Wind tunnel test device

A technology of wind tunnel test and test model, which is applied in the field of wind tunnel test, can solve the problems of increasing the force of supporting equipment, affecting the safety of equipment, and large pressure loss of flow pipes, so as to avoid the interference of flow field, increase the authenticity, Versatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

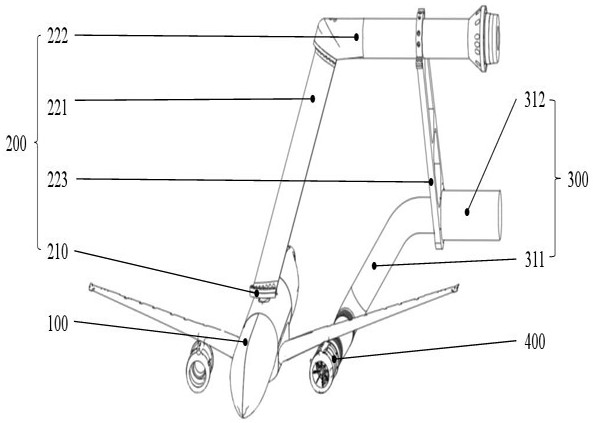

[0037] Such as figure 1 As shown, embodiment 1 of the present invention provides a kind of wind tunnel test device, comprises support system, test model and piping system:

[0038] One end of the support system 200 is connected to the top of the test model 100;

[0039] The test model 100 is provided with a ventilation module 400;

[0040] The pipeline system 300 is connected to the support system 200, and the pipeline system 300 is connected to the test model 100; the pipeline system 300 includes a first pipeline part 311 and a second pipeline part 312, the first pipeline part 311 One end of a pipe part 311 is connected to one end of the ventilation module 400 , and both the first pipe part 311 and the second pipe part 312 are connected to the support system 200 .

[0041] The ventilation module 400 is usually a part of an aircraft engine, generally called a nacelle. The nacelle (Enginenacelle) generally refers to the nacelle inlet on the engine structure. As an important...

Embodiment 2

[0052] Embodiment 2 of the present invention provides a kind of method of wind tunnel test, and concrete steps are as follows:

[0053] Step 1: Connect the pressure measuring points in the air intake duct of the ventilation module 400 with the pressure guiding pipes in accordance with the programmed sequence, and connect them to the steady-state pressure measuring system, test the pressure measuring system and ensure that it can work normally;

[0054] Step 2: Install the pressure sensor on the dynamic pressure measuring point, and then debug to ensure that the dynamic pressure sensor and the data acquisition system can work normally;

[0055] Step 3: Install the support system 200 above the test model 100 through the transfer mechanism 210;

[0056] Step 4: Connect one end of the first pipeline part 311 of the pipeline system 300 to the ventilation module 400 of the test model 100;

[0057] Step 5: Connect the other end of the first pipeline part 311 of the pipeline system 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com