Double-stage-supercharging air compressor system of fuel cell vehicle

An air compressor and two-stage supercharging technology, which is applied to combustion engines, internal combustion piston engines, mechanical equipment, etc., can solve the problem of motor heat dissipation, rotor heat dissipation, and rotor dynamics stability cannot be solved, so as to ensure pressure and prevent The effect of electromagnetic interference and large flow demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

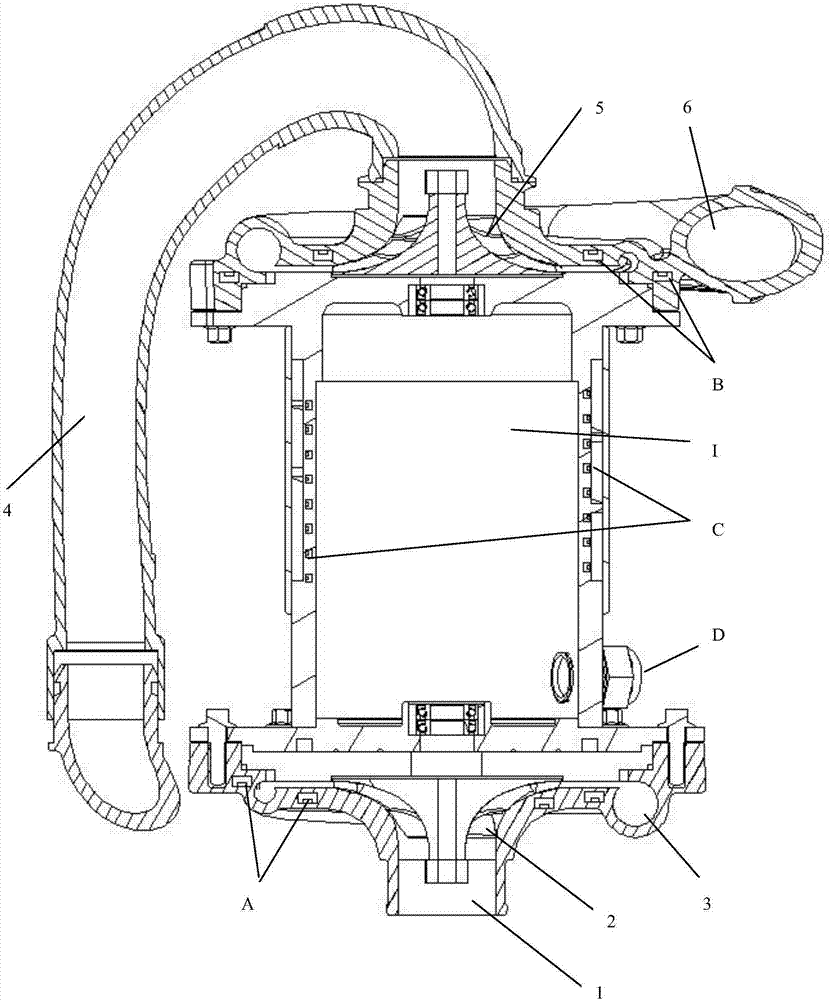

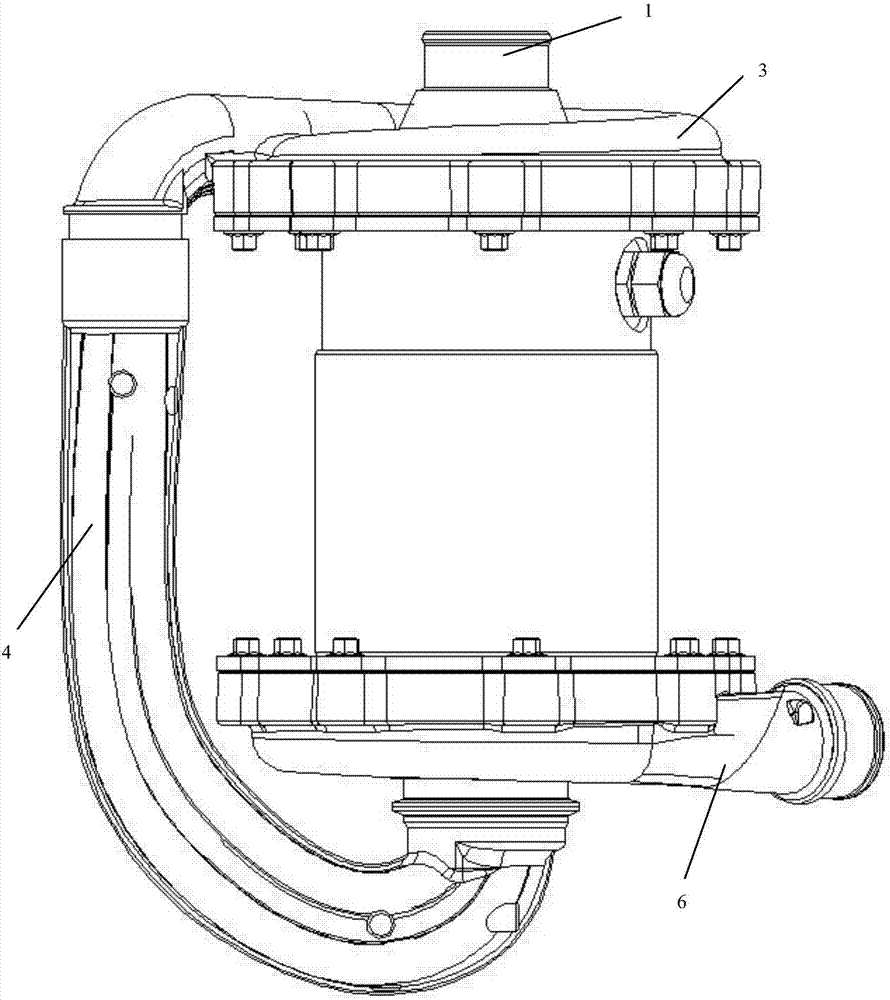

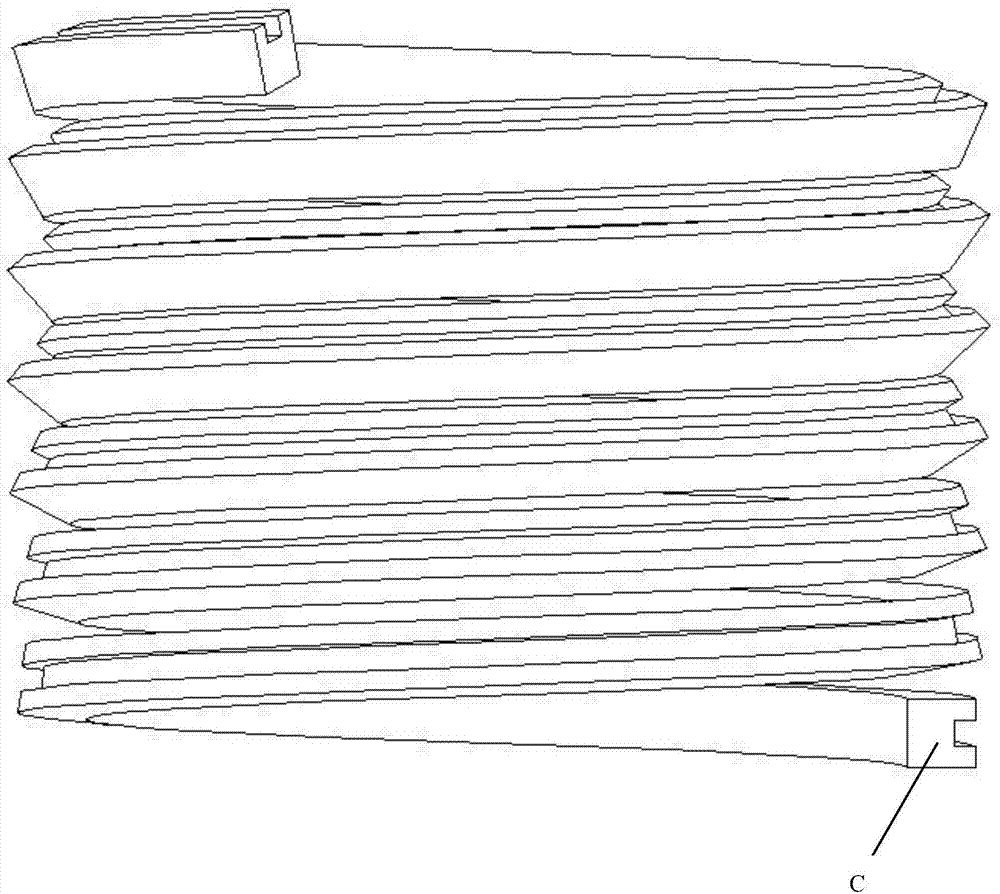

[0041] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , the present invention describes a dual-cooling, high-speed, high-flow, two-stage booster air compressor system for a fuel cell vehicle. The two-stage booster air compressor includes: a two-stage booster air compressor body E, an air compressor Driver F; wherein the two-stage booster air compressor body includes double volutes 3, 6, double impellers 2, 5, high-voltage DC motor I and a special spiral cooling water channel C, and the air compressor driver F includes voltage regulators G, Rectifier G, fuse G, shielding layer G, circuit board G and internal programming G.

[0042] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the air is pressurized by the first-stage impeller 2 at the first-stage inlet 1 of the dual-cooling, high-speed, large-flow two-stage booster air compressor E, and is drained by the volute 4 in the flow channel of the fluid design volute 3. Reaching the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com