Patents

Literature

73results about How to "Improve anti-sulfur performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

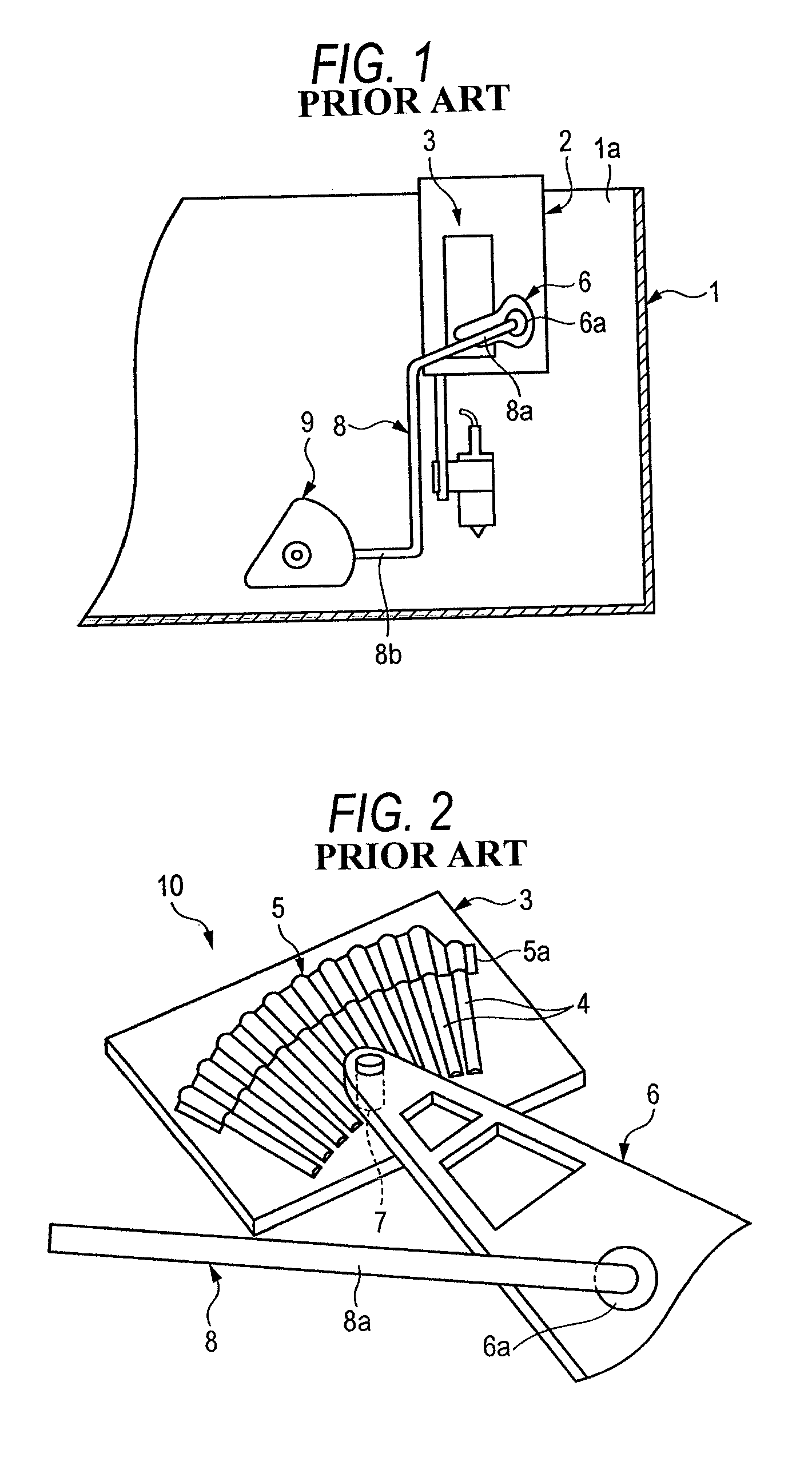

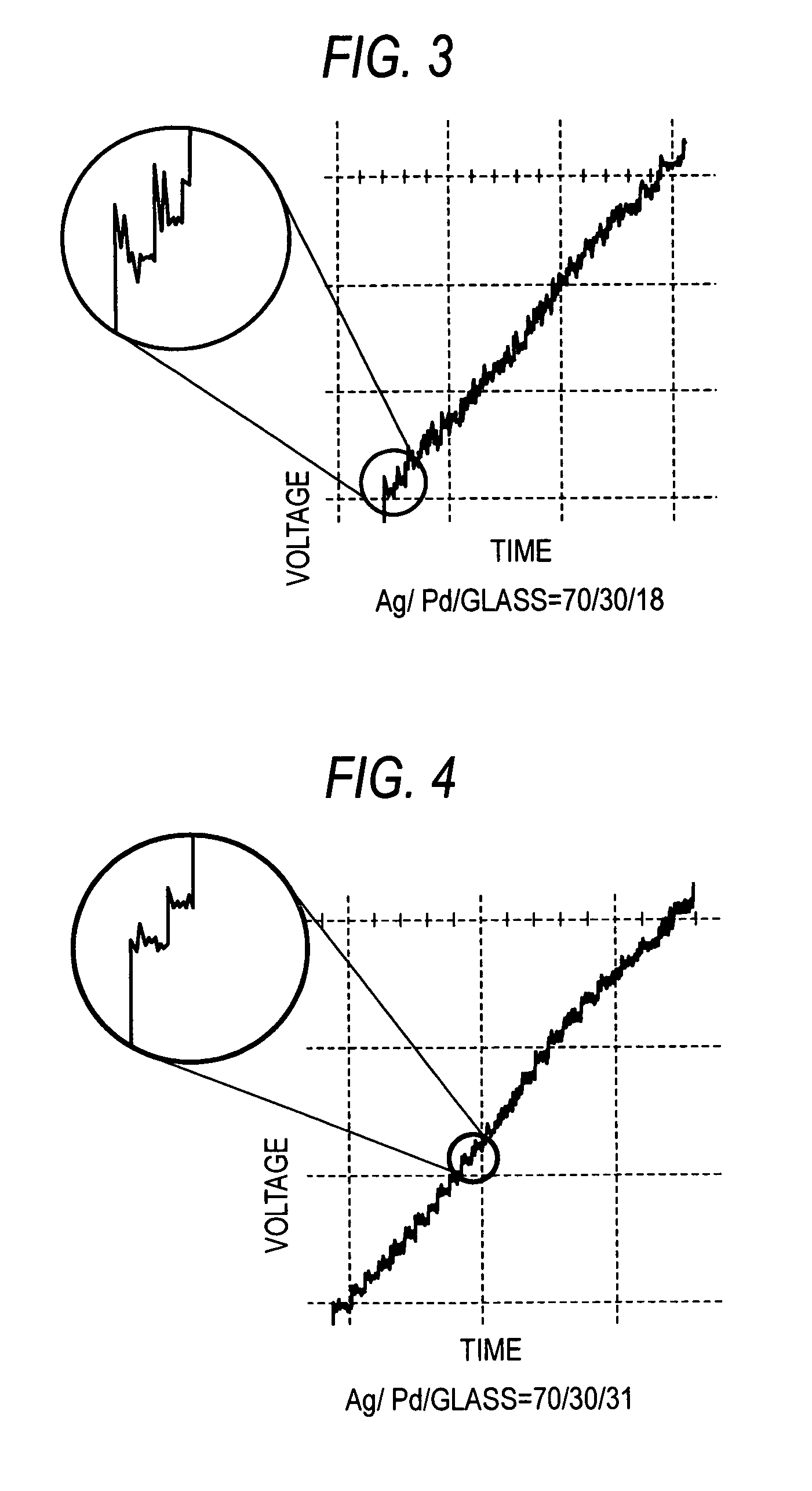

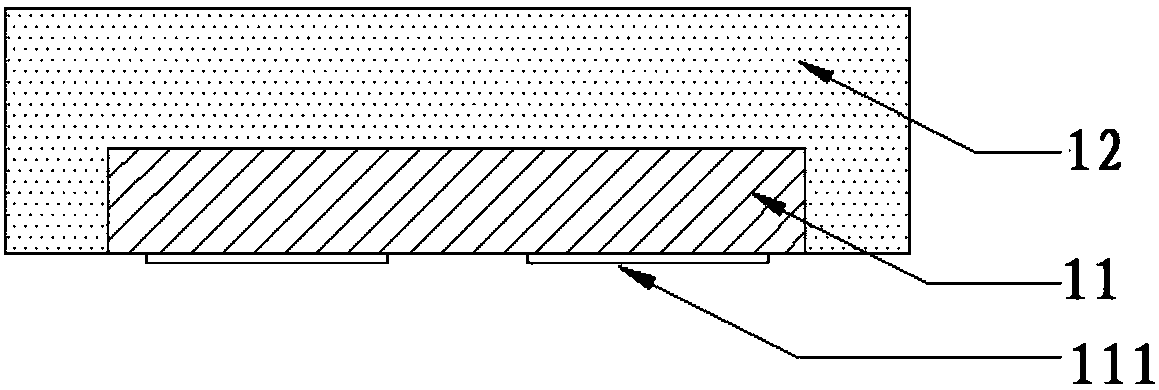

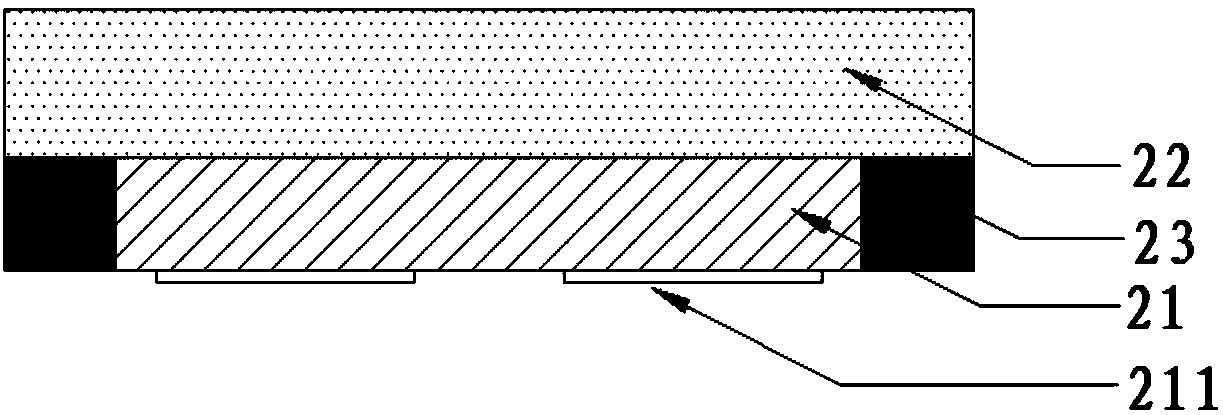

Sliding fluid level-detecting device

InactiveUS20070163341A1Improve anti-sulfur performanceImpart durabilityMachines/enginesLubrication indication devicesFuel tankAlloy

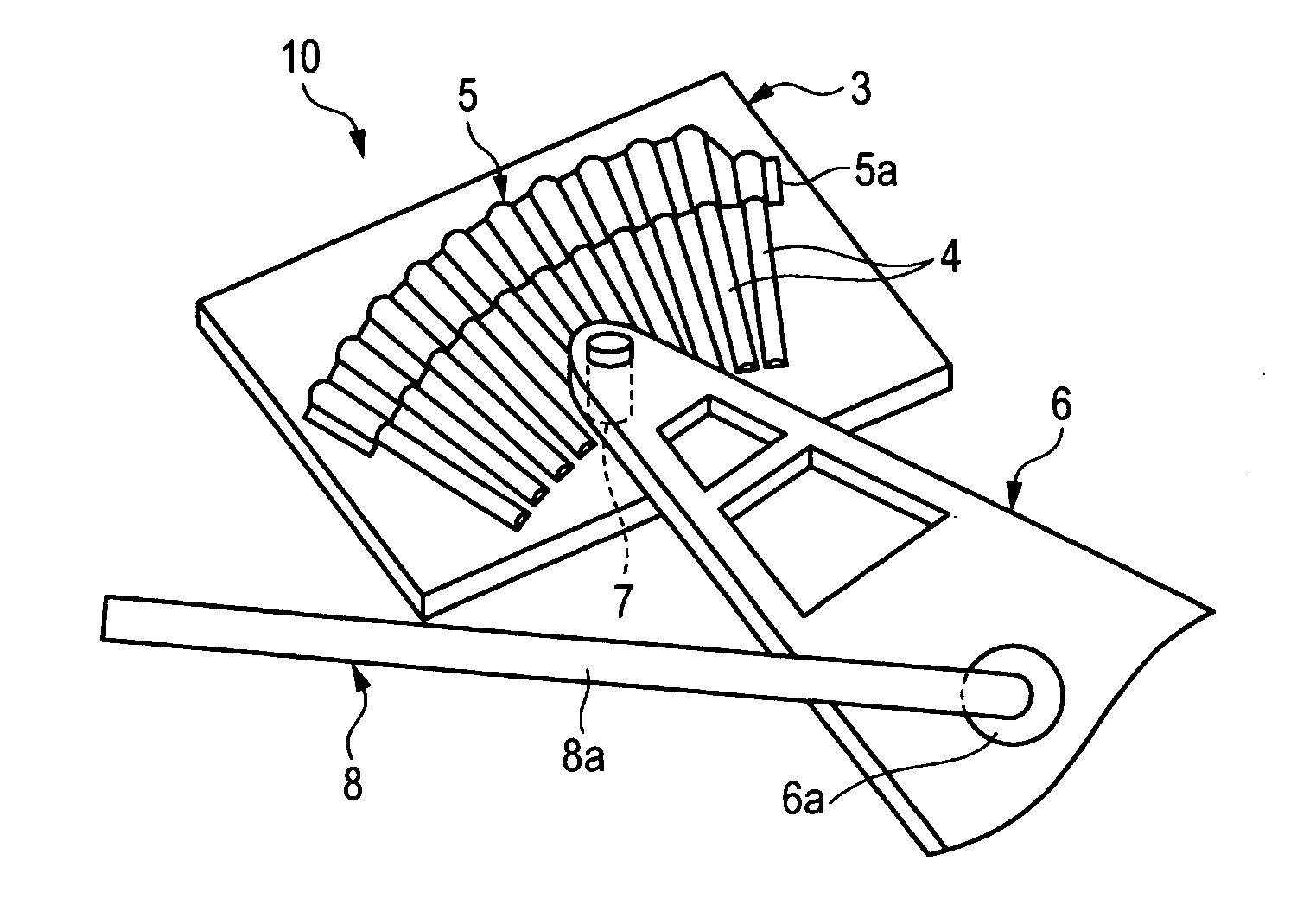

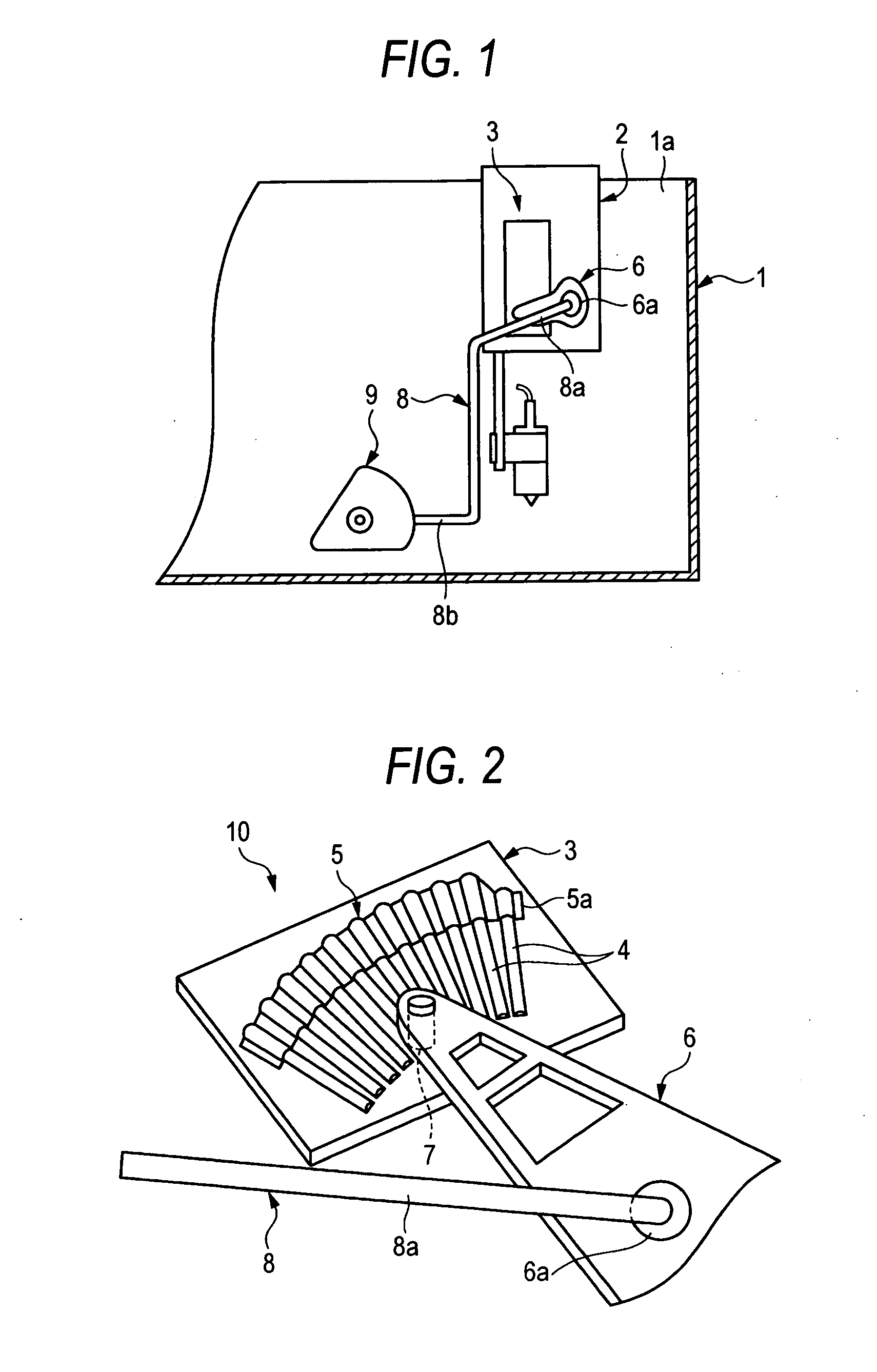

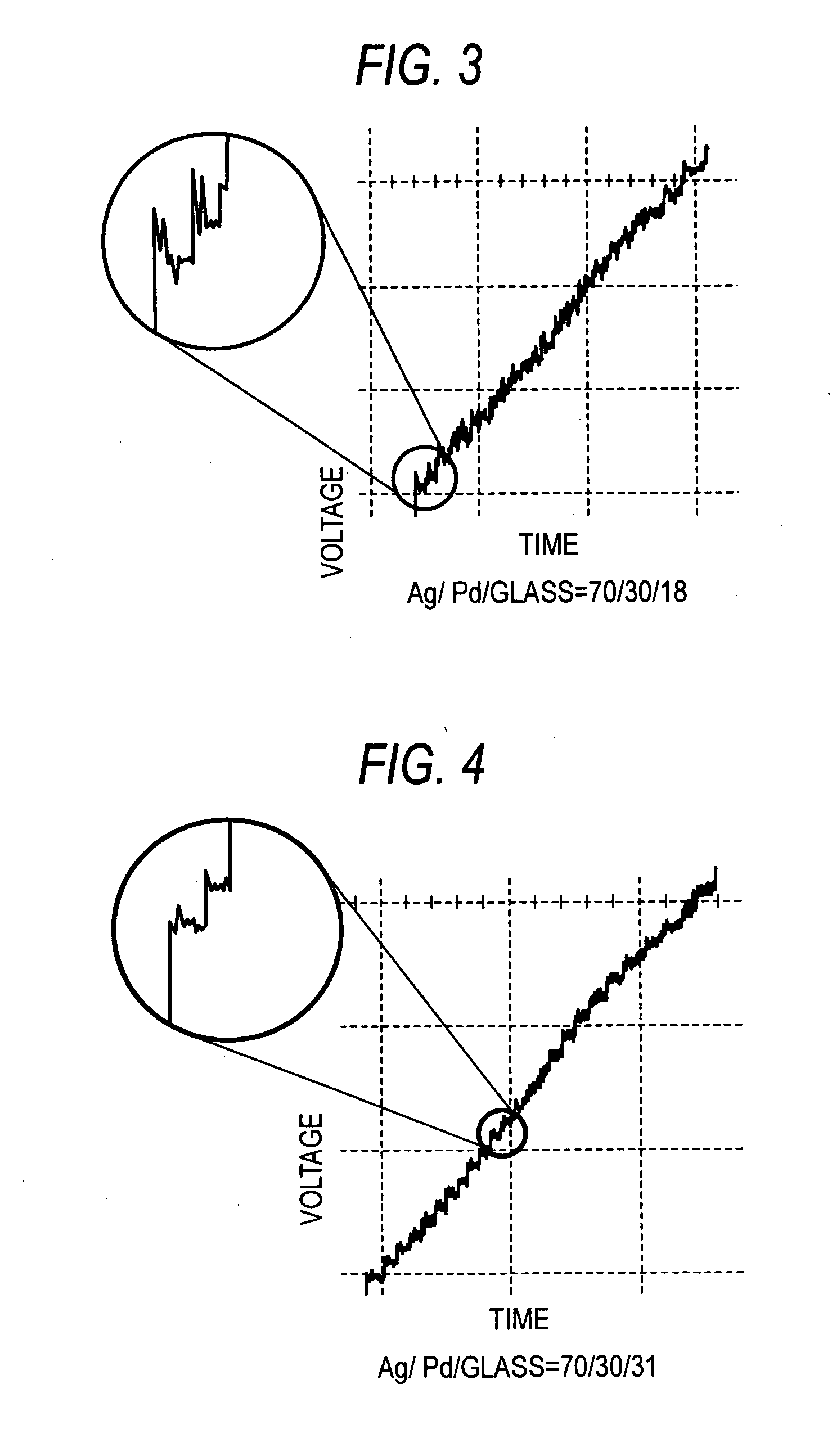

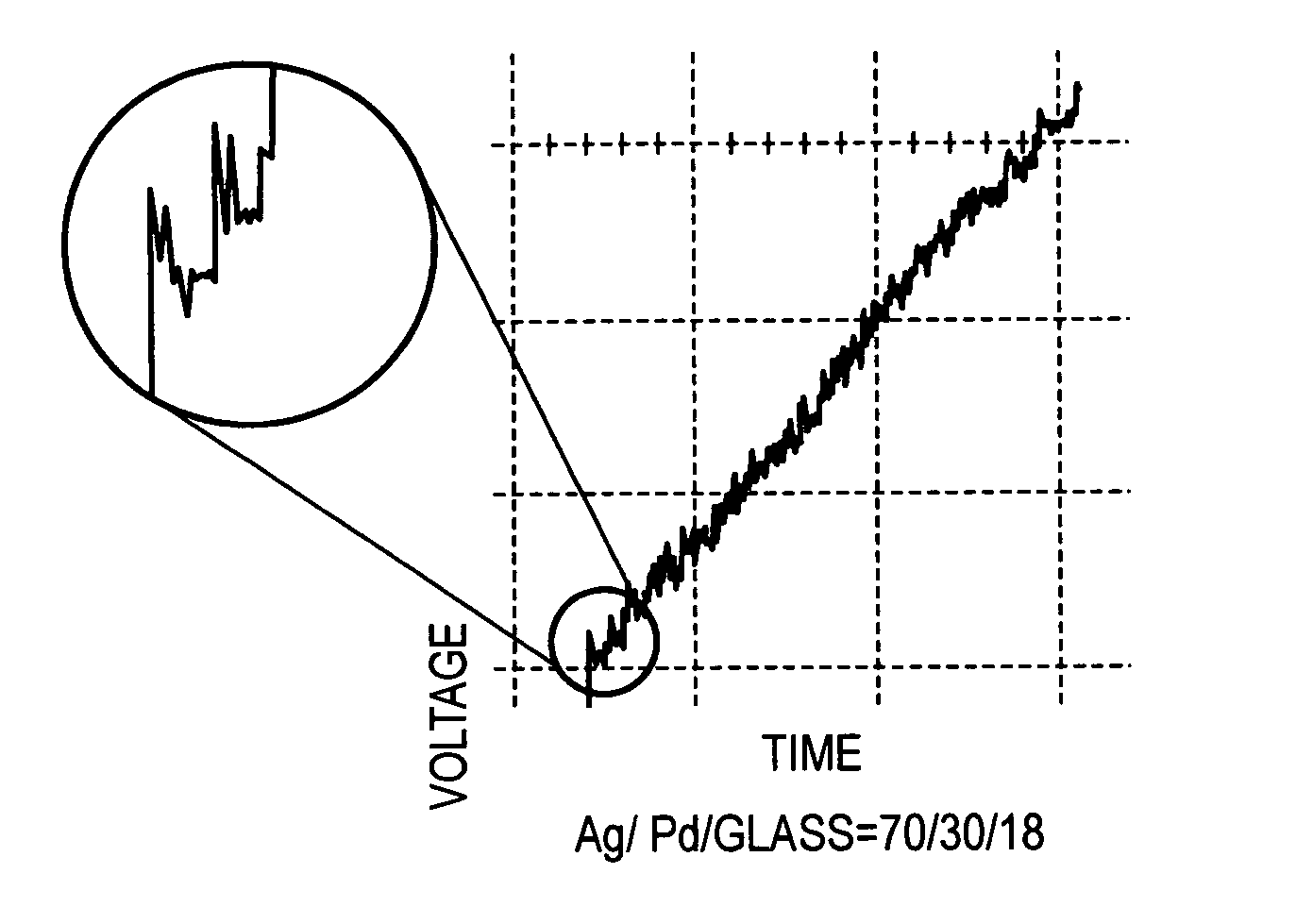

A sliding fluid level-detecting device which is mounted in a fuel tank of a vehicle and detects a remaining amount of a liquid fuel in the tank by sliding, on a plurality of stripes of an electrode formed at an electrode part electrically connecting with a fuel meter, a contact point provided on a slider interlocking with displacement of a float floating on a fluid surface of the liquid fuel, wherein the electrode is formed out of a glass-incorporated silver-palladium alloy where glass is mixed in an amount of 30 to 50 parts by weight per 100 parts by weight of a silver-palladium alloy and the contact point is formed out of a conductive material having a Vickers hardness (Hv) of 190 to 250.

Owner:YAZAKI CORP

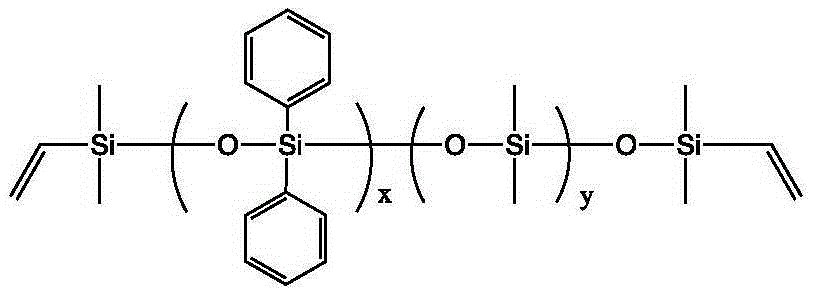

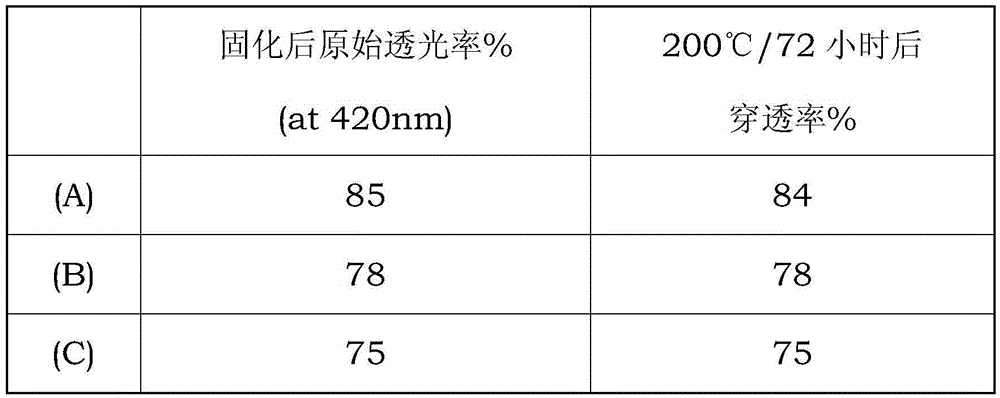

High-refractive-index organosilicon material for light-emitting diode (LED) packaging and preparation method of high-refractive-index organosilicon material

ActiveCN102863799AGuaranteed mechanical strengthHigh mechanical strengthSemiconductor devicesPtru catalystSilanes

The invention relates to a high-refractive-index organosilicon material for light-emitting diode (LED) packaging and a preparation method of the high-refractive-index organosilicon material. The technical scheme includes that according to a formula ration, three materials of a phenyl vinyl silicone resin, a phenyl hydrogen silicone resin and nano silicon dioxide (particle size distribution 5-15nm) which is treated by a silane coupling agent are placed in a 2L internal mixer to be internally mixed for one hour, then a platinum catalyst with a platinum content of 200-1000ppm is added to a nitrogen atmosphere, internal mixing is performed for 10 minutes again, finally, an alkynol compound is added, and internal mixing is continuously performed for 10 minutes to obtain the high-refractive-index organosilicon material. Compared with existing high-refractive-index organosilicon materials for LED packaging, the high-refractive-index organosilicon material for LED packaging is higher in drawing strength and larger in cohesive force under the condition of the same refractive index and light transmittance.

Owner:东莞市贝特利新材料有限公司

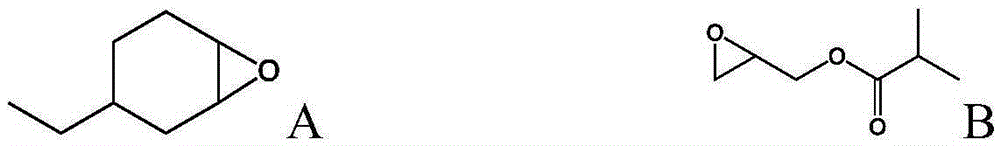

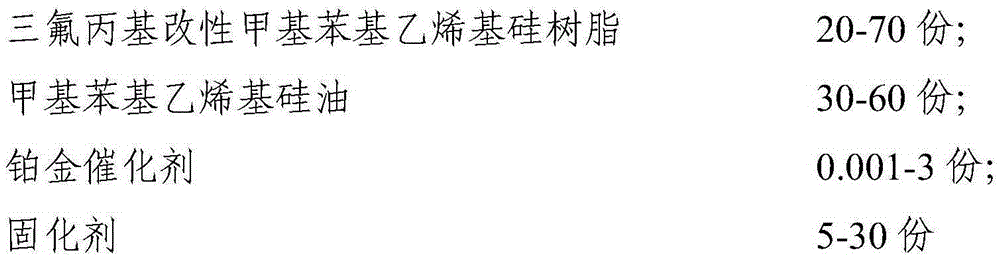

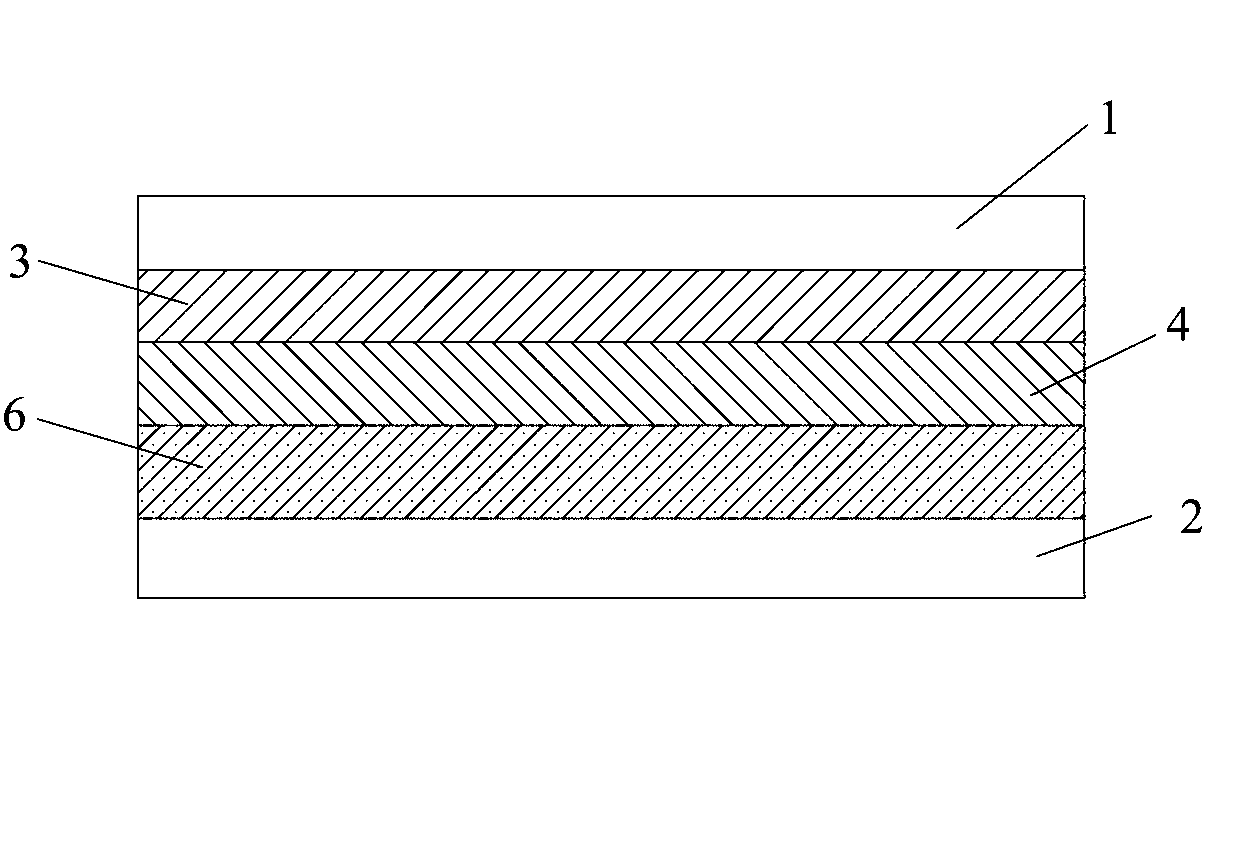

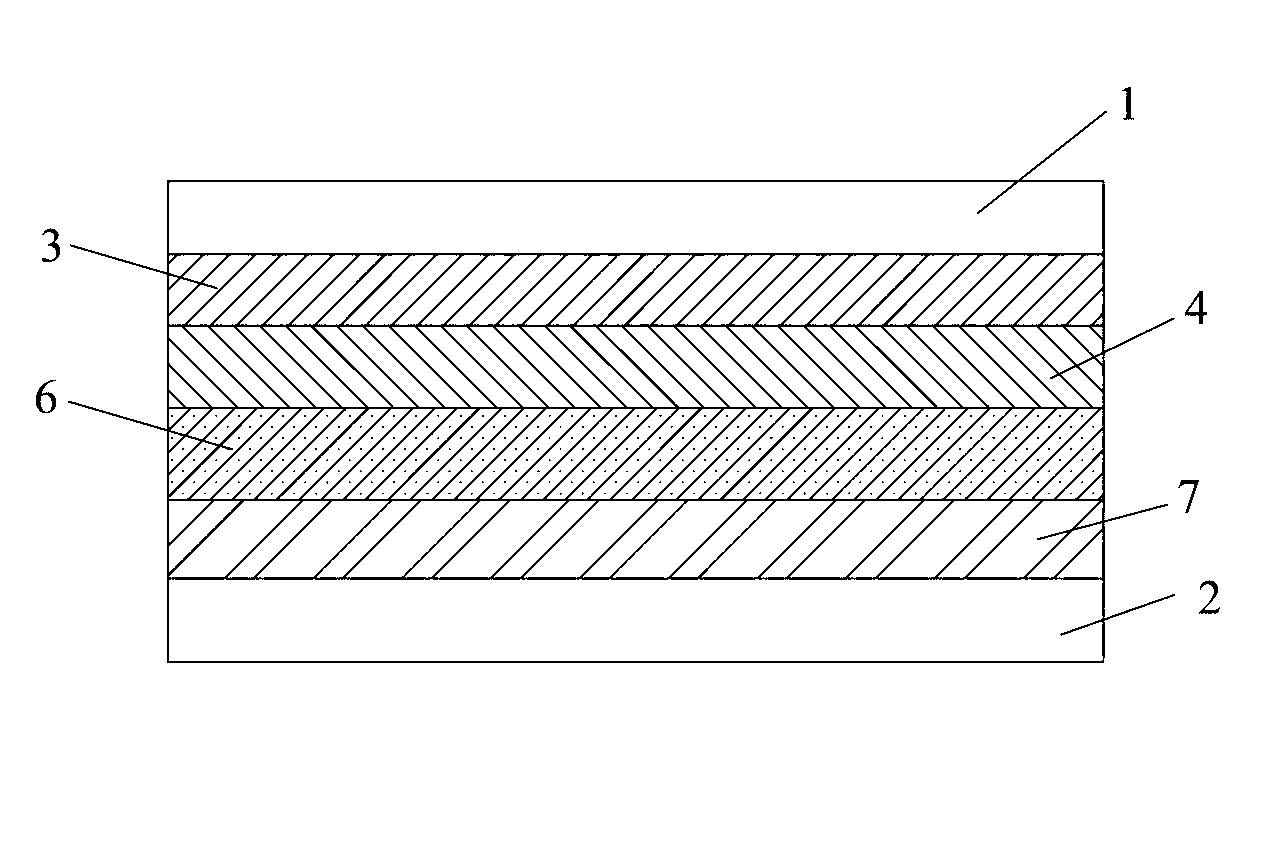

Trifluoropropyl-group-modification methyl phenyl vinyl silicon resin and LED packaging adhesive

ActiveCN105418928AGood weather resistanceImprove anti-sulfur performanceNon-macromolecular adhesive additivesSemiconductor devicesVulcanizationBond strength

The invention relates to a trifluoropropyl-group-modification methyl phenyl vinyl silicon resin. The general molecular formula of the trifluoropropyl-group-modification methyl phenyl vinyl silicon resin is (R13SiO0.5)a(R12SiO)b(R1SiO1.5)c, wherein R1 is Me, Vinyl, Ph and CF3CH2CH2-, the resin contains Me, Vinyl, Ph and CF3CH2CH2- at the same time and at least contains two pieces of Vinyl, and a, b and c are integers larger than 0. As a trifluoropropyl group is introduced into the structure, the heat stability of a modification material is improved, and the defect that an existing epoxy modification organosilicon material is poor in heat stability is effectively overcome; after LED packaging adhesive containing the silicon resin is mixed, heated and cured, colloid is high in bonding strength, good in heat stability and low in moisture permeability and oxygen permeability, and photoelectric attenuation caused by vulcanization can be effectively reduced.

Owner:GUANGDONG HENGDA NEW MATERIALS TECH

Silver alloy reflection film, and electrochromic device provided with the same

ActiveCN102851525AImprove anti-tarnishImprove anti-sulfur performanceNon-linear opticsRare-earth elementAlloy

The invention provides a silver alloy reflection film, and an electrochromic device provided with the same, which include silver, palladium and rare earth element. The rare earth element is selected from La and / or Yb. The silver alloy reflection film, and the electrochromic device provided with the same can effectively improve resistance of the reflection film to discoloration and sulfurization.

Owner:BYD CO LTD

Method of preparing bore diameter gradient FeAl intermetallic compound homogeneity filtering membrane

InactiveCN101108312AImprove antioxidant capacityExcellent anti-vulcanization performanceSemi-permeable membranesFiltration separationSputteringOxidation resistant

The invention discloses a method for preparing aperture grads FeAl metal intermetallic compound Homogeneous filtering membrane, which adopts Fe and Al element powder of component matching and particle size matching. By the way of die pressing and isostatic cool pressing, make out platy or tubular filtering adobe, then adopts the way of magnetron sputtering, ion plating or vacuum evaporation to plate a layer of metal Al membrane and a layer of metal Fe membraqne on one surface of the filtering adobe evenly, and also adopts the way of non pressure sintering, prepare FeAl metal intermetallic compound homogeneous filtering membrane finally. The method doesn't need adding pore former during preparing process, lowers energy consumption almost without pollution. The prepared filtering membrane has good antioxidation performance, antisulfuration performance and anticorrosion performance, which increase the service life of inorganic membrane and can be widely used in strict environment field, in particular the filtering, separating, purifying and contracting in high temperature, strong corrosion and sulfuration environment filed.

Owner:CENT SOUTH UNIV

Silver alloy, sputtering target material thereof, and thin film thereof

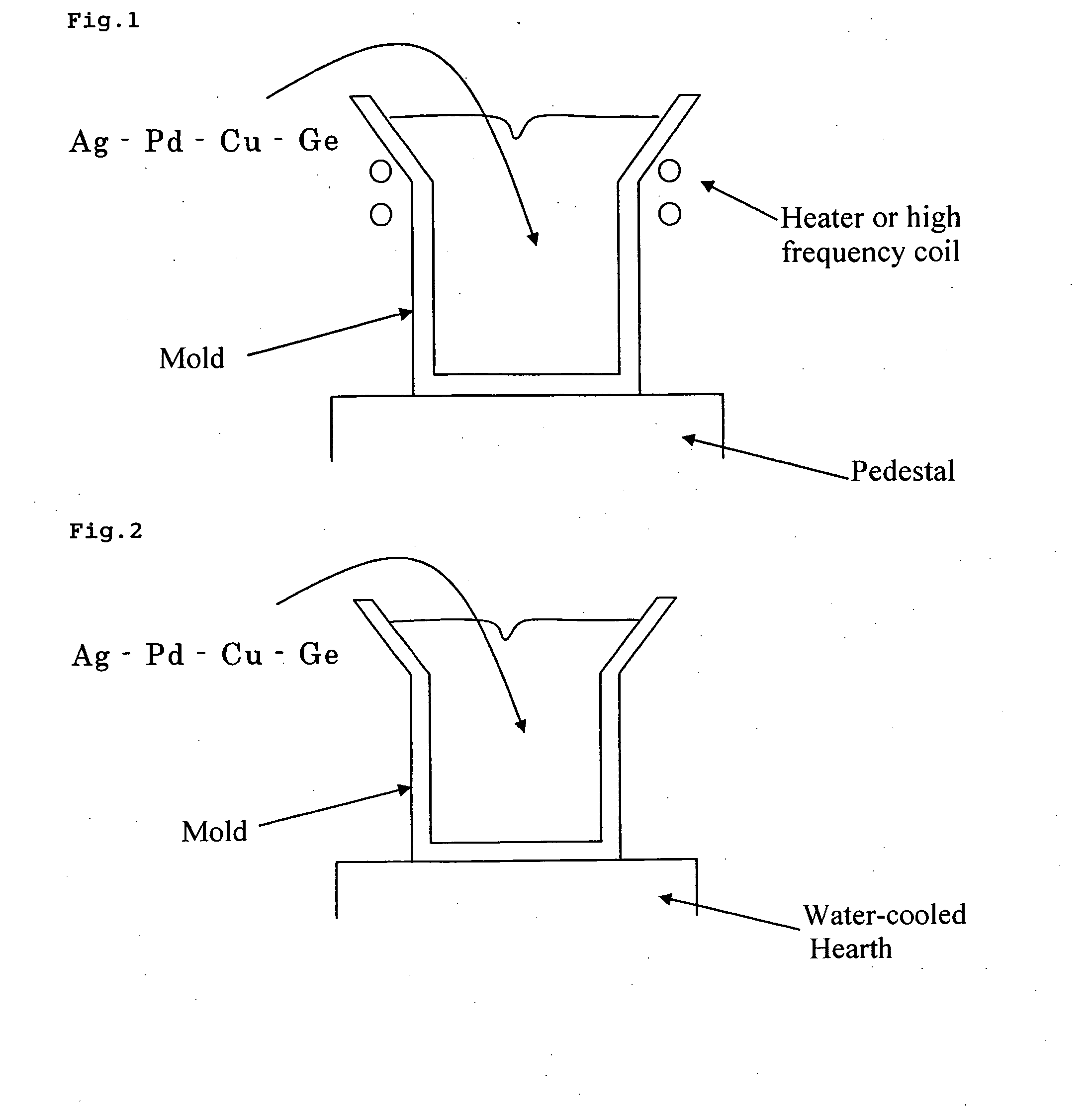

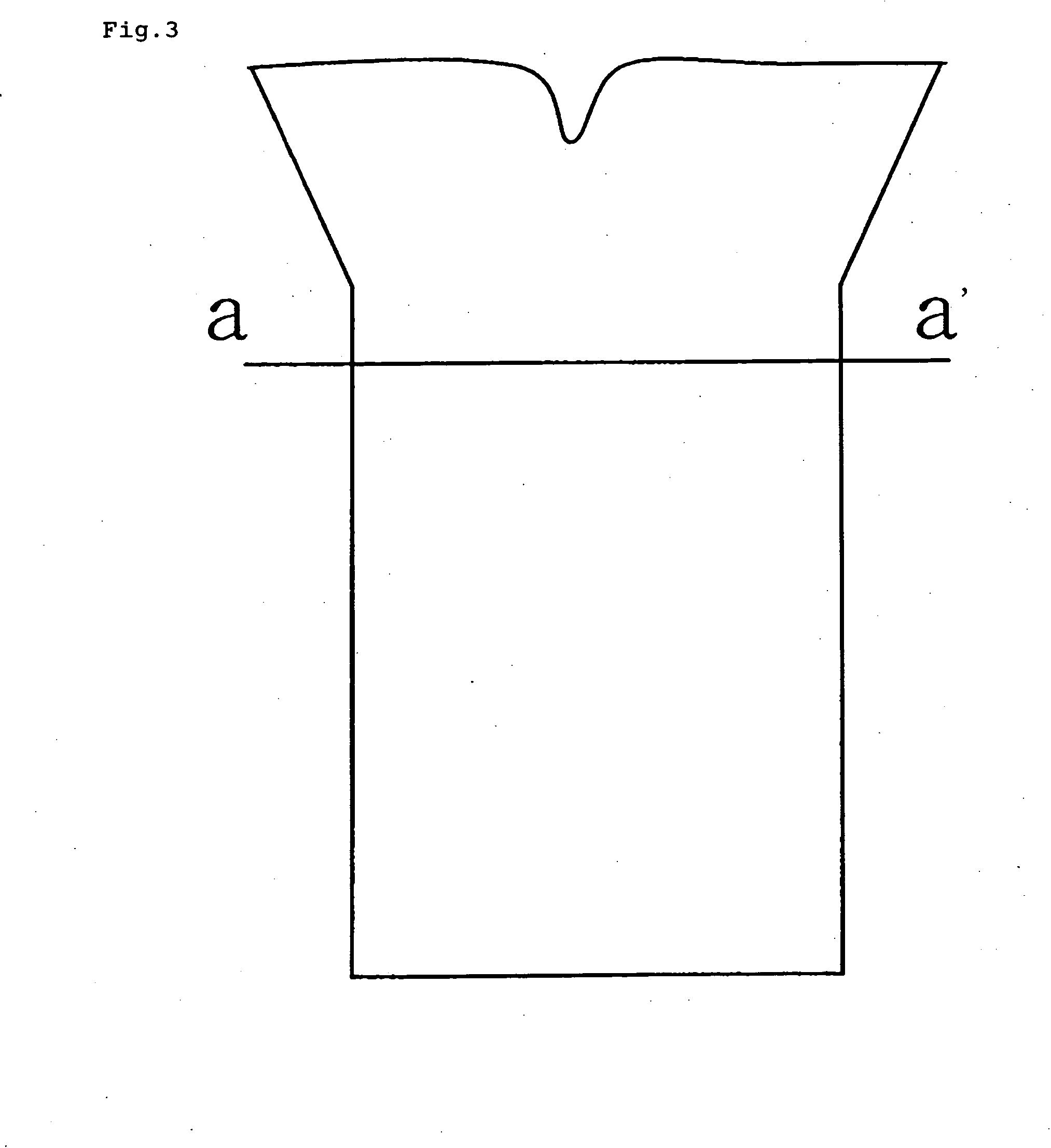

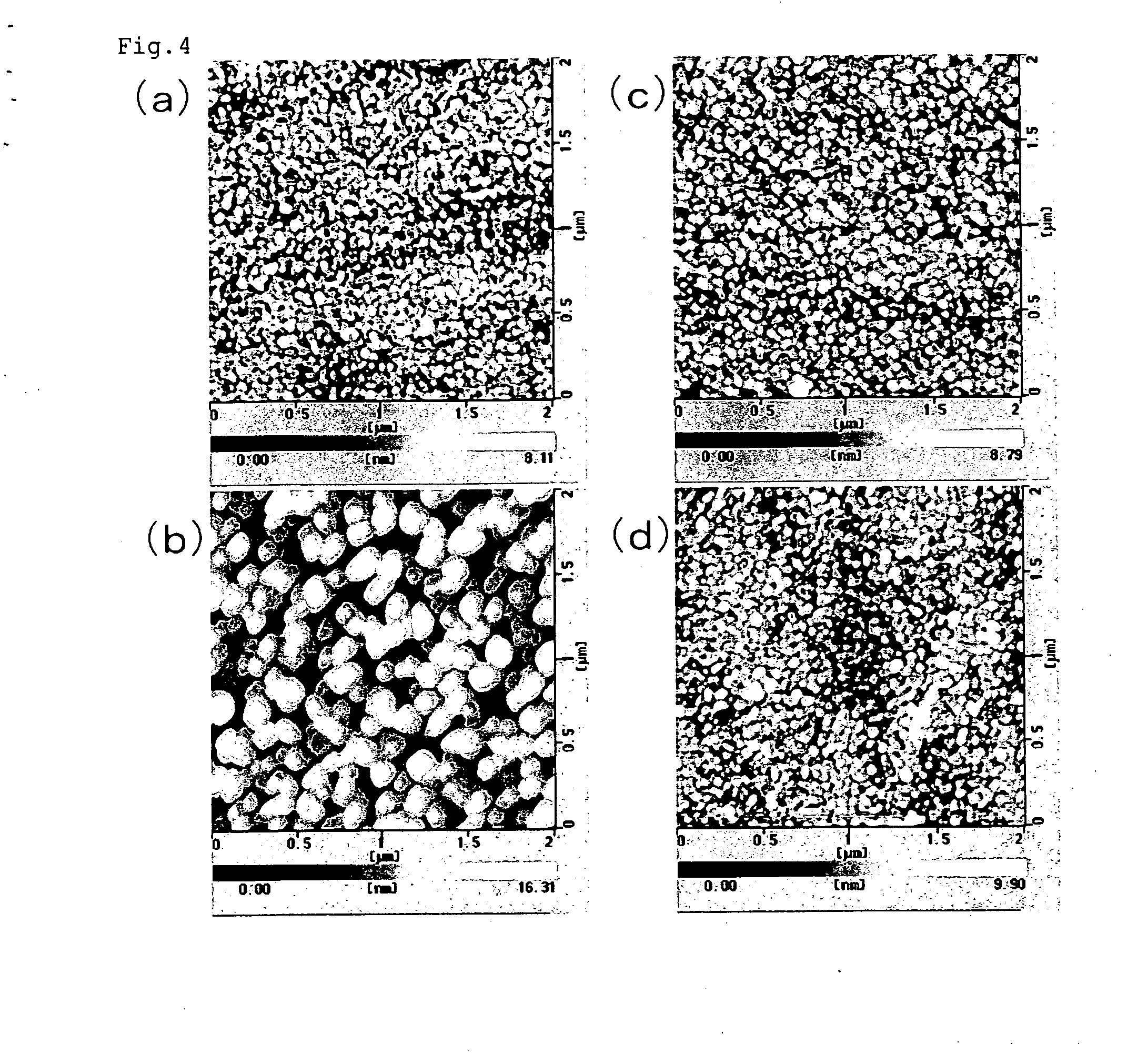

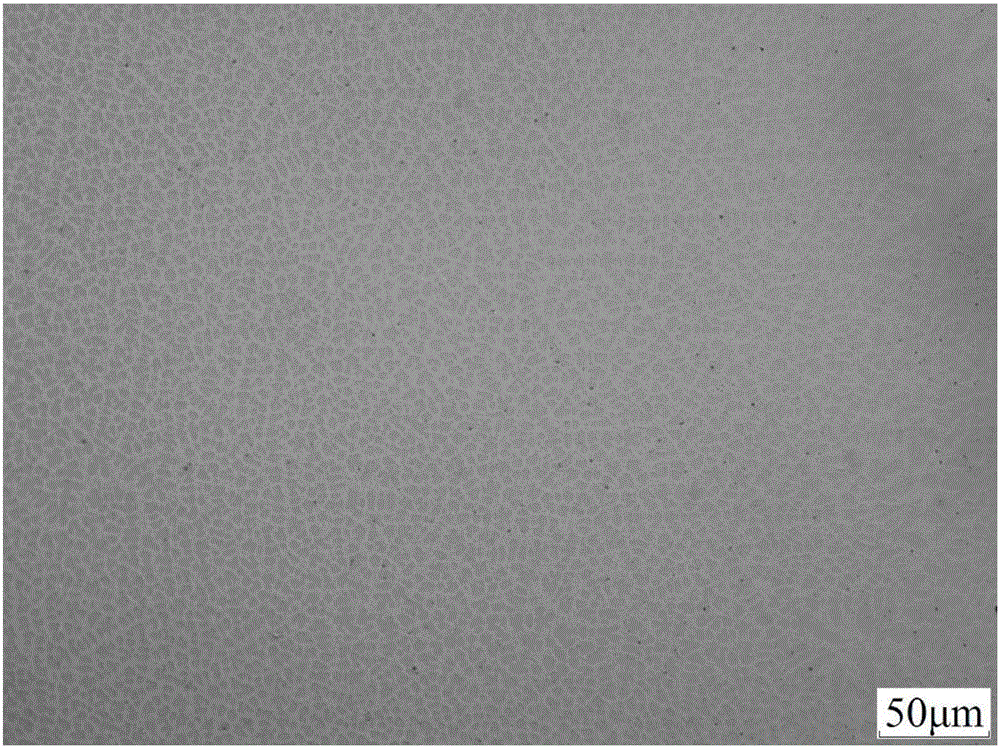

InactiveUS20070110968A1Improve weatherabilityHigh heat resistanceVacuum evaporation coatingSputtering coatingReflectivityLiquid-crystal display

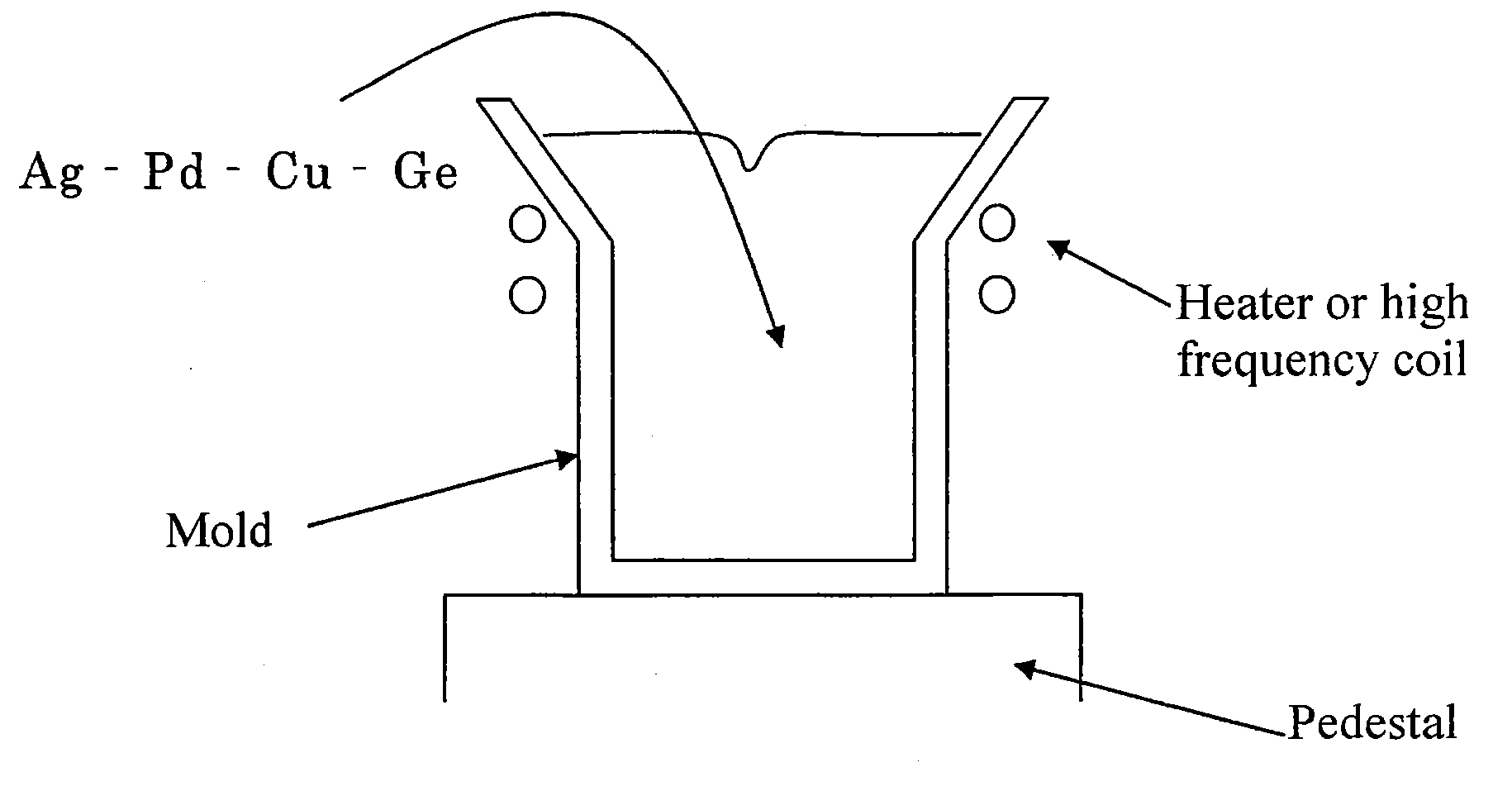

It is an object of the present invention to provide a Ag—Pd—Cu—Ge type silver alloy which can form a reflective electrode film having such two characteristics that it is very reduced in the lowering of reflectance caused by thermal deterioration and has resistant to yellowing caused by sulfurization even after a heating step in a process of producing a color liquid crystal display. The silver alloy according to the present invention includes a composition containing at least four elements including Ag as its major component, 0.10 to 2.89 wt % of Pd, 0.10 to 2.89 wt % of Cu and 0.01 to 1.50 wt % of Ge, and the total amount of Pd, Cu and Ge is 0.21 to 3.00 wt %.

Owner:FURUYA KINZOKU KK

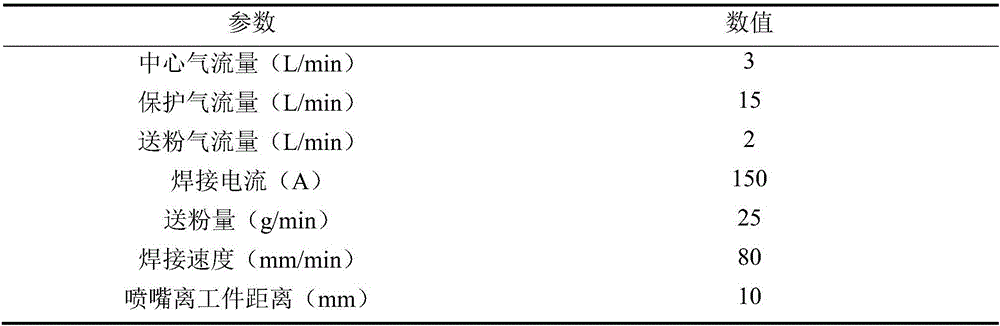

Cobalt-based powder used for plasma arc surfacing and capable of resisting high-temperature corrosion and wear

ActiveCN106825988ASimple processLow equipment requirementsPlasma welding apparatusWelding/cutting media/materialsRare earthWear resistance

The invention relates to cobalt-based powder used for plasma arc surfacing and capable of resisting high-temperature corrosion and wear. The powder is prepared from components in percentage by mass as follows: 12%-14% of Cr, 20%-24% of Mo, 2.5%-3.2% of Si, 3%-6% of Al, 1%-3% of Ta, 0.3%-0.8% of Y2O3, 0.1%-0.2% of CeO2 and the balance of Co; the particle size of original powder ranges from 200 meshes to 350 meshes. Through reasonable component proportioning of Cr, Mo, Si, Al, Y2O3, CeO2 and other rare earth oxides, high oxidation resistance and sulfuration resistance of a cobalt-base alloy are guaranteed while the strength and the wear resistance are guaranteed.

Owner:HEBEI UNIV OF TECH

Method for spraying and preparing high temperature sulfidation resistant alloy layer on the surface of cast iron

InactiveCN101575693ASufficient binding strengthHigh bonding strengthMolten spray coatingWire rodSulfidation

The invention belongs to the technical field of metal surface spray and provides a method for spraying and preparing a high temperature sulfidation resistant alloy layer on the surface of cast iron. The method includes the following steps of: (1) pre-treating the surface of a cast iron workpiece before spraying, and exposing the clean and coarsening metal surface of the workpiece; (2) adopting a subsonic speed oxyacetylene flame hot spray method to spray prime coat on the surface of the cast iron workpiece, wherein the prime coat adopts nickel aluminum compound powder; and (3) adopting a high speed arc wire spray method to spray an FeCrAl working layer on the surface of the cast iron workpiece. The technique of the invention is characterized by simple and convenient operation and strong applicability, can save high alloy material and is convenient for promotion and use. Compared with the overall high temperature sulfidation resistant material, the cast iron part prepared by means of the method is low in cost, has excellent resistance to high temperature sulfidation and favorable wearing resistance, and can strikingly improve the service life of the cast iron part in a high temperature sulfidation environment.

Owner:HENAN POLYTECHNIC UNIV

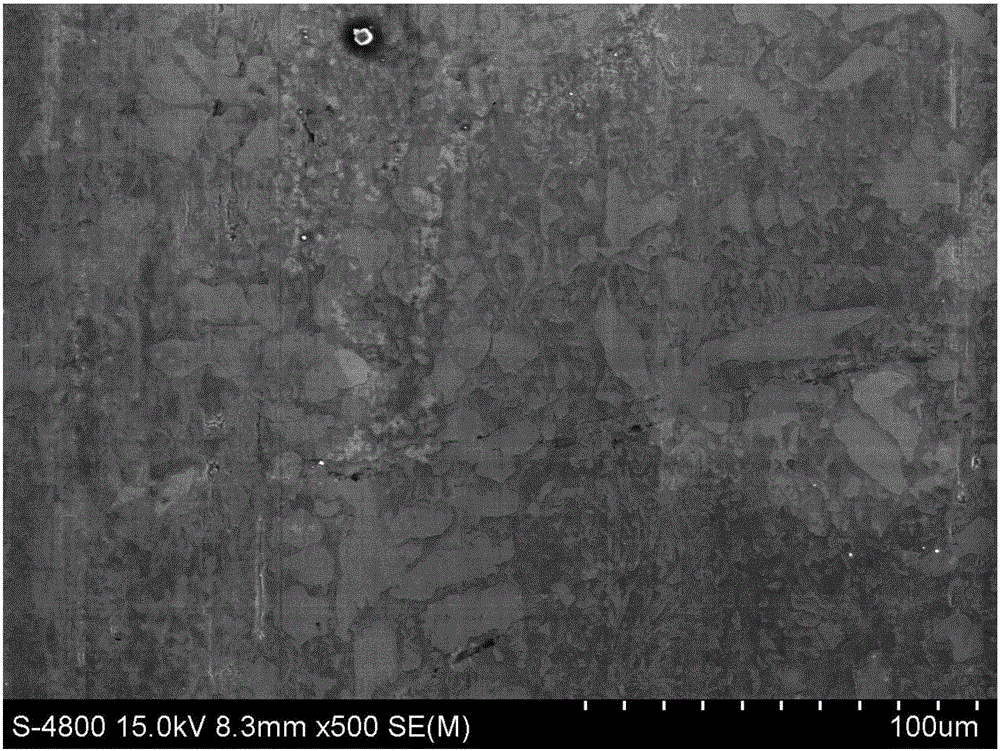

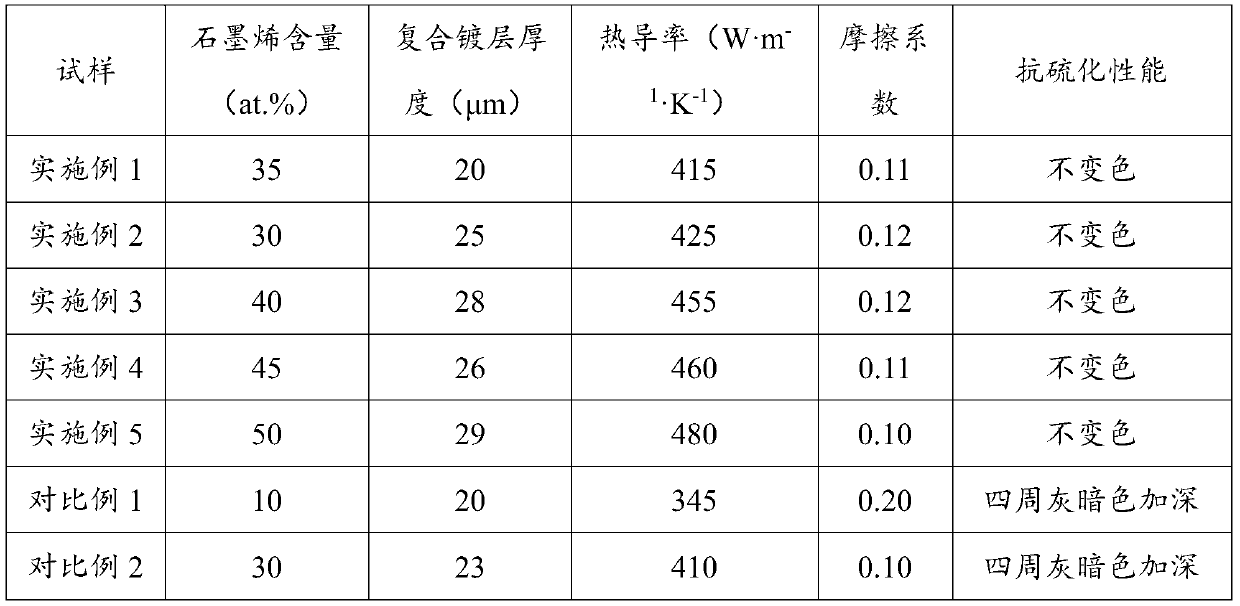

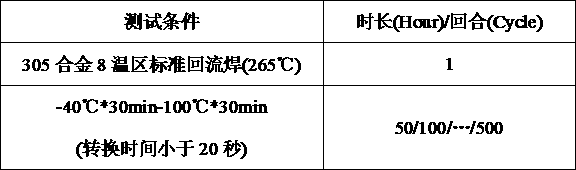

Silver/graphene composite plating solution, using method thereof and silver/graphene composite plating layer

ActiveCN111519232AControl deposition directionImprove anti-sulfur performanceElectrolytic coatingsPhysical chemistryGraphene flake

The invention provides a silver / graphene composite plating solution. The silver / graphene composite plating solution comprises a 3-80 g / L of AgNO3, 30-400 g / L of KI, 6-300 g / L of Na2S2O3, 1-20 g / L of HNO3, 0.1-10 g / L of a dispersing agent, 0.1-10 g / L of an auxiliary agent, 0.01-3 g / L of a defoaming agent, 0.5-5 g / L of graphene sheets and water. According to the provided silver / graphene composite plating solution, by adding the dispersing agent, the auxiliary agent and the defoaming agent, a complex on the surface of graphene can be controlled, so that graphene sheets are uniformly parallel to abase body surface, vulcanization of a silver layer is prevented, isolation of silver and harmful gas is realized, and the vulcanization resistance of a composite plating layer is improved; and experimental results show that a provided silver / graphene composite plating layer does not change color after being soaked in a Na2S solution with the volume fraction of 5% for 240 hours, and the sulfur resistance far exceeds the requirements of aviation industry standard QJ485-1988.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +4

Gold alloy bonding wire and manufacturing method thereof

ActiveCN108922876AHigh tensile strengthImprove anti-sulfur performanceSemiconductor/solid-state device detailsSolid-state devicesSulfidationHigh field strength

The invention provides a gold alloy bonding wire and further provides a manufacturing method of the gold alloy bonding wire. The gold alloy bonding wire is characterized in that the gold alloy bondingwire comprises, by weight, 0.5-2% of Pd, 15-30% of Ag, 0.5-3% of Cu, 0.1-2% of Pt, 2-200 ppm of a minor additive element and the balance gold, wherein the minor additive element is one or two or moreof Ca, In, Co, Be, Ga, Mg, Ce and Ni. The gold alloy bonding wire has excellent high reliability and sulfidation resistance, high tensile strength and good welding spot connectivity, and can lower the cost.

Owner:NICHE TECH KAISER SHANTOU

Diesel engine post-treatment system

InactiveCN102733897AAdapt to qualityImprove anti-sulfur performanceExhaust apparatusSilencing apparatusType metalFuel oil

The invention relates to a diesel engine post-treatment system, comprising a tight coupling oxidation catalytic reactor, a first-grade flow-through type metal filter and a wall-flow type ceramic filter, wherein the tight coupling oxidation catalytic reactor is arranged on an outlet of an exhaust manifold (a natural aspirated diesel engine) or an turbine outlet of an exhaust gas turbocharger (a turbocharged diesel engine), the part flow-through type metal filter is arranged behind the tight coupling oxidation catalytic reactor, and a wall-flow type ceramic filter is arranged behind the first-grade flow-through type metal filter. In addition, a fuel oil additive including Fe or Ce is injected into a fuel tank and mixed with fuel oil, and then the obtained product is injected into a cylinder. The system can reduce the regeneration temperature of soot caught by a filtration system to 400 DEG C so as to reduce the energy needed to be consumed in a regeneration process, and in addition, risks of scorification or cracking of the ceramic filter in the regeneration process can be largely reduced. Finally, ash content collected into the metal filter can be cleaned by high pressure air back flushing or other ways after the filter is removed.

Owner:杨德胜

Gold alloy bonding wire and manufacturing method thereof

InactiveCN108796269AHigh hardnessImprove anti-sulfur performanceSemiconductor devicesVulcanizationGold alloy

The invention relates to a gold alloy bonding wire which is characterized by comprising, by weight, 2.1%-8% of Pd, 20%-30% of Ag, 2.1%-6% of Pt, 2-200 ppm of trace additive elements and the balance gold. The trace additive elements are a combination of one or more than two of Ca, In, Co, Be, Ga, Mg, Ce and Ni. The invention further comprises a manufacturing method of the above gold alloy bonding wire. The gold alloy bonding wire has the excellent strength of extension, is suitable for packaging of low wire arcs and high wire arcs, and meanwhile is high in vulcanization resistance and reliability and low in cost.

Owner:NICHE TECH KAISER SHANTOU

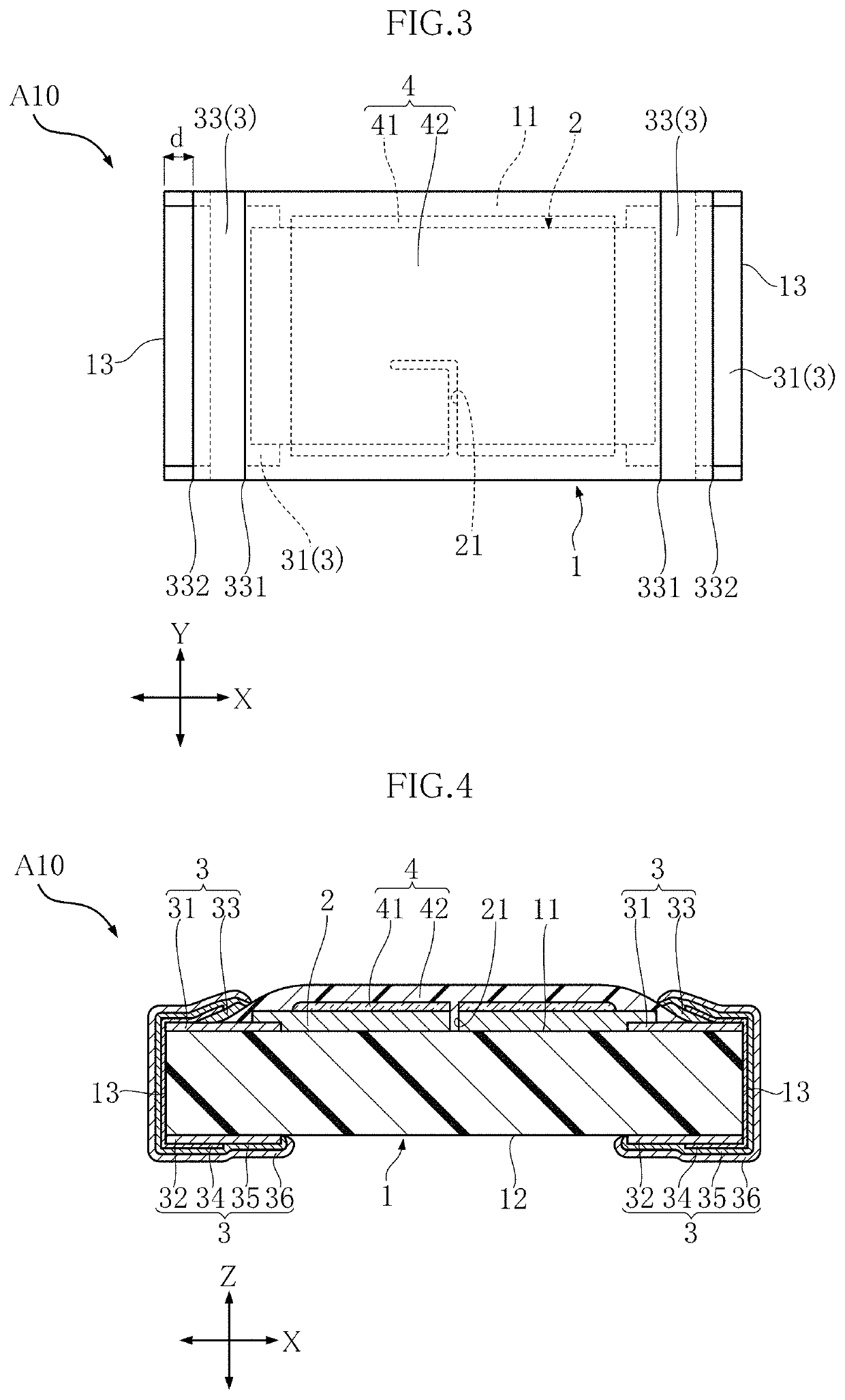

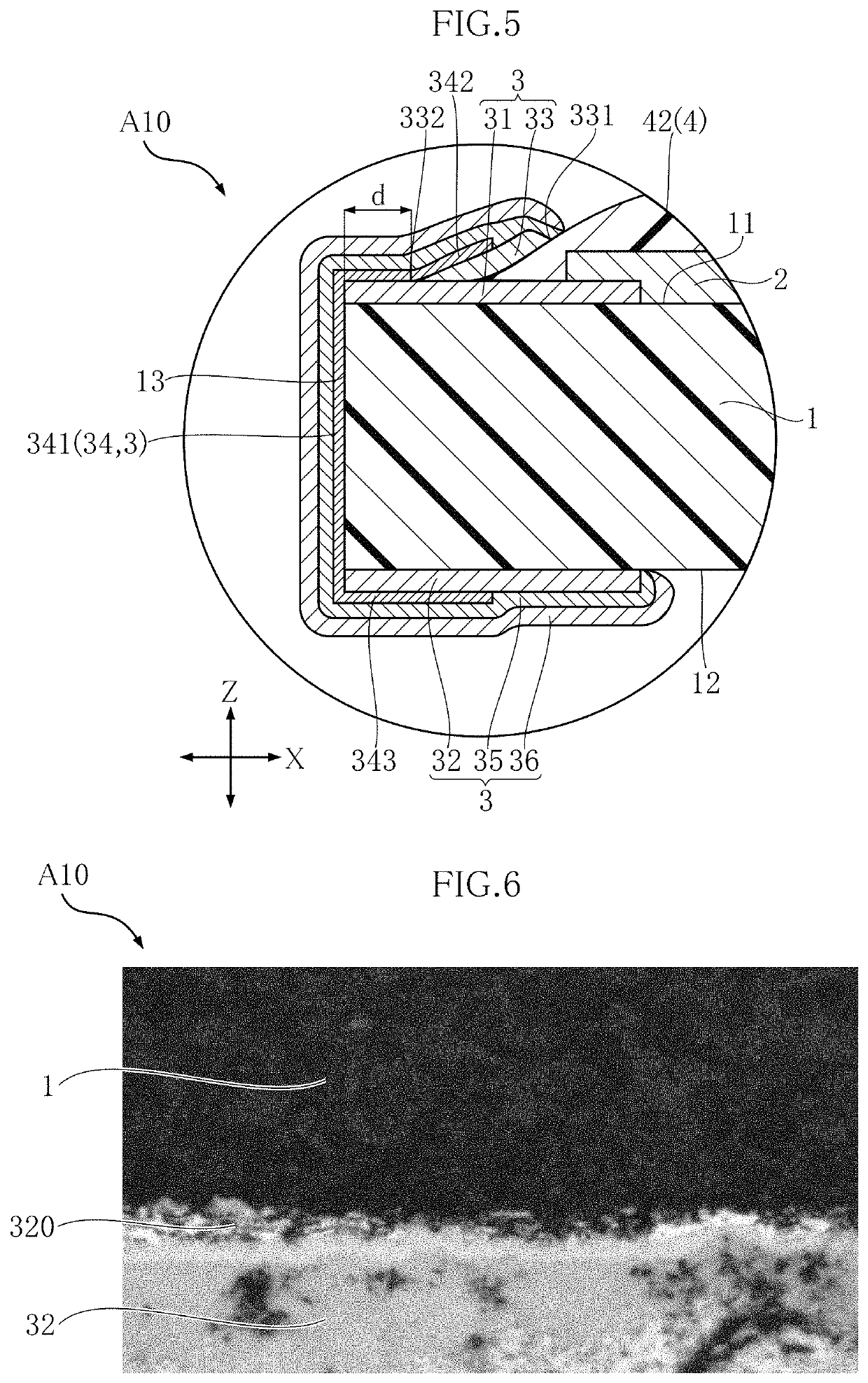

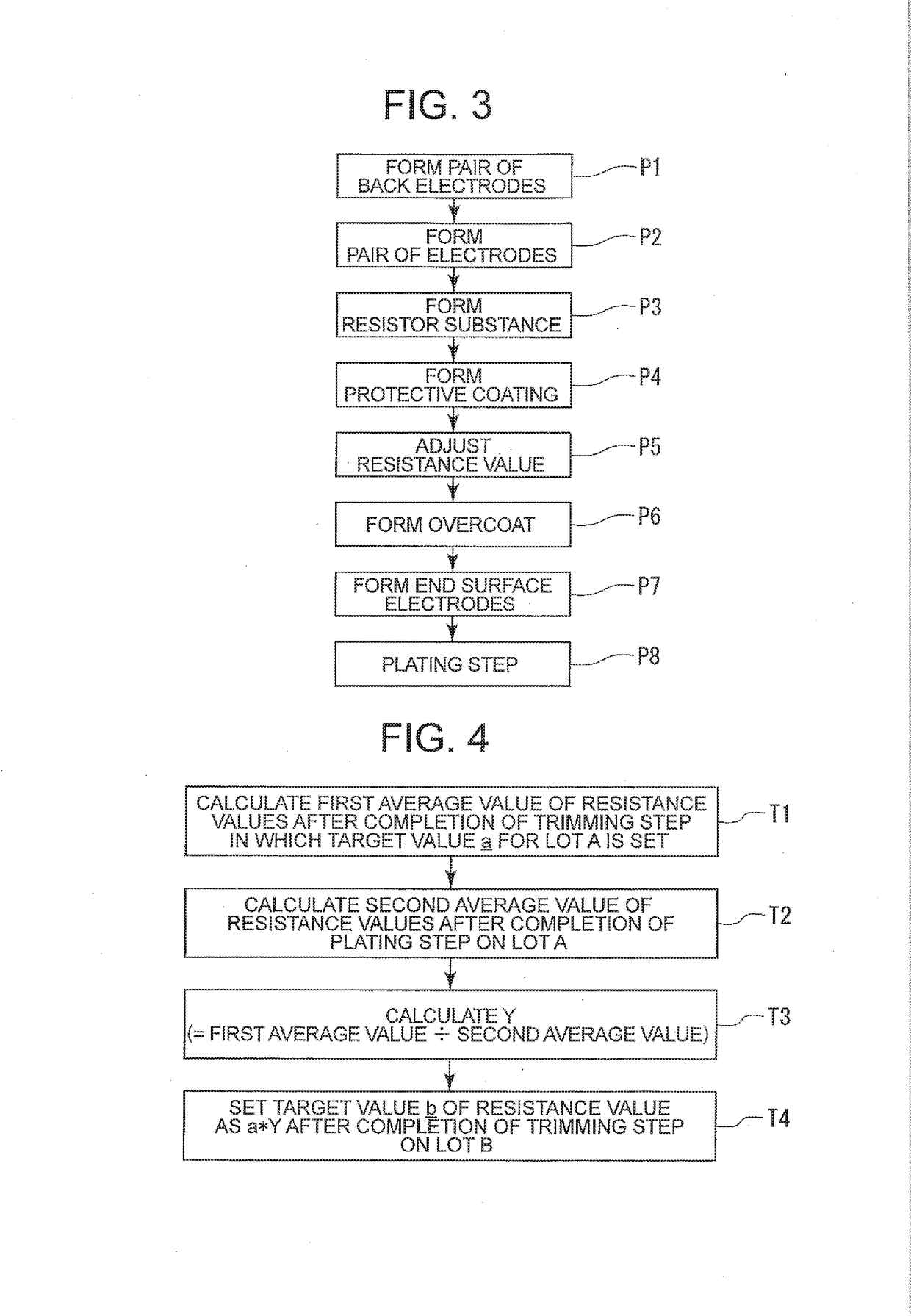

Chip resistor and method for manufacturing same

ActiveUS20200066429A1Improve anti-sulfur performanceResistor chip manufactureResistor terminals/electrodesEngineeringElectrical and Electronics engineering

One aspect of the present disclosure provides a chip resistor. In the chip resistor, a top electrode is disposed on a front surface of a substrate. A resistor is disposed on the front surface and electrically connected to the top electrode. A protective layer covers the resistor. A protective electrode is electrically connected to the top electrode. A side electrode is electrically connected to the top electrode. The side electrode has a side portion disposed on the side surface, and a top portion and a bottom portion respectively overlapping the front surface and the back surface in plan view. An intermediate electrode covers the protective electrode and the side electrode. An outer electrode covers the intermediate electrode. The protective electrode is in contact with both the top electrode and the protective layer and covers a portion of the top electrode and a portion of the protective layer.

Owner:ROHM CO LTD

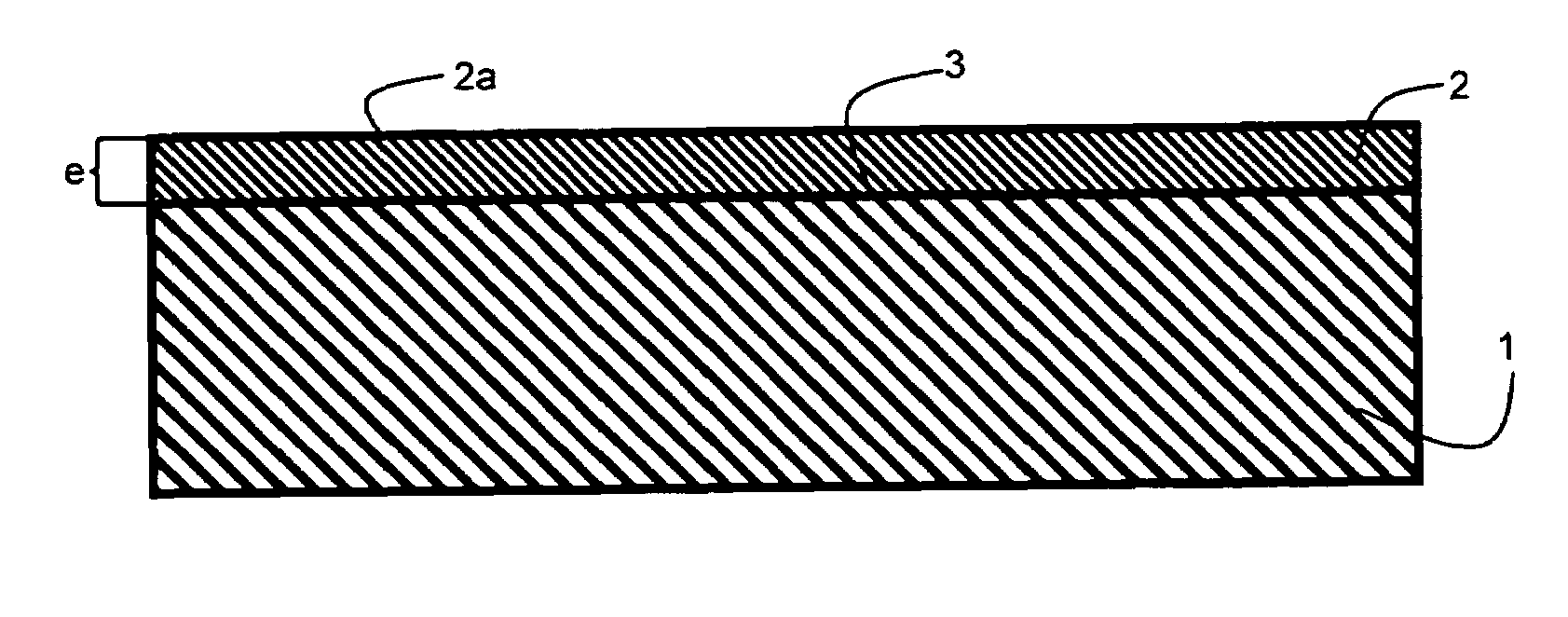

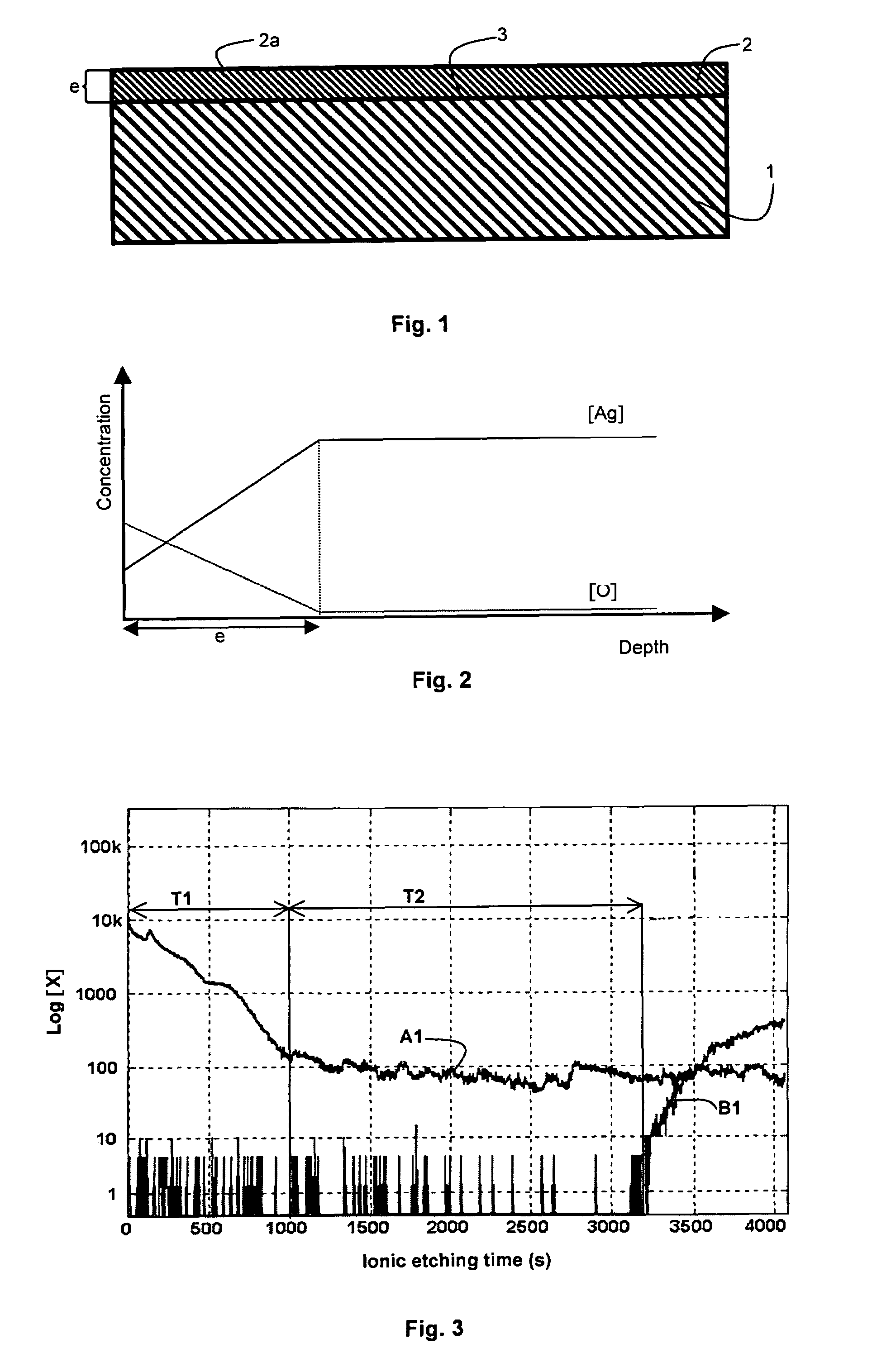

Sulfidation-resistant silver-base coating, method for depositing such a coating and use thereof

InactiveUS7670689B2Improve anti-sulfur performanceVacuum evaporation coatingSputtering coatingGas phaseSulfidation

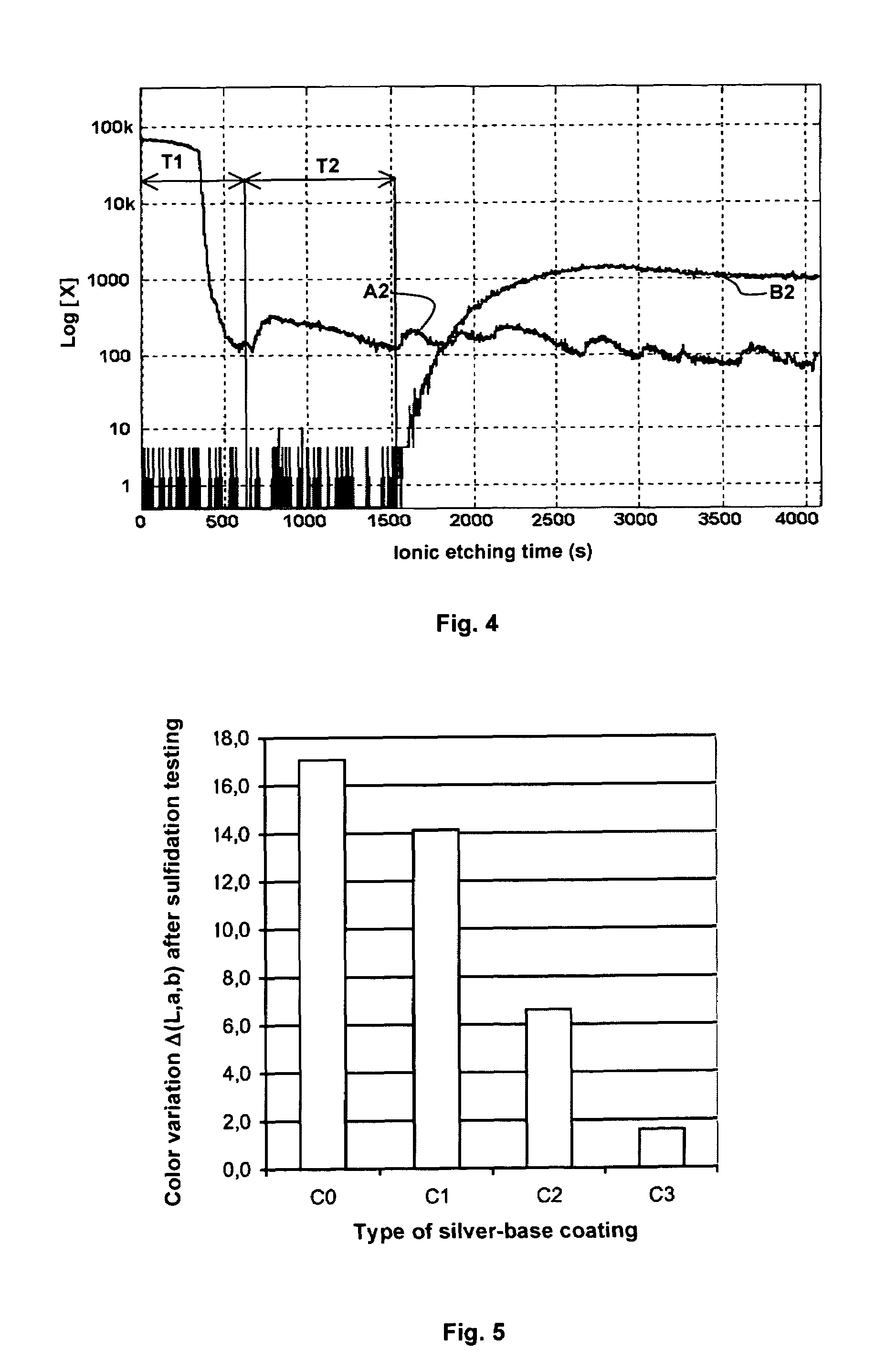

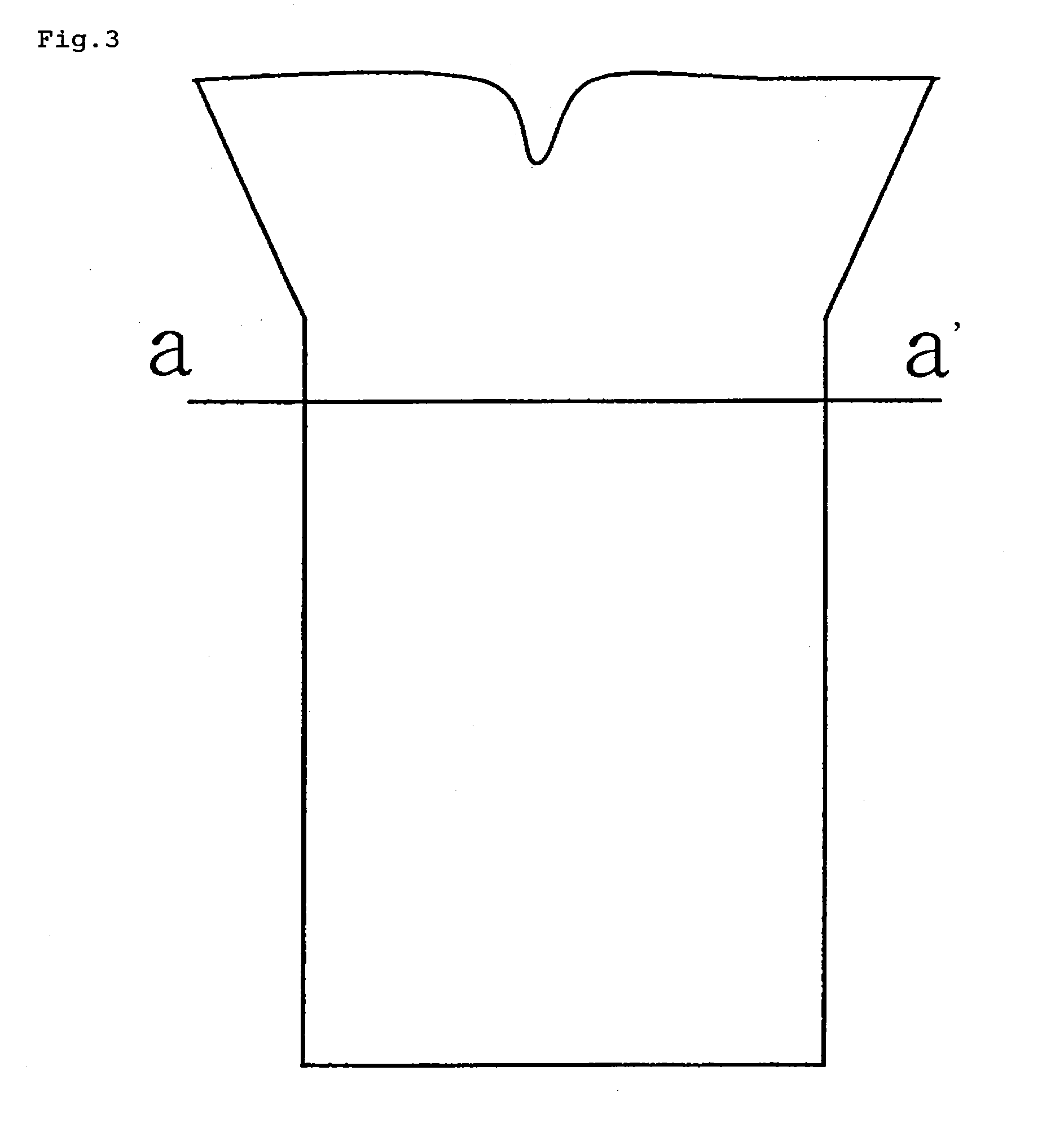

The sulfidation resistance of a silver-base material coating is further improved by making a concentration gradient of silver, oxygen and of one or more oxidizable alloying elements that may be present in the material, from the free surface of the coating up to a depth comprised between 10 nm and 1 μm and more particularly between 100 nm and 1 μm. Thus, the coating comprises a stack of one main layer made from silver-base material and of one oxidized thin film. The thin film, with a thickness comprised between 10 nm and 1 μm, thus presents a decreasing silver concentration gradient from the interface between the thin film and the main layer to the free surface of the thin film. Deposition of the coating on a support can be achieved by two successive physical vapor deposition steps, and more particularly by magnetron cathode sputtering.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Silver alloy, sputtering target material thereof, and thin film thereof

ActiveUS20110003173A1Increase resistanceImprove heat resistanceDiffusing elementsConductive materialLiquid-crystal displayAlloy

It is an object of the present invention to provide a Ag—Pd—Cu—Ge type silver alloy which can form a reflective electrode film having such two characteristics that it is very reduced in the lowering of reflectance caused by thermal deterioration and has resistant to yellowing caused by sulfurization even after a heating step in a process of producing a color liquid crystal display. The silver alloy according to the present invention includes a composition containing at least four elements including Ag as its major component, 0.10 to 2.89 wt % of Pd, 0.10 to 2.89 wt % of Cu and 0.01 to 1.50 wt % of Ge, and the total amount of Pd, Cu and Ge is 0.21 to 3.00 wt %.

Owner:FURUYA KINZOKU KK

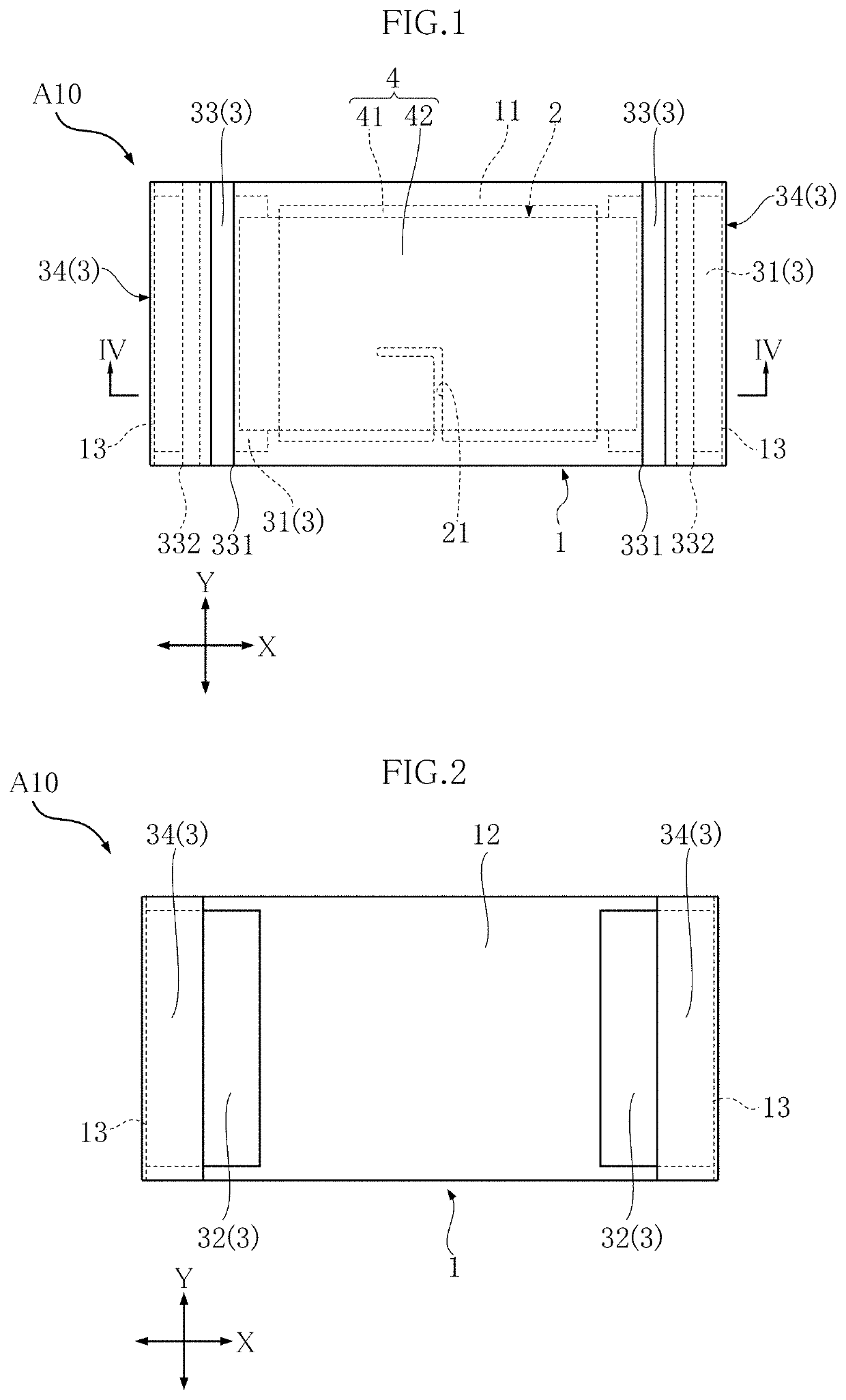

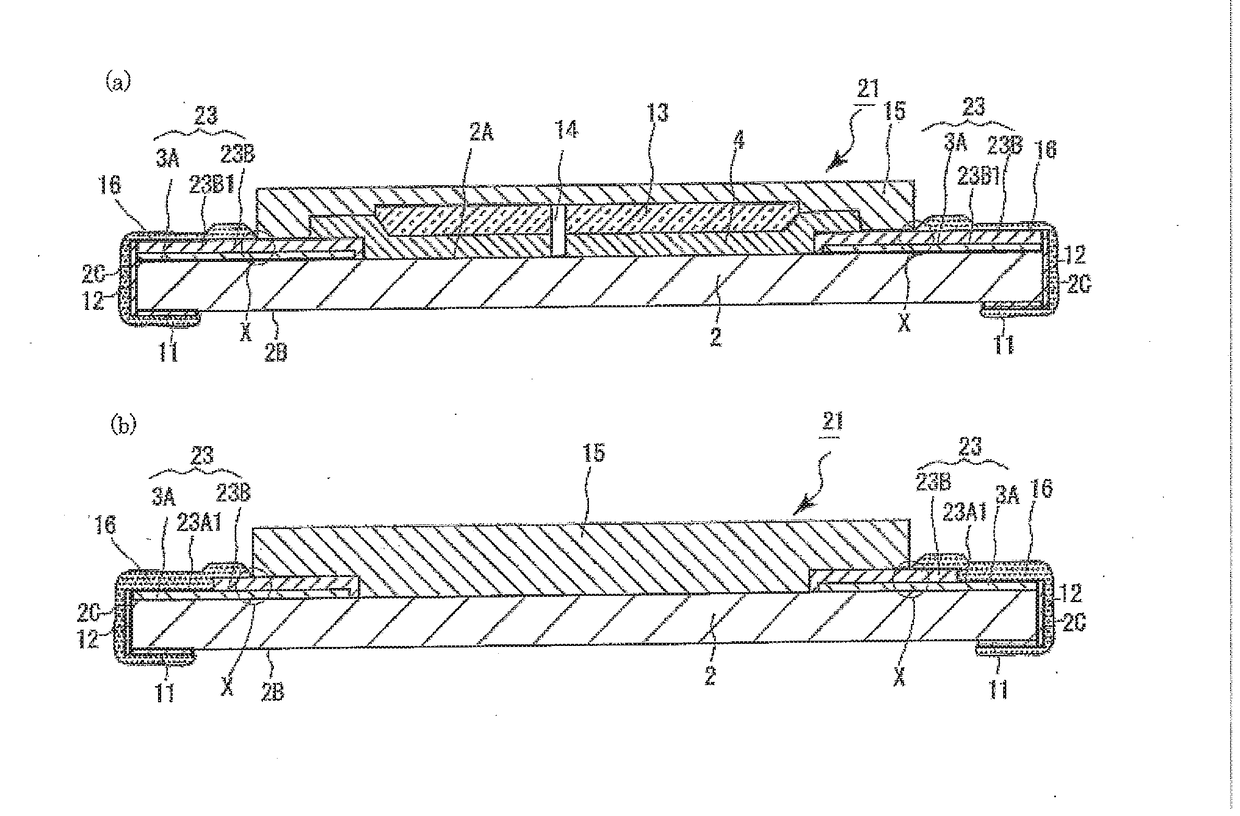

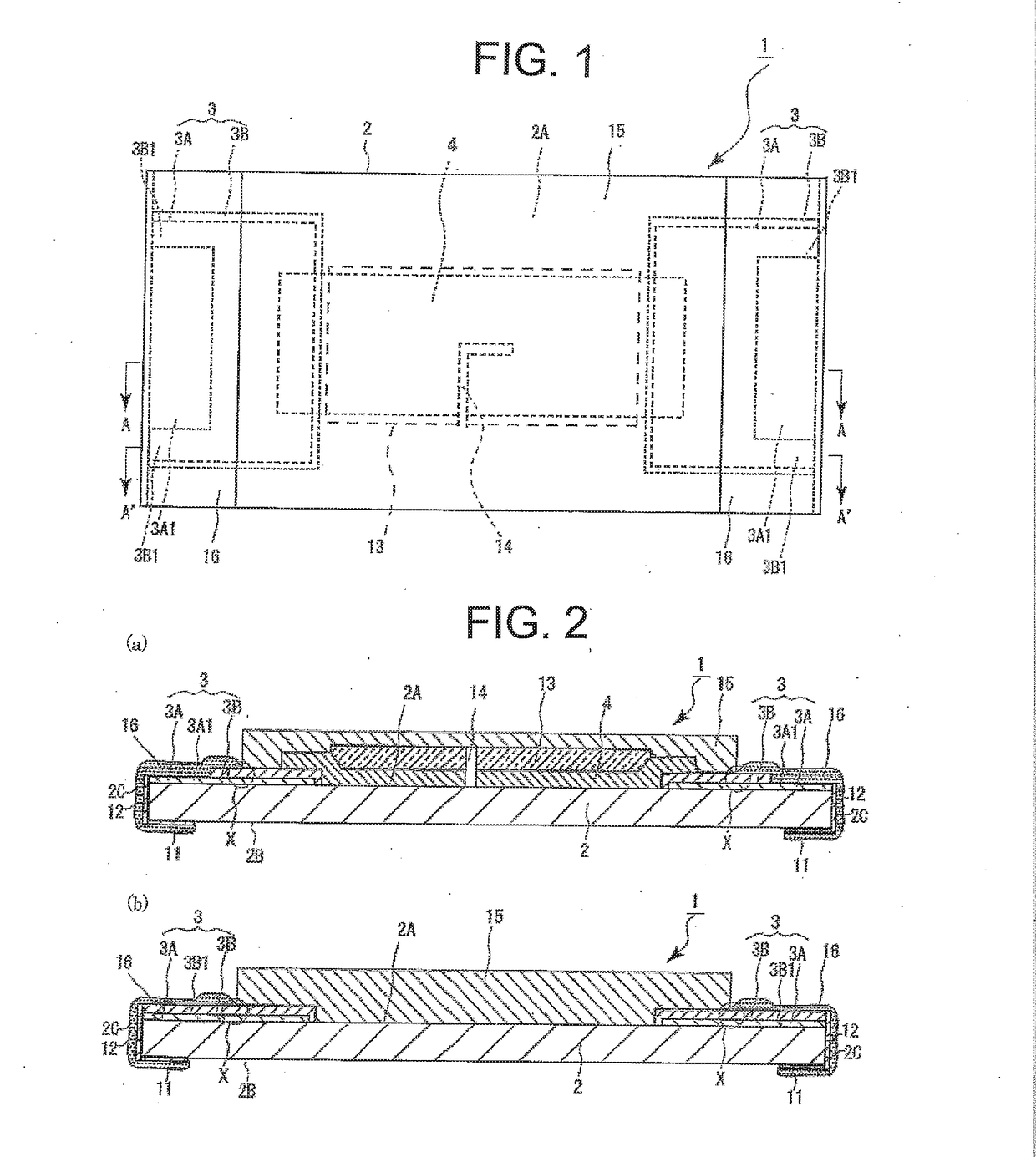

Chip Resistor and Method for Manufacturing Same

ActiveUS20170084364A1Improve accuracyHigh resistance of electrodeResistor chip manufactureCurrent collector arrangementsAuxiliary electrodeMetal

Provided are: a chip resistor whose resistance value can be adjusted with high accuracy while maintaining high sulfurization resistance of electrodes of the chip resistor even in the case where the resistance value of the chip resistor is low; and a method for manufacturing this chip resistor. This chip resistor (1) includes: an insulating film that covers a resistor substance (4) formed so as to make contact with both of a pair of electrodes (3, 3) formed on an upper surface (2A) of an insulating substrate (2). Each of the pair of electrodes (3, 3) includes: (1) a main electrode layer (3B) that contains silver as a main metal component and 10 weight % or more of palladium as another metal component, and an auxiliary electrode layer (3A) that is lower in specific resistance than the main electrode layer (3B); (2) a laminate part where the auxiliary electrode layer (3A) and the main electrode layer (3B) are sequentially laminated in this order on a single surface of the insulating substrate (2); and (3) an exposed part (3A1) of the auxiliary electrode layer (3A) where a part of the auxiliary electrode layer (3A) is not covered with the main electrode layer (3B) on a far side from the resistor substance (4), and parts (3B1) that extend from a near side to the far side with respect to the resistor substance (4).

Owner:KOA CORP

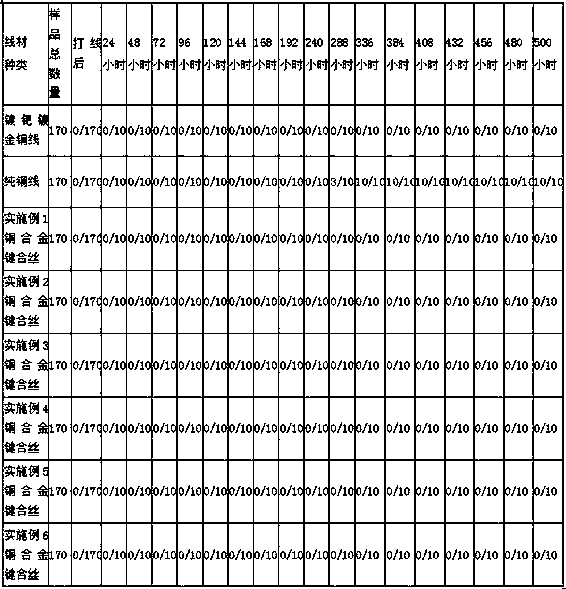

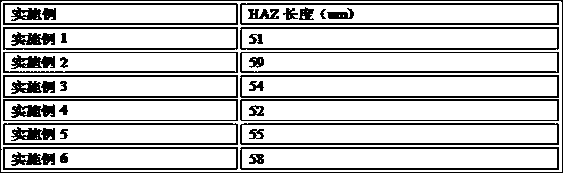

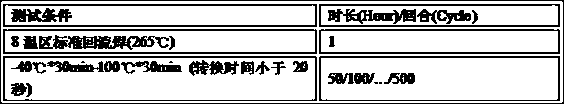

Copper alloy wire and manufacturing method thereof

PendingCN109411438AImproved wire bonding workabilityImprove antioxidant capacitySemiconductor/solid-state device detailsSolid-state devicesHigh resistanceWire rod

The invention relates to a copper alloy wire. The copper alloy wire contains 0.1-3% of Ag, 460-1000 ppm of a trace additive element and the balance of copper; and the trace additive element is the combination of one or more in Ca, Be, In and Ge. The invention further provides a manufacturing method of the copper alloy wire. The copper alloy bonding wire in the invention has the beneficial effectsthat: after being routed, the product has high resistance to humidity in high-temperature, high-humidity and high-voltage conditions; the adhesive power between a welding spot and a bonding pad is good; the copper alloy bonding wire has excellent operability and reliability; the anti-aging performance is good; the hardness of a wire rod is relatively proper; the routing camber height is greatly reduced; when IC routing is carried out, breakage and damage to a welding electrode are avoided; the good bonding performance is provided; and the cost is relatively low.

Owner:NICHE TECH KAISER SHANTOU

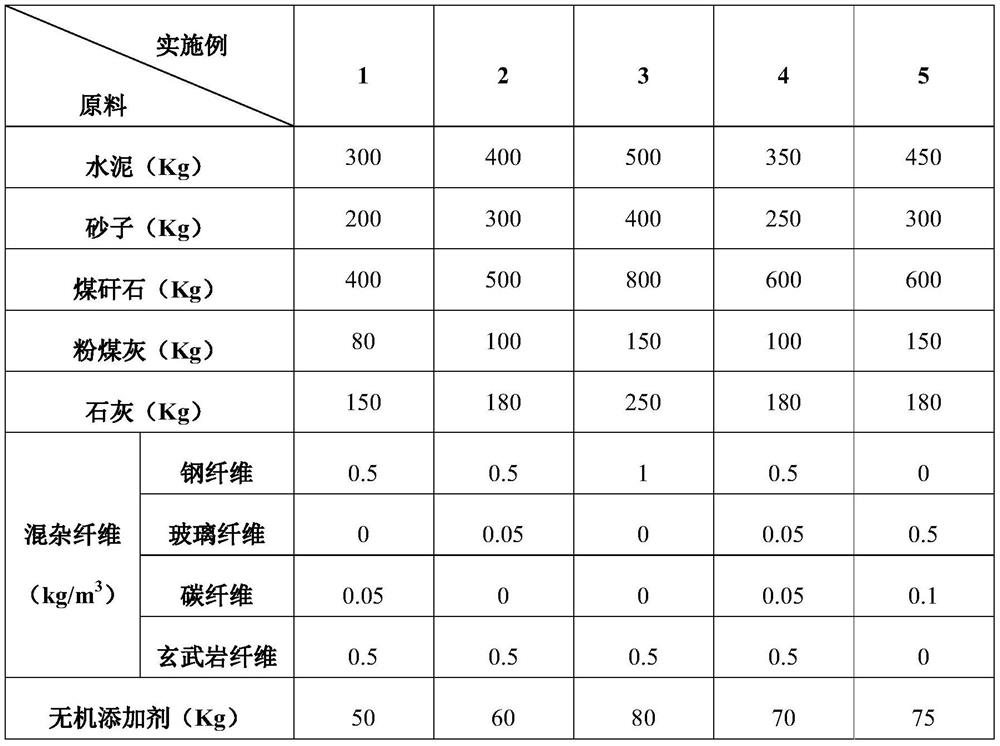

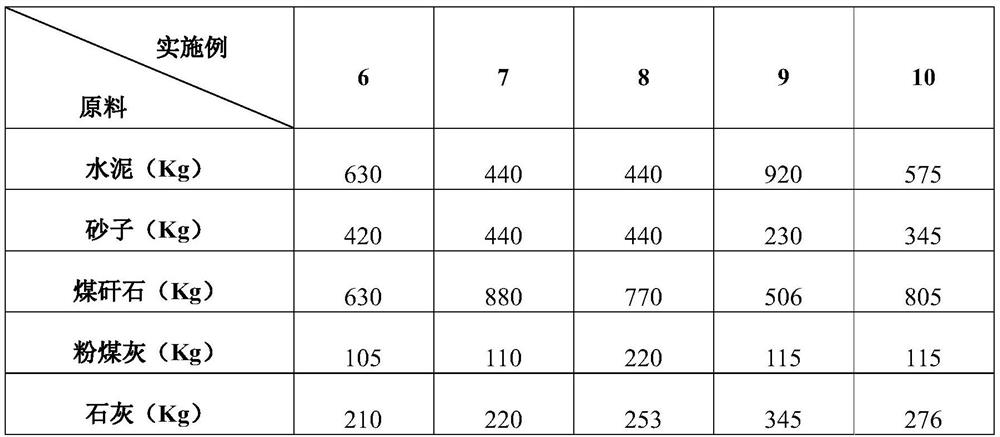

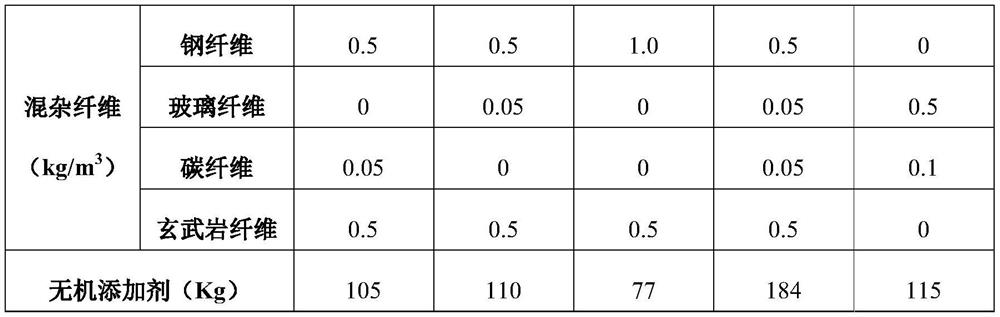

Waste coal mine filler based on coal gangue

InactiveCN112897964AImprove fire resistanceReduce intensitySolid waste managementMaterial fill-upBasalt fiberMaterials science

Owner:陕西拉发纪新材料科技有限公司 +1

Copper alloy bonding wire and production method thereof

InactiveCN108823463AImproved wire bonding workabilityImprove antioxidant capacitySemiconductor devicesWork performanceHardness

The invention provides a copper alloy bonding wire. The copper alloy bonding wire is characterized by being prepared from the following components according to the weight: 0.3 to 5 percent of Ag, 1 to450ppm of a trace additive element and the balance of copper, wherein the trace additive element is one or a combination of more than two of Ca, In, Be and Ge. The invention further provides a production method of the copper alloy bonding wire. The copper alloy bonding wire provided by the invention has the following beneficial effects that (1) the working performance and the reliability are excellent; (2) the anti-ageing performance is good; (3) the copper alloy bonding wire has relatively proper wire hardness and the camber height of wire bonding is extremely reduced; (5) cracks and damagesto a welding electrode are not caused in an IC wire bonding process; (5) the copper alloy bonding wire can provide good bonding performance; (6) the cost is relatively low.

Owner:NICHE TECH KAISER SHANTOU

Sliding fluid level-detecting device

InactiveUS7752912B2Improve anti-sulfur performanceImpart durabilityMachines/enginesLubrication indication devicesFuel tankHardness

Owner:YAZAKI CORP

Corrosion-resistant gold-based precise hardware material

The invention discloses a corrosion-resistant gold-based precise hardware material. The corrosion-resistant gold-based precise hardware material consists of gold, silver, copper, nickel, gadolinium, yttrium, praseodymium and platinum, and the weight parts of the components of the corrosion-resistant gold-based precise hardware material are as follows: 50-62 parts of gold, 10-17 parts of silver, 8-15 parts of copper, 6-13 parts of nickel, 1-7 parts of gadolinium, 2-8 parts of yttrium, 3-9 parts of praseodymium, and 5-11 parts of platinum. The corrosion-resistant gold-based precise metal material has the characteristics of being high in conductivity, high in thermal conductivity, high in corrosion resistance, high in vulcanization resistance and high in wear resistance.

Owner:张家港市勇峰精密机械有限公司

Silver alloy with high hardness and aging softening resistance and preparation method thereof

InactiveCN103710565AImprove mechanical propertiesSolve the problem of poor anti-aging softening performanceOxidation resistantHardness

The invention provides a silver alloy with high hardness and aging softening resistance. The silver alloy has the beneficial effects as follows: the silver ingredient of which the weight component is 92.5-95.0, particularly preferably 92.5 is adopted, so that on the one hand, the silver is large in ratio, so as to take up value advantage, and on the other hand, the other ingredients are added on the basis of the silver with the ratio. Therefore, the problem of poor aging softening resistance of the silver alloy prepared by the silver alloy production technology in modern society is solved when the mechanical property of the alloy is obviously improved, and the oxidation resistance of the silver alloy is improved by other alloy ingredients. Therefore, the silver alloy has a great development prospect.

Owner:中山银海首饰有限公司

Chip scale package LED light source and manufacturing method thereof

InactiveCN109728153AHigh mechanical strengthImprove stress resistanceSemiconductor devicesVulcanizationAdhesive

The invention provides a chip scale package LED light source and a manufacturing method thereof. During the manufacturing of the chip scale package LED light source, after chip scale package LEDs arefixed onto a circuit board, a protective adhesive layer covering the chip scale package LEDs is formed on the circuit board, and the areas, opposite to the light-out surfaces of the chip scale packageLEDs, of the protective adhesive layer are transparent adhesive layers. Thus, the protective adhesive layer on the circuit board wraps the chip scale package LEDs, the mechanical strength of the chipscale package LEDs is enhanced by the outer protective adhesive layer, the stress resistance is enhanced, and the situation in which some LEDs fail due to breakage under stress caused by external force or temperature difference is avoided. Meanwhile, the protective adhesive layer wrapping the chip scale package LEDs can also avoid the fluorescence call around the chip or the come-off of white glue after multiples cycles of high and low temperatures and ensure the consistency of the light color. The protective adhesive layer can prevent outside sulfur element from entering the light source toa certain extent, so as to improve the vulcanization resistance of the chip scale package LED light source.

Owner:WUHU JUFEI PHOTOELECTRIC TECH CO LTD

Insulating corrosion-resistant bonding wire with inorganic amorphous coating and preparation method of insulating corrosion-resistant bonding wire

ActiveCN110718525AImprove corrosion resistanceImprove anti-sulfur performanceSemiconductor/solid-state device detailsSolid-state devicesWire rodVulcanization

The invention discloses an insulating corrosion-resistant bonding wire with an inorganic amorphous coating. The bonding wire comprises a bonding wire substrate and an inorganic amorphous plating layer, and the inorganic amorphous plating layer is composed of the following components in percentage by weight: 40%-60% of SiO2, 15%-30% of Al2O3, 10%-25% of B2O and 0.1%-5% of Li2O. The bonding wire provided by the invention has higher corrosion resistance and vulcanization resistance, high tensile strength and good routing operation performance, and does not influence the bonding property of welding of the substrate bonding wire and a chassis; by using the method, the arc height can be reduced, the insulating corrosion-resistant inorganic amorphous plating layer can enhance the adhesion betweenthe wire and glue in the packaging process, the welding reliability is improved, the harmful substances such as C and S cannot be generated, and the corrosion resistance is far higher than that of anorganic coating; compared with palladium plating, gold plating and other metal plating materials, the bonding wire is low in preparation cost, wide in application range, free of pollution to the environment and suitable for the integrated circuit and LED packaging industry.

Owner:烟台一诺电子材料有限公司

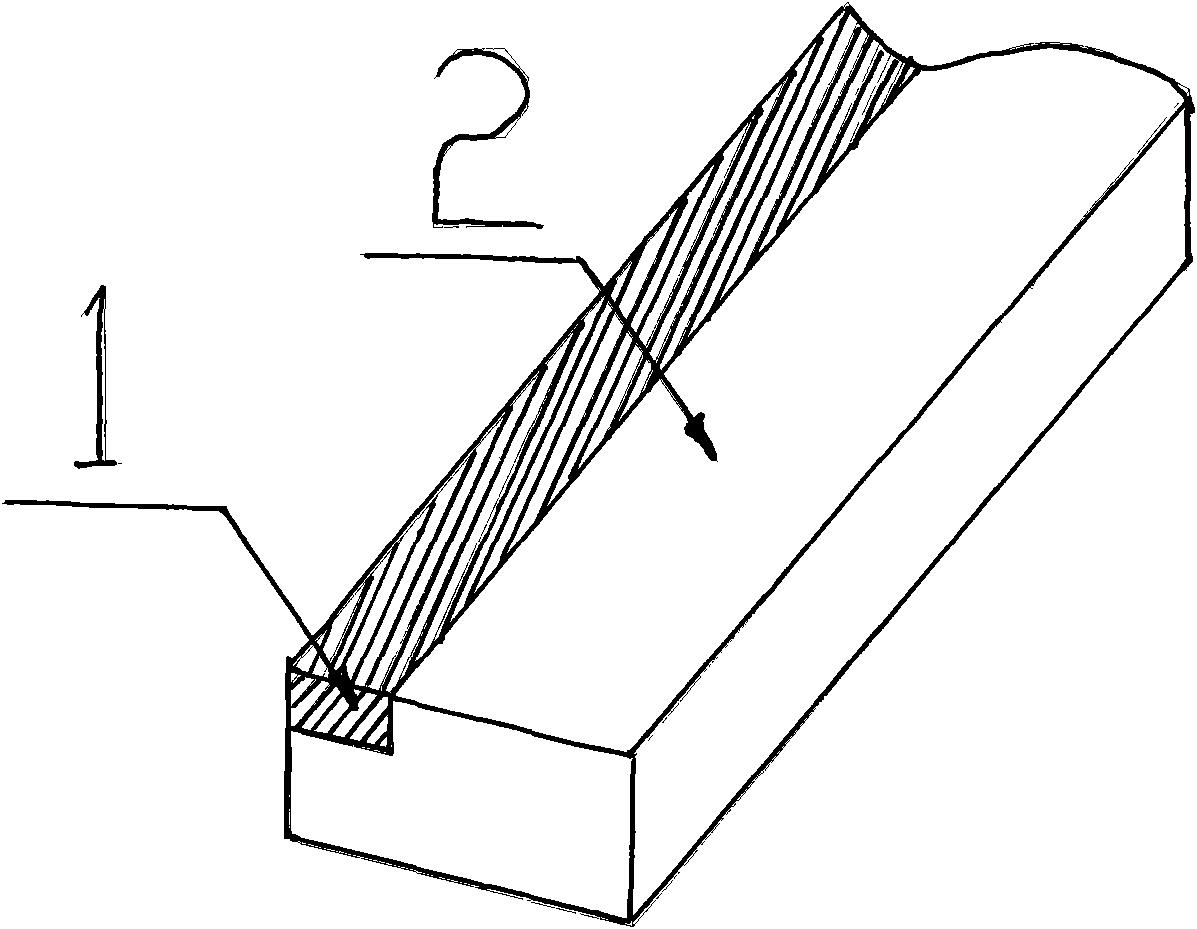

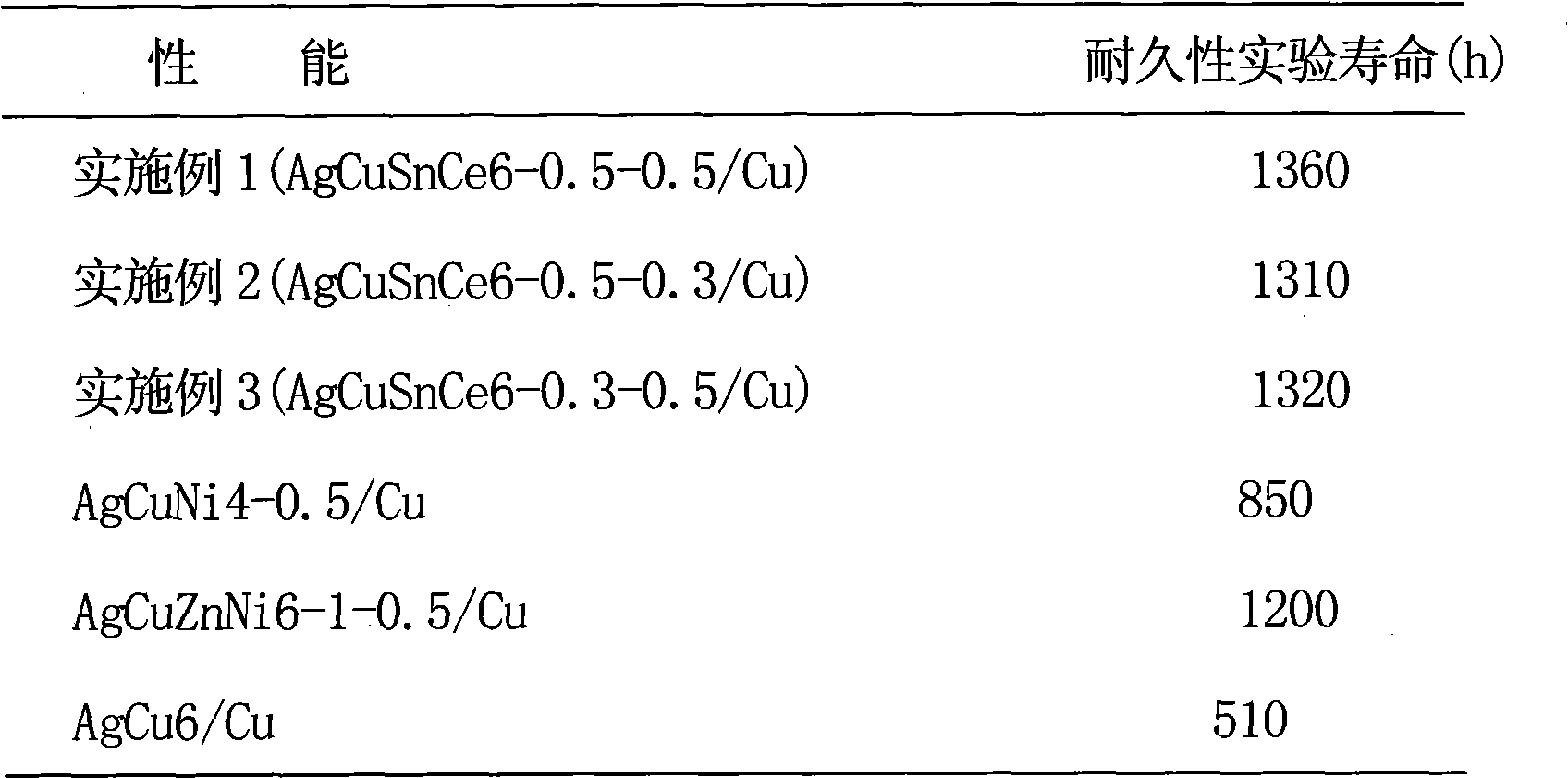

Silver-copper-rare earth composite material

InactiveCN101645572AImprove electrical contact performanceExtended service lifeRotary current collectorElectrical resistance and conductanceRare earth

The invention discloses a silver-copper-rare earth composite material used for manufacturing micromotor commutator components, comprising a copper layer and a silver alloy layer inlaid and compoundedon the copper layer. The composite material is characterized in that the silver alloy layer is silver alloy containing 3-8% of Cu, 0.2-0.8% of Sn, 0.2-0.8% of Ce and the balance Ag. The silver alloy layer (1) is inlaid and compounded on part of the surface of the copper layer (2). The material features excellent abrasion resistance, arc ablation resistance, welding resistance, sulfurization resistance and metal transfer resistance, and low and stable contact resistance. The micromotor commutator components manufactured by the material are suitable for the manufacturing industries of audio-visual electronic equipment, office automation equipment, communication equipment, automobiles and household appliances and for such electronic devices as electronic toys, etc.

Owner:KUNMING INST OF PRECIOUS METALS

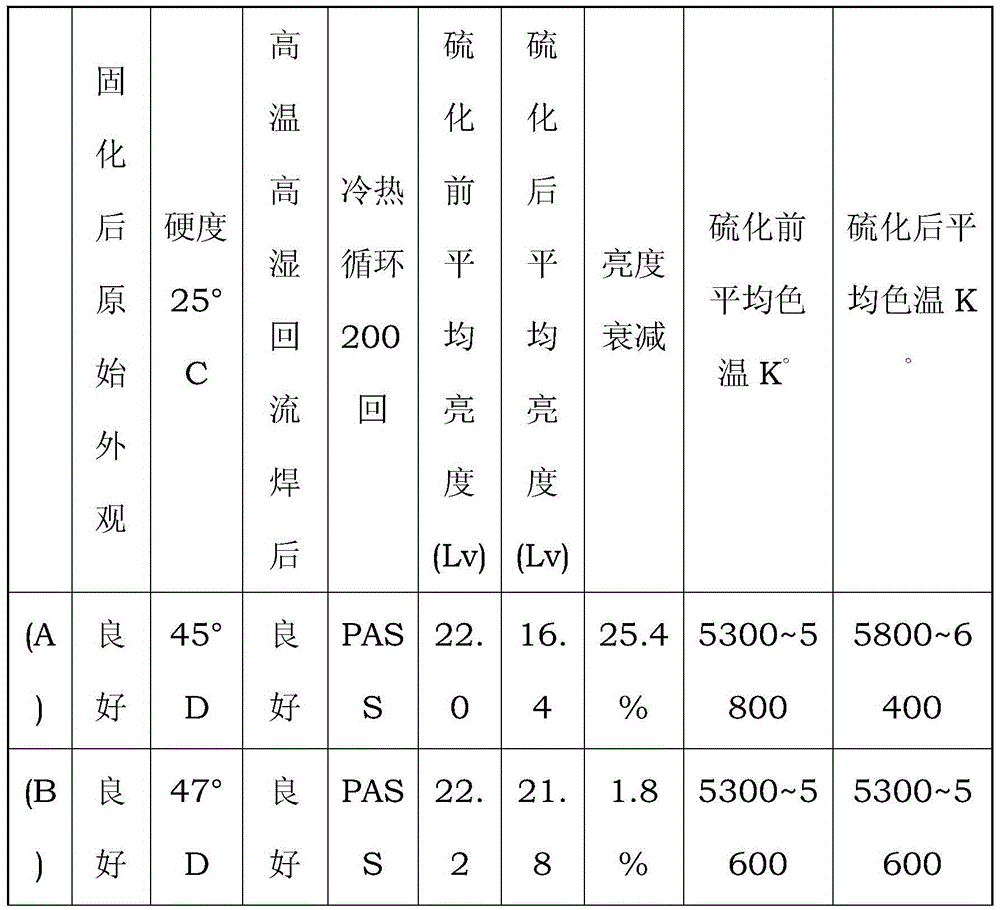

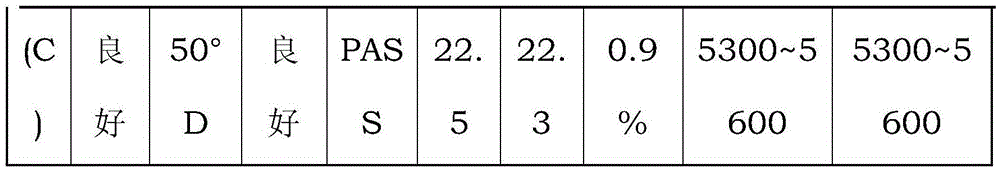

Curable organic polysiloxane composition and application thereof

InactiveCN105602259APrevent oxidationEffective silver layerSemiconductor devicesChemistryMagnesium silicate

The invention discloses a curable organic polysiloxane composition. The composition is one or more of magnesium oxide, magnesium hydroxide, magnesium carbonate, hydrotalcite, hydrotalcite-like compounds and britesorb. The organic polysiloxane composition added in a semiconductor of a light-emitting component can be used for effectively inhibiting penetration of hydrogen sulfide or sulfide under the condition that the original light-emitting efficiency is not influenced, so that the silver layer is prevented from being oxidized to achieve the effect of effectively protecting the silver layer, and the effect of resisting vulcanization is improved.

Owner:DONGGUAN TIANKAI ELECTRONICS CO LTD

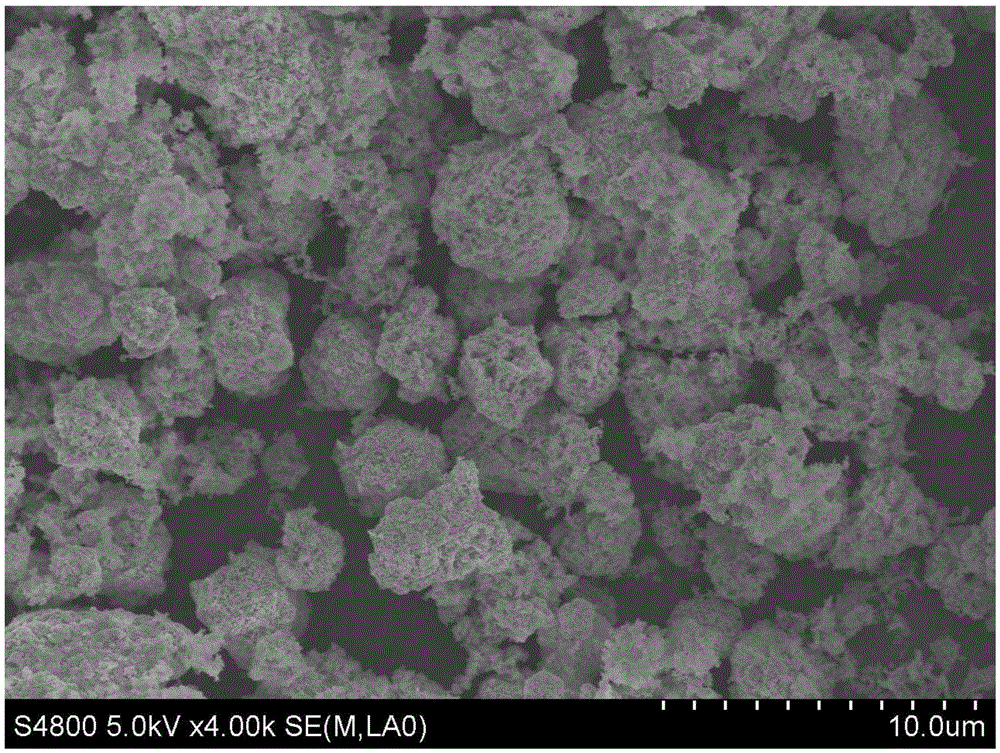

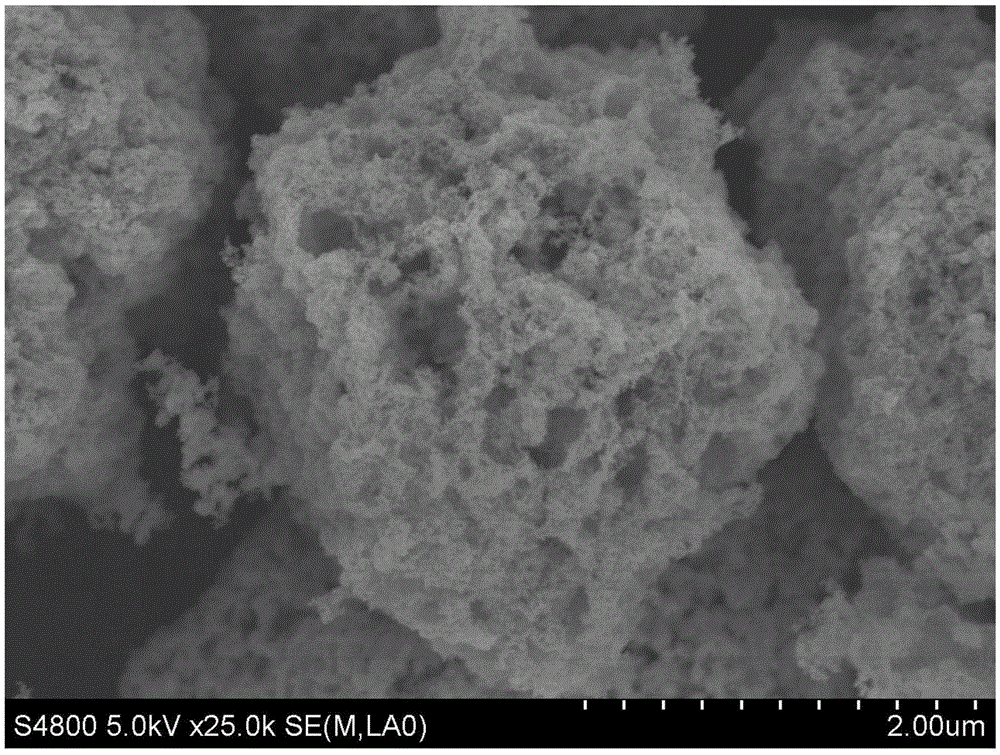

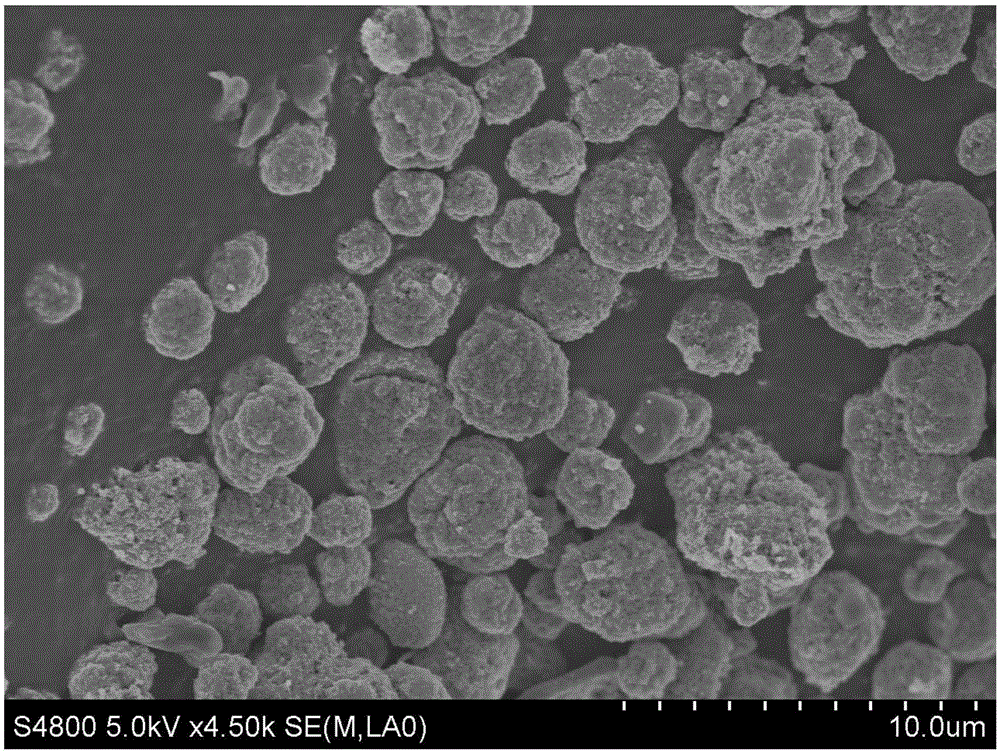

A kind of CEO2 base scr catalyst and preparation method thereof

InactiveCN104128193BEnhanced Surface AcidityImprove anti-sulfur performancePhysical/chemical process catalystsDispersed particle separationPhosphateHeteropoly acid

The invention discloses a CeO2 based SCR catalyst and a preparation method thereof. The preparation method comprises the following steps: taking a proper amount of a metal oxide powder containing CeO2 or a metal salt solution including soluble salt of Ce; soluble salts; taking a proper amount of a mixed water solution containing soluble phosphate and soluble salt of zirconium, wherein the molar ratio of Zr<4+> and PO43 in the mixed water solution is 0.5-2, and the ion total concentration of Zr<4+> and PO4<3-> is 0.1-5mol / L; forming a porous heteropoly acid substance by the Zr<4+> and PO4<3-> in the mixed aqueous solutions; adsorbing the heteropoly acid substance on the surface of metal oxide by using an impregnation method, or complexing the soluble salt solution of Ce and the heteropoly acid substance to form sol under the assistance of a complexing agent by using a sol gel method; and finally drying and roasting to prepare a catalyst powder. The mass fraction of metal oxide in the catalyst is 60%-95%, and the mass fraction of heteropoly acid substance is 5%-40%. The catalyst prepared by the invention has strong water thermal aging and sulfuration resistance ability, and low cost.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Copper alloy wire with plating on surface and manufacturing method thereof

PendingCN109390309AChange the crystal structureHigh strengthSemiconductor/solid-state device detailsSolid-state devicesHigh humidityHardness

The invention provides a copper alloy wire with a plating on the surface. The copper alloy wire comprises a core wire and the plating which coats the outer surface of the core wire. The core wire comprises, by weight, 0.1 to 3% of Ag, 460 to 1000 ppm of trace addition element, and balance of copper. The trace addition element is one or the combination of two or more of Ca, Be, In and Ge. The plating is a gold plating, a palladium plating or a composite plating. Compared with the prior art, the copper alloy wire with the plating on the surface, which is provided by the invention, has the advantages that (1) a product has strong resistance to humidity under high temperature, high humidity and high pressure after routing, and the adhesion of a solder joint and a pad is great; (2) oxidation resistance is great; (3) anti-aging performance is great; (4) the wire has excellent workability and reliability; (5) the wire has suitable wire hardness, and the arc height of routing is greatly reduced; and (6) when IC routing is carried out, a welding electrode is not cracked and damaged; and (7) the wire can provide great bonding.

Owner:NICHE TECH KAISER SHANTOU

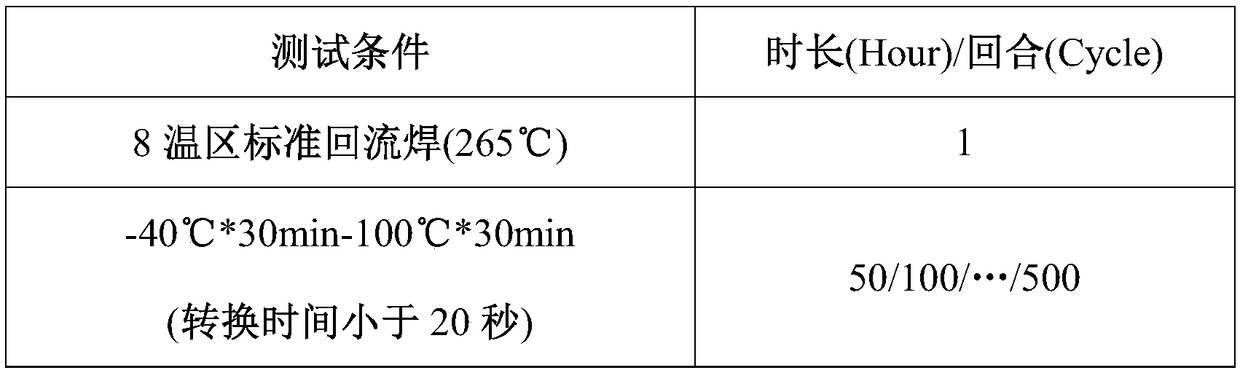

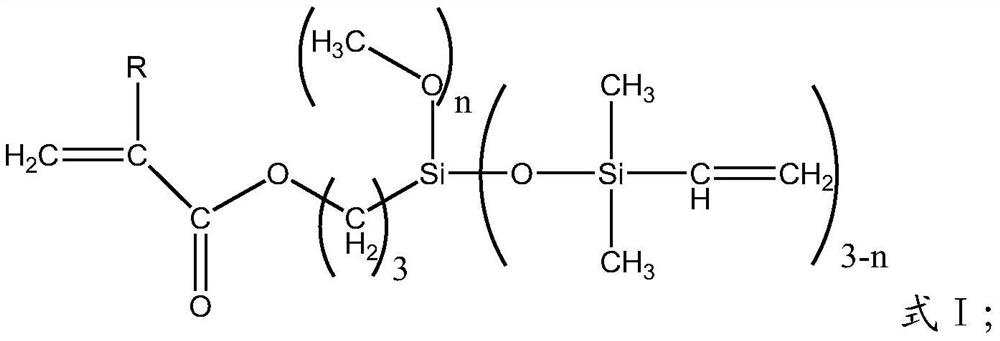

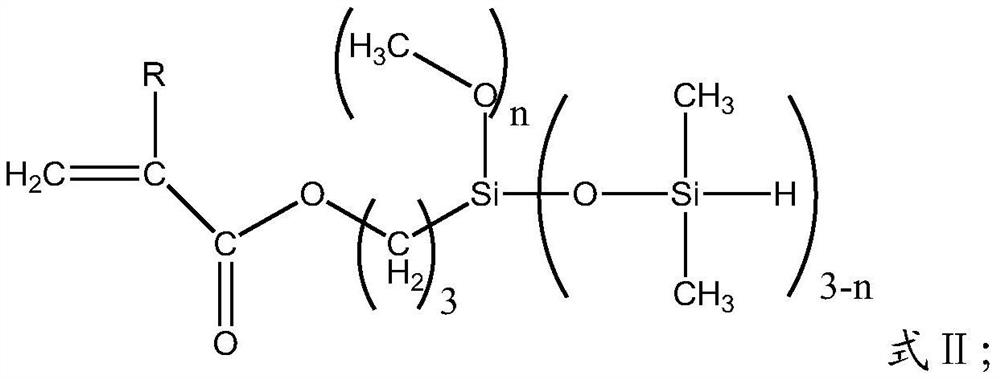

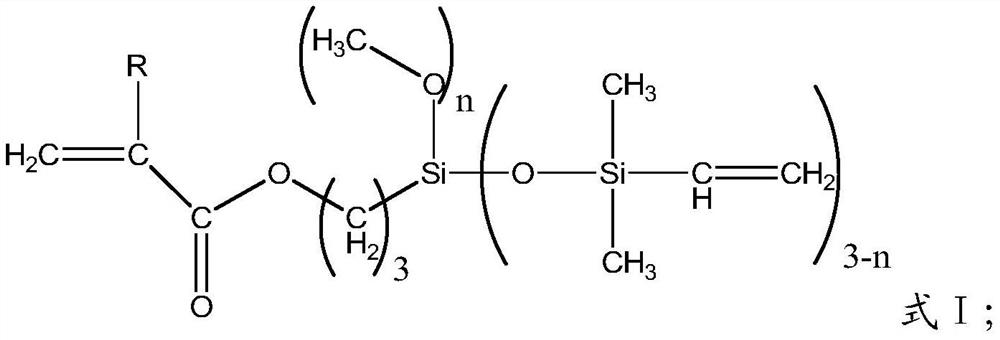

Organic silicon prime paint composition and preparation method thereof

The invention provides an organic silicon prime paint composition. The organic silicon prime paint composition comprises A) an acrylate polymer containing silicon vinyl and silicon-hydrogen bonds at the same time; and B) a solvent. The organic silicon prime paint composition provided by the invention forms a coating in a functional area of an LED device, and the LED device can be bonded with a sealing material composed of the addition reaction organic silicon composition for sealing the LED device. After the organic silicon prime paint composition is cured, the contact between external impurities and a silver layer can be isolated, and the vulcanization resistance is improved. The adhesion between the LED device and the sealing material composed of the addition reaction organosilicon composition for sealing the LED device is improved, and corrosion of the metal electrode formed on the substrate is prevented. Meanwhile, the performance requirements on vulcanization resistance and cold and hot impact resistance are met.

Owner:东莞市贝特利新材料有限公司

High-performance alloy material and strap-shape composite material for micromotor electric bush and producing method thereof

The invention relates to a high-performance alloy material and a strap-shape composite material for a micromotor electric bush and a producing method thereof. The high-performance alloy material for the micromotor electric bush is prepared from, by weight, 40-50wt% of Ag, 0.3-0.5 wt% of Pt, 35-45 wt% of Pd and the balance copper. The strap-shape composite material comprises the high-performance alloy material for the micromotor electric bush and a copper alloy base material. The high-performance alloy material for the micromotor electric bush is compounded in a groove body in the surface of the copper alloy base material. The performance of the alloy material is substantially improved, the Vickers hardness of the material where solid solution aging treatment is performed can be improved about by 50, and abrasion resistance is also greatly improved. The strap-shape composite material is low in production cost, the micromotor electric bush made from the strap-shape composite material is installed and tested, and performance is remarkably improved in a high-temperature and high-humidity environment or under the condition of large torque.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com