Device for carrying out static-dynamic force multifunction testing on support

A multi-functional testing, static and dynamic technology, applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of large force on the moving beam, increase the torque of the test piece, error, etc., and reduce the processing time. , reduce the risk of leakage, and meet the effect of experimental accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

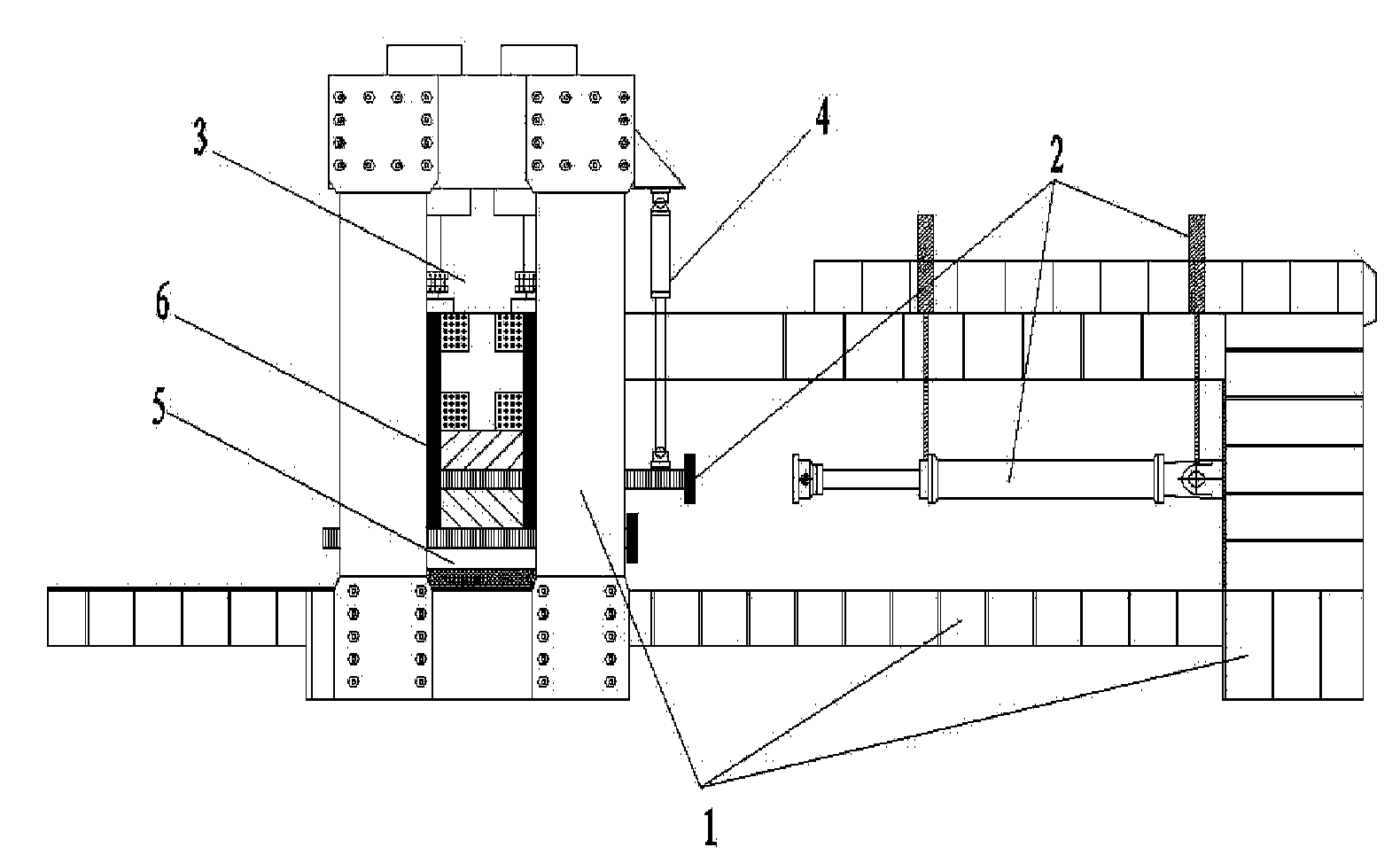

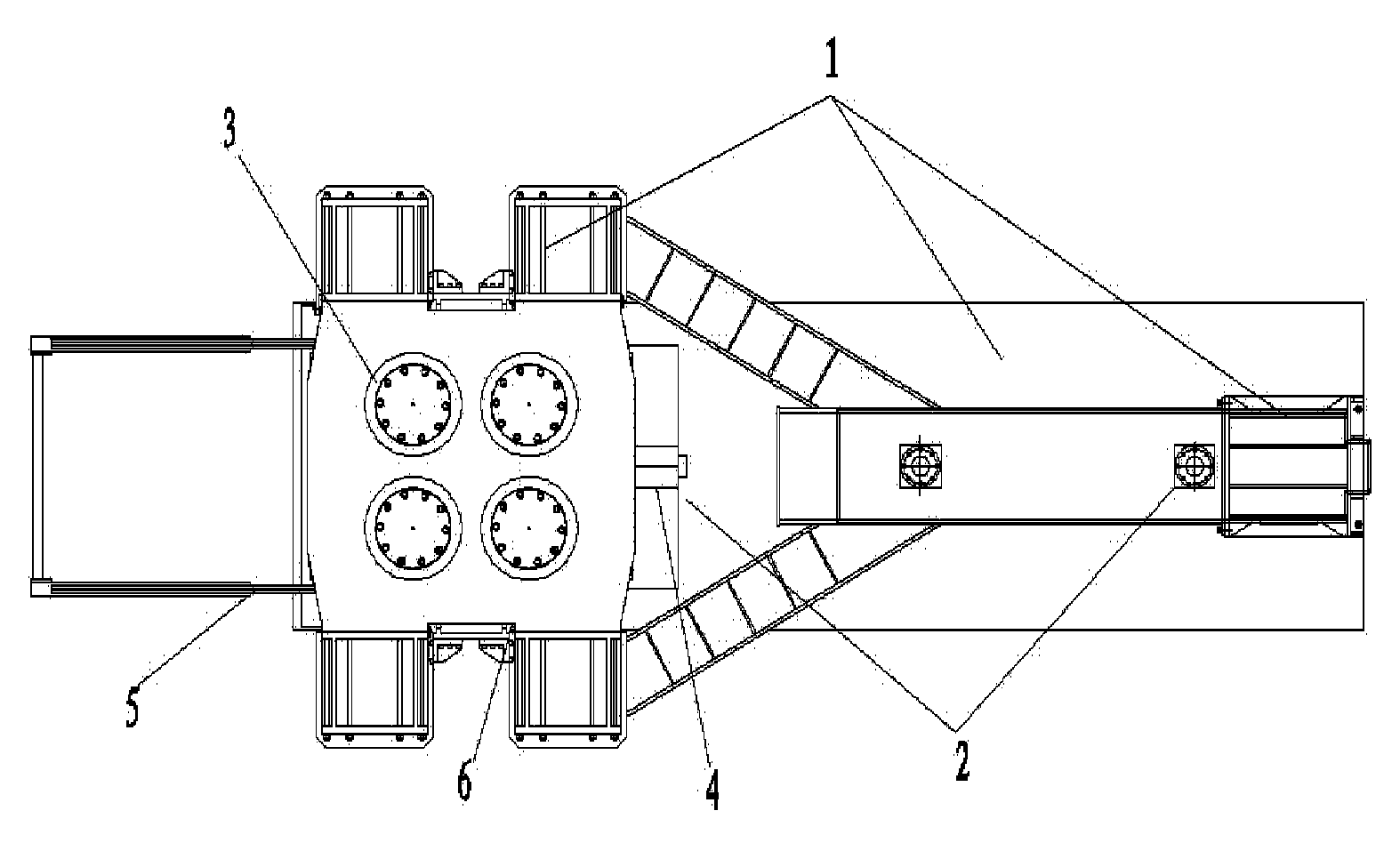

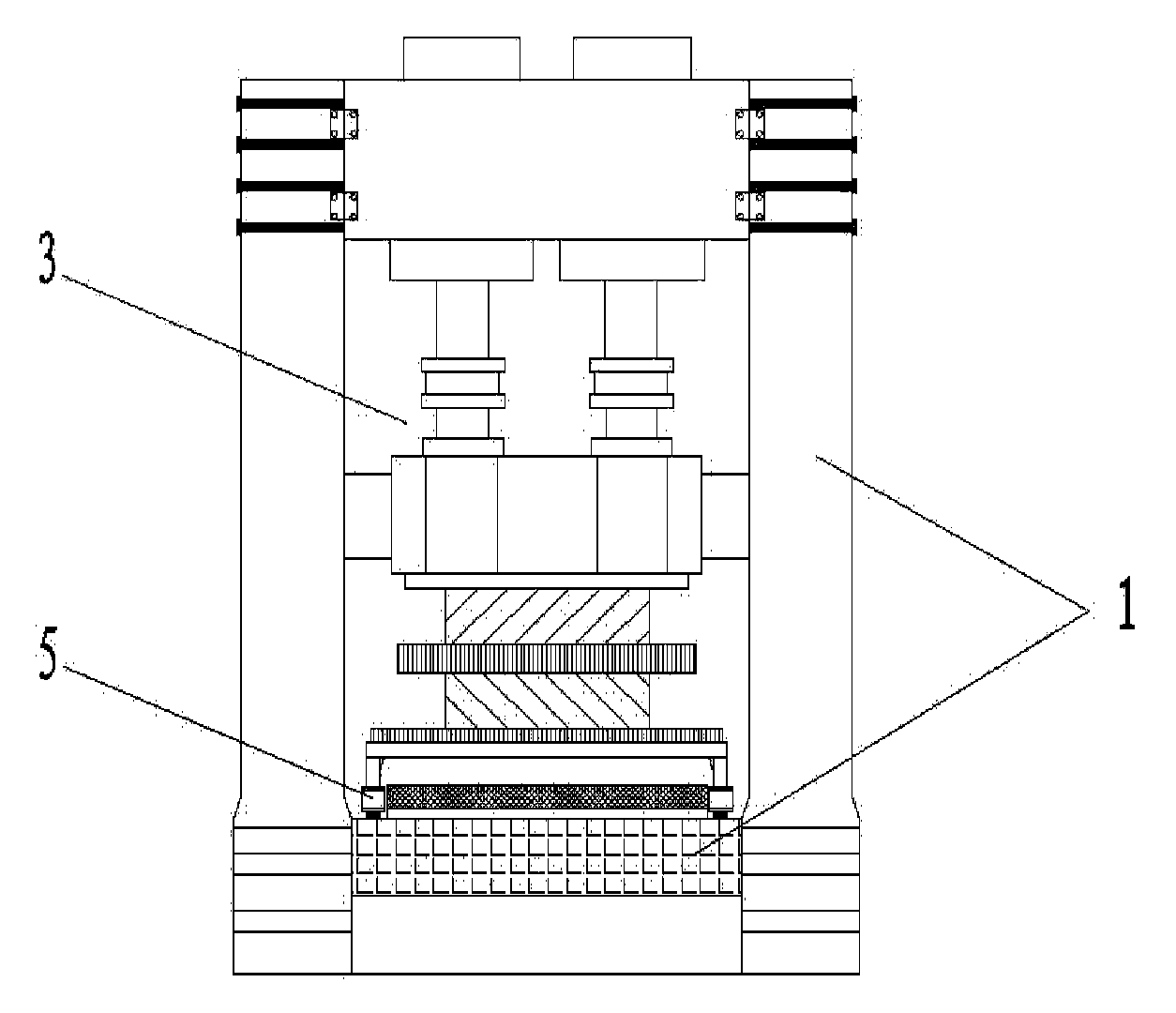

[0035] like Figure 1 to Figure 3 As shown, the device for performing static and dynamic multi-function testing on the support provided by the present invention includes a main machine mechanical part 1, a horizontal shearing part 2, a vertical loading part 3, a corner loading part 4, a transport trolley 5, a linear guide device 6, Environmental box, measurement and control part and hydraulic part. The horizontal shearing part 2, the vertical loading part 3 and the corner loading part 4 are installed on the main machine mechanical part 1 to constitute the loading main body. The horizontal servo actuator 201 is suspended horizontally, and is hinged with the inner chute of the self-balancing column 103 of the main machine part 1 to provide h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com