Numerical control supersonic machining apparatus for general lathe

A common lathe and processing device technology, applied in the field of numerically controlled ultrasonic processing devices, can solve problems such as low processing efficiency, inability to perform ultrasonic processing, and high labor intensity of workers, and achieve high processing accuracy, reduced labor intensity, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

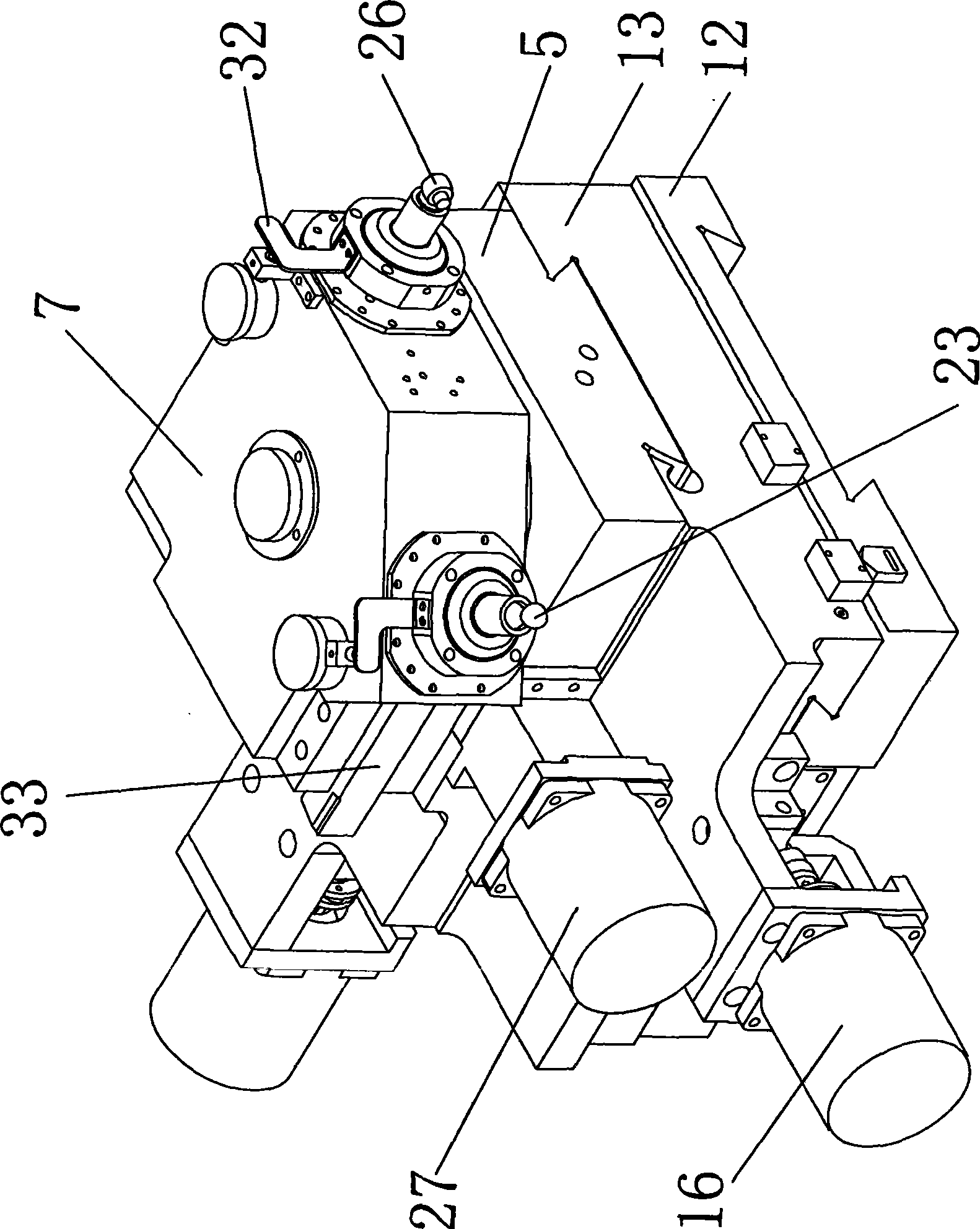

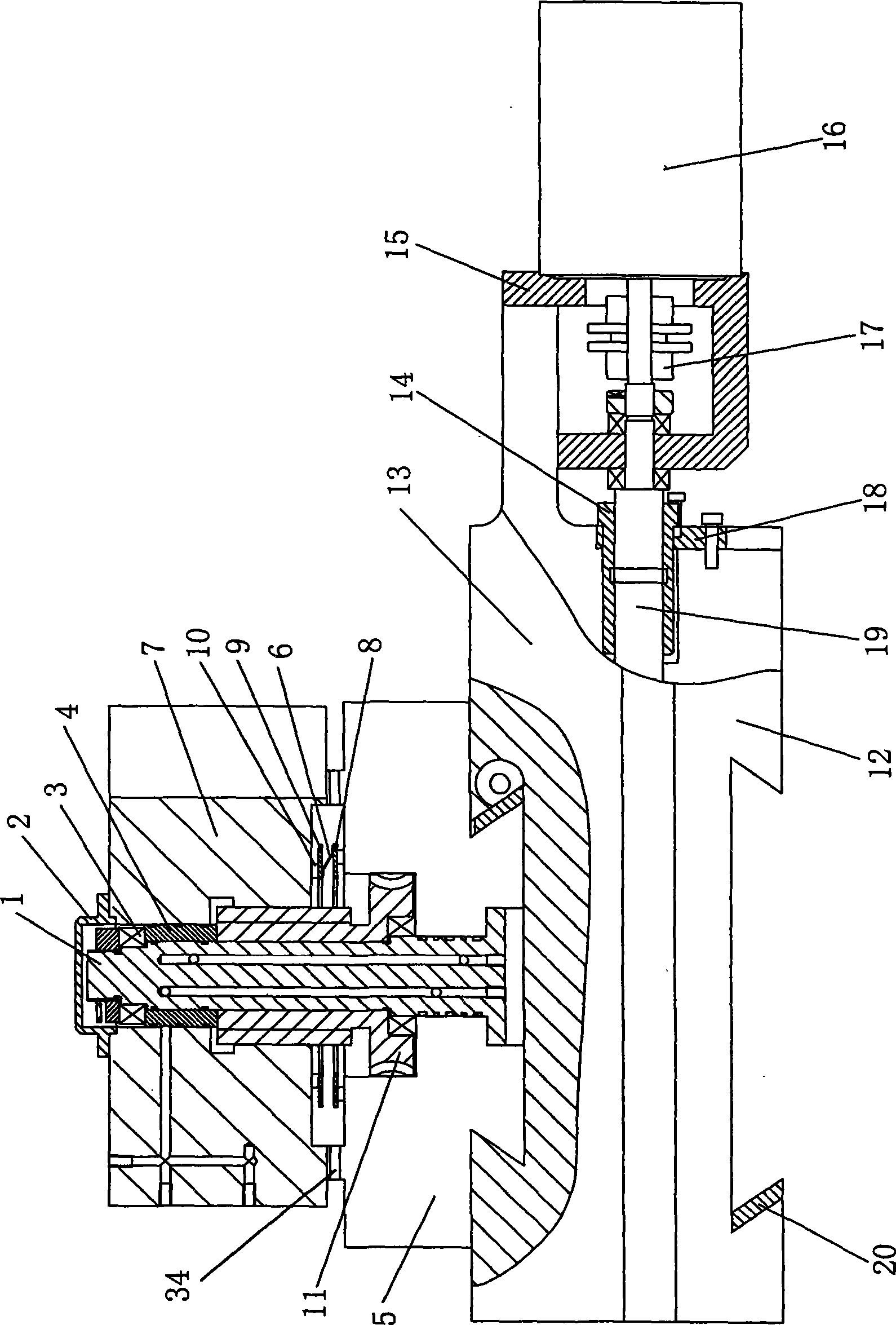

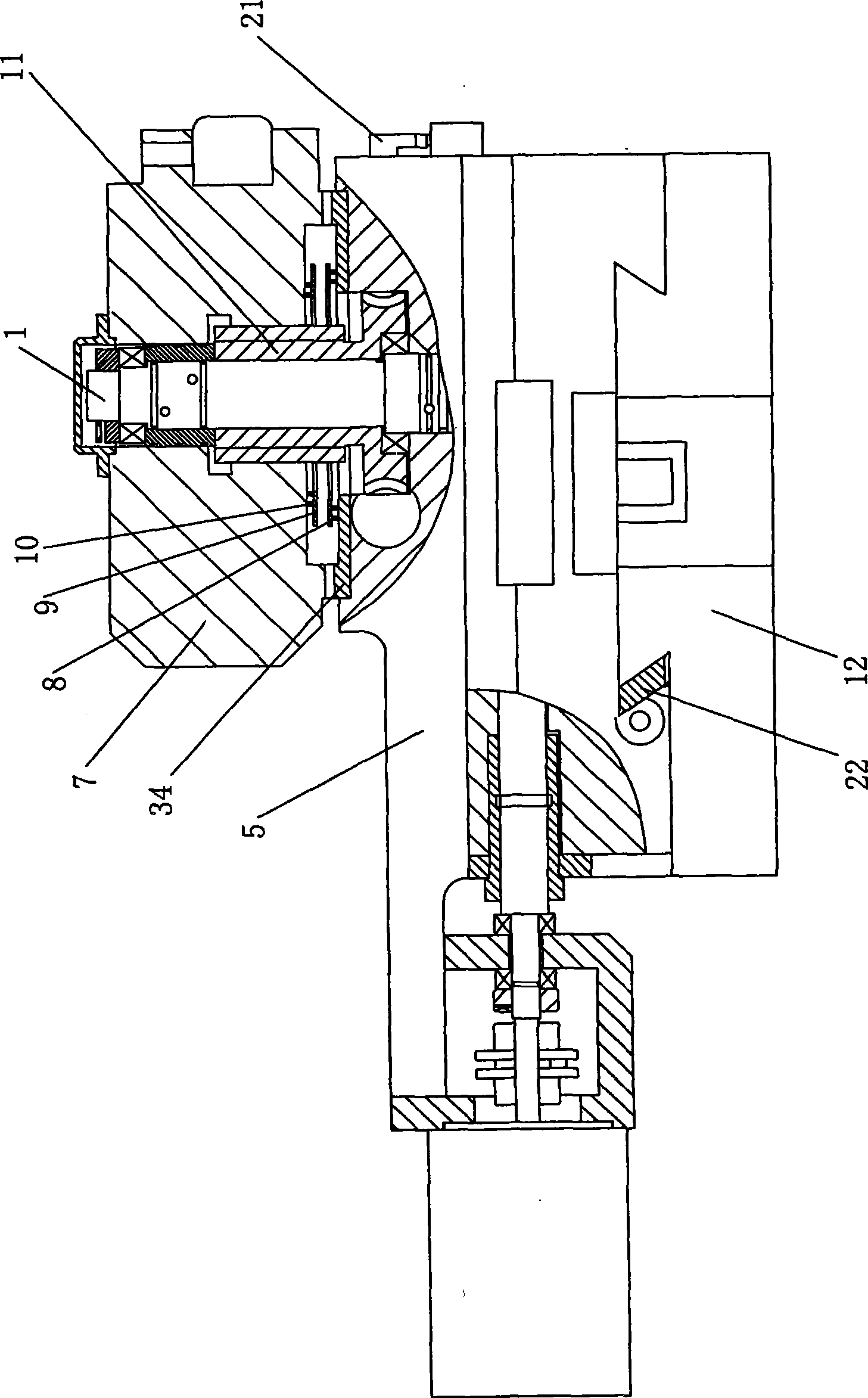

[0021] Such as figure 1 As shown, the numerically controlled ultrasonic machining device for ordinary lathes of the present invention mainly includes a base 12 , a middle guide rail 13 , an upper carriage 5 and a rotary tool holder 7 . see figure 2 , the bottom surface of the base 12 has a dovetail groove, and is fixedly installed on the dovetail guide rail of the large carriage of a common lathe by a pressing plate 20. The upper and lower sides of the middle guide rail 13 are respectively provided with a longitudinal dovetail groove and a transverse dovetail groove. The middle guide rail 13 is installed on the base 12 through the dovetail guide rail, and can move on the base 12. The stroke of the middle guide rail 13 is controlled by a travel switch. The dovetail guide rail is provided with wedge iron 22 (referring to image 3 ). The upper carriage 5 is installed on the middle guide rail 13, and the two are also connected by the dovetail guide rail. The upper carriage 5 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com