Large flow nozzle-baffle structure

A baffle structure, large flow technology, applied in the direction of the lift valve, valve details, engine components, etc., can solve the problems of increasing the movement stroke of the solenoid valve actuator, increasing the opening, and the rapid solenoid valve cannot meet the use requirements, etc. Achieve the effect of simple structure, meeting the demand of large flow, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

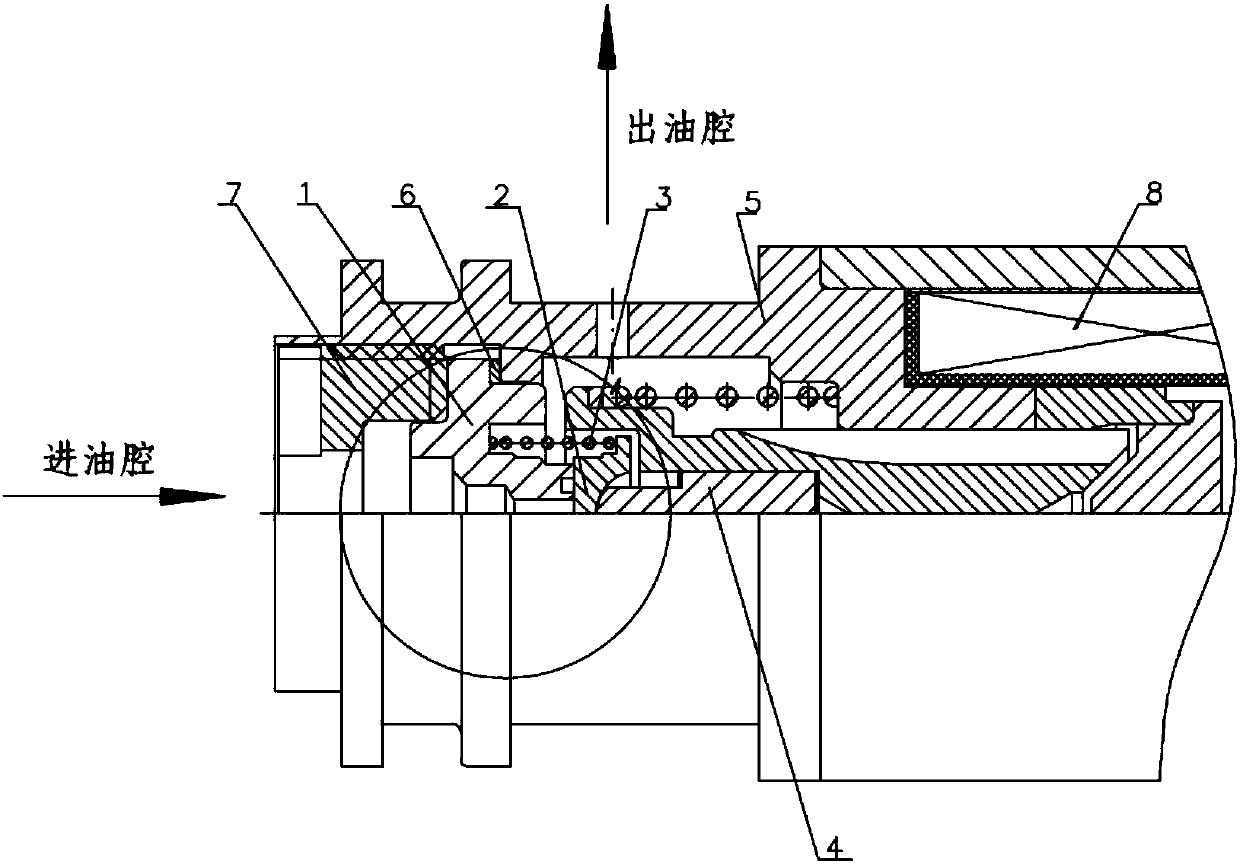

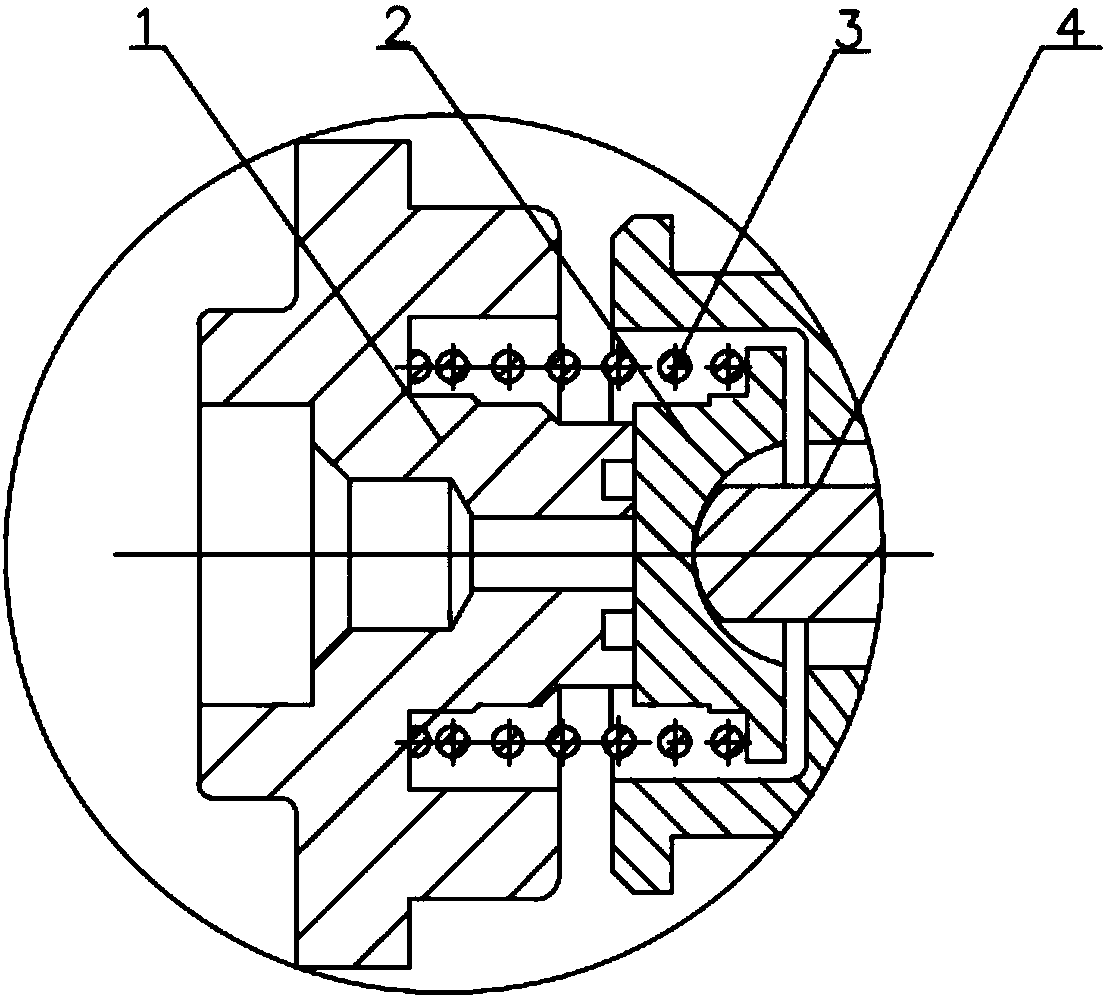

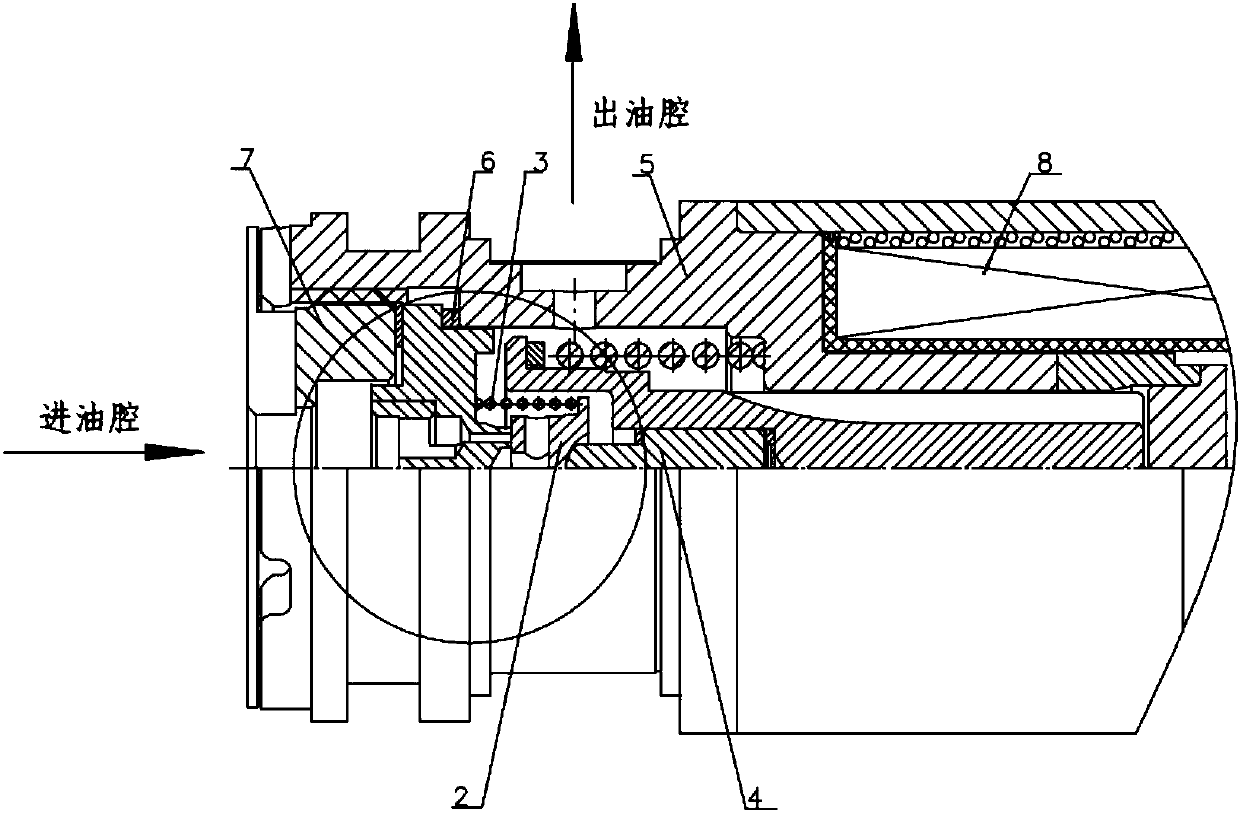

[0015] A large flow nozzle-baffle plate structure, its functional structure includes: the nozzle assembly is composed of a porous nozzle 9 and a nozzle seat 10, a baffle plate 2, a spring 3, a solenoid valve actuator 4, a housing 5, a sealing gasket 6, a screw Plug 7, electromagnet unit 8;

[0016] The porous oil nozzle 9 has a stepped shaft shape, and the outside is divided into two sections, and the outer diameter decreases successively from left to right. The left end of the porous oil nozzle 9 has a central blind hole 9a, and the bottom surface of the blind hole is opened with uniformly distributed oil holes 9b and The junction surfaces of the two outer cylindrical sections are connected, and the right end surface of the porous nozzle 9 has a central blind hole 9c that forms a uniform sealing ring with the outer cylindrical surface; the nozzle seat 10 has a stepped shaft shape, and the inner central through hole is divided into 3 sections, from left to right They are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com