Biodegradable peanut protein plastic

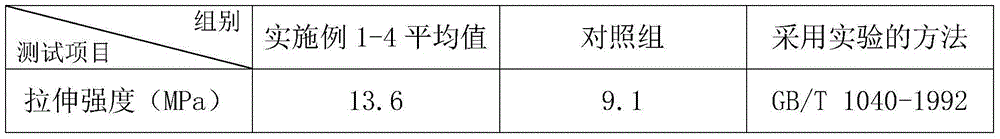

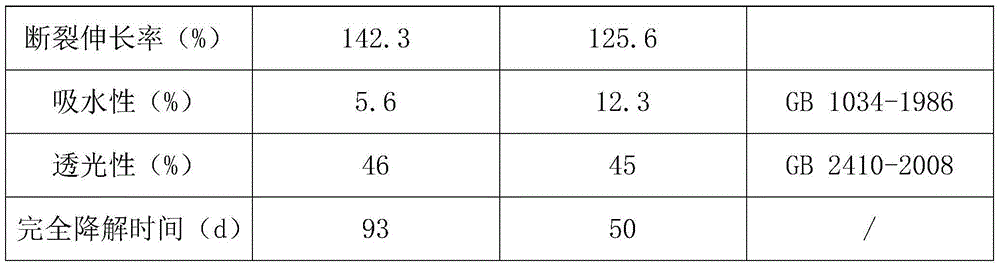

A peanut protein, biodegradable technology, applied in the field of plastics, can solve the problems of low water absorption, high brittleness, low tensile strength, etc., to improve tensile and impact resistance, improve wear and tear resistance, The effect of improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A biodegradable peanut protein plastic proposed by the present invention, its raw materials include by weight: 35 parts of hydroxybutyrate valeric acid copolyester PHBV, 55 parts of modified poly-β-hydroxybutyric acid PHB, 20 parts of peanut protein powder, jute 2 parts of fiber, 4 parts of silk fiber, 1.1 parts of silane coupling agent A-151, 3 parts of sodium lactate, 0.5 parts of sodium dehydroacetate, 2.3 parts of dioctyl terephthalate DOTP, 2 parts of epoxy octyl stearate , 28 parts of carbon black N550, 12 parts of heavy calcium carbonate, 7 parts of kaolin, 0.7 parts of antioxidant 1076, wherein the modified poly-β-hydroxybutyrate PHB is a blend of poly-β-hydroxybutyrate PHB and ethylene-propylene rubber Obtained by modification, the silk protein content in the silk fiber is 72wt%;

[0014] During the preparation process, add silane coupling agent A-151 to jute fiber and silk fiber and stir at a stirring speed of 16rpm for 12min, then add peanut protein powder an...

Embodiment 2

[0016] A biodegradable peanut protein plastic proposed by the present invention, its raw materials include by weight: 30 parts of hydroxybutyric acid valeric acid copolyester PHBV, 60 parts of modified poly-β-hydroxybutyric acid PHB, 15 parts of peanut protein powder, jute 2.4 parts of fiber, 3 parts of silk fiber, 1.3 parts of silane coupling agent A-151, 2 parts of sodium lactate, 0.8 parts of sodium dehydroacetate, 1.7 parts of dioctyl terephthalate DOTP, 4 parts of epoxy octyl stearate , 25 parts of carbon black N550, 16 parts of heavy calcium carbonate, 4 parts of kaolin, 0.9 parts of antioxidant 1076, wherein the modified poly-β-hydroxybutyrate PHB is a blend of poly-β-hydroxybutyrate PHB and ethylene-propylene rubber Obtained by modification, the silk protein content in the silk fiber is 75wt%;

[0017] During the preparation process, add silane coupling agent A-151 to jute fiber and silk fiber and stir at a stirring speed of 14rpm for 13min, then add peanut protein pow...

Embodiment 3

[0019] A biodegradable peanut protein plastic proposed by the present invention, its raw materials include by weight: 34 parts of hydroxybutyrate valeric acid copolyester PHBV, 56 parts of modified poly-β-hydroxybutyric acid PHB, 19 parts of peanut protein powder, jute 2.1 parts of fiber, 3.6 parts of silk fiber, 1.23 parts of silane coupling agent A-151, 2.5 parts of sodium lactate, 0.6 parts of sodium dehydroacetate, 2.1 parts of dioctyl terephthalate DOTP, 2.6 parts of epoxy octyl stearate , 27 parts of carbon black N550, 13 parts of heavy calcium carbonate, 6 parts of kaolin, 0.75 parts of antioxidant 1076, wherein the modified poly-β-hydroxybutyrate PHB is a blend of poly-β-hydroxybutyrate PHB and ethylene-propylene rubber Obtained by modification, the silk protein content in the silk fiber is 74wt%;

[0020] During the preparation process, add silane coupling agent A-151 to jute fiber and silk fiber and stir at a stirring speed of 18rpm for 10min, then add peanut protein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com