Hot in-place recycling ultrathin overlaying machine of bituminous pavement and construction method thereof

A technology of asphalt pavement and covering machine, which is applied in the direction of roads, roads, and road repairs, can solve problems such as short service life, affecting pavement performance, material temperature loss, etc., to improve comfort and safety, improve pavement appearance, The effect of increasing the strength of the road surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

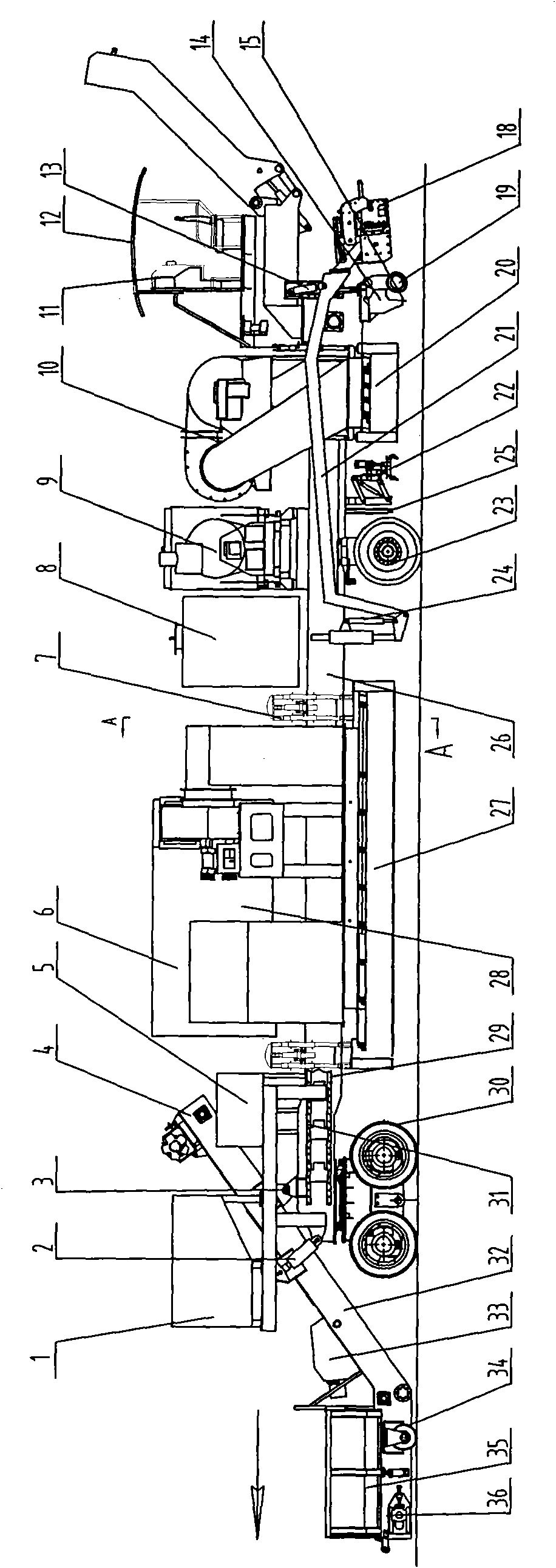

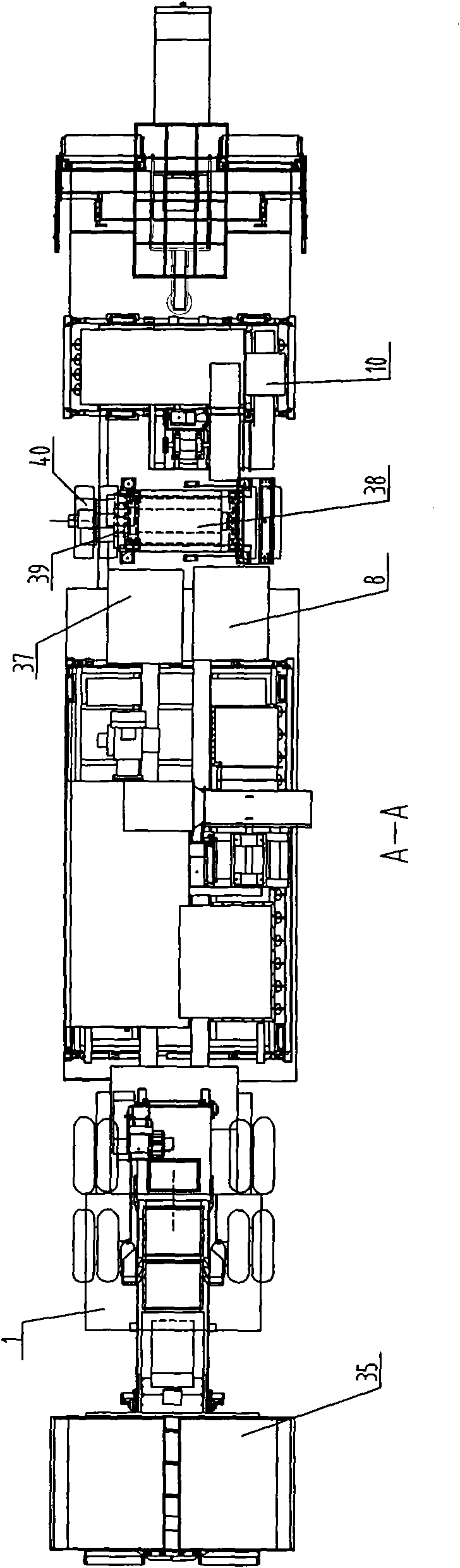

[0086] The construction method of the asphalt pavement hot-in-place regeneration ultra-thin overlay machine of the present invention comprises the following steps:

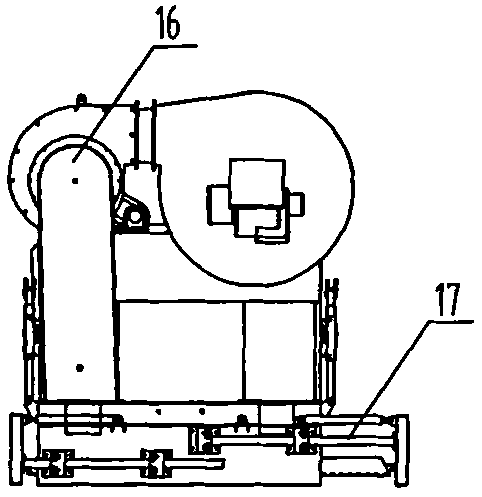

[0087] 1) The asphalt pavement hot-in-place regeneration ultra-thin overlay machine starts to work from the beginning of the road section to be repaired. First, the receiving device 35 receives and stores new asphalt mixture. When the receiving device 35 receives the After the feeding instruction, just start to feed, and new asphalt mixture is sent in the material chute at material receiving end 36 place on the inclined conveyor 32; Described inclined conveyor 32 can adopt scraper conveyor.

[0088] 2) The inclined conveyor 32 starts to load and run after receiving the new asphalt mixture. At the same time, the heating and heat preservation device 33 on the inclined conveyor 32 also starts to work, and the new asphalt mixture that is constantly advancing is heated. Insulation treatment, the new asphalt mixture tha...

Embodiment 2

[0099] When the road surface is heated to 160°C, the temperature is 110°C at a depth of 20mm from the ground surface, the spacing between raking or plowing is 30mm, the raking depth is 30mm, and the thickness of the thin layer after paving and compaction is 20mm, other processes and examples 1 At the same time, the use of new asphalt materials can be saved by 50-60%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com