Serial-parallel centrifugal fan and control method thereof

A centrifugal fan and control method technology, applied in pump control, mechanical equipment, machine/engine, etc., can solve the problems of large size, low external static pressure of the fan machine, complex structure, etc., achieve high product reliability and avoid complex structure , Simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

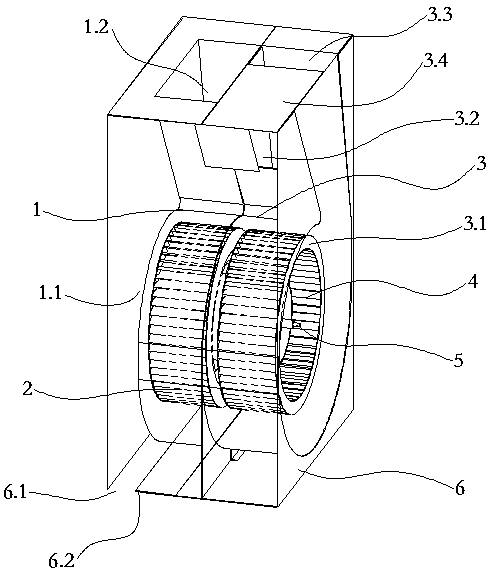

[0036] Such as figure 1 As shown, the series-parallel centrifugal fan provided by the present invention includes a left volute (1), a left centrifugal fan (2), a right volute (3), a right centrifugal fan (4), a motor assembly (5), an outer cover ( 6).

[0037] Such as figure 1 As shown, the left volute (1) of the series-parallel centrifugal fan is provided with a left volute air inlet (1.1) and a left volute air outlet (1.2); the left centrifugal fan (2) is arranged on the left volute (1) Inside; after the air flow enters the centrifugal fan from the left volute air inlet (1.1), it can only flow out of the centrifugal fan from the left volute air outlet (1.2).

[0038] The right volute (3) of the series-parallel centrifugal fan is provided with a right volute air inlet (3.1), a right volute air outlet (3.2), and a second air outlet (3.3); the right centrifugal blade (4) It is arranged inside the right volute (3).

[0039] Further, such as figure 1As shown, the right volut...

Embodiment 2

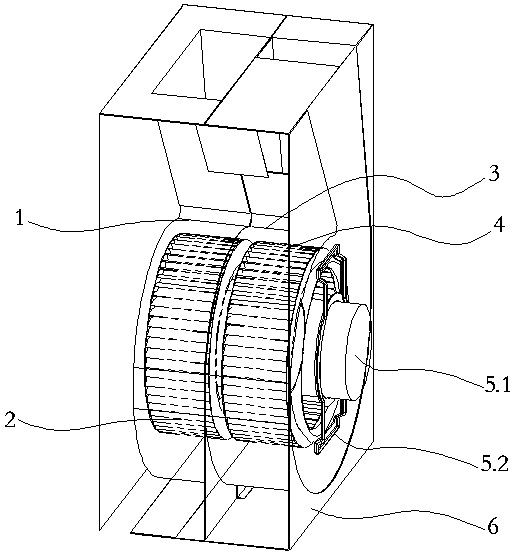

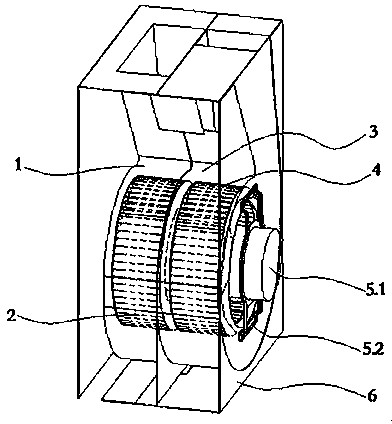

[0050] Such as figure 2 As shown, different from Embodiment 1, in Embodiment 2, the motor assembly (5) of the series-parallel centrifugal fan is arranged on the outer cover (6).

[0051] The motor assembly (5) includes a motor (5.1) and a motor bracket (5.2), the motor (5.1) is fixed on the motor bracket (5.2) by bolts, and the motor bracket (5.2) is installed on the outer cover (6).

[0052] The rotating shaft of the motor (5.1) extends into the inside of the left volute (1) and the right volute (3).

[0053] The left centrifugal fan blade (2) and the right centrifugal fan blade (4) are installed on one end of the motor (5.1) rotating shaft respectively. The other structures and working principles of the centrifugal fan in Embodiment 2 are the same as those in Embodiment 1, and will not be repeated here.

[0054] The invention solves the problems of low external static pressure, large size and complex structure of the fan in the prior art, and makes the centrifugal fan hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com