Patents

Literature

639 results about "Medial axis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The medial axis of an object is the set of all points having more than one closest point on the object's boundary. Originally referred to as the topological skeleton, it was introduced by Blum as a tool for biological shape recognition. In mathematics the closure of the medial axis is known as the cut locus.

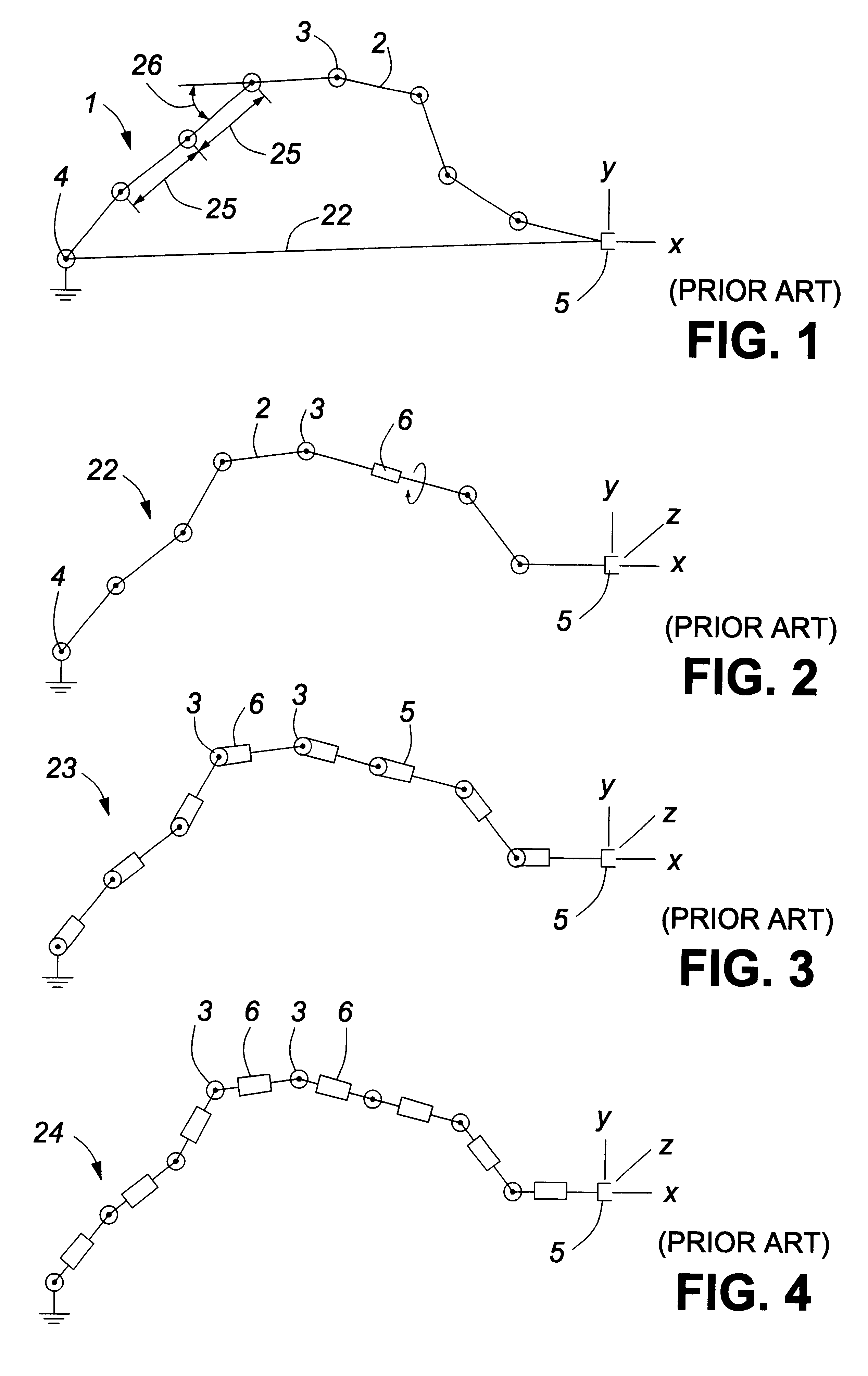

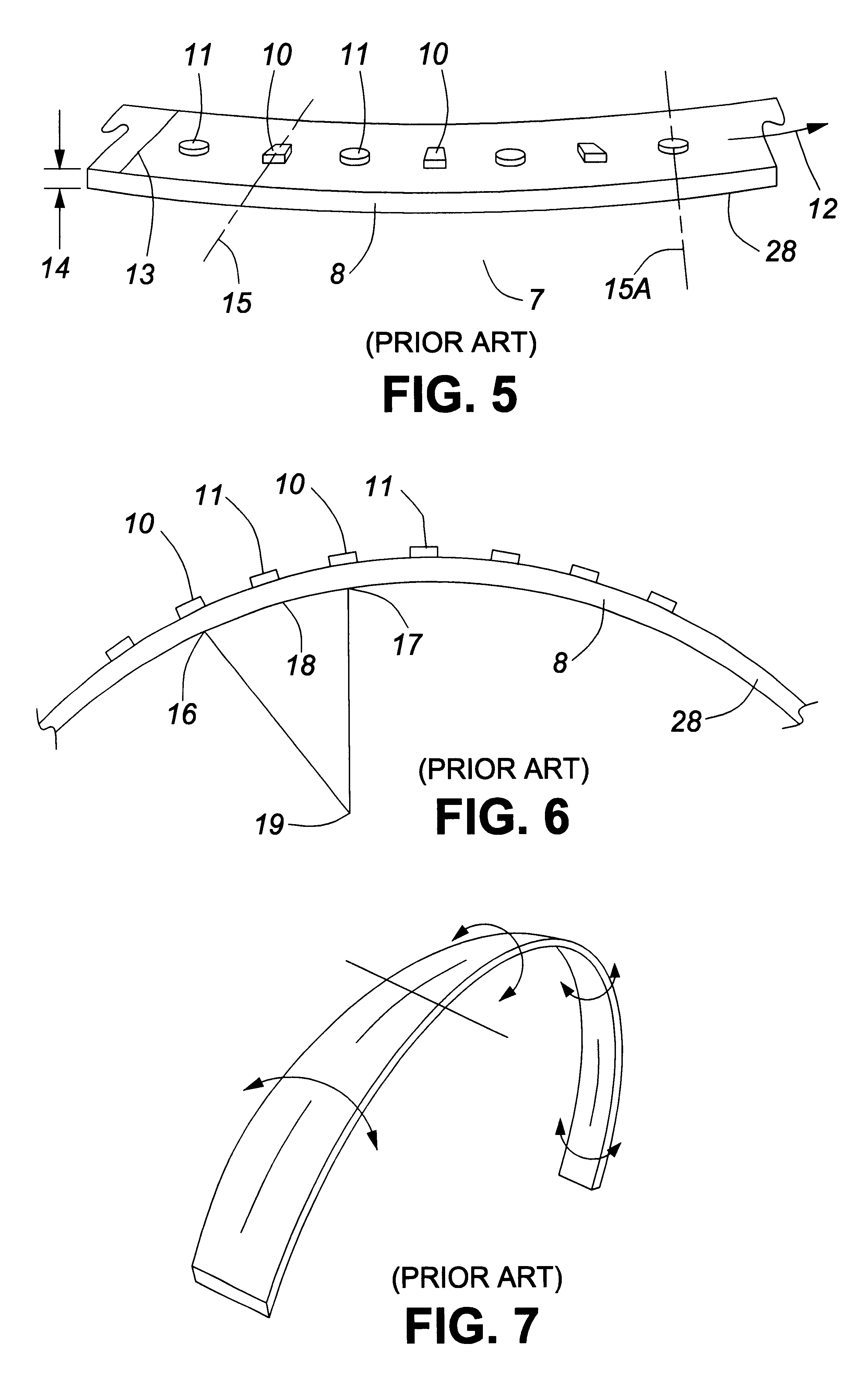

Topological and motion measuring tool

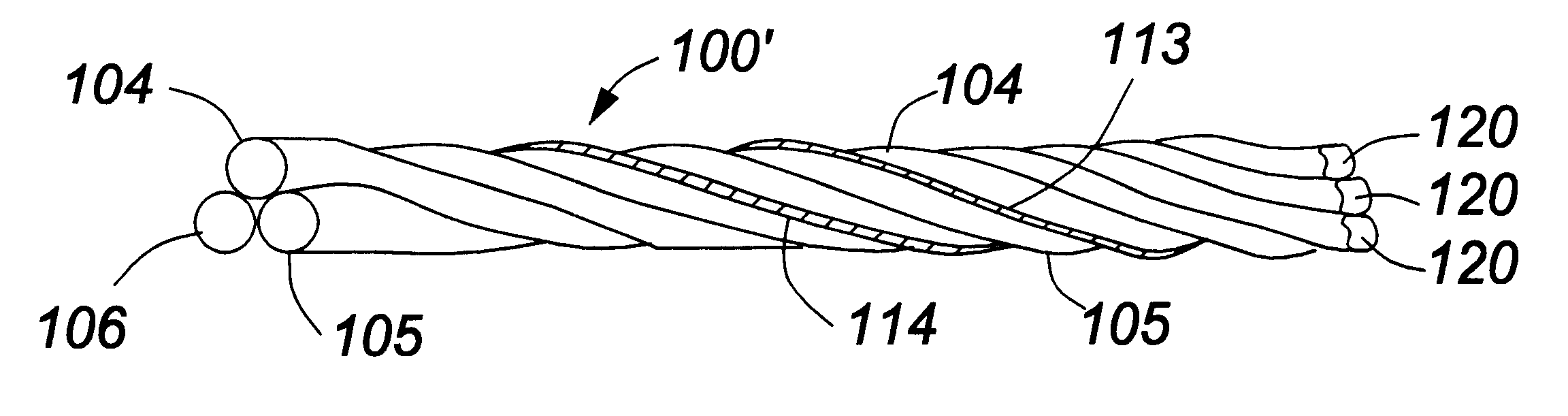

InactiveUS6563107B2Significant lateral deflectionEnhance strength and stabilityRadiation pyrometryWeft knittingFiberMedial axis

A measuring device for providing data corresponding to a geometric configuration in space, in the form of a flexible, compliant, measurement member capable of bending in at least one degree of freedom and extending along a medial axis or plane. The member has spaced flexure sensors distributed at known locations on the member and separated by known sensor spacing intervals to provide flexure signals indicating the local state of flexure present at the locations. The member comprises a multiplicity of formed, i.e. shaped, fibers, these fibers including sensing fibers having sensing portions which provide the flexure sensors, the sensing portions of different fibers being located at differing distances along the member so as to be located at the sensor spacing intervals, the formed fibers being in mutually supporting relationship, as by continuous or repeated contact with each other. Such fibers may constitute most or all of the member.

Owner:CANADIAN SPACE AGENCY

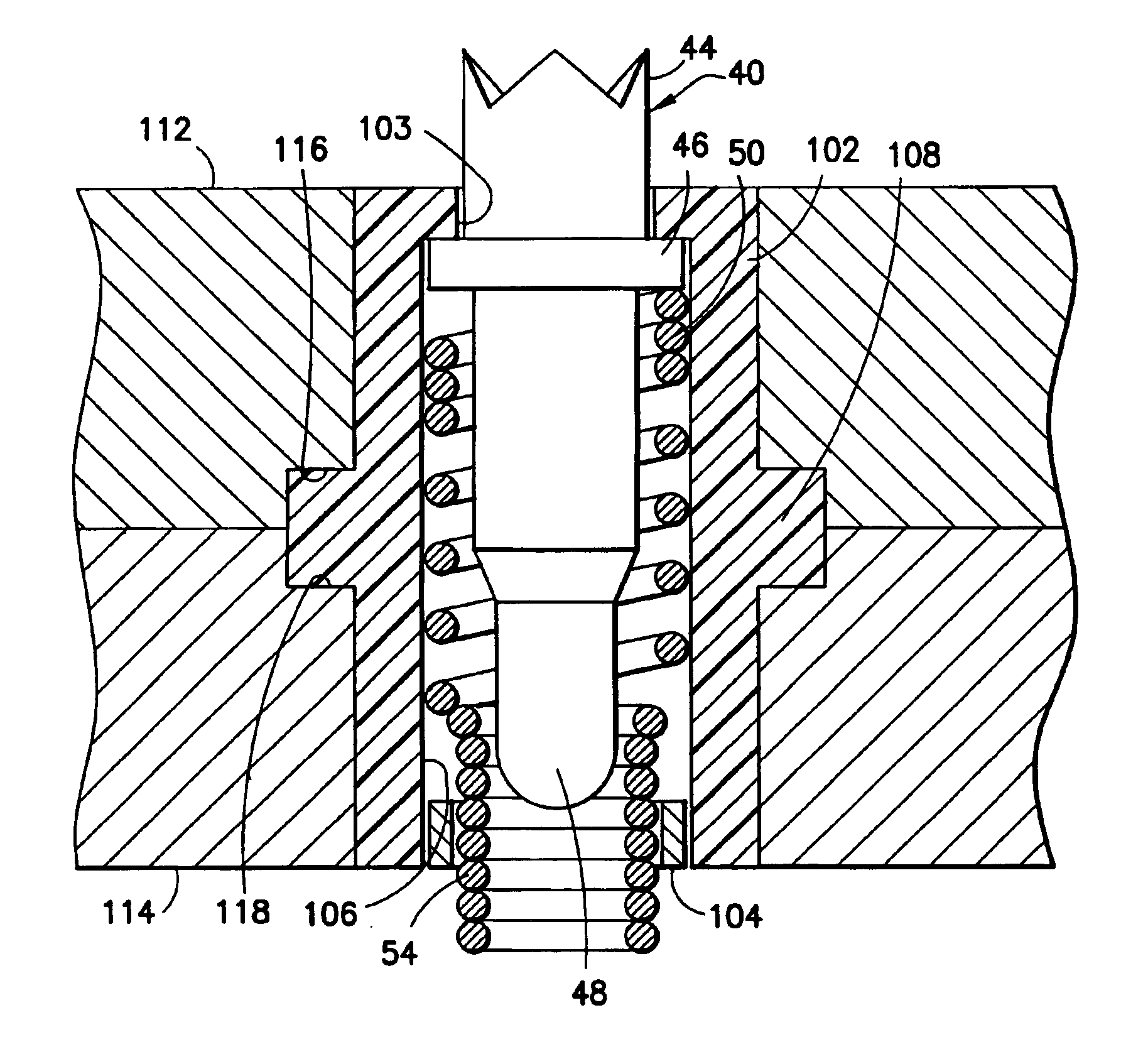

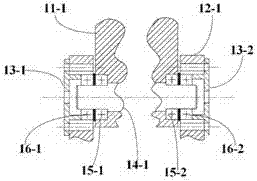

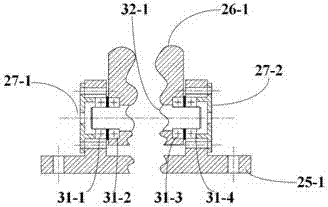

Shielded integrated circuit probe

InactiveUS6937045B2Reliable electrical connectionLow insertion force parameterCoupling contact membersMeasurement instrument housingElectricityElectrical resistance and conductance

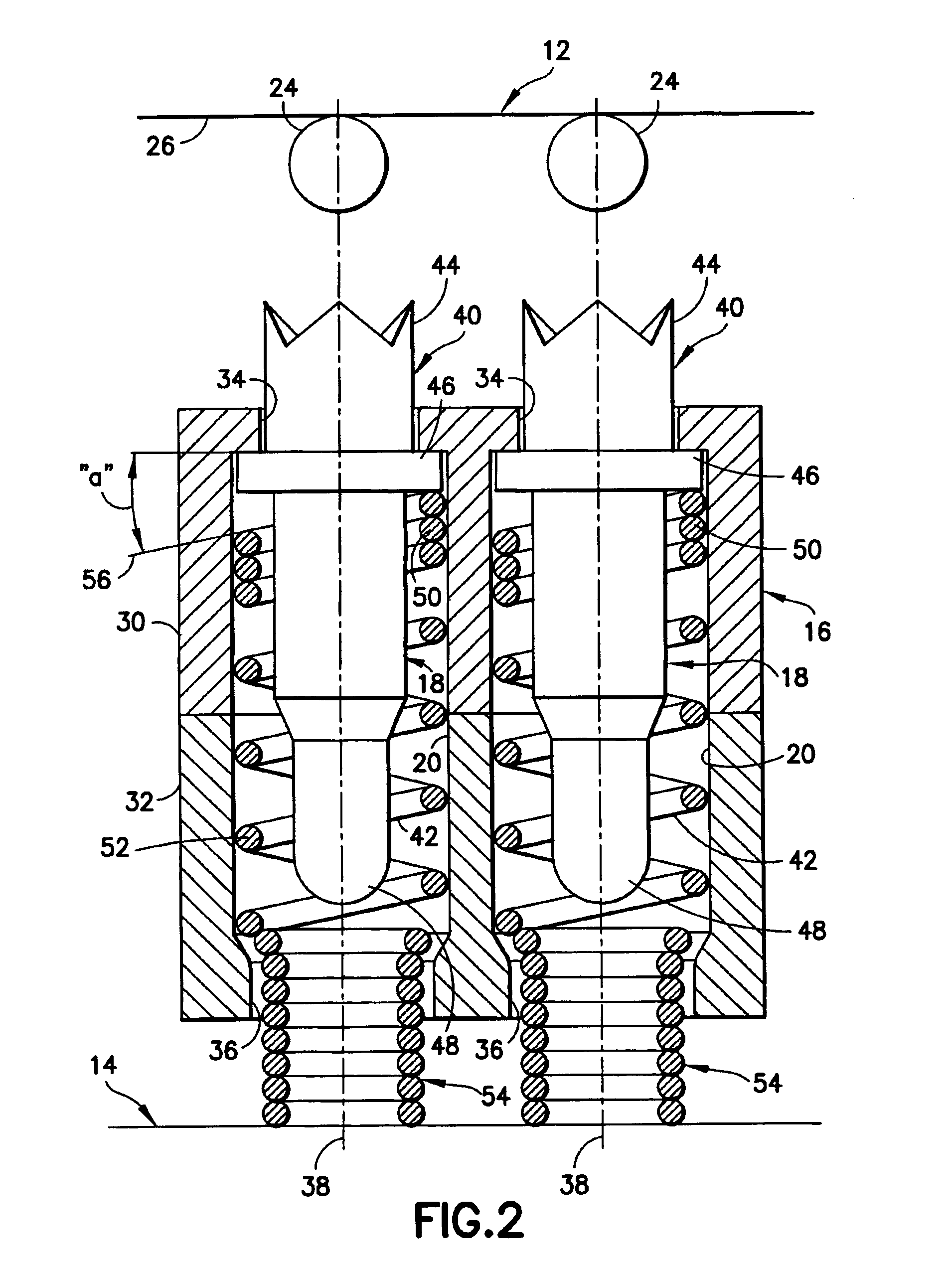

A test probe consists of an elongated screw machine contact biased by a helical spring and mounted in a through hole of a non-conductive substrate. One end of the contact includes a crown for engaging a solder ball lead of an IC package, and the contact includes an intermediate collar which maintains the contact within the through hole. The helical spring is disposed about the contact, with one end thereof engaging the lower end of the collar. The other end of the helical spring has contiguous coils and is of a reduced diameter so as to extend beyond the lower end of the non-conductive substrate to make electrical contact with a printed circuit board. When the test probe is compressed between the IC package and the printed circuit board, the inherent twisting of the helical spring causes the contact to tilt and make electrical contact with the contiguous coils, thereby establishing a direct electrical path between the IC package and the printed circuit board, with minimum resistance and minimum inductance. In an alternate embodiment, each probe is disposed within a dielectric housing which, in turn, is disposed in a through hole in a conductive substrate to effectively shield the probe from electrical interference.

Owner:ARIES ELECTRONICS

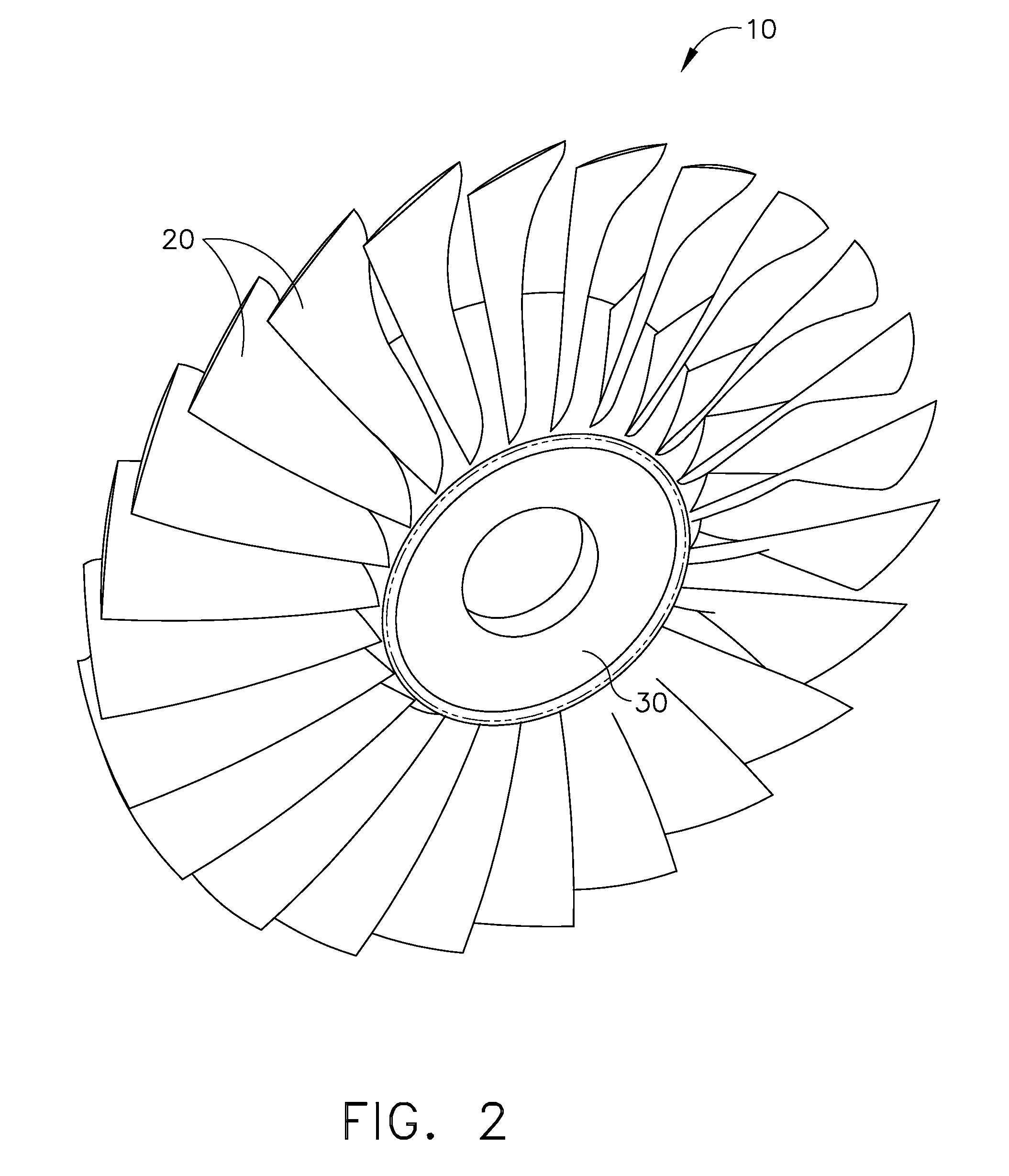

Laser net shape manufacturing and repair using a medial axis toolpath deposition method

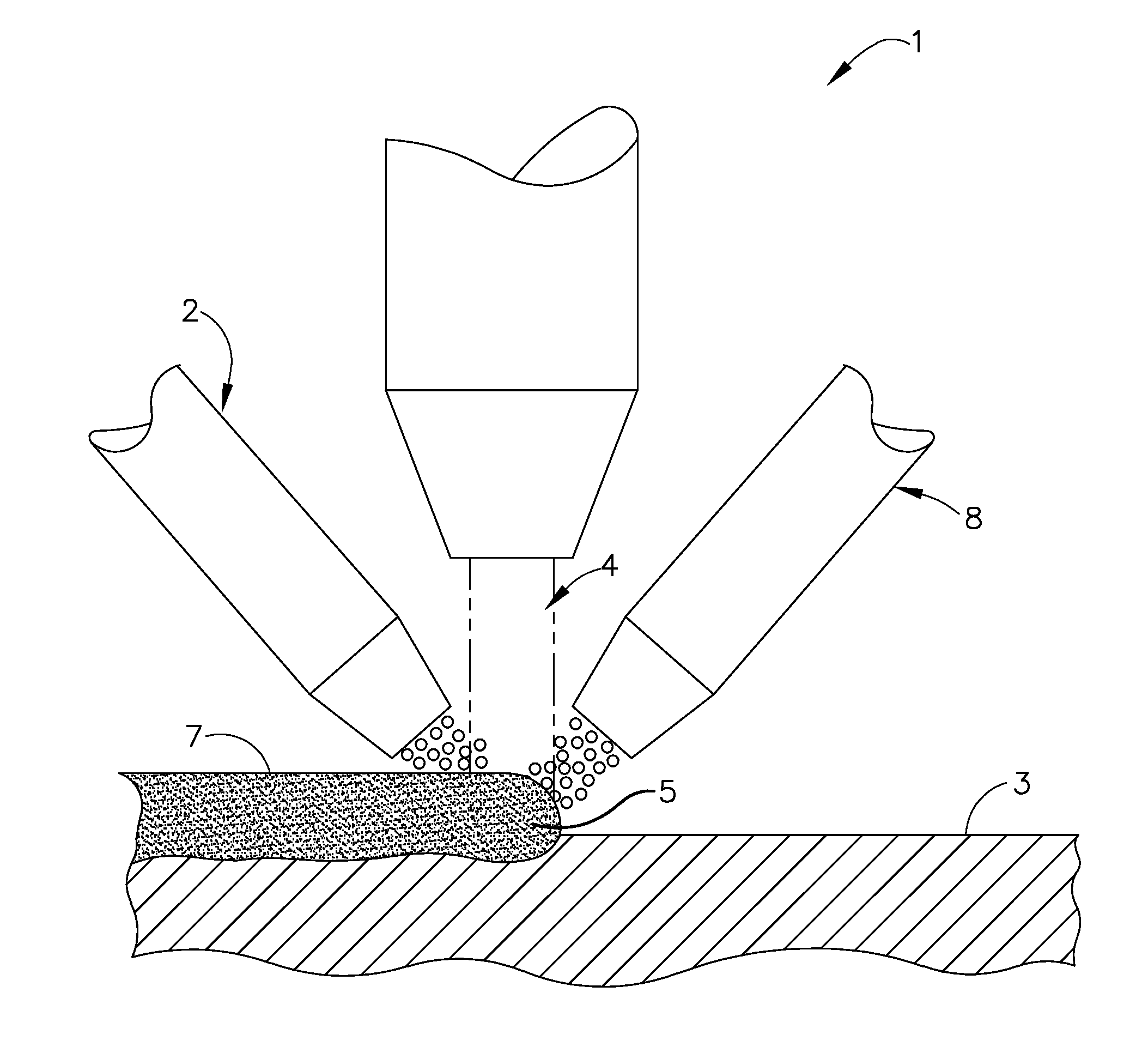

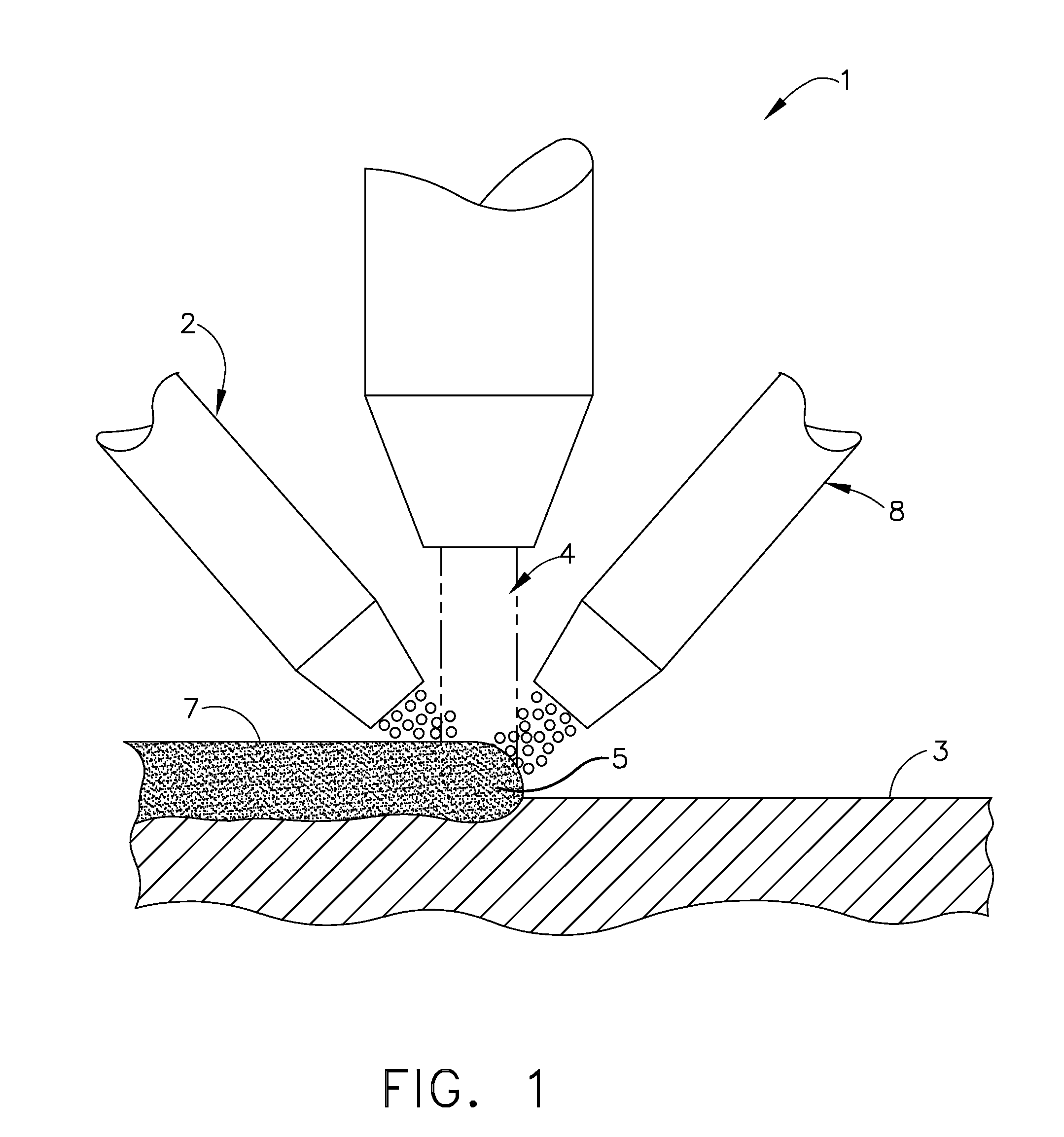

InactiveUS20080182017A1Eliminate and reduce numberAdditive manufacturingTurbinesMedial axisNet shape

A method is disclosed for laser net shape manufacturing a part or repairing an area of a part comprising providing a CAD model of the part to be manufactured or repaired, digitally slicing the CAD model into a plurality of deposition layers, determining a medial axis for each of the deposition layers of the part or repair area; and depositing a bead of a material in a pattern centered upon the medial axis of each of the deposition layers so as to build-up the material by each of the deposition layer until the part is manufactured or repaired.

Owner:GENERAL ELECTRIC CO

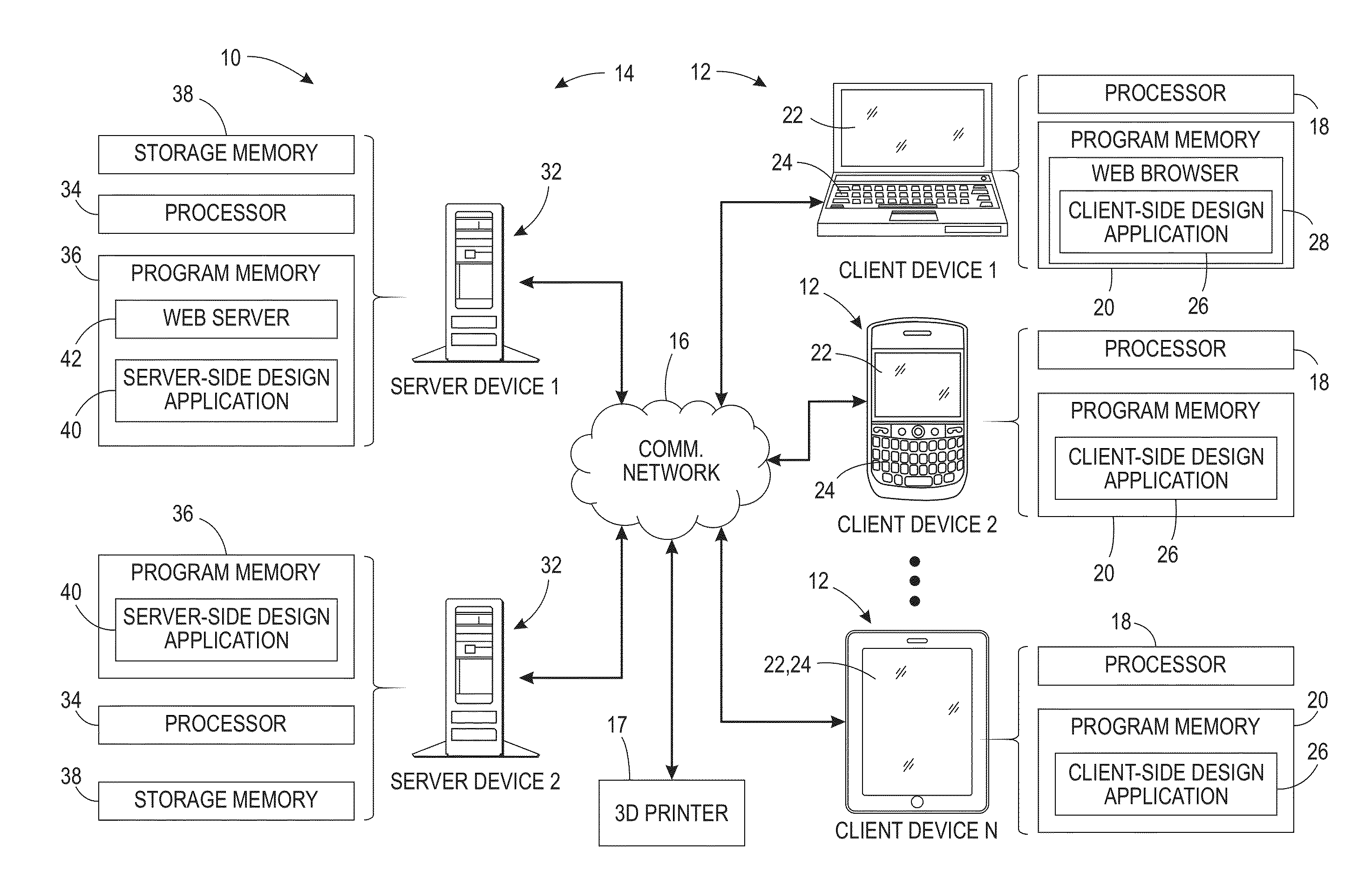

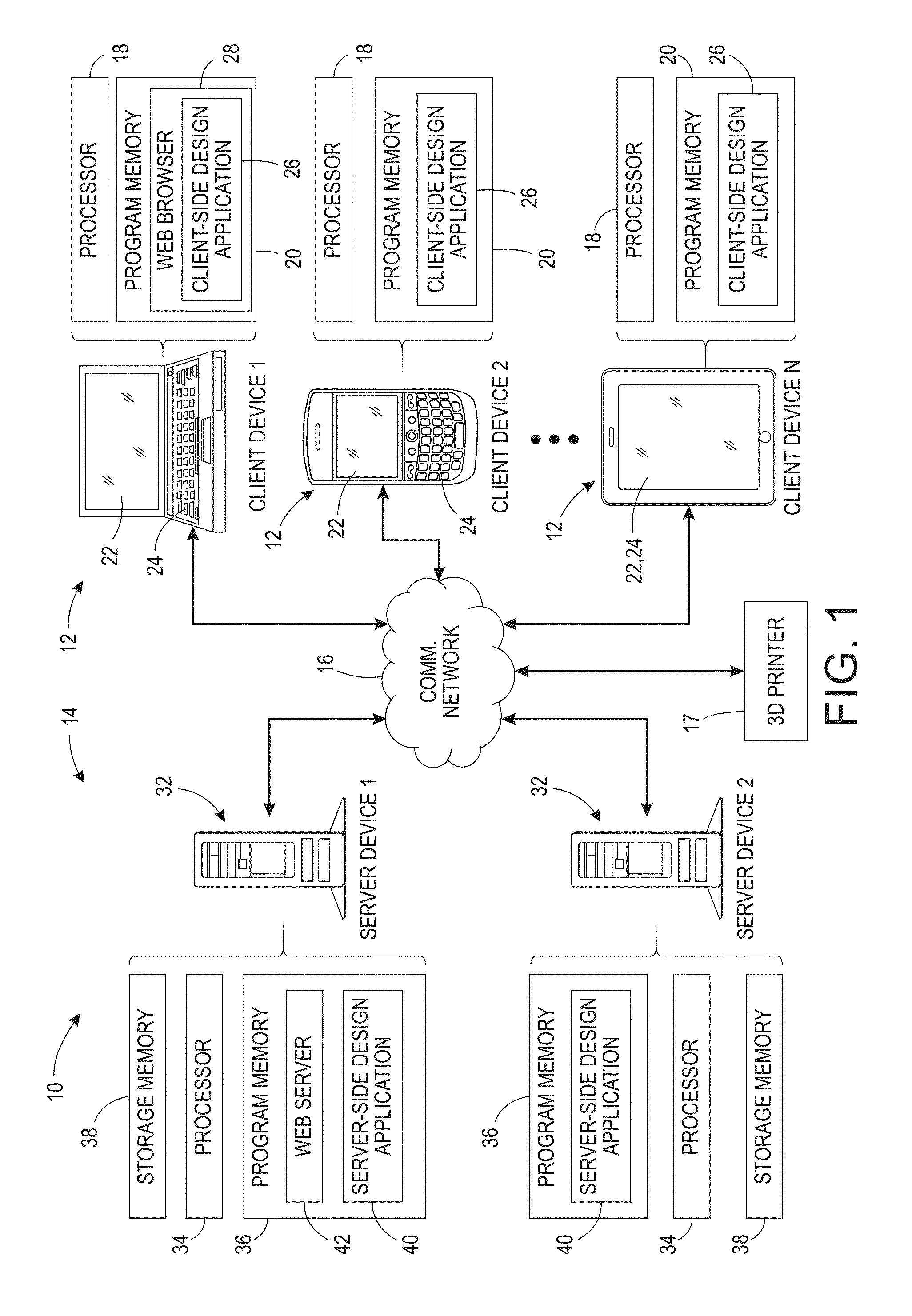

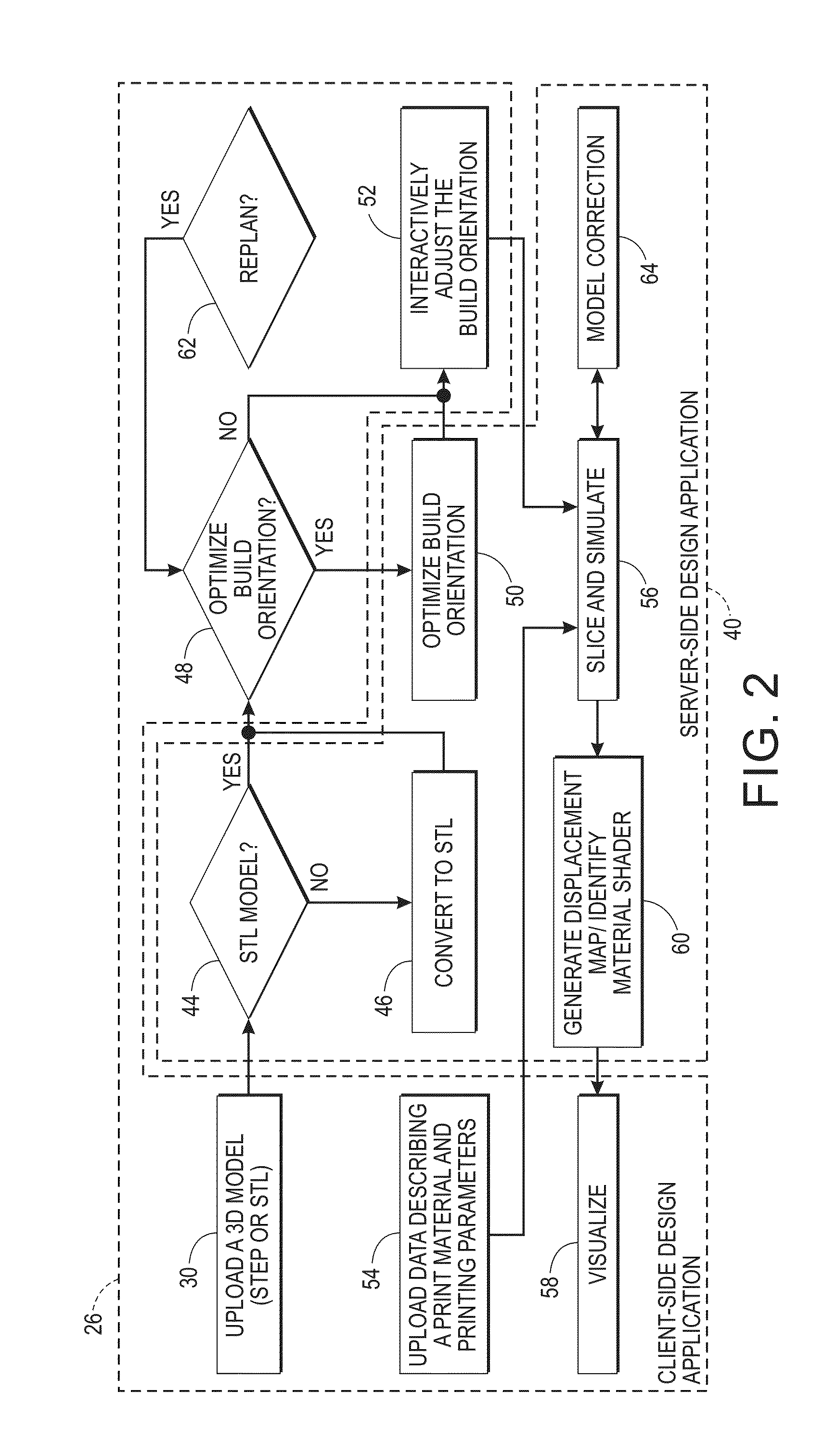

Automated metrology and model correction for three dimensional (3D) printability

A system and a method automate metrology, measurement, and model correction of a three dimensional (3D) model for 3D printability. Slices of the 3D model are received or generated. The slices represent 2D solids of the 3D model to be printed in corresponding print layers. Medial axis transforms of the slices are calculated. The medial axis transforms represent the slices in terms of corresponding medial axes. A local feature size at any point along a boundary of the slices is determined as the shortest distance from the point to a corresponding medial axis.

Owner:XEROX CORP

Three-dimensional printing preparation

ActiveUS20130297059A1Additive manufacturing apparatusComputer aided designMedial axisImage resolution

Embodiments disclosed herein provide systems and methods for preparing geometry for 3D printing. In one embodiment, a 3D printing preparation application receives 3D geometry and repairs non-manifold edges and non-manifold vertices, producing a topological manifold geometry. The 3D printing preparation application then welds coincident edges without coincident faces and fills holes in the geometry. The 3D printing preparation application may further perform resolution-aware thickening of the geometry by estimating distances to a medial axis based on distances to distance field shocks, and advecting the distance field using a velocity field. A similar approach may be used to perform resolution-aware separation enforcement. Alternatively, one component may be globally thickened and subtracted from another for separation enforcement. The 3D printing preparation application may also split large models and add connectors for connecting the split pieces after printing. In addition, the 3D printing preparation application may generate a 3D print preview.

Owner:AUTODESK INC

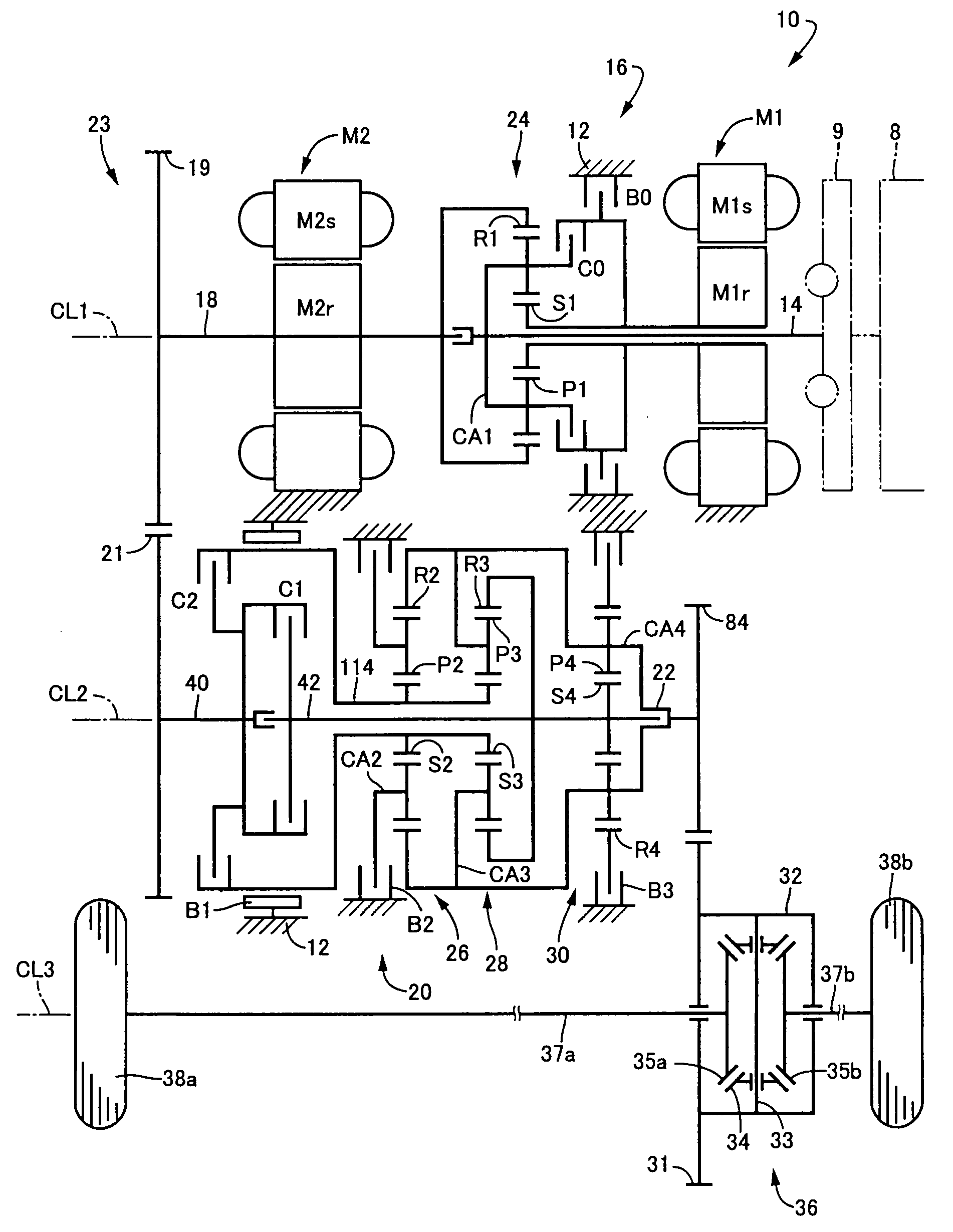

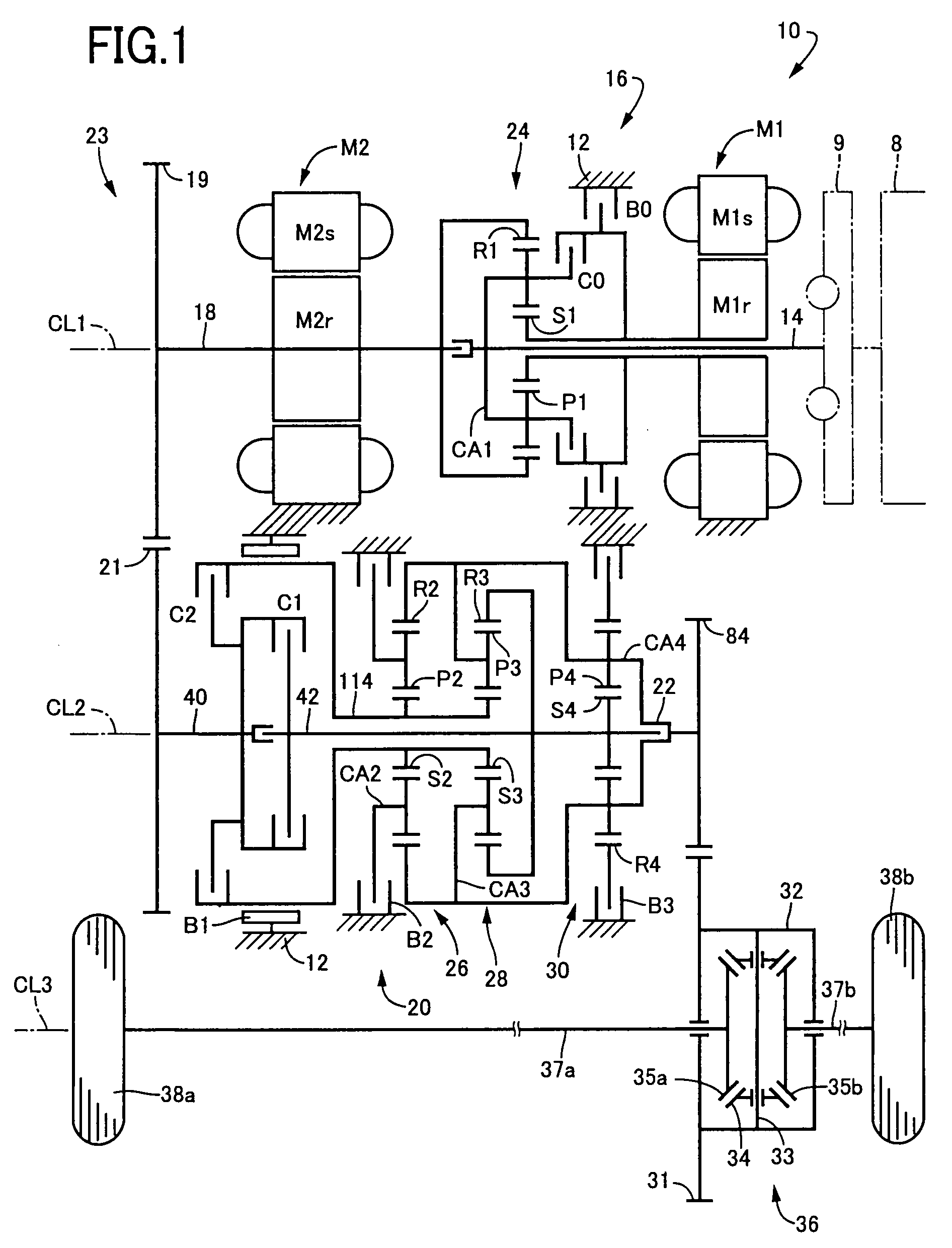

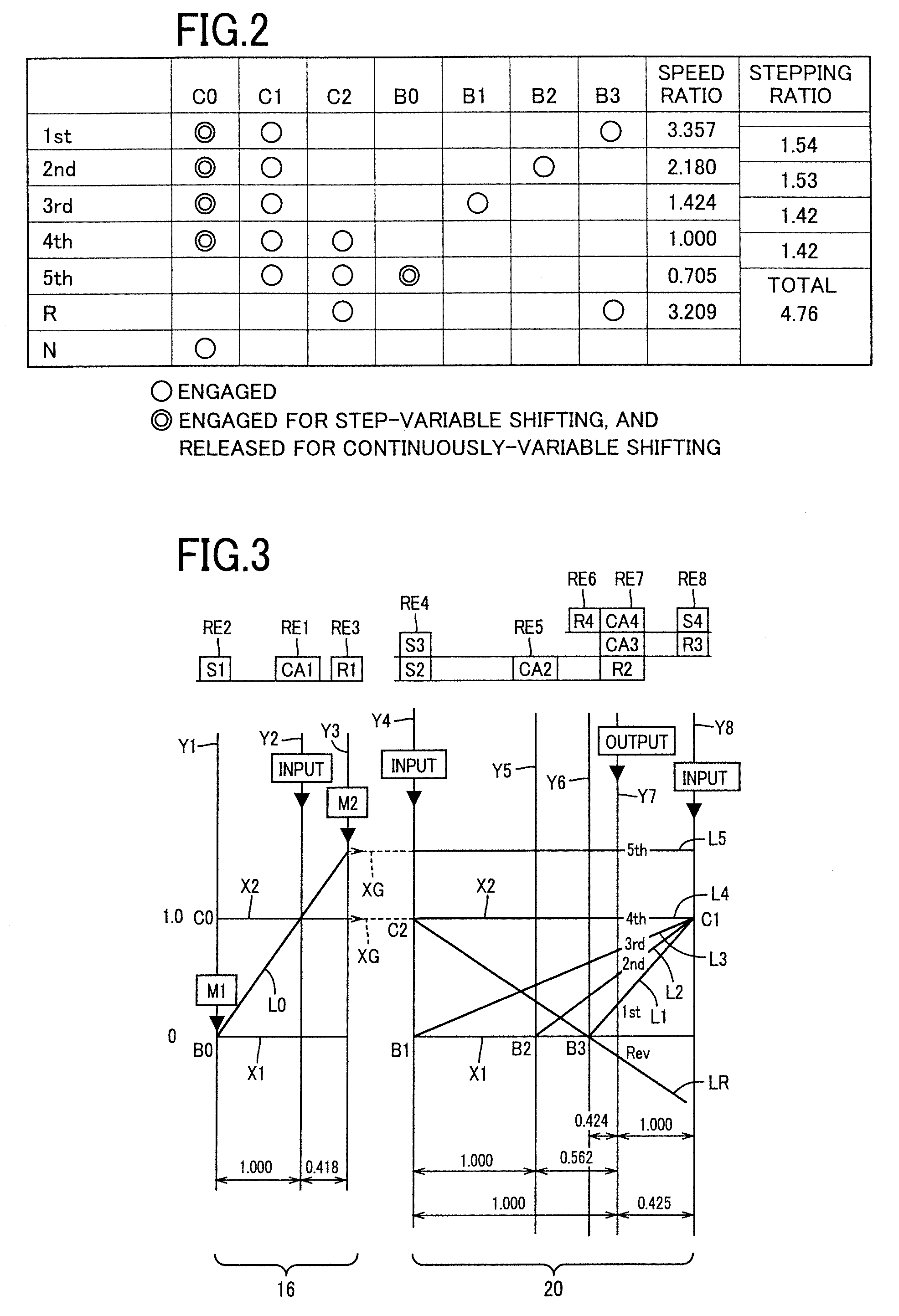

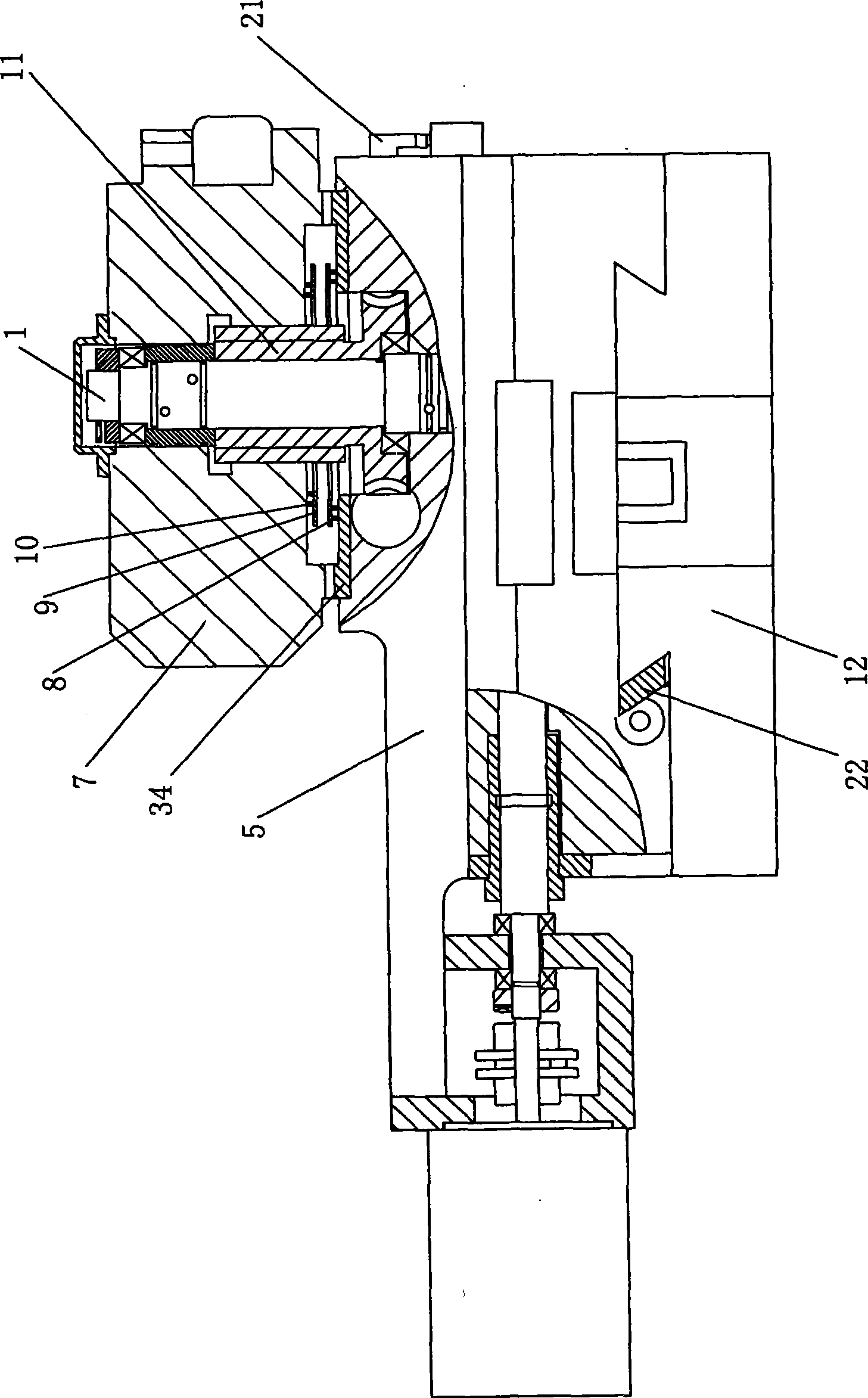

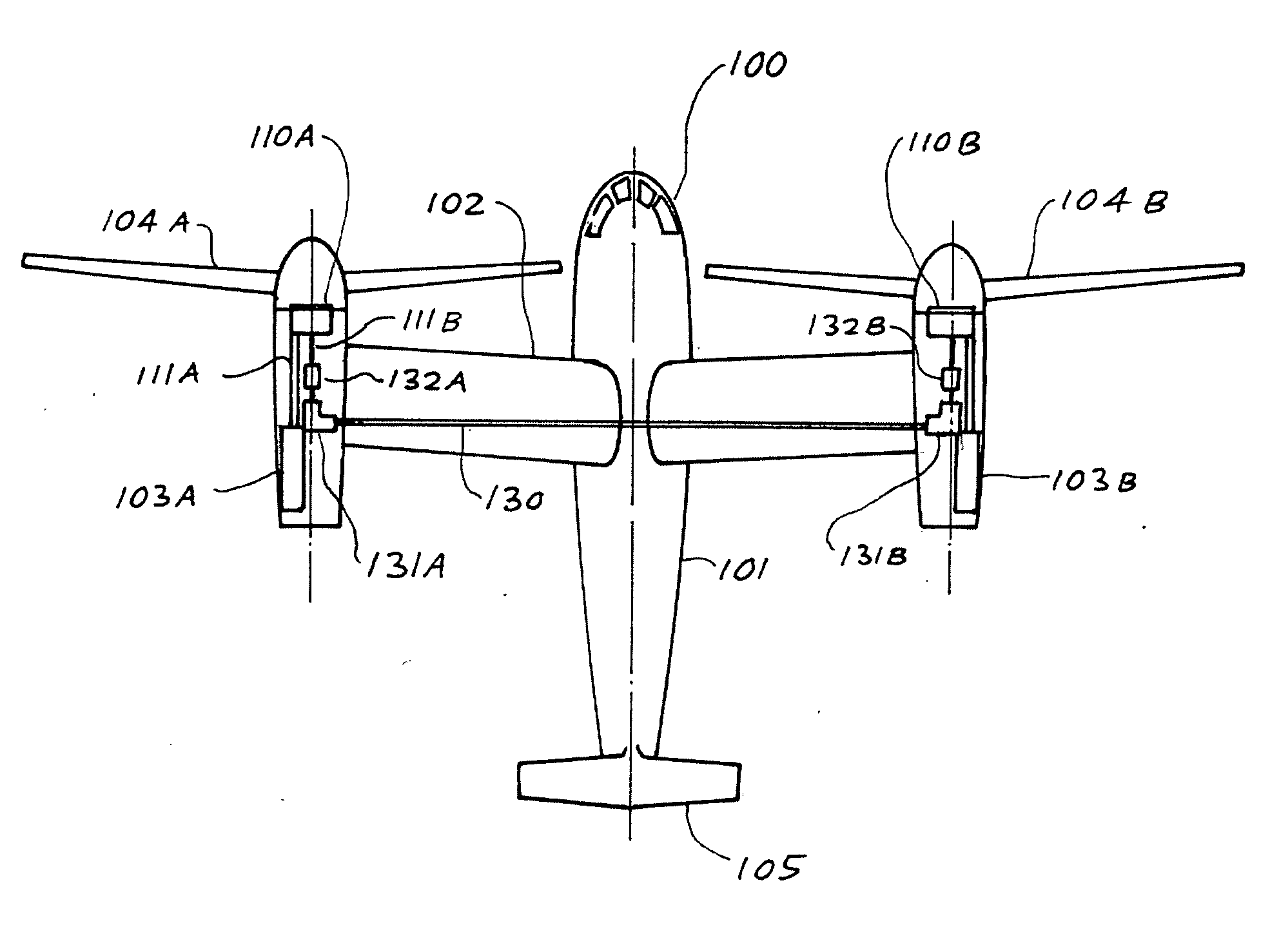

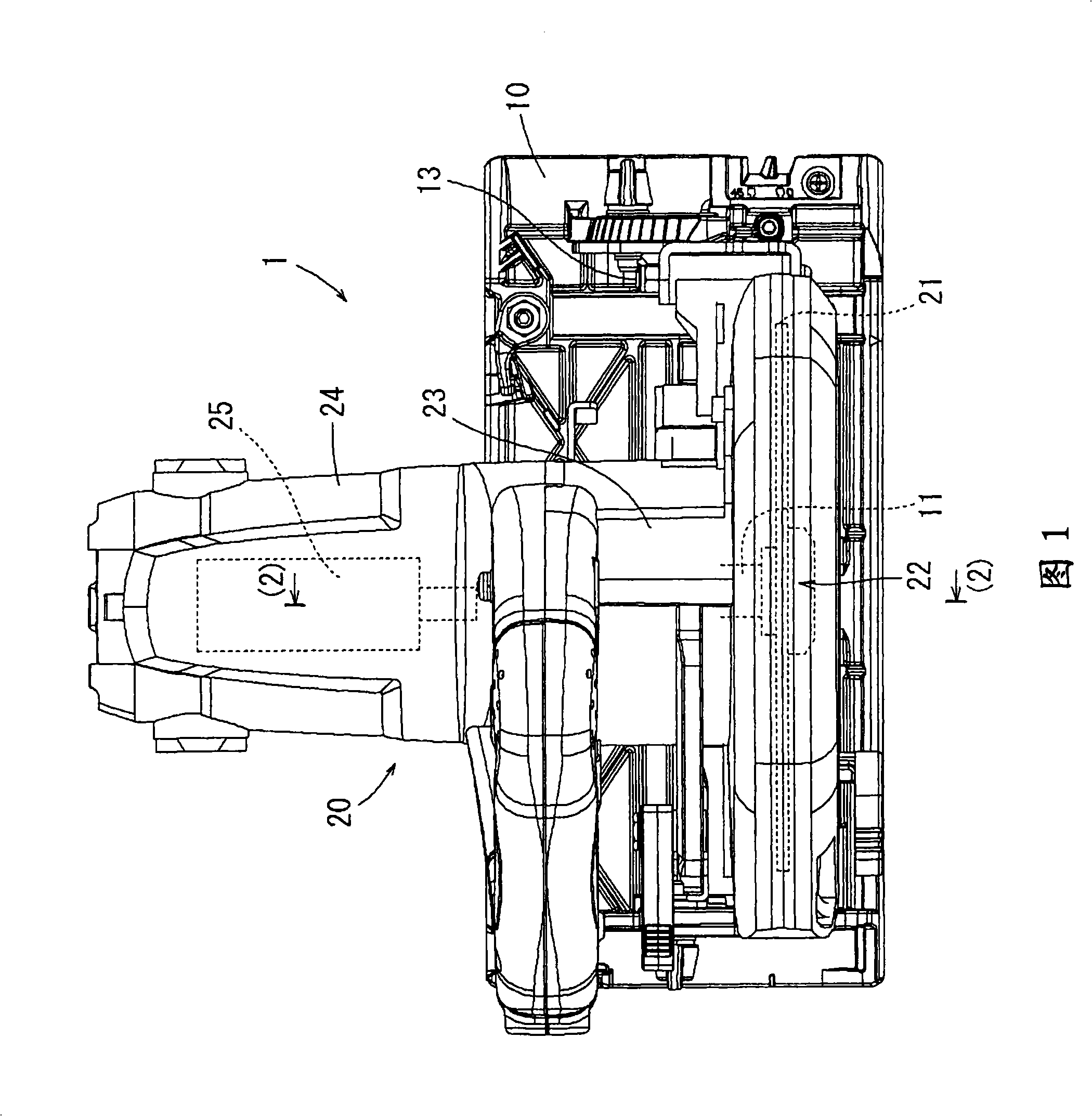

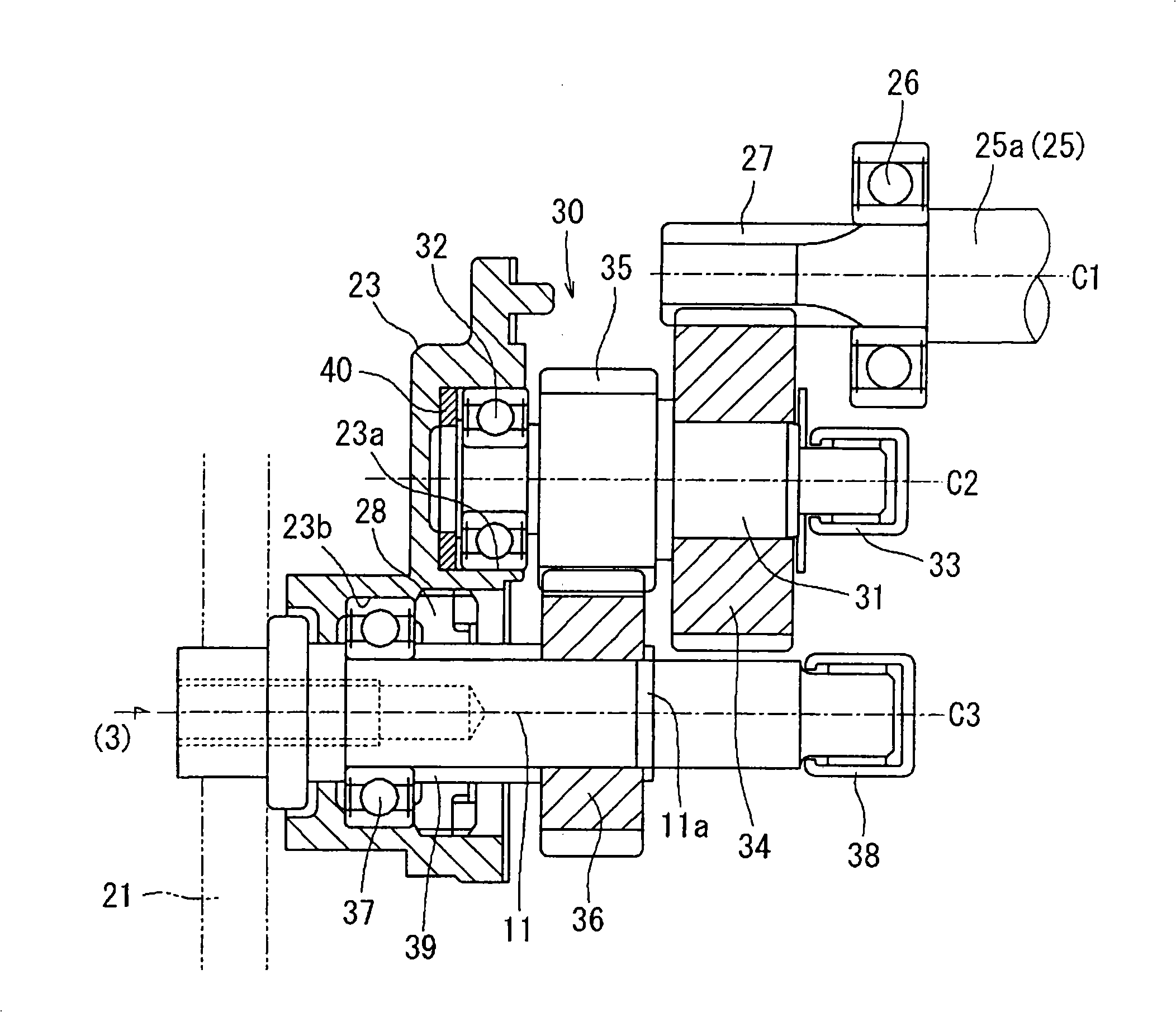

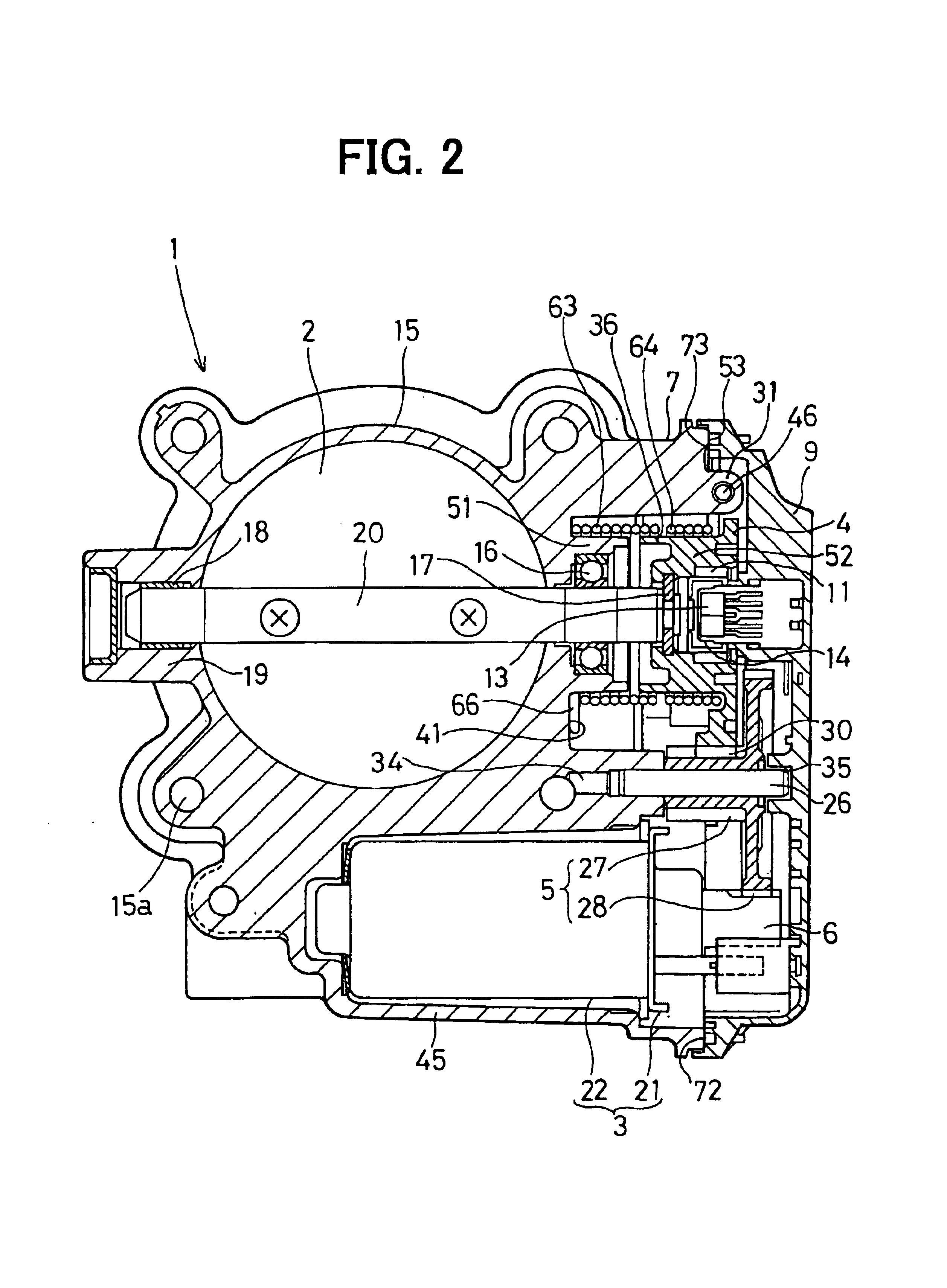

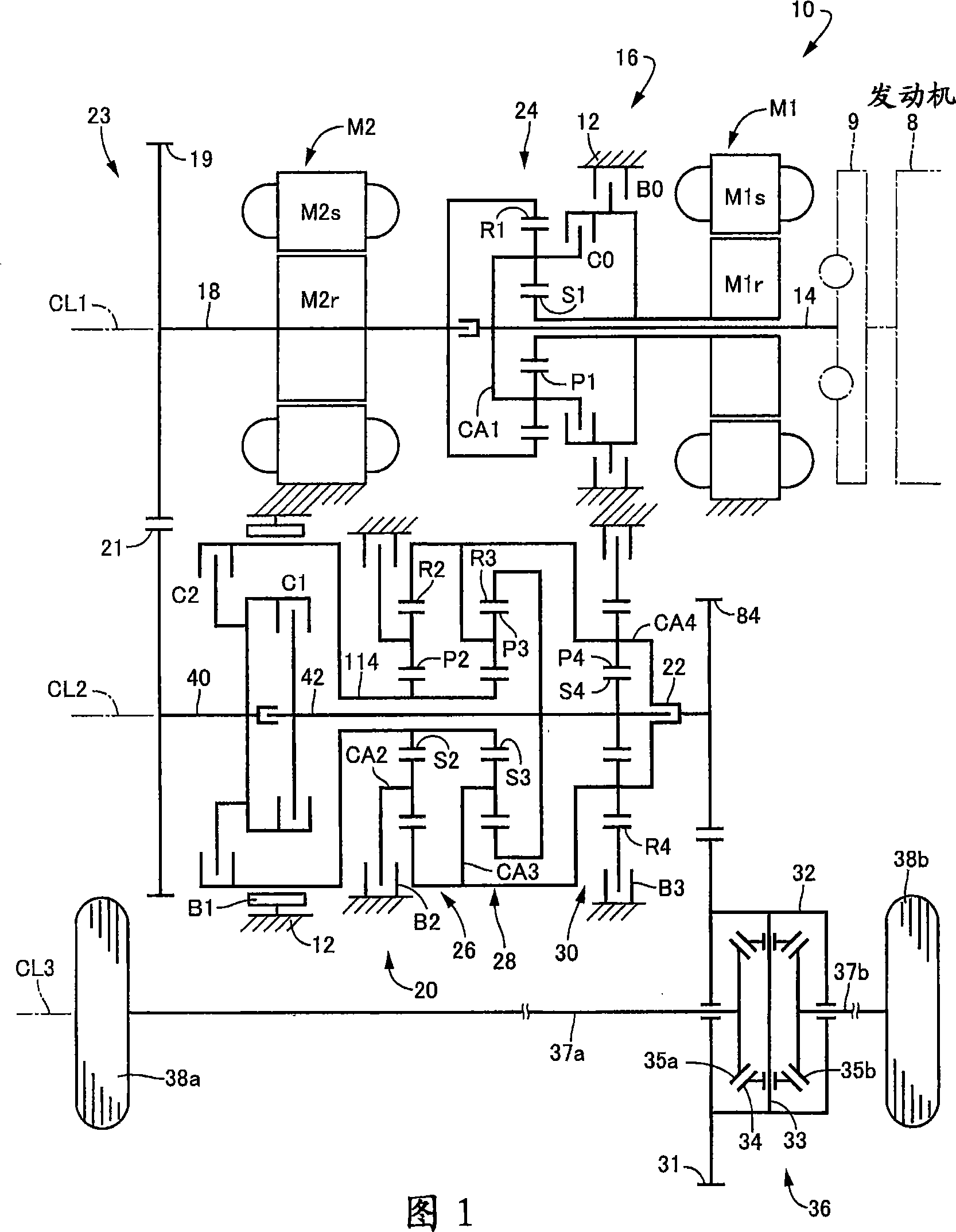

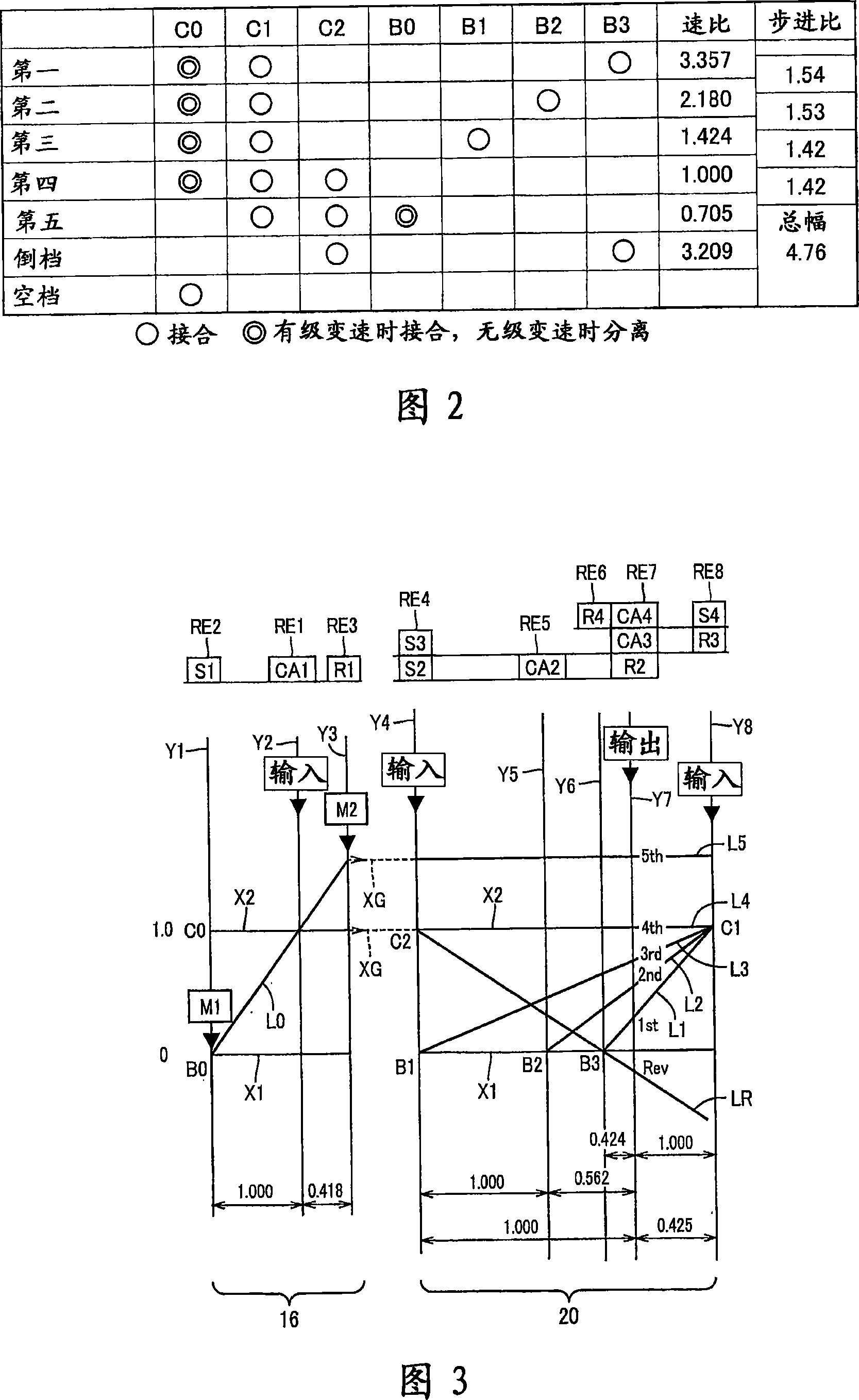

Drive device for vehicle

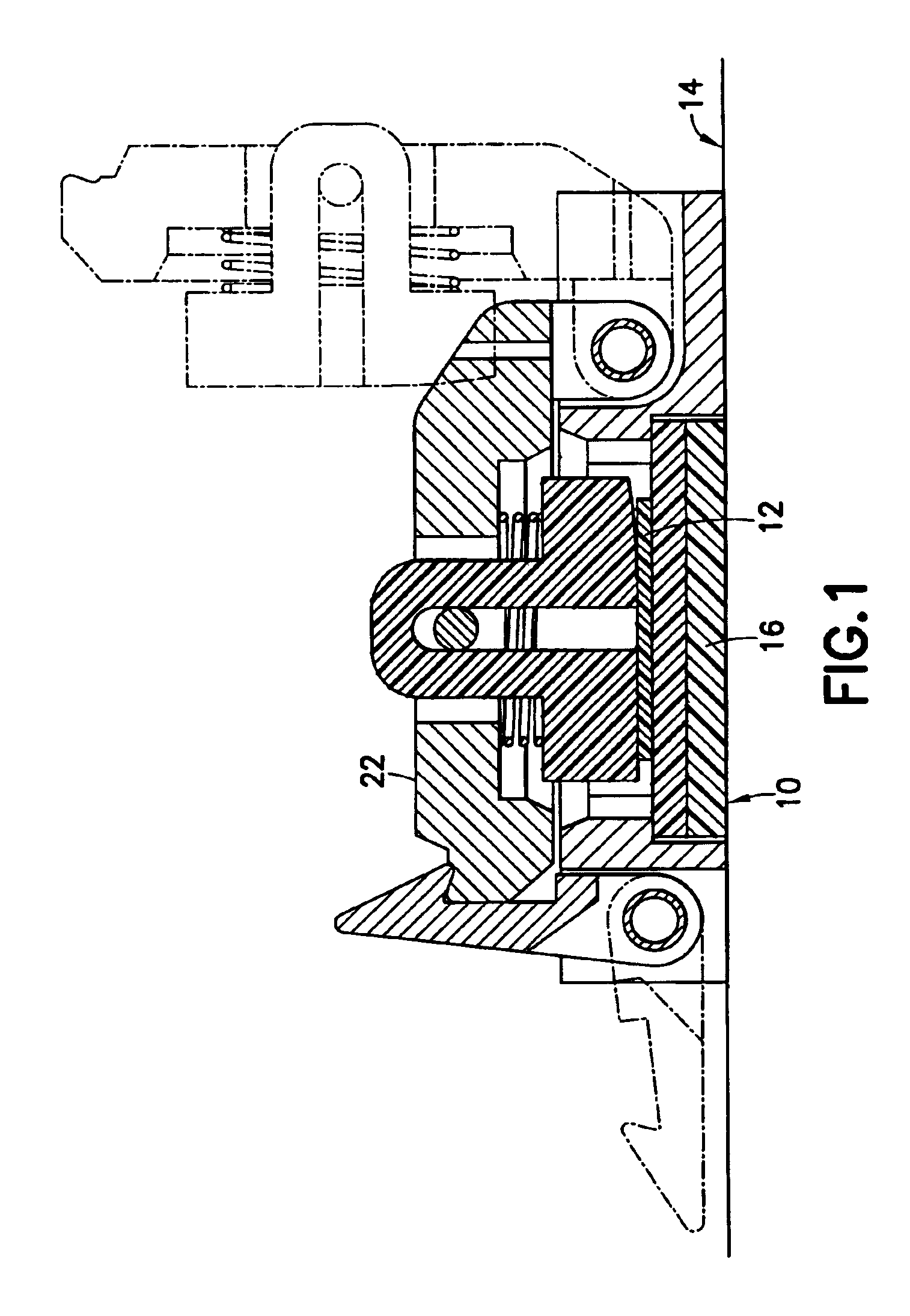

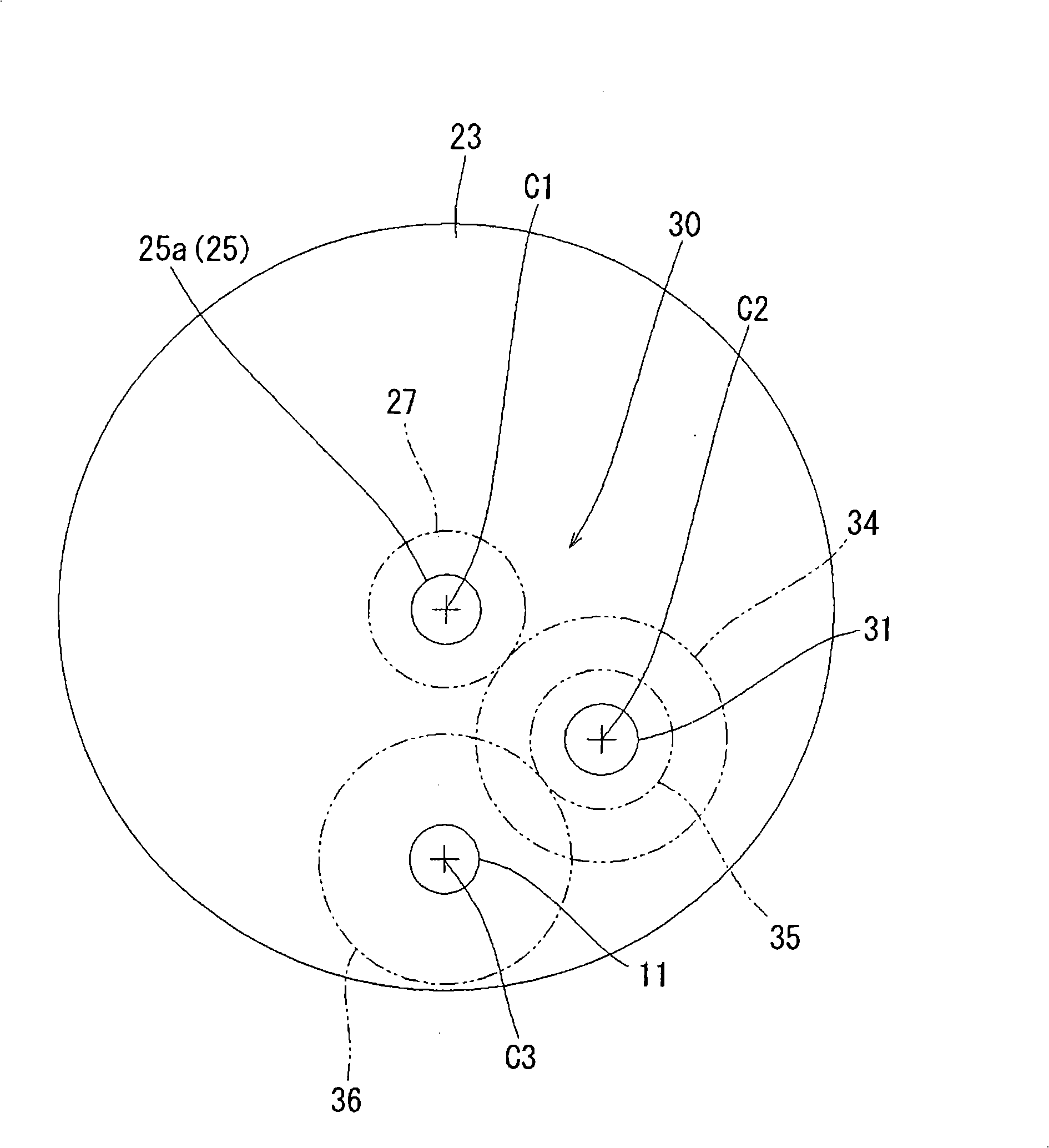

InactiveUS20090098969A1Downsized vehicular driveHigh trafficElectric propulsion mountingPropulsion using engine-driven generatorsRotational axisAutomatic transmission

A miniaturized vehicular drive apparatus is provided with a reduced size in an axial direction without increasing the number of parallel shafts. A first electric motor M1 and a power distributing mechanism (differential portion) 16 are disposed on a first axis CL1, forming a rotational axis of an input rotary member 14, in series starting therefrom and an automatic transmission (transmission portion) 20 is disposed on a second axis CL2 parallel to the first axis CL1. A drive linkage 23 is provided between a power transmitting member 18, acting as a rotary member placed on the first axis CL1 at an end portion thereof in opposition to the input rotary member 14, i.e., in opposition to an engine 8, and a first intermediate shaft (rotary member) 40, disposed on the second axis CL2 at an end portion thereof in opposition to the input rotary member 14, for power transmitting capability. Thus, a power transmitting path is formed in a C-shape, i.e., a U-shape with a reduction in size of the axial direction, enabling the miniaturization to provide a simplified structure without increasing the number of parallel shafts.

Owner:TOYOTA JIDOSHA KK

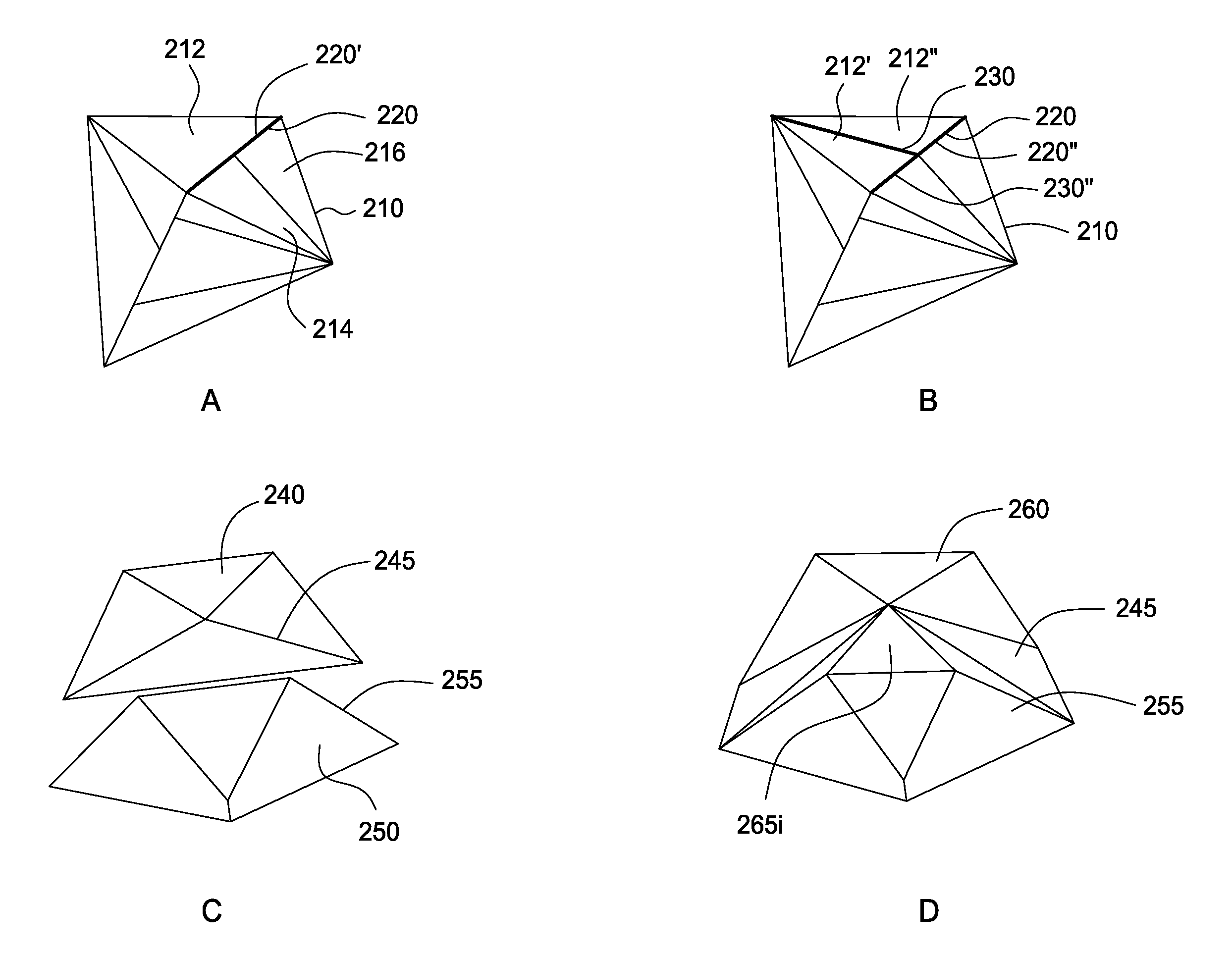

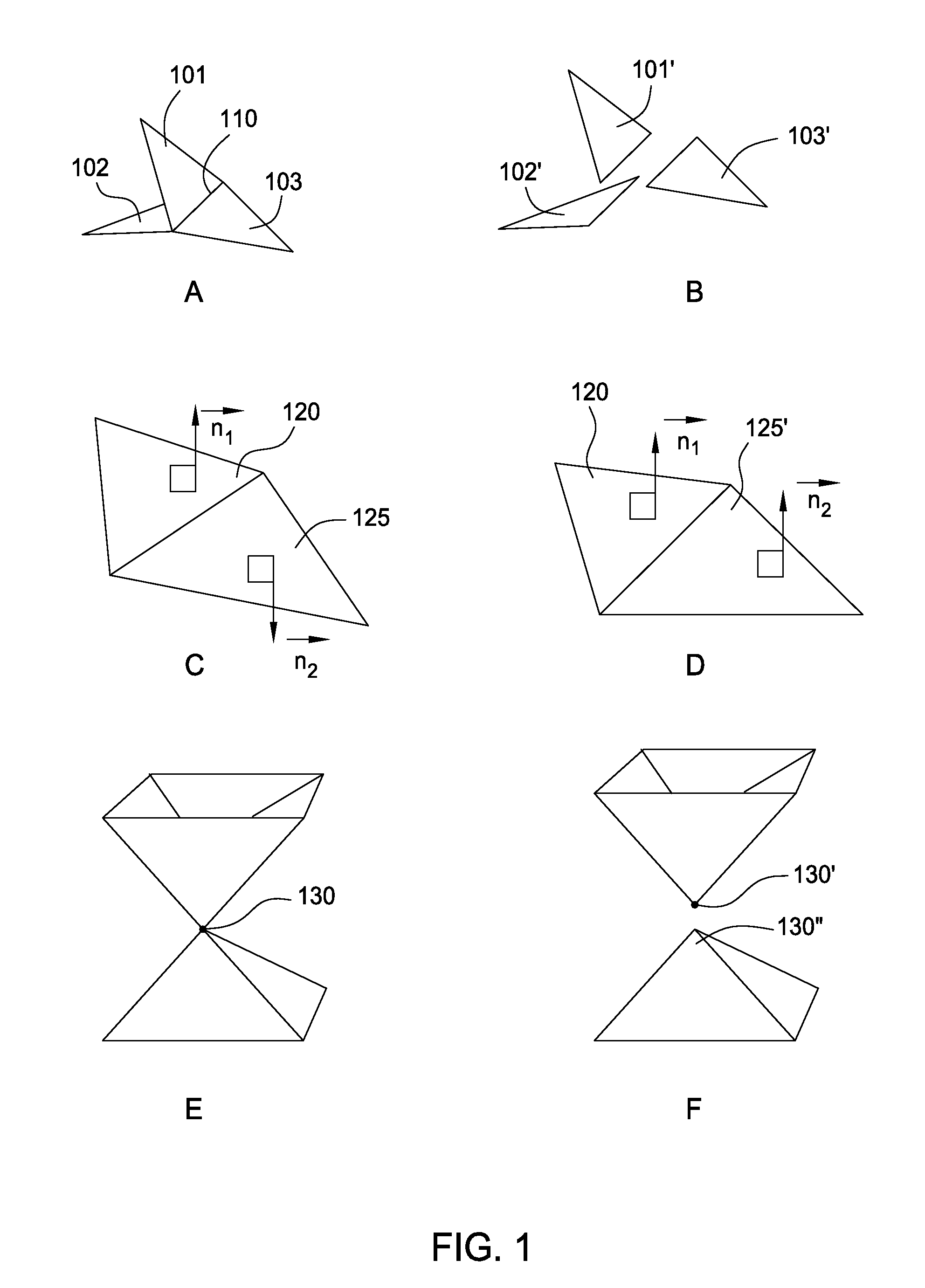

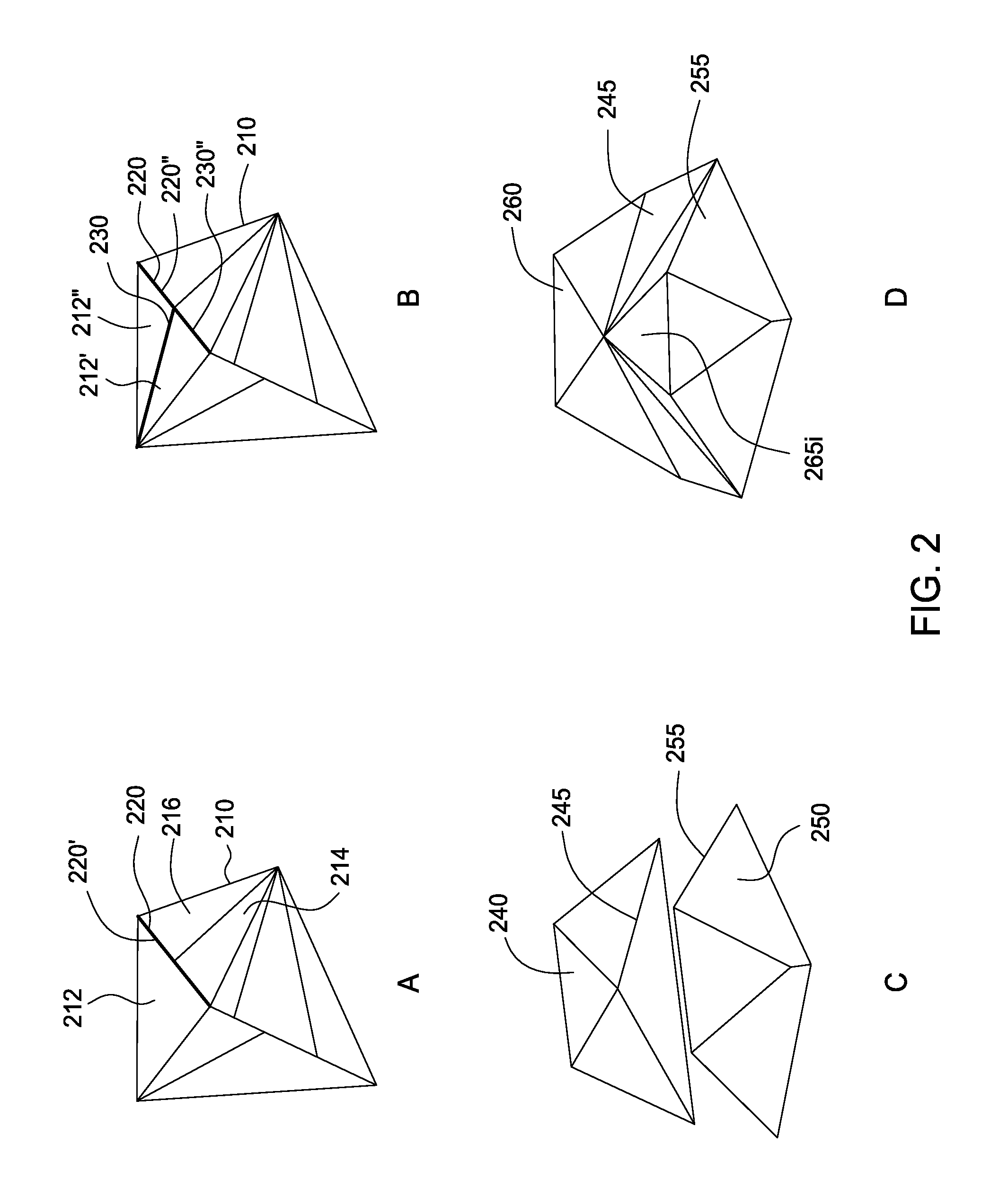

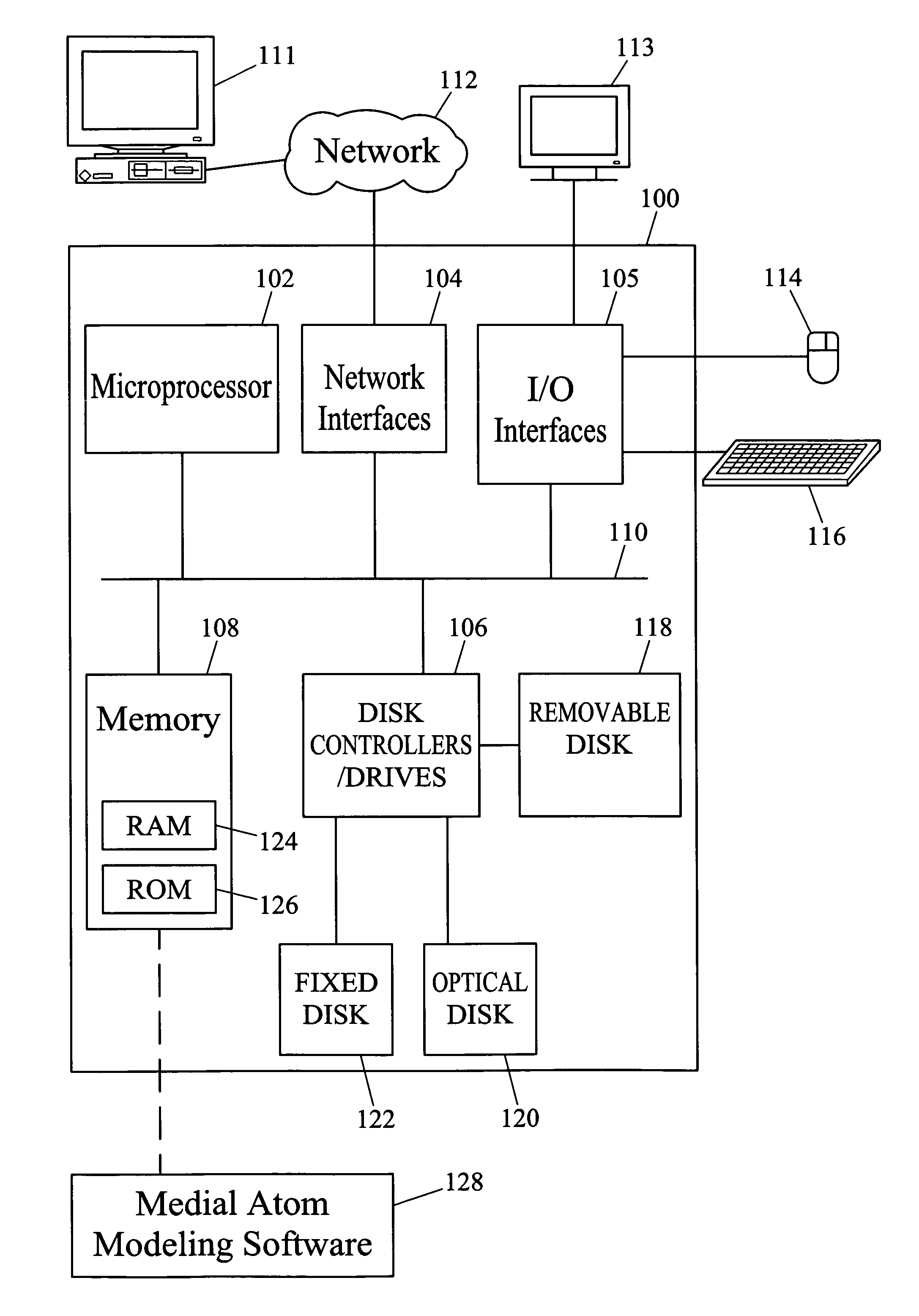

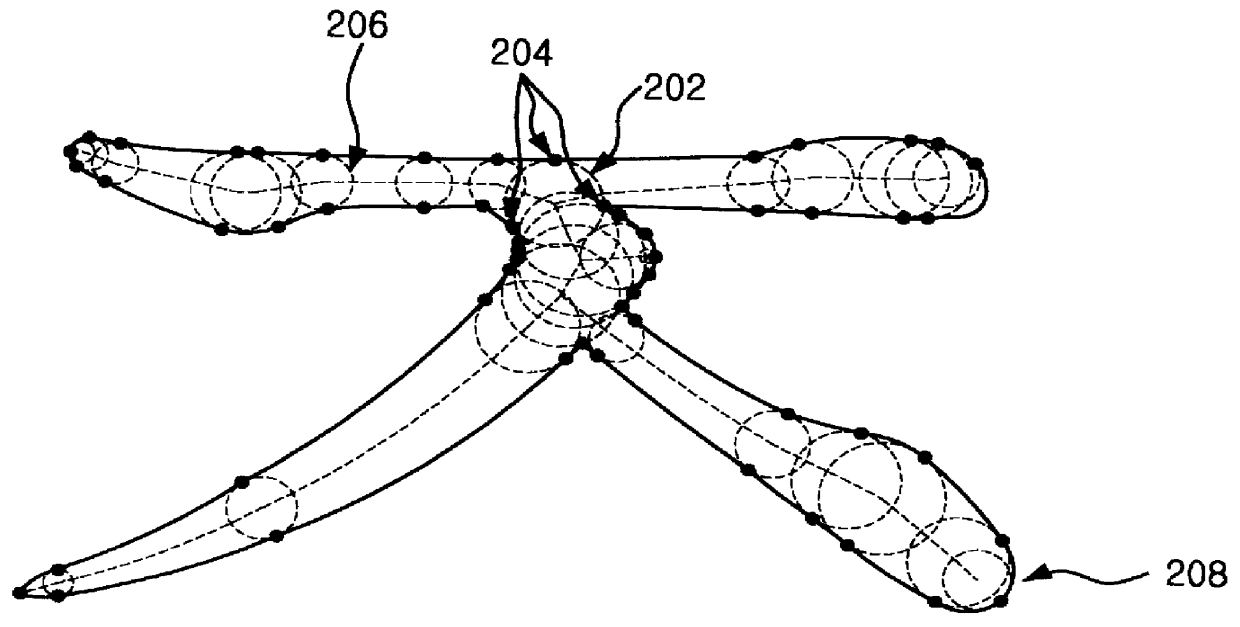

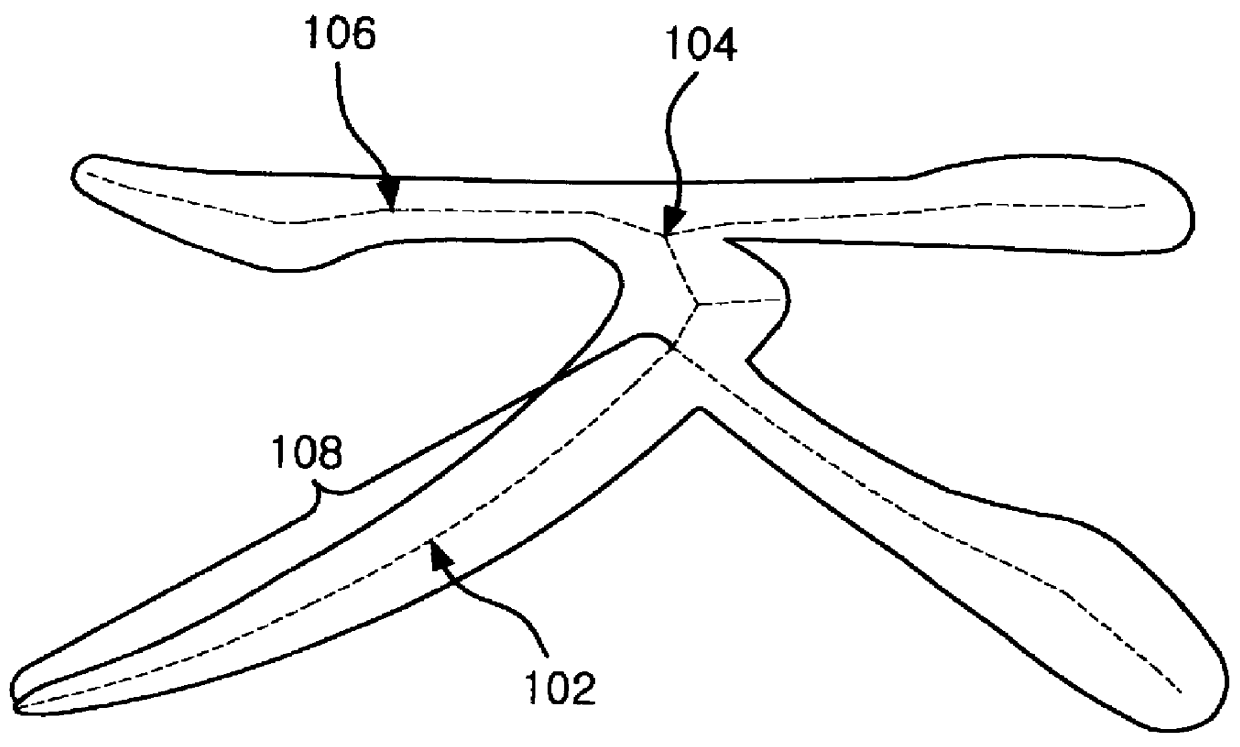

Methods and systems for modeling objects and object image data using medial atoms

ActiveUS7200251B2Shorten the timeReduce the amount requiredAnalogue computers for chemical processesCharacter and pattern recognitionGraphicsTwo-vector

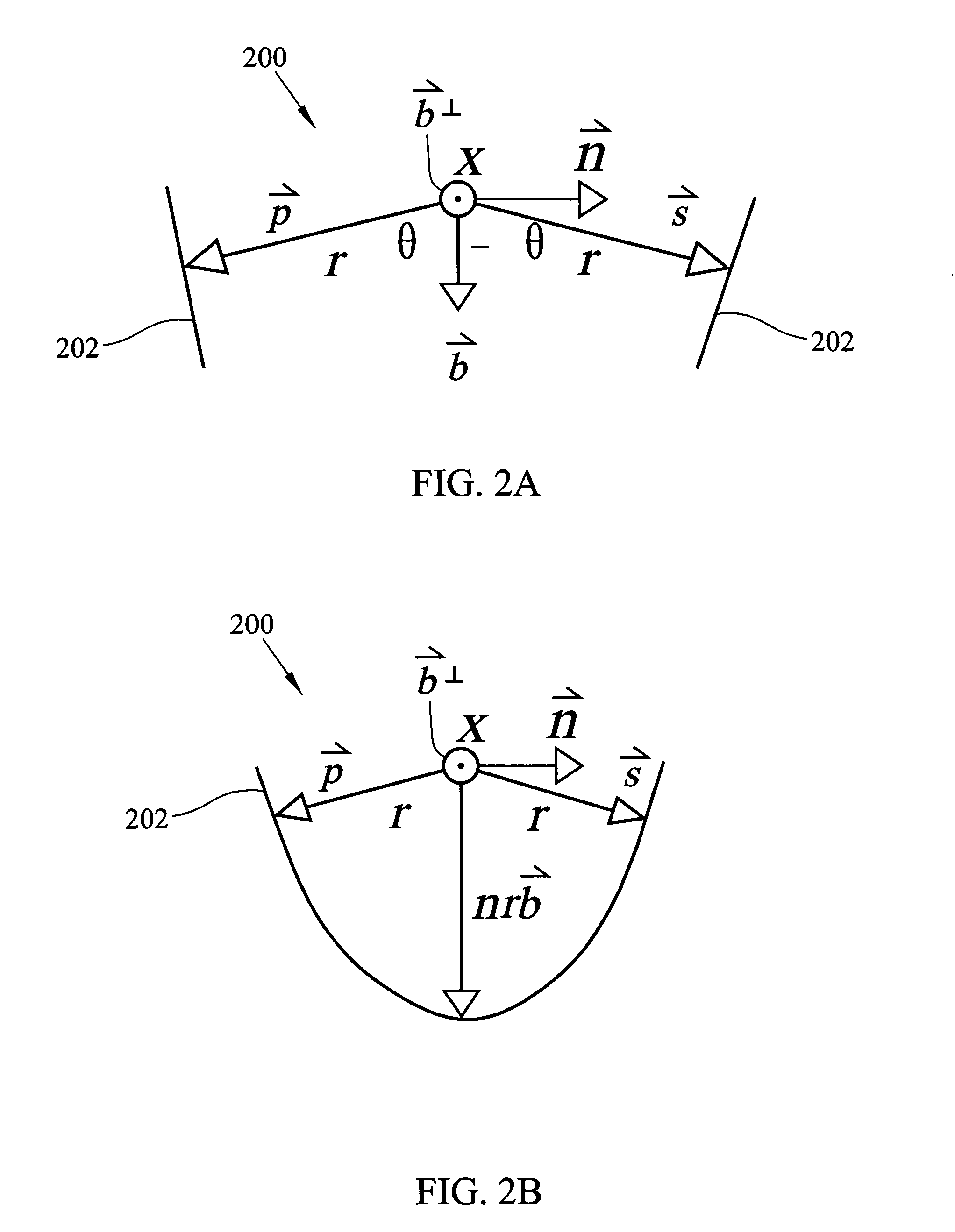

Methods and systems for modeling objects and object image data using medial atoms are disclosed. Objects and object image data can be modeled using medial atoms. Each medial atom includes at least two vectors having a common tail and extending towards an implied boundary of a model. The medial atoms may be aligned along one or more medial axes in the model. The model may include multiple sub-components, referred to as figures. The model and each of its figures may be represented in model-based and figure-based coordinates. The model may be automatically deformed into target image data using a hierarchy of geometric or probabilistic transformations.

Owner:NORTH CAROLINA UNIV OF THE

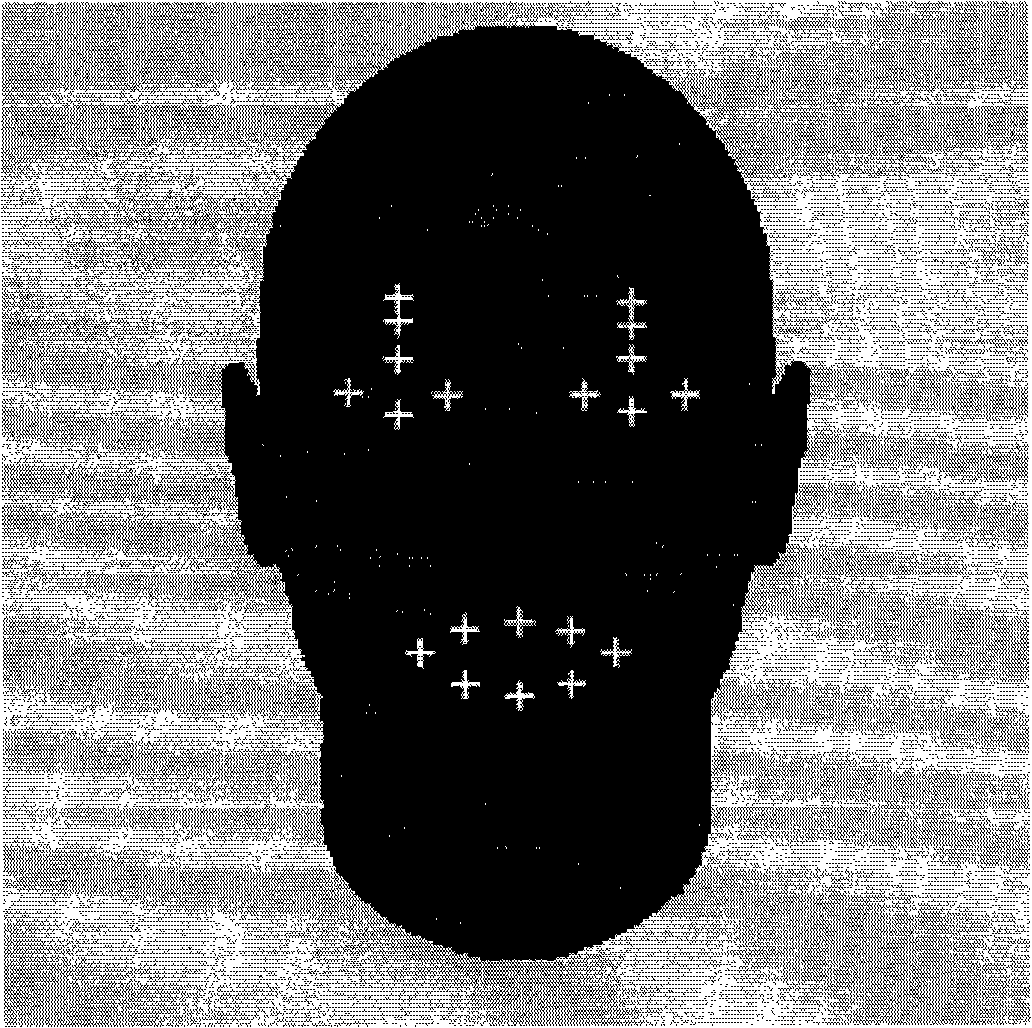

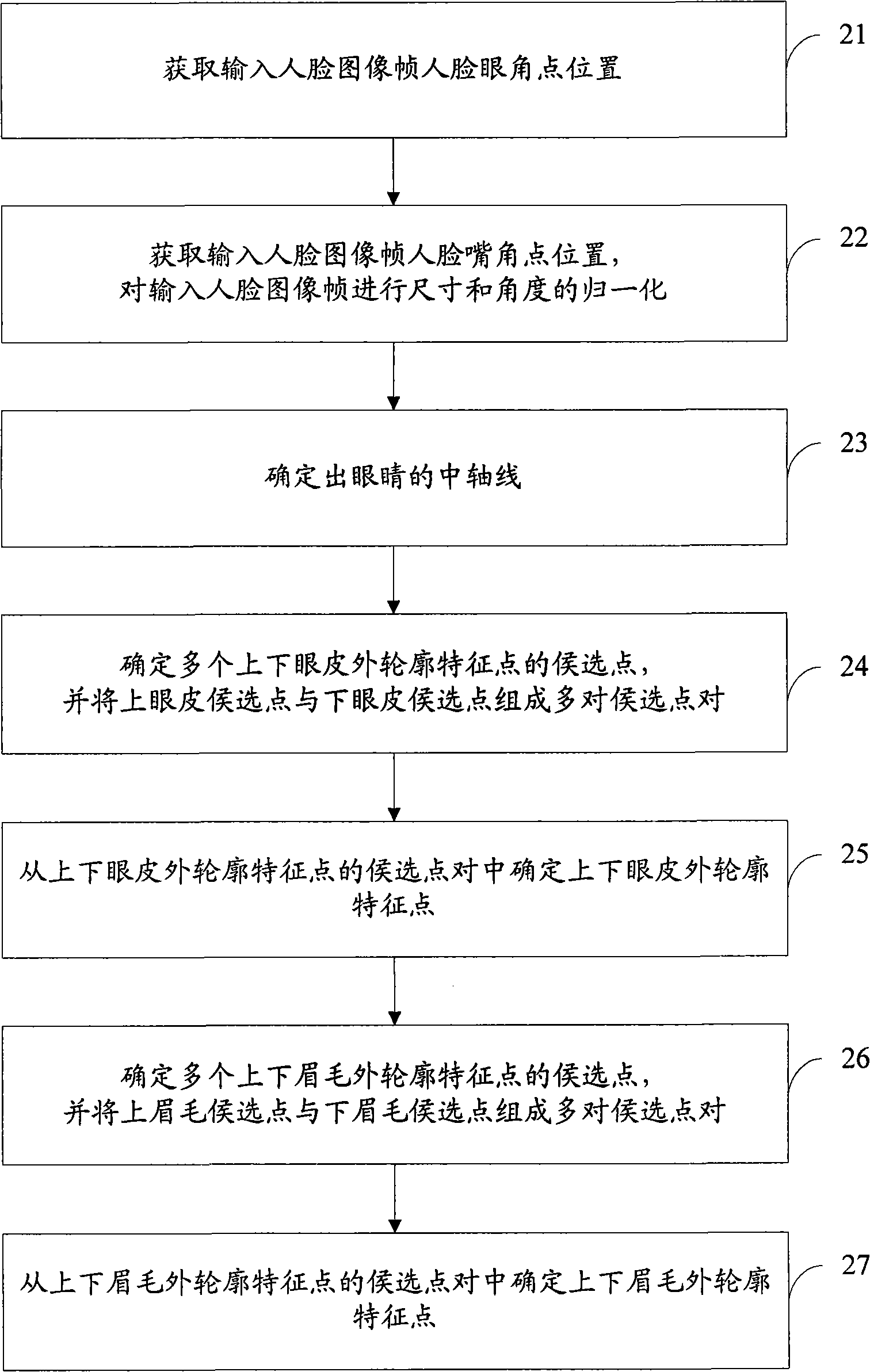

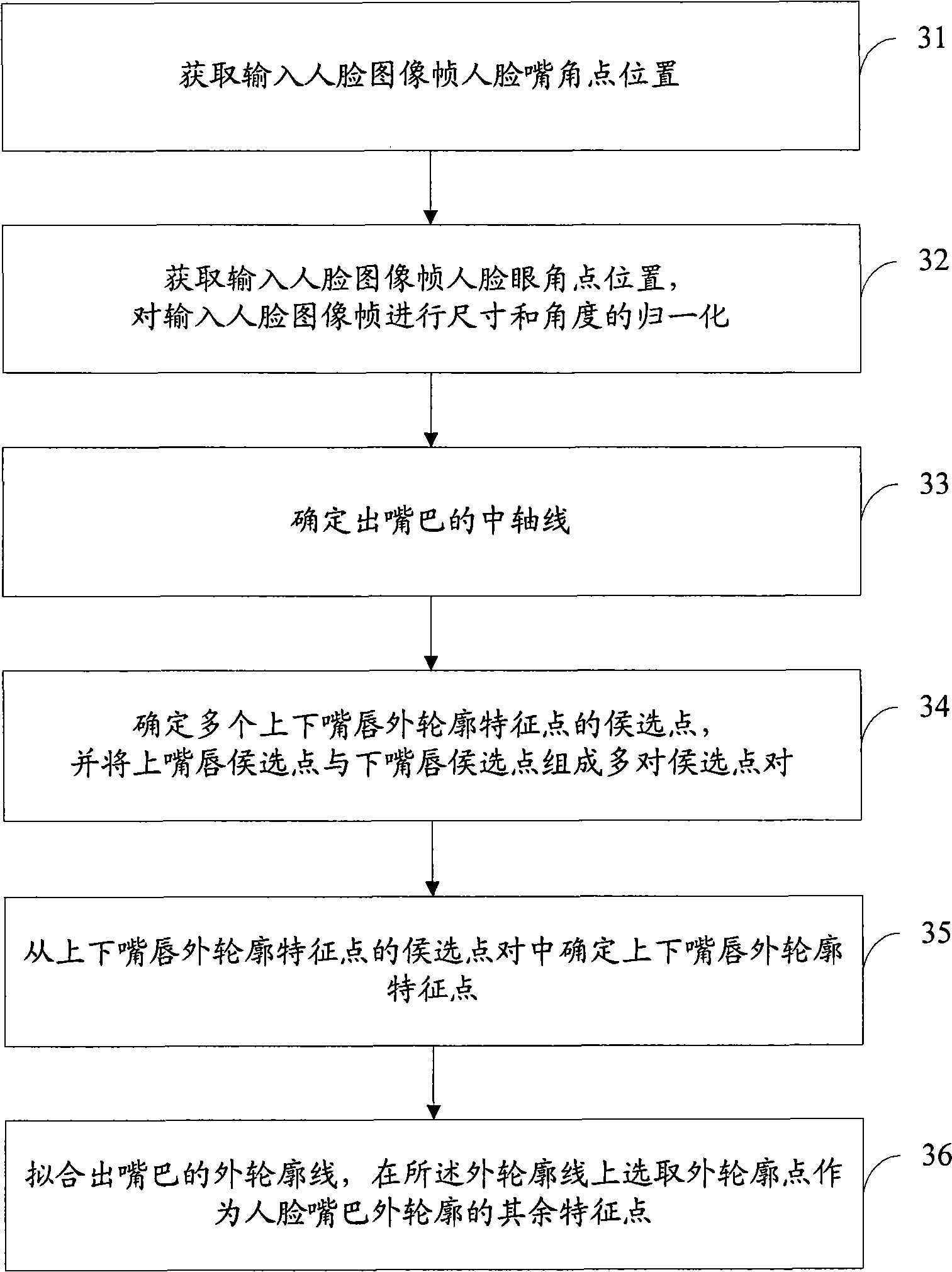

Human face critical organ contour characteristic points positioning and tracking method and device

The invention discloses a method for positioning and tracking outer contour feature points of key face organs and a device thereof, comprising the following steps: first, the positions of canthi points and angulus oris points on the face are obtained; the medial axis of the eyes and the mouth is identified based on the positions; the outer contour feature points of the eyes and eyebrows are identified on the medial axis of the eyes, and the outer contour feature points of the mouth are identified on the medial axis of the mouth. Consistent positioning and tracking of outer contour feature points of key face organs are conducted on such a basis. The technical proposal provided by the embodiment of the invention solves the problem of inaccurate positioning of outer contour feature points of eyes, mouth and eyebrows when people makes various faces; based on the positioning of the feature points, the existing two-dimensional and three-dimensional face models can be real-time driven, and face expressions and motions such as frowning, blinking and mouth opening of people before a camera can be real-time simulated, thus creating various real and vivid face animations.

Owner:BEIJING VIMICRO ARTIFICIAL INTELLIGENCE CHIP TECH CO LTD

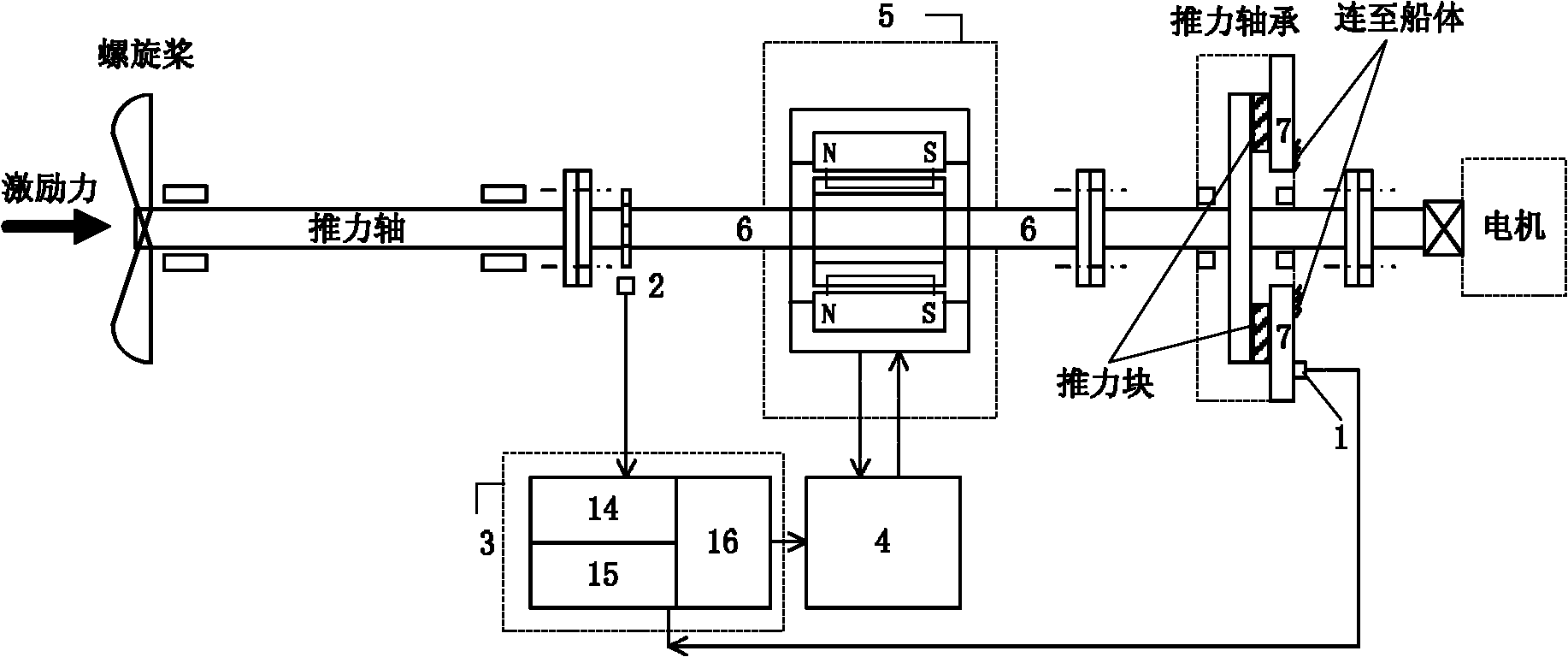

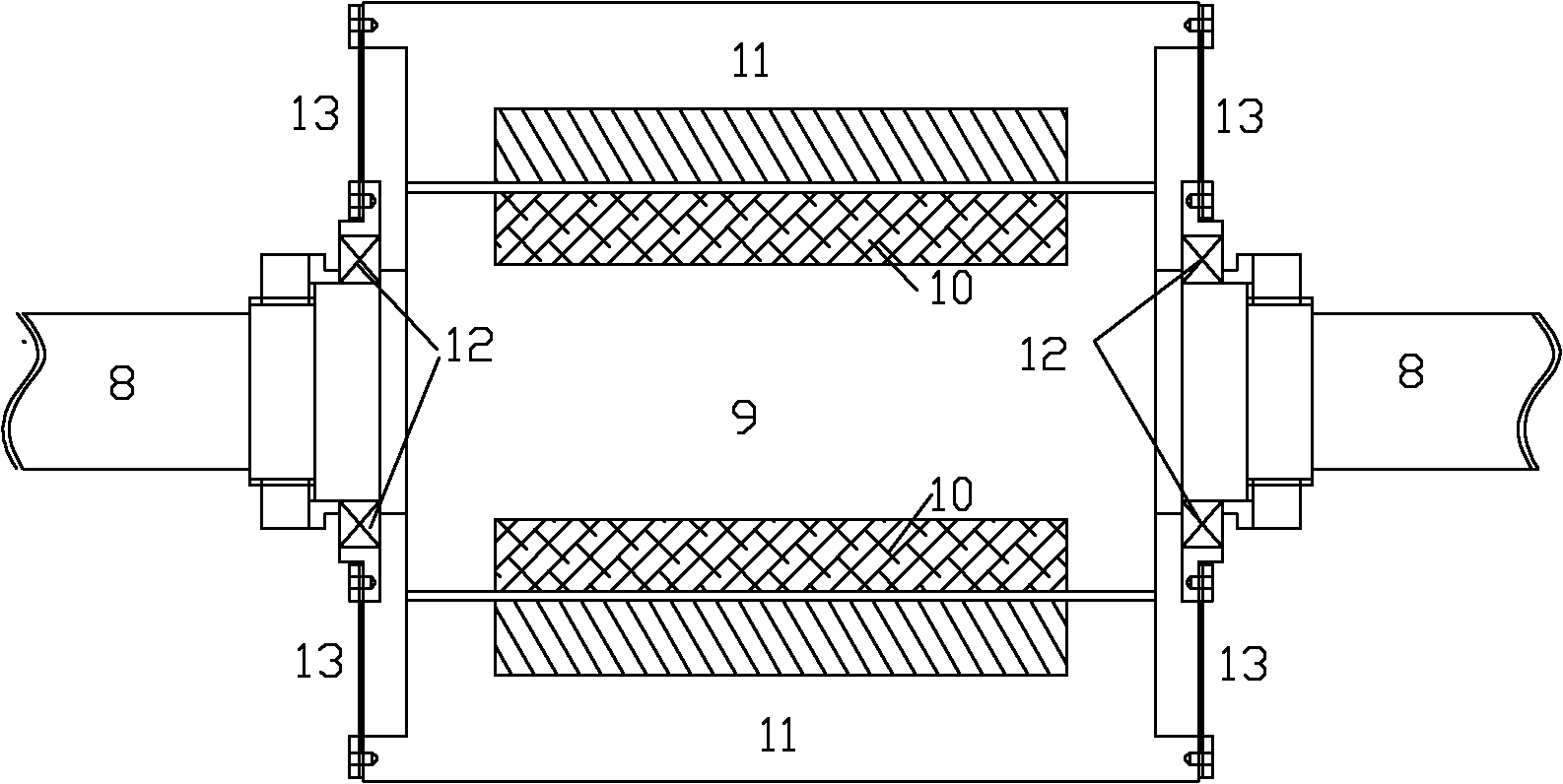

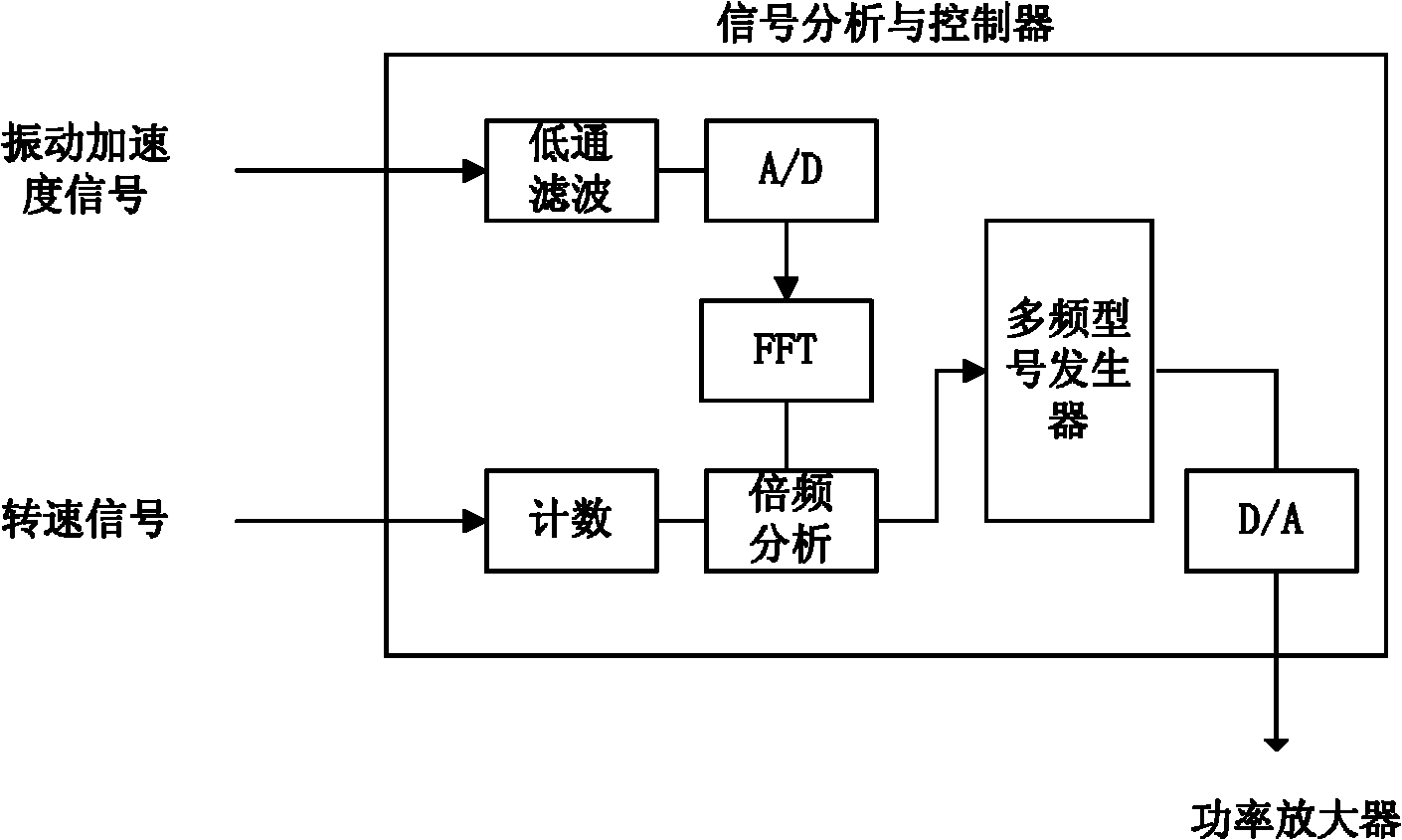

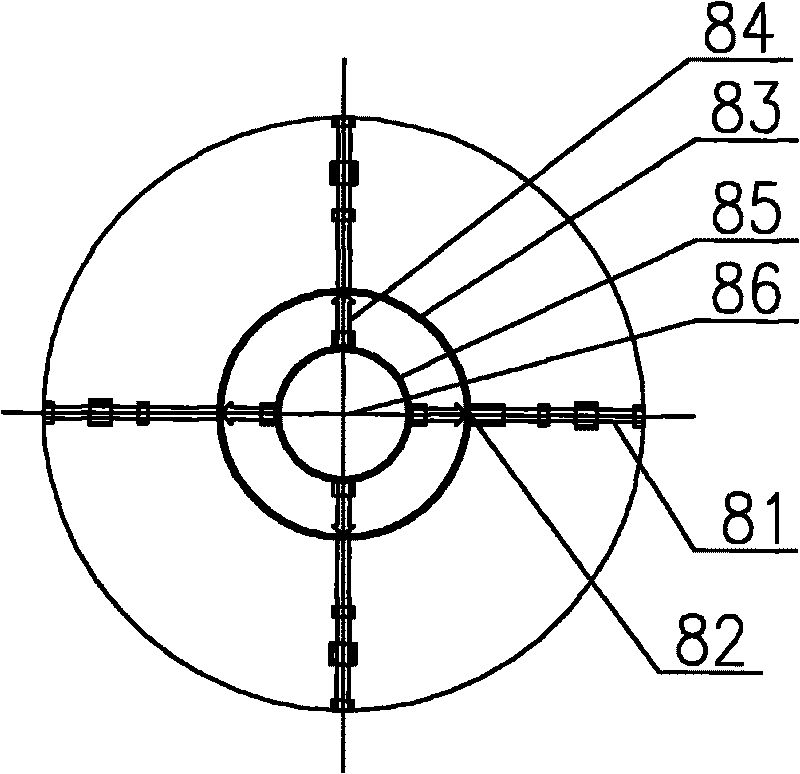

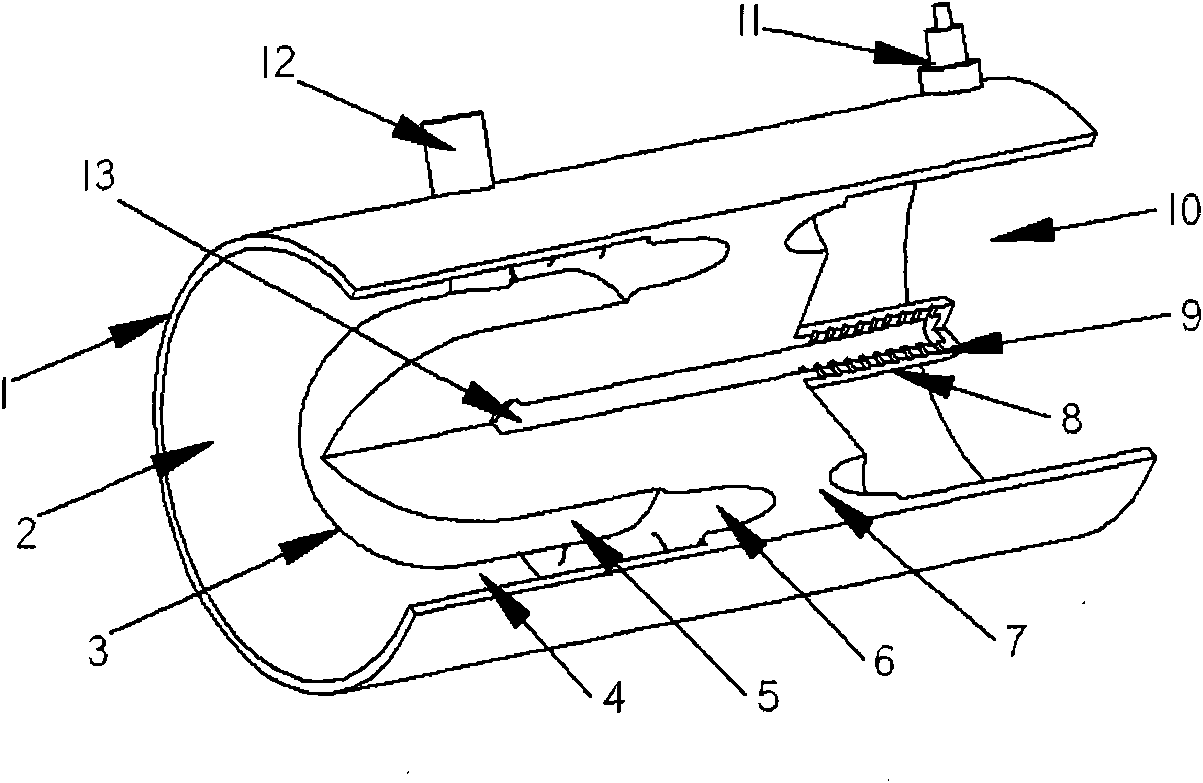

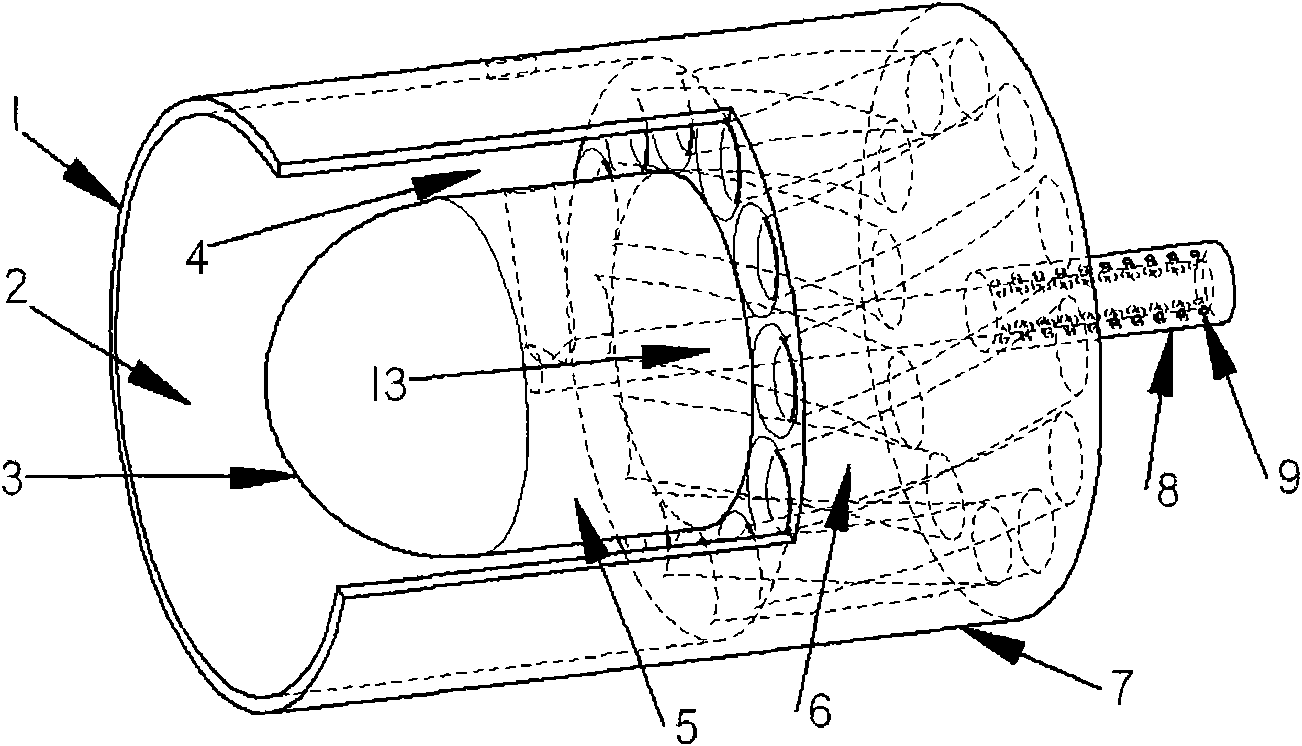

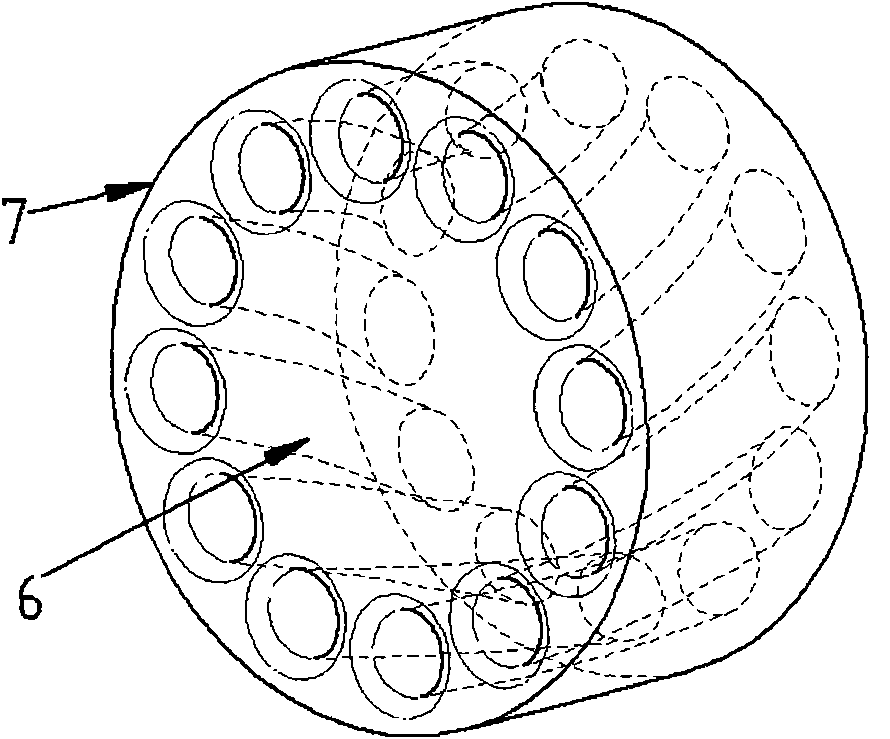

Electromagnetic active control device for longitudinal vibration of marine shafting

InactiveCN102072276AAvoid the disadvantages of vibration amplitude amplificationDoes not change intrinsic stiffness propertiesNon-rotating vibration suppressionWater acting propulsive elementsFrequency spectrumVibration acceleration

An electromagnetic active control device for longitudinal vibration of a marine shafting, belonging to the technical field of oceanographic engineering, comprises: an acceleration transducer, a tachometer, a signal analysis and control module, a power amplifier and an electromagnetic actuator, wherein the acceleration transducer and the tachometer are respectively located on a thrust bearing base and a middle shaft and output a measured vibration acceleration electric signal of the base and a photoelectric signal of the shafting to the signal analysis and control module; the signal analysis and control module receives the vibration acceleration electric signal and the photoelectric signal, performs spectrum analysis and characteristic signal extraction on the received signals to generate corresponding action control signals, and outputs the action control signals to the power amplifier for amplification; and the electromagnetic actuator is arranged on the middle shaft and receives the amplified control signals to generate a corresponding longitudinal actuation force applied on the middle shaft, thereby implementing the control for the longitudinal vibration of the shafting. The electromagnetic active control device for longitudinal vibration of the marine shafting effectively reduces the longitudinal vibration of the shafting, so that vibration response of a marine structure is reduced finally, and the control device not only is effective to low frequency line spectra, but also has excellent control effect on broadband random excitation.

Owner:SHANGHAI JIAO TONG UNIV

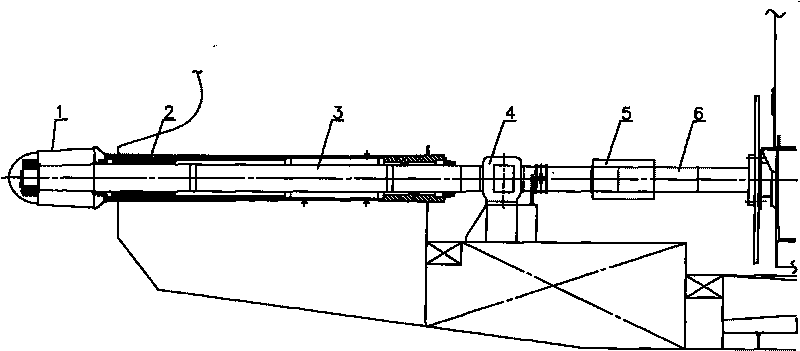

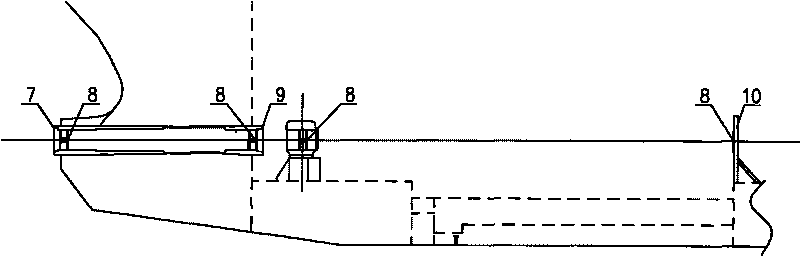

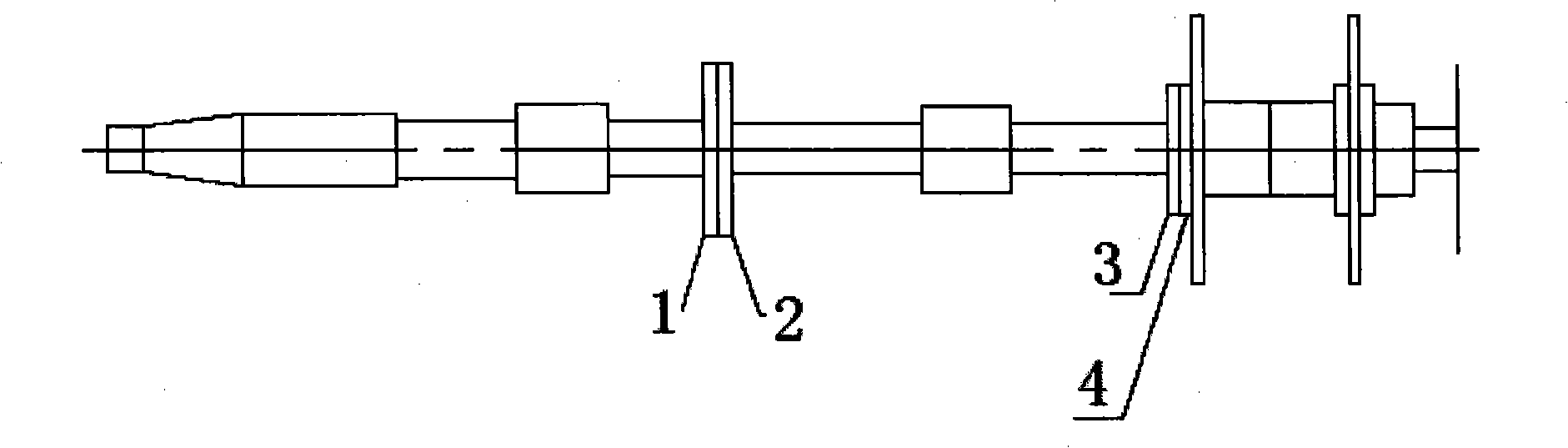

Installation method of ship single shafting without setting front bearing of stern shaft tube

ActiveCN101723057AControl precisionGuaranteed accuracyVessel partsMedial axisPulp and paper industry

The invention discloses an installation method of ship single shafting without setting a front bearing of a stern shaft tube, mainly comprising the following steps of: determining the position of a boring hole of a bearing installing hole by using a tail datum point and a head datum point on a shafting central line as datum and adopting an illumination method; positioning a middle bearing by using the central point of a bearing installing hole at the front end of the stern shaft tube and the central point of the bearing installing hole at the back end as the datum and adopting the illumination method; and hoisting a stern shaft, a central shaft and a main machine and then connecting the central shaft with the stern shaft into single shafting. The invention initially positions the central bearing through adopting the illumination method twice to ensure that the installation precision of the ship single shafting without setting the front bearing of the stern shaft tube is effectively controlled, and can enhance the installation efficiency, ensure the installation precision of the shafting and accord with the requirements of the ship design, and the shafting installed by the installation method can run more stably so as to ensure the using safety of the bearing and the main machine.

Owner:JIANGNAN SHIPYARD GRP CO LTD

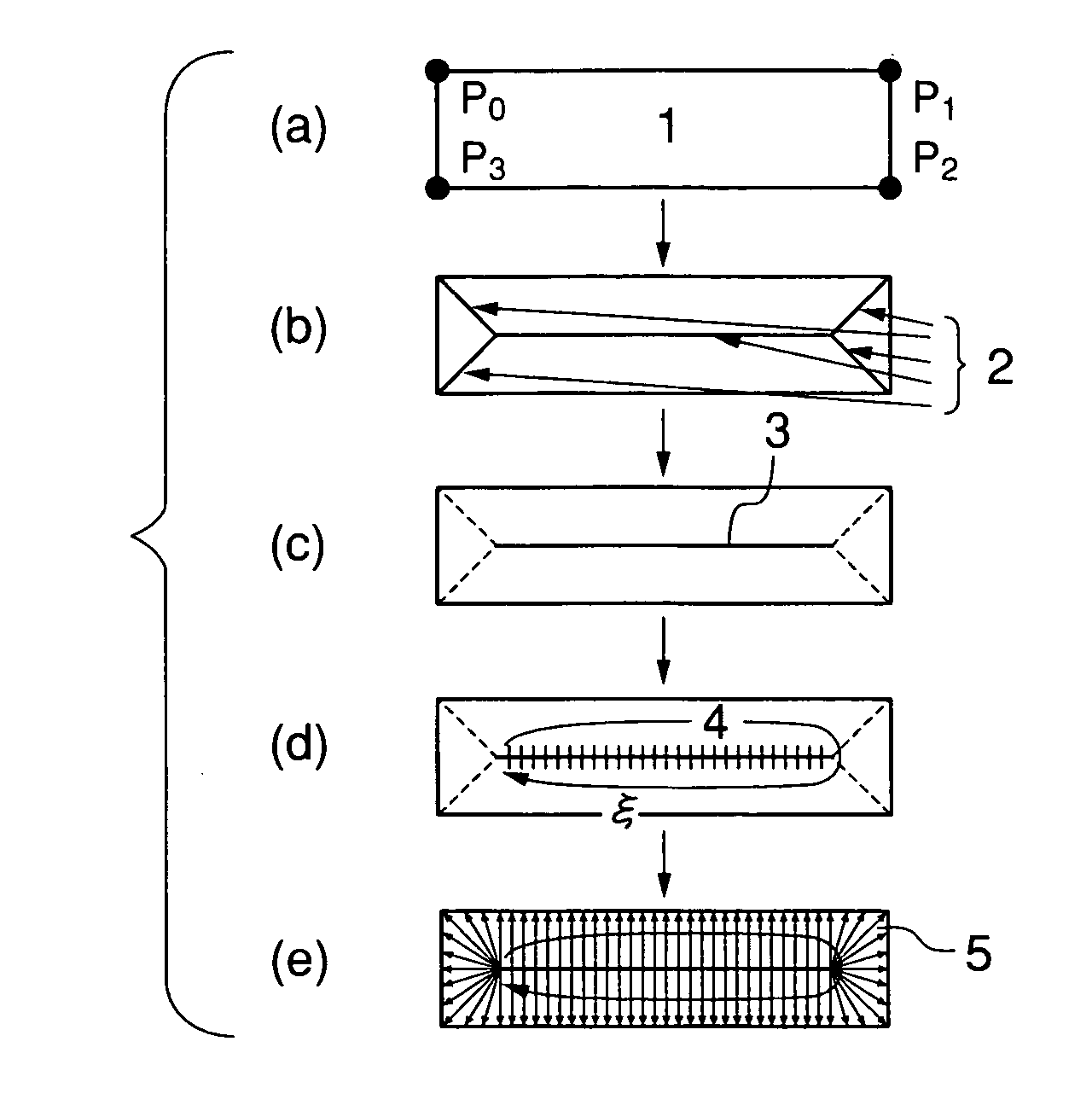

Methods of transforming a basic shape element of a character

The present invention relates to an outline font. The purpose lies in supplying a transforming and rendering method in the shape where the important form of the shape, such as the thickness of the stroke, will be maintained from the basic shape, and at the same time the whole size of the shape can be fitted into a given bounding box. The present invention supplies the transformation method of a handwriting font including searching for the medial axis of a given element, obtaining contact points by using maximal inscribed circles with the medial axis and points of the medial axis as a center, and applying the information about the medial axis points and the contact points in case of a transformation of the element in the transformation method of handwriting where a given element can be optionally transformed in sizes in order to achieve the purpose. The present invention enables the transformation of the shape. In resizing the given element from the box surrounding element to the box where the new element is placed, the important form of the shape, such as the thickness of the stroke, is maintained, and at the same time the size of the whole is transformed in accordance with the optionally given box.

Owner:HYUNDAI ELECTRONICS IND CO LTD +2

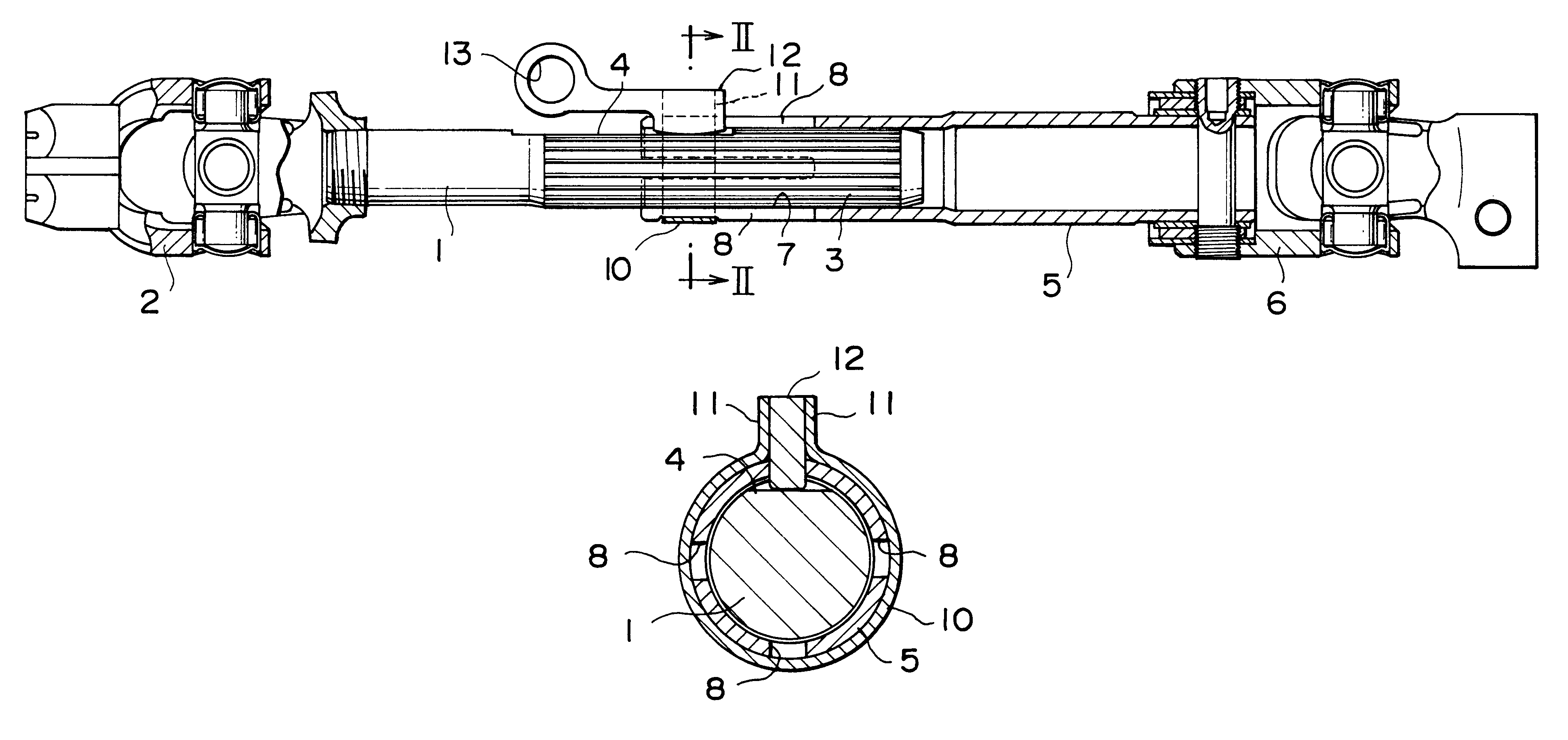

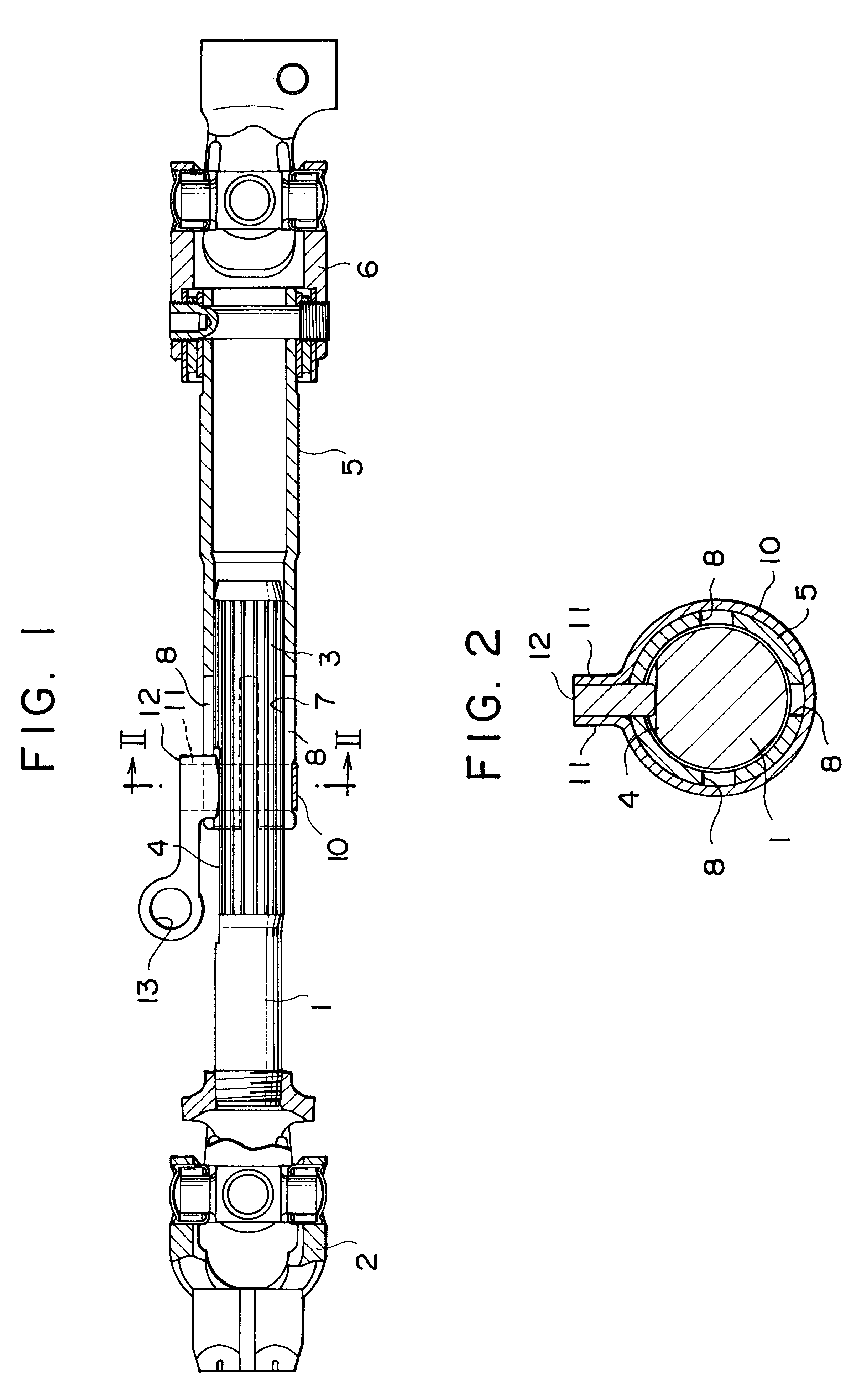

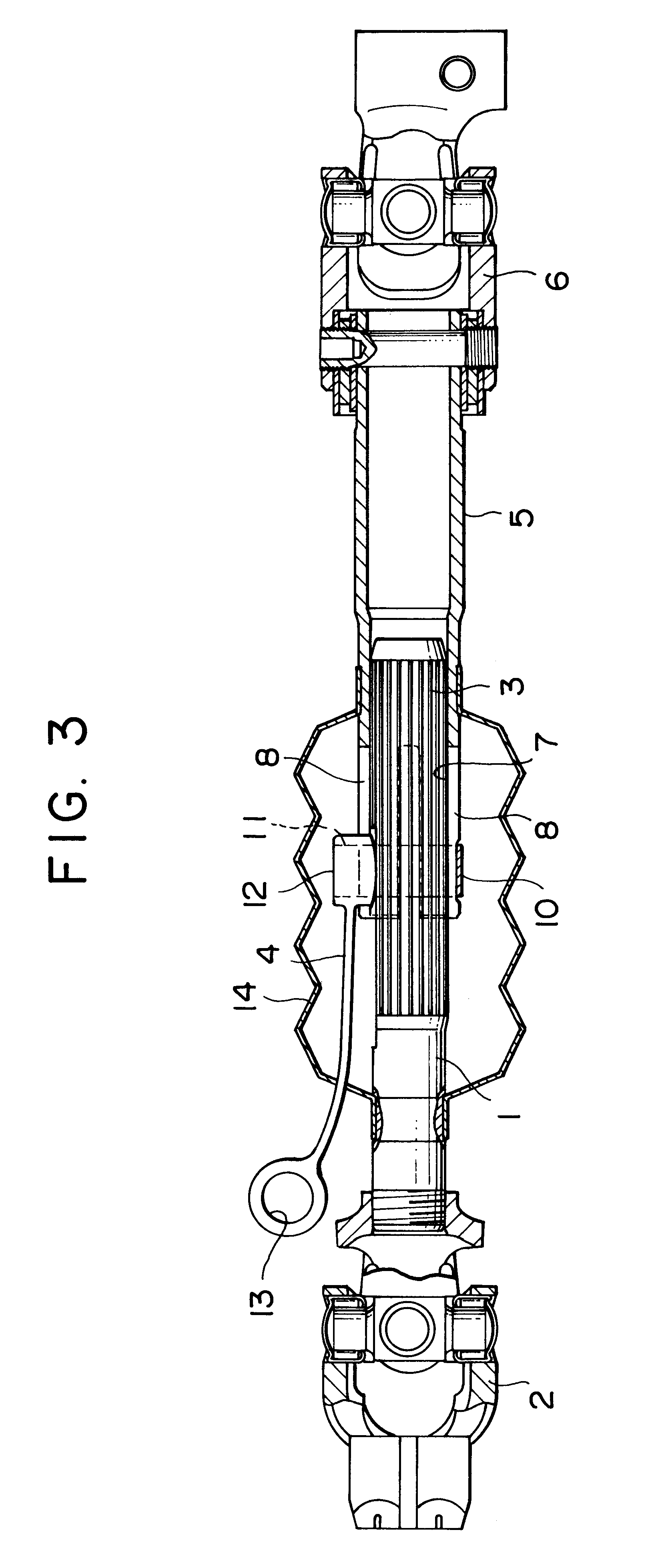

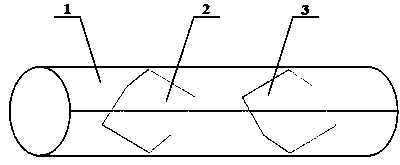

Coupling structure of variable length shaft

InactiveUS6267528B1Reduce pipe resistanceImprove workabilityYielding couplingShaftsCouplingMedial axis

A coupling structure of a variable length shaft, comprises a pipe member having an end formed with a plurality of slits elongated in the axial direction to be capable of expanding and diminishing in diameter, an intermediate shaft spline-fitted in the end of the pipe member, and a ring member fitted on an outer periphery of the end of the pipe member, the intermediate shaft being fastened by the end of the pipe member. A holder is releasably attached to an end of the ring member to expand a diameter thereof and thereby reduce a slide frictional resistance of the pipe member against the intermediate shaft. When the holder is released, the ring member diminishes in diameter, and a fastening force of the pipe member on the intermediate shaft is increased.

Owner:NSK LTD

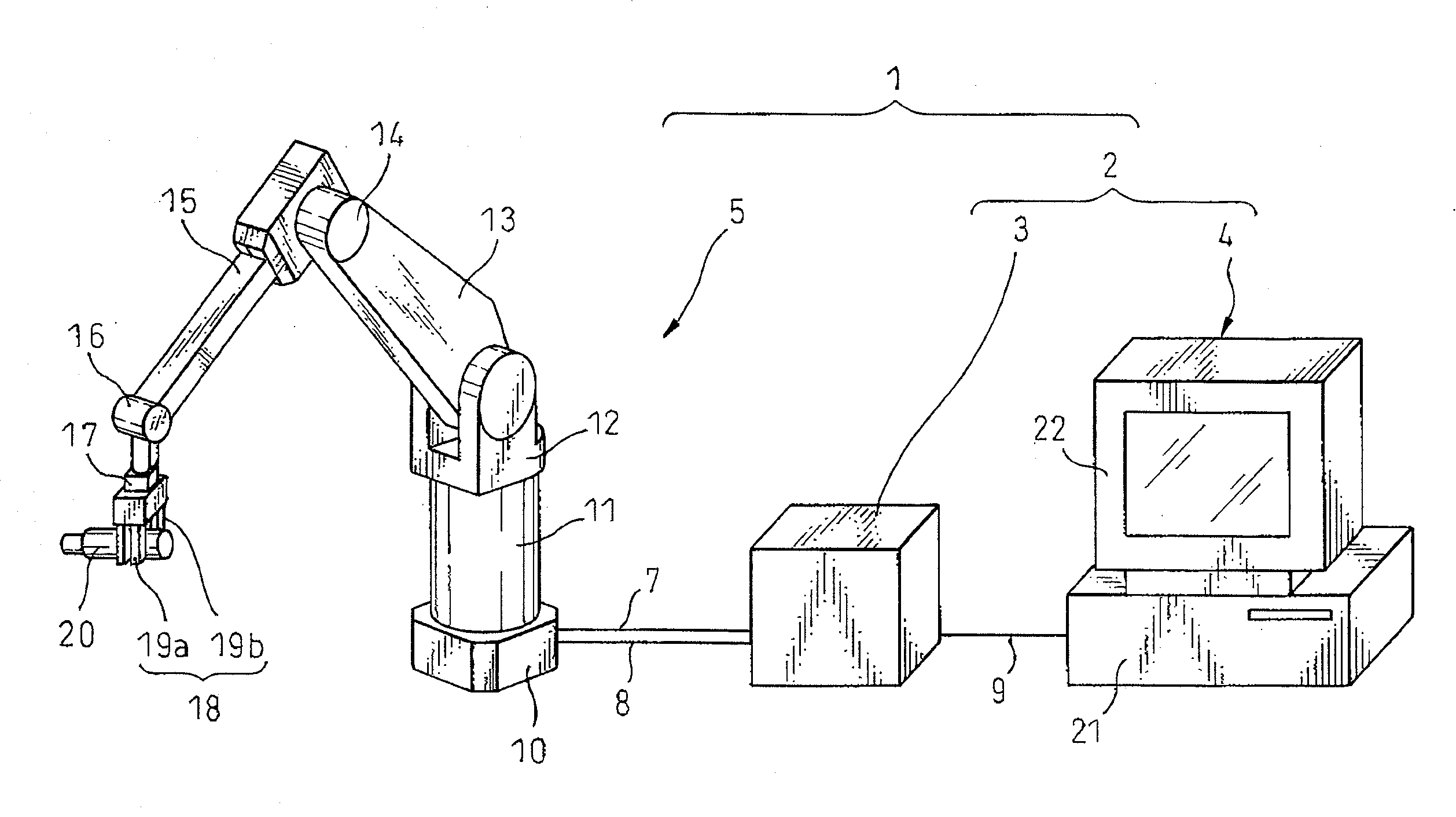

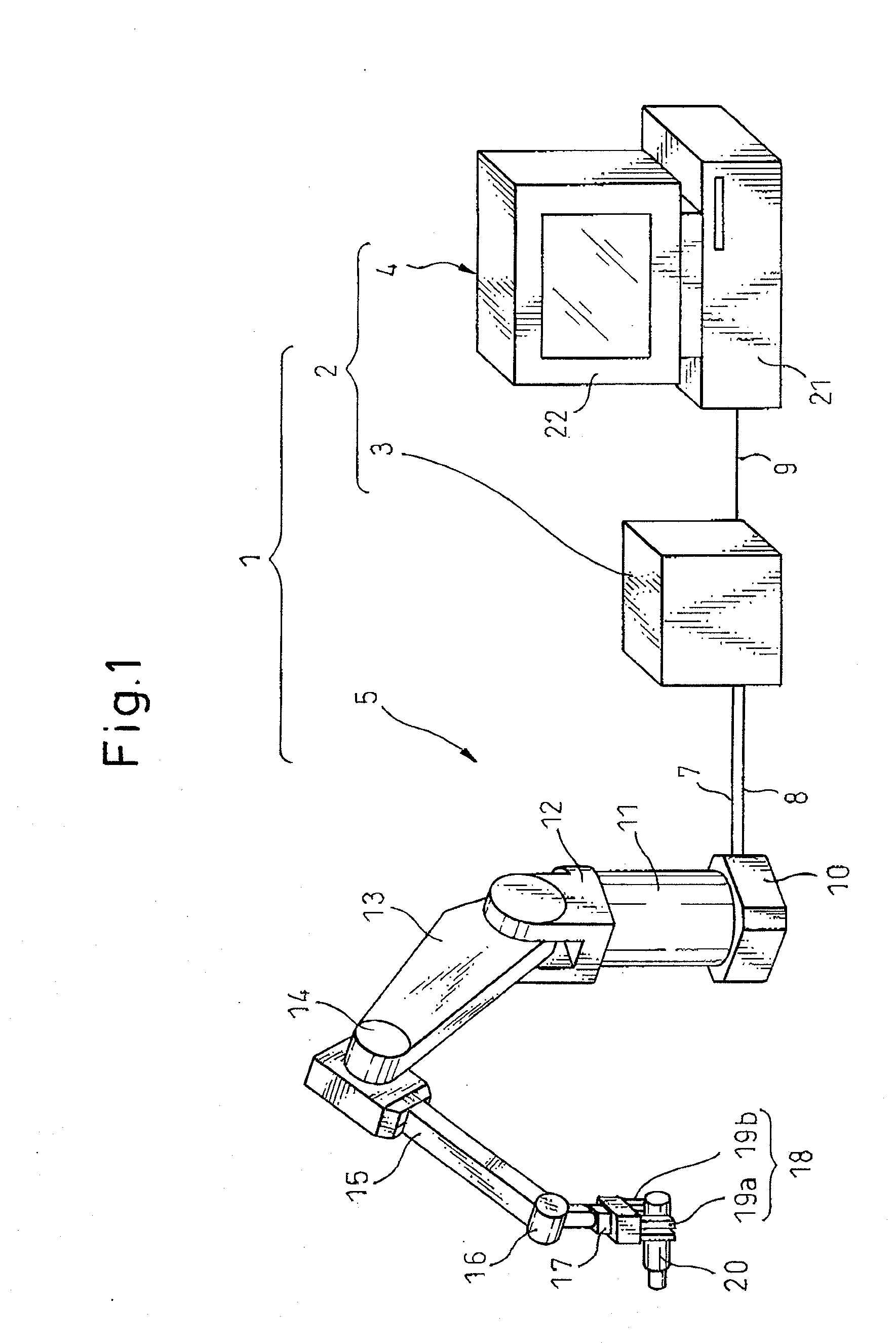

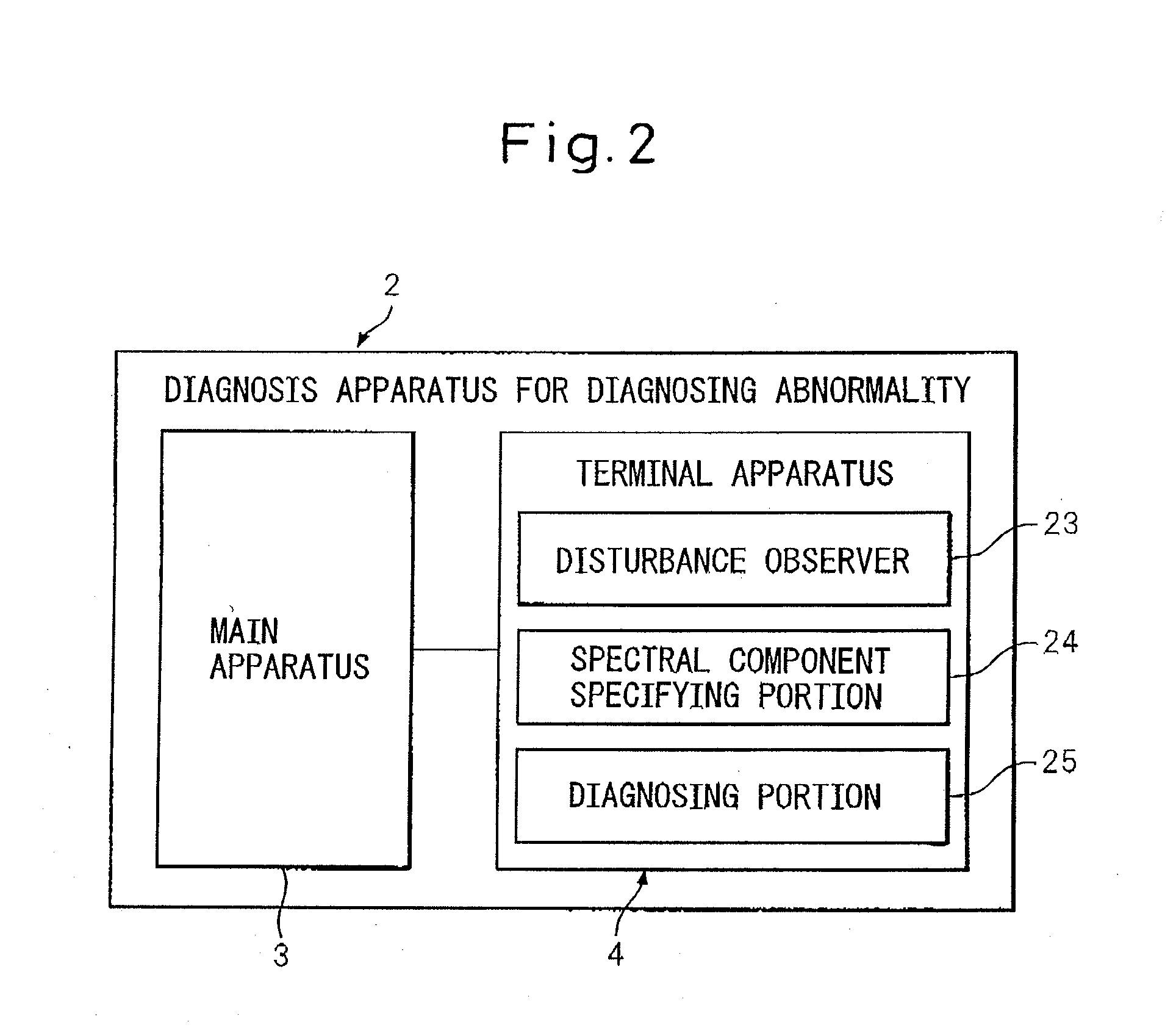

Method of diagnosing abnormality of reduction gear and apparatus for carry out the method

InactiveUS20080215292A1Improve usabilityIncrease productivityMachine part testingNuclear monitoringFrequency spectrumMedial axis

An apparatus for carry out a method of diagnosing abnormality of a reduction gear, the reduction gear including an intermediate shaft element disposed between an input shaft and an output shaft and rotating in proportion to a rotation of the input shaft to transmit the rotation to the output shaft, the apparatus has: a disturbance observer that obtains an estimated disturbance value regarding the reduction gear, based on a torque instruction and a velocity feedback-value acquired when a pair of driven members which rotate relative to each other with a motor as a driving source are in relative rotation at a constant velocity; a specific spectral component specifying portion for extracting a specific spectral component corresponding to a constant multiple of a rotational frequency of the intermediate shaft element from a frequency components of the estimated disturbance value obtained by frequency analysis; and a diagnosing portion, which compares an amplitude of the specific spectral component specified by the specific spectral component specifying portion with a threshold value, and diagnoses an abnormality in a case where the amplitude of the specific spectral component exceeds the threshold value, or a normality in a case where the amplitude of the specific spectral component is equal to or less than the threshold value.

Owner:FANUC LTD

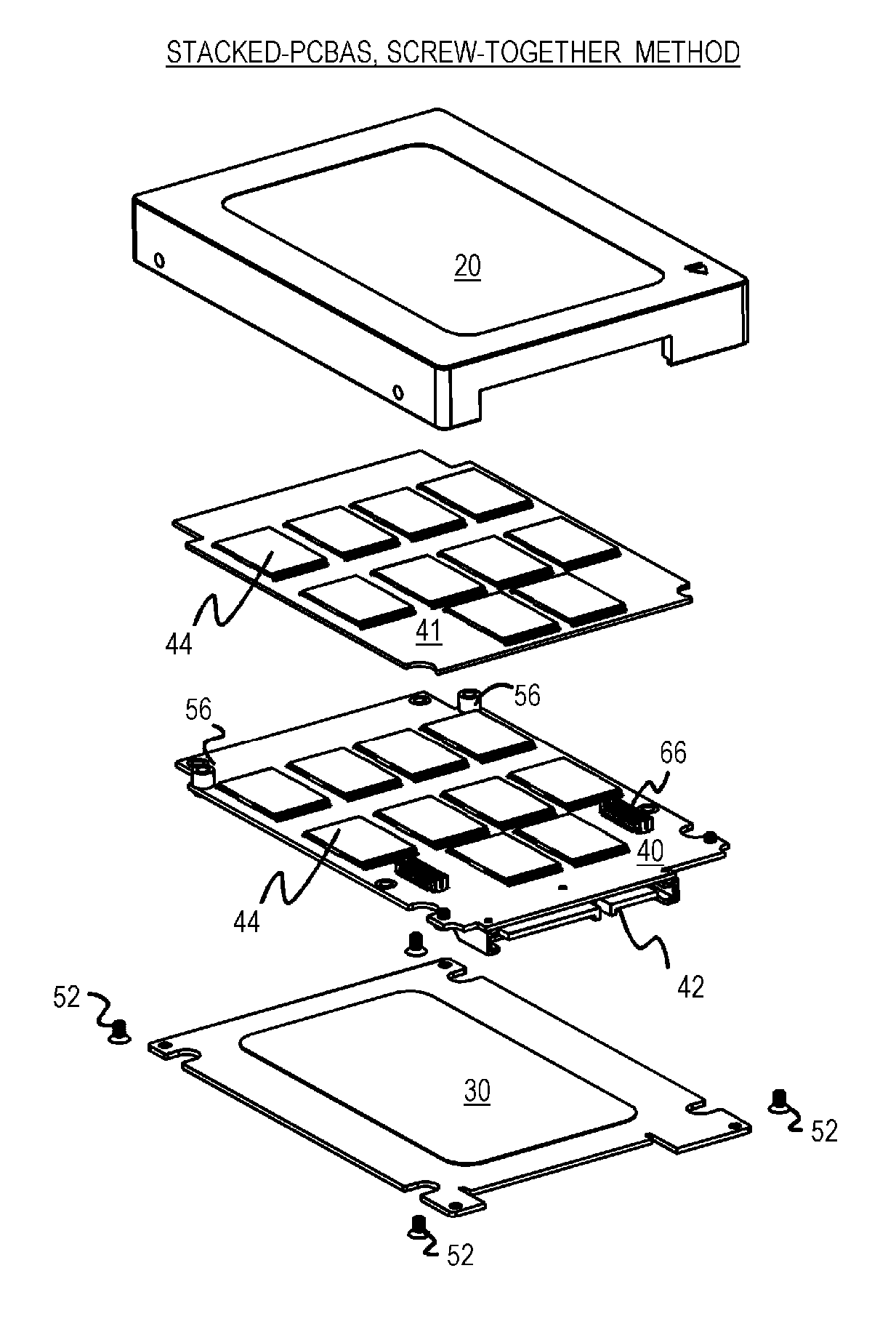

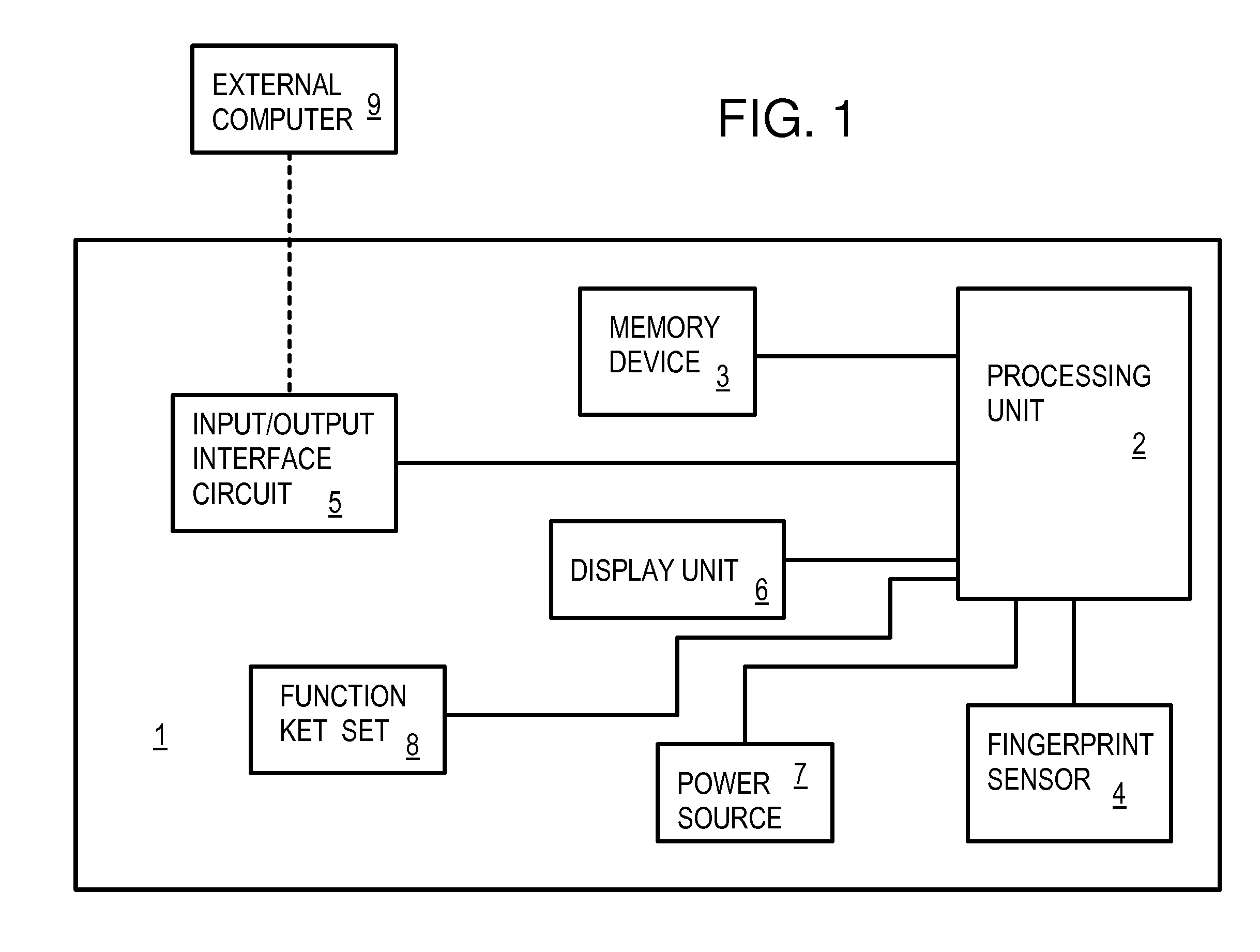

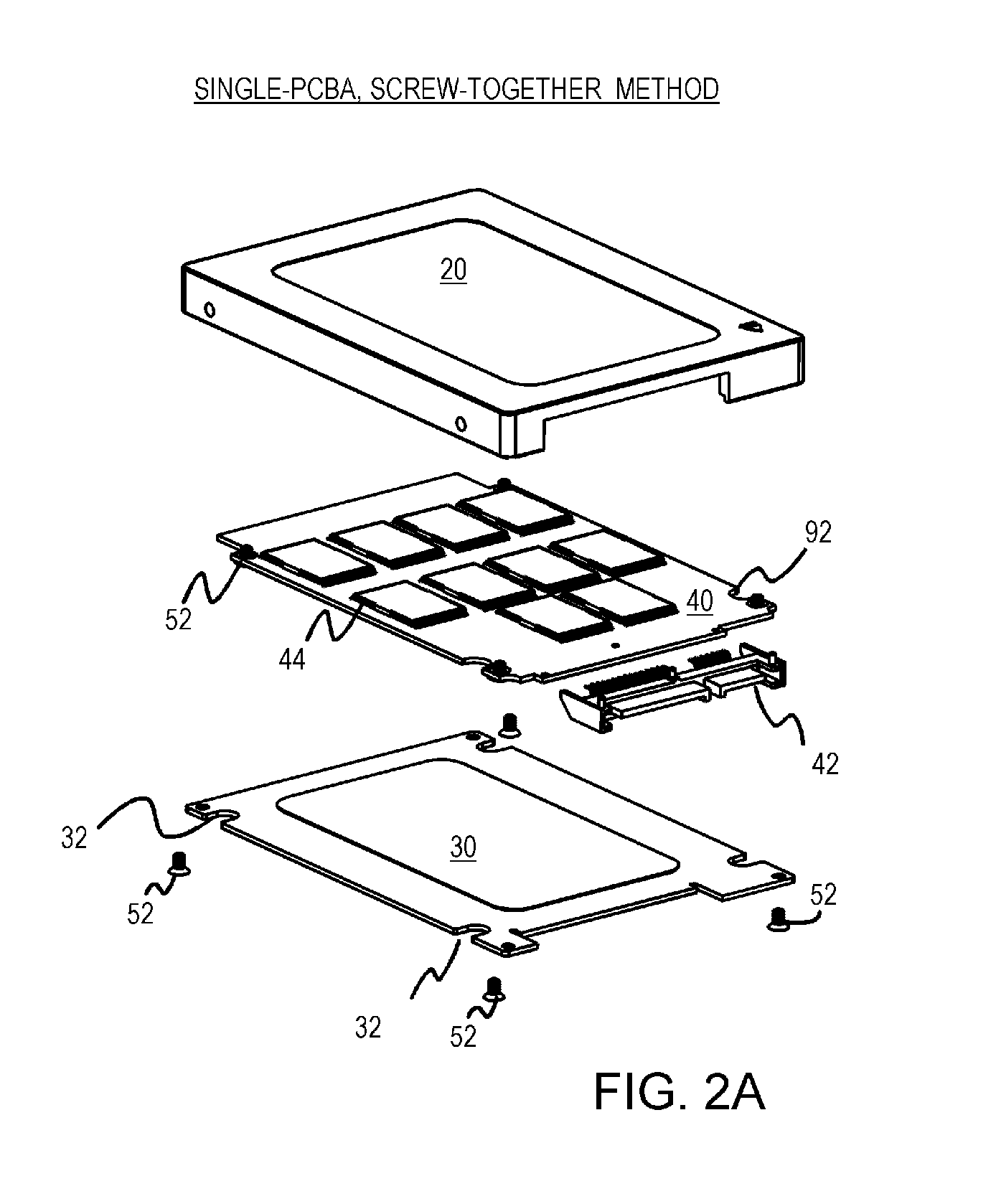

Hard Drive with Metal Casing and Ground Pin Standoff to Reduce ESD Damage to Stacked PCBA's

A case-grounded flash-memory drive has a printed-circuit board assembly (PCBA) with flash-memory chips and a controller chip. The PCBA is encased inside an upper case and a lower case, with a Serial AT-Attachment (SATA) connector that fits through an opening between the cases. The cases can be assembled with the PCBA by a screw-together or thermal-bond adhesive method. Triple-axis case-grounding tabs draw any electro-static-discharges (ESD) current off the upper case along a primary axis and onto a PCBA ground through a secondary axis that is screwed into the PCBA. An intermediary axis between the primary and secondary axes fits around a PCBA notch while the secondary axis passes through a metalized alignment hole on the PCBA for grounding. When the SATA connector is inserted into a host, the host ground sinks ESD currents collected by the triple-axis case-grounding tabs.

Owner:SUPER TALENT ELECTRONICS

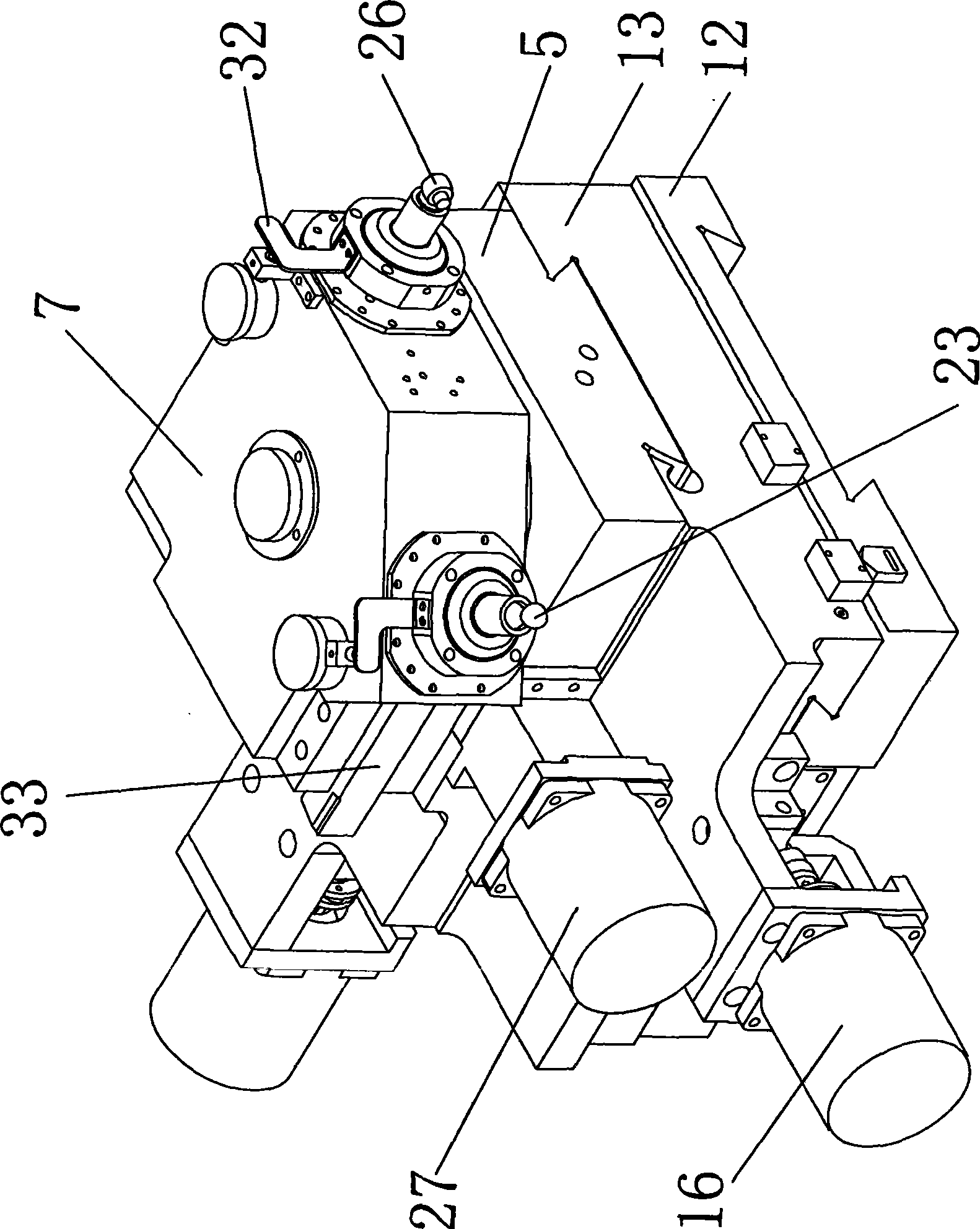

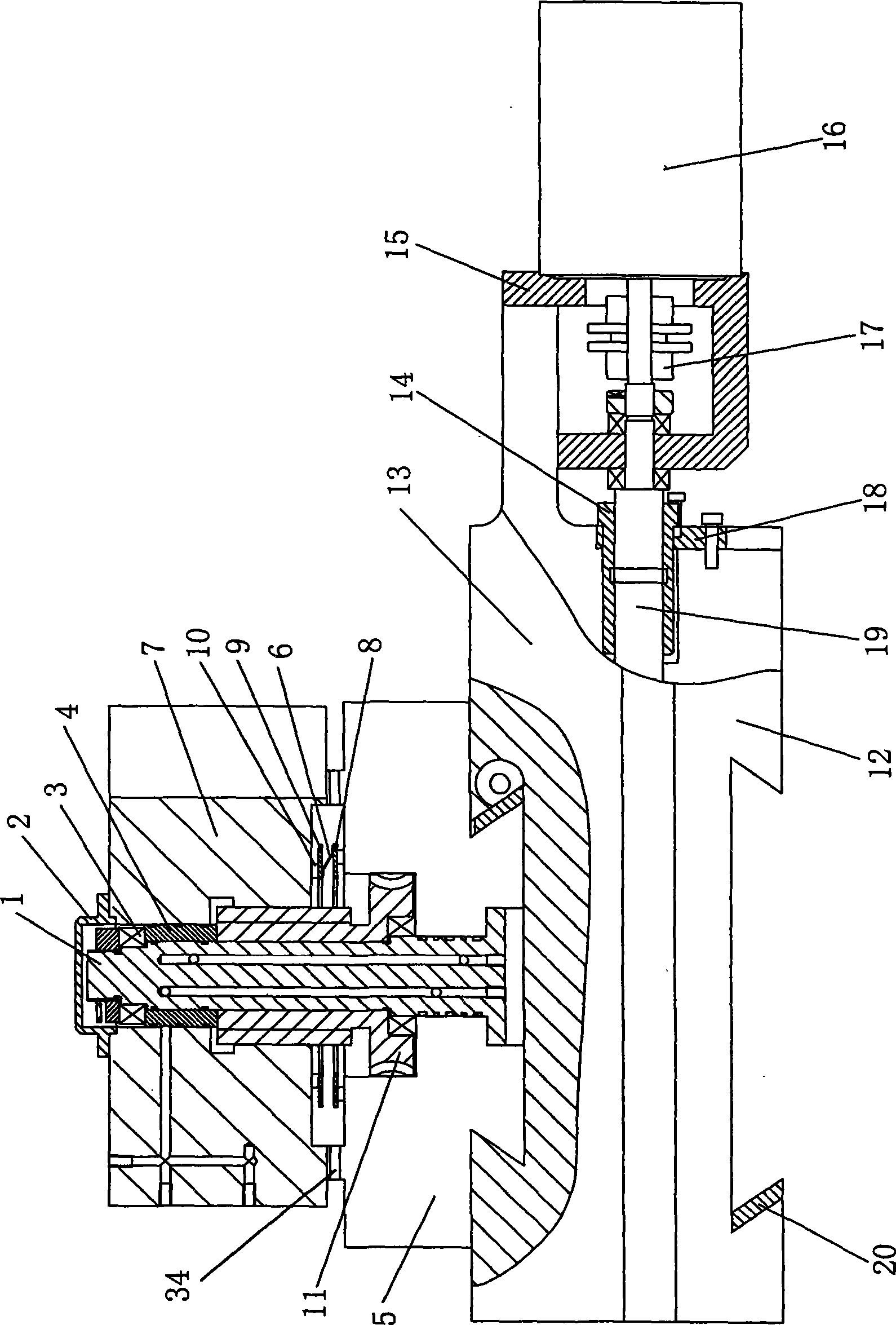

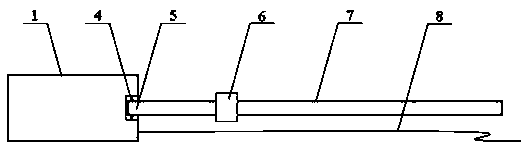

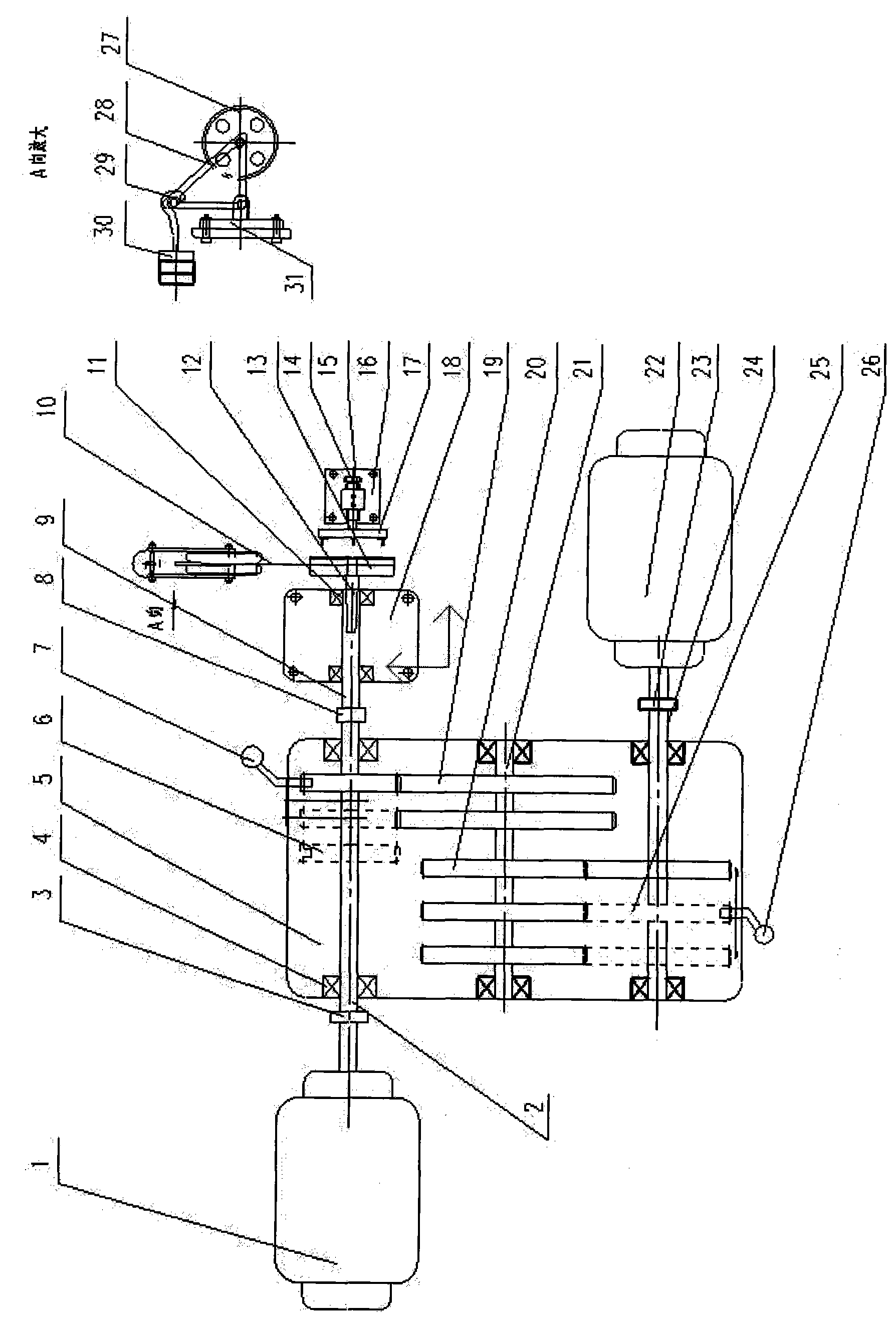

Numerical control supersonic machining apparatus for general lathe

InactiveCN101503755AReduce labor intensitySolve the problem that complex surfaces such as arcs cannot be processedAuxillary equipmentMechanical vibrations separationNumerical controlPatch panel

The invention provides a digital control ultrasonic processing device for a common lathe. The device comprises a pedestal, an intermediate guide rail, an upper support plate and a rotary tool rest, wherein the bottom surface of the pedestal is provided with a dovetail groove; the intermediate guide rail is arranged on the pedestal through a vertical guide rail; the upper support plate is arranged on the intermediate guide rail through a horizontal guide rail; an intermediate shaft is arranged inside the upper support plate; the rotary tool rest is arranged on the intermediate shaft; a patch panel and an electric brush panel are arranged between the rotary tool rest and the upper support plate; an electric brush is connected between the patch panel and the electric brush panel; a lead screw feeding mechanism is arranged on the intermediate guide rail and the upper support plate; a tool rest automatic tool change mechanism is arranged between the upper support plate and the rotary tool rest; a lathe tool, a round amplitude transformer and an external circular amplitude transformer are arranged on the rotary tool rest; and a processing tool bit is arranged on the two amplitude transformers and connected with an energy converter respectively. The digital control ultrasonic processing device for the common lathe has high efficiency and high processing precision and can complete turning, ultrasonic processing of the external circular face and ultrasonic processing of the crown face by clamping for one time.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

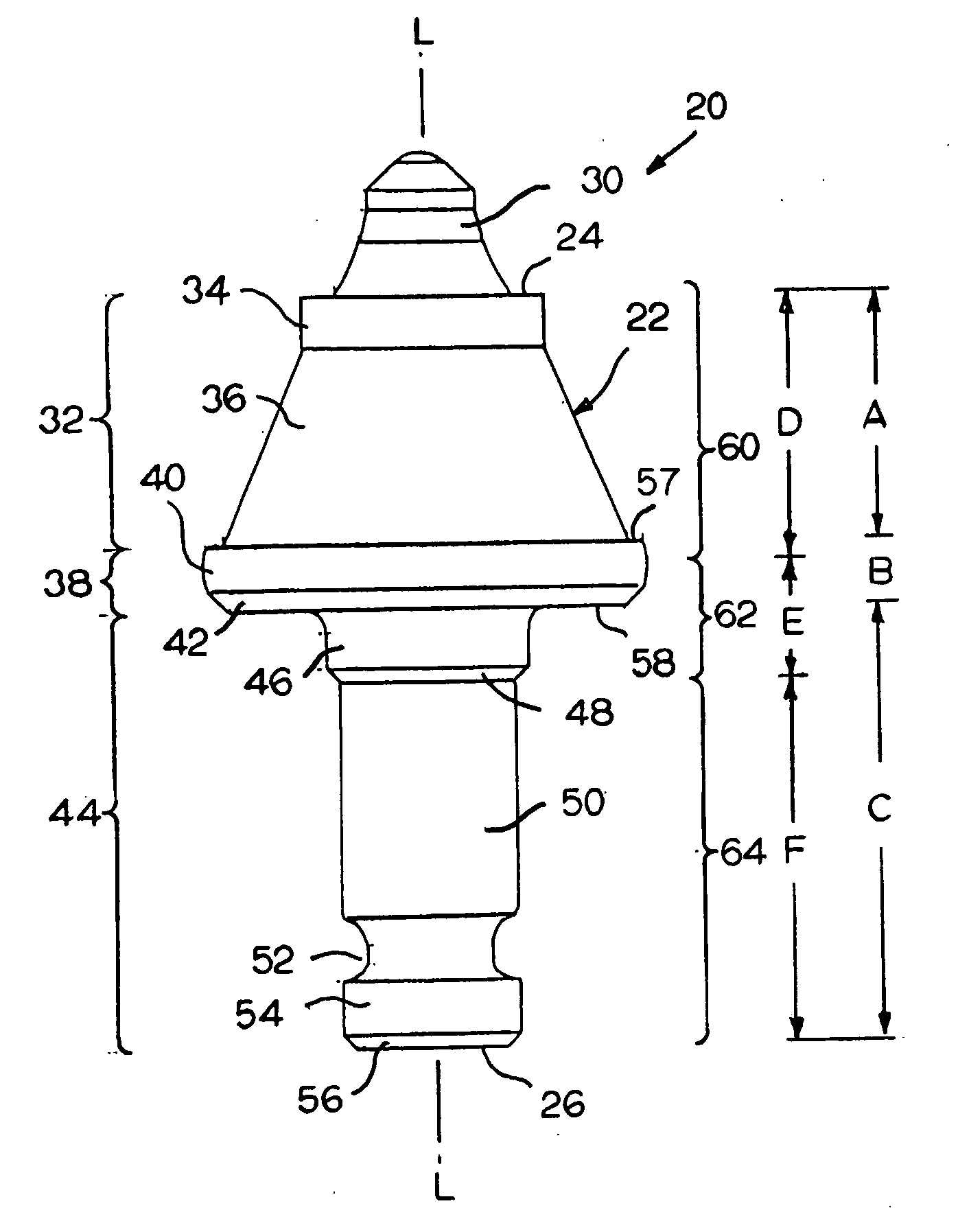

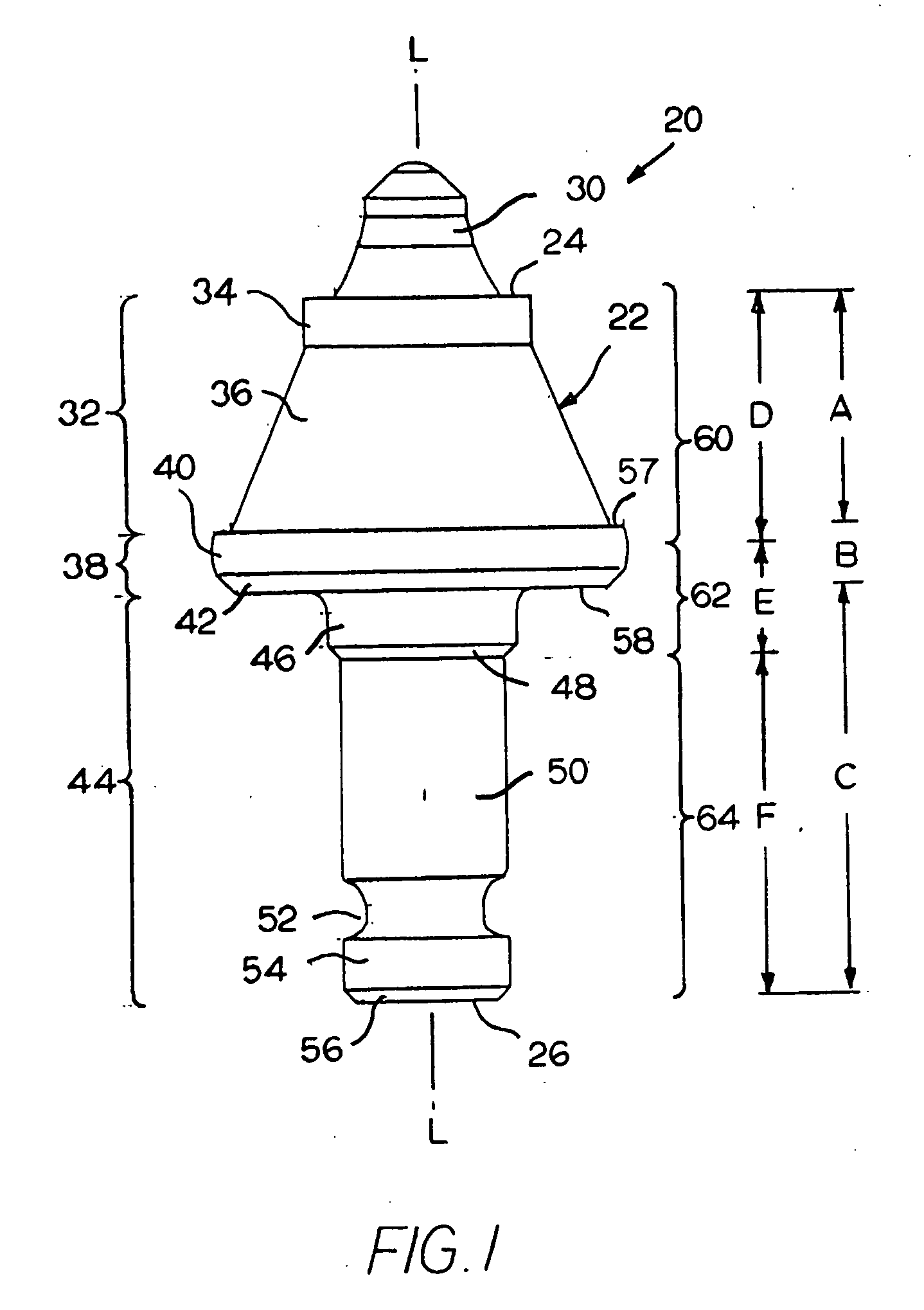

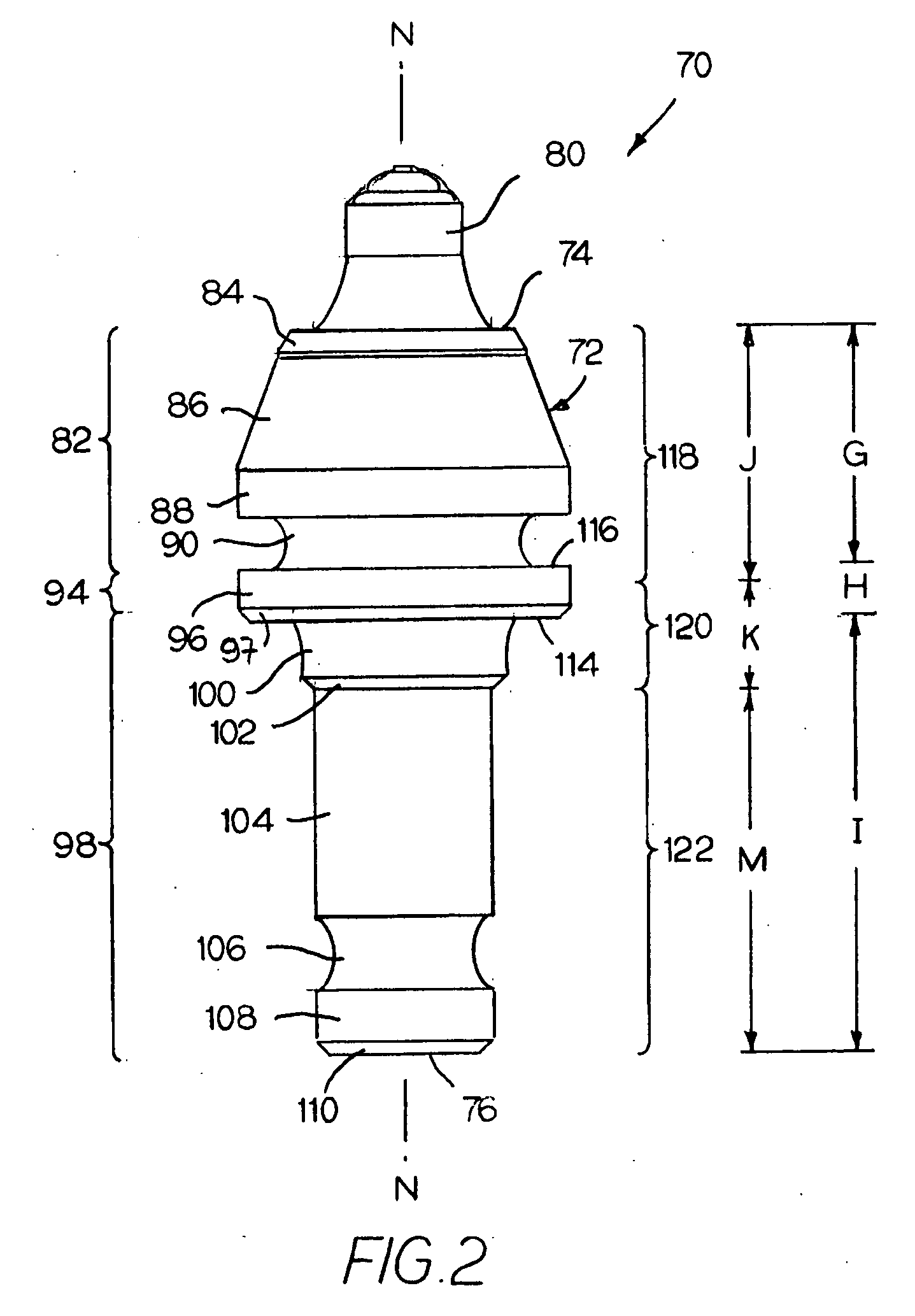

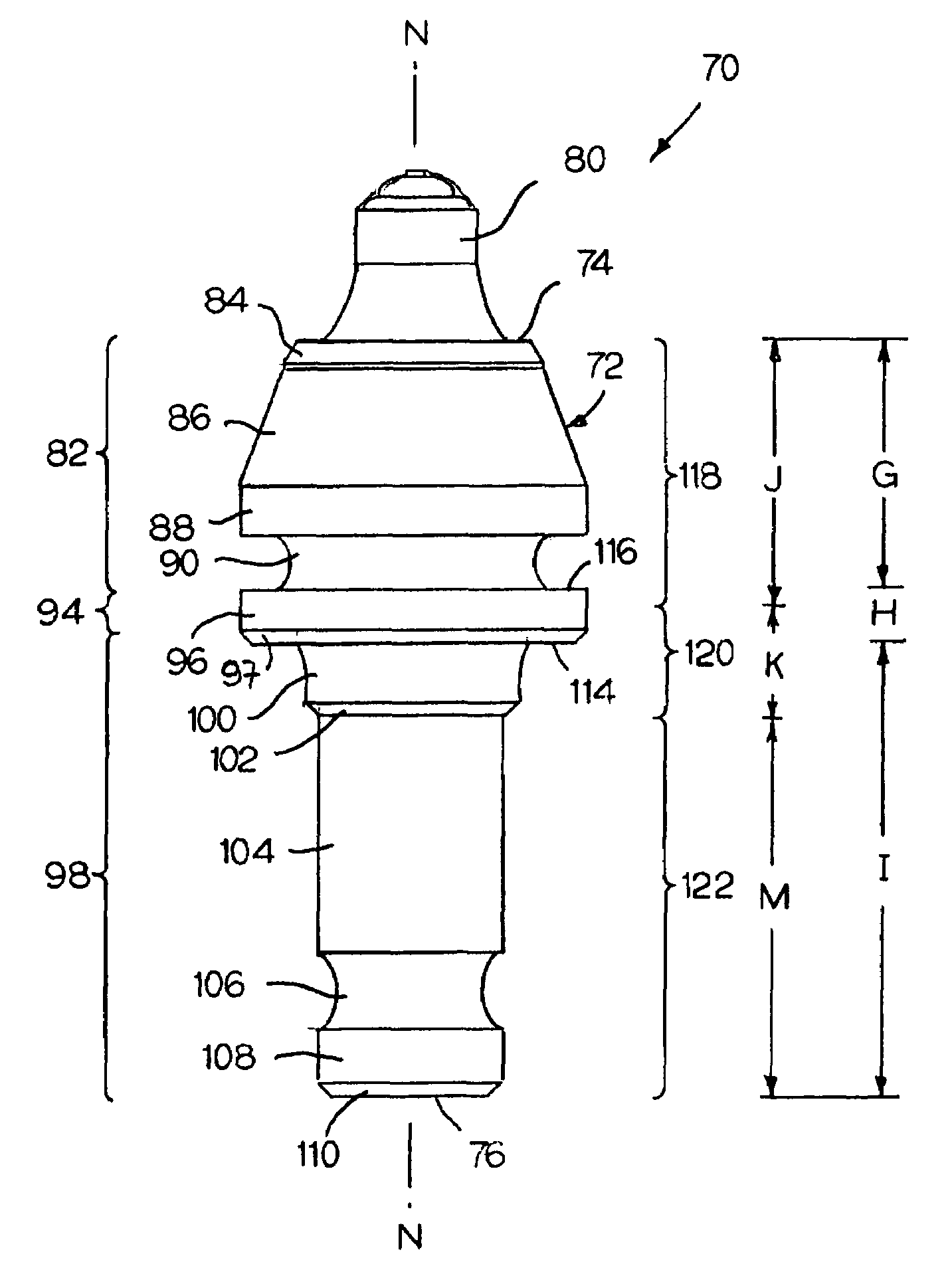

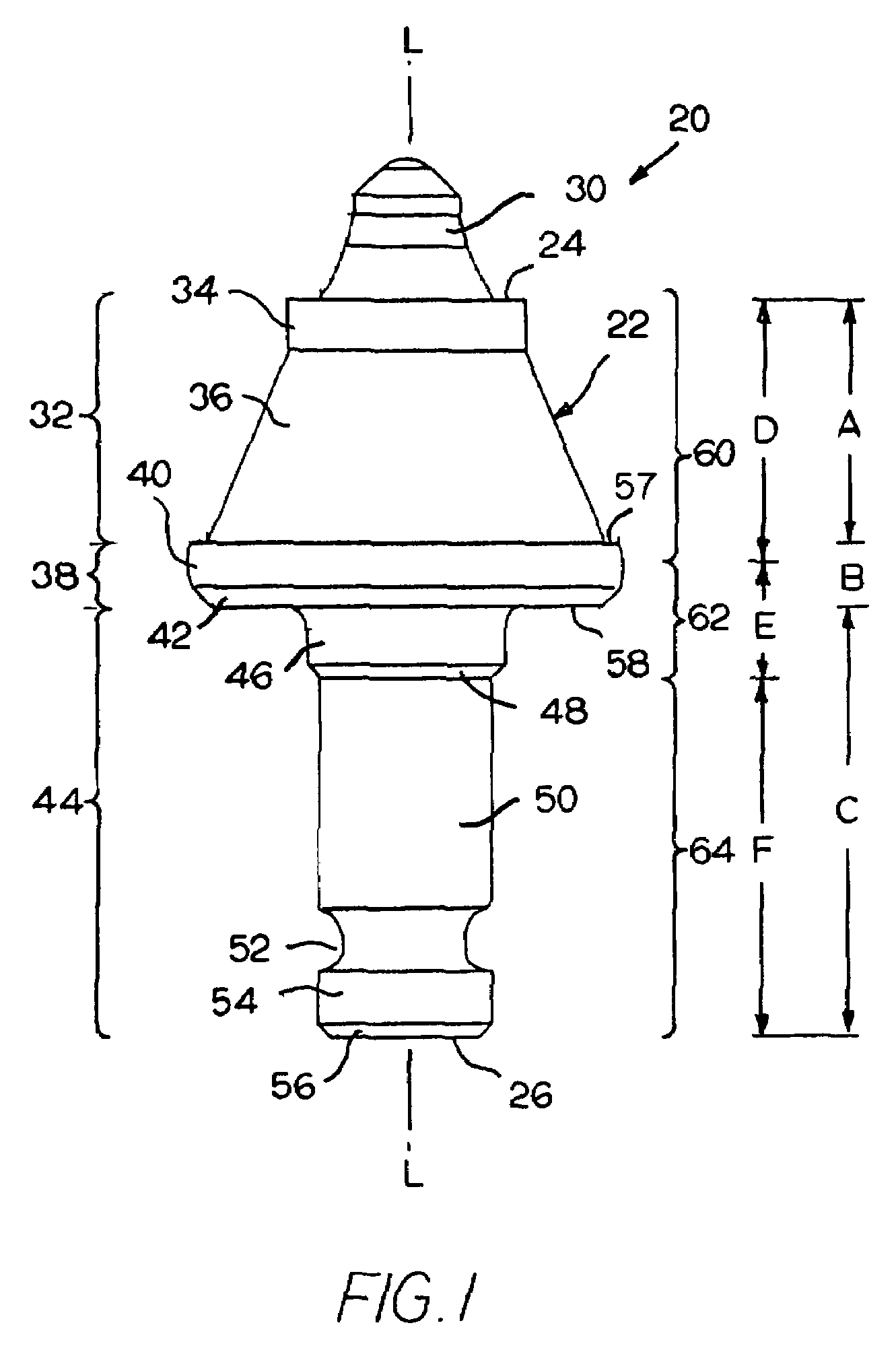

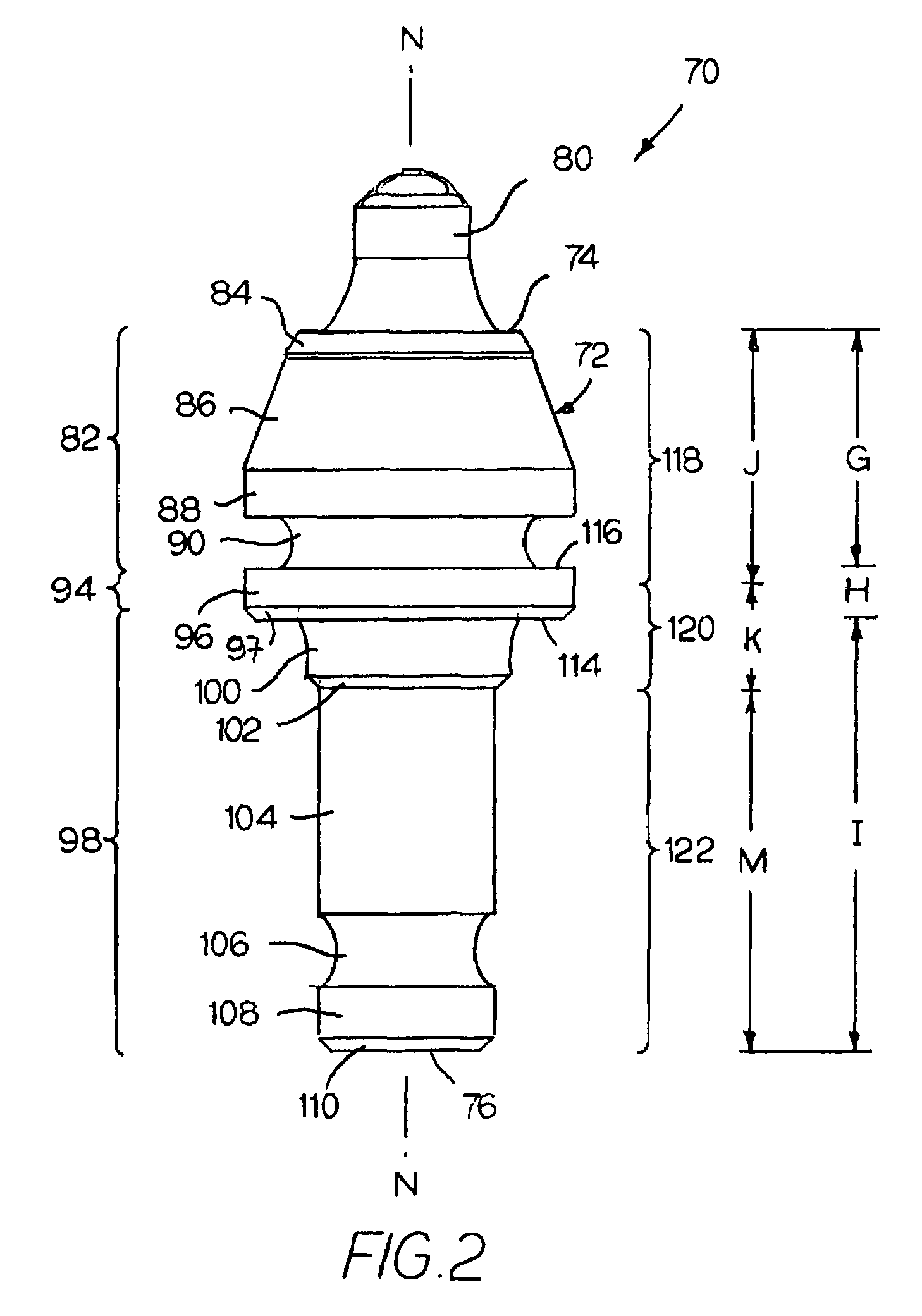

Rotatable cutting tool and cutting tool body

A rotatable cutting tool carried in a bore of a holder wherein the holder has a forward surface surrounding a forward end of the bore. The rotatable cutting tool includes an elongate cutting tool body that has a central longitudinal axis, an axial forward end and an axial rearward end. The cutting tool body contains a socket in the axial forward end thereof whereby the socket receives a hard insert therein. The cutting tool body has an enlarged diameter collar mediate of the axial forward end and the axial rearward end. The mediate collar presents an axial forward facing surface and an axial rearward facing surface. The cutting tool body has an axial forward hardness region beginning at and extending a first pre-selected distance in an axial rearward direction from the axial forward end to encompass the axial forward facing surface of the collar. The axial forward hardness region has a hardness equal to or greater than a first hardness, as well as a first average hardness. The cutting tool body has an axial rearward hardness region beginning at and extending a second pre-selected distance in an axial forward direction from the axial rearward end to encompass an axial rearward section of the shank portion. The axial rearward hardness region has a third average hardness. The cutting tool body has a transition hardness region mediate of and contiguous with the axial forward hardness region and the axial rearward hardness region. The transition hardness region encompasses the axial rearward facing surface of the collar and an axial forward section of the shank portion. The transition hardness region has a second average hardness. The second average hardness is less than the first hardness, and the third average hardness is less than the second average hardness.

Owner:KENNAMETAL INC

Method for locating and installing deep soft rock geostatic stress testing device

InactiveCN103510951AEasy to solveEasy to calculateBorehole/well accessoriesRelative displacementMedial axis

The invention discloses a method for locating and installing a deep soft rock geostatic stress testing device. According to the method, a stress sensing column is manufactured, the stress sensing column is a cement concrete cylinder comprising two three-directional pressure boxes, and the center of each cubic pressure box is located on the medial axis of the cylinder; the front end of a push rod is connected with the stress sensing column, an angle testing device is installed, rotation angle and length of the stress sensing column are recorded when the push rod is pushed from a hole mouth to a tested point at the hole bottom, and accurate data necessary for stress resolving can be obtained. According to the method, no sharp protrusion exists at the front end or the side face of the stress sensing column, the hole wall will not collapse easily in the pushing process, relative positions of a pair of three-directional pressure sensors are fixed through the stress sensing column, the two three-directional pressure sensors will not move or rotate relatively in the pushing process, and the accuracy for calculating the geostatic stress of the tested point can be ensured.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

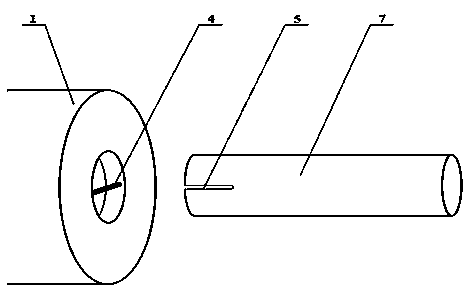

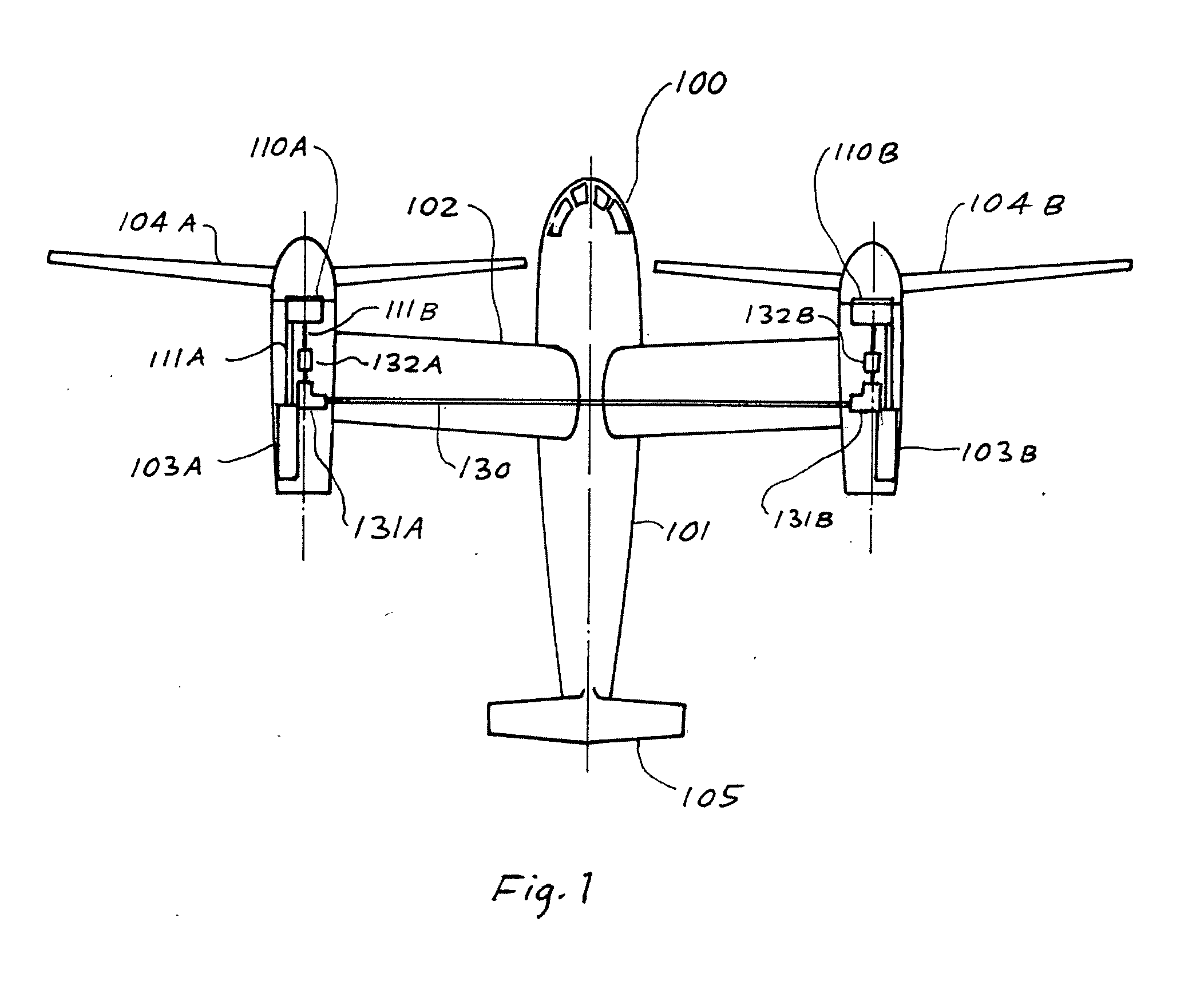

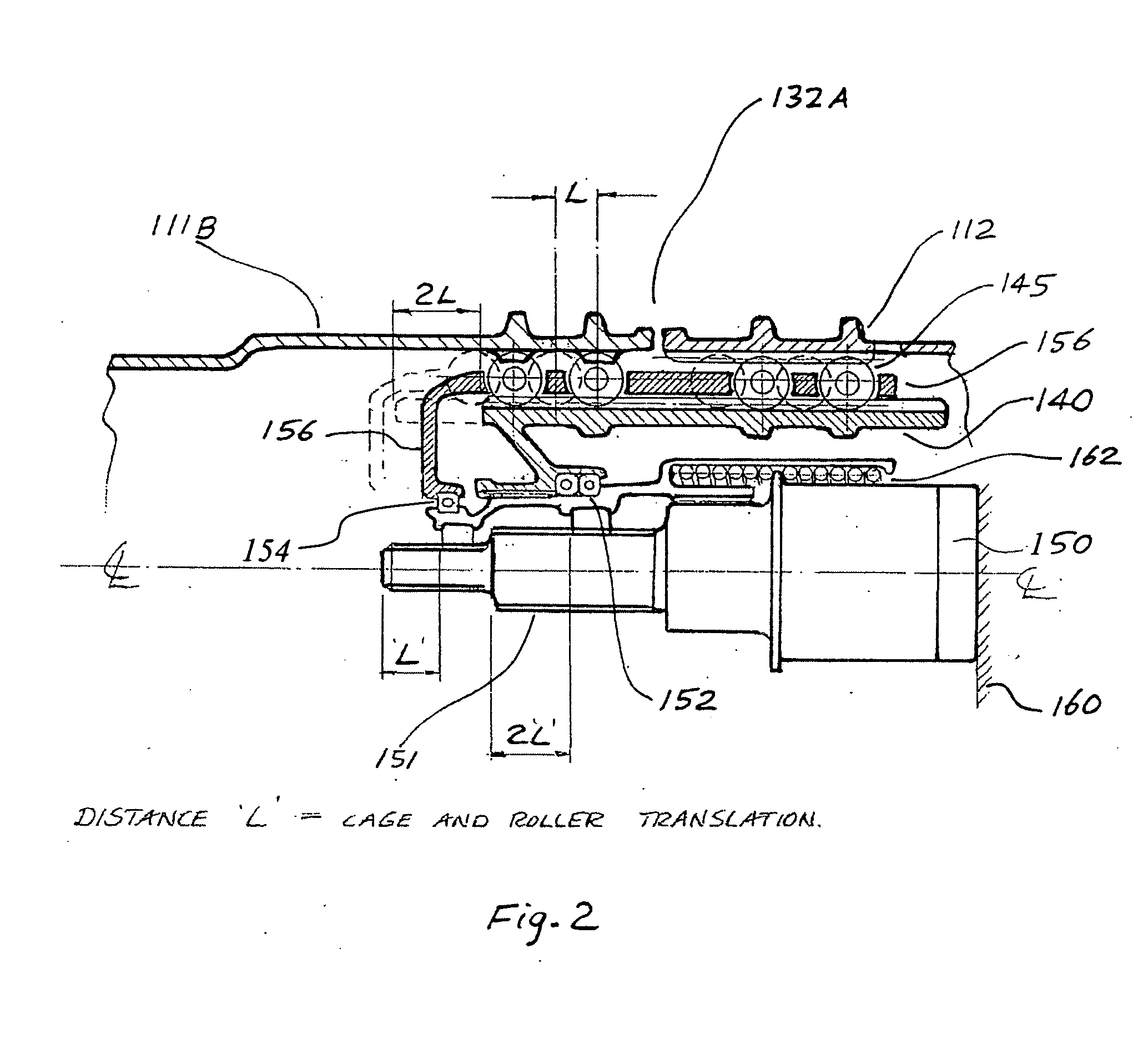

Separable under load shaft coupling

Contemplated couplings include an intermediate shaft internal and coaxial to a driver and a driven shaft, wherein the intermediate shaft moves a plurality of teethed rollers that engage with corresponding splined inner surfaces of the driver and the driven shaft. Such devices allow separation of the shafts under load using substantially reduced force and will typically have a friction coefficient virtual μ of less than 0.05.

Owner:KAREM AIRCRAFT INC

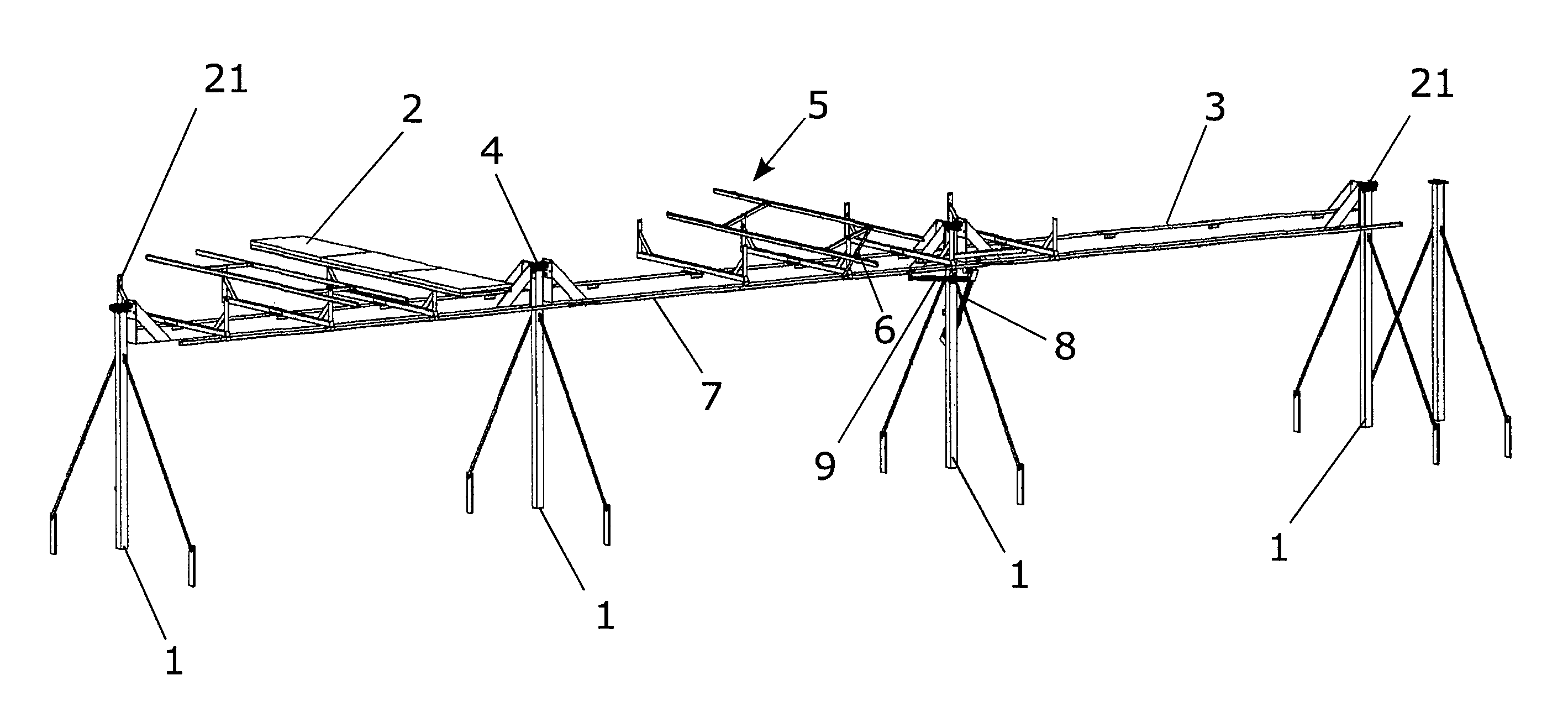

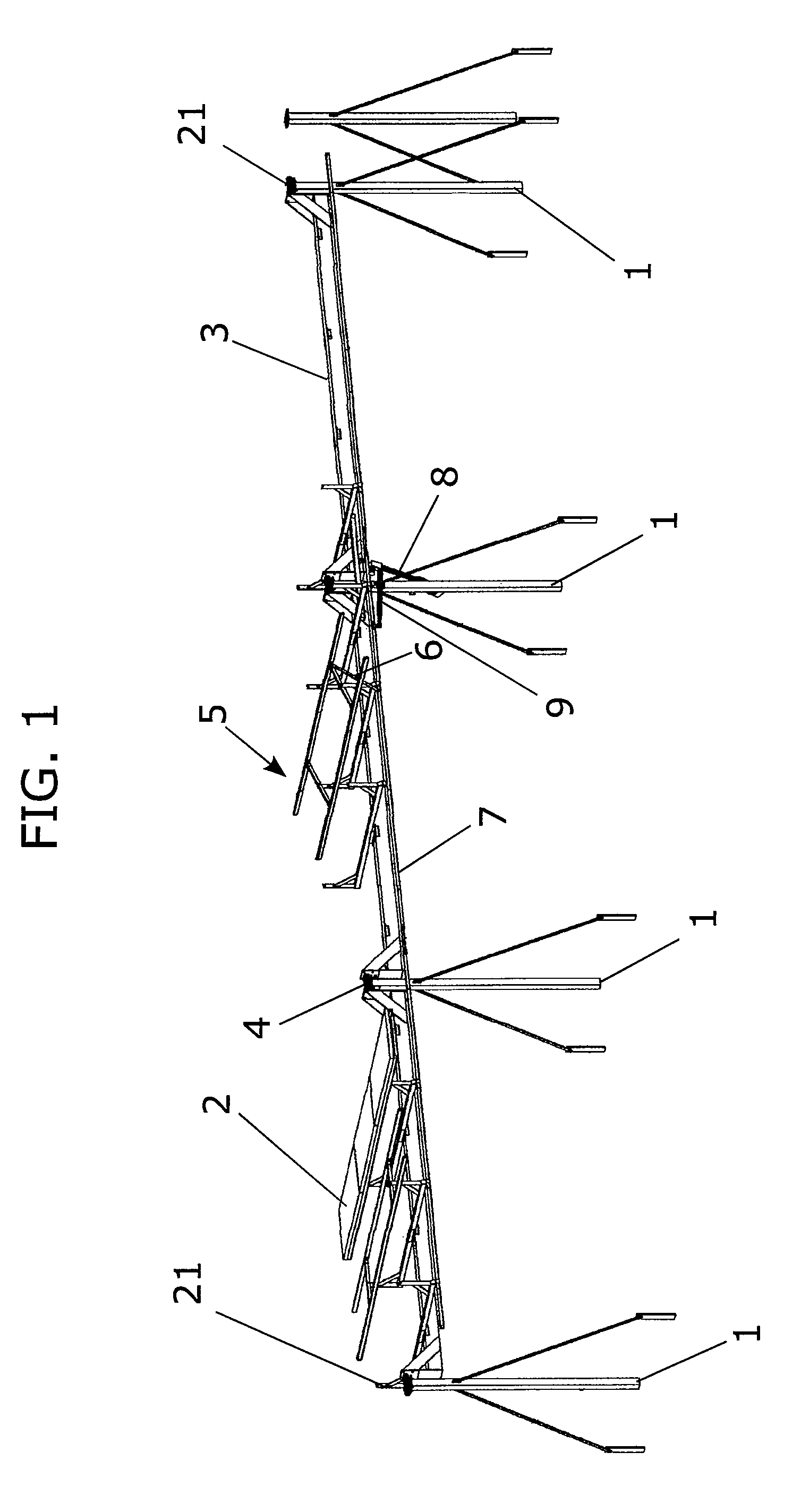

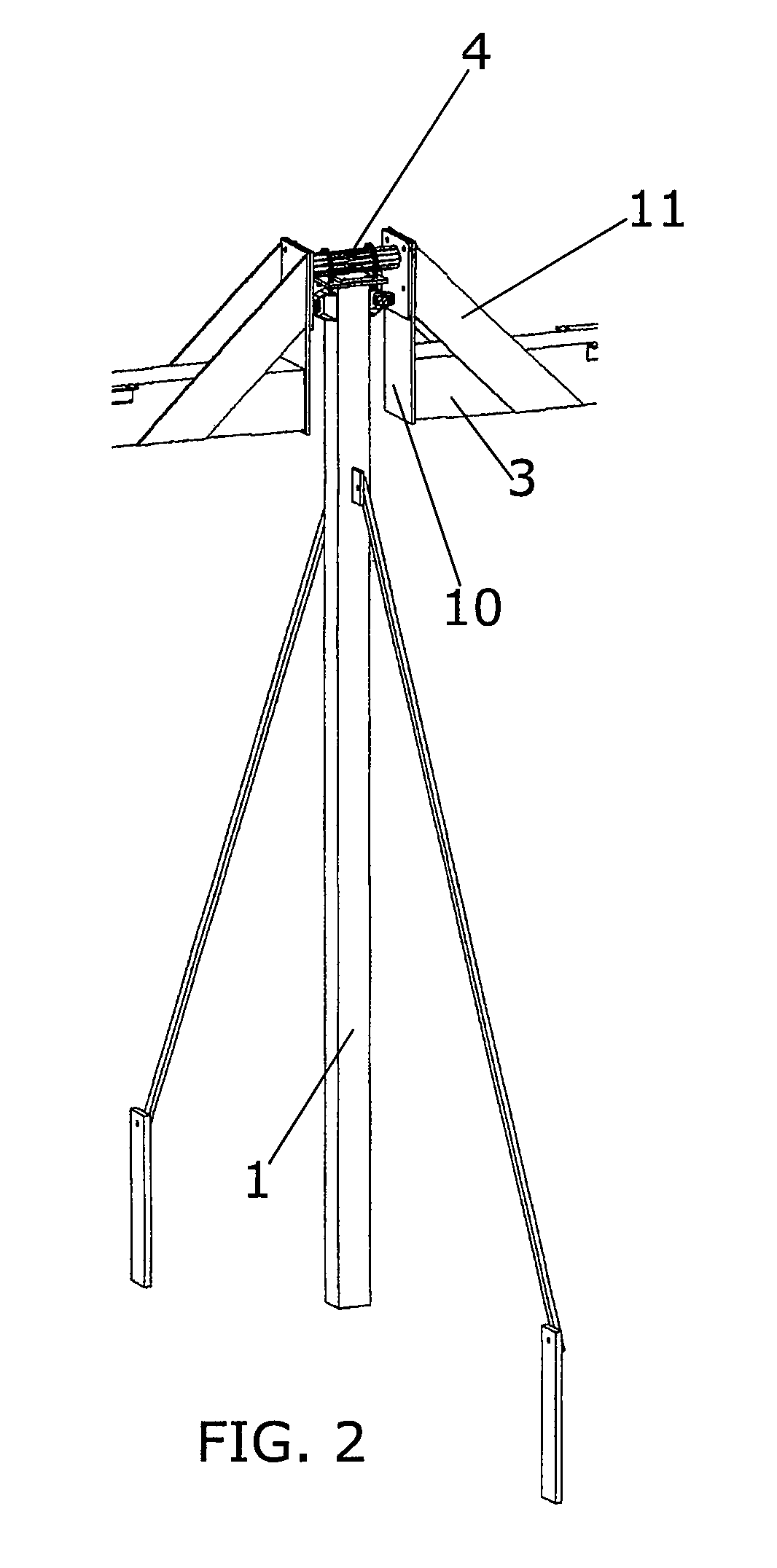

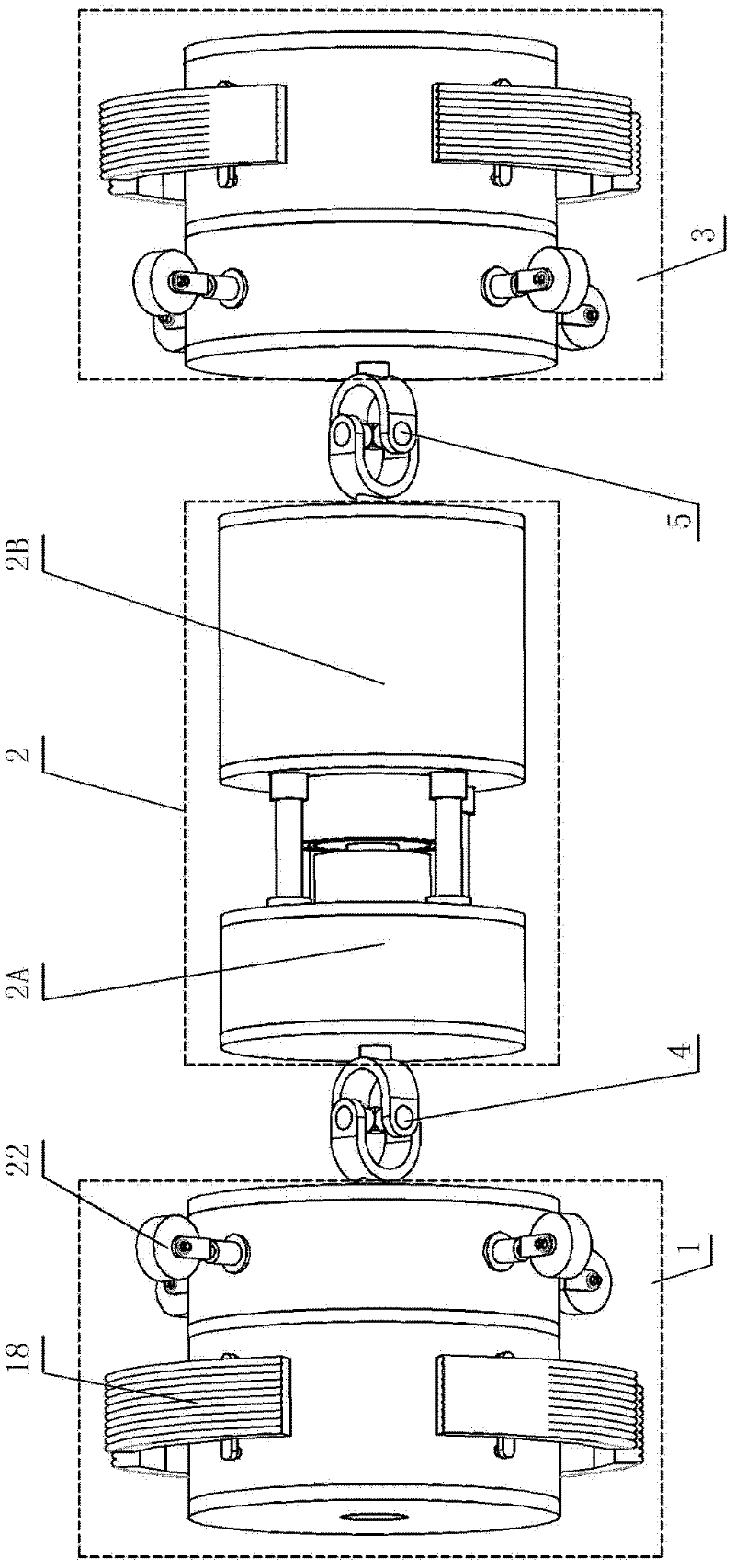

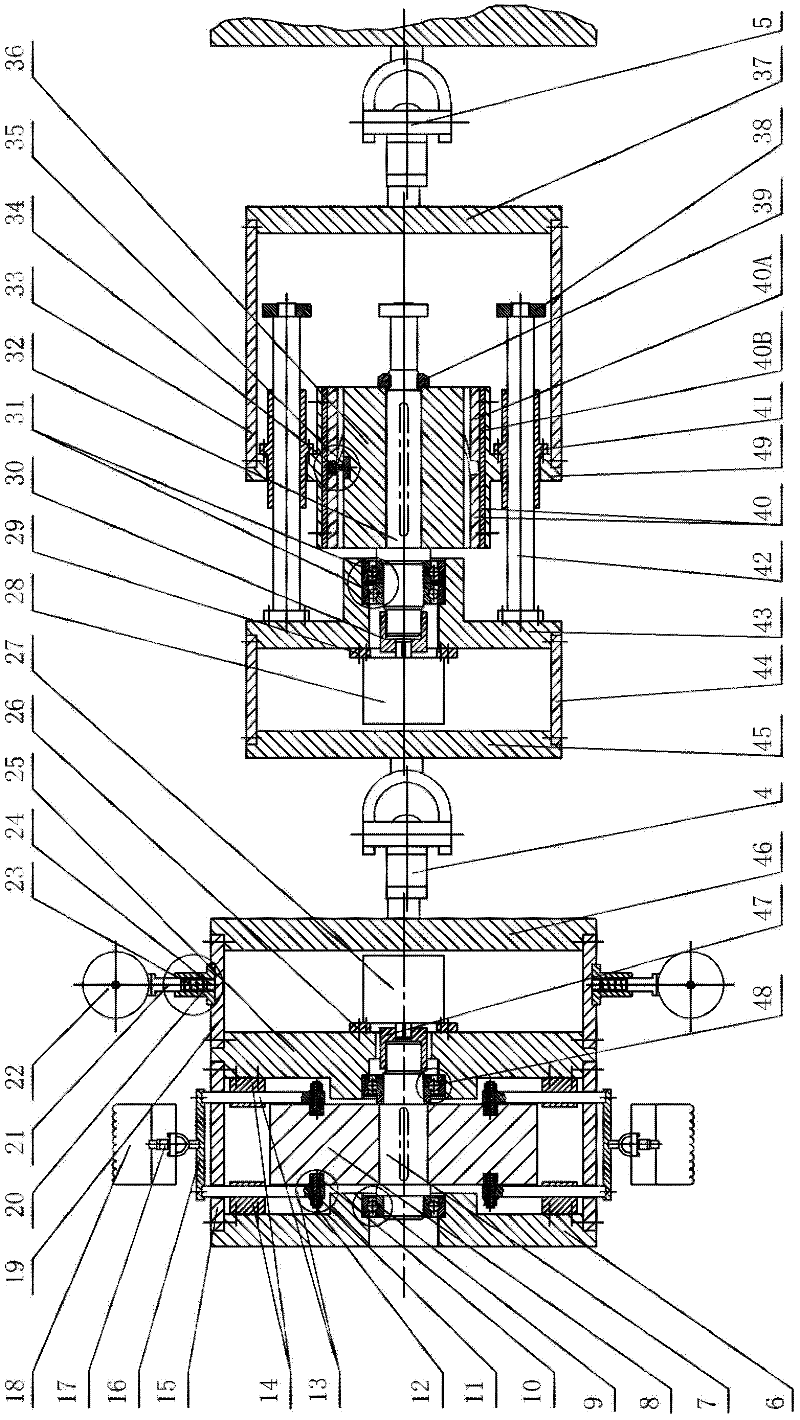

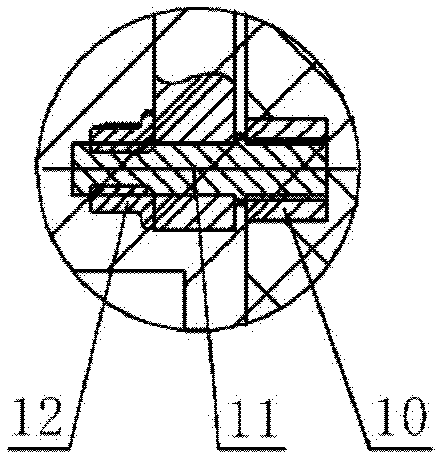

Dual axle solar tracker

InactiveUS8203110B2Reduce sensitivityConsiderable structural advantageSolar heating energyPhotometry using reference valueMedial axisGravity center

Solar tracker with a principal substructure comprising a series of posts between which sections of beams are arranged, joined by intermediate axles and which can turn in respect of a longitudinal axle; it is also provided with secondary substructures comprising a frame for attachment of the solar panels which rotate in respect of an axle transversal to the longitudinal and with connection parts between the frames and the beams, and in respect of which they are articulated, with the frames being activated by connecting rods joined to a common slide. The centre of gravity of the structure overall is arranged such that it is very close to the longitudinal axle, which facilitates its actuation, reduces wind sensitivity and facilitates erection in addition to being provided with a certain degree of longitudinal tolerance, which enables better use to be made of land, as it is possible to achieve greater power per square meter.

Owner:ENERGIA ERCAM

Bionic squirm type pipeline travelling mechanism and control method thereof

The invention relates to a bionic squirm type pipeline travelling mechanism and a control method thereof. The travelling mechanism is characterized in that a forebody section radial support unit and an afterbody section radial support unit are symmetrically arranged on the two ends of a middle axial input unit; a periodicity intermittent radial breathing motion between the radial support unit andthe inner wall of a pipeline and a periodicity intermittent axial stretching motion of the middle axial input unit are adjusted, and the travelling mechanism imitates motion gait and a rule of a wormsomite in the pipeline to walk in a squirm manner; and the travelling mechanism can replace labour to carry out different pipeline job tasks through carrying corresponding instrument, and missions ofvertical underground mine disaster detection and rescue and the like can be implemented. The travelling mechanism provided by the invention has the advantages of simple compact body, reliable stable operation, easiness in control, cheap manufacturing cost, and can be suitable for multiple occasion applications and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

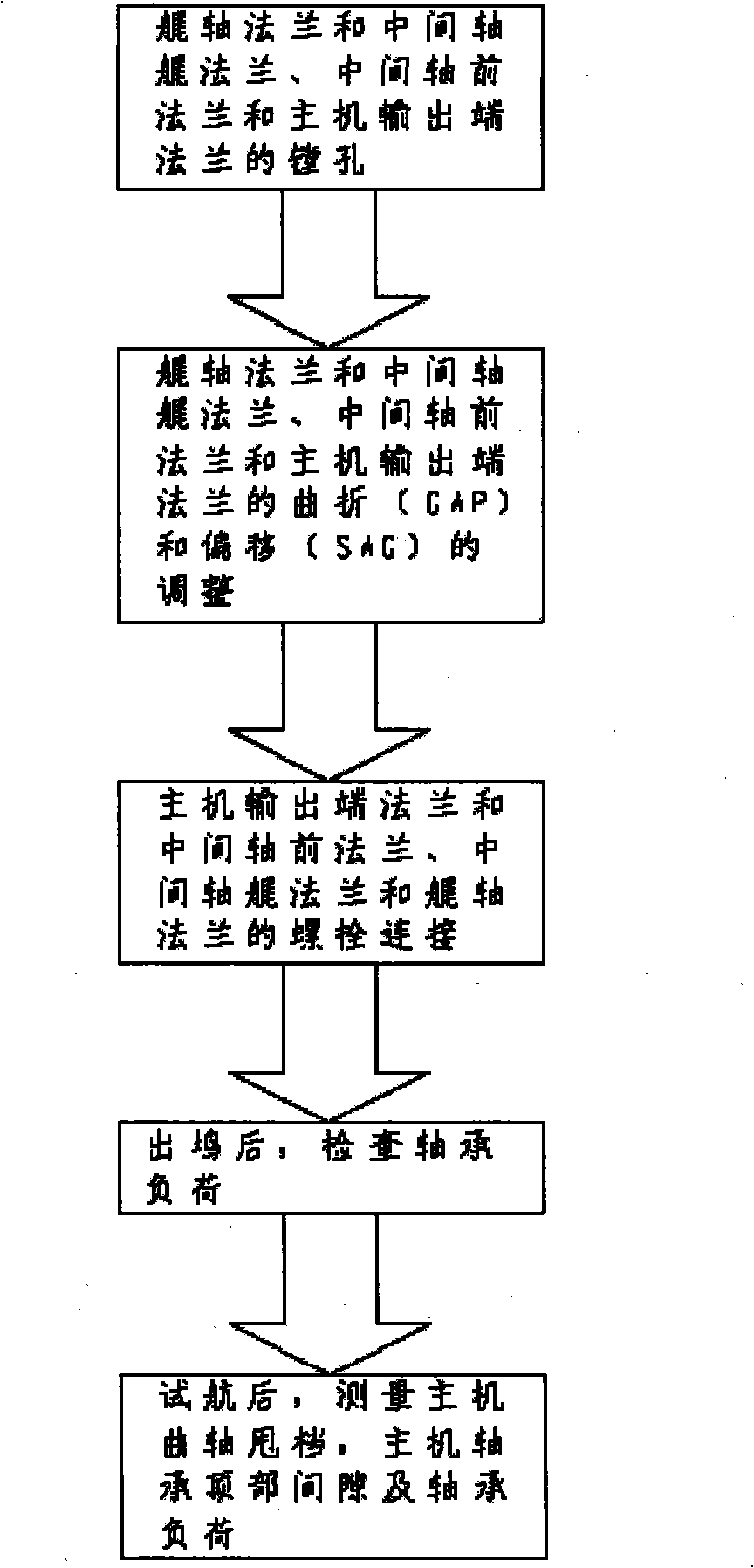

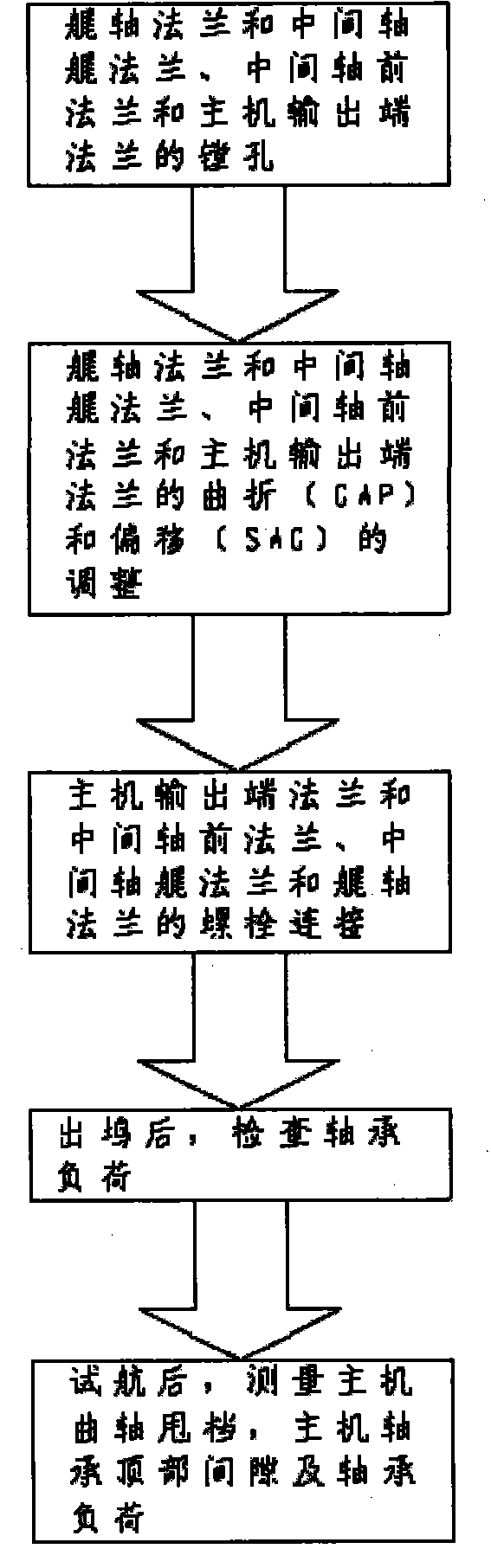

Method for improving shaft system centering process for ship building

InactiveCN101913409AShorten the timeRealize regulationVessel partsMetal working apparatusMedial axisPulp and paper industry

The invention relates to a method for improving a shaft system centering process for ship building. The method comprises the following steps of: boring holes on a screw shaft flange, a middle screw shaft flange, a middle shaft front flange and a host machine output end flange; adjusting the tortuosity and deviation of the screw shaft flange and the middle screw shaft flange and the tortuosity and deviation of the middle shaft front flange and the host machine output end flange; and connecting the host machine output end flange and the middle shaft front flange and connecting the middle screw shaft flange and the screw shaft flange through bolts, and the like. The method of the invention has the advantages of greatly shortening the working time of the shaft system after a ship is undocked, lowering the pressure of a dock mooring test and contributing to shortening the mooring test period of a dock of a company.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING

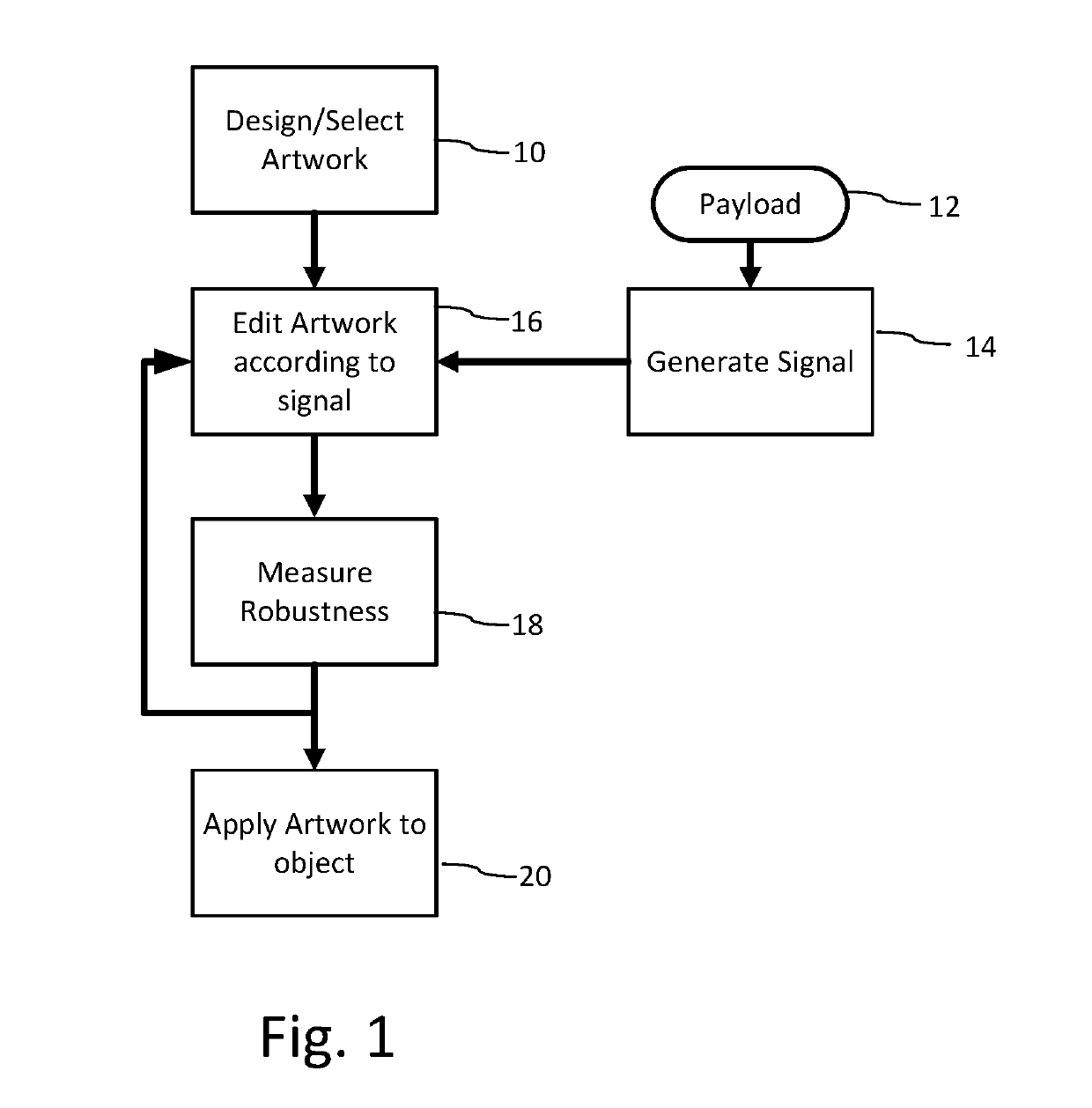

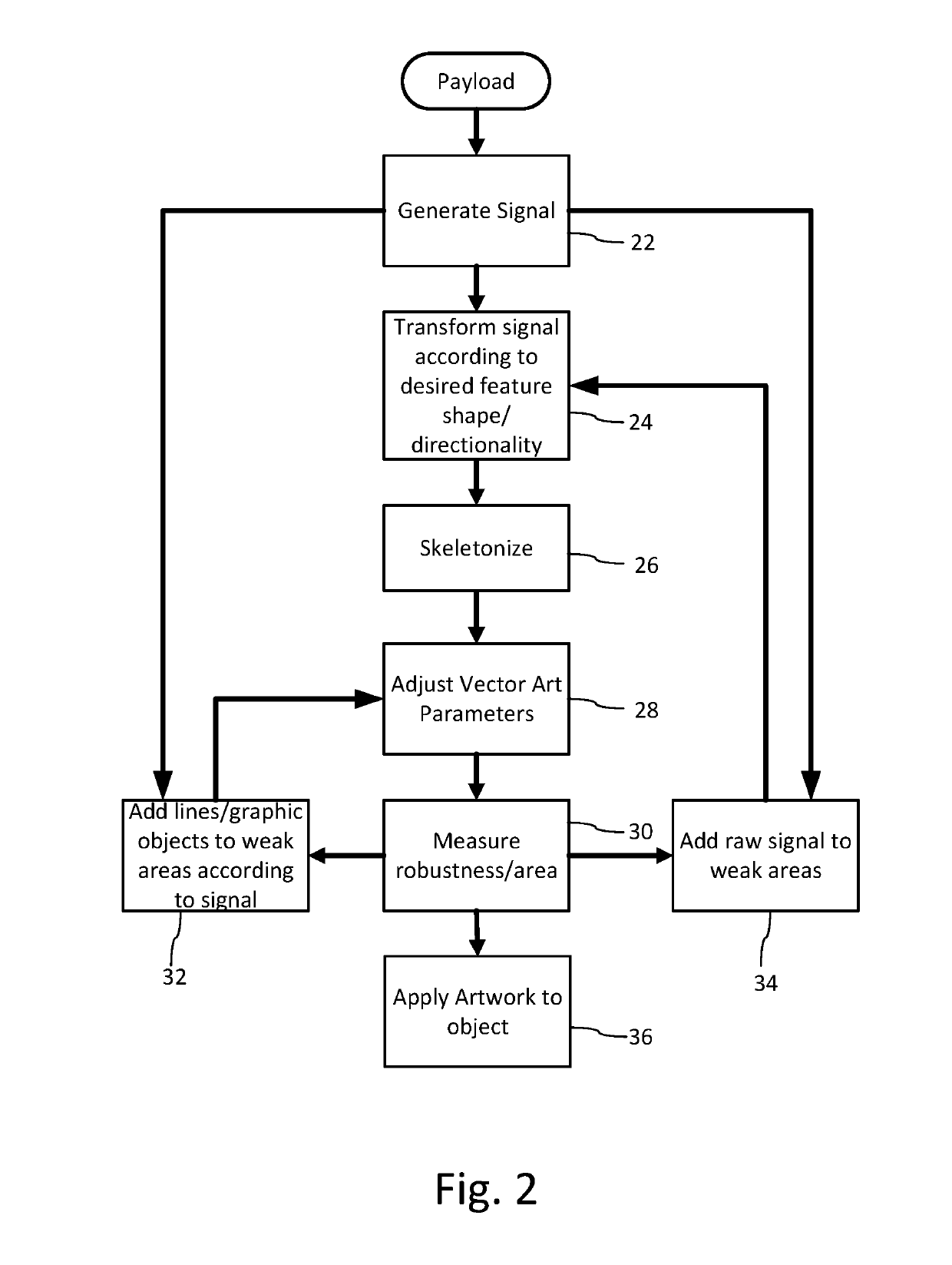

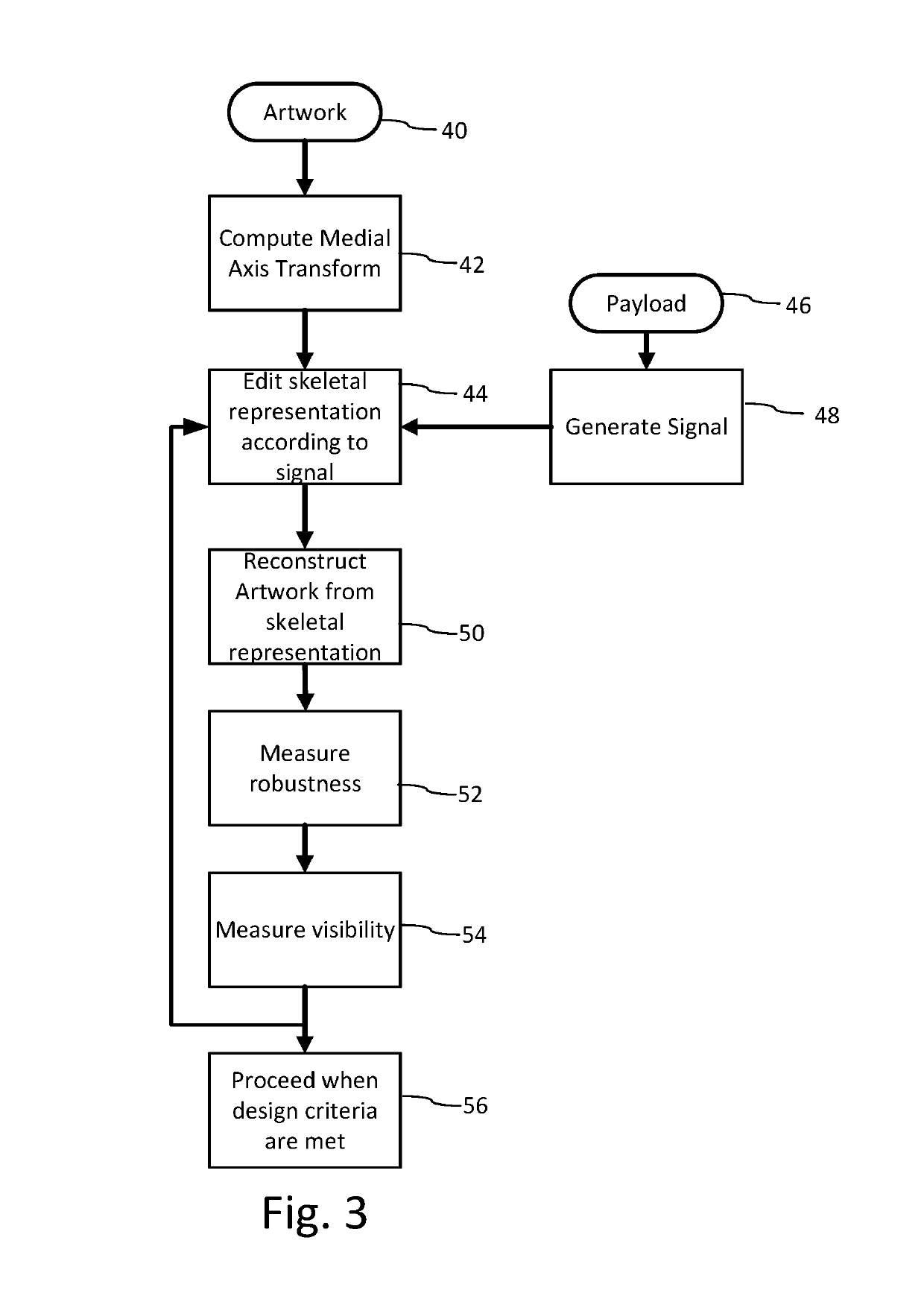

Generating artistic designs encoded with robust, machine-readable data

ActiveUS20190139176A1Reduce visual impactReliable readImage enhancementImage analysisGraphicsMedial axis

Artwork carrying machine readable data is generated by editing artwork according to a data signal or transforming the data signal into artwork. The machine-readable data signal is generated from a digital payload and converted into an image tile. Artwork is edited according to the image tile by moving graphic elements, adapting intersections of lines, or altering line density, among other techniques. Artwork is generated from the data signal by skeletonizing it and applying morphological operators to a skeletal representation, such as a medial axis transform. Artistic effects are introduced by filtering the data signal with directional blurring or shape filters.

Owner:DIGIMARC CORP

Rotatable cutting tool and cutting tool body

A rotatable cutting tool carried in a bore of a holder wherein the holder has a forward surface surrounding a forward end of the bore. The rotatable cutting tool includes an elongate cutting tool body that has a central longitudinal axis, an axial forward end and an axial rearward end. The cutting tool body contains a socket in the axial forward end thereof whereby the socket receives a hard insert therein. The cutting tool body has an enlarged diameter collar mediate of the axial forward end and the axial rearward end. The mediate collar presents an axial forward facing surface and an axial rearward facing surface. The cutting tool body has an axial forward hardness region beginning at and extending a first pre-selected distance in an axial rearward direction from the axial forward end to encompass the axial forward facing surface of the collar. The axial forward hardness region has a hardness equal to or greater than a first hardness, as well as a first average hardness. The cutting tool body has an axial rearward hardness region beginning at and extending a second pre-selected distance in an axial forward direction from the axial rearward end to encompass an axial rearward section of the shank portion. The axial rearward hardness region has a third average hardness. The cutting tool body has a transition hardness region mediate of and contiguous with the axial forward hardness region and the axial rearward hardness region. The transition hardness region encompasses the axial rearward facing surface of the collar and an axial forward section of the shank portion. The transition hardness region has a second average hardness. The second average hardness is less than the first hardness, and the third average hardness is less than the second average hardness.

Owner:KENNAMETAL INC

Bearing-gear multi-fault coupled simulation experiment table

InactiveCN101576438AFacilitate experimental researchImprove bindingMachine gearing/transmission testingMachine bearings testingExperimental researchMedial axis

The invention discloses a bearing-gear multi-fault coupled simulation experiment table, which comprises a first direct-current adjustable speed motor and an input shaft which passes through a gear box body and is connected with the first direct-current adjustable speed motor. The input shaft is connected with a transmission shaft of a bearing box body, a mandrel of the bearing box body is provided with a replaceable bearing housing, one side of the replaceable bearing housing is provided with a tip and a top tray, the input shaft in the gear box body is sleeved with an input shaft shifting slide gear, a gear box middle shaft and a gear box output shaft which extends out of the gear box body and is connected with a second direct-current adjustable speed motor are also arranged in the gear box body, the gear box middle shaft is provided with a middle shaft pinion and a middle shaft gearwheel, and the gear box output shaft is provided with an output shaft shifting slide gear which is meshed with the middle shaft pinion. The experiment table not only can simulate respective fault rotating table, but also can synchronously simulate fault states of a bearing and a gear so that the fault characteristics are closer to the actual conditions on site, and the experimental study and production practice are combined more conveniently.

Owner:XI AN JIAOTONG UNIV

Speed-down mechanism of electric tool

ActiveCN101403425ALarge adjustment rangeReduce vibrationMetal sawing devicesToothed gearingsMedial axisAxial thrust

The present invention provides a secondary retarding mechanism of an electric tool, wherein the retarding mechanism is used to retard the output revolution speed of the motor and output it to the main shaft, an axial thrust is acted on an intermediate shaft through the mesh of a beveled wheel so that the intermediate shaft vibrates along the axial direction to produce noises. The object of the present invention is to restrain the intermediate shaft vibration and noise of a portable fretsaw with a secondary retarding mechanism adopting beveled wheels. The secondary retarding mechanism has the following structure that an intermediate shaft can be supported in a mode of moving along the axial direction, the teeth directions of two beveled wheels supporting the intermediate shaft are identical, accordingly a forward axial thrust is acted on the intermediate shaft, the axial thrust is configured to bear by a buffering component on the front side of the intermediate shaft to absorb the vibration.

Owner:MAKITA CORP

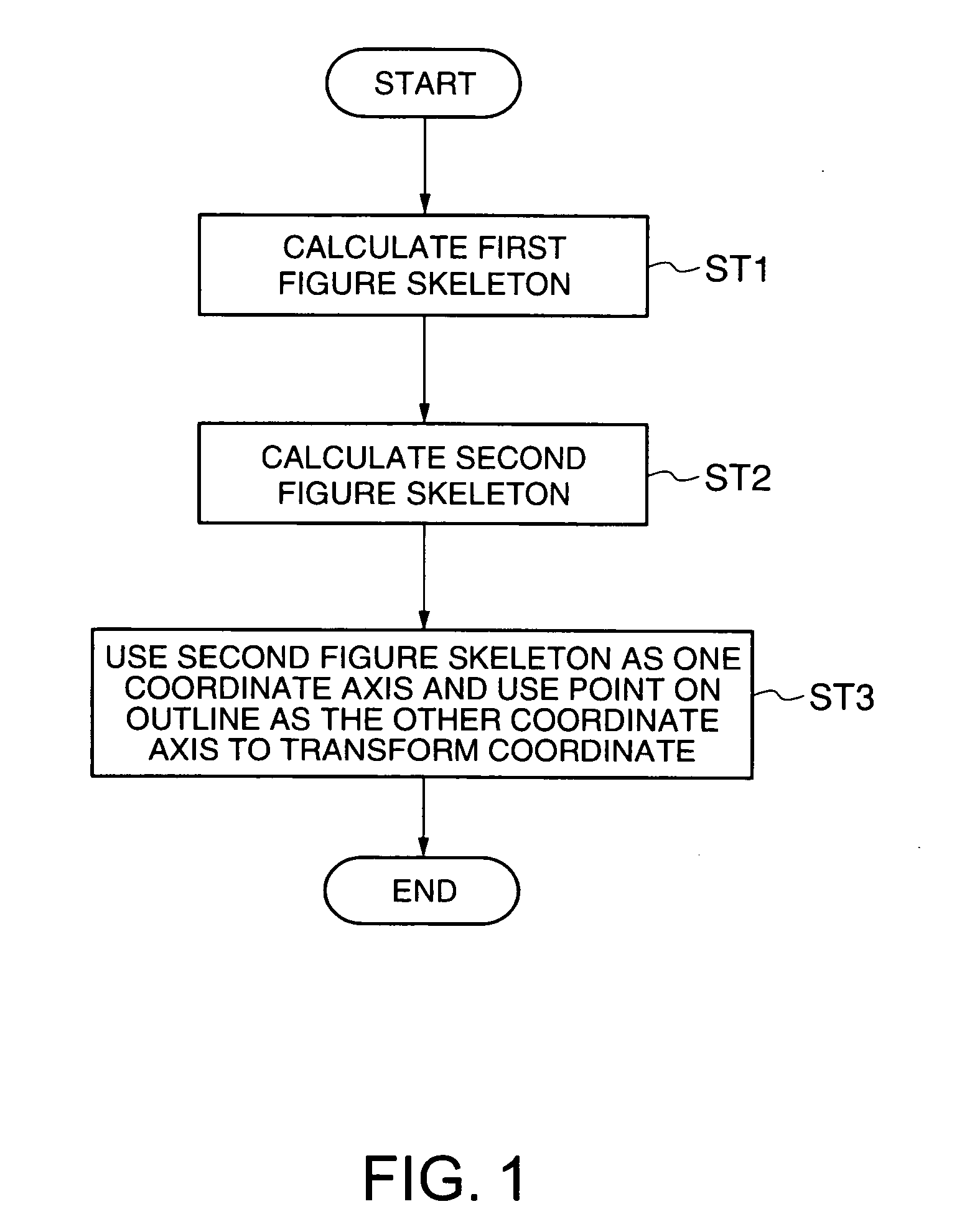

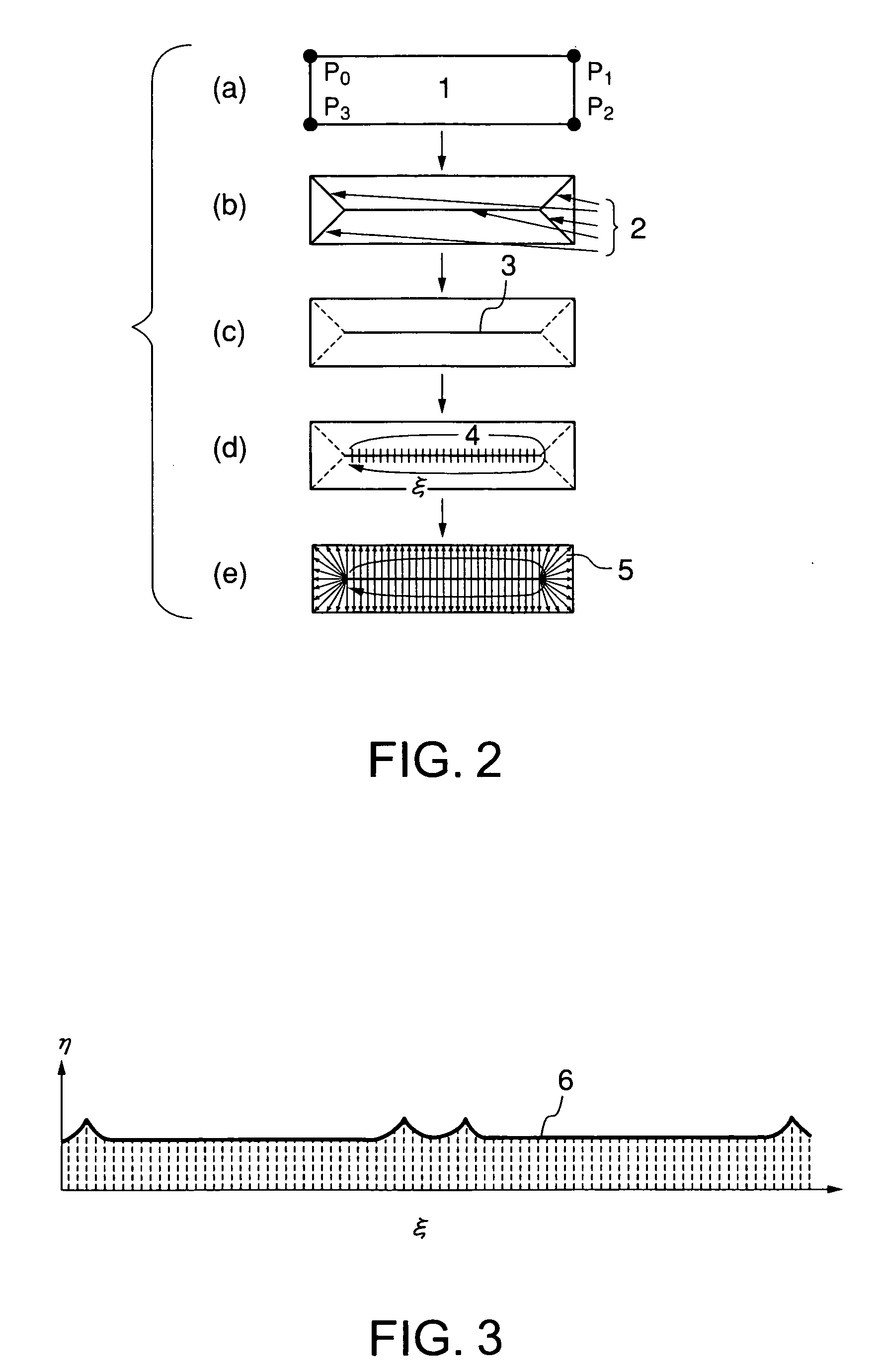

Graphic processing method and device

InactiveUS20050024361A1Reduce positioningImage enhancementDrawing from basic elementsGraphicsMedial axis

There is disclosed a graphic processing method in which a first figure skeleton apart from an outline of a figure by each equal distance in a central direction of the figure is calculated using at least one of a medial axis and a chordal axis with respect to a figure representing the outline of the object shape reflected in a digital image by a set of points, branch lines to the skeleton from a vertex of the figure in the calculated first figure skeleton are removed to obtain a second figure skeleton, and a curve coordinate system is defined using the second figure skeleton as one coordinate axis and using a distance between the second figure skeleton and the outline of the figure as the other coordinate axis with respect to data obtained by one circulation of the outline of the figure using one end point of the second figure skeleton as a start point and using the other end point as a terminal point to transform the coordinate of points on the outline of the figure into the other coordinate axis of the curve coordinate system.

Owner:KK TOSHIBA

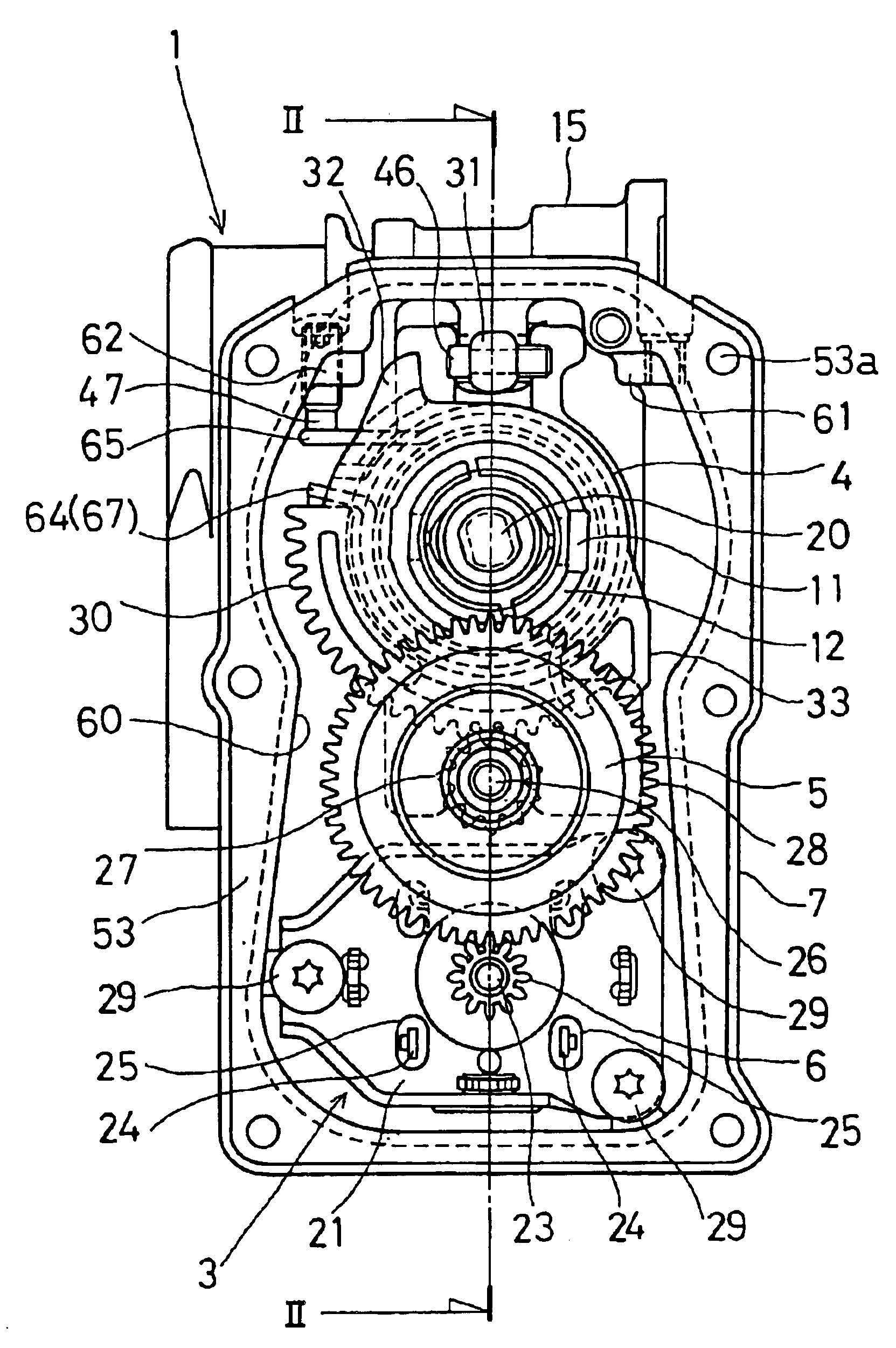

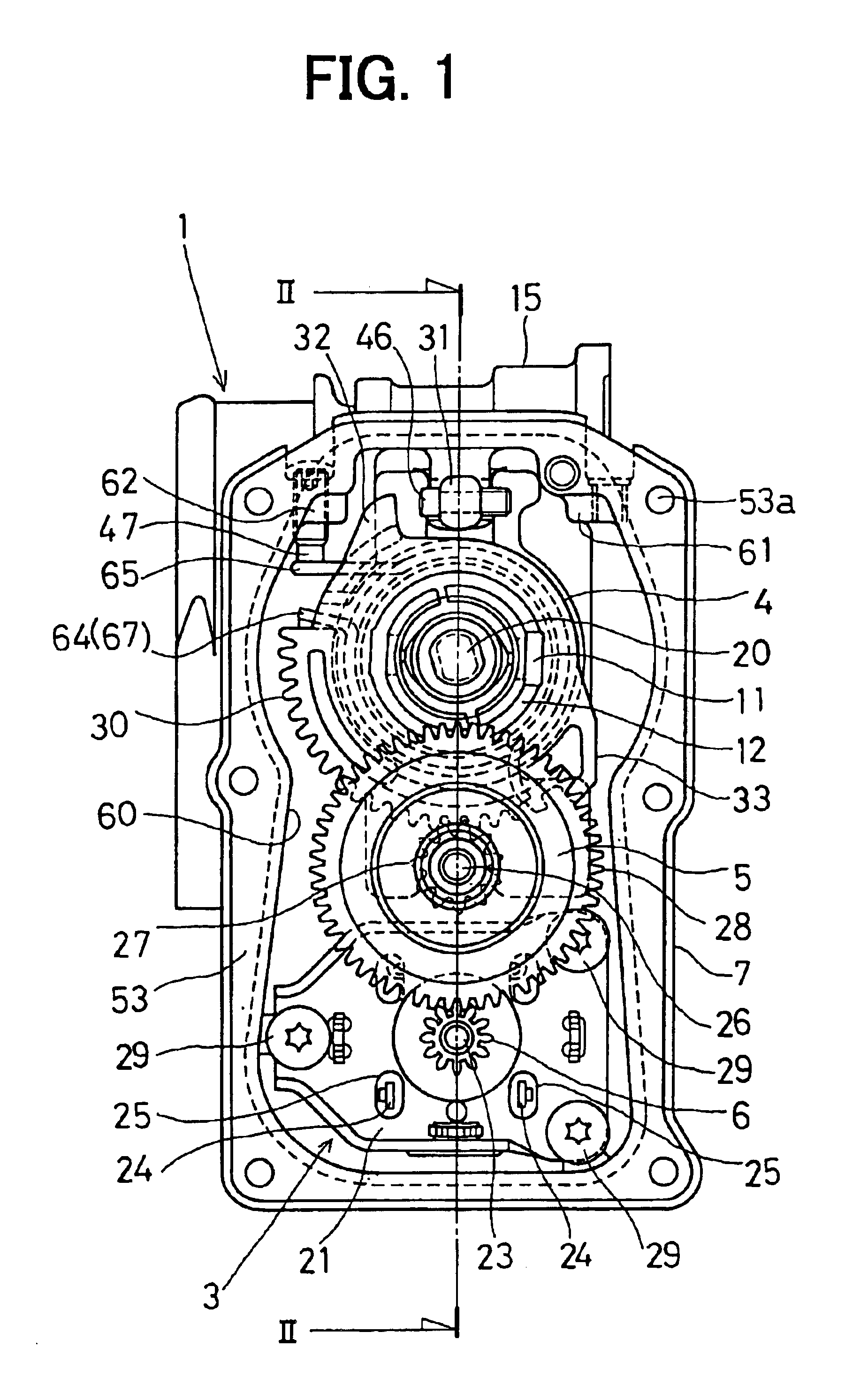

Electronically controlled throttle control apparatus

ActiveUS6912994B2Reduce in quantityLow costOperating means/releasing devices for valvesEngine controllersCar modelThrottle control

In a gear case of a throttle body, a valve gear is fixed to one end of a throttle shaft, an intermediate reduction gear is rotatable around an intermediate shaft, a pinion gear is fixed to a motor shaft of a drive motor, and a full close position stopper is provided for defining the full close position of a throttle valve. Those are provided all in alignment with the longitudinal centerline of the gear case. For car models where the throttle body bore inside diameter is identical but the rotation direction of the drive motor differs, only some components in the gear case need be replaced and the other components in the gear case can be used as common components.

Owner:DENSO CORP

Novel parallel mechanism having reconfigurable characteristic

InactiveCN105437216AAchieve foldingAchieve expansionProgramme-controlled manipulatorSlider bearingMedial axis

The invention discloses a parallel mechanism having a reconfigurable characteristic. The parallel mechanism comprises a base component, first, second and third branch chain components, lower shafts of the first, second and third branch chains, middle shafts of the first, second and third branch chains, a middle platform component and a tail end platform component, wherein a bearing seat at the rear end of the lower part of the first branch chain is connected with a first base slider bearing seat on the base component through the lower shaft of the first branch chain; the bearing seat at the front end of the lower part of the first branch chain is connected with a first middle platform bearing seat of the middle platform component through the middle shaft of the first branch chain; an end cover of the upper part of a first spherical hinge of the first branch chain component is connected with a first tail end platform connecting part of the tail end platform component; the second and third branch chain components are totally the same as the first branch chain component; a bevel gear of a base rotates to drive a wing plate screw to rotate so that a rectilinearly-moving slider of the base performs rectilinear motion along linear guide rails of the base; a screw motor rotates to drive a middle rectilinearly-moving screw to rotate, so that a middle rectilinearly-moving slider can move along middle rectilinearly-moving guide rails.

Owner:BEIJING JIAOTONG UNIV

Drive device for vehicle

InactiveCN101247969AReduce axial sizeImprove cooling effectHybrid vehiclesGearboxesAutomatic transmissionMedial axis

Provides small vehicle drives with reduced axial dimensions without increasing the number of parallel shafts. The first electric motor (M1) and the power distributing mechanism (differential part) (16) are arranged on the first axis (CL1) which is the rotation center of the input rotating member (14) in order from the input rotating member (14), automatically The transmission (transmission unit) (20) is arranged on a second axis (CL2) parallel to the first axis (CL1). The transmission member (18), which is a rotating member located on the first axis (CL1) at the end opposite to the input rotating member (14), and arranged on the second axis at the end opposite to the input rotating member (14) Between the first intermediate shaft (rotating member) (40) on (CL2), a driving connection device (23) is provided to be able to transmit power. In this way, the power transmission path becomes a C-shape or a U-shape with reduced axial dimension, which can reduce the size and simplify the structure without increasing parallel shafts.

Owner:TOYOTA JIDOSHA KK

Air inlet of air-breathing pulse detonation engine

The invention discloses an air inlet of an air-breathing pulse detonation engine. The housing of the engine constitutes the circular air inlet, wherein an inlet cone is arranged on the medial axis at the rear end of the air inlet; a cylindrical structure at the rear part of the inlet cone and the housing of the engine constitute a ring-shaped channel; the air flow is fed into a special-shaped channel having a special-shaped structure via the ring-shaped channel; the special-shaped channel is evenly distributed on the circumference of the air inlet with the distance between the central symmetrical curve of the special-shaped channel and the medial axis of the engine remaining unchanged but deviating along the circumference; a fuel channel is arranged on the medial axis of the inlet cone, and the two ends of the fuel channel are connected with the fuel inlet and a fuel injection lever located on the medial axis outside the rear end of the cylindrical structure; the fuel injection lever is particularly a hollow oil tube with one end thereof being closed; a plurality of fuel injection holes are formed on the lateral surface of the fuel injection lever; the housing of the engine and the rear end surface of the cylindrical structure constitute a mixing chamber; and an igniter is located on the lateral wall of the mixing chamber. The invention can improve the atomization and evaporation of the fuel and reduce the impact of reversed fuel on the air inlet.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com