Fixing method of explosion vibration testing geophone

A technology of blasting vibration and fixing method, which is used in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problem that the foundation is not tightly combined with the weathered layer or the soil layer, and achieves accurate accuracy and simple on-site construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

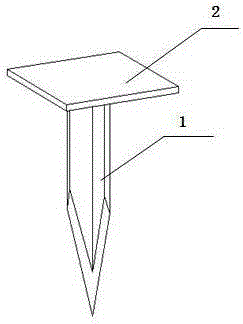

[0019] In order to further describe the present invention, a method for fixing a vibration pickup for blasting vibration testing according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

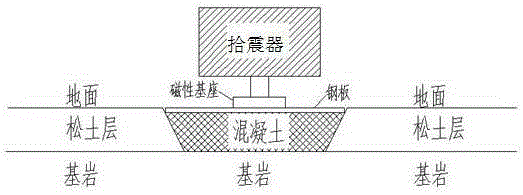

[0020] Depend on figure 1 It can be seen from the schematic diagram of the fixing method of the vibration pick-up when the prior art adopts the concrete platform base structure that the method for fixing the base of the vibration pick-up in this way is: only dig a shallow groove on the ground surface, and after cleaning out the loose soil in the groove , Pour the concrete table, place steel plate or iron plate on the table, adjust the steel plate or iron plate to the level, after the concrete solidifies, put the shock picker with magnetic base.

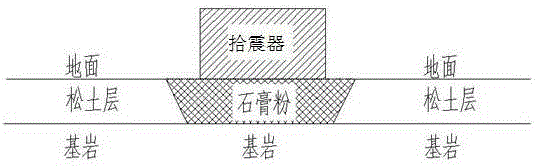

[0021] Depend on figure 2 It can be seen from the schematic diagram of the fixed mode of the vibration pickup when the prior art adopts the gypsum base structure that the method for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com