Circumferential pressurizing device for large-diameter Hopkinson pressure bar

A technology of Hopkinson pressure rod and pressure device, which is applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, instruments, etc., can solve the problem of inability to clearly explain the structure and working principle of the hoop pressure device, Unable to test impact mechanical properties, unable to provide accurate and stable hoop pressure, etc., to improve test success rate and test accuracy, ensure accuracy, and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

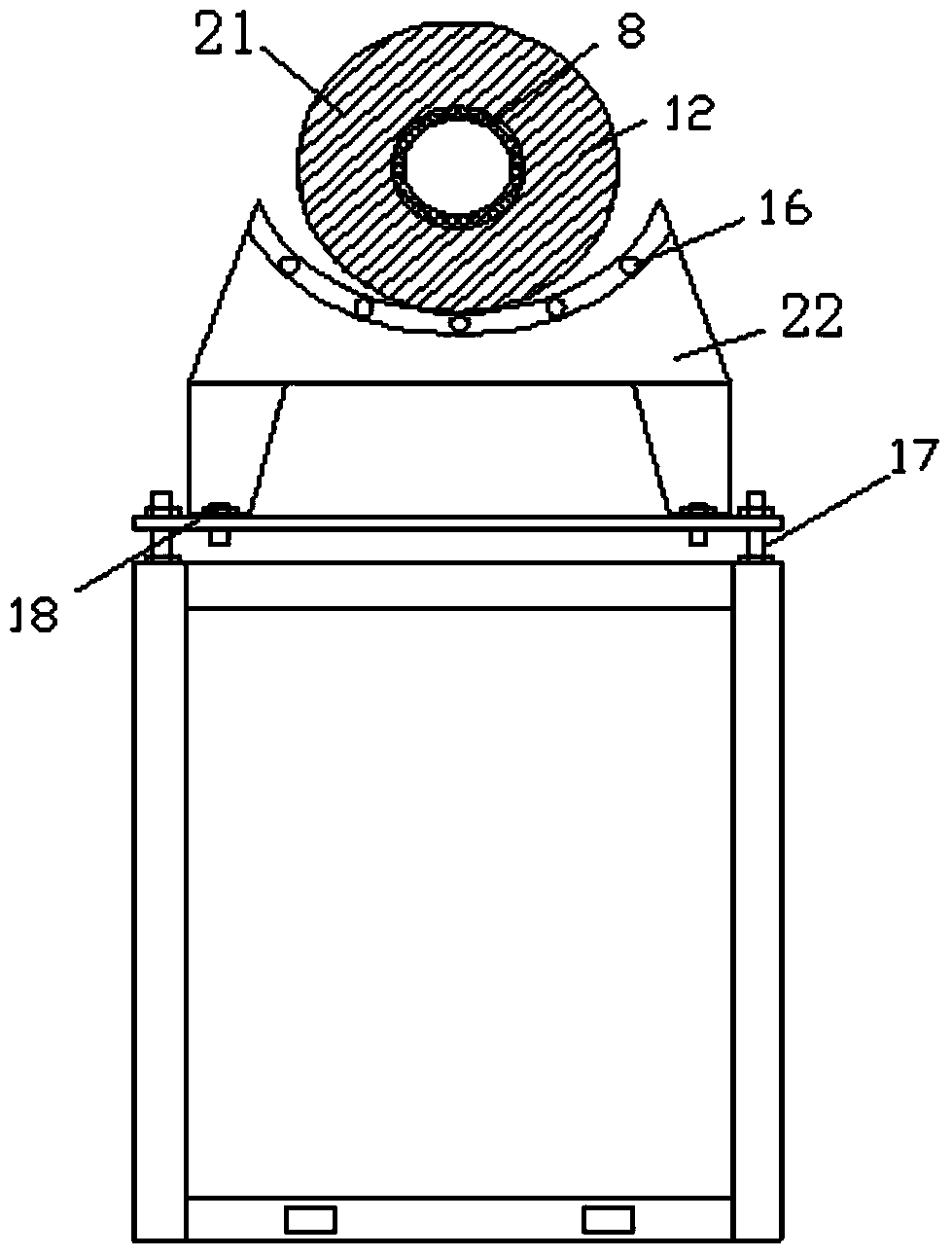

[0034] This embodiment is a hoop pressurizing device for a large-diameter Hopkinson bar, which includes a support 19 , a moving platform and a pressurizing cylinder 21 . The mobile platform is installed on the upper surface of the bracket 10, and the height of the mobile platform in the Z direction is adjusted by the bracket nut 17, and the displacement of the mobile platform in the Y direction is adjusted by the stand nut 18. The pressurized cylinder 21 is placed on the upper surface of the mobile platform, and moves in the X direction through the balls on the upper surface of the mobile platform.

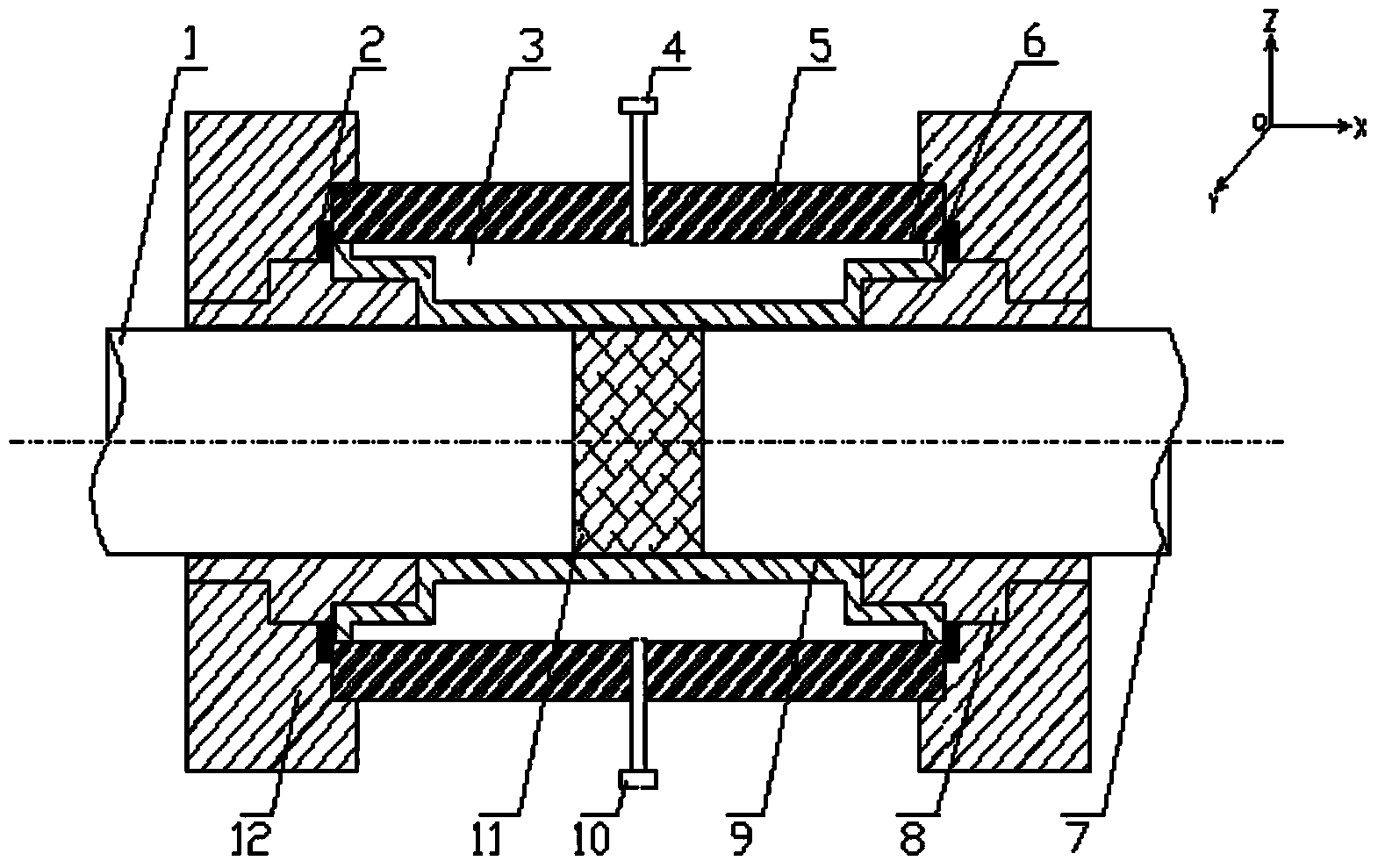

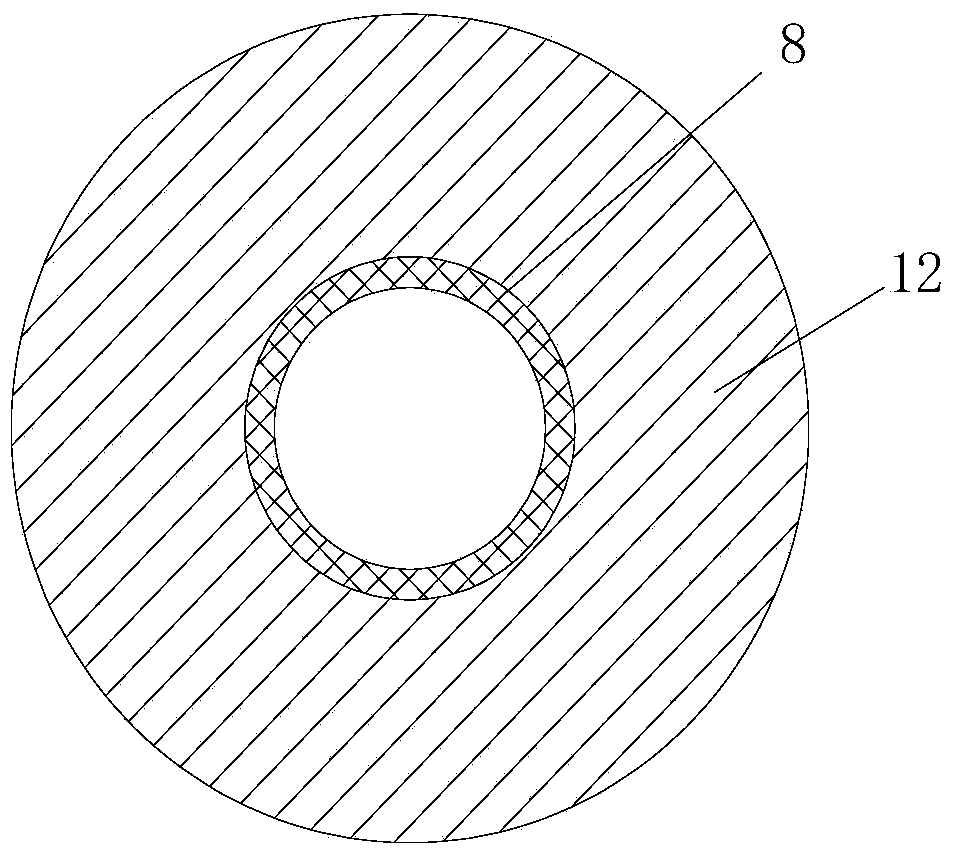

[0035] The pressurized cylinder 21 includes a hydraulic oil chamber 3 , an oil cylinder 5 , an oil-proof rubber sleeve 6 , a protective sleeve 9 , a pair of inner bushes 8 and a pair of outer sleeves 12 . Wherein, the outer peripheral surfaces of a pair of inner bushings 8 are stepped, and the peripheral surfaces of the outer two ends of the inner bushings are respectively the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com