High-flow pressure stabilizer

A voltage stabilizing device and high-flow technology, applied in the field of sanitary ware, can solve problems such as inability to use, and achieve the effects of saving costs, saving transfer space, and reducing transfer risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

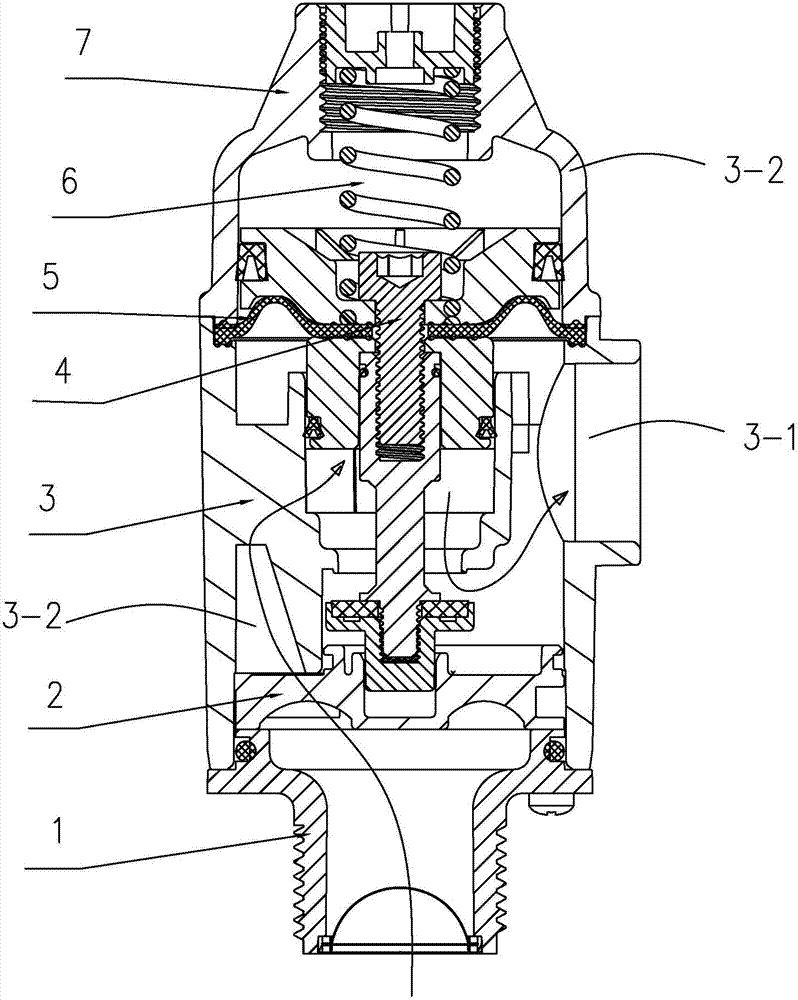

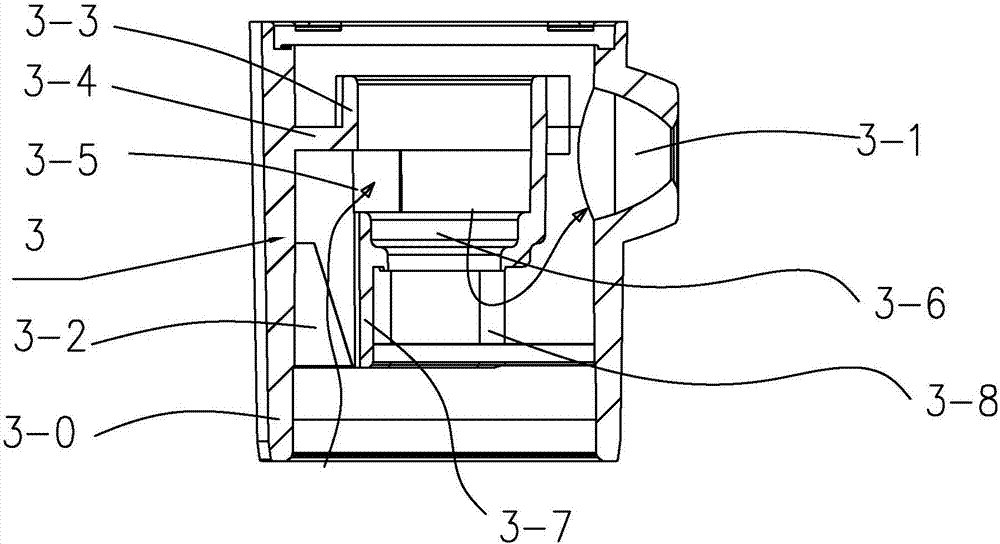

[0036] For specific embodiments of the present invention, refer to Figure 1 to Figure 3 , a large flow voltage stabilizing device, mainly composed of a water inlet joint 1, a sealing bracket 2, a body 3, a piston assembly 4, a stabilizing diaphragm 5, a stabilizing spring 6, and a gland 7.

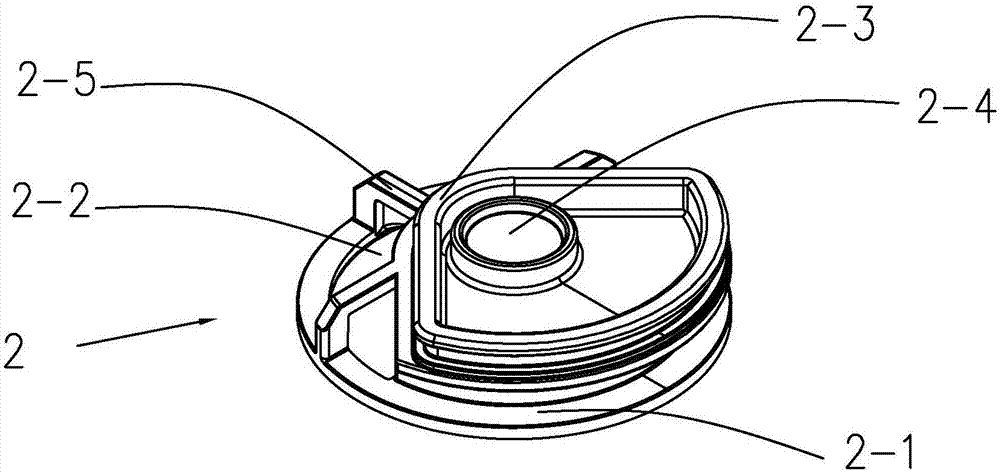

[0037] see image 3 , the seal bracket 2 includes a disc-shaped seat body 2-1, the center of the seat body 2-1 is provided with a piston rod movable jack 2-4, and the left side of the piston rod movable jack 2-4 is provided with a water hole 2- 2. A sealing ring 2-3 protruding from the upper surface of the base body is provided between the water passage hole 2-2 and the piston rod movable socket 2-4. In this embodiment, the sealing ring surrounds the area of the movable socket 2-4 of the piston rod. In this embodiment, a reinforcing rib 2-5 is also provided, the left end of the reinforcing rib 2-5 extends upward from the upper surface of the seat body 2-1 on the left side of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com