Novel parallel mechanism having reconfigurable characteristic

A parallel and characteristic technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as single motion performance indicators, inability to adapt to flexible task working environments, etc., to achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in conjunction with the accompanying drawings.

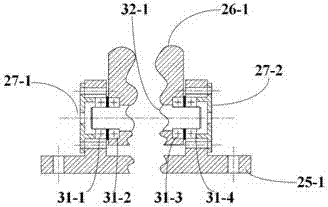

[0034]A parallel mechanism with reconfigurable properties, such as figure 1 , 19 , 20, the parallel mechanism includes: base assembly 1, first to third branch chain assemblies 2-1, 2-2, 2-3, first to third branch chain lower shafts 8-1, 8- 2. 8-3, the first to third branch chain intermediate shafts 14-1, 14-2, 14-3, the middle platform assembly 3, and the end platform assembly 4.

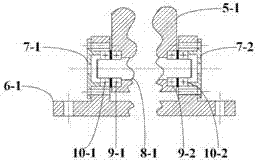

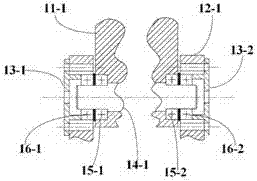

[0035] like figure 2 , 3 As shown, the first branch chain lower rear end bearing seat 5-1 of the first branch chain assembly 2-1 passes through the first branch chain lower shaft 8-1 and the first base slider on the base assembly 1 The bearing housings 6-1 are connected to form a rotating pair, wherein the inner rings of the first to second branch chain lower bearings 9-1, 9-2 cooperate with the first branch chain lower shaft 8-1, and the outer rings cooperate with the first branch chain lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com