Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

A connection node, prefabricated technology, applied in the direction of floors, building components, buildings, etc., can solve the problems of difficulty, failure, and few applications, and achieve the effect of enhancing strength and preventing relative movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] Example 1 - Prefabricated densely ribbed composite panel unit

[0103] Preferably: the prefabricated ribbed composite floor unit has four connection surfaces. In order to better illustrate the connection surfaces, the form of the connection surfaces depends on the connection objects and requirements, and the four connection surfaces are different.

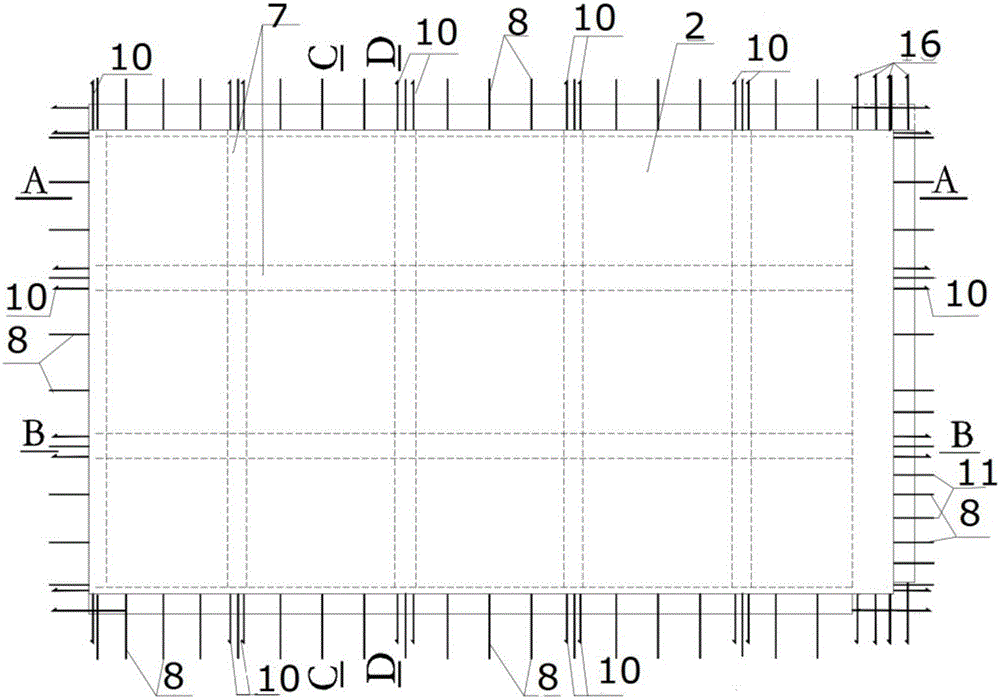

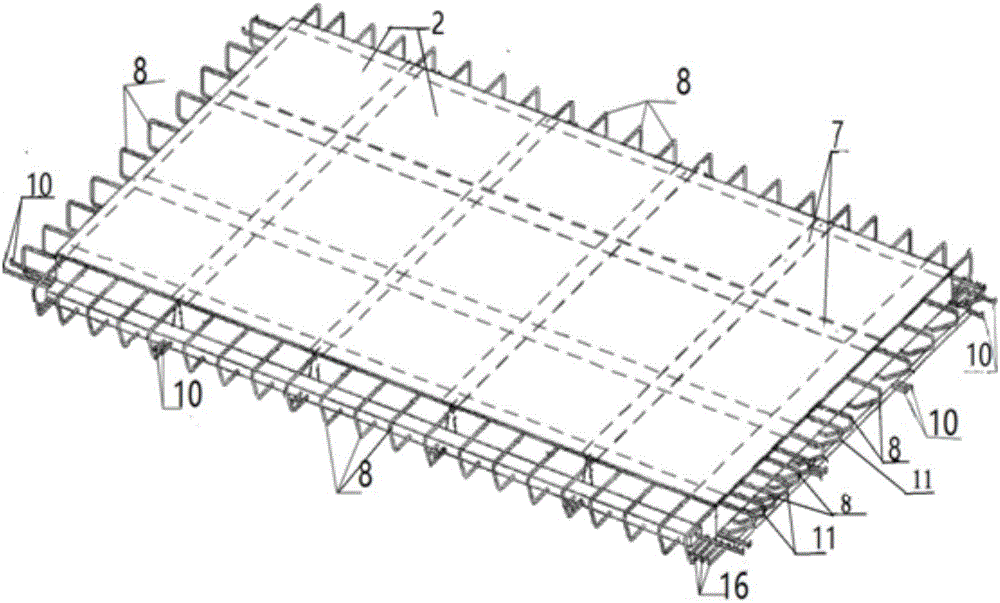

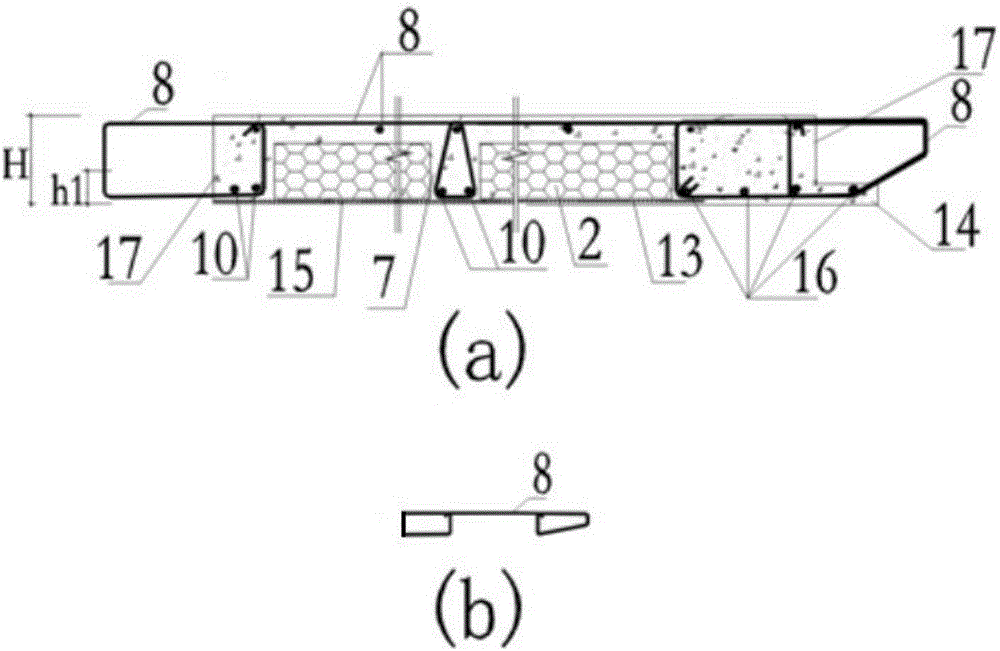

[0104] Figure 1-6 It is a structure of prefabricated dense-ribbed composite panel unit of the present invention.

[0105] like Figure 1-6 shown in figure 1 The direction and orientation of the prefabricated densely ribbed composite slab unit is a flat cuboid prefabricated component with upper and lower surface surfaces and four connecting surfaces, and there are several ribbed prefabricated floor slab ribs arranged vertically and horizontally inside. 7. There are two ribbed lower steel bars protruding from the connecting surface at each slab rib, and a linear prefabricated prefabricated floor slab reinforcement 10 with ...

Embodiment 2

[0109] Example 2 - Prefabricated Solid Panel Units

[0110] Figure 7-10 It is a prefabricated solid panel unit structure of the present invention.

[0111] like Figure 7-10 As shown, the prefabricated solid slab unit is a flat cuboid prefabricated component with upper and lower surfaces and four connecting surfaces, each side has an edge member, and the bottom reinforcement of the component is equipped with prefabricated floor lower reinforcement 10, and its four connecting surfaces All are rough surfaces, and the area of the rough surface is not less than 80% of the joint surface.

[0112]The four connecting surfaces of the prefabricated solid slab unit are reserved with connecting steel bars and the lower part of the prefabricated floor slab 10; The upper transverse section and the lower transverse section of the closed connecting steel bar are parallel to the plate surface, and the exposed section protruding from the vertical connecting surface 17 is shorter. form a...

Embodiment 3

[0117] Example 3 - Connection nodes of prefabricated full-thickness prefabricated floor slabs

[0118] Figure 11-30 It shows the connection nodes of the prefabricated full-thickness prefabricated floor slab of the present invention.

[0119] Figure 11 It is a schematic diagram of the assembly of the full-thickness prefabricated floor slab, including four prefabricated floor slabs with ribbed composite panels b 1 , b 2 , b 3 , b 4 , the vertical component column 1 and the load-bearing wall 6, the horizontal component beam 3; specifically, unit b 1 with b 2 are spliced together, and the connection nodes are 2C and 2D, forming a whole prefabricated floor, b 1 and b 2 with b 4 The joints 2A and 2B connected to form a wide flat beam are supported on the column 1, b 1 and b 2 The nodes connected to the load-bearing wall 6 are 1A and 1B, and the connection is also applicable to the beam, b 2 with b 3 At the same time, the joints 1C and 1D connected by the beam 3 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com