Edge cutting machine

An edge trimmer and edge trimming technology are applied in the direction of shearing devices, attachments of shearing machines, knives used in shearing machines, etc., which can solve the problems of not seeing edge trimmers, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

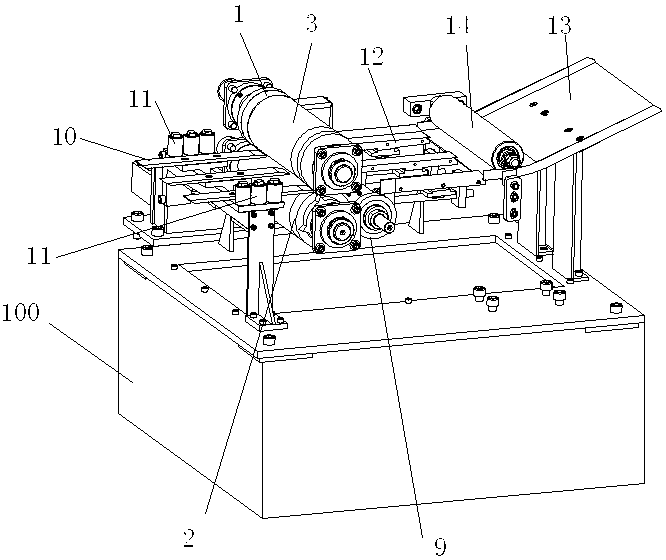

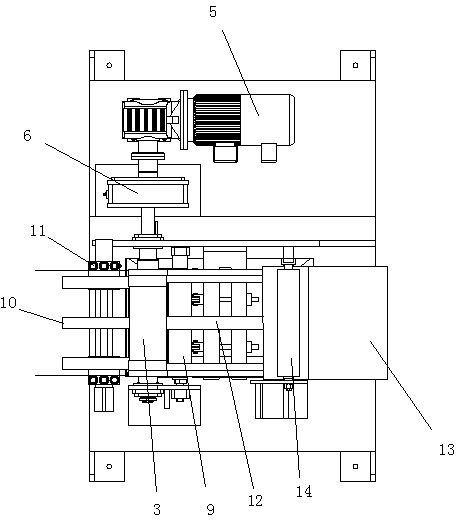

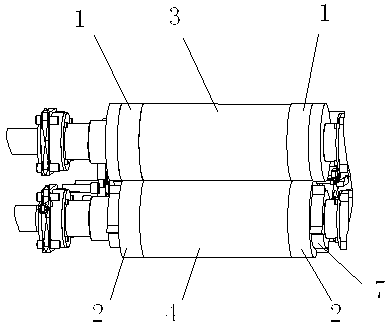

[0028] Such as Figure 1-4 As shown, the edge trimmer in the present invention includes a frame 100 and an edge trimming device, a shredding device, an introduction mechanism and an output mechanism arranged on the frame 100 . The trimming device comprises two upper cutters 1, two lower cutters 2, an upper drum 3, a lower drum 4 and a drum driving device composed of a motor 5 and a reducer 6. The upper drum 3 and the lower drum 4 are respectively arranged on the frame 100 through bearings at both ends. The axes of the upper roller 3 and the lower roller 4 are arranged parallel to each other, and preferably, they are located on the same vertical plane. There is a set gap between the adjacent roll surfaces of the upper drum 3 and the lower drum 4 in the vertical direction, and the gap should be determined according to the thickness of the lead tape to be cut. In general, the gap should be equal to or slightly larger than that of the lead tape. thickness. Both the upper drum 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com