Functionalized wide-width implanted microelectrode array, manufacturing method and application thereof

A micro-electrode array, functionalized technology, applied in electrodes, head electrodes, cardiac electrodes, etc., can solve the problems of increasing process complexity, low yield, and difficulty in meeting long-term implant effectiveness and safety, and achieves improved performance. Efficacy and safety, improving reliability and effectiveness, and reducing the risk of surgical implantation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

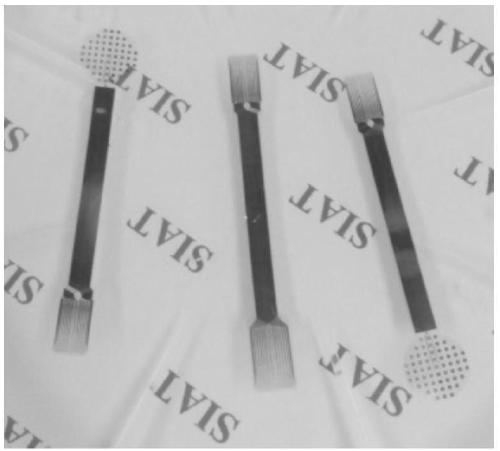

[0056] This embodiment provides an implantable microelectrode array, and its preparation method includes the following steps:

[0057] Spin-coat a layer of polyimide with a thickness of 10 μm on the surface of a 4-inch cleaned and dried silicon wafer (substrate), then spin-coat a layer of AZ5214 photoresist on the surface, and expose and develop. Next, a gold layer with a thickness of 150nm was formed by magnetron sputtering, and then the second layer of polyimide was spin-coated and cured. The electrode stimulation sites and pad points were exposed by RIE etching, and the electrodes were separated from the substrate. Released on and off to obtain a 126-channel flexible electrode array.

[0058] The back of the obtained electrode was first treated with plasma for 3 minutes, and then exposed to the vapor atmosphere of fluorosilane for 5 minutes to obtain a functionalized wide-width electrode treated with a fluorinated monomolecular layer.

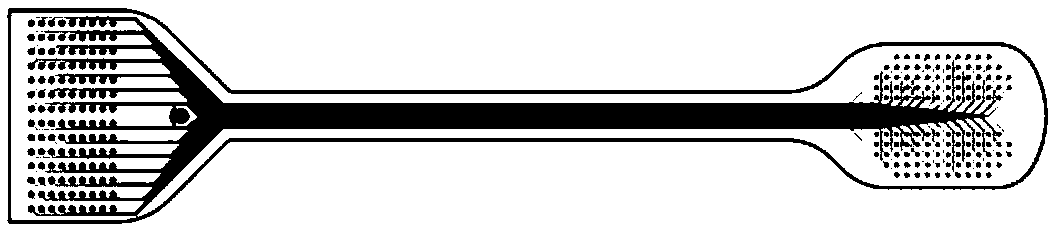

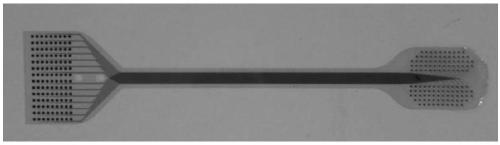

[0059] The structure of the implante...

Embodiment 2

[0061] This embodiment provides an implantable microelectrode array, and its preparation method includes the following steps:

[0062] Spin-coat a layer of polyimide (base layer) on the surface of a 4-inch cleaned and dried silicon wafer (base layer), then spin-coat a layer of AZ5214 photoresist on the surface, and expose and develop. Next, a gold layer with a thickness of 120nm was formed by magnetron sputtering, and then the second layer of polyimide was spin-coated and cured. The electrode stimulation sites and pad points were exposed by RIE etching, and the electrodes were separated from the substrate. Released on and off to obtain a 126-channel flexible electrode array.

[0063] The microelectrode array obtained above was treated with vinyl silane on the back of the polyimide (base layer), and gamma rays were used to initiate the copolymerization of caprolactone monomer mixed with black phosphorus and vinyl silane for 30 minutes to achieve chemical grafting. , and finall...

Embodiment 3

[0069] This embodiment provides an implantable microelectrode array, and its preparation method includes the following steps:

[0070] Spin-coat a layer of polyimide with a thickness of 10 μm on the surface of a 4-inch cleaned and dried silicon wafer, then spin-coat a layer of AZ5214 photoresist on the surface, and expose and develop. Next, a platinum layer with a thickness of 120 nm was formed by magnetron sputtering, and then a second layer of polyimide with a thickness of 8 μm was spin-coated and cured. After the electrode sites were exposed by RIE etching, the electrodes were removed from the The substrate was released to obtain a 256-channel flexible electrode array.

[0071] Further, a polyethylene glycol functional layer with a thickness of 100 μm was coated on the back of the electrode.

[0072] The structure of the implanted microelectrode array obtained in this embodiment includes a stimulating end, a lead part and a welding pad end. The stimulation end is circular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com