Crown block high altitude integrated suspension transposition construction method

A construction method and crane technology, which are applied in the direction of load block, load hanging components, cranes, etc., can solve the problems of crane impact, tedious procedures, and inability to install cranes, so as to achieve short construction time, avoid assembly process, and simplify construction. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

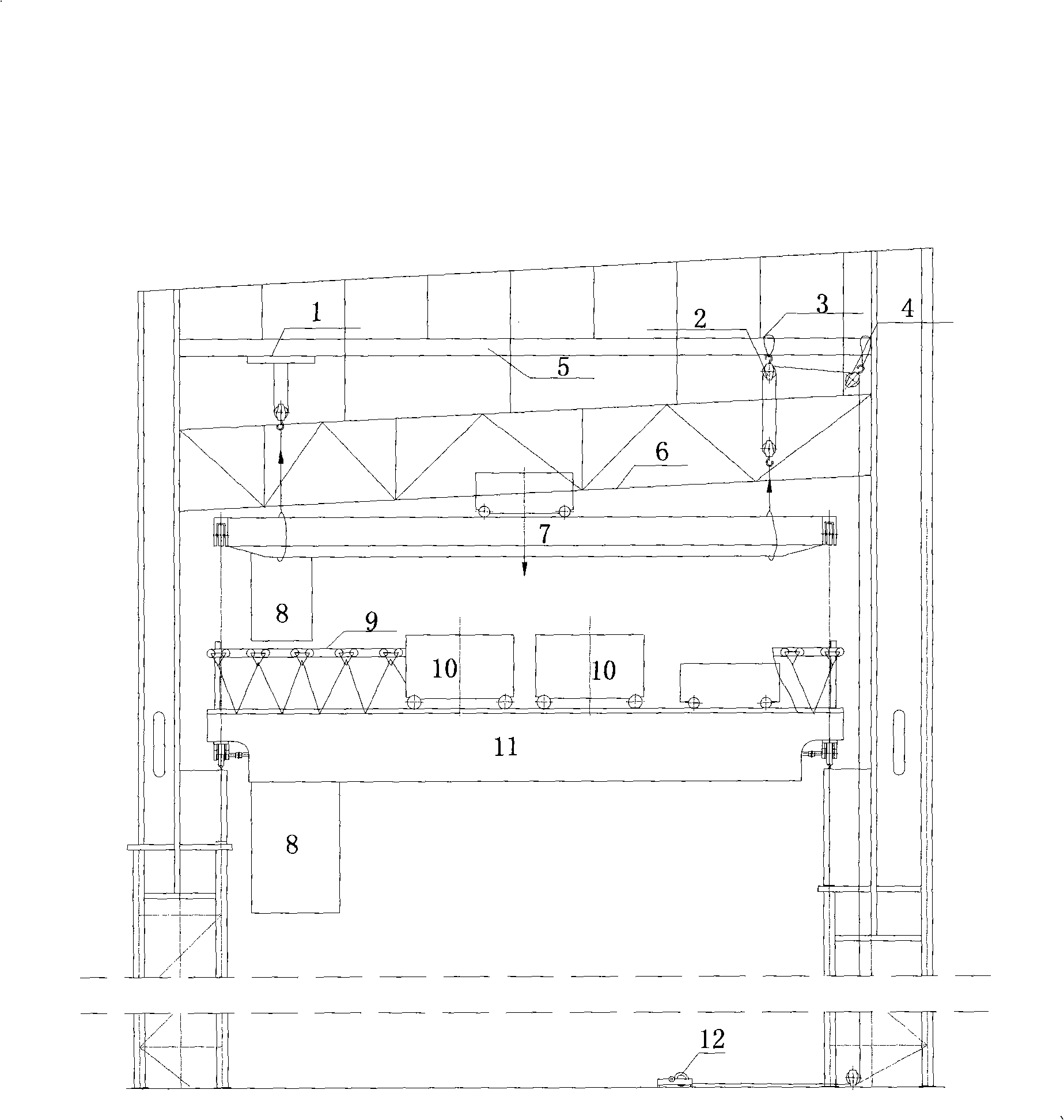

[0009] The construction method of crane transposition is described below in conjunction with specific embodiment, and construction method adopts following steps, as figure 1 Shown:

[0010] ①Use the electric hoist 1 on the line layer to hoist one end of the main beam of the suspended crane 7, set a pulley block 2 at the other end of the roof truss monorail beam 5 to hoist the other end of the suspended crane 7, and hoist the suspended crane 7 to the space between the two roof trusses space;

[0011] ② Pass the running crane 11 under the suspended crane 7 and run to the designed position;

[0012] ③The electric hoist 1 and the pulley block 2 slowly fall back to suspend the crane 7 to the rail surface.

[0013] ④ Restore the pulley of the crane that has been lowered, check the working condition of the crane, and put it into use if there is no abnormality. So far, the crane transposition work has been completed and the design layout requirements have been met.

[0014] Althoug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com