Leveling control system structure capable of realizing switching of multiple flow ranges and using method

A technology of control system and flow range, applied in manufacturing tools, fluid pressure actuating devices, presses, etc., can solve the problems of slow dynamic response speed, flow interference, large flow gain of large flow servo valve, etc. The effect of response speed, reduced high flow requirements, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

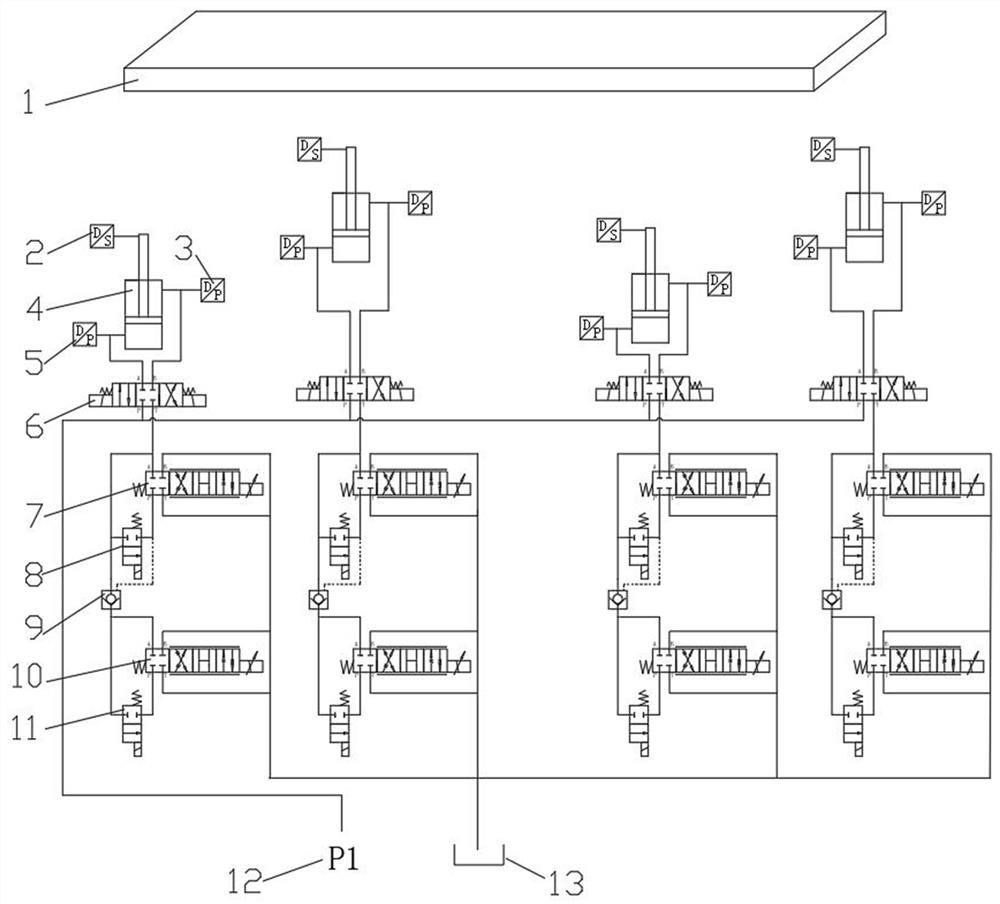

[0044] As shown in the figure, the structure of the leveling control system that realizes the switching of various flow ranges is used for leveling the slider at the pressure output end of the press. Each corner of the slider 1 is provided with a constant pressure A leveling unit powered by an oil source 12; the leveling unit is in contact with the corner end of the slider with a leveling cylinder 4 equipped with a displacement sensor 2; the rod cavity of the leveling cylinder is connected with the first pressure sensor 3, The rodless cavity is connected with the second pressure sensor 5; the oil inlet end of the leveling cylinder is connected with the constant pressure oil source through the oil inlet and outlet switch valve 6, and the oil return end is connected with the control valve group through the oil inlet and outlet switch valve 6 to perform multiple Various flow ranges can be switched to meet the different flow requirements of the system under multiple working conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com