Method for locating and installing deep soft rock geostatic stress testing device

A technology for positioning, installing, and testing devices, which is applied in earth-moving drilling, wellbore/well components, etc., and can solve problems affecting sensor push, sensor torsion, hole wall damage, etc. , The effect of easy on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

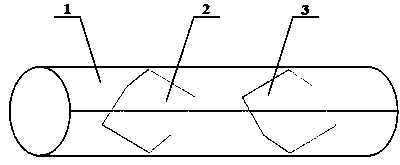

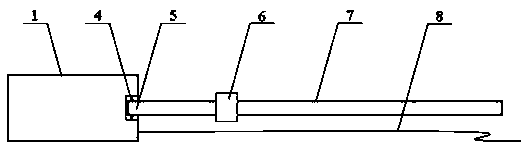

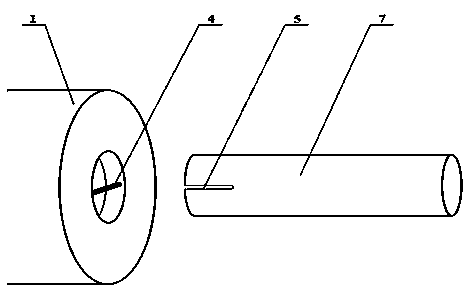

[0035] First make the sensing column 1. For the soft rock of 800-1000m deep coal-measure strata, use C5 grade concrete mortar (cement and fine sand preparation) to wrap two cubic three-way pressure boxes 2 and 3 to form a concrete cylinder with a diameter of 125mm. The centers of the two cube-shaped three-way pressure sensors are all on the central axis of the cylindrical concrete body. The central axis of one end of the three-way pressure box 2 and 3 leads from the stress sensing column 1 forms a cylindrical groove during pouring, with a depth of 8 cm and a diameter of 5 cm, which is the same as the outer diameter of the push rod 7 . A connecting cross bar 4 made of stainless steel is fixed along the cylinder diameter in the groove. The sensing column 1 is cured by adding water to 30-60% of the standard strength, and it is ready for use.

[0036] The push rod 7 is made of a hollow stainless steel tube, and the two ends of the diameter of the front end tube wall are axially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com