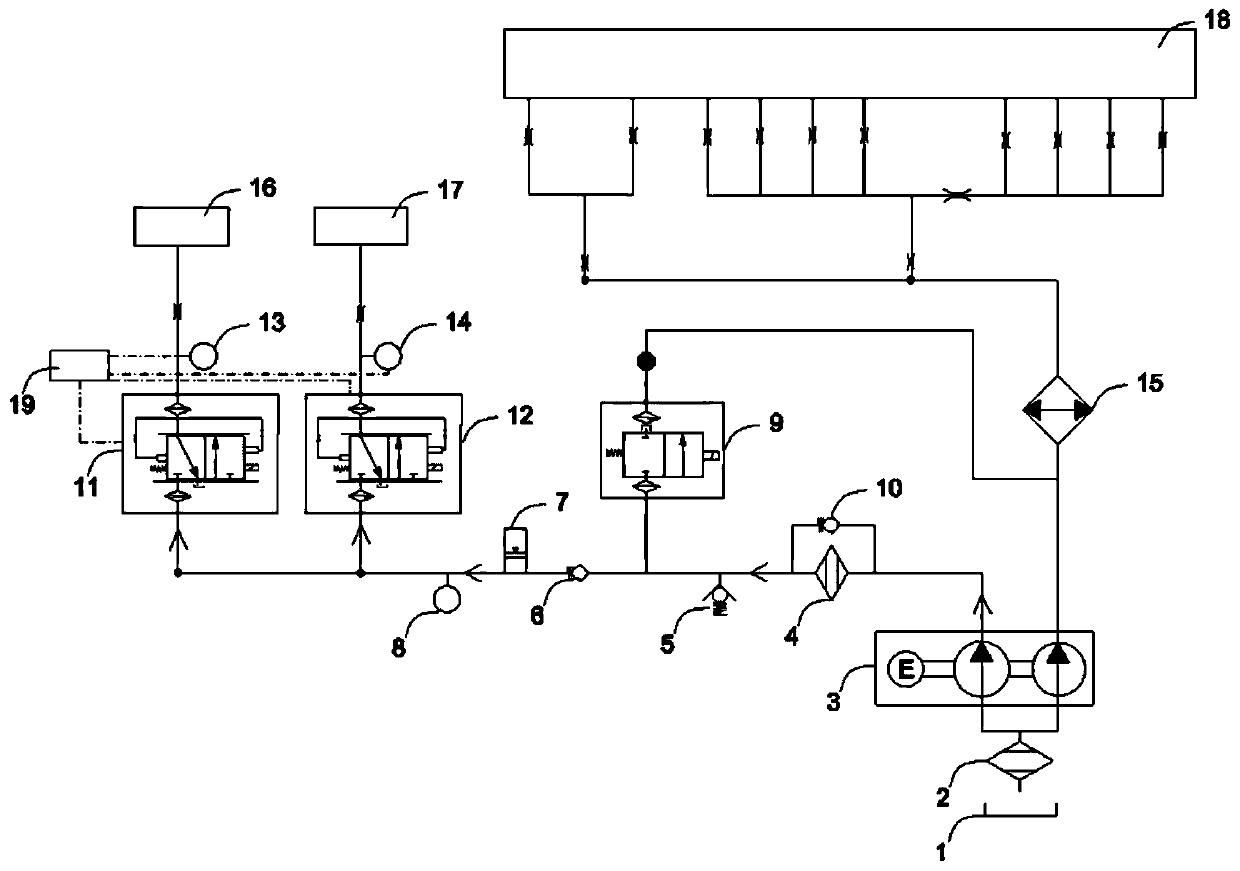

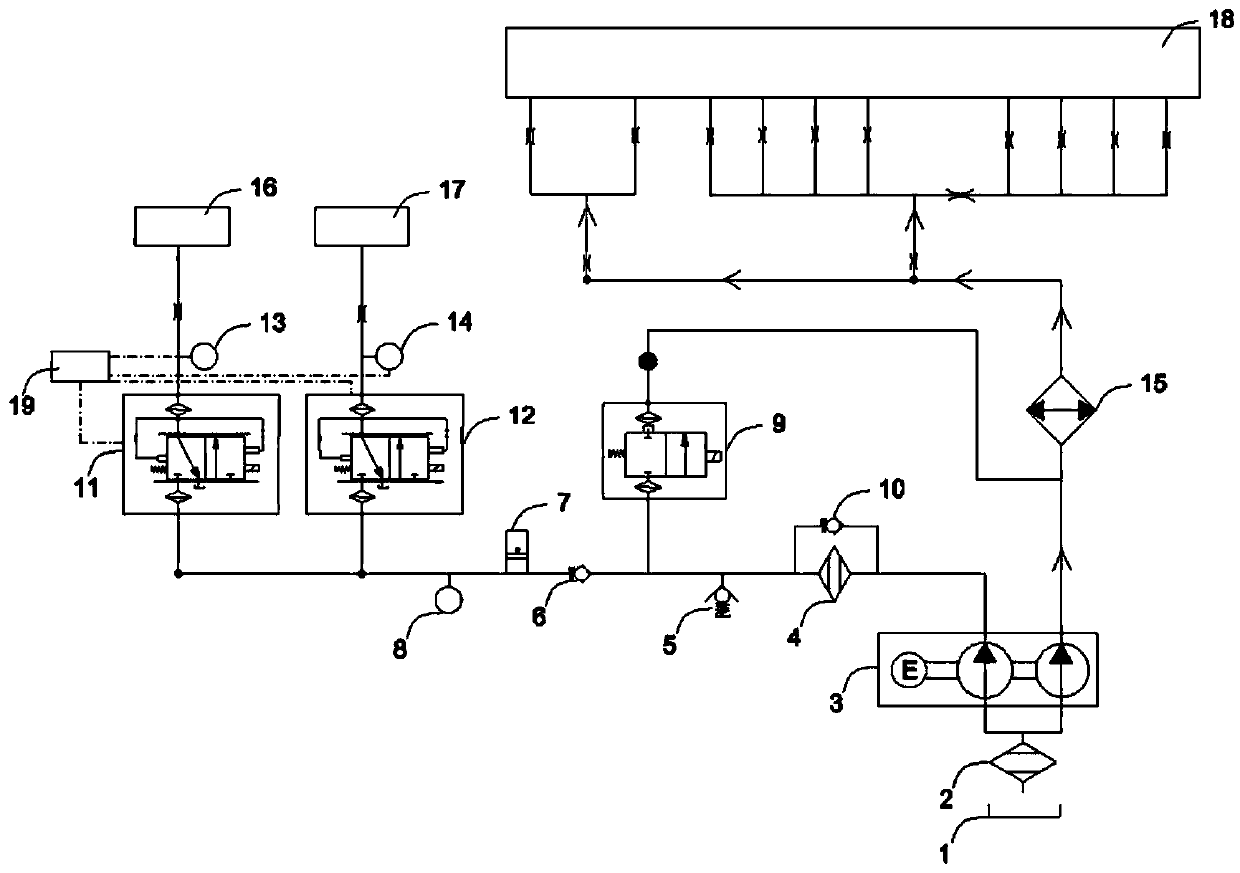

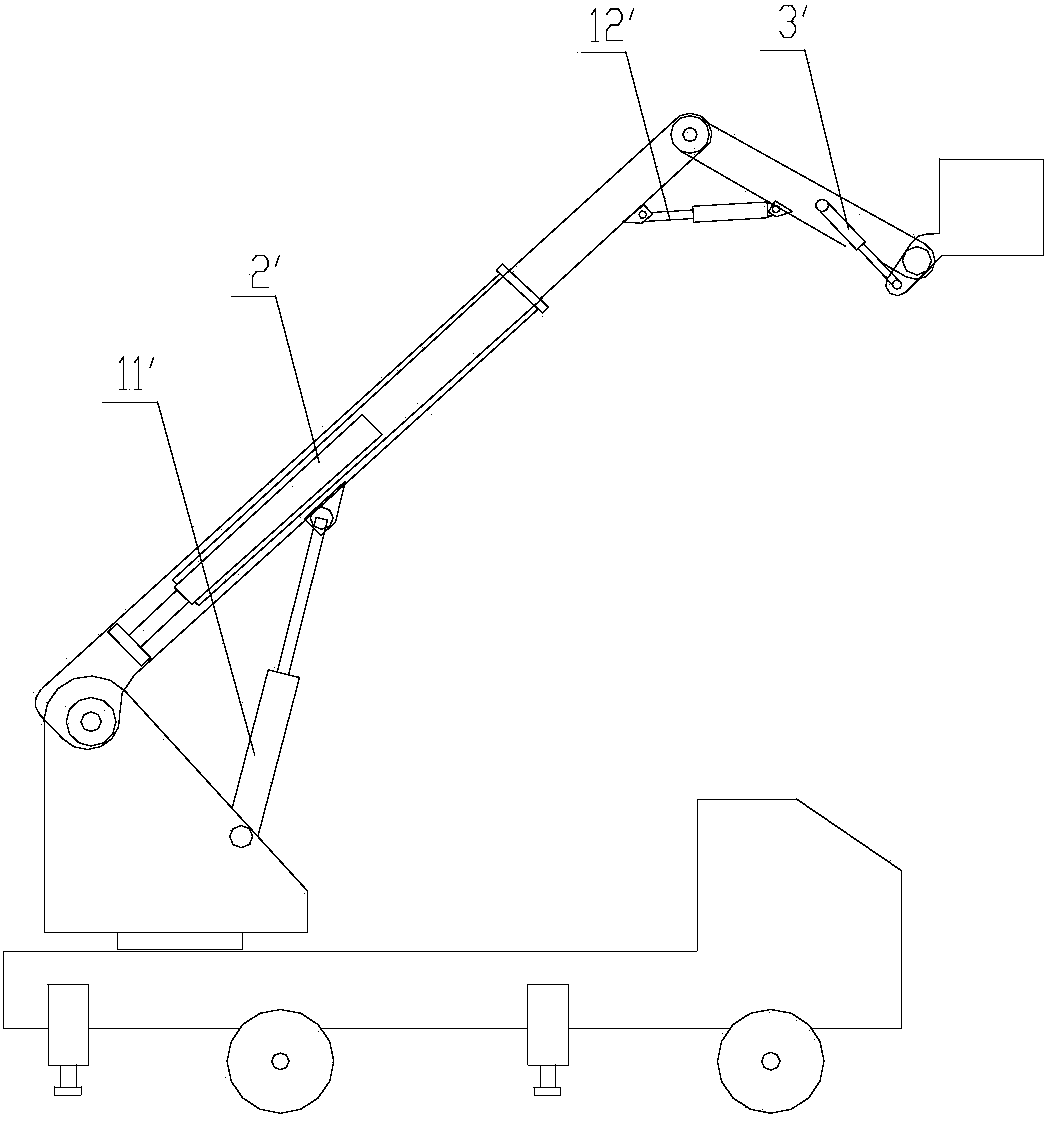

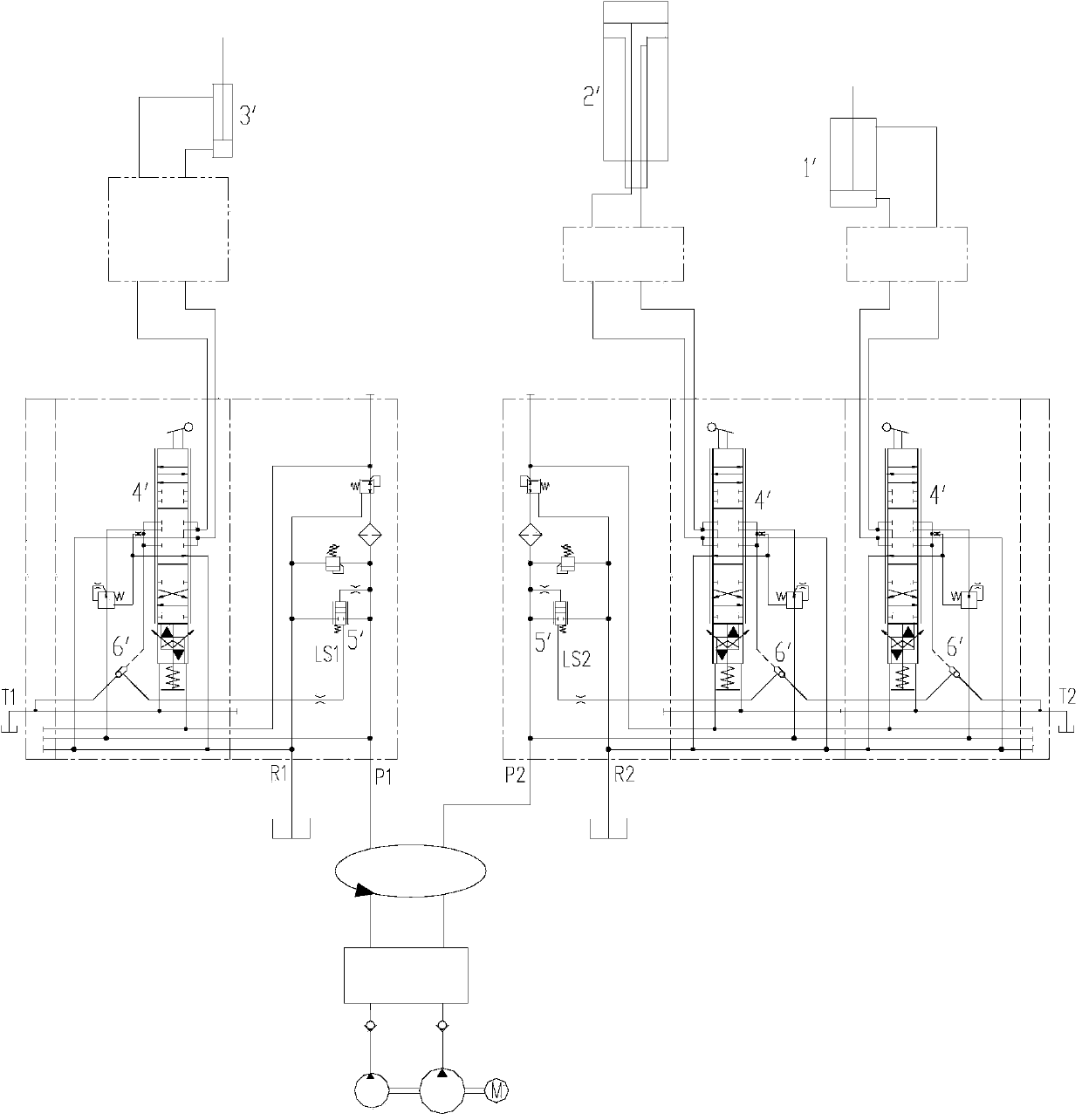

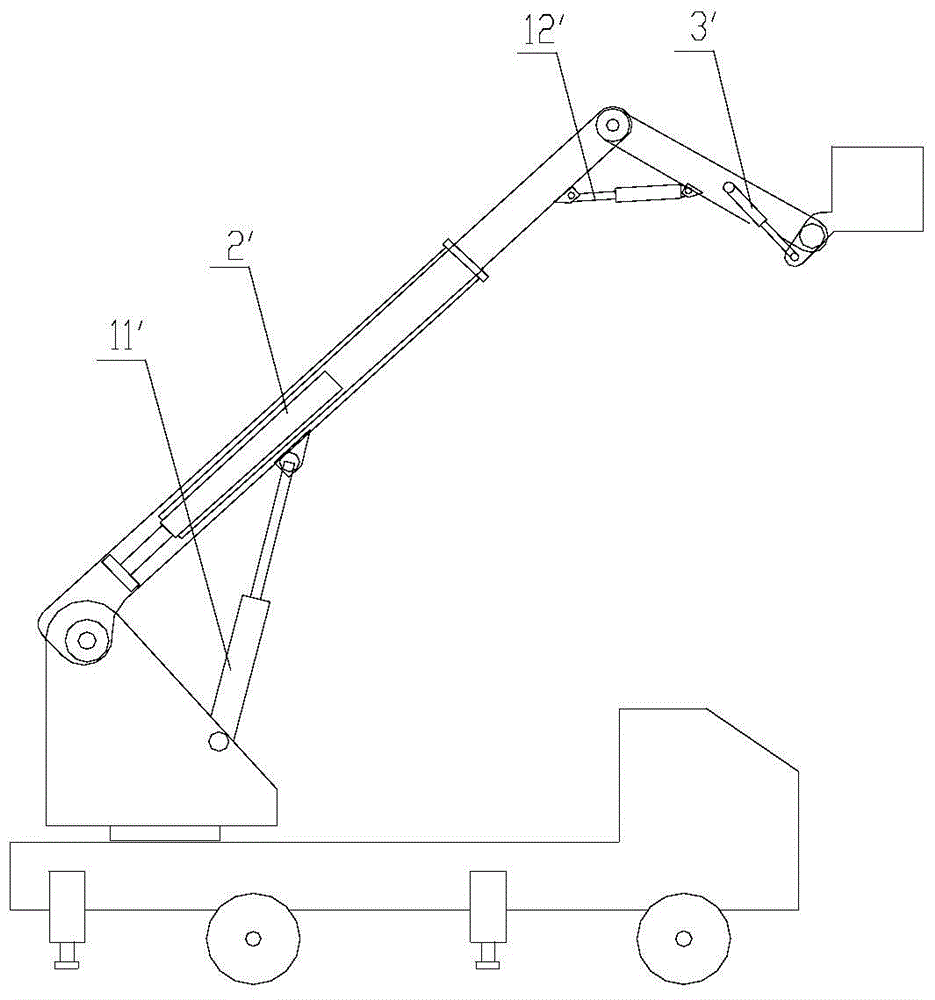

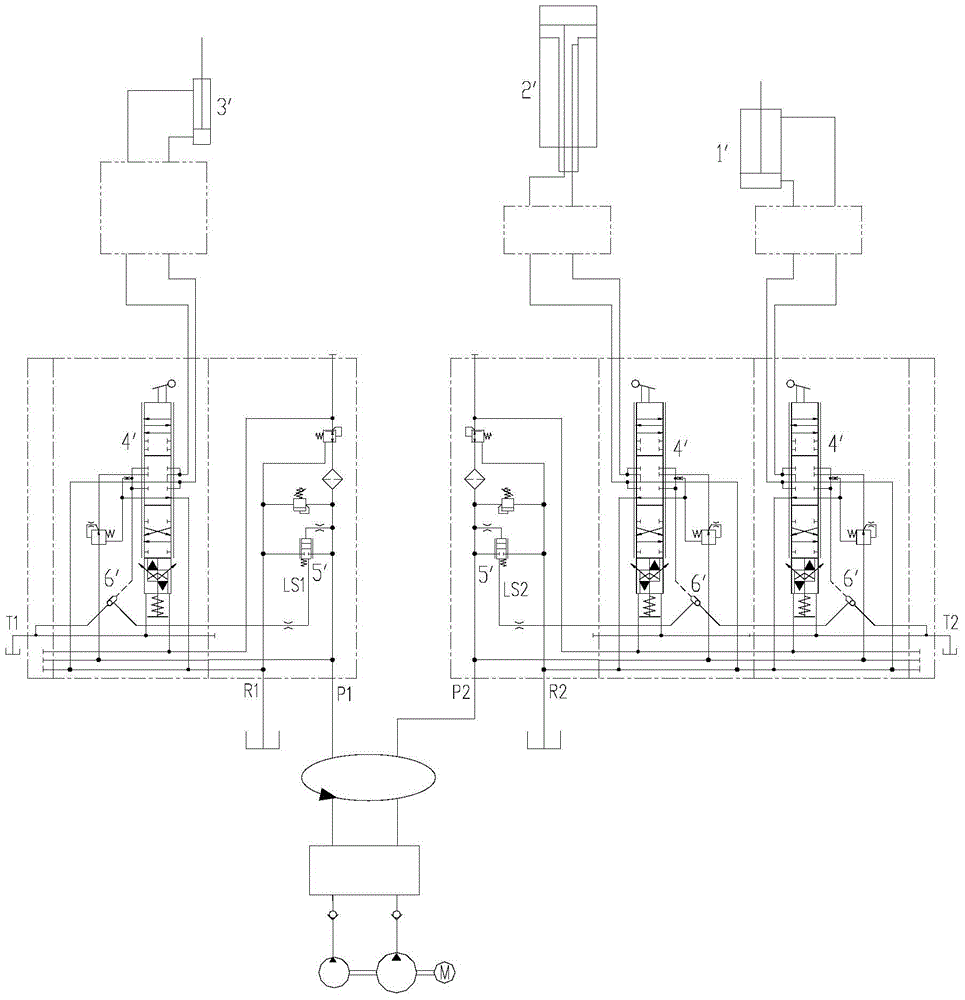

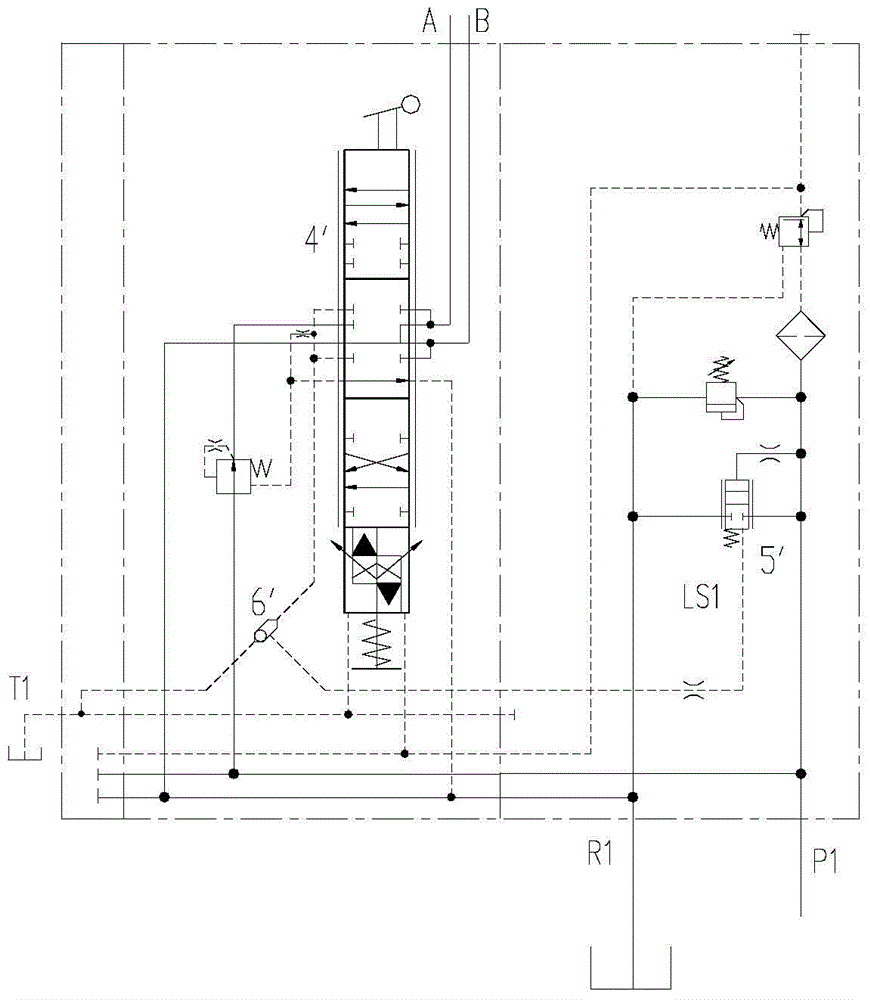

Dual-pump bidirectional confluence control system and fire truck adopting same

ActiveCN104179739ASatisfy traffic demandMeet the needs of large flowServomotor componentsServomotorsControl systemTruck

The invention provides a dual-pump bidirectional confluence control system and a fire truck adopting the same, and aims to reduce energy loss and lower system temperature rise. The control system comprises a first oil pump for supplying oil for a levelling cylinder, as well as a second oil pump for supplying oil for a telescopic cylinder and a variable amplitude cylinder; the two oil pumps are driven coaxially; a first pressure compensator and a second pressure compensator for adjusting flow are arranged at the oil outlets of the two oil pumps respectively; the levelling cylinder, the telescopic cylinder and the variable amplitude cylinder are controlled through a levelling reversing valve, a telescopic reversing valve and a variable amplitude reversing valve respectively; oil unloading openings and oil supplement openings are formed in the levelling reversing valve, the telescopic reversing valve and the variable amplitude reversing valve respectively; when each reversing valve is positioned at a neutral position, each oil unloading opening is communicated with the corresponding oil supplement opening; the oil outlet of the first pressure compensator is communicated with the oil supplement opening of the telescopic reversing valve and the oil supplement opening of the amplitude reversing valve through an oil supplement oil line; the oil outlet of the second pressure compensator is communicated with the oil supplement opening of the levelling reversing valve through another oil supplement oil line; the oil supplement oil lines are communicated with the oil inlets of the corresponding reversing valves through on-off valves respectively.

Owner:XCMG FIRE FIGHTING SAFETY EQUIP CO LTD

Airflow energy mixing measuring system

The invention relates to the field of wind tunnel tests, and discloses an airflow energy mixing measuring system which comprises an inlet section, a throttling section and a mixing section, a throttling cone is arranged in the throttling section, and the mixing section is connected with the throttling section. A protective cover is arranged in the mixing section, and a cavity is formed between the outer wall of the protective cover and the inner wall of the mixing section; an air supply pipeline and an injection nozzle are arranged at the front part of the mixing section; the air supply pipeline is communicated with the injection nozzle and provides high-pressure air flow for the injection nozzle. The problems that in a wind tunnel air inlet channel test in the prior art, due to a gas flow testing and adjusting device, the overall length of an air inlet channel test device is too long, a model and a test device are troublesome to mount and dismount, and efficiency is reduced are effectively solved. According to the system, the effects of flow simulation, adjustment and measurement can be integrally achieved.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

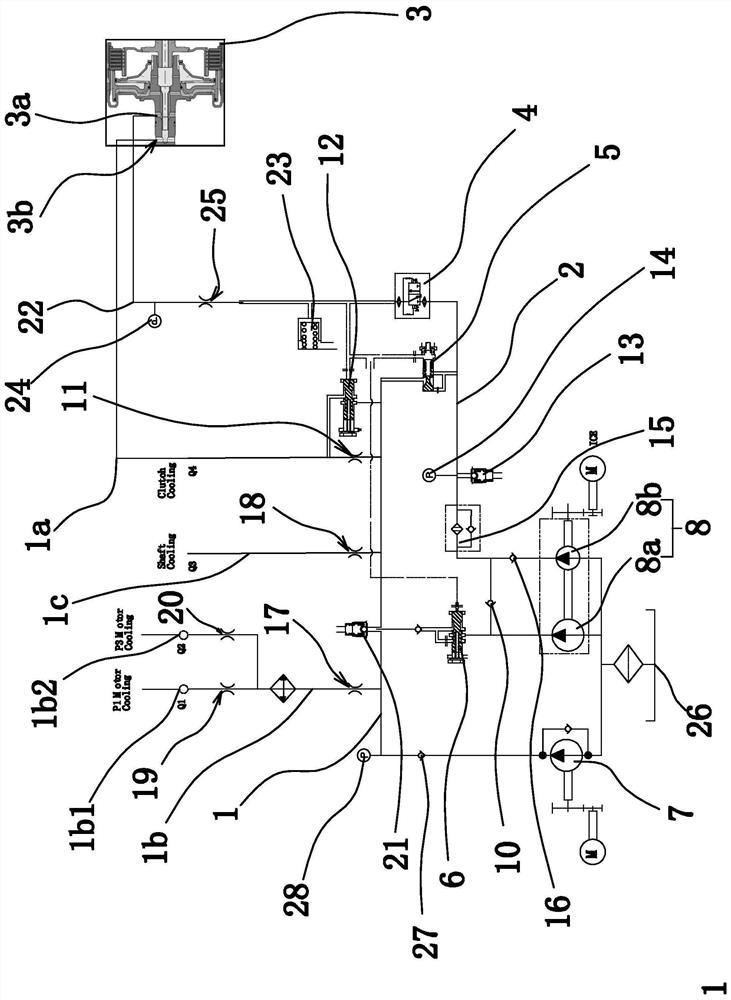

Hydraulic system of automobile hybrid power transmission

ActiveCN112594372ALow costImprove efficiencyGear lubrication/coolingGearing controlElectric machineryControl valves

The invention provides a hydraulic system of an automobile hybrid power transmission, and belongs to the technical field of hydraulic pressure. The problems that an existing transmission hydraulic system is poor in cold start performance, high in energy consumption and high in cost are solved. The hydraulic system comprises a cooling lubricating oil way, a high-pressure oil way, a reversing valve,a mechanical lubricating pump and a duplex mechanical pump driven by an engine or a P1 motor. The high-pressure oil way is connected with a clutch piston cavity through a first control valve, and thehigh-pressure oil way is connected with the cooling lubricating oil way through an overflow valve. The mechanical lubricating pump is driven by the output end of a differential mechanism and connected with the cooling lubricating oil way, the duplex mechanical pump comprises a large-displacement pump and a small-displacement pump, the large-displacement pump communicates with a first oil inlet ofthe reversing valve and the high-pressure oil way, and a left oil outlet and a right oil outlet of the reversing valve both communicate with the cooling lubricating oil way. A reversing pilot pressure cavity of the reversing valve is connected with a clutch piston cavity, and the small-displacement pump communicates with a high-pressure oil way. The system is low in cost, good in cold start performance and low in energy consumption.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +3

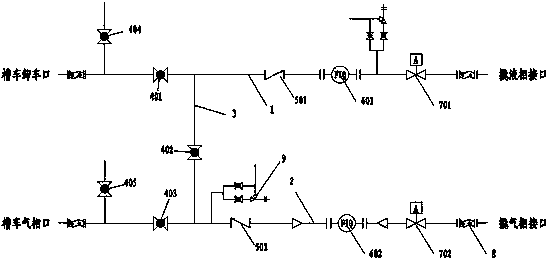

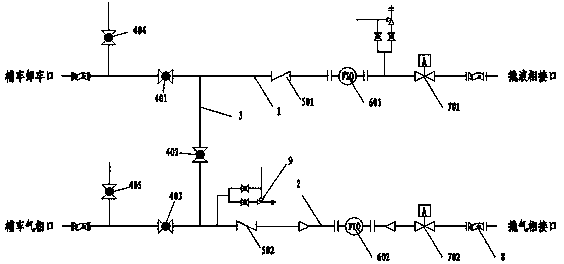

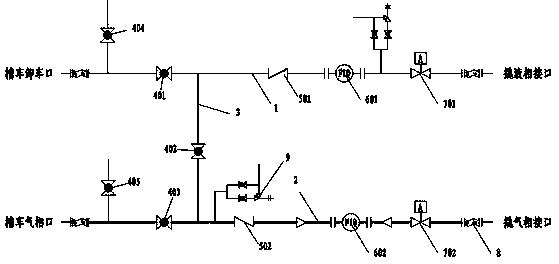

LNG (liquefied natural gas) high-flow-rate gas release column

ActiveCN103470956AConvenient and quick unloading meteringMeet the needs of large flowPipeline systemsFluid phaseGas release

The invention discloses an LNG (liquefied natural gas) high-flow-rate gas release column, which belongs to the technical field of LNG liquid addition. The LNG high-flow-rate gas release column comprises a liquid adding pipeline and a gas return pipeline, wherein the two ends of the liquid adding pipeline are respectively provided with a tank car unloading opening and a prying equipment liquid phase interface, the two ends of the gas return pipeline are respectively a tank car gas phase opening and a prying equipment gas phase interface, the middle part of the liquid adding pipeline is communicated with the middle part of the gas return pipeline through a pressure regulating pipeline, a first stop valve is arranged between a connecting point of the pressure regulating pipeline and the tank car unloading opening of the liquid adding pipeline, a first mass flow rate meter is arranged between the connecting point of the pressure regulating pipeline of the liquid adding pipeline and the prying equipment liquid phase interface, a second stop valve is arranged between the tank car gas phase interface of the gas return pipeline and the connecting point of the pressure regulating pipeline, a second mass flow rate meter is arranged between the connecting point of the pressure regulating pipeline of the gas return pipeline and the prying equipment gas phase interface, and a second stop valve is arranged on the pressure regulating pipeline. The LNG high-flow-rate gas release column has the advantages that the high-flow-rate requirements can be met, and a tank car can be conveniently and fast moved for realizing the unloading metering.

Owner:HOPE CLEAN ENERGY (GRP) CO LTD

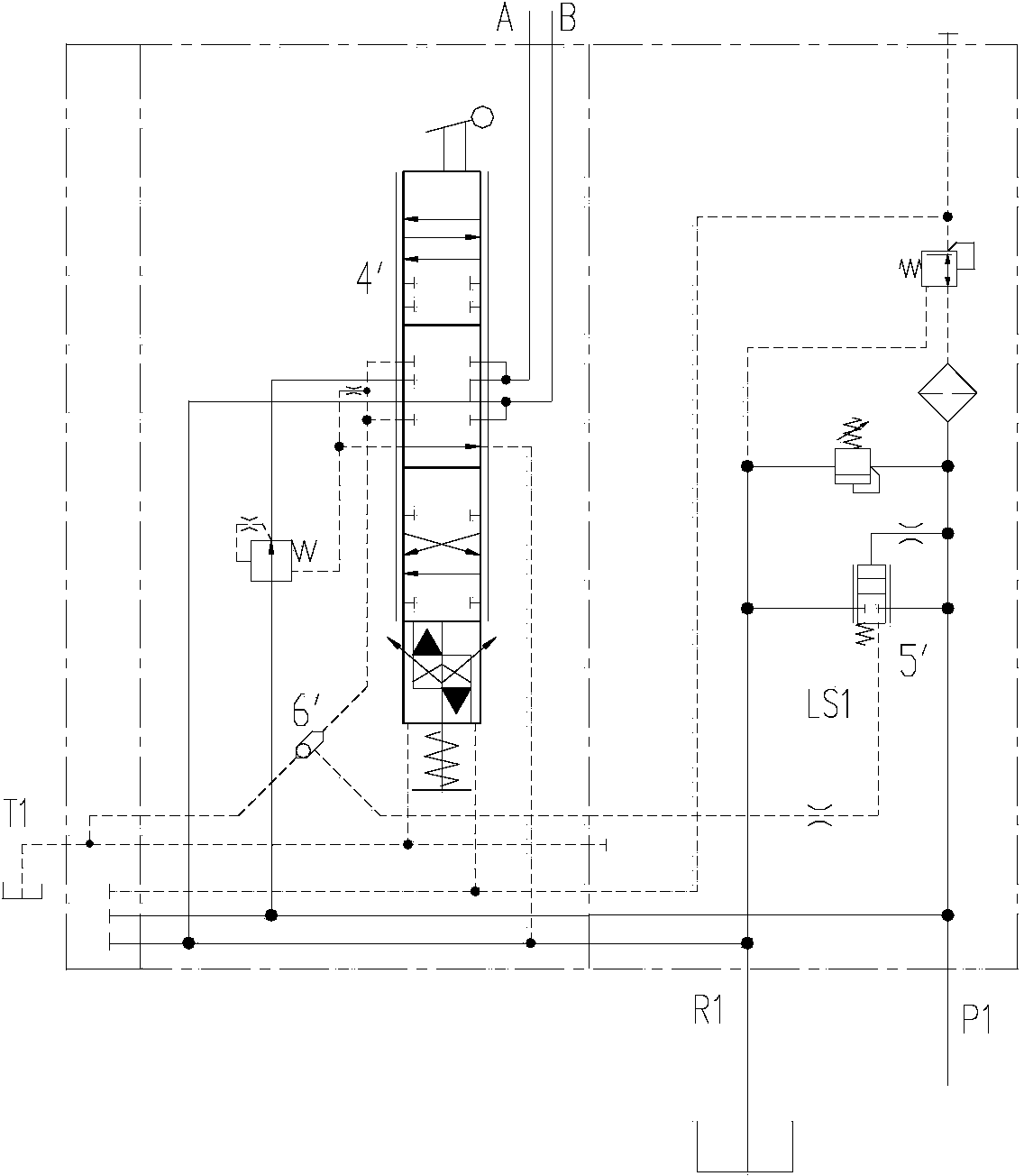

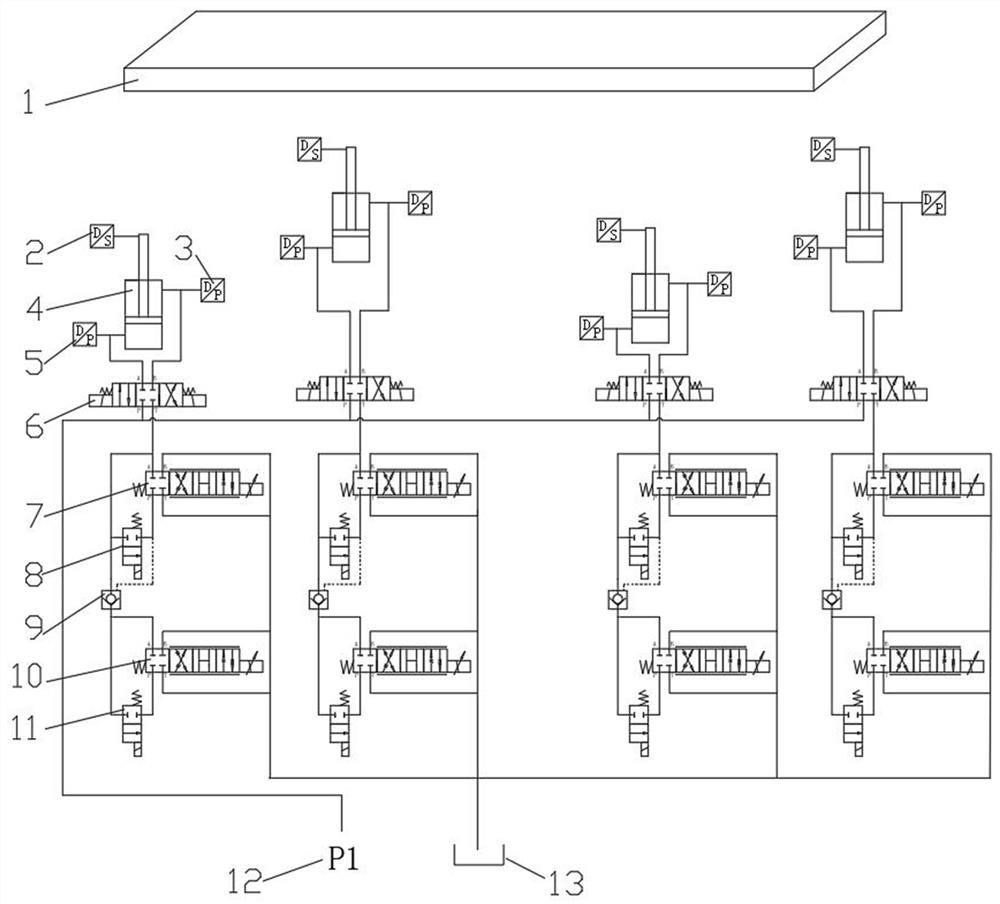

Leveling control system structure capable of realizing switching of multiple flow ranges and using method

ActiveCN112594234AHigh precisionExactly match traffic demandServomotor componentsServomotorsSynchronous controlControl system

The invention provides a leveling control system structure capable of realizing switching of multiple flow ranges. The leveling control system structure is used for leveling a pressure output end sliding block of a press, and a leveling unit powered by a constant-pressure oil source is arranged below each corner end of the sliding block; each leveling unit is in contact with the corner end of thesliding block through a leveling cylinder provided with a displacement sensor; a rod cavity of each leveling cylinder is connected with a first pressure sensor, and a rodless cavity of each leveling cylinder is connected with a second pressure sensor; and an oil outlet path of each leveling cylinder is connected with a control valve bank so as to switch the multiple flow ranges to meet different flow requirements of the system under multiple working conditions, and the levelness of the sliding block during falling is guaranteed by improving the position synchronous control precision of the leveling cylinders of the leveling units. According to the leveling control system structure, the flow requirements under various working conditions can be accurately matched, so that the flow control accuracy of the leveling system is improved.

Owner:FUZHOU UNIV

One-way valve and hydraulic system

PendingCN113236827AIncrease delivery flowMeet the demand of large flowOperating means/releasing devices for valvesPositive displacement pump componentsOil pressurePetroleum engineering

Owner:MILTON ROY IND SHANGHAI

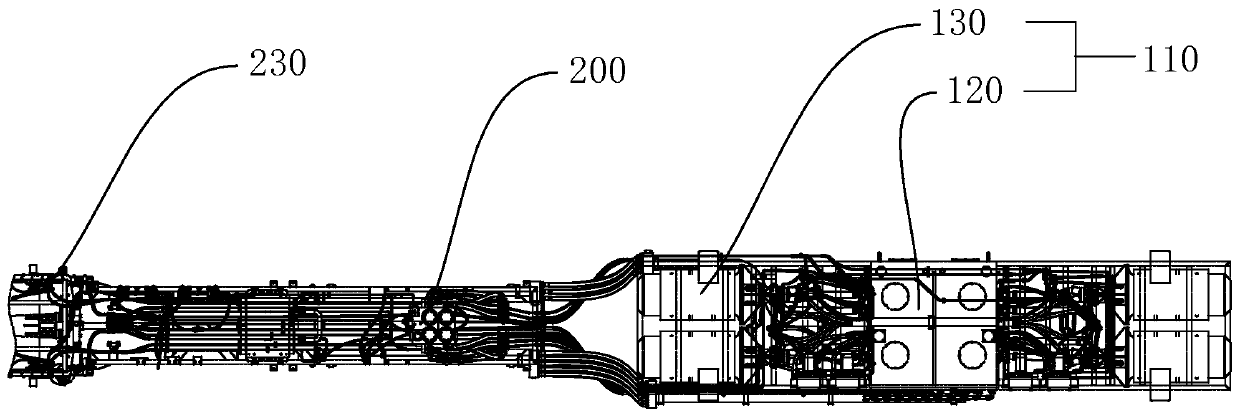

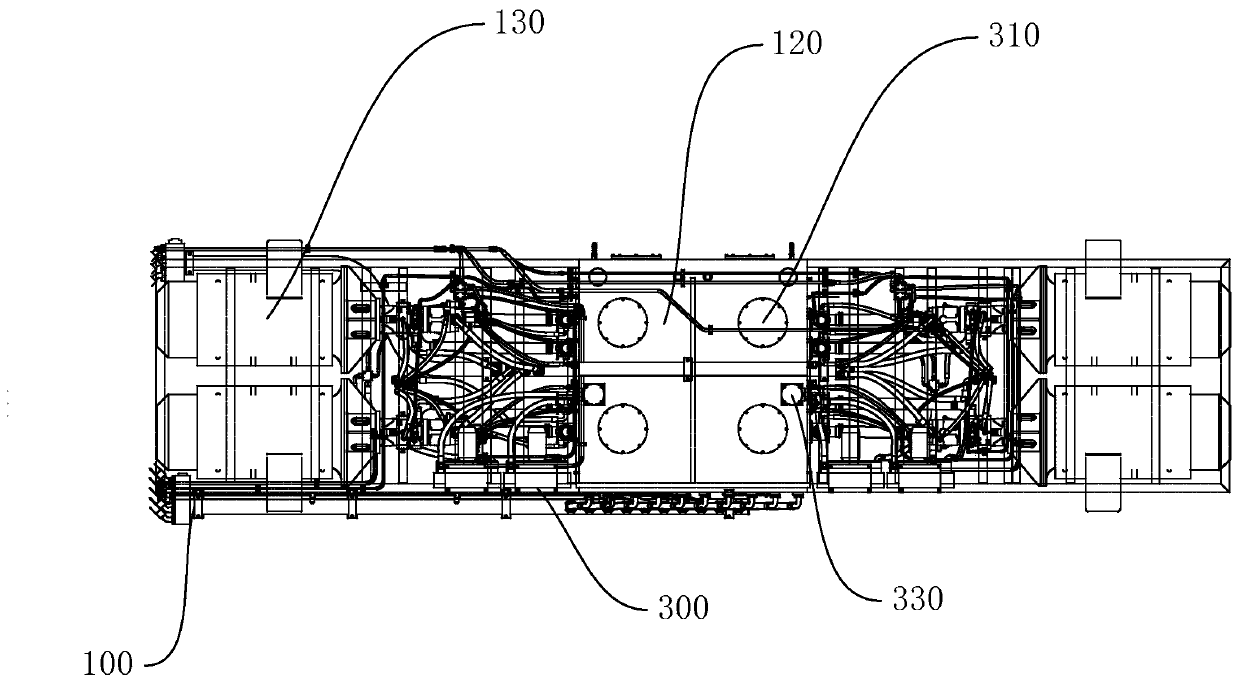

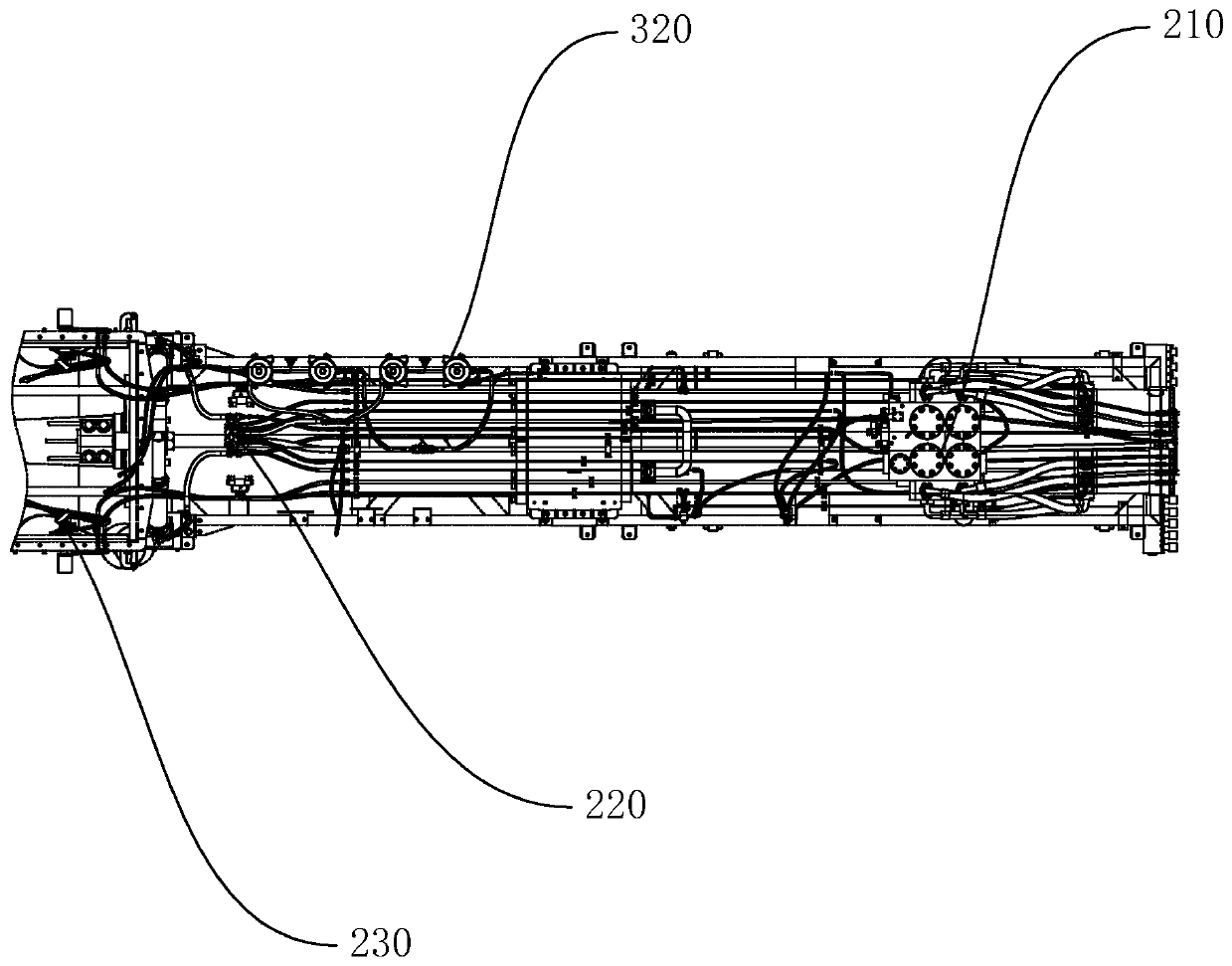

Piston type filling industrial pump hydraulic system

PendingCN111075798ACompact layoutSmall footprintFluid-pressure actuator componentsEngineeringPower apparatus

The invention discloses a piston type filling industrial pump hydraulic system. The piston type filling industrial pump hydraulic system comprises a power device and a pumping device; the power deviceis formed by connecting at least two power units in parallel, each power unit comprises an oil tank and a motor oil pump set, each motor oil pump set comprises a main oil pump and a flow dividing oilpump, every two power units are paired and oppositely arranged, and the multiple pairs of power units are tightly attached and arranged side by side; the pumping device is connected with a motor oilpump set through a pipeline and comprises a main valve set, a distribution valve set and an S-pipe pump valve, the S-pipe pump valve is used for pumping materials, the main valve set receives power from a main oil pump and provides the power for the S-pipe pump valve, the distribution valve set receives power of the flow dividing oil pump so as to control reversing of the S-pipe pump valve, and the distribution valve set is further connected with the power device through the pipeline. The power device is compact in layout, occupied space is saved, and the pumping device can effectively meet the large-volume and high-pressure conveying requirements.

Owner:FENY

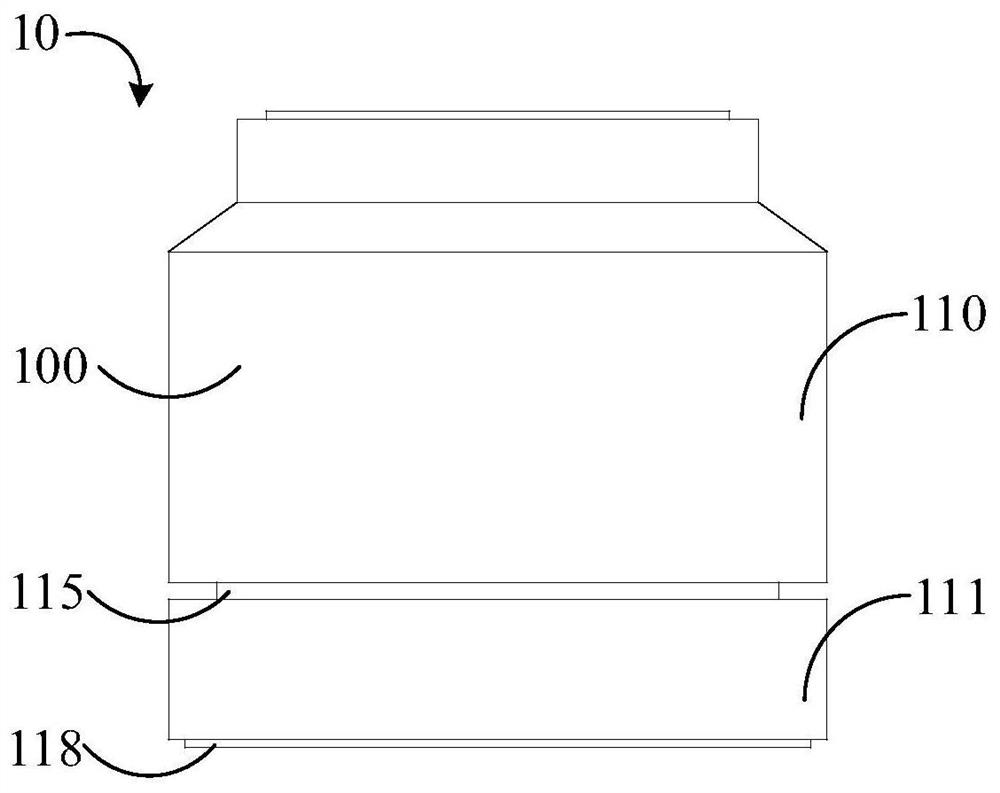

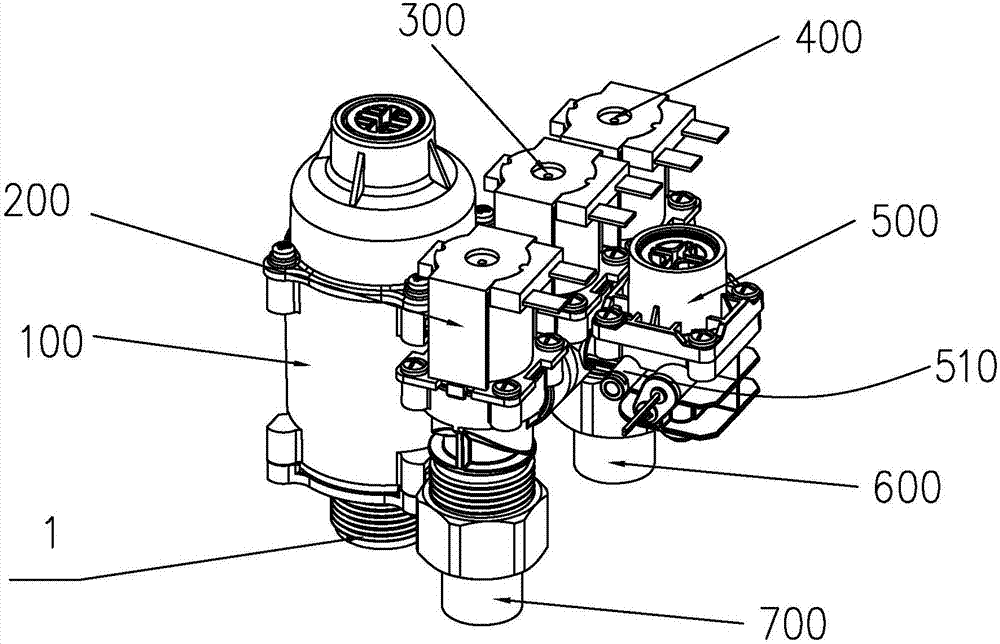

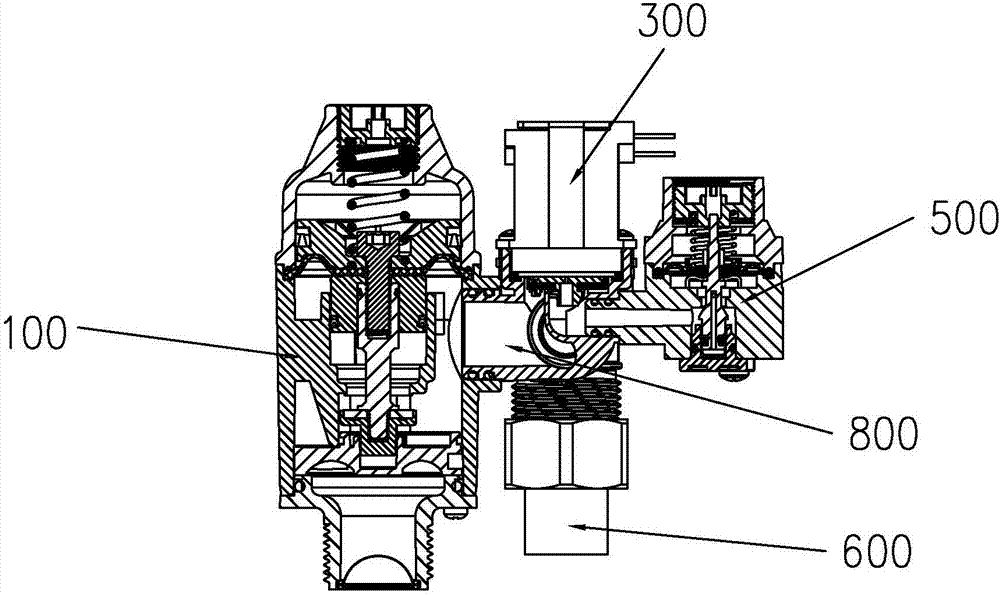

Water distribution device of water-tank-free pedestal pan

ActiveCN107299665ASave transfer spaceReduce the risk of transferFlushing devicesService pipe systemsStream flowSource water

The invention discloses a water distribution device of a water-tank-free pedestal pan. The water distribution device comprises a first pressure stabilization unit (100), a brush ring electromagnetic valve unit (200), a washing electromagnetic valve unit (300), an ejection electromagnetic valve unit (400) and a washing pressure stabilization unit (500), wherein a water inlet of the first pressure stabilization unit is connected with a water source, water flow is subjected to primary pressure stabilization after entering the first pressure stabilization unit (100), and a water outlet of the first pressure stabilization unit is connected with a multi-channel pipeline (800); the outlet end of the multi-channel pipeline (800) is divided into a middle-path water outlet (810), a left-path water outlet (820) and a right-path water outlet (830). The water distribution device is particularly suitable for water division of large-flow pedestal pans.

Owner:BESTTER XIAMEN TECH

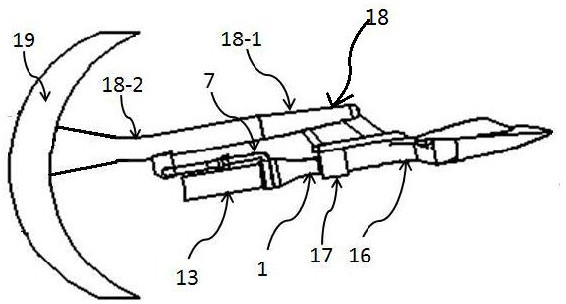

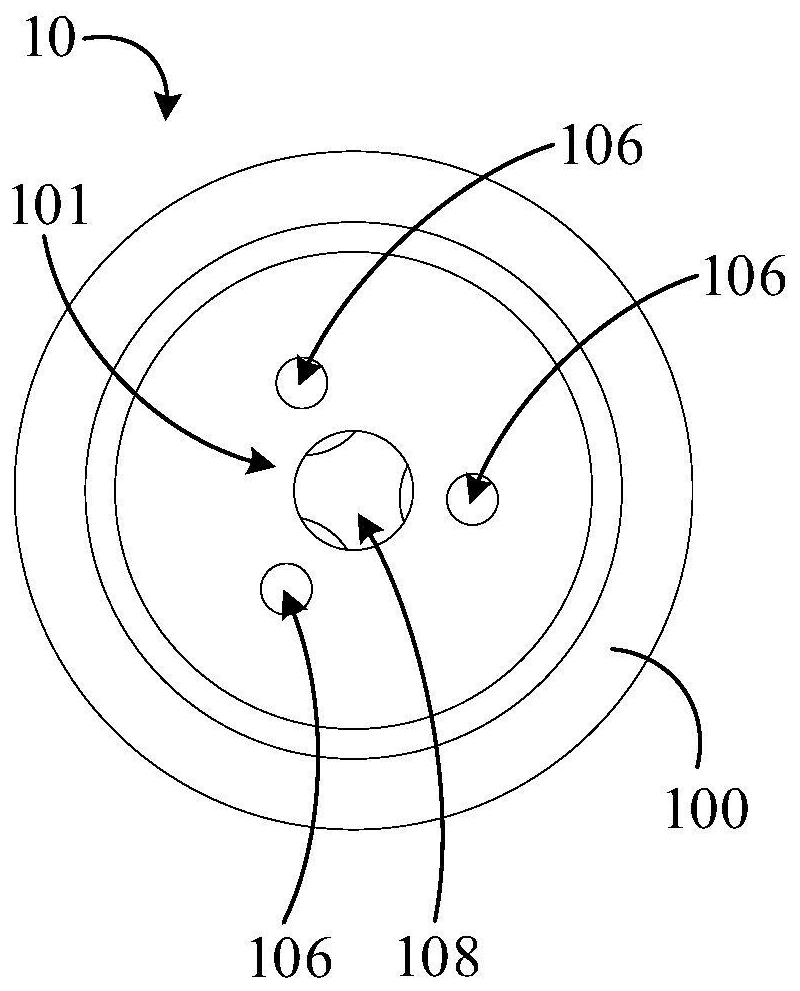

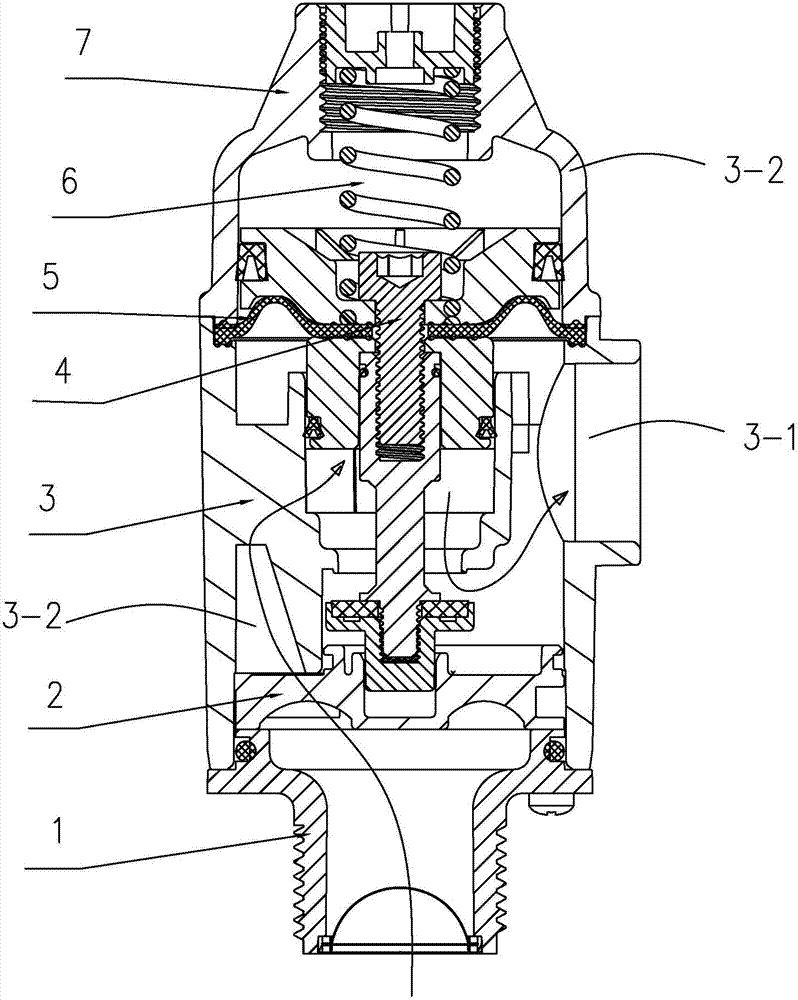

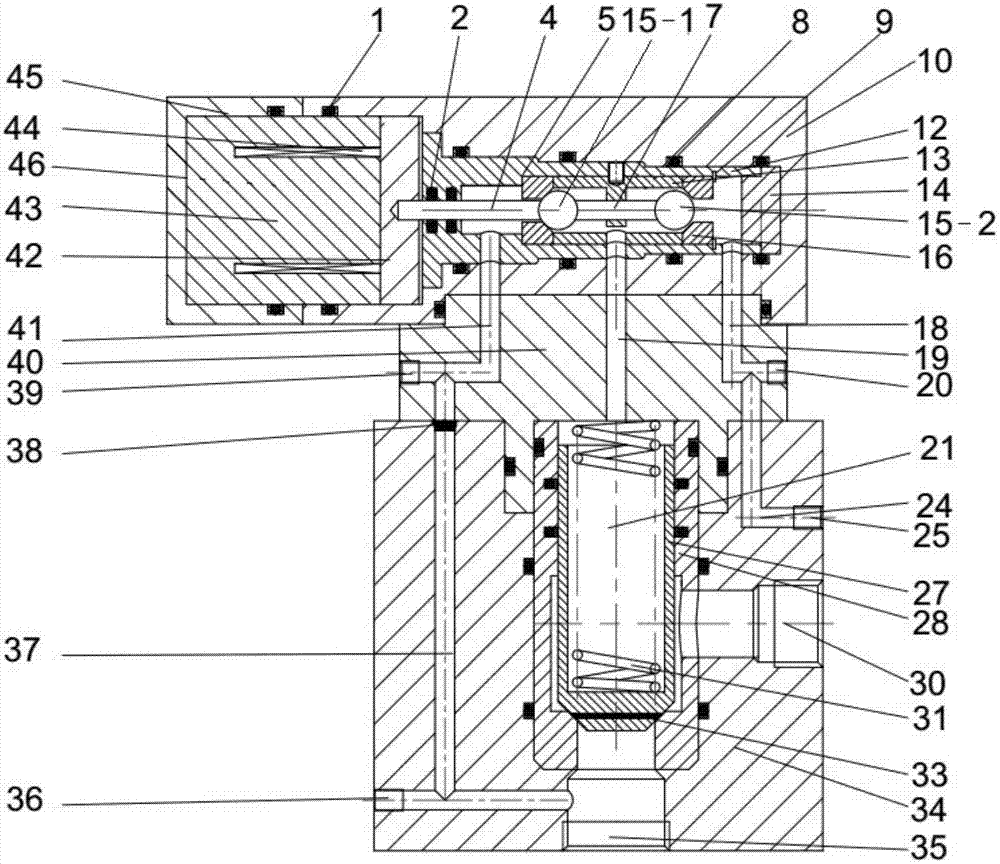

High-flow pressure stabilizer

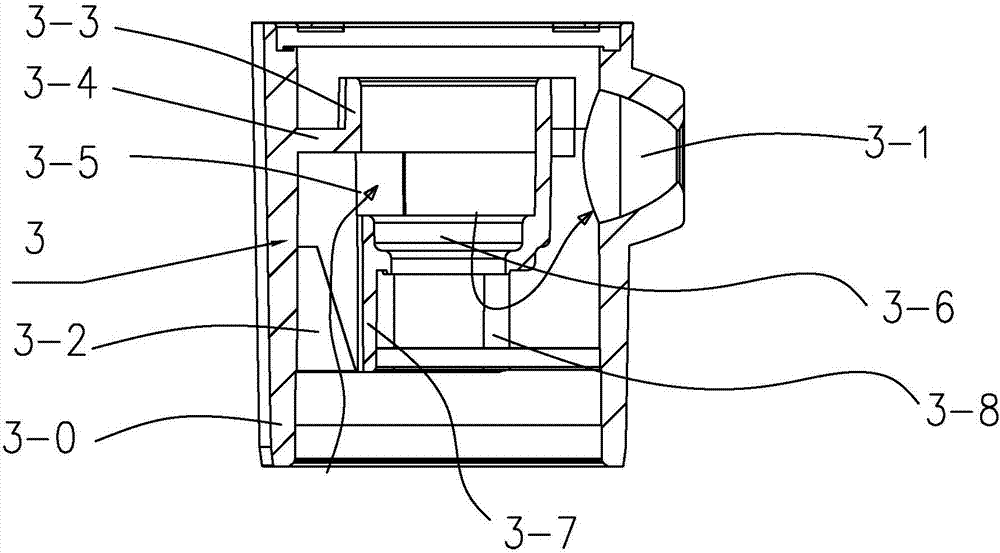

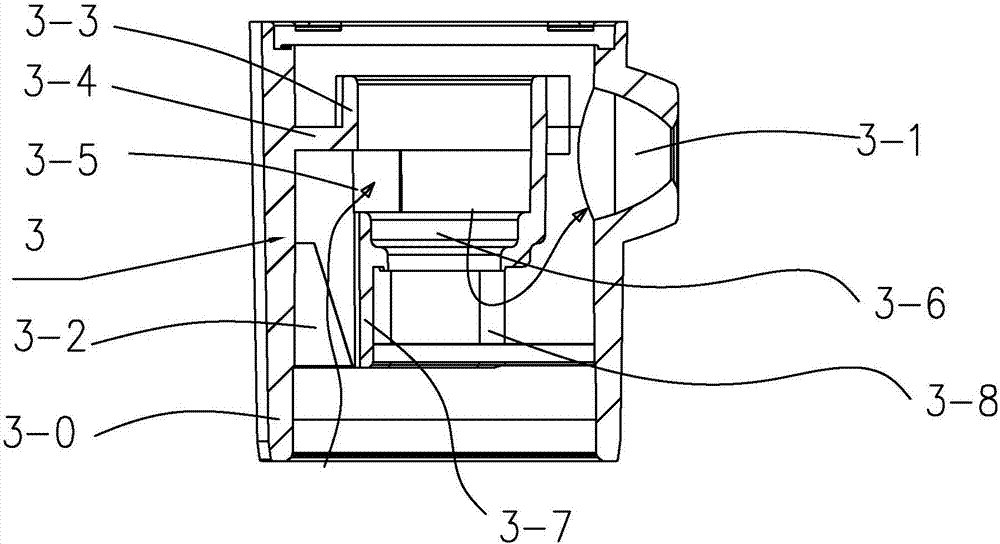

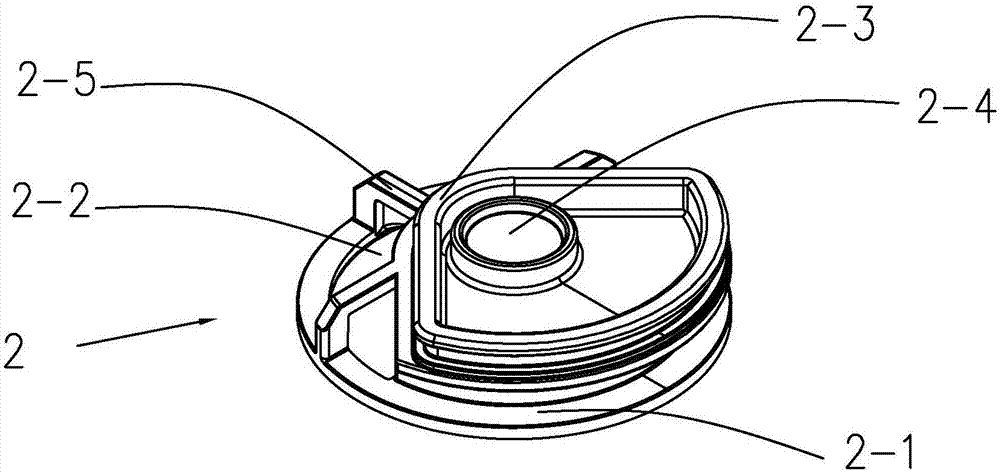

ActiveCN107237383AMeet voltage regulationImprove space utilizationLavatory sanitoryHydro energy generationCircular discEngineering

The invention discloses a high-flow pressure stabilizer. The high-flow voltage stabilizer includes a cylindrical body (3) and a piston assembly (4) which is arranged in the body (3), and the high-flow voltage stabilizer is characterized in that the water inlet end of the body (3) is provided with a sealed support (2); the sealed support (2) includes a disc-shaped base (2-1); the body (3) includes a cylindrical outer cylinder (3-0), and an inner cylinder (3-3) is arranged in the outer cylinder (3-0); the lower end of the inner cylinder is located certain distance away from the upper surface of the sealed support (2); a retaining wall (3-7) which extends downwards is arranged at the end of one side of the inner cylinder, and the retaining wall is inserted between a water discharge hole area of the sealed support (2) and a sealed area of the sealed support (2); the piston assembly (4) includes a piston rod (4-4), and at least one middle sealed body (4-1) and one lower sealed body (4-5) which move synchronously are arranged on the piston rod (4-4). The high-flow voltage stabilizer further includes a piston restoring unit. The high-flow voltage stabilizer can achieve voltage stabilization under high flow.

Owner:BESTTER XIAMEN TECH

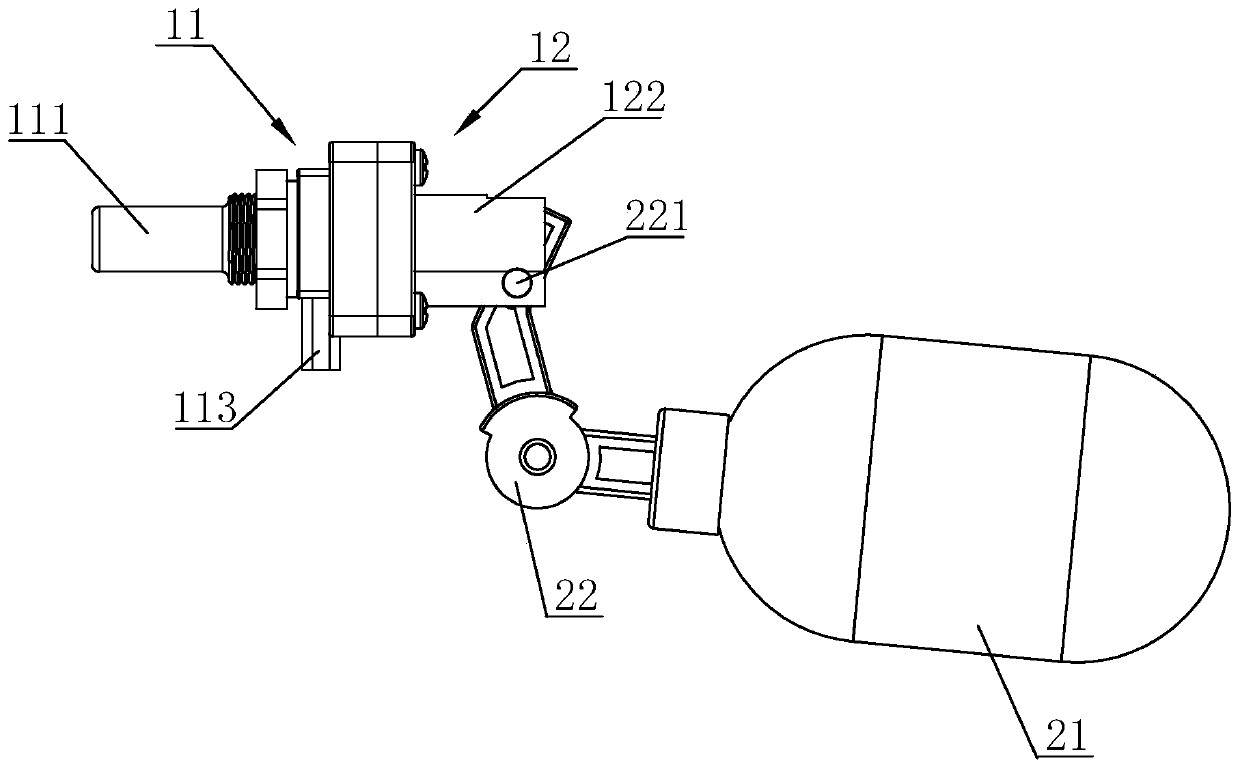

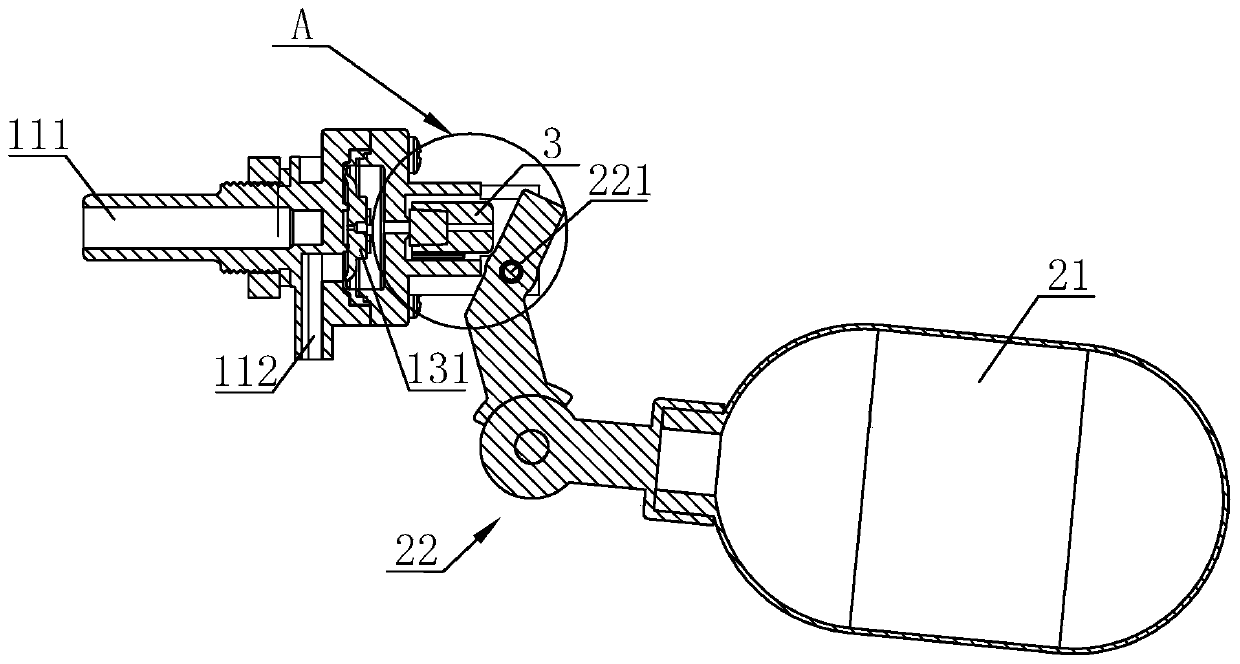

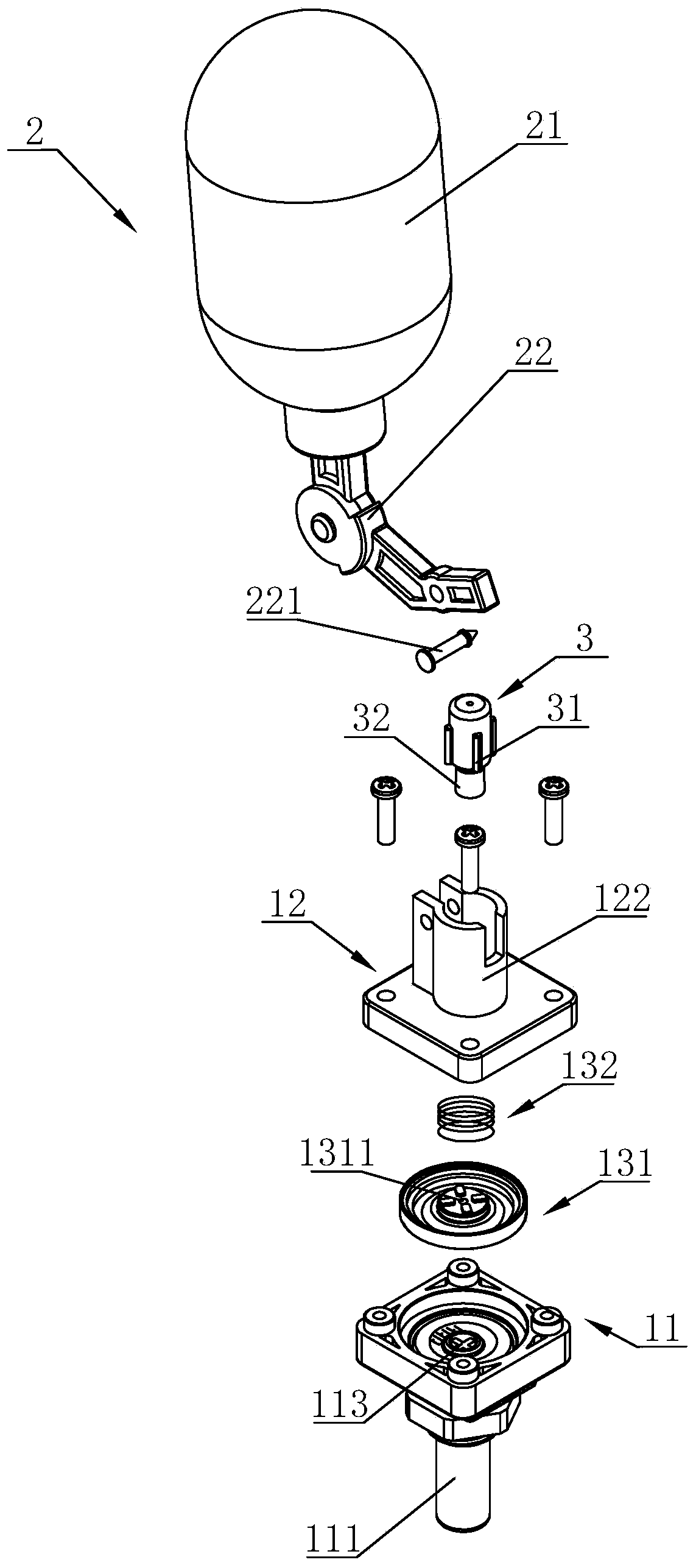

Large-flow floating ball switc

PendingCN110906048AGood blocking effectImprove the blocking effectOperating means/releasing devices for valvesLift valveEngineeringMechanics

The invention discloses a large-flow floating ball switch. By providing a block passage, the motion trajectory of a block is limited to a linear translational motion, and a good blocking effect is achieved. A small-diameter pressure relief hole is blocked by the block, and a sealing diaphragm is pressed against a sealing surface reversely by means of the water pressure of a water inlet, such thatthe need for large flow can be satisfied. An elastic reset member can be used to satisfy the need for small flow by pressing the sealing diaphragm tightly against the sealing surface in case of smallflow and an insufficient pressure difference between left and right chambers.

Owner:宁波照华环保科技有限公司

High pressure and mass flow pneumatic electromagnetic switch valve

ActiveCN107883000ALight structureLight in massOperating means/releasing devices for valvesLift valveGas cylinderGas passing

The invention provides a high pressure and mass flow pneumatic electromagnetic switch valve. The high pressure and mass flow pneumatic electromagnetic switch valve is provided with two air inlet passages, two exhaust passages, an electromagnet unit, a valve sleeve unit, a valve body unit, and a valve core unit; the two air inlet passages are connected with gas cylinders of different pressures, andthe two exhaust passages are connected with the external environment; the valve body unit moves within the valve sleeve unit under the action of the electromagnet unit and gas pressure of the gas cylinders to periodically open and close the air inlet passages and the exhaust passages, so that gas in the gas cylinders enters into a pneumatic engine through a exhaust port.

Owner:NANJING UNIV OF SCI & TECH

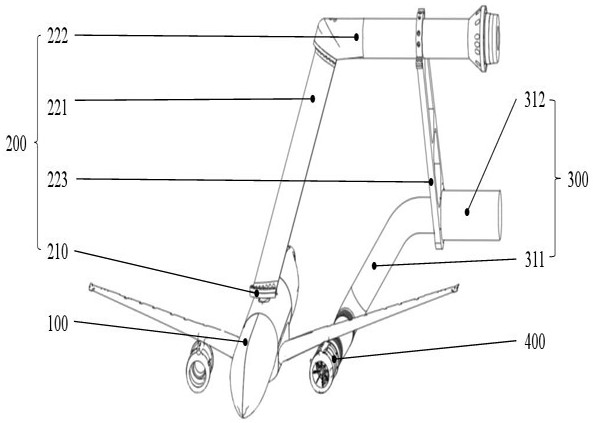

Wind tunnel test device

ActiveCN113049211AReduce gas flowMeet the needs of large flowAerodynamic testingSupporting systemPressure stabilization

The invention is suitable for the technical field of wind tunnel tests, and provides a wind tunnel test device, which comprises a support system, a test model and a pipeline system, and one end of the support system is connected above the test model; a ventilation module is arranged on the test model; the pipeline system is connected to the support system, and the pipeline system is connected to the test model; the pipeline system comprises a first pipeline part and a second pipeline part, one end of the first pipeline part is connected with one end of the ventilation module, and the first pipeline part and the second pipeline part are both connected to the support system. The wind tunnel test device has the advantages of being stable in pressure, high in universality, simple and convenient to use and capable of meeting the requirement for the large sideslip angle in a limit crosswind state.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

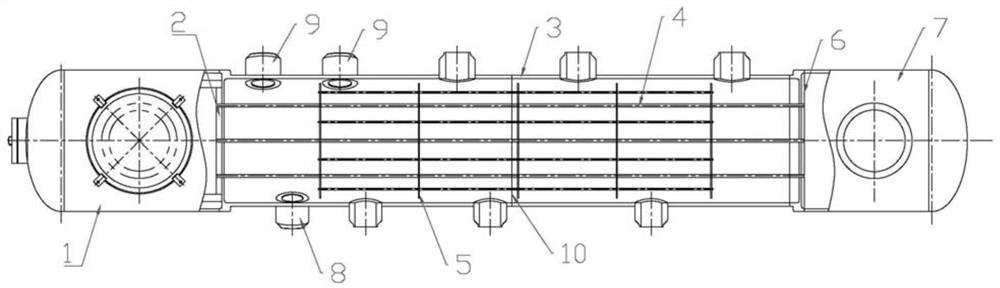

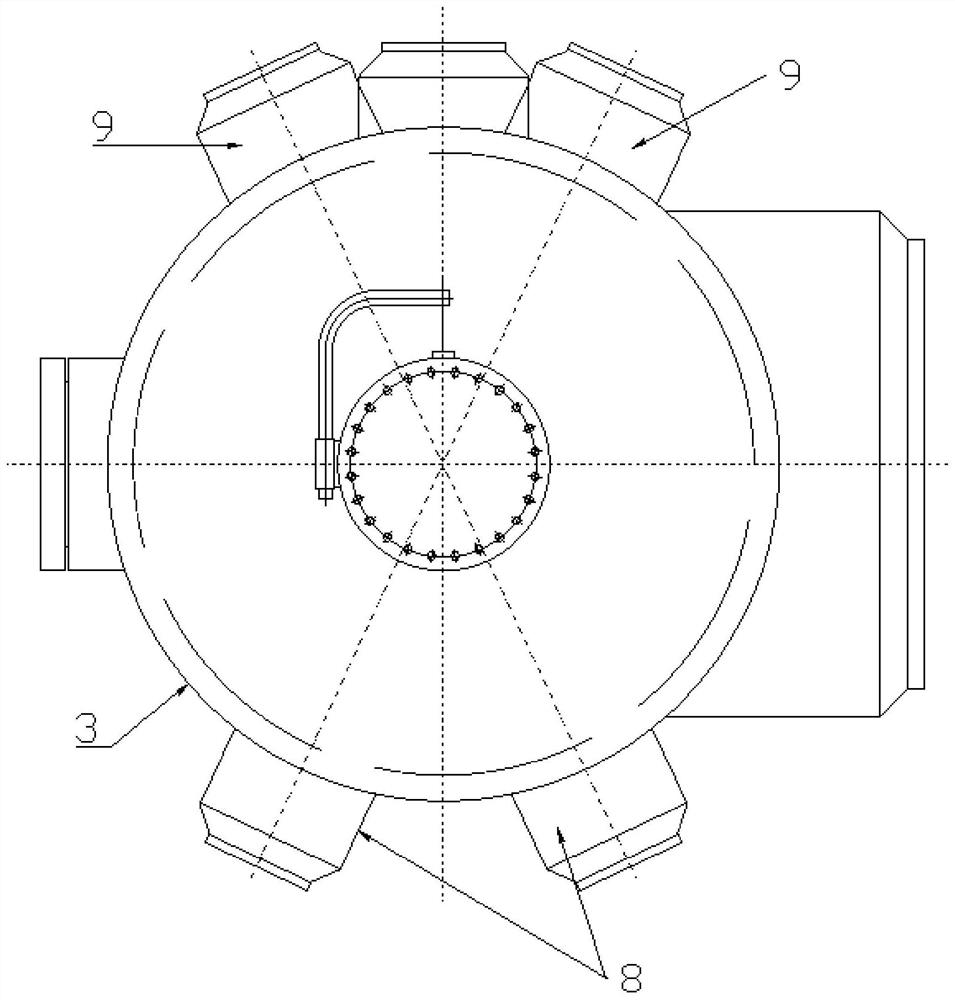

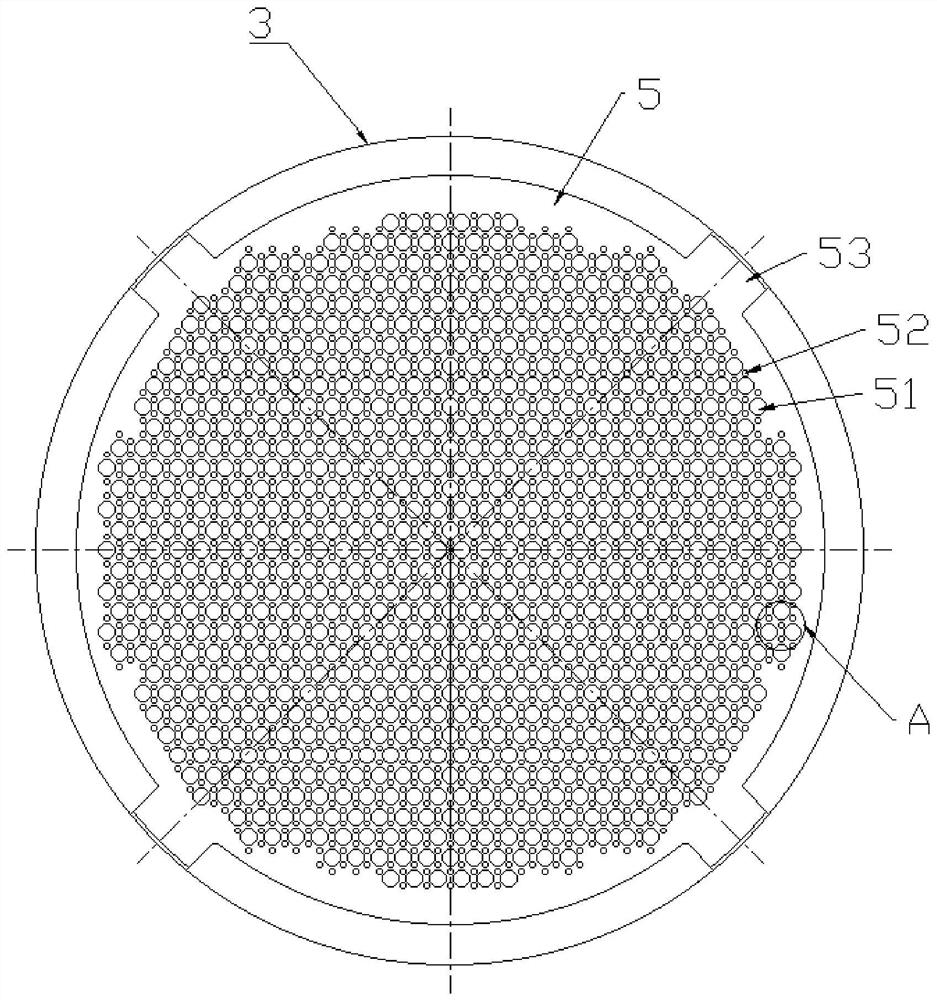

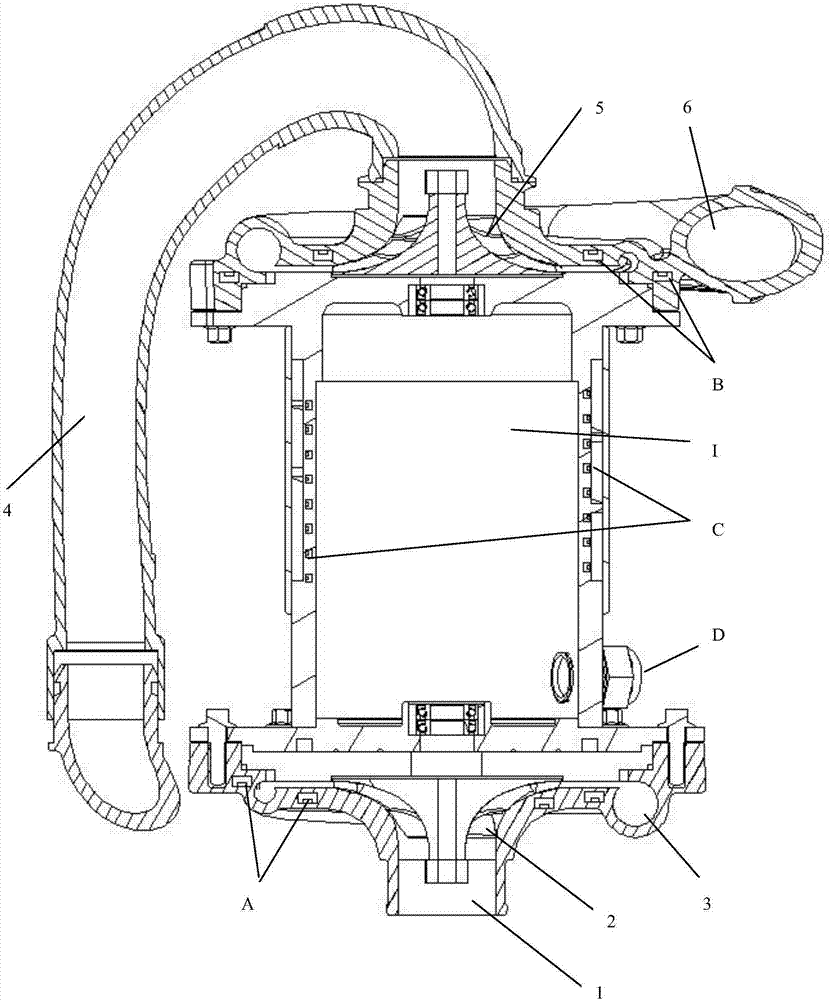

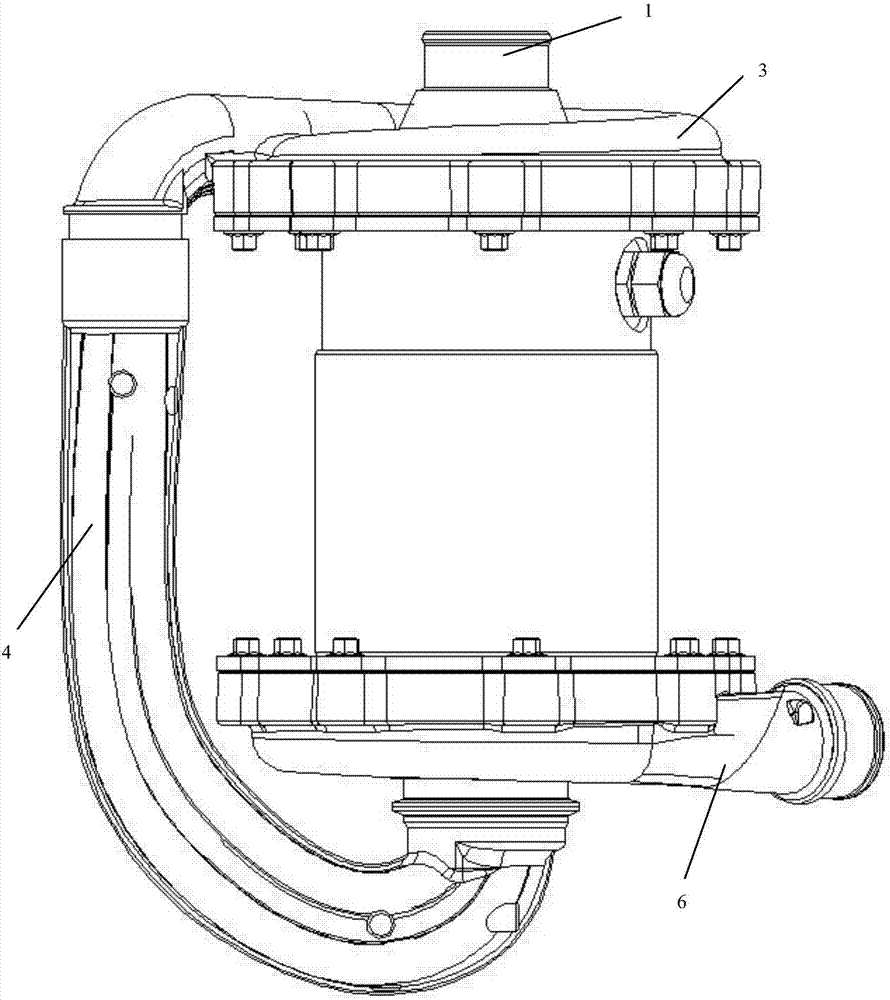

Phase change type quenching heat exchanger

PendingCN112254556AMeet the demand of large flowGuaranteed StrengthCorrosion preventionHeat exchanger casingsEngineeringPetrochemical

The invention relates to the technical field of petrochemical equipment, and particularly relates to a phase change type quenching heat exchanger. The phase change type quenching heat exchanger comprises an inlet pipe box, a front pipe plate, a shell, a plurality of heat exchange pipes, a supporting plate, a rear pipe plate and an outlet pipe box. Due to the fact that heat exchange at the positionclose to the front pipe plate is intense, a plurality of bubbles are formed by vaporization of a cooling medium; at least two inlet connectors and at least two outlet connectors are arranged on the section, close to the front pipe plate, of the shell; every two inlet connectors are symmetrically distributed on the two sides of the bottom of the shell relative to the longitudinal section parallelto the axial direction of the shell; and every two outlet connectors are symmetrically distributed on the two sides of the top of the shell relative to the longitudinal section parallel to the axial direction of the shell. The requirement for large flow of the cooling medium can be met, more cooling media flow in, more steam is discharged, the productivity is improved, the single inlet connector or outlet connector does not need to be opened too large, and the strength of the shell is guaranteed. Heat exchange close to the rear portion is gentle, and the inlet connectors and the outlet connectors can be connected with the shell in a common manner.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Double-stage-supercharging air compressor system of fuel cell vehicle

ActiveCN106870121AGuaranteed temperatureGuaranteed pressureInternal combustion piston enginesEngine componentsImpellerElectricity

The invention relates to a double-stage-supercharging air compressor system of a fuel cell vehicle. The double-stage-supercharging air compressor system of the fuel cell vehicle comprises a double-stage-supercharging air compressor body and an air compressor driver. The double-stage-supercharging air compressor body comprises double volutes, double impellers, a high-voltage direct-current motor and special cooling water flow channels. The air compressor driver comprises a voltage stabilizer, a rectifier, a fuse, a shielding layer, a circuit board and an internal program. In the operation process of the double-stage-supercharging air compressor, the rotation speed of the air compressor can be accurately controlled through the air compressor driver, it is guaranteed that the system can conduct accurate feedback in real time, and achievement of operation at a high rotation speed needs the cooling function of the special cooling water flow channels. Compared with the prior art, the double-stage-supercharging air compressor system of the fuel cell vehicle adopts the special cooling water flow channels and the shielding layer, it is guaranteed that the pressure and flow range requirements of the double-stage-supercharging air compressor system are met, and the double-stage-supercharging air compressor system of the fuel cell vehicle has the advantages of being high in rotation speed, low in electricity consumption, small in size, easy to maintain and the like.

Owner:德燃(浙江)动力科技有限公司

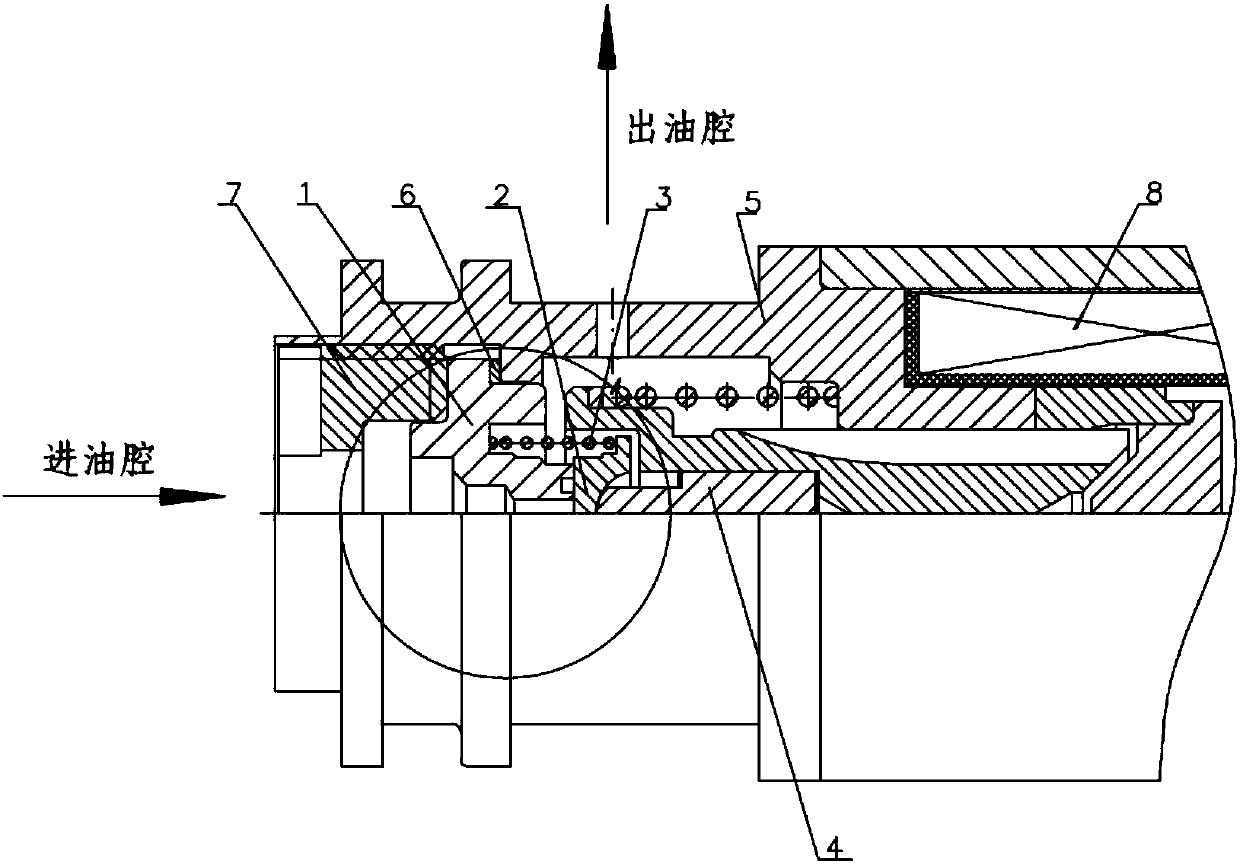

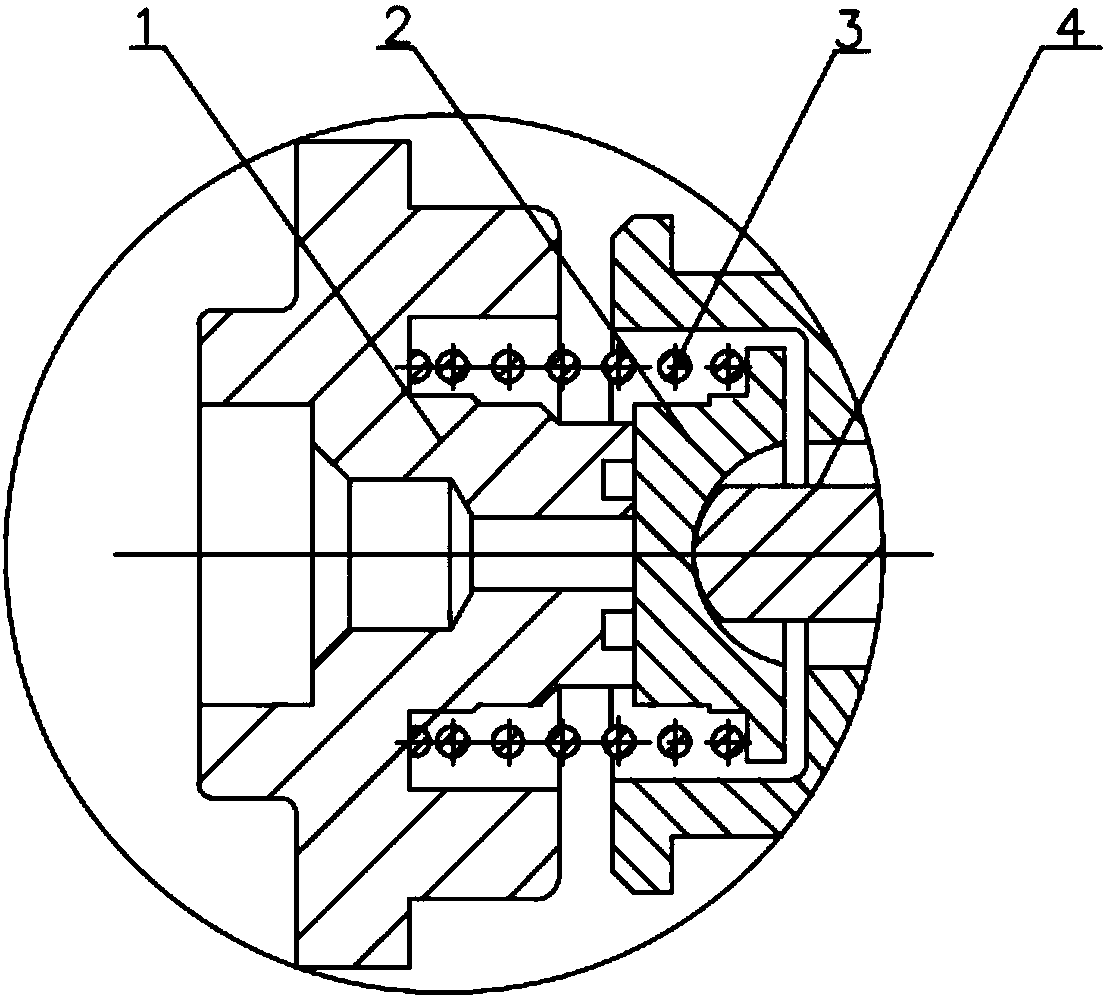

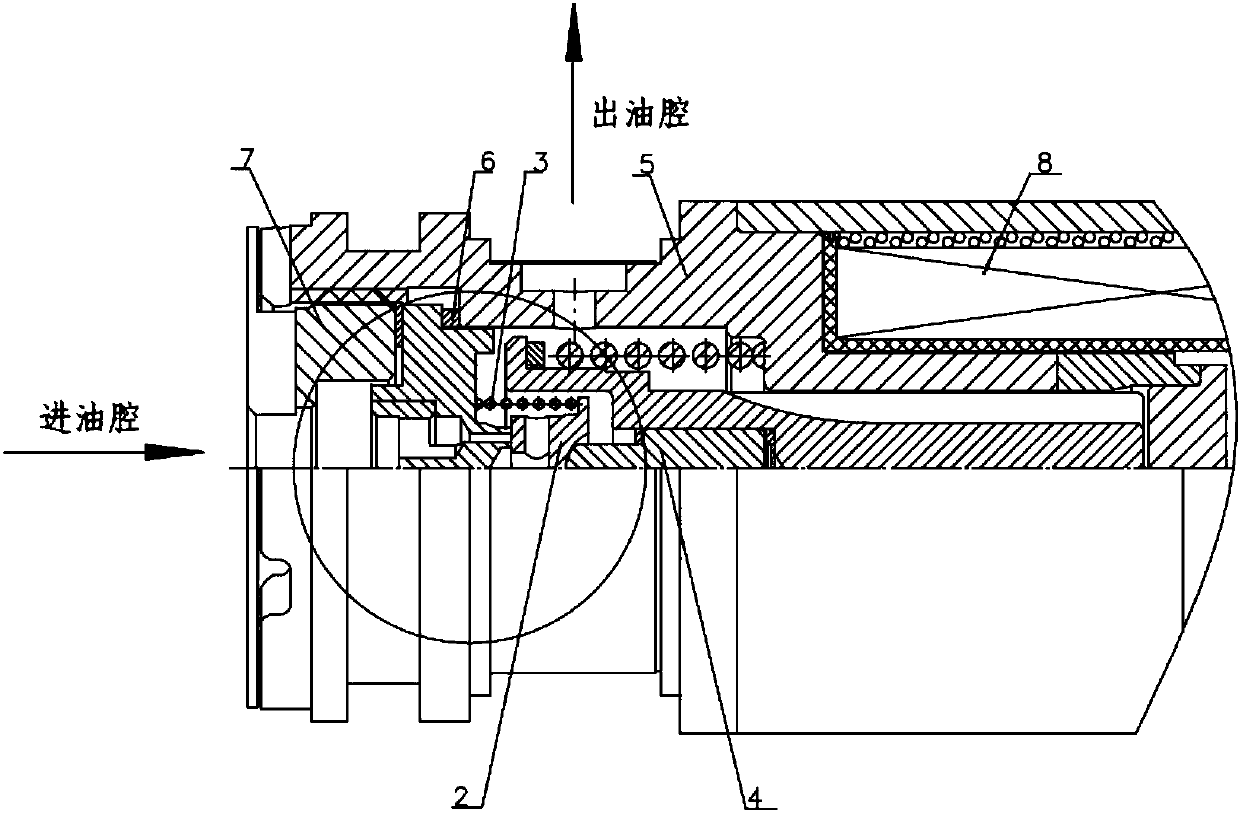

Large flow nozzle-baffle structure

ActiveCN109654282AEasy to driveRealize the role of large flow outputOperating means/releasing devices for valvesLift valveElectro hydraulicSpray nozzle

The invention relates to a multihole nozzle-baffle structure, in particular to a multihole nozzle-baffle structure of a large-flow rapid electromagnetic valve, belonging to the technical field of electro-hydraulic conversion devices. The multihole nozzle-baffle structure comprises a nozzle assembly, a baffle (2) and a shell (5), wherein the nozzle assembly and the baffle (2) are sealed by an end face and are arranged in the shell (5); an oil hole communicating the outside world with a cavity in which the baffle is located is formed in the shell (5); and an oil outlet of the nozzle assembly isan annular oil passage. The large flow nozzle-baffle structure provided by the invention achieves the effect of large flow output under the stroke of a relatively small electromagnet core, enables anelectromagnet unit to be easily driven, has good sealing performance and simple structure, is safe and reliable and satisfies the requirement of an existing fuel regulator on large flow.

Owner:XIAN AERO ENGINE CONTROLS

Method and system for carrying out direct communication of data among base stations

ActiveCN102421145BRealize data offloadReduce the burden onNetwork traffic/resource managementTraffic capacityAccess network

The invention provides a method and a system for carrying out direct communication of data among base stations. The method comprises the following steps that: after receiving a service initiating request sent by a calling subscriber terminal, a source base station broadcasts and sends a called subscriber searching request to adjacent base station through direct connection interface between the base stations; each adjacent base station searches a called subscriber terminal corresponding to the called subscriber searching request according to prestored in-cell member information; the adjacent base station which searches the called subscriber terminal replies a search success message to the source base station as a target base station; and after the source base station receives the search success message, a data direct communication link is established between the source base station and the target base station through the direct connection interface between the base stations. A great amount of data services are borne through the direct connection interfaces among the base stations, so that the direct communication of the data is realized, the load of a core network is reduced and the requirement of an access network on high flow is met.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

Double-pump confluence energy-saving forklift hydraulic system

ActiveCN105084261BMeet the needs of large flowReduce lossesServomotor componentsServomotorsInlet valveEngineering

The invention relates to a dual-pump confluent energy-saving type forklift hydraulic system. The dual-pump confluent energy-saving type forklift hydraulic system comprises an oil tank, a first oil pump, a second oil pump, a multiway valve, tilting oil cylinders, lifting oil cylinders and a steering oil cylinder. The multiway valve is composed of an oil inlet valve plate, a lifting reversing valve plate, a tilting reversing valve plate, a fitting reversing valve plate and an oil return valve plate. The multiway valve is internally provided with an annular oil return passage and a center oil passage, wherein the center oil passage is communicated with the lifting reversing valve plate, the tilting reversing valve plate, the fitting reversing valve plate and the oil return valve plate. The oil inlet valve plate is composed of a priority valve and a steering safety valve. The lifting reversing valve plate is composed of a one-way valve, a lifting reversing valve, a hydraulic control one-way valve and a main safety valve. The tilting reversing valve plate comprises a tilting reversing valve and a tilting one-way valve. The fitting reversing valve plate comprises a fitting reversing valve and a fitting one-way valve. The lifting reversing valve adopts a three-position eight-way reversing valve, dual-pump oil supplying only during lifting is achieved, and the large flow demand is met; portal-frame tilting and fitting acting which need smaller flow can be achieved through one-pump oil supplying, the pressure loss of the system is low, and the energy loss is low.

Owner:ANHUI HELI CO LTD

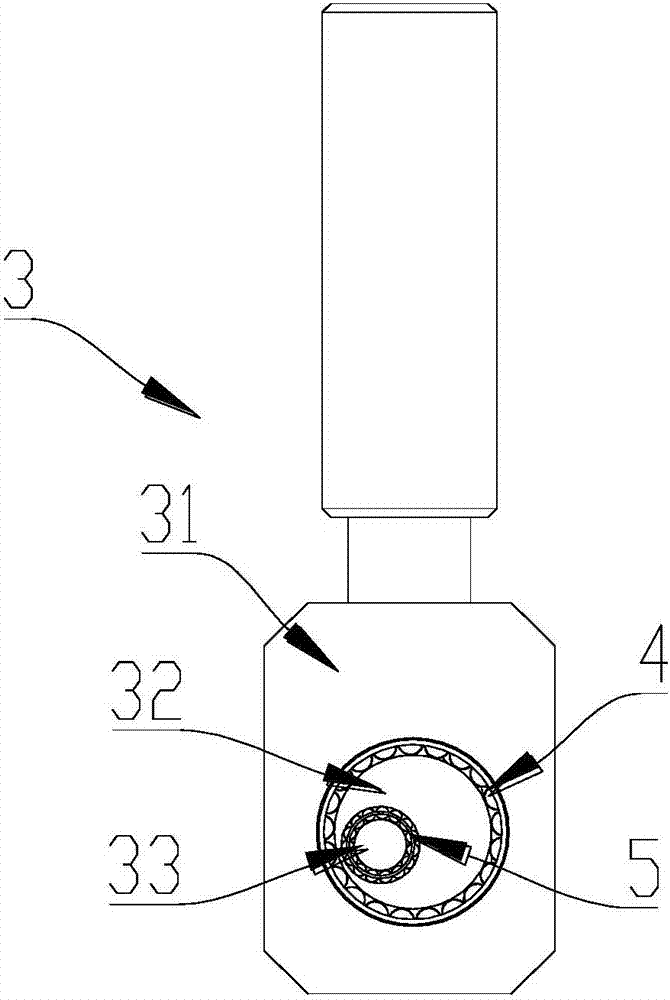

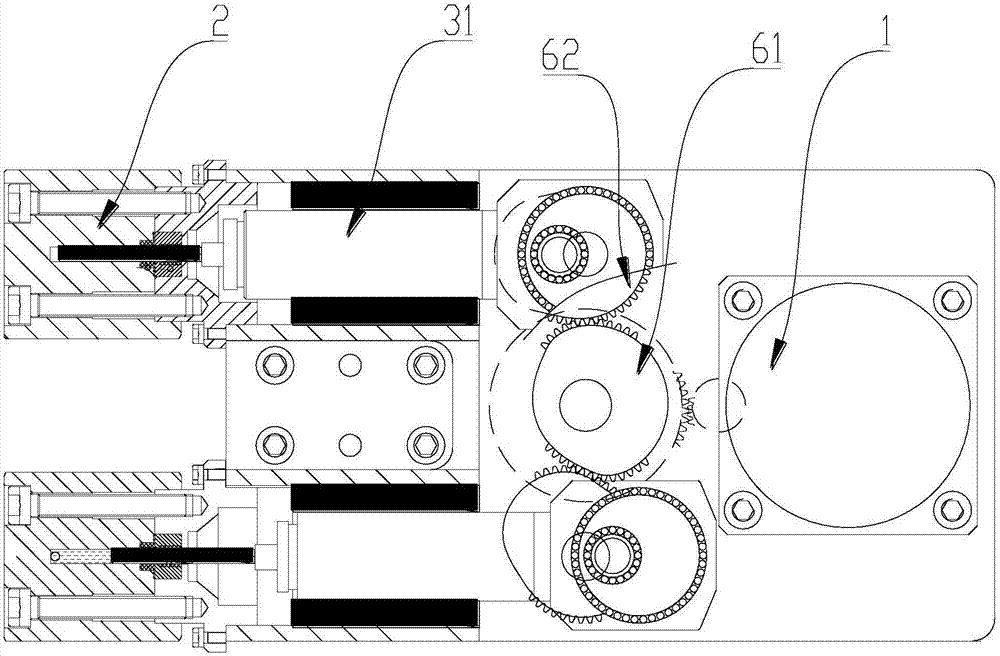

Plunger pump transmission device

InactiveCN107327554AReduce axial sizeEquipment is smallPositive displacement pump componentsGearingPlunger pumpEngineering

The invention relates to a plunger pump transmission device. The plunger pump transmission device comprises a driving device and pump bodies, and further comprises power executing assemblies, wherein the power executing assemblies comprise guide rod shafts which move in the pump bodies in a reciprocating mode, eccentric discs and eccentric shafts; round swinging holes are formed in the ends, extending the pump bodies, of the guide rod shafts; the eccentric discs are round, the eccentric discs are arranged in the swinging holes and are rotationally connected with the swinging holes, round eccentric holes are formed in the eccentric discs, and the rotation axes of the eccentric holes are parallel to the rotation axes of the eccentric discs; and the eccentric shafts comprise power output ends and power input ends, the power output ends are arranged in the eccentric holes and are rotationally connected with the eccentric holes, and the power input ends are connected with the driving device. The plunger pump transmission device cannot only be applied to a small-flow region for a long time, but also can be applied to a large-flow area; and the plunger pump transmission device is long in service life, compact in structure and small in size.

Owner:殷图源

Double-pump two-way confluence control system and fire truck using this system

ActiveCN104179739BSatisfy traffic demandMeet the needs of large flowServomotor componentsServomotorsFire-control systemControl system

The invention provides a double-pump two-way confluence control system and a fire truck using the system to reduce energy loss and system temperature rise. The two-pump two-way confluence control system includes a first oil pump that supplies oil to the leveling cylinder and a second oil pump that supplies oil to the telescopic cylinder and the luffing cylinder. The two oil pumps are coaxially driven, and the oil outlets of the two are respectively equipped with The first pressure compensator and the second pressure compensator to adjust the flow rate, the leveling cylinder, the telescopic cylinder and the luffing cylinder are respectively controlled by the leveling reversing valve, the telescopic reversing valve and the luffing reversing valve, the leveling and reversing valve, telescopic reversing valve and luffing reversing valve all have an oil discharge port and an oil replenishment port. When in the neutral position, the oil discharge port communicates with the oil replenishment port; The oil supply port of the telescopic reversing valve is connected with the oil supply port of the luffing reversing valve, the oil outlet of the second pressure compensator is connected with the oil supply port of the leveling reversing valve through the oil supply circuit, and each oil supply The oil passage communicates with the oil inlet of the corresponding reversing valve through the switching valve.

Owner:XCMG FIRE FIGHTING SAFETY EQUIP CO LTD

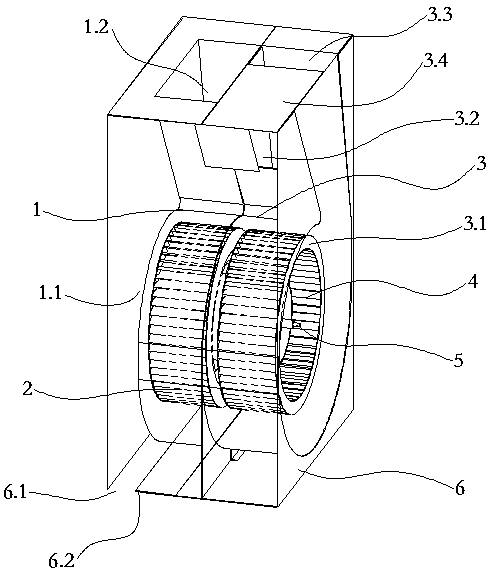

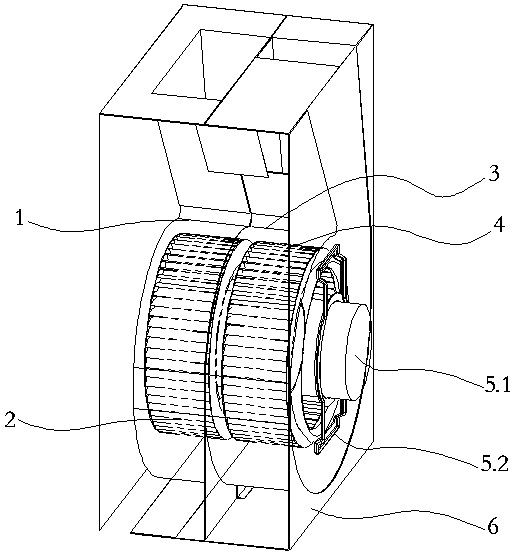

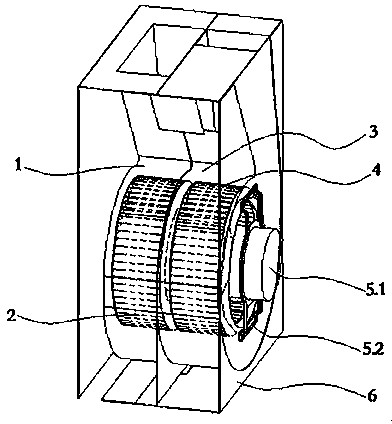

Serial-parallel centrifugal fan and control method thereof

InactiveCN109838406AMeet the needs of large flowNo added noisePump componentsPump controlAir volumeControl engineering

The invention provides a serial-parallel centrifugal fan and a control method thereof. The serial-parallel centrifugal fan comprises a left volute (1), a left centrifugal fan blade (2), a right volute(3), a right centrifugal fan blade (4), a motor assembly (5) and an outer cover (6). The left volute (1) is provided with a left volute air inlet (1.1) and a left volute air outlet (1.2). The right volute (3) is provided with a right volute air inlet (3.1), a right volute air outlet (3.2), a second air outlet (3.3) and an air outlet control assembly (3.4). The outer cover is provided with an outer cover left air inlet (6.1) and an outer cover left air inlet control assembly (6.2). The opening or closing of the right volute air outlet (3.2) and the second air outlet (3.3) is controlled throughthe air outlet control assembly (3.4), the opening or closing of the outer cover left air inlet (6.1) is controlled through the outer cover left air inlet control assembly (6.2), and the switching operation of the centrifugal fan in three modes of the small air volume high static pressure mode, the large air volume low static pressure mode and the middle air volume middle static pressure mode isrealized through different combinations, so that the requirements of products for different working conditions of the centrifugal fan are met.

Owner:宁波引同工业设计有限公司

A device for static and dynamic multifunctional testing of supports

ActiveCN103512740BOutstanding structural featuresSignificant technological progressMachine part testingServo actuatorEngineering

The invention discloses a device for carrying out static-dynamic force multifunction testing on a support. The device comprises a main machine mechanical part, a horizontal shearing part, a vertical loading part, a corner loading part, a conveying trolley, a straight line guiding track device, an environment box, a measurement and control part and a hydraulic part. A horizontal servo actuator of the horizontal shearing part is hung horizontally and is hinged to a sliding groove in the inner side of a self-balancing stand column of the main machine mechanical part, and horizontal loading is provided for the support to be tested. The upper end of a vertical servo actuator of the vertical loading part is fixed on an upper horizontal beam of the main machine mechanical part, the lower end of the vertical servo actuator is connected with a movable horizontal beam, and vertical loading is provided for the support to be tested. The corner loading part is parallel to the vertical loading part and is fixed on the outer side of the upper horizontal beam of the main machine mechanical part, and the corner loading part is used for completing corner testing. The conveying trolley is arranged on a conveying track of the main machine mechanical part, and the straight line guiding track device is arranged on the inner side of a bearing stand column of the main machine mechanical part. The measurement and control part and the hydraulic part are connected with the horizontal shearing part, the vertical loading part and the corner loading part respectively.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

A Large Flow Nozzle-Baffle Structure

ActiveCN109654282BEasy to driveRealize the role of large flow outputOperating means/releasing devices for valvesLift valveElectromagnetic valveElectromagnet

The invention relates to a multihole nozzle-baffle structure, in particular to a multihole nozzle-baffle structure of a large-flow rapid electromagnetic valve, belonging to the technical field of electro-hydraulic conversion devices. The multihole nozzle-baffle structure comprises a nozzle assembly, a baffle (2) and a shell (5), wherein the nozzle assembly and the baffle (2) are sealed by an end face and are arranged in the shell (5); an oil hole communicating the outside world with a cavity in which the baffle is located is formed in the shell (5); and an oil outlet of the nozzle assembly isan annular oil passage. The large flow nozzle-baffle structure provided by the invention achieves the effect of large flow output under the stroke of a relatively small electromagnet core, enables anelectromagnet unit to be easily driven, has good sealing performance and simple structure, is safe and reliable and satisfies the requirement of an existing fuel regulator on large flow.

Owner:XIAN AERO ENGINE CONTROLS

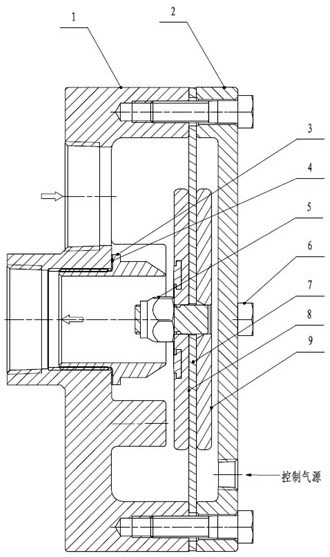

Pressure balance valve for hot scarfing machine

PendingCN113175551AAvoid disintegrationExtend your lifeOperating means/releasing devices for valvesEqualizing valvesEngineeringPressure balance

The invention relates to a pressure balance valve for a hot scarfing machine. The valve is composed of a valve body, a valve cover, a nozzle and a diaphragm assembly, wherein the diaphragm assembly is composed of a diaphragm, a sealing copper plate and a diaphragm pressing plate, a central threaded interface of the valve body is a medium outlet, one end of the nozzle extends into the central threaded interface of the valve body, and a gasket is arranged at the joint between the nozzle and the valve body to ensure the sealing of the nozzle and the valve body; the diaphragm assembly is arranged at the other end of the nozzle, the edge of the diaphragm is attached to the valve body, the sealing copper plate is arranged at the attaching position of the diaphragm and the valve body, the valve body is covered with the valve cover, the valve cover is fixed to the valve body through hexagon bolts, and therefore it is guaranteed that the pressure balance valve is sealed and free of leakage; and the diaphragm divides the valve body, the valve cover and the nozzle into three cavities, namely a medium upstream cavity, a control air source cavity and a discharge cavity. The valve has the remarkable advantages of compact structure, sensitive adjustment, wide application range, large flow and durability.

Owner:振东冶金科技江苏有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com