Assembled board-column structure floor slab, dividing method thereof, and floor slab unit components

A slab-column structure and prefabricated technology, applied in floors, building components, building structures, etc., can solve the problems of high technical requirements of construction personnel, few applications, resistance and other problems, and achieve direct and simple force transmission, direct and simple structure, The effect of reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

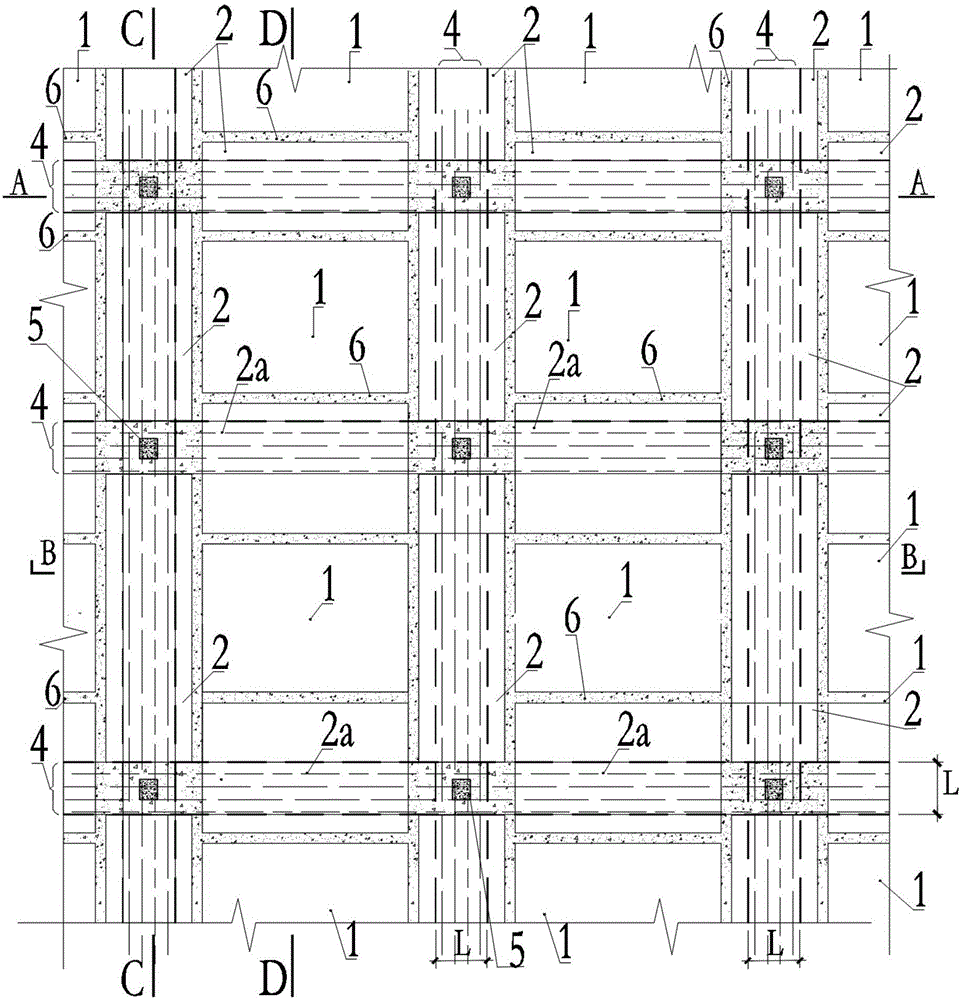

[0051] The prefabricated slab-column structure floor of this embodiment and its division method and floor unit components are implemented in the following manner:

[0052] Such as figure 1 , Figure 5-6 , Figure 8 As shown in Figures 11-14, the prefabricated slab-column structure floor includes (divided into) several prefabricated floor unit components including adjacent column connecting strips 4 and several conventional prefabricated floor unit components 1, which include Between the prefabricated floor unit components with adjacent column connecting plate bands 4 and between the prefabricated floor unit components containing adjacent column connecting plate bands 4 and the structural columns 5 are connected through post-cast concrete connecting bands 6, the conventional prefabricated floor slabs Between the unit components 1 and between the conventional prefabricated floor unit components 1 and the prefabricated floor unit components including the adjacent column connect...

Embodiment 2

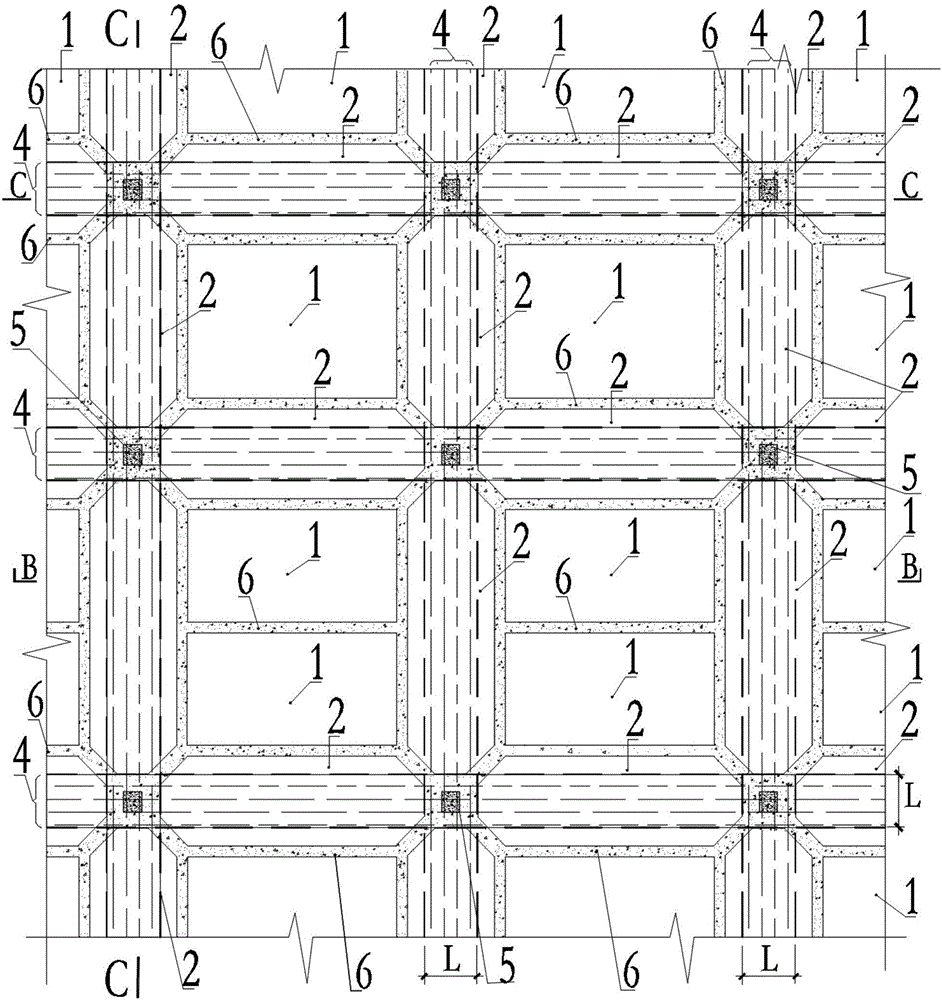

[0059] Such as figure 2 , Figure 5 , Figure 7 with Figure 12-14 As shown, the difference between this embodiment and Embodiment 1 is that, in this embodiment, in the B1 type prefabricated floor unit component 2, the conventional floor connecting strips located on both sides of the adjacent column connecting strips 4 The end face is provided with a 45° chamfer. And there is no B2 type prefabricated floor unit component 2a in this embodiment.

[0060] Referring to Fig. 13(b), in this embodiment, the reinforcement of the adjacent column connecting slabs 4 adopts a full-length concealed beam type; and the bottom reinforcement 7 is prestressed to become a prestressed precast floor unit component.

[0061] In this implementation, other implementations other than those described above are carried out with reference to Example 1.

Embodiment 3

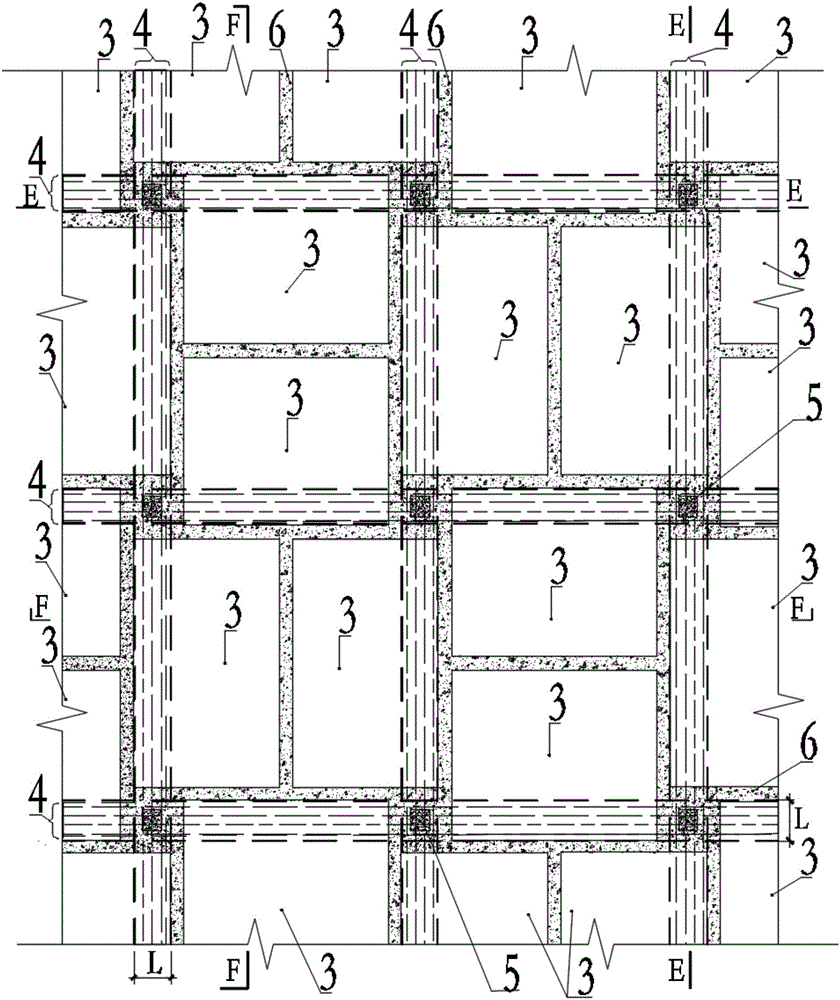

[0063] Such as image 3 , Figure 9-10 As shown in Figures 15-16, the difference between this embodiment and Embodiment 1 is that in this embodiment, the prefabricated slab-column structure floor includes (divides) several adjacent column connecting plates The prefabricated floor unit components with 4, between the prefabricated floor unit components including the adjacent column connecting plate bands 4 and between the prefabricated floor unit components including the adjacent column connecting plate bands 4 and the structural columns 5 are post-cast Concrete connecting bands 6 are connected to form an integral floor slab. In this embodiment, conventional prefabricated floor unit elements 1 are not used.

[0064] see image 3 As shown in Fig. 16, the prefabricated floor unit component comprising the adjacent column connecting plate strip 4 is a B3 type prefabricated floor slab unit component 3, and the B3 type prefabricated floor slab unit component 3 is one side centered on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com