Patents

Literature

193results about How to "On-site construction is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shared parking spot parking management system and method for controlling intelligent parking locks online

PendingCN108133617AReduce power consumptionSignal transmission is stableTicket-issuing apparatusIndication of parksing free spacesClose rangeMobile client

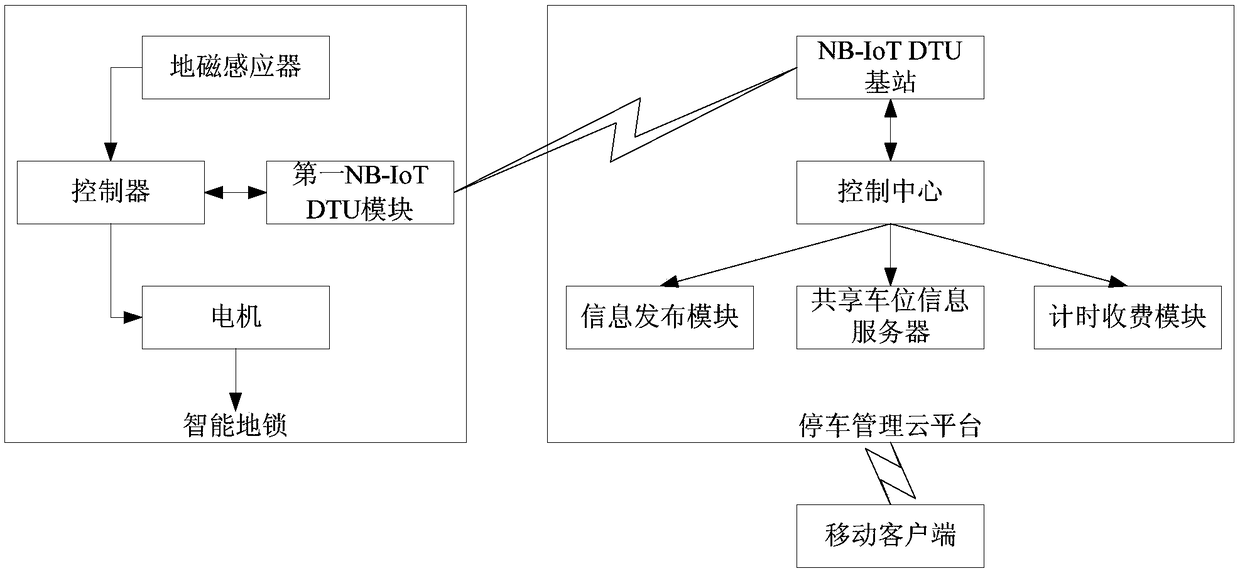

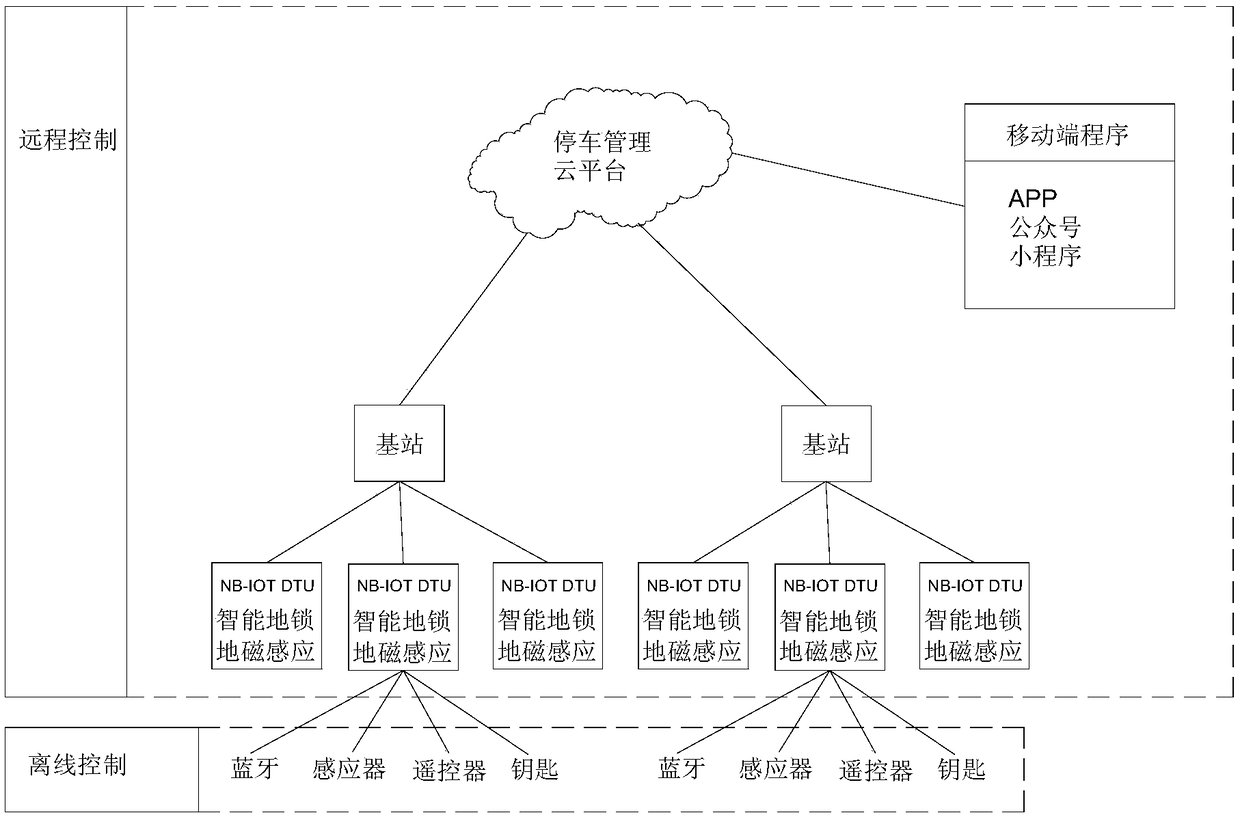

The invention discloses a shared parking spot parking management system and method for controlling intelligent parking locks online. The system comprises an intelligent parking lock (containing a first NB-IoT DTU module, a geomagnetic sensor, a controller and a motor), a parking management cloud platform, and a mobile client. According to the method, the intelligent parking lock is connected to the parking management cloud platform by using the narrow band Internet of things NB-IoT technology, and the state information of the intelligent parking lock can be acquired and the intelligent parkinglock can be controlled online. The NB-IoT technology has the characteristics of low power consumption, low traffic, wide laying range, remote control, convenience and reliability, and the like, and facilitates the realization of parking spot sharing. The system and the method overcome the problem that the existing intelligent parking lock depends on close-range Bluetooth or ultrasonic control andthe system cannot acquire the real-time state of the parking lock, can only control the parking lock offline and cannot manage the parking lock remotely. A good solution is provided for solving the difficulty of parking in cities through shared parking spots. The system and the method are convenient to implement, and have good economic benefit and application prospect.

Owner:NANJING NORMAL UNIVERSITY

Method for locating and installing deep soft rock geostatic stress testing device

InactiveCN103510951AEasy to solveEasy to calculateBorehole/well accessoriesRelative displacementMedial axis

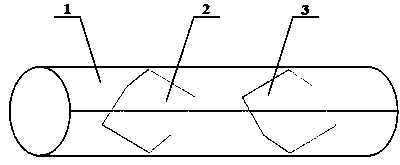

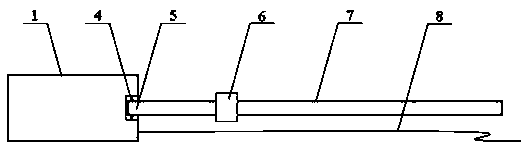

The invention discloses a method for locating and installing a deep soft rock geostatic stress testing device. According to the method, a stress sensing column is manufactured, the stress sensing column is a cement concrete cylinder comprising two three-directional pressure boxes, and the center of each cubic pressure box is located on the medial axis of the cylinder; the front end of a push rod is connected with the stress sensing column, an angle testing device is installed, rotation angle and length of the stress sensing column are recorded when the push rod is pushed from a hole mouth to a tested point at the hole bottom, and accurate data necessary for stress resolving can be obtained. According to the method, no sharp protrusion exists at the front end or the side face of the stress sensing column, the hole wall will not collapse easily in the pushing process, relative positions of a pair of three-directional pressure sensors are fixed through the stress sensing column, the two three-directional pressure sensors will not move or rotate relatively in the pushing process, and the accuracy for calculating the geostatic stress of the tested point can be ensured.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Inorganic colorized decoration mortar and preparation method thereof

The invention which belongs to the technical field of building materials concretely relates to an inorganic colorized decoration mortar and a preparation method thereof. The motor is characterized in that the motor comprises the following components, by weight, 15-40% of cement, 40-70% of an aggregate, 1-30% of an auxiliary material, 0.5-5.0% of nanoscale micropowder, 0.5-4.0% of a thixotropic agent, 0.1-3% of an early strength agent, 1-10% of a dispersant, 0.1-1.5% of a thickener, 0.1-1.5% of a water repellent and 0.01-8% of a coloring agent, wherein the total weight percentage of all the components is 100%. The inorganic colorized decoration mortar prepared by uniformly mixing the components according to above proportions in a factory has the advantages of excellent cohesiveness with a wall base, very good hydrophobicity and permeability, and excellent contamination resistance, and the weatherability and the long-term stability are better than that of organic coatings. The inorganic colorized decoration mortar can be prepared by adding 10-25% of water at a building site and uniformly and mechanically stirring when being used. The mortar can be directly daubed or sprayed on the base, so the mortar has the characteristics of simple construction and easy operation.

Owner:汪峻峰 +1

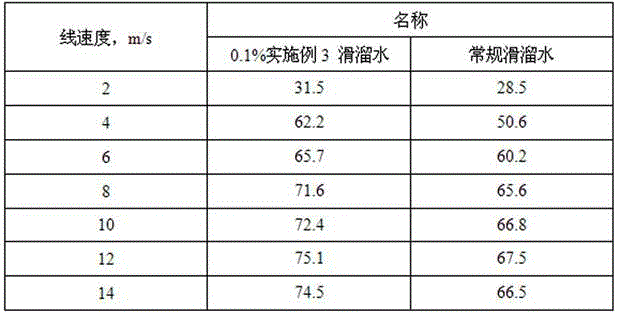

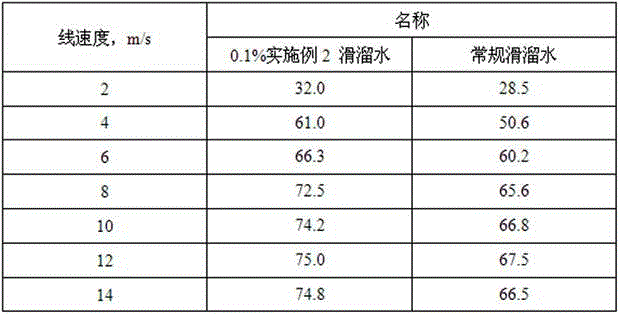

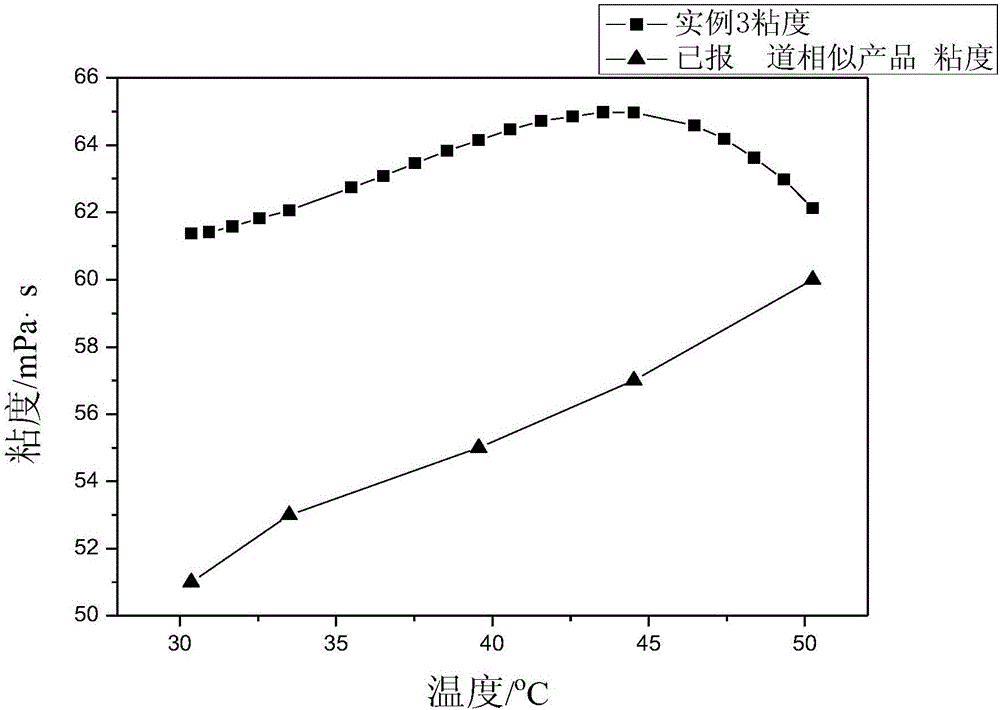

Preparation method of multifunctional emulsion type drag reducer for shale gas fracturing

InactiveCN105669895AExcellent anti-expansion abilityIncrease connection forceDrilling compositionReaction temperatureOil phase

The invention provides a preparation method of a multifunctional emulsion type drag reducer for shale gas fracturing. The preparation method comprises steps as follows: (1) firstly, an aqueous phase is prepared from water, anionic monomers, nonionic monomers and cationic monomers, the anionic monomers are added to the water, the mixture is neutralized to have the pH of 7 by the aid of a functional base, and then the nonionic monomers, the cationic monomers and an aid are added; (2) an oil phase is prepared from a solvent and an emulsifier which accounts for 5%-20% of the solvent in mass; (3) the aqueous phase and the oil phase are mixed, the water accounts for 10%-60% of the mixture in mass in the aqueous phase and oil phase mixture, high-speed shearing emulsification is performed, and then an initiator is slowly added at the reaction temperature of 20-80 DEG C under protection of nitrogen so as to initiate an emulsion polymerization reaction; (4) after the reaction is ended, a product is cooled to the room temperature, a low-surface-tension reverse phase agent is added, and the multifunctional drag reducer is obtained. The preparation method has the benefits as follows: the anti-swelling ability is outstanding, the discharge aiding effect is good, the drag reducer is multifunctional, and construction is convenient.

Owner:SHENGLI OILFIELD SHENGLI CHEM

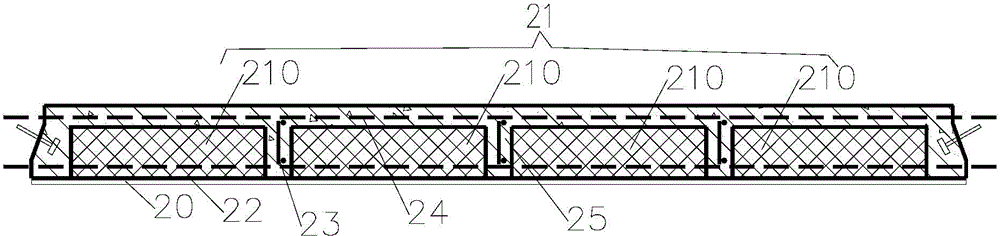

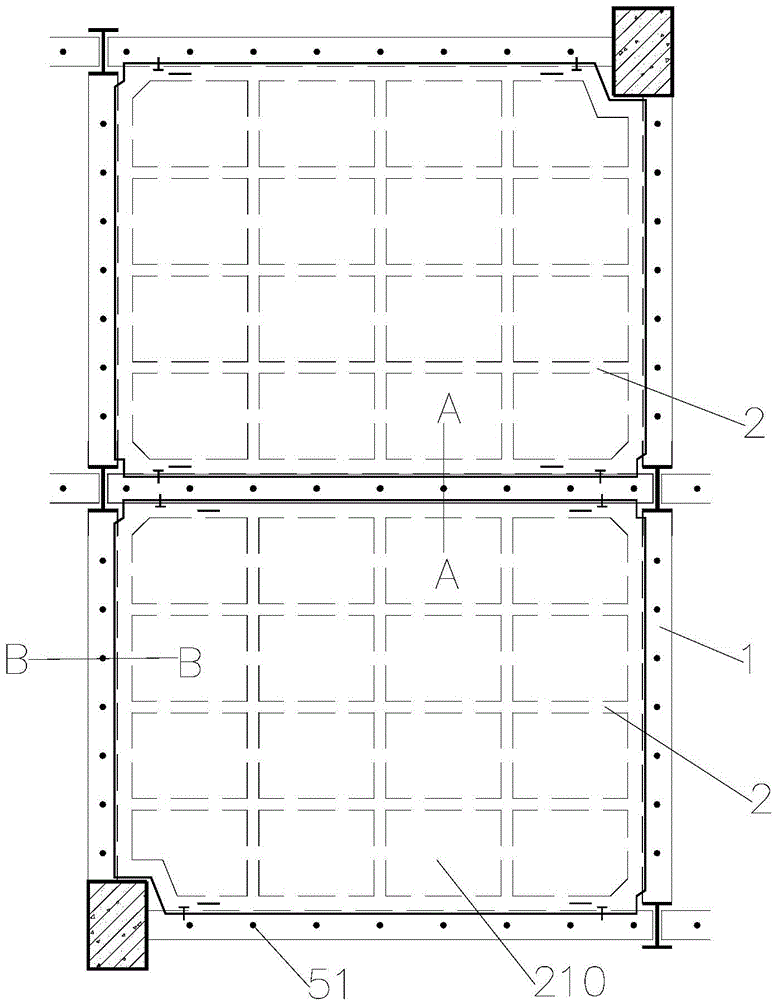

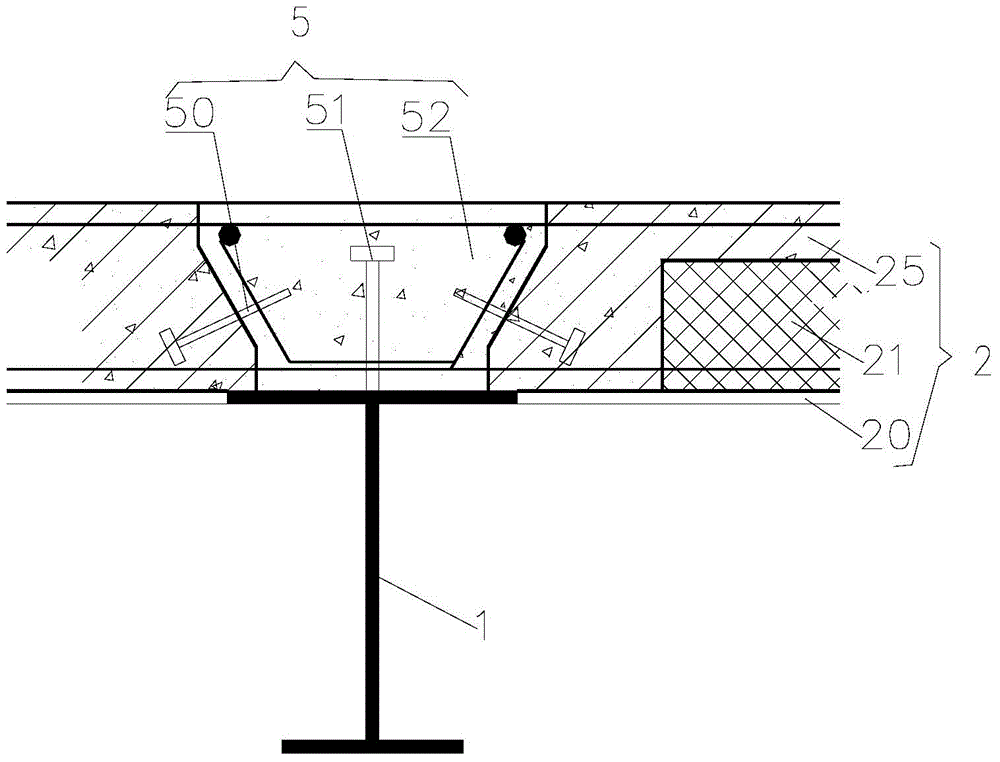

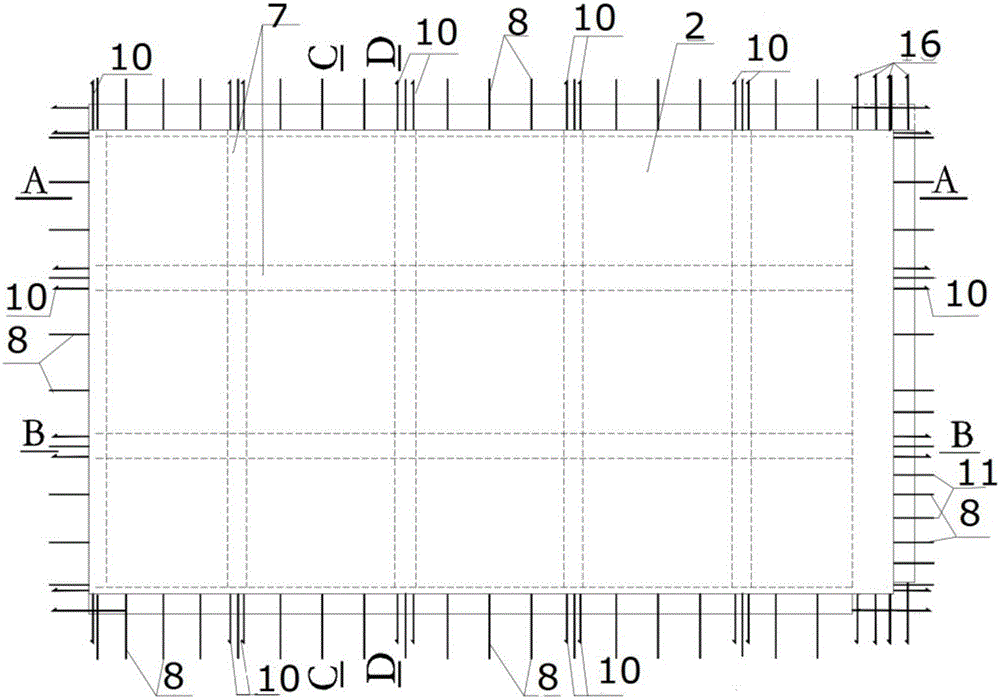

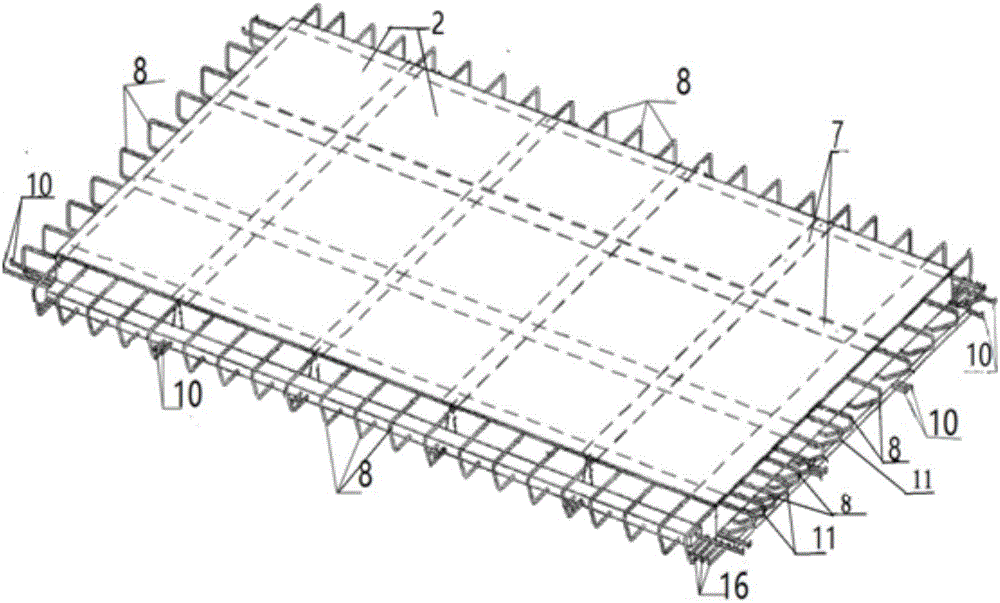

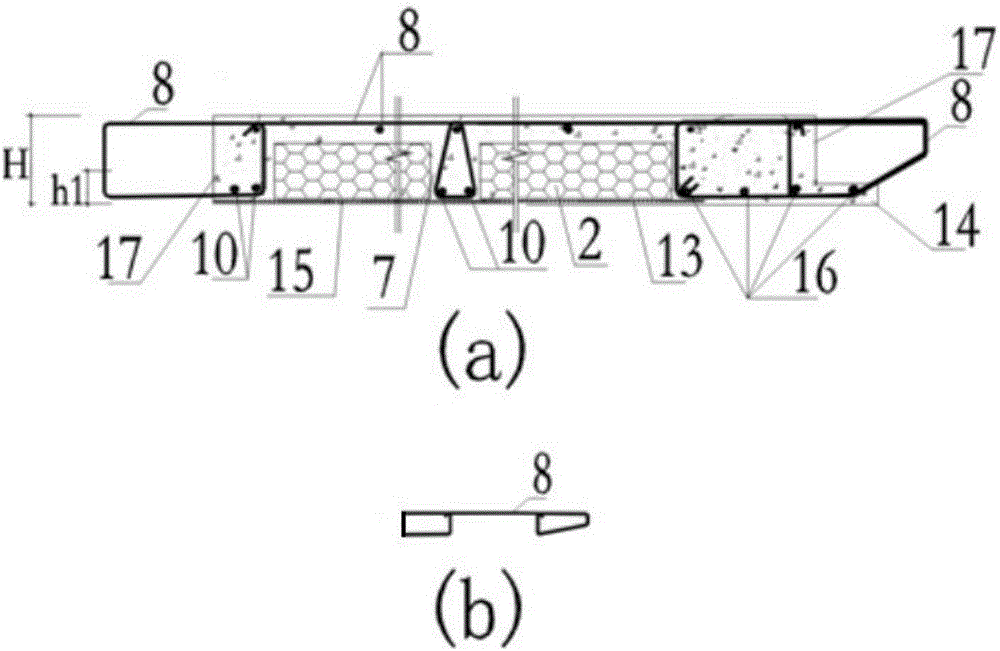

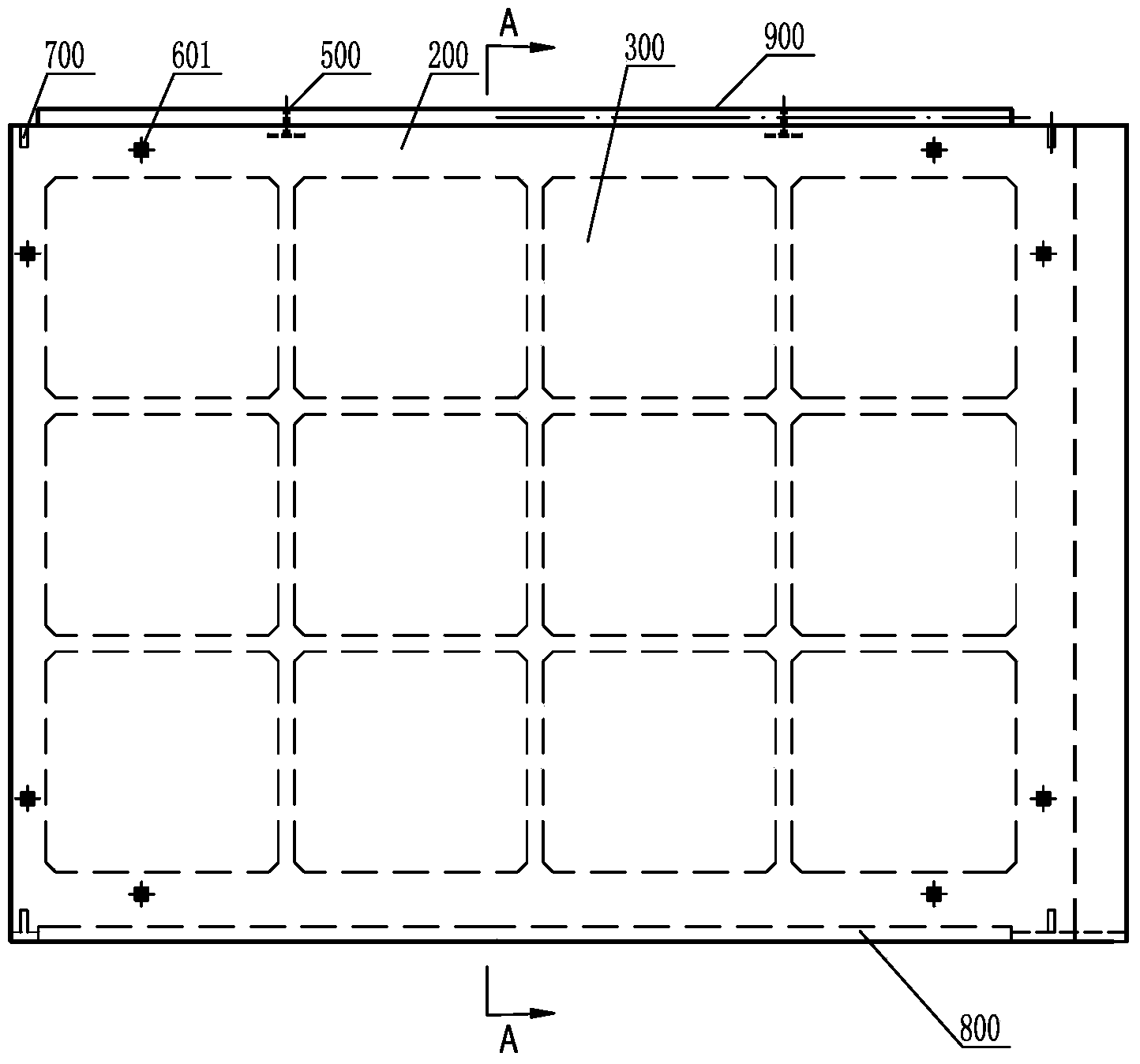

Prefabricated and light floor cover plate and industrialized building house floor plate structure

The invention discloses a prefabricated and light floor cover plate and an industrialized building house floor plate structure. The prefabricated and light floor cover plate comprises a facing layer, light packing layers where light packing blocks on the back face of the facing layer are arranged and bonding piece for fixing the facing layer and the light packing layers in a locating mode, steel reinforcement framework sheets are arranged between the light packing blocks, steel reinforcement meshes are laid at the backs of the light packing layers, and concrete structure layers are poured at the backs of the light packing layers and extend to gaps between the light packing layers to enable the facing layer, the steel reinforcement meshes, the steel reinforcement framework sheets and the light packing layers to be bonded to form a whole. The industrialized building house floor plate structure comprises a plurality of prefabricated and light floor cover plates transversely and fixedly arranged on a supporting beam, prefabricated lower sunk grooves, prefabricated balcony assemblies and cast-in-place concrete connecting pieces. The industrialized building house floor plate structure is simple in construction process and has the advantages of being light in weight, high in anti-shocking capacity, safe and the like.

Owner:黄涛 +1

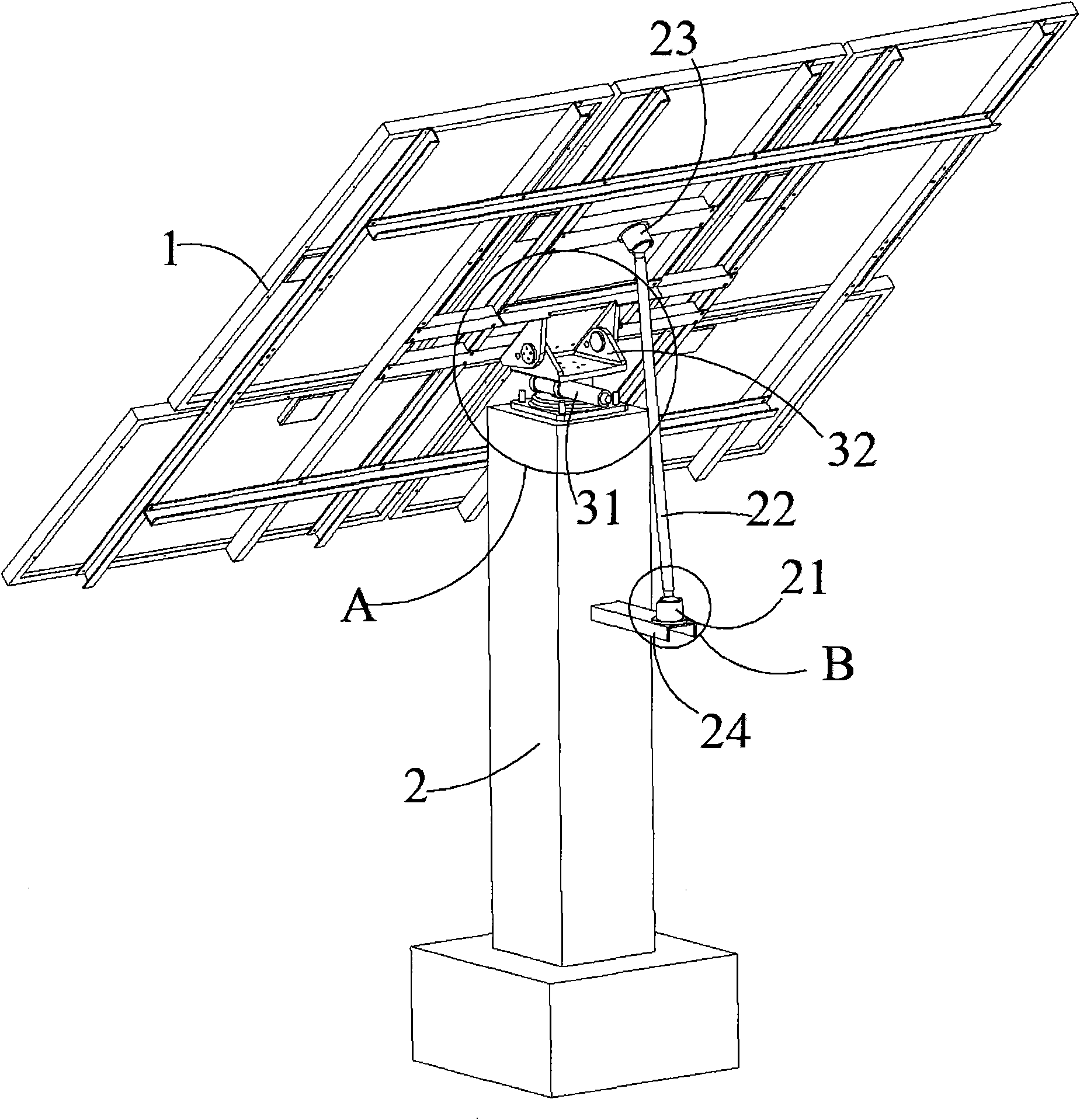

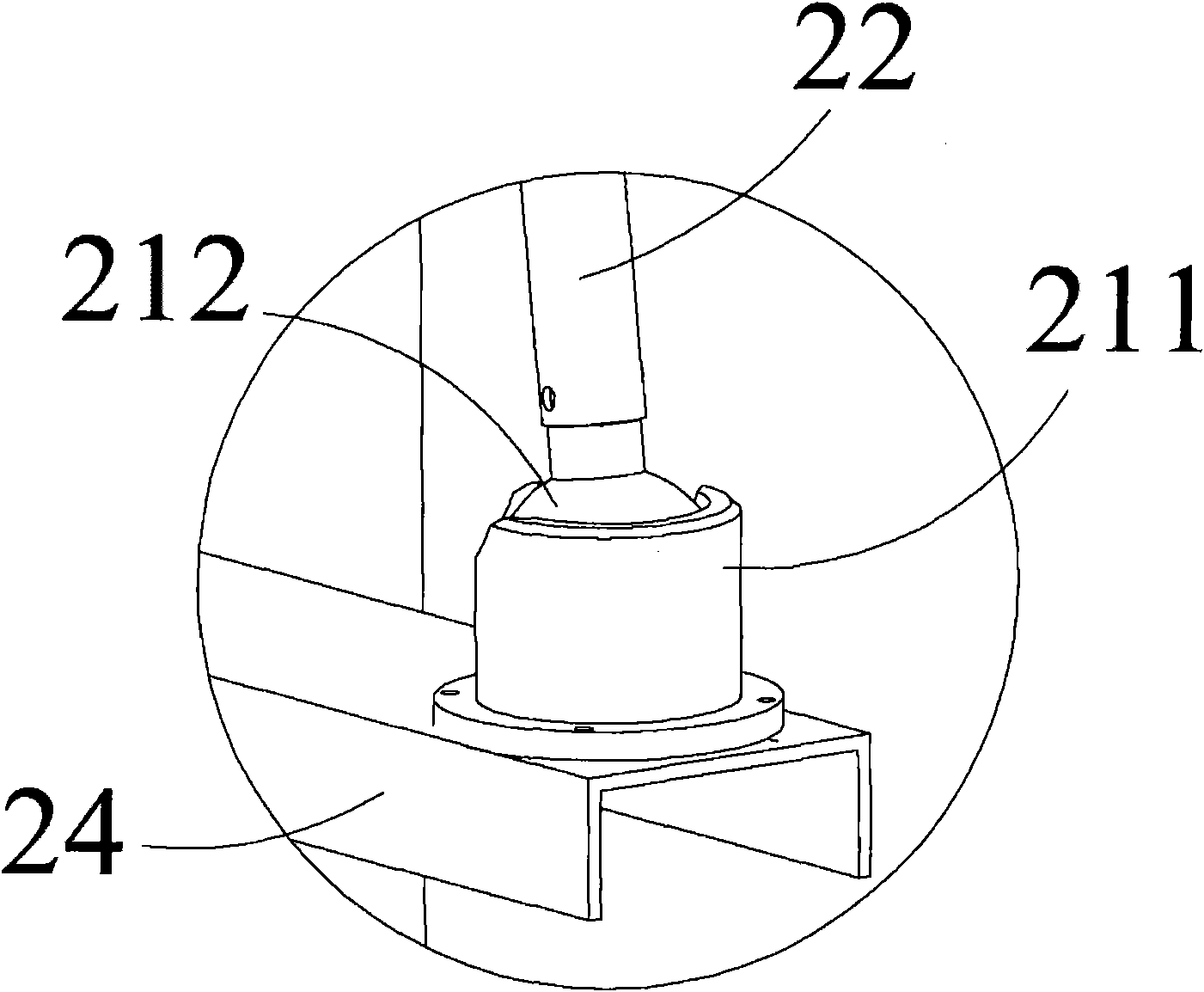

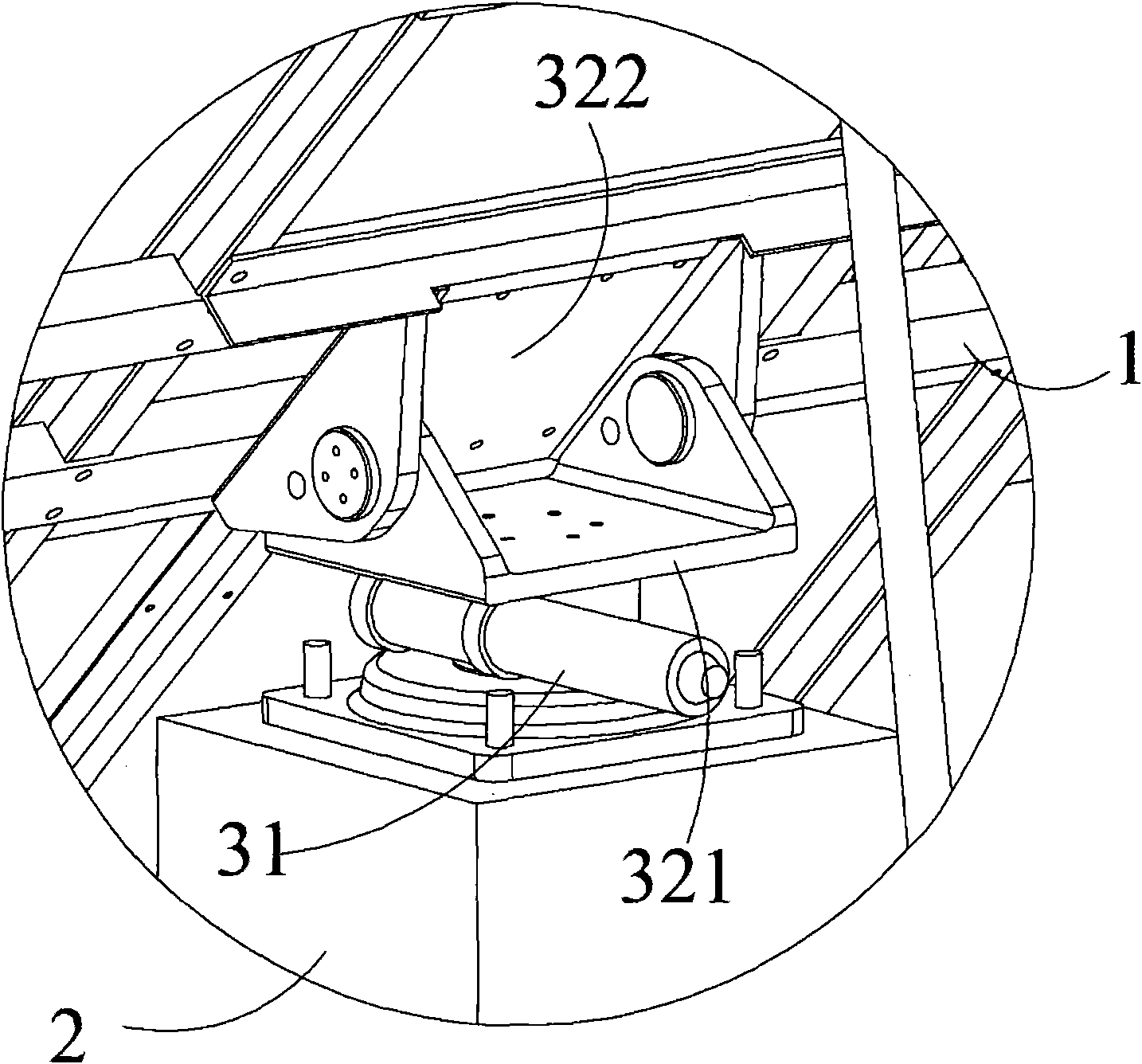

Photovoltaic power generation device with two-dimensional photovoltaic sun-positioning mechanism

InactiveCN102035435AImprove power generation efficiencySimple mechanical structurePhotovoltaic supportsControl using feedbackPhotovoltaic power generationElectric motor

The invention relates to a photovoltaic power generation device with a two-dimensional photovoltaic sun-positioning function. The photovoltaic power generation device comprises a photovoltaic battery plate and a support pillar and also comprises a two-dimensional photovoltaic sun-positioning mechanism, wherein the two-dimensional photovoltaic sun-positioning mechanism contains a first multi-turn element, a second multi-turn element, a connecting piece and a one-dimensional steering unit; the first multi-turn element is arranged on the side edge of the support pillar; the second multi-turn element is arranged on the back of the photovoltaic battery plate; the connecting piece is connected with the steering output ends of the first multi-turn element and the second multi-turn element; the one-dimensional steering unit contains an electric motor and a transmission device; and the electric motor is controlled by a drive unit to realize that the photovoltaic battery plate rotates along with the axial direction of the support pillar.

Owner:北京意科能源技术有限公司

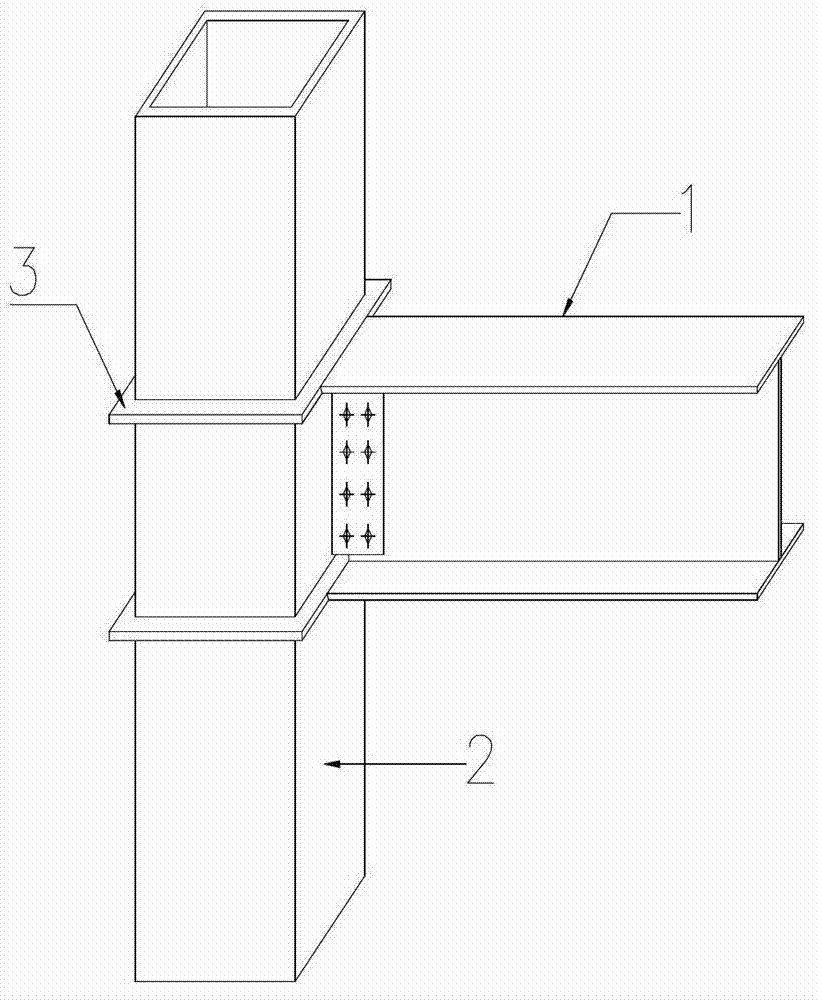

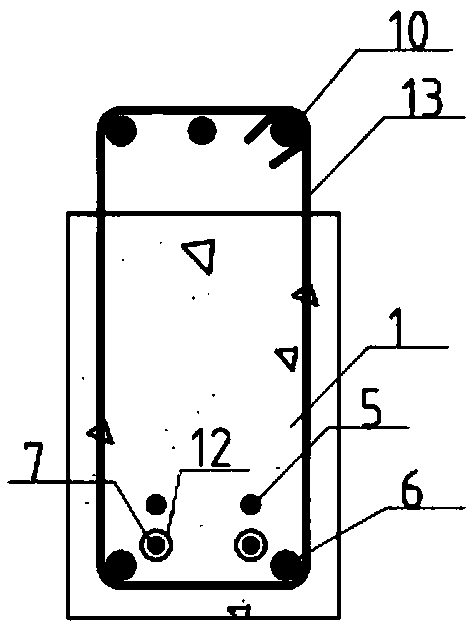

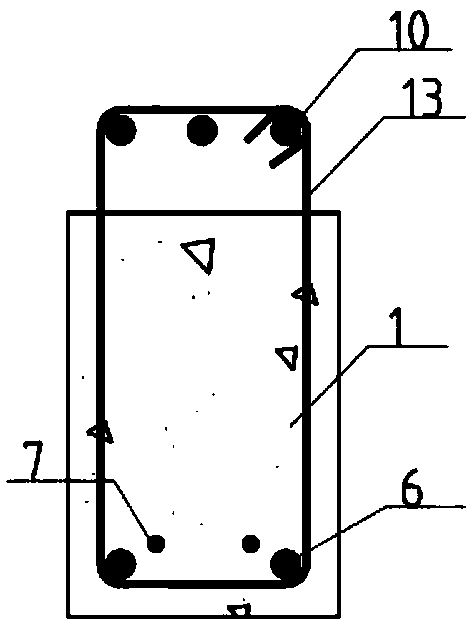

Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

The invention discloses a connecting node of an assembled whole thick prefabricated slab. Connecting steel bars are reserved on the connecting surface of a prefabricated slab unit in the mode, the exposed parts of the connecting steel bars are ' '-shaped, and the exposed parts and the connecting surface form a closed polygon. In the connecting mode for the prefabricated slab unit and a beam or a wall, the connecting steel bars of the prefabricated slab unit are inserted with steel bars configured for the beam or the wall together at the connecting positions in a penetrating mode. Viewing from the cross section of the whole connecting node, the connecting steel bars and the steel bars configured for the beam or the wall form a single closed stirrup or a composite stirrup, and longitudinal bolt steel bars penetrate into the inner corner position of the single closed stirrup or the composite stirrup. The connecting node of the whole thick prefabricated slab unit can achieve the equivalent performance as a prefabricated slab connecting nodes and a cast-in-place concrete structure while achieving higher prefabrication rate and assembly rate. The invention further provides the whole thick prefabricated slab unit for achieving the connecting mode.

Owner:刘祥锦

Concrete repairing material suitable for ocean environment and preparation method thereof

The invention relates to a concrete repairing material suitable for an ocean environment and a preparation method thereof. The repairing material is prepared from the following components in parts bymass: 100 to 230 parts of portland cement, 20 to 47 parts of aluminate cement, 10 to 25 parts of dihydrate gypsum, 0 to 110 parts of mineral powder, 3.0 to 4.5 parts of water reducer, 0 to 2 parts ofearly strength agent, 0.01 to 0.02 part of air entraining agent, 5 to 20 parts of polyester fiber, 0.10 to 0.15 part of antifoaming agent and 300 to 500 parts of quartz. ,According to the invention, the portland cement is complexed with the aluminate cement, so that the early strength and later strength are ensured, resistance of mortar to chlorine salt, sulfate and magnesium salt in the ocean environment is enhanced. The concrete repairing material is suitable for ocean-eroded concrete repairing engineering, is large in market space, and is high in practicability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Cement-based rapid repair material with high early strength, and preparation method thereof

The invention discloses a cement-based rapid repair material with high early strength, wherein the cement-based rapid repair material is prepared from the following raw materials by mass: 500-650 parts sulphoaluminate cement, 200-400 parts of ordinary Portland cement, 800-900 parts of quartz sand, 4.5-9.0 parts of nanometer silicon dioxide, 0.25-0.6 part of a dispersing agent, 1.1-10.8 part of a water reducing agent, 0.045-0.160 part of a retarder, 0.10-0.25 part of a defoaming agent and 315-360 parts of water. The invention further provides a preparation method of the cement-based rapid repair material with improved early strength. According to the invention, the field preparation is convenient and easy, sulphoaluminate cement and Portland cement are compounded so as to ensure the early strength and the later strength, the microstructure of the composite repair system is obviously improved through the nanometer material, the early mechanical property of the cement-based material is remarkably improved, the driving quality and the driving safety of the repaired pavement are ensured, the repair cost is low, and the practicability is high.

Owner:GANSU ELECTRIC POWER DESIGN INST

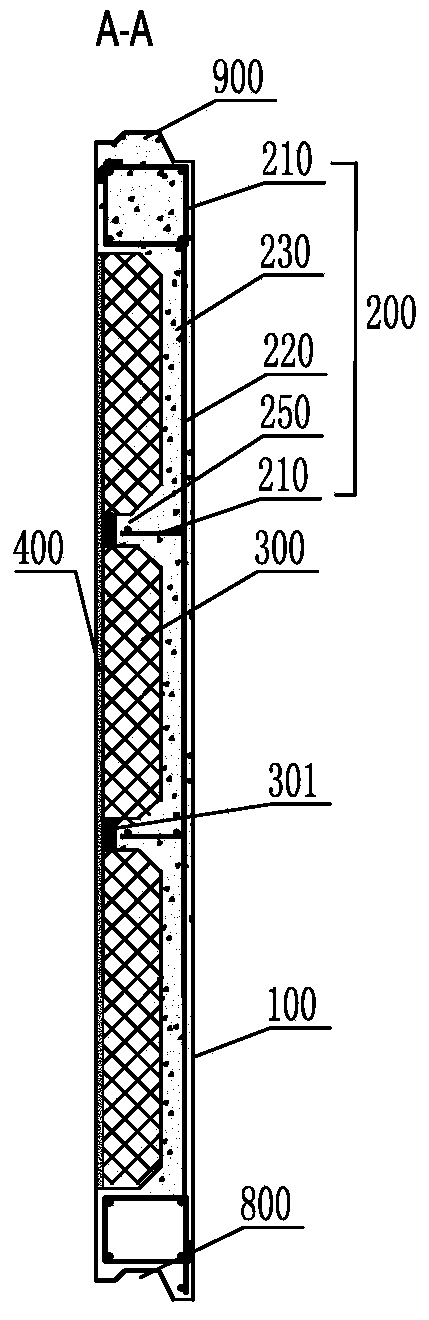

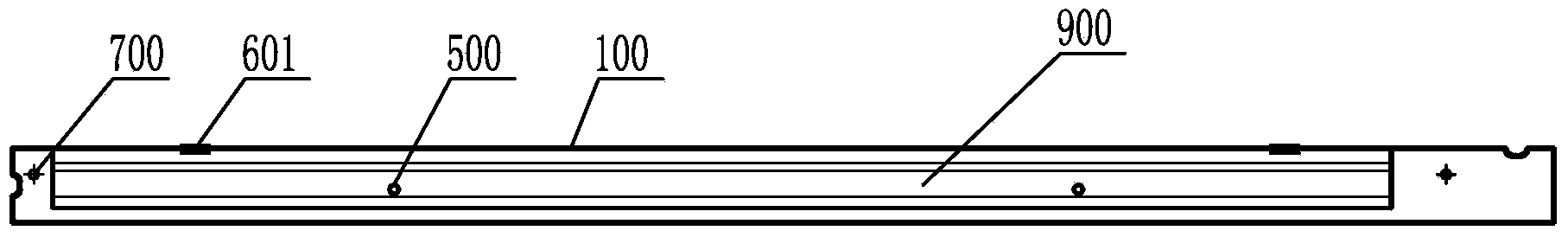

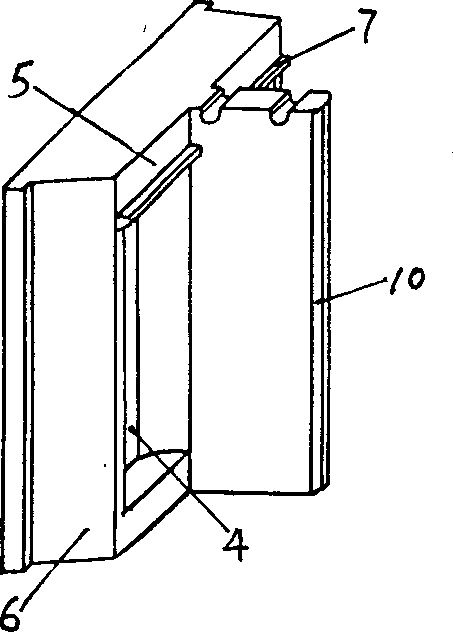

Integrally prefabricated multifunctional composite external wall panel and industrial building external wall

The invention discloses an integrally prefabricated multifunctional composite external wall panel and an industrial building external wall. The external wall panel comprises an outer decoration layer, a reinforcing bar fine aggregate concrete structural layer, a light-weight heat insulation layer and an indoor decoration layer which are fixedly connected from the outside to the inside, wherein the reinforcing bar fine aggregate concrete structural layer is filled into the light-weight heat insulation layer for forming plate ribs; heat insulation pads are arranged on the end surfaces of the plate ribs; first connecting elements are arranged on the periphery of the external wall panel; the top and the bottom of the external wall panel are respectively provided with positioning mechanisms; the top of the external wall panel is provided with hanging rings; and pre-buried accessories are arranged in the external wall panel. The external wall is formed by the external wall panels through vertical and horizontal distribution, surrounding and shielding, the periphery of each external wall panel is provided with a connecting mechanism connected with a main body stress component; the back part of the connecting mechanism is pre-buried in the reinforcing bar fine aggregate concrete structural layer of the external wall panel; and the adjacent external wall panels are sealed and connected through telescopic sealing elements. The integrally prefabricated multifunctional composite external wall panel and the industrial building external wall have the advantages that the industrial production can be realized; the weight is light; the transportation and the construction are convenient; the heat insulation performance and the sound isolation performance are good; the intensity and the weatherability are good; the internal and external decoration construction is not needed; and the installation is convenient.

Owner:黄涛 +1

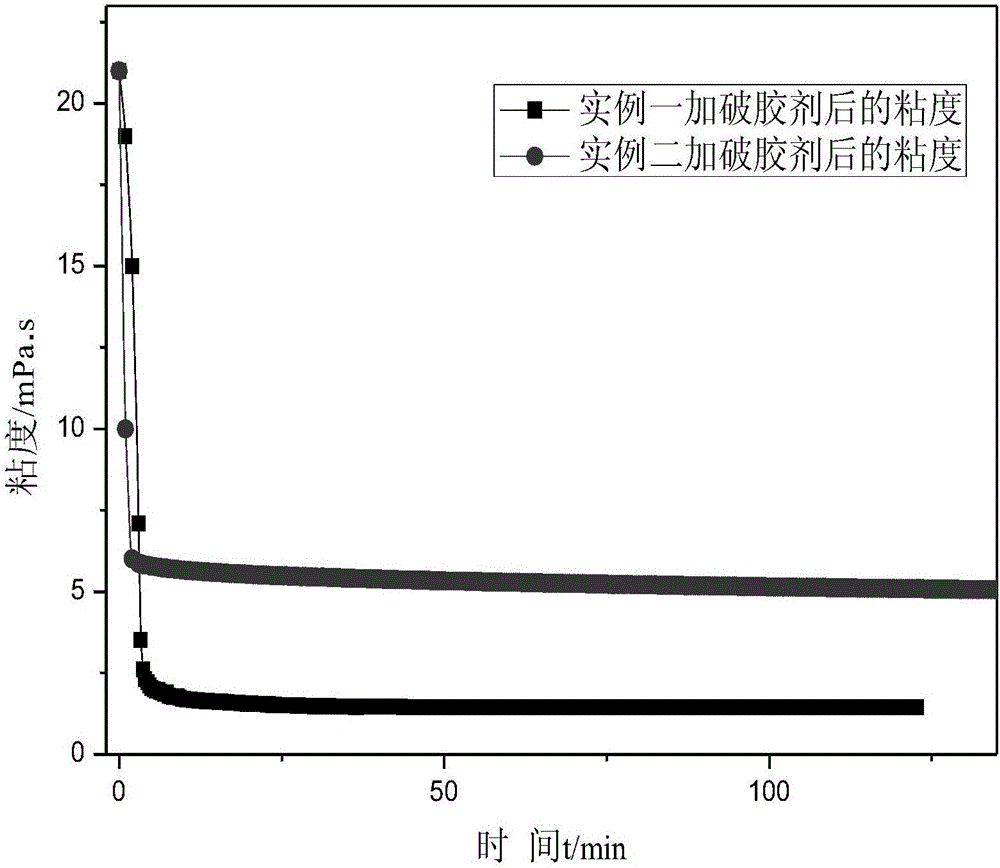

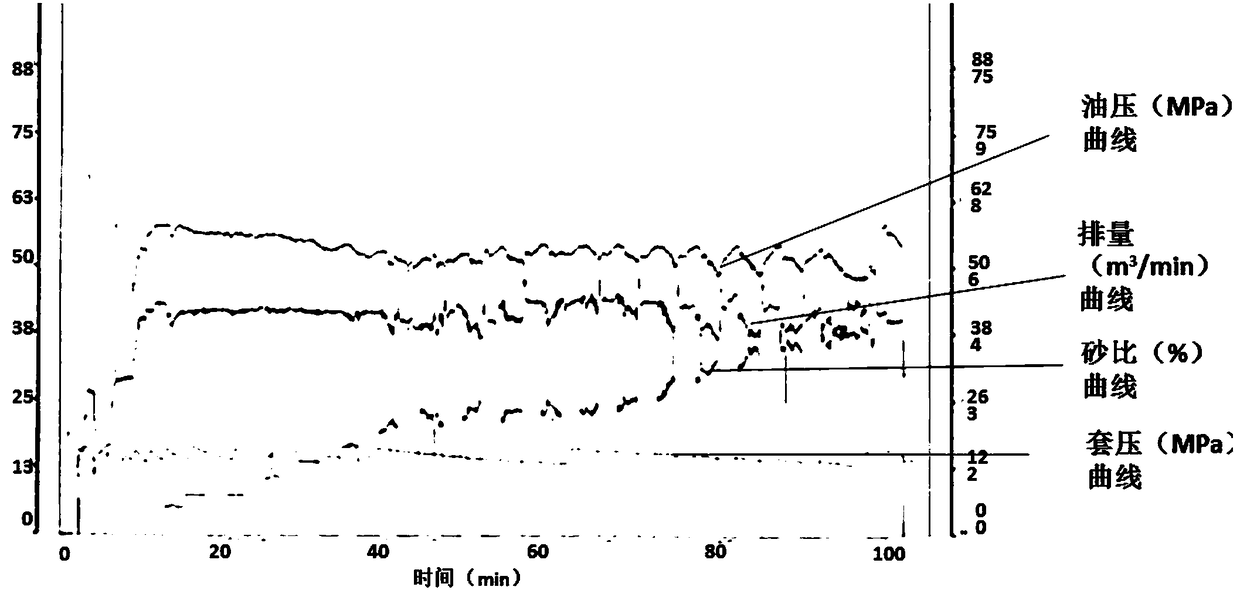

Preparation and application of anionic clean fracturing liquid and gel breaker thereof

InactiveCN106566521AGood effectGood sand carryingFluid removalDrilling compositionFracturing fluidSURFACTANT BLEND

The invention relates to the technical field of oil filed fracturing, and specifically relates to an anionic clean fracturing liquid, which is composed of 0.5 to 10% of anionic surfactant, 5 to 20% of counter-ion salts, and the balance being water. The provided clean fracturing liquid preserves all advantages of conventional clean fracturing liquids. The species of additives can be reduced and the requirements on liquid blending equipment can be lowered by using the clean fracturing liquid. The fracturing liquid can be used in oil fields with a high mineralization degree. The gel breaking time can be well controlled by using a gel breaker and the cost is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

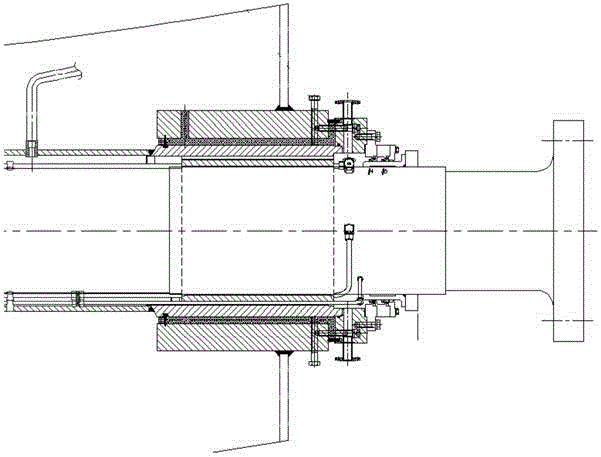

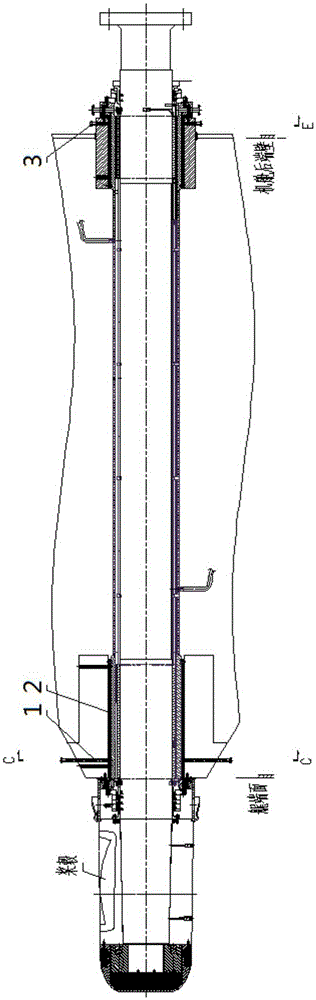

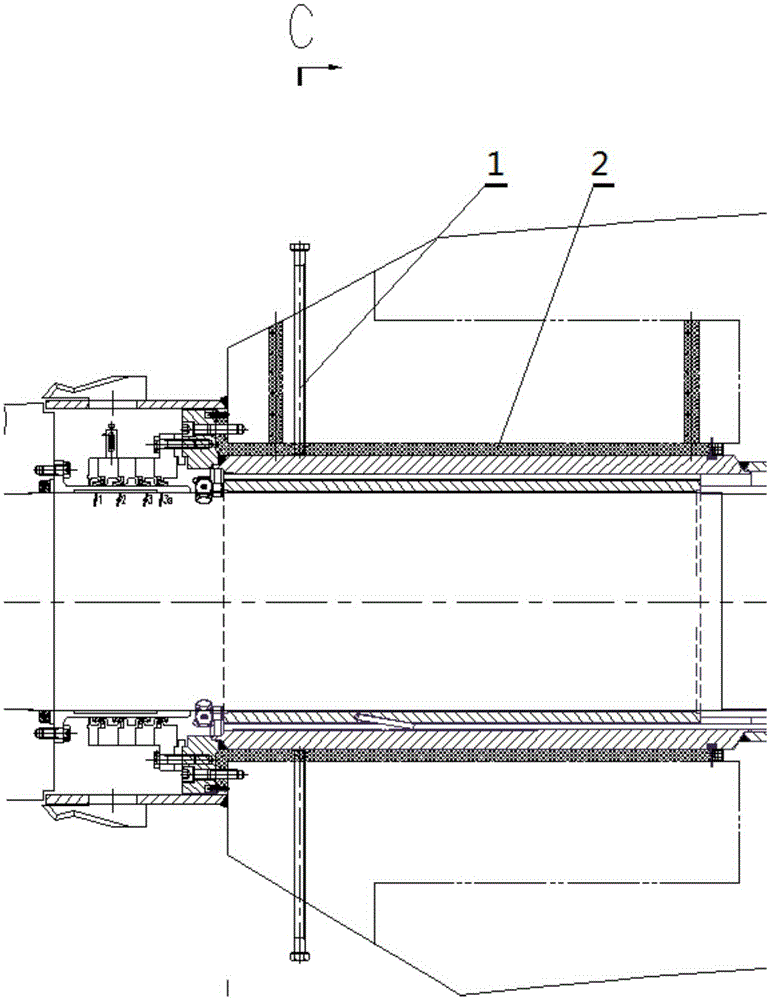

Ship shafting integral tail pipe alignment positioning structure and positioning method

InactiveCN105253252ASolve the problem of accuracy and accuracyHigh precisionTransmission with propulsive element synchronisationRadial positionMarine engineering

The invention relates to a ship shafting integral tail pipe alignment positioning structure and positioning method. An adjusting bracket and adjusting bolts are arranged at each of the front and rear ends of a ship shafting tail pipe; each adjusting bracket is L-shaped, and one end of the adjusting bracket is transversely welded and fixed onto one corresponding fixing base; two pairs of the adjusting bolts are respectively arranged at the front and rear ends, perpendicularly penetrate through two side surfaces of the respective adjusting brackets, and are respectively propped against the ship shafting tail pipe axially and radially, so as to adjust the axial and radial positions of the ship shafting tail pipe; after positioning is finished, an epoxy cushion block is cast between the ship shafting tail pipe and the fixing bases; the adjusting brackets are disassembled, the exposed parts of the adjusting bolts are cut off, and sealing treatment is performed; the fixing base at the front part of the ship shafting tail pipe is a bearing steel casting, and the fixing base at the rear part of the ship shafting tail pipe is a sternpost. Through adoption of the structure and method provided by the invention, alignment positioning is performed on the ship shafting tail pipe in a three-dimensional space, so as to greatly improve the mounting accuracy; the adjusting bolts are not in contact with an epoxy medium, and bubbles and the like are unlikely to generate on the contact surfaces, so that the quality of epoxy casting can be effectively improved.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

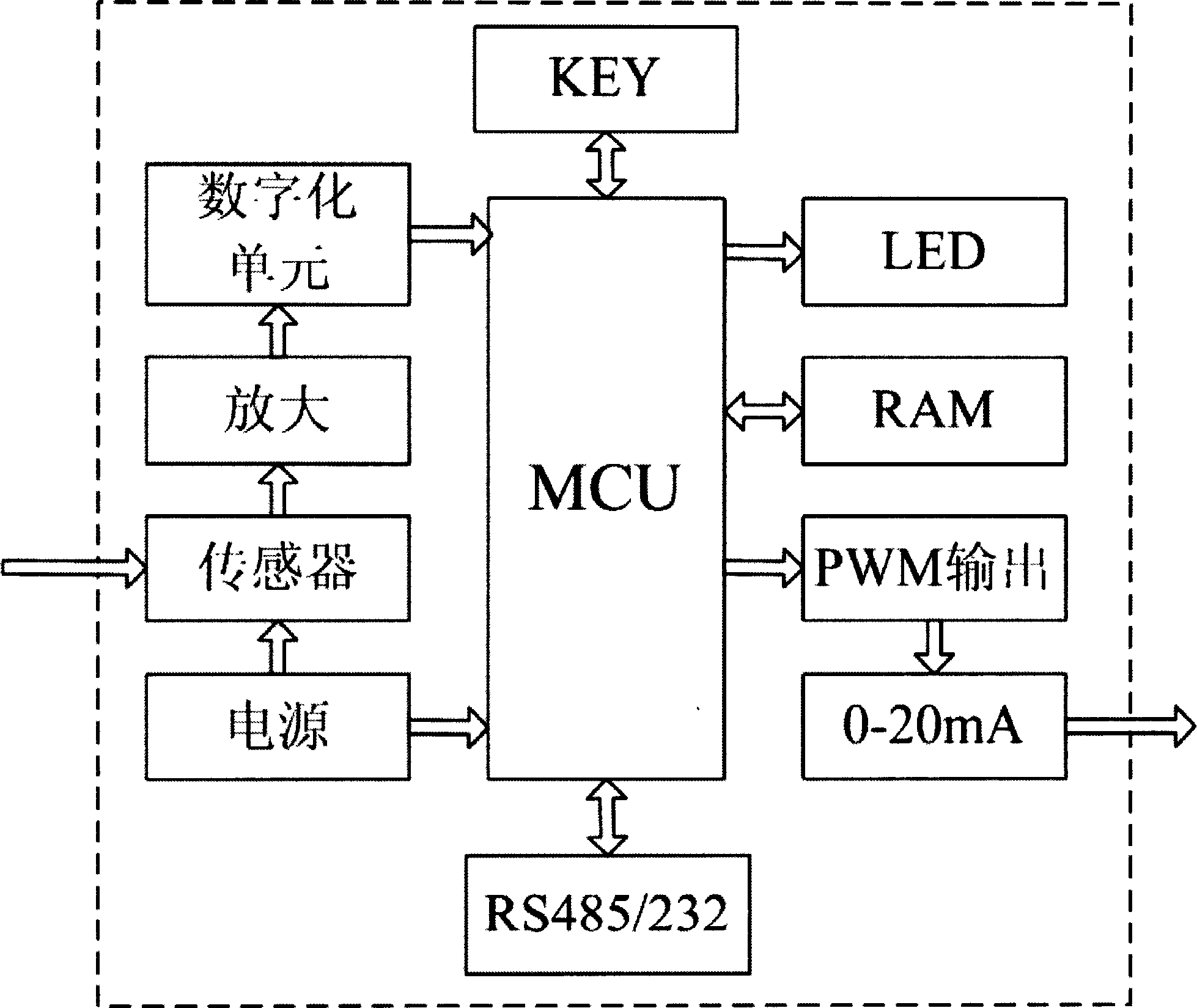

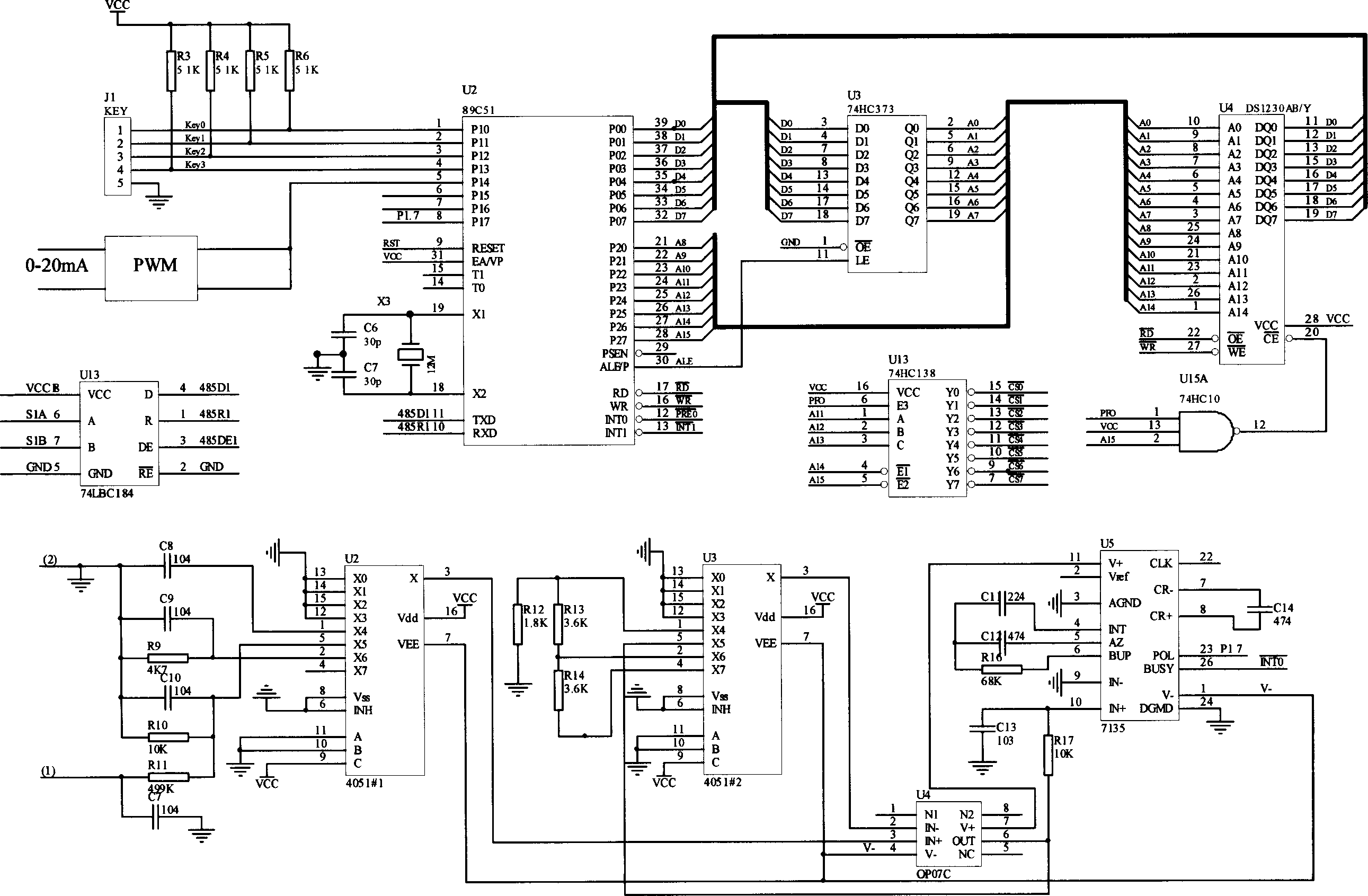

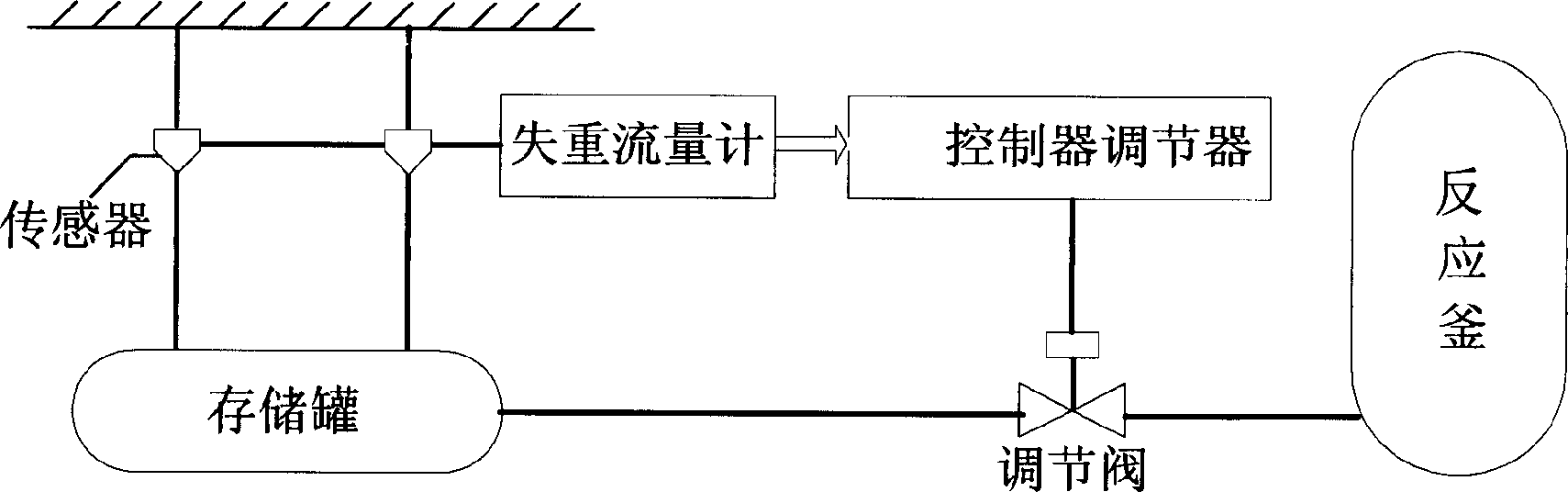

Zero-gravity flowmeter and weightlessness flow controller

InactiveCN1811647AFulfil requirementsAnti-corrosionFlow control using electric meansControl signalControl manner

The present invention discloses a zero-gravity flowmeter and zero-gravity method flow controller. Its structure includes power supply, also includes sensor, said sensor can be used for making the measured weight value signal be passed through an amplifier and digital converter to obtain digital signal, then making the digital signal be fed into microprocessor; said microprocessor can be used for processing said signal and outputting said signal; said control signal can be communicated with upper-position machine by means of interface circuit, the weight and flow values can be transferred to the upper-position machine, the upper-position machine can make monitoring management, the measured weight value also can be fed into memory, and the weight and flow values can be displayed by means of display device.

Owner:UNIV OF JINAN

Fracturing inclusion self-dissolving diversion agent and preparation method thereof

InactiveCN103484095ANo clogging effectImprove plugging efficiencyDrilling compositionSodium bicarbonateTriethoxysilane

The invention relates to a fracturing inclusion self-dissolving diversion agent and a preparation method thereof. The diversion agent is prepared by using 10-15 parts of guanidine collagen powder, 30-40 parts of ferric trichloride, 30-40 parts of alumina, 1-2 parts of sodium bicarbonate, 8-10 parts of ammonium persulfate, 1-2 parts of potassium ferricyanide and 1 part of gamma-aminopropyltriethoxysilane, has an inclusion form and is spherically granular in shape. The preparation method of the diversion agent comprises the following steps: sequentially dissolving the guanidine collagen powder, the ferric trichloride, the alumina, the sodium bicarbonate, the ammonium persulfate and the potassium ferricyanide in water according to above formula proportions at room temperature, stirring for 5min, carrying out drying caking of the above obtained solution, crushing, milling, spraying the surface of ammonium persulfate with the gamma-aminopropyltriethoxysilane coupling agent, wrapping the external layer of ammonium persulfate crystals by the above prepared powder to form spherical particles, and drying the particles to prepare the diversion agent. The diversion agent has a gel breaker inclusion form, has a self-dissolving capability, and does not need a gel breaking degradation agent in the construction.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

Novel steel structure building system

InactiveCN102900149AReduce pollutionImprove bearing capacityConstruction materialFloor slabSteel bar

The invention discloses a novel steel structure building system comprising a steel pipe concrete column, a steel main beam, an auxiliary beam, a floor and a wall surface, wherein the floor is an assembled steel bar truss floor support plate, and the auxiliary beam is a precast concrete auxiliary beam; the wall surface is a CCA board and aerated concrete composite lath, the composite lath comprises an upper layer, a core layer and a lower layer, the upper layer and the lower layer are CCA boards, the core layer is an aerated concrete layer, the core layer is covered on the lower layer, and the upper layer is covered on the core layer. The novel steel structure building system disclosed by the invention is accurate in stress, simple in member connection, convenient and quick in construction, convenient for industrial production, beneficial for reducing the environmental pollution and improve the living environment, and good in economical efficiency.

Owner:HANGXIAO STEEL STRUCTURE

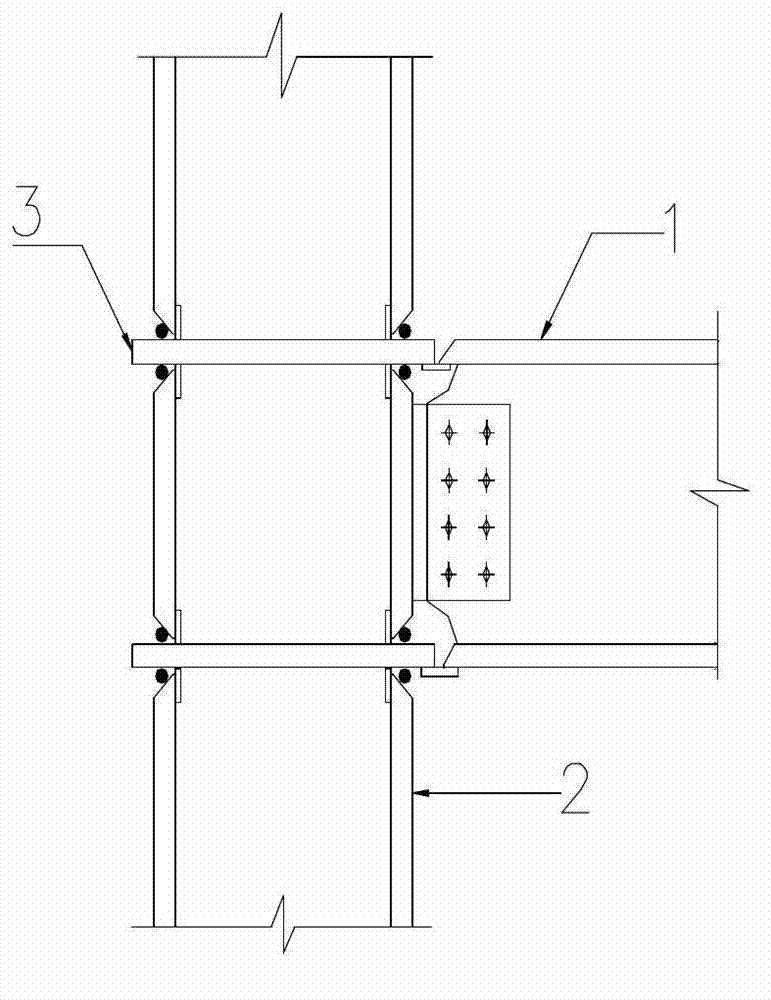

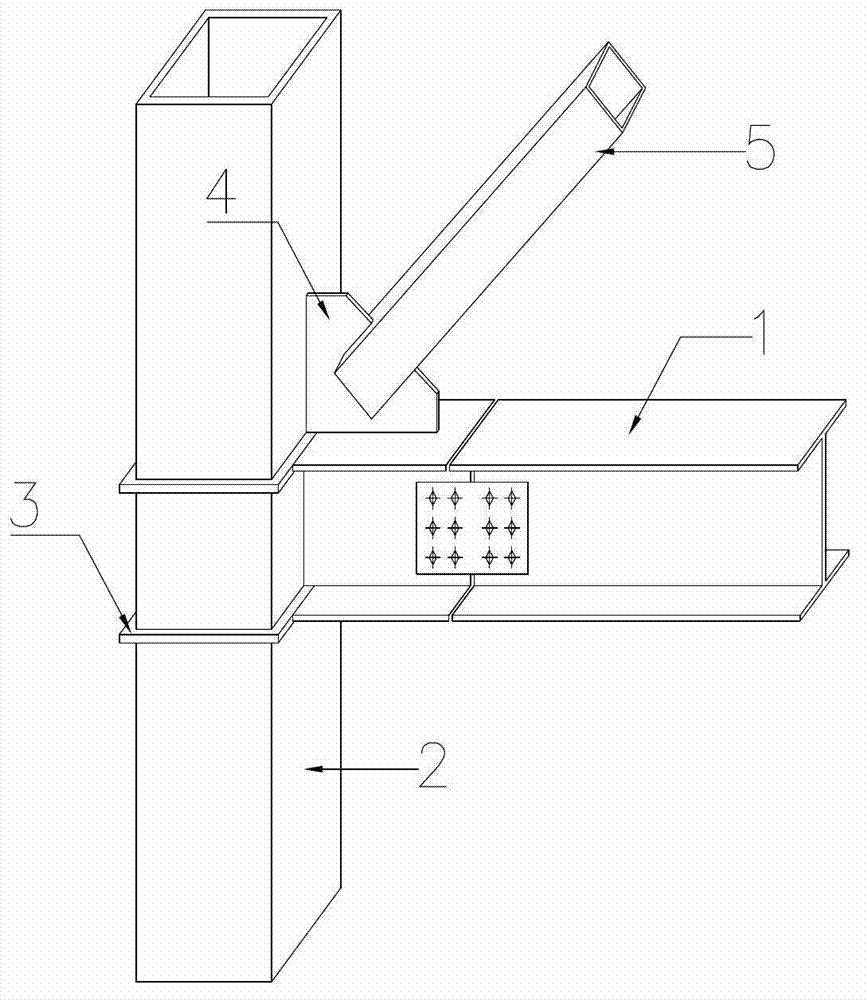

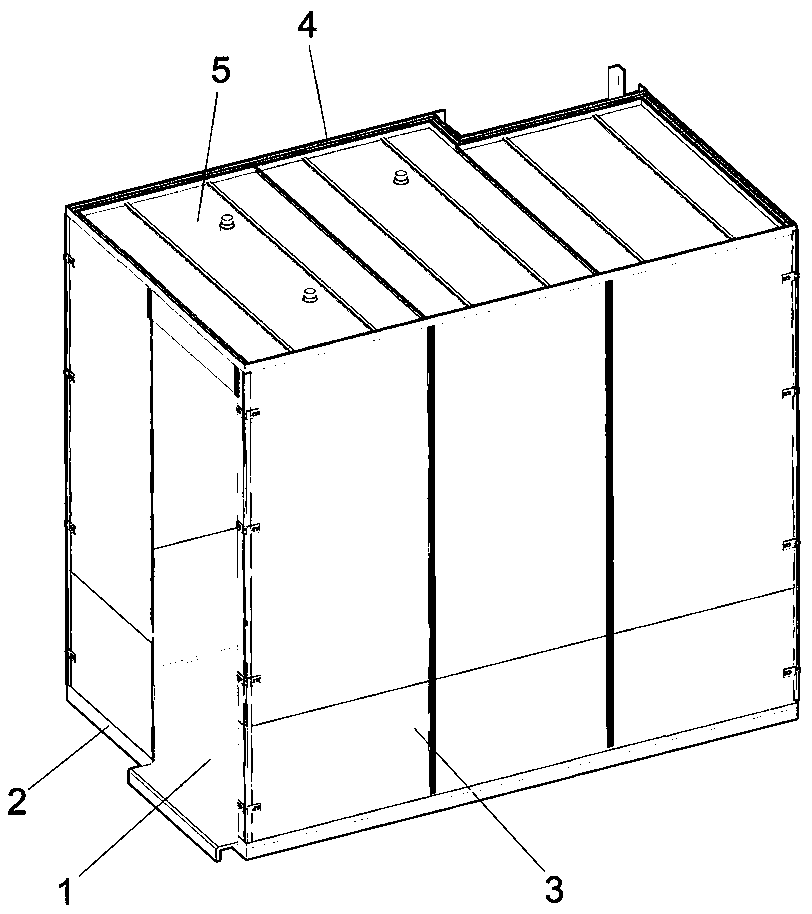

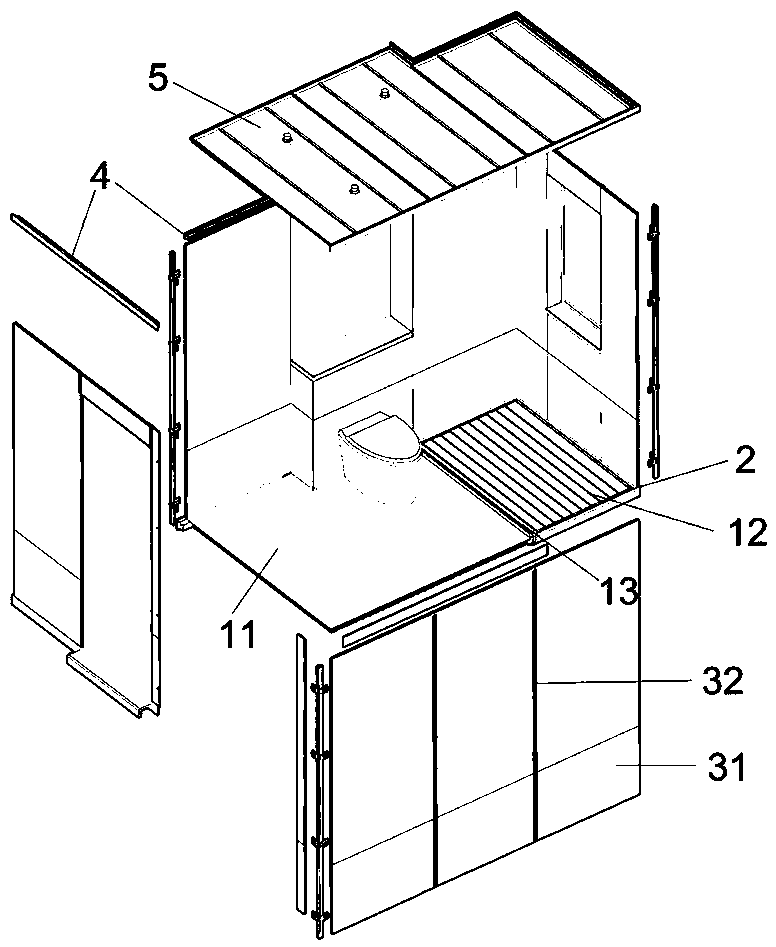

Assembly type bathroom and installing method thereof

The invention discloses an assembly type bathroom and an installing method thereof. The assembly type bathroom comprises bases arranged on the ground, a bottom keel arranged around the bases, a wall face structure arranged on the bottom keel, a top keel arranged on the wall face structure, and a top panel fixedly arranged on the top keel. The bases of the bathroom are the independent dry area base and wet area base, installation and transport are convenient, and a wall face and a ceiling are fixedly installed through the keels. The assembly type bathroom is simple in structure, modular and standardized production of a factory is achieved, water resistance and reliability are achieved, quality is stable, site construction is simple and fast, and assembly type decoration is facilitated to be developed better.

Owner:宁波群住住宅科技有限公司

Site construction preparation method for coal bed methane fuzzy-ball drilling fluid

InactiveCN107556987AImprove stabilityStrong leakage prevention and control abilityDrilling compositionLiquid densityApparent viscosity

The invention relates to a site construction preparation method for a coal bed methane fuzzy-ball drilling fluid. The site construction preparation method comprises the following steps: sequentially adding 5-8 parts by weight of a ball-fuzzy agent, 2-5 parts by weight of a ball mass agent and 1-2 parts of a ball containing agent into 400 parts by weight of clear water, and continually performing stirring for at least 30 min to obtain a fuzzy-ball drilling fluid; utilizing a liquid densimeter to measure the density value of the fuzzy-ball drilling fluid, and utilizing a six-speed rotary viscometer to measure the fuzzy-ball drilling fluid so as to obtain the apparent viscosity, the plastic viscosity, the yield value and the dynamic shear force ratio and to obtain the coal bed methane fuzzy-ball drilling fluid. The invention aims to provide the site construction preparation method for the coal bed methane fuzzy-ball drilling fluid, which is simple in site construction, low in formation damage, good in coal bed well wall stabilizing effect and strong in leakage prevention and control capability and can effectively solve the problems of severe coal bed collapse, much loss of the drilling fluid and the like in the coal bed gas drilling operation process.

Owner:BEIJING LIHUILAB ENERGY TECH

Water dispersion composite sand-fixing agent formula

The invention relates to a formula of water dispersing compounding sand consolidation agent. It is made up from modified phenol-formaldehyde resin 5-8%, organic silicon resin 0.02-0.25%, furfural compounding 5-15%, alcohol compounding 0.5-5%, phosphoric acid series compounding 0.05-0.15% and water 89.43-81.6%. The benefit is that the sand consolidation agent has low viscosity, low usage quantity, low cost, etc.

Owner:赵彧

Cover plate type fiber bragg grating sensor and packaging method thereof

InactiveCN102980684AImprove firmnessHigh data acquisition accuracyThermometer detailsThermometers using physical/chemical changesFiberGrating

The invention discloses a cover plate type fiber bragg grating sensor and a packaging method thereof. The cover plate type fiber bragg grating sensor comprises a grating and a protection sleeve, wherein a wire jumper and tensile fibers are fixed in the protection sleeve. One end of the protection sleeve is fixedly connected with a flange interface, and the other end of the protection sleeve is fixedly connected with a temperature sensing box. The grating is packaged in the temperature sensing box, the wire jumper and the grating are connected with each other in the temperature sensing box. The packaging method of the cover plate type fiber bragg grating sensor includes preparing the sleeve, painting temperature-resistant AB glue, welding the wire jumper and the grating in fusion mode, leading the wire jumper to penetrate through the protection sleeve, fixing one end of the wire jumper not provided with the grating with the flange interface, arranging the grating at the central position of a sensing protection groove, and buckling a packaging cover plate on the sensing protection groove. Compared with the prior art, the cover plate type fiber bragg grating sensor is good in mechanical performance, sensor performance, insulation performance and firmness, and improves sensor firmness, data collection accuracy and data collection speed. The packaging method of the cover plate type fiber bragg grating sensor greatly improves production efficiency and production survival rate, simultaneously improves sensor firmness and enables the sensor not to split or fall easily.

Owner:YIBIN POWER SUPPLY COMPANY STATE GRID SICHUAN ELECTRIC POWER +1

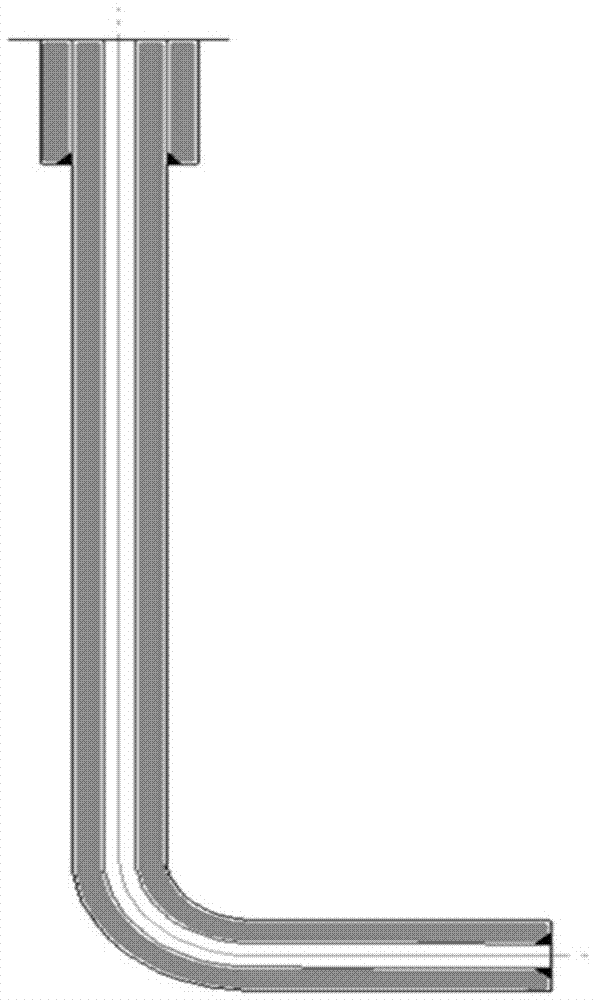

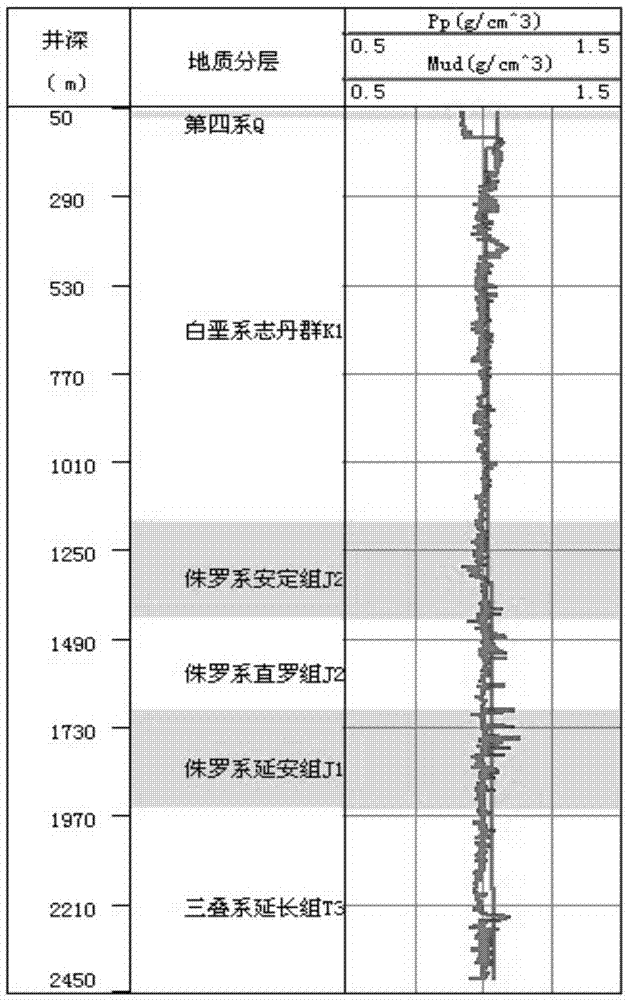

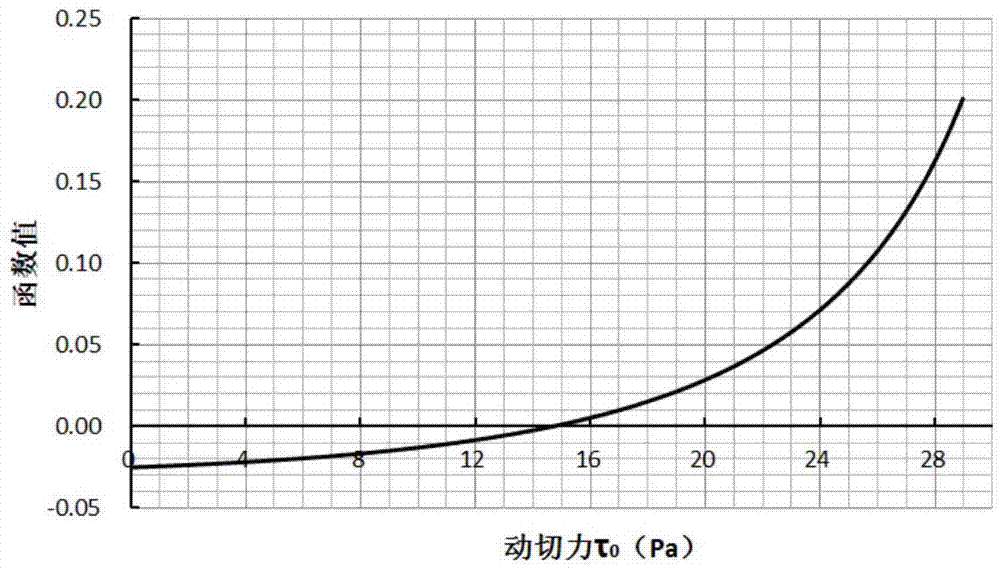

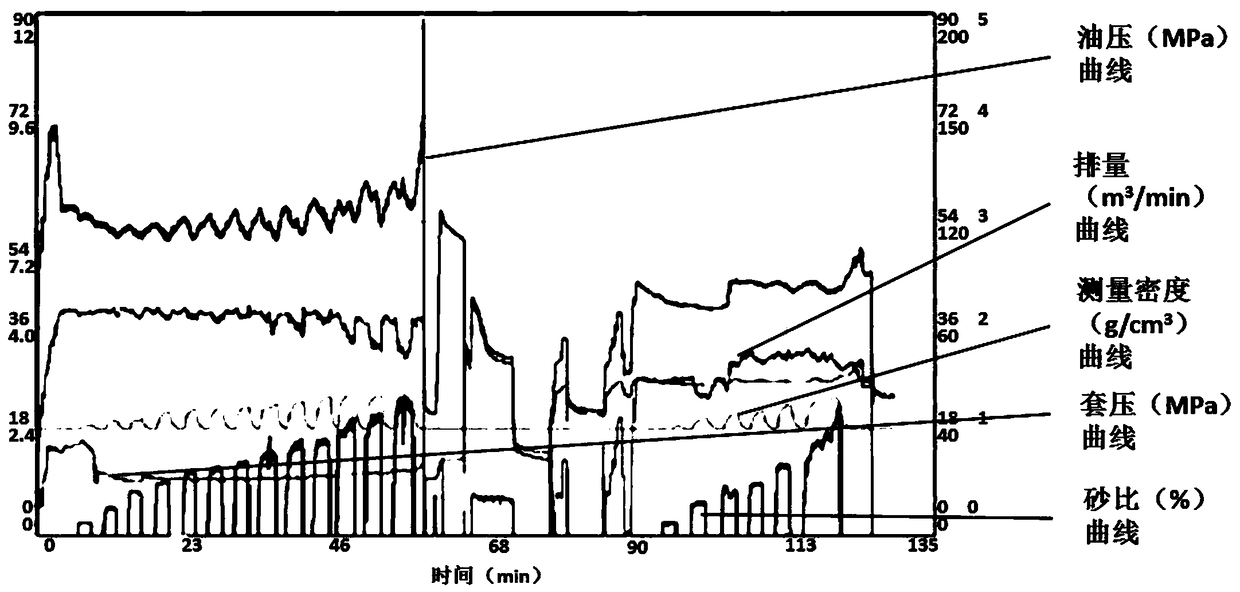

Horizontal well oil-string casing well cementation method

ActiveCN105443072ASolve the problem of low cementing qualitySimple and fast operationSealing/packingWell drillingWell cementing

The invention discloses a horizontal well oil-string casing well cementation method and belongs to the technical field of petroleum and natural gas well cementation. The horizontal well oil-string casing well cementation method comprises the steps that the drilling fluid density maintained when a casing descends is determined according to stratum pressure, centering devices are additionally arranged at a horizontal section, an inclined shaft section and a plumb shaft section, and drilling fluid is circulated in a sectioned mode; rheological parameters and critical displacement of cement paste are calculated according to different fluid types, spacer fluid and the cement paste are injected in sequence under the premise that it is ensured that the actual wellhead pressure does not exceed the upper limit value in the paste replacing process, and a well is shut down for cement setting after paste replacement is finished. The horizontal well oil-string casing well cementation method can solve the problem that oil-string casing well cementation quality is low for special well types such as a three-dimensional horizontal well and a stair-step horizontal well; in addition, operation is easy and convenient, field construction is easy, well cementation cost can be greatly lowered, and a powerful guarantee can be provided for subsequent reservoir reconstruction, oil production engineering construction and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for achieving high-speed channel through self-accumulating propping agent

ActiveCN109372489AAchieve the effect of self-aggregationRealize self-cleaningFluid removalDrilling compositionEngineeringSilt

The invention provides a method for achieving a high-speed channel through a self-accumulating propping agent. By means of the material of the self-accumulating propping agent, a channel fracturing technology is completely implemented from the seam end to a seam opening, and a real channel fracturing technology is formed. According to the method, the advantages of the self-accumulating propping agent are achieved, the defects of traditional channel fracturing improvement are overcome, the effect that a high-flow conductivity channel is formed through channel fracturing is achieved better, theseam opening is supported, and the flow conductivity is improved, backflow of the propping agent is reduced; and silt is gathered and concreted in a two-time aggregation manner, new propping agent masses are formed, construction is easy and convenient, and a new output-growing technology guided by the self-accumulating propping agent is formed.

Owner:青岛大地新能源技术研究院

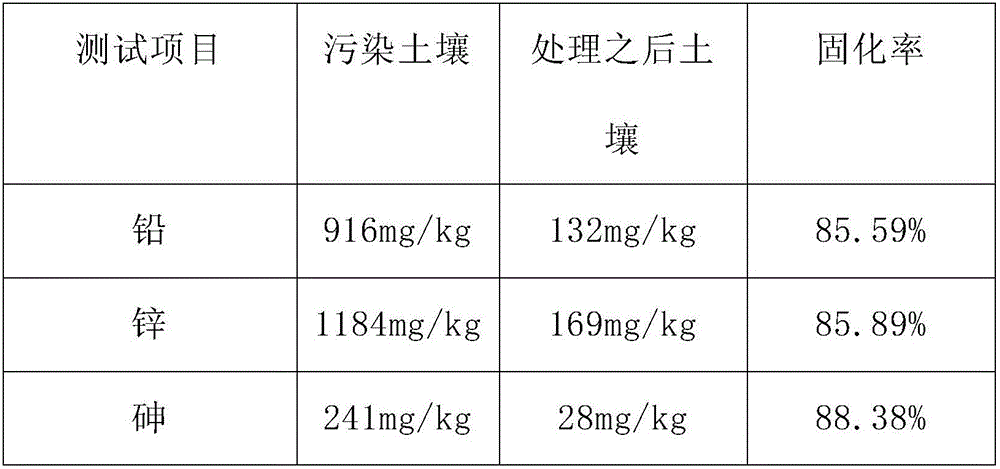

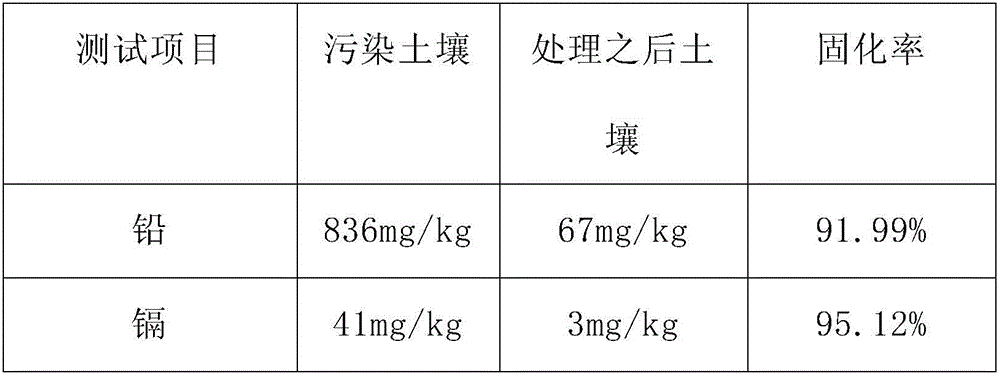

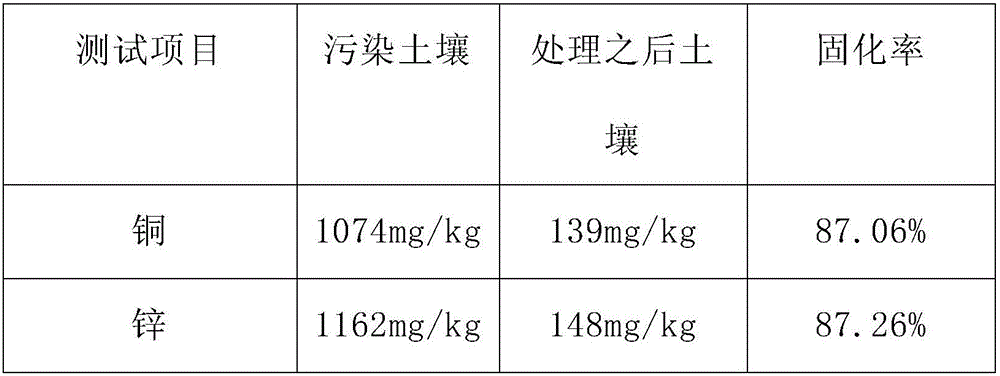

Heavy metal pollution soil restoration agent and use method thereof

InactiveCN106433668AImprove adsorption capacityEffectively fixedOrganic fertilisersSoil conditioning compositionsSocial benefitsTO-18

The invention provides a heavy metal pollution soil restoration agent, and relates to a soil restoration agent. The restoration agent comprises a pretreatment curing ingredient and an excitation curing ingredient, wherein the pretreatment curing ingredient comprises modified expanded vermiculite; the excitation curing ingredient comprises 4 to 18 percent of slaked lime, 4 to 10 percent of chitosan, 16 to 34 percent of water glass and 45 to 60 percent of fly ash. The heavy metal pollution soil restoration agent and the use method have the advantages that the efficient curing of soil heavy metal can be realized; the soil heavy metal pollution problem is solved; in addition, the high acidity or high alkality and secondary pollution can be effectively avoided; the uniformity of environment benefits and social benefits is realized.

Owner:广东省润土环境治理有限公司

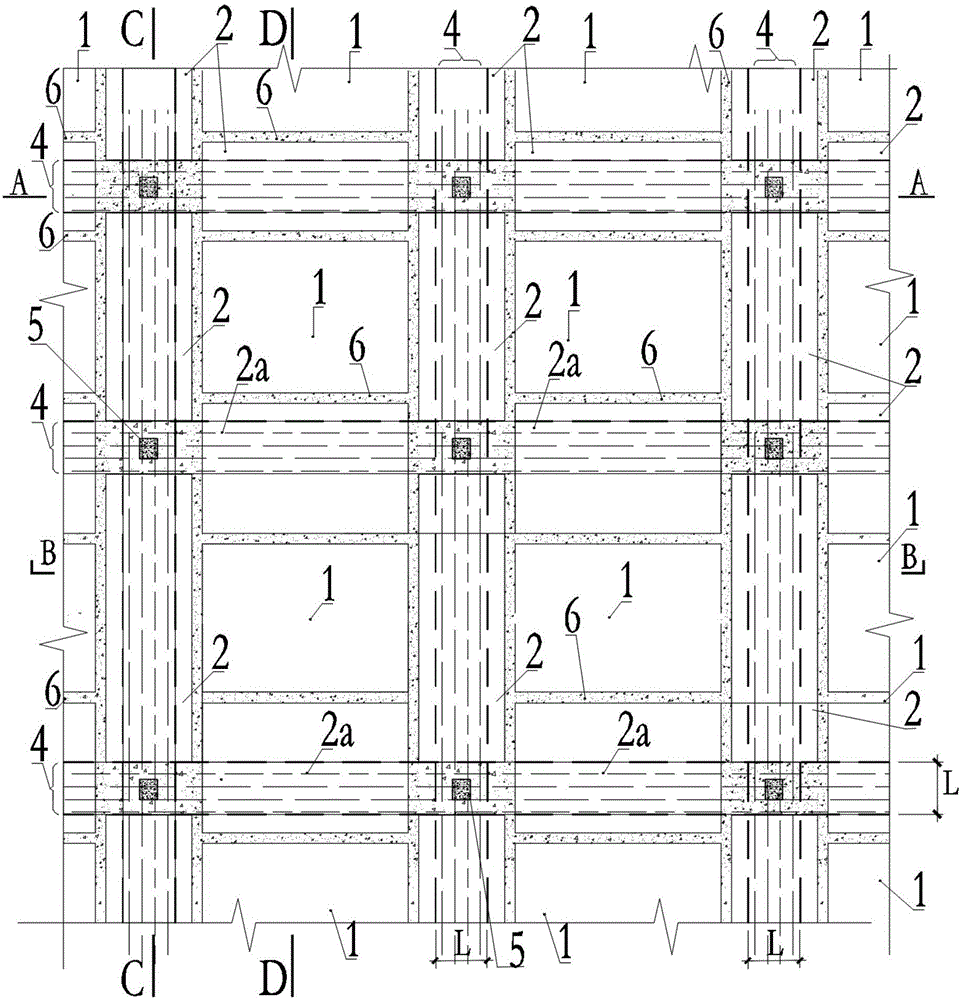

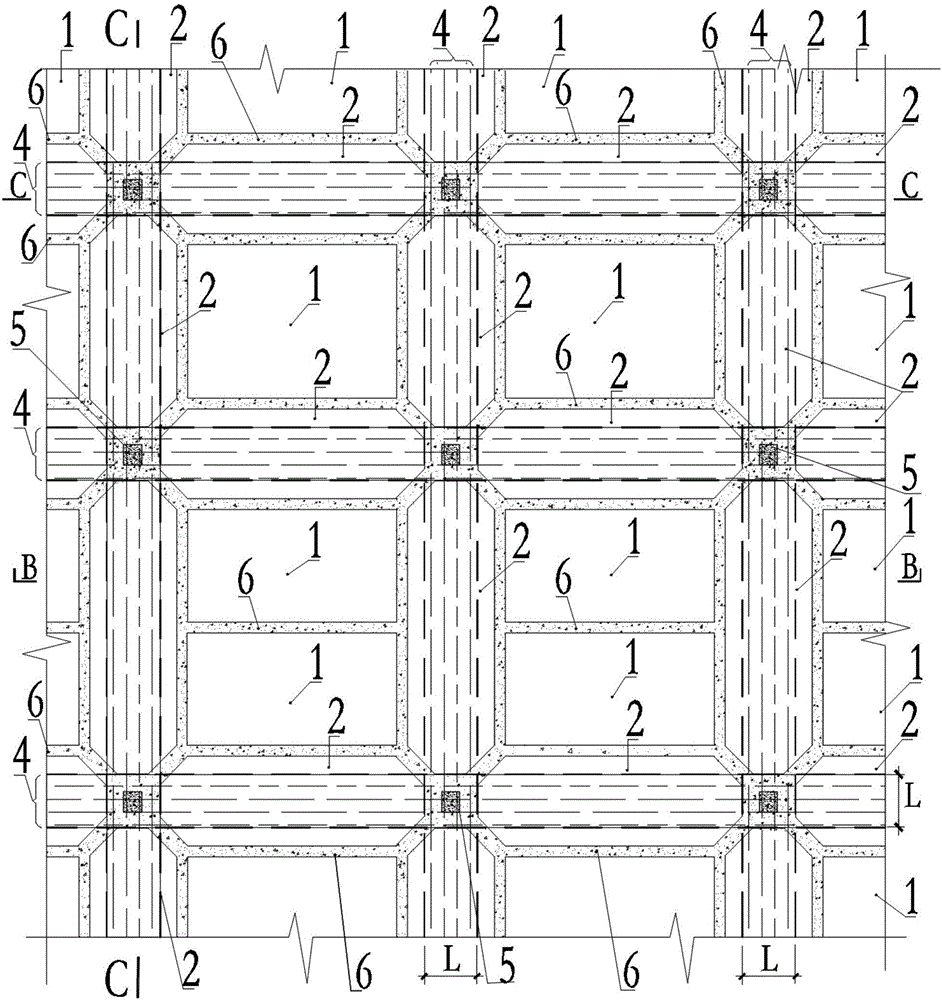

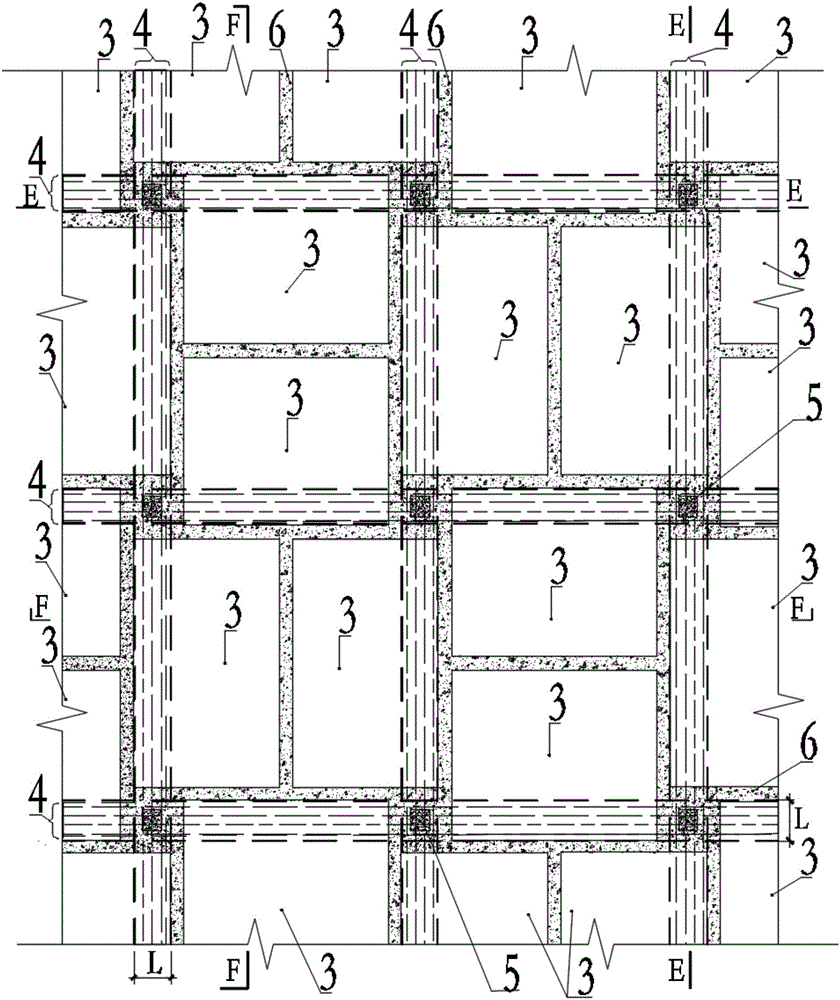

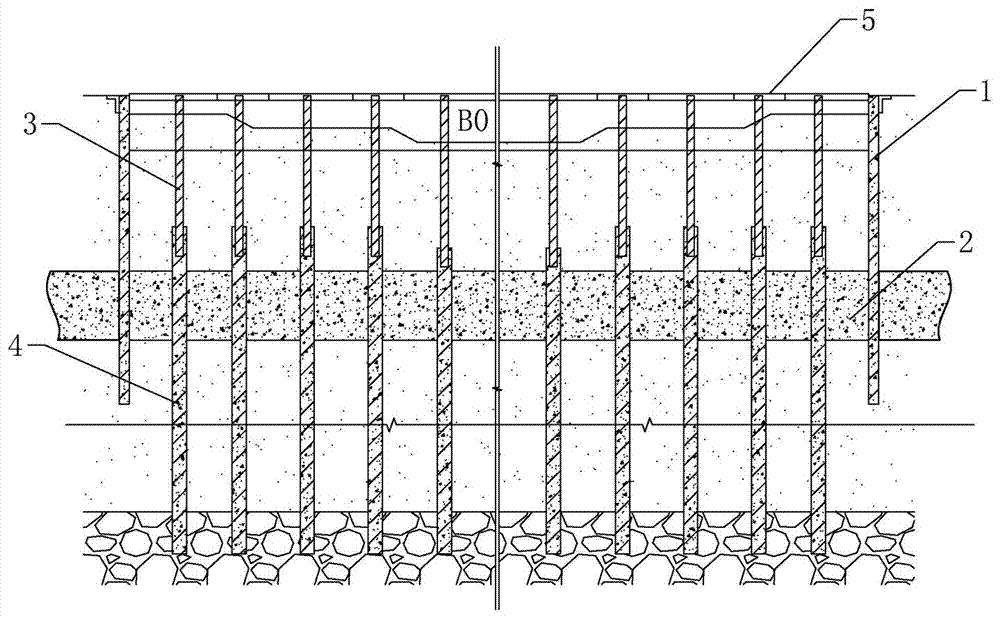

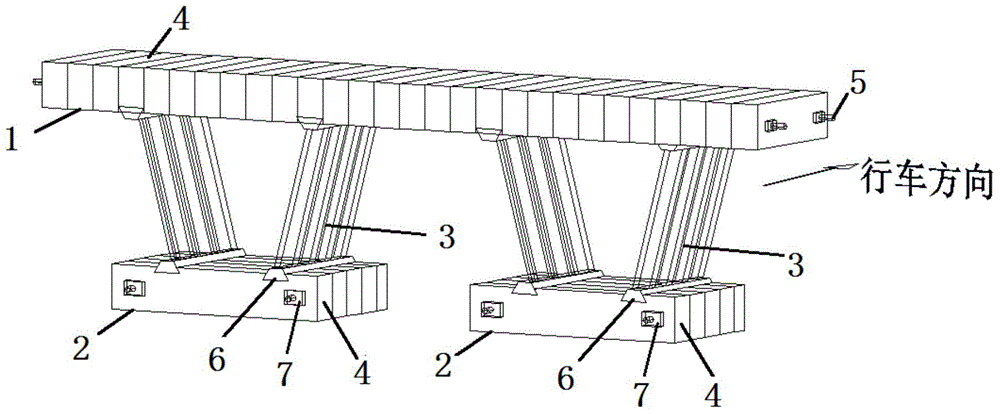

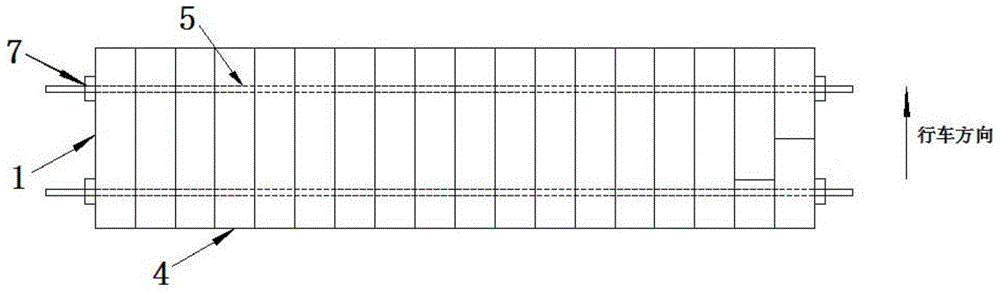

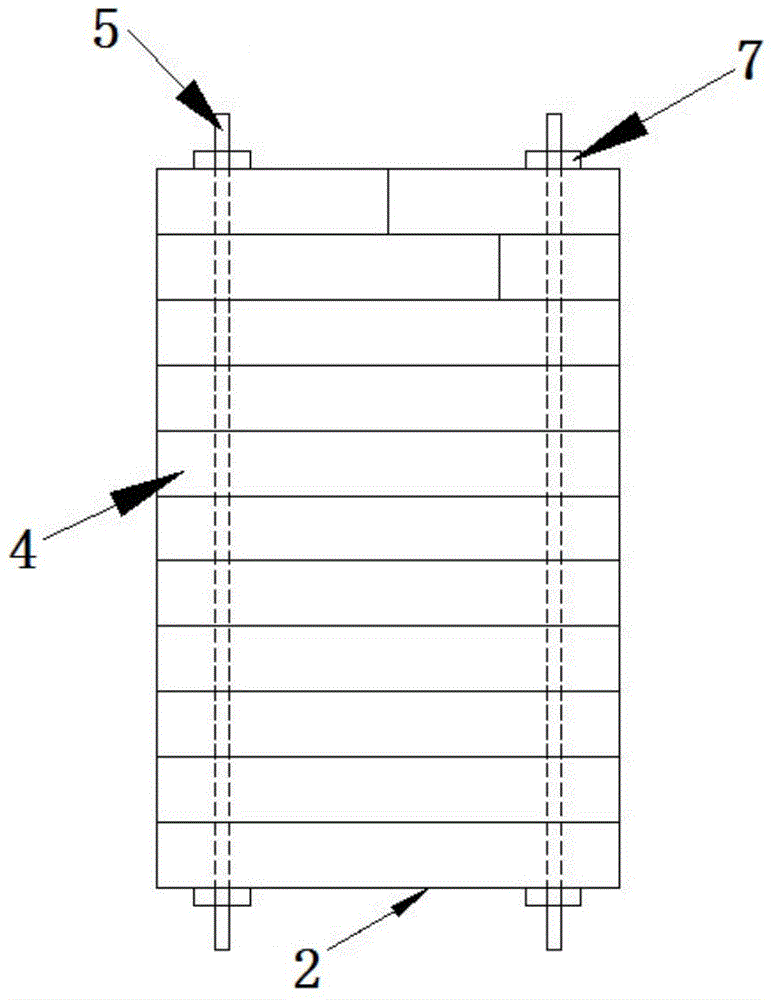

Assembled board-column structure floor slab, dividing method thereof, and floor slab unit components

ActiveCN106522552AImprove reliabilityHigh costFloorsBuilding material handlingAgricultural engineeringFloor slab

The invention discloses an assembled board-column structure floor slab, a dividing method thereof, and floor slab unit components. The assembled board-column structure floor slab comprises the multiple prefabricated floor slab unit components comprising adjacent column connection board belts, or the assembled board-column structure floor slab comprises the multiple prefabricated floor slab unit components comprising the adjacent column connection board belts, and the multiple conventional prefabricated floor slab unit components. The adjacent column connection board belts in the prefabricated floor slab unit components comprising the adjacent column connection board belts are long-strip-shaped belt boards integrally stretching across every two adjacent columns. The connection line of section centroids of the two adjacent structure columns connected through each adjacent column connection board belt serves as a reference line of the adjacent column connection board belt, and the width of each adjacent column connection board belt is larger than or equal to the longest side length of the connection sides of the two adjacent structure columns connected through the adjacent column connection board belt. The adjacent column connection board belts are provided with direct-through bottom reinforcing bars in the span direction. By the adoption of the technical scheme, cost can be reduced, construction is convenient, and safety and reliability of the board-column structure of the prefabricated floor slab can be improved at the same time.

Owner:刘祥锦

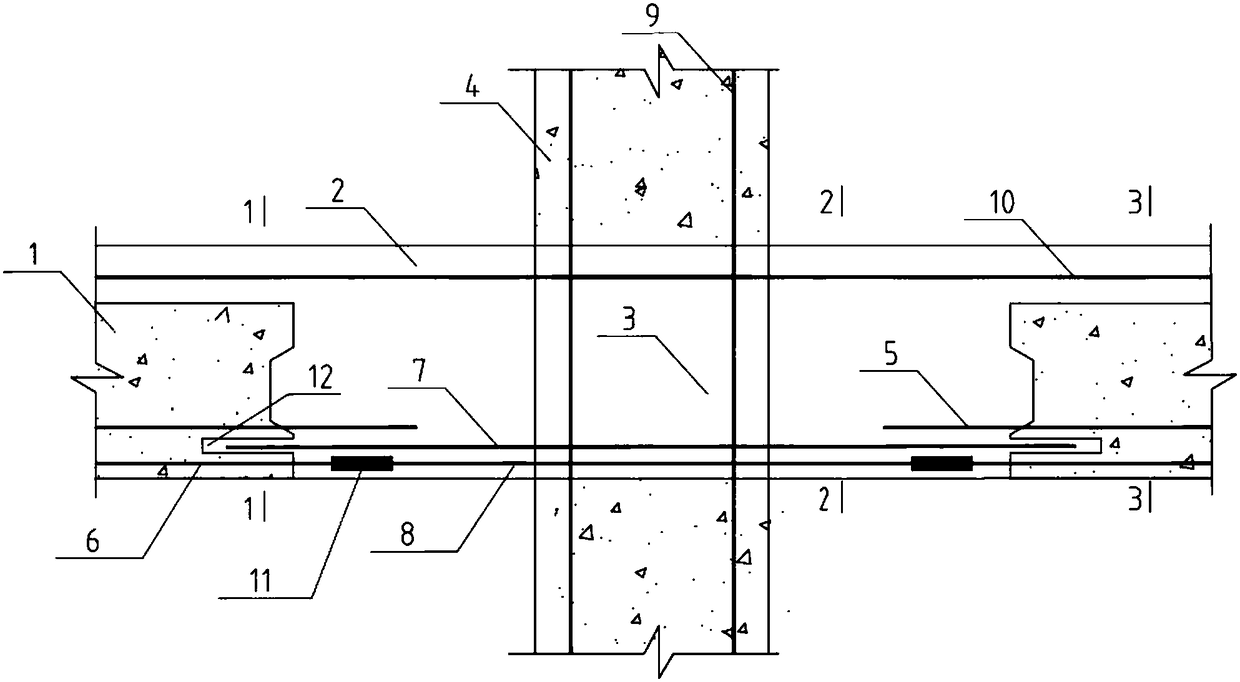

Prefabricated prestress concrete frame beam-column joint with additionally-arranged steel bars and sleeves

InactiveCN108487461AIncrease the reinforcement ratioCrack controlBuilding reinforcementsRebarEngineering

The invention discloses a prefabricated prestress concrete frame beam-column joint with additionally-arranged steel bars and sleeves. The prefabricated prestress concrete frame beam-column joint comprises a beam-column joint post-cast area, prefabricated concrete beams arranged on the horizontal two ends of the beam-column joint post-cast area, prefabricated concrete columns arranged at the upperend and the lower end of the beam-column joint post-cast area, and a superposed beam cast-in-situ area arranged above the prefabricated concrete beams and the beam-column joint post-cast area. Anti-seismic steel bars and the additionally-arranged steel bars are horizontally arranged on the lower portion of the beam-column joint post-cast area, the anti-seismic steel bars and stirrups in the beam-column joint post-cast area are connected, and the superposed beam cast-in-situ area and the beam-column joint post-cast area are cast into a whole. Longitudinal ordinary stress steel bars on the lowerside and the anti-seismic steel bars are connected through sleeves, and the additionally-arranged steel bars extend into bar inserting holes of the ends of the prefabricated concrete beams. Accordingto the prefabricated prestress concrete frame beam-column joint, the on-site construction difficulty is reduced, the size of a beam section and the steel using quantity are reduced, and the development and rotation performance of beam end plastic hinges and the anti-seismic performance such as integrity and ductility of the beam-column joint are ensured.

Owner:SOUTHEAST UNIV

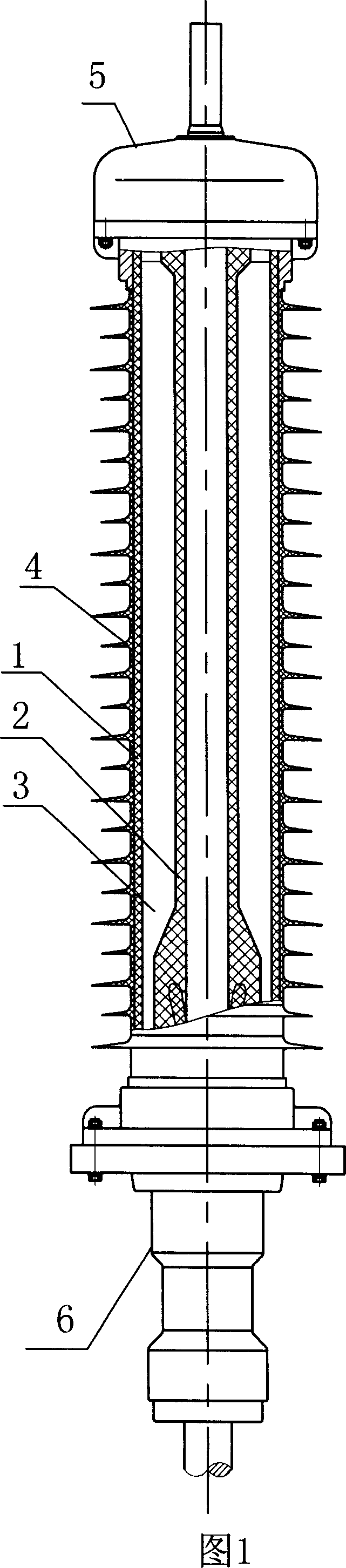

Rigid dry high-voltage cable terminal end

InactiveCN1976150ANo pollution in the processNot easy to cause pollutionCable terminationsEpoxyPolymer insulation

A high voltage cable terminal head of hard dry type is prepared as packing silicon gel insulation material between silicon rubber composite epoxy sleeve and stress controlling body for forming a polymer insulation layer, sealing both top and bottom ends of silicon rubber composite epoxy sleeve and stress controlling body separately by seal cap and tail pipe seal.

Owner:GCA CO LTD

T-type multifunctional small block and its production forming method

InactiveCN1341798AReduce dosageIncrease productivityConstruction materialCeramic shaping apparatusMultiple formsAdditional values

The present invention relates to a T-type multifunctional small block and its production forming method. Said invention adopts T-shaped block type series and composite forming process to solve the problem of combination of several layer materials in the production of concrete small blocks, and greatly raise technical content and additional value of product, implement high prefabrication extent ofsmall blocks, improved reinforcement scheme of block and block bonding body, and can more flexibly and reaonsably arranged steel bar, can conveniently make construction and can flexibly form various structures with different forms, and can obviously raise strength of block hollow bonding body so as to raise quality and efficiency of building construction.

Owner:虞新华

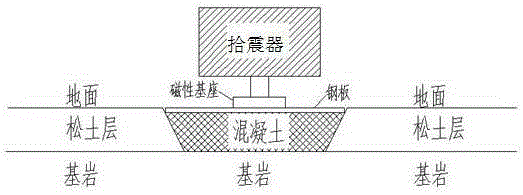

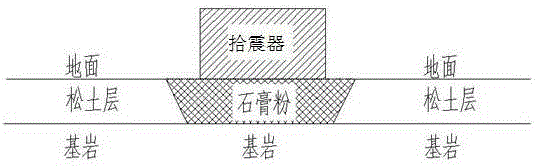

Fixing method of explosion vibration testing geophone

InactiveCN105203205ASolve the problem of poor integrationGuaranteed accuracySubsonic/sonic/ultrasonic wave measurementGeophoneEngineering

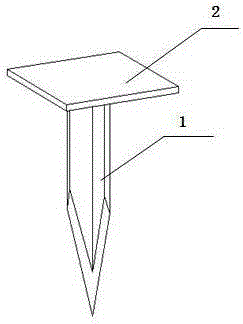

The invention discloses a fixing method of an explosion vibration testing geophone. An employed fixing pedestal is a T-shaped conical pedestal formed by combining an iron plate (2) with an iron cone (1). Before a three-dimensional geophone (4) is installed and fixed at a field, first of all, the iron cone (1) of the T-shaped conical pedestal is hammered into the ground deep into a soil layer or a weathering layer by use of a hammer, and the iron plate (2) is adjusted to be flush with the ground; and slurry-form gypsum blended by adding water is poured to the iron plate (2) to form a gypsum layer (3), then the lower-portion pedestal of the three-dimensional geophone (4) is placed on the gypsum layer (3), a horizontal bubble at the top of the three-dimensional geophone (4) is adjusted to be at a center position, the X direction of the three-dimensional geophone (4) is oriented towards the center of an explosion area, and after the gypsum layer (3) is solidified, a special-purpose connecting line is used for connecting a monitor with the three-dimensional geophone (4). According to the invention, the employed iron cone (1) at the lower portion of the T-shaped conical pedestal can be deep into the ground according to the thickness of the weathering layer or the soil layer to be connected integrally with the ground, and explosion vibration detected on the pedestal can reflect real vibration intensity of a building at a certain place.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

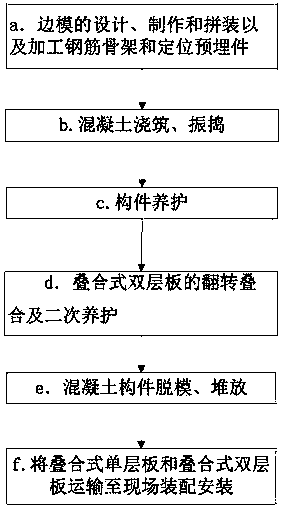

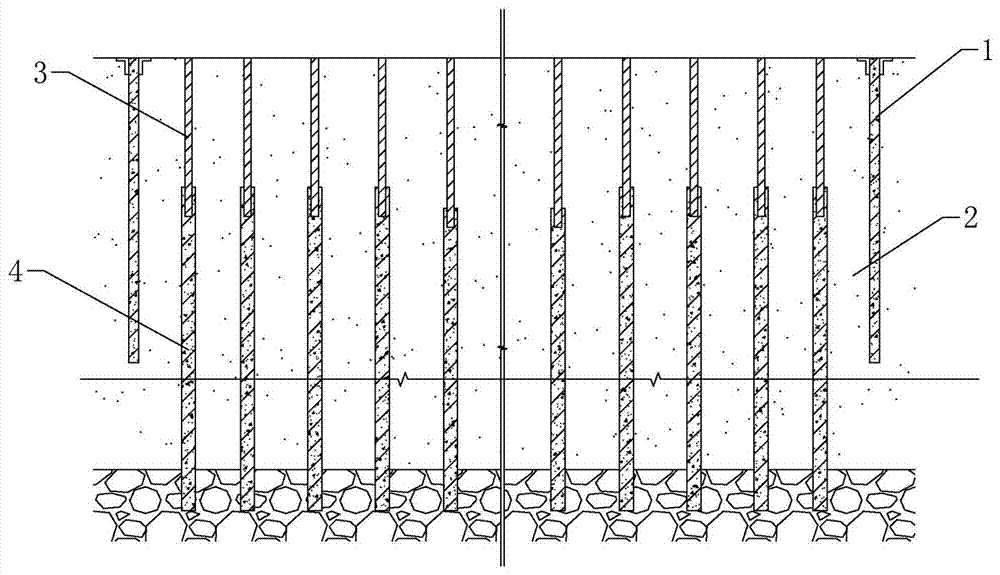

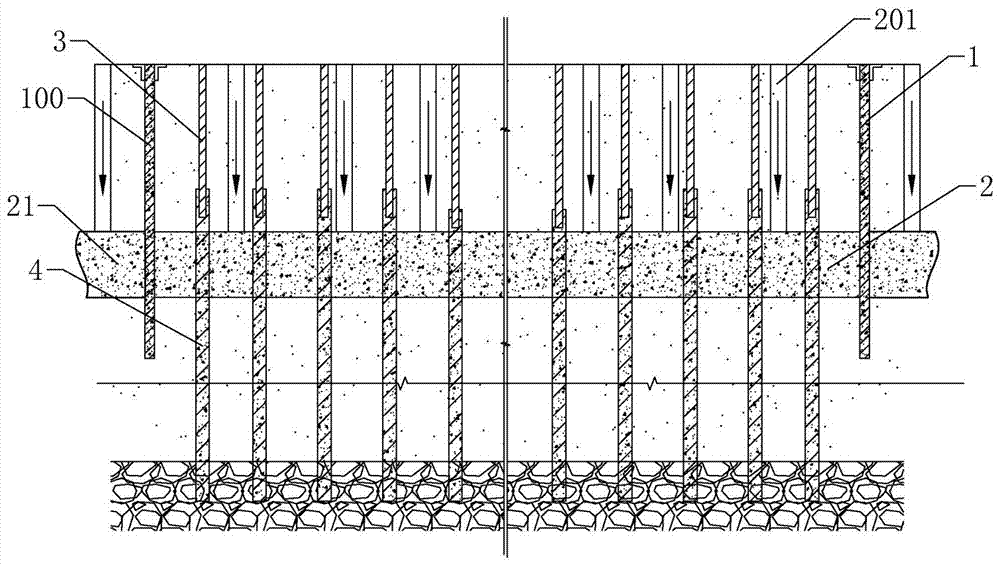

Superimposed fabricated pipe gallery structure system component industrialization construction device and method

InactiveCN108193712AGood lookingReduce usageArtificial islandsUnderwater structuresIntelligent managementRebar

The invention relates to a superimposed fabricated pipe gallery structure system component industrialization construction device and method. The superimposed fabricated pipe gallery structure system component industrialization construction device comprises a production intelligent management system. The superimposed fabricated pipe gallery structure system component industrialization constructionmethod comprises the steps that a, edge formworks are manufactured, pre-buried components are mounted on manufactured steel reinforcement frameworks, and the steel reinforcement frameworks and the edge formworks are subjected to formwork assembly operation on a formwork table; b, by adopting a distribution machine, concrete is poured onto the steel reinforcement frameworks and the edge formworks which are subjected to formwork assembly, and vibrated, and thus concrete components are obtained; c, the concrete components are cured in a curing kiln through steam; d, single sided boards loaded with superimposed-type double-layer boards are superimposed and sent to the curing kiln for secondary curing; e, the components are subjected to formwork release and stored on a component stacking field,and in the storing process, the superimposed-type single-layer boards and the superimposed-type double-layer boards are subjected to water spraying curing through a spraying system; and f, the components are conveyed to a site to be assembled and mounted. According to the superimposed fabricated pipe gallery structure system component industrialization construction device and method, on-site construction is easy, energy saving and environmental friendliness are achieved, long-time exposure of a foundation pit is reduced, the influence of weather on construction is small, and pollution emission and cost are reduced.

Owner:THE 4TH CONSTR ENG CO LTD OF CHINA RAILWAY NO 4 ENG GRP +1

Reversed construction method for suspension-type containment deep, large and long foundation pit fabricated structure

The invention relates to the field of building underground engineering, in particular to a reversed construction method for a suspension-type containment deep, large and long foundation pit fabricated structure. The method includes the several steps of (1) design calculation, (2) foundation pit engineering construction, (3) underwater control, (4) foundation pit bracing construction, (5) establishment of a basement reinforcement impermeable layer, (6) reversed construction and (7) floor slab structural construction. According to the reversed construction method for the suspension-type containment deep, large and long foundation pit fabricated structure, construction quality of a foundation pit can be controlled easily, the waterproof effect of a basement is good and can be monitored easily, and quality control, overhaul and maintenance are made easy.

Owner:武汉正远岩土科技有限公司

Steel and bamboo combined box girder

InactiveCN104963276AFull play against bucklingGive full play to the ability of crack resistanceBridge structural detailsPre stressRebar

The invention discloses a steel and bamboo combined box girder. The steel and bamboo combined box girder comprises a top plate and at least one bottom plate, wherein the bottom plate is arranged under the top plate; each bottom plate is connected with the top plate through two symmetrically arranged corrugated steel webs; the top plate is obtained by pressing a plurality of single bamboo veneers through pre-stressed steel bars, wherein the single bamboo veneers have equal heights and are arranged in parallel with lengths in a bridge traffic direction; and meanwhile, the corrugated steel webs are connected with the top plate and the bottom plates through shear steel sheets. The steel and bamboo combined box girder disclosed by the invention is advantaged in that anti-buckling and anti-crack capacities of the corrugated steel webs and the tensile capacities of the bamboo veneers are maximized; the structural integrity is good, the box girder is not prone to crack; the field construction is easy; the period is short; the material is environment-friendly and durable; and requirements of various different-span bridges can be satisfied.

Owner:JIANGSU DEFENG CONSTR GRP +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com