Installation method of ship single shafting without setting front bearing of stern shaft tube

An installation method and a technology for stern tubes, which are applied to ship parts, ship construction, transportation and packaging, etc., can solve problems such as the difficulty of shafting installation accuracy, and achieve the effects of improving installation efficiency, ensuring accuracy, and ensuring safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with the accompanying drawings, the present invention will be described in detail by taking a single-shaft installation method of a liquefied gas carrier with a volume of 22,000 cubic meters as an example.

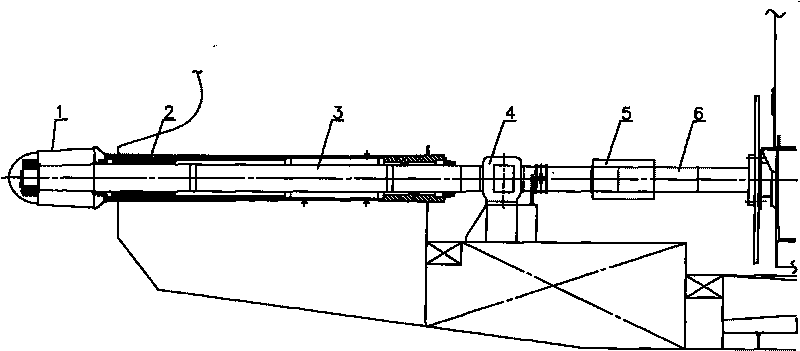

[0027] The single shaft system of the liquefied gas carrier is as figure 1 As shown, it includes a propeller 1, an intermediate shaft 6 and a stern shaft 3 connected by a hydraulic coupling 5, and a stern tube rear bearing 2 and an intermediate bearing 4. Due to the positioning of the middle bearing of the shafting of the ship, it is impossible to follow the conventional shafting installation method with the front and rear bearings of the stern tube. Therefore, during the shafting installation process, how to control the influence of the hull deformation and ensure the installation accuracy of the shafting There is a certain degree of difficulty. For this reason, the present invention firstly determines the position of the stern tube bearing mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com