High pressure and mass flow pneumatic electromagnetic switch valve

An electromagnetic switching valve and high flow technology, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of large energy loss, achieve large cross-sectional area, light weight, and meet the effect of large flow requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

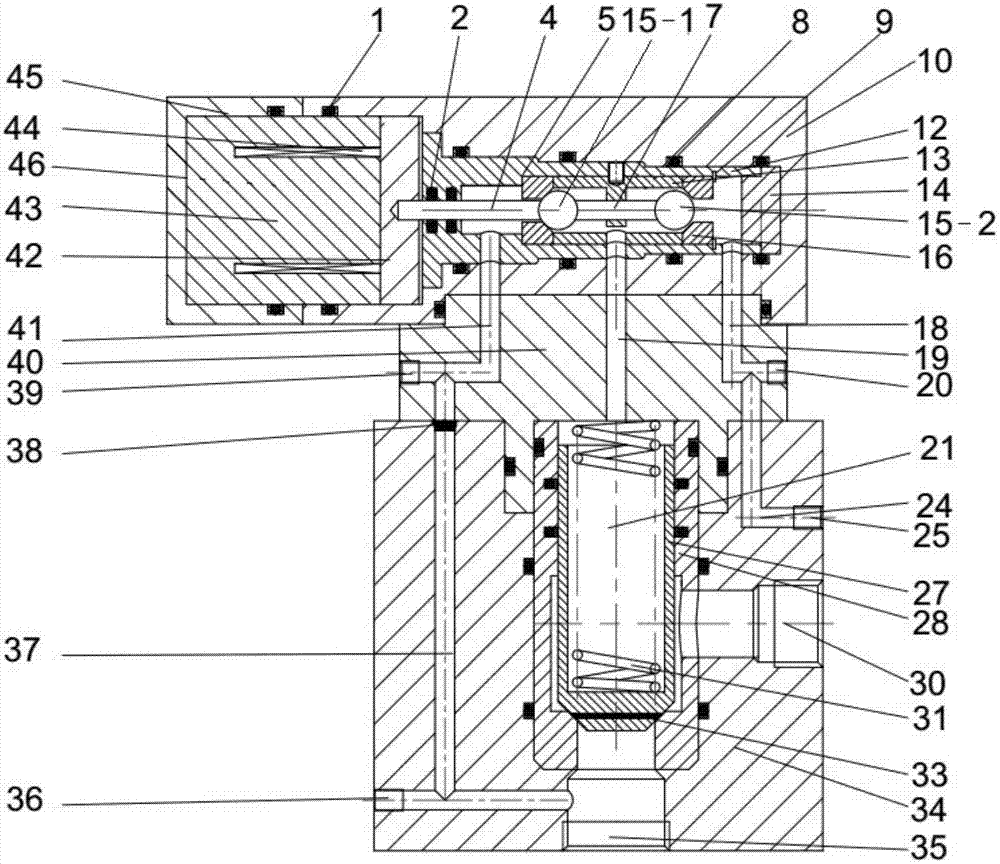

[0015] combine figure 1 , a high-pressure large-flow pneumatic electromagnetic switch valve is characterized in that it includes a housing, an electromagnet unit, a valve core unit, a valve sleeve unit, a valve body unit, a sealing plug 38, and a high-pressure gas inlet plug 39. The casing includes a pilot valve body 10 , an electromagnet end cover 45 , a control cover plate 40 and a main valve 34 . Among them, the control cover plate 40 is connected to the pilot valve body 10 and the main valve 34; the valve sleeve cavity 8 is set in the pilot valve body 10, and a groove body is set on the left side of the valve sleeve cavity 8, and the electromagnet end cover 45 is fixed on the pilot valve body 10 The left side cooperates with this tank body to form an electromagnet chamber 46; the control chamber 21 is set in the main valve 34, and an air inlet 35 and an exhaust port 30 are also arranged on the main valve 34, and the air inlet 35 connects the gas cylinder and connects the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com