Speed-down mechanism of electric tool

A technology of deceleration mechanism and electric motor, which is applied to manufacturing tools, mechanical equipment, transmission devices, etc., can solve problems such as noise, and achieve the effect of expanding the adjustment range and suppressing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

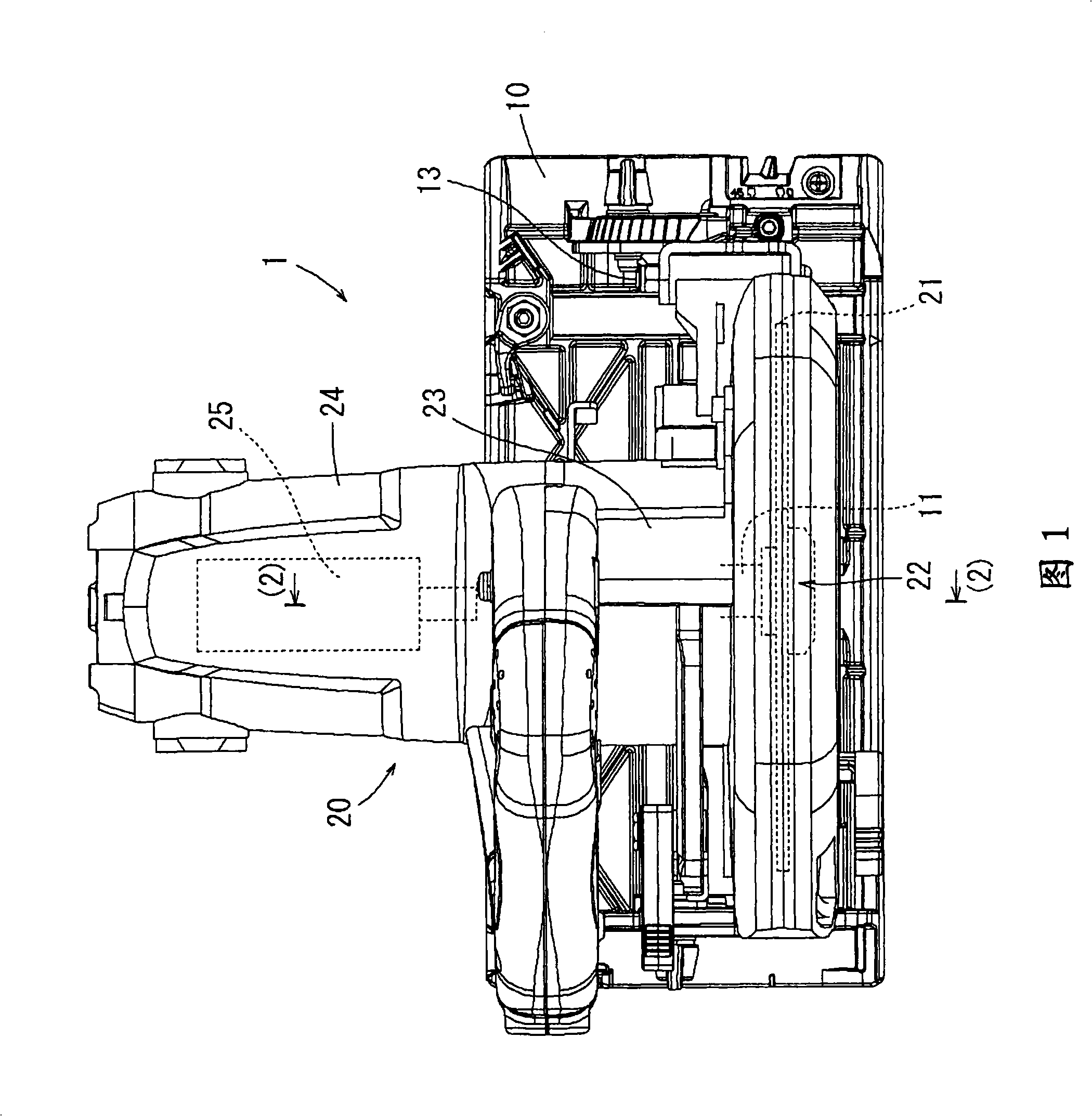

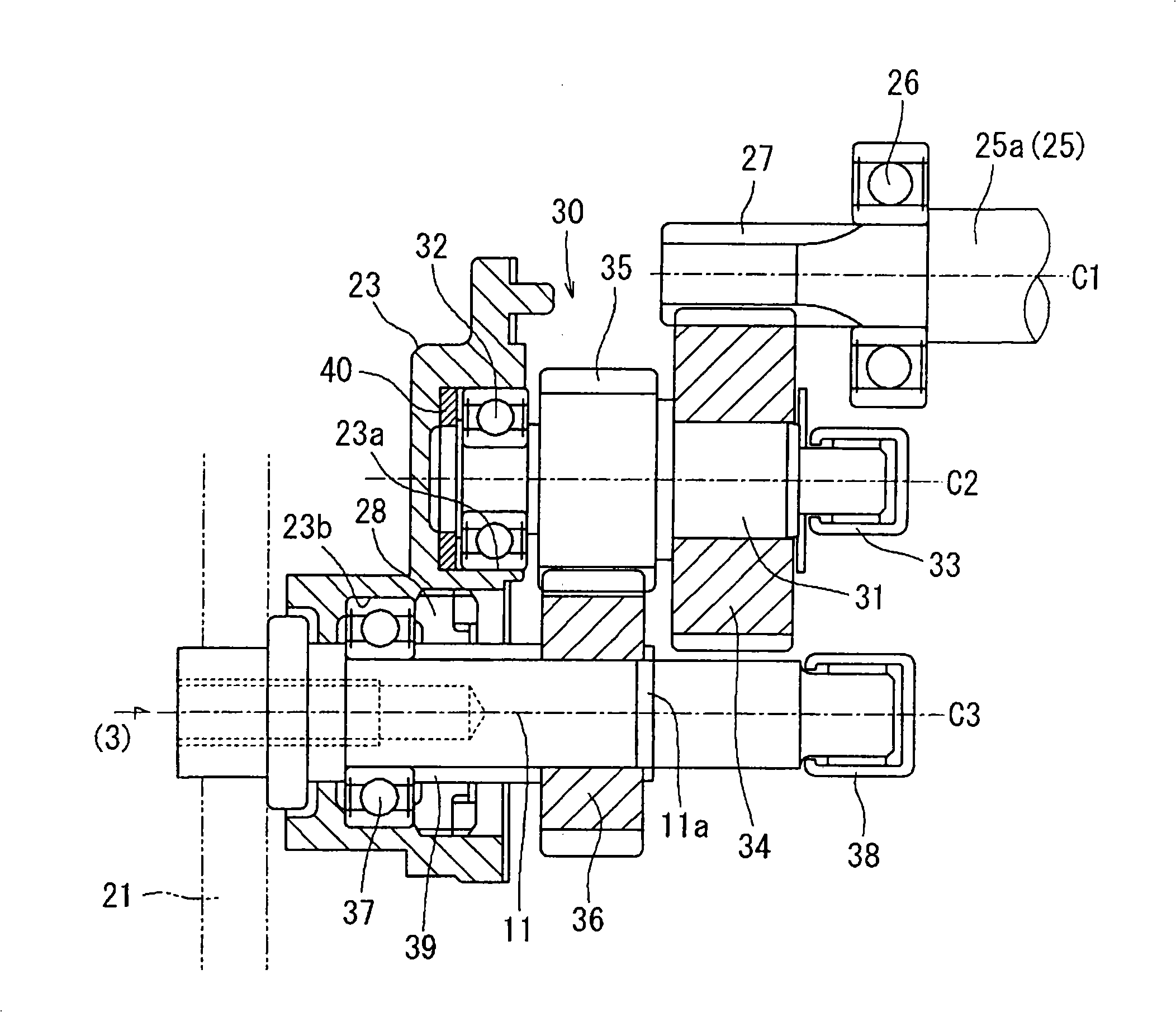

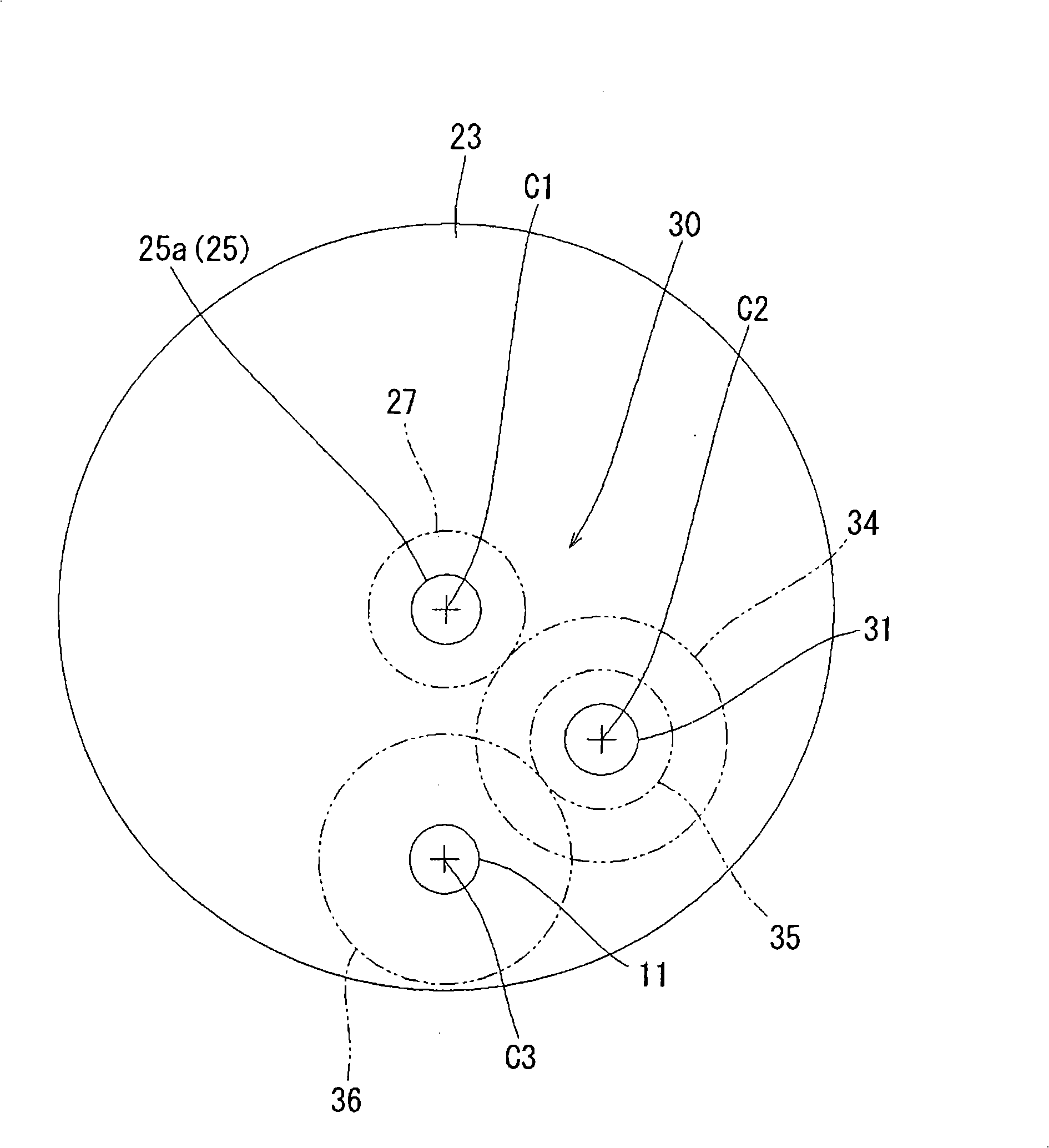

[0029] Next, refer to Figure 1~ image 3 Embodiments of the present invention will be described. Fig. 1 shows a complete cutting machine 1 in which a reduction mechanism as an embodiment of the present invention is used. In this embodiment, a portable circular saw will be described as an example of a cutting machine. This cutter 1 has a structure in which a cutter main body 20 is supported by a support shaft 13 on the upper surface side of a flat base 10 (the side facing out of the paper in FIG. 1 ) so as to be swingable upward and downward. , when working, the base 10 is placed on the material to be processed.

[0030] The cutting machine main body 20 has a blade guard 22 covering approximately the upper half of the circular saw blade 21 . The front end portion of the blade guard 22 in the cutting direction is supported by the above-mentioned support shaft 13, and the blade guard 22 can swing vertically. A gear case 23 is attached to the rear surface (upper side in FIG. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com