Pressure balance valve for hot scarfing machine

A technology of cleaning machine and balancing valve, applied in the field of pressure balancing valve, can solve the problems of easy damage, high vibration frequency of diaphragm and sealing parts, large instantaneous flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

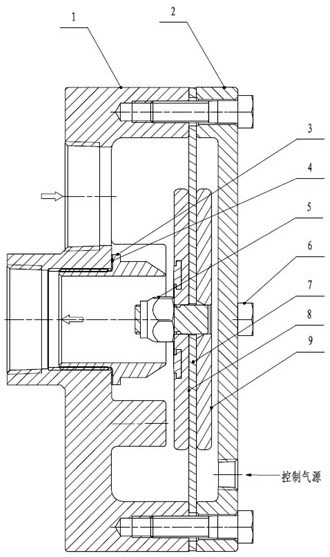

[0022] Such as figure 1 Shown, a kind of pressure balance valve that the present invention proposes is used for flame cleaning machine, valve body 1, valve cover 2, nozzle 3, diaphragm 7, sealing copper plate 8 and diaphragm pressure plate 9 and other main components. Its main feature is that the central threaded interface of the valve body is the outlet of the medium, and a gasket is provided between the nozzle 3 and the valve body 1 to ensure its sealing; the right side of the nozzle 3 is composed of a lock nut 5, a diaphragm 7, a sealing copper plate 8, and a diaphragm pressure plate Diaphragm assembly composed of 9, a diaphragm pressure plate 9 is provided between the valve cover 2 and the diaphragm 7, the edge of the diaphragm 7 is attached to the valve body 1, and finally the main valve cover 2 is fixed on the valve body by 8 evenly distributed hexagonal bolts On the valve body 1, so as to ensure that the valve is sealed without leakage.

[0023] The valve cover 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com