Patents

Literature

214 results about "High field strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geochemistry the term high field strength is mostly reserved for elements Hf, Zr, Ti, Nb and Ta as a group.

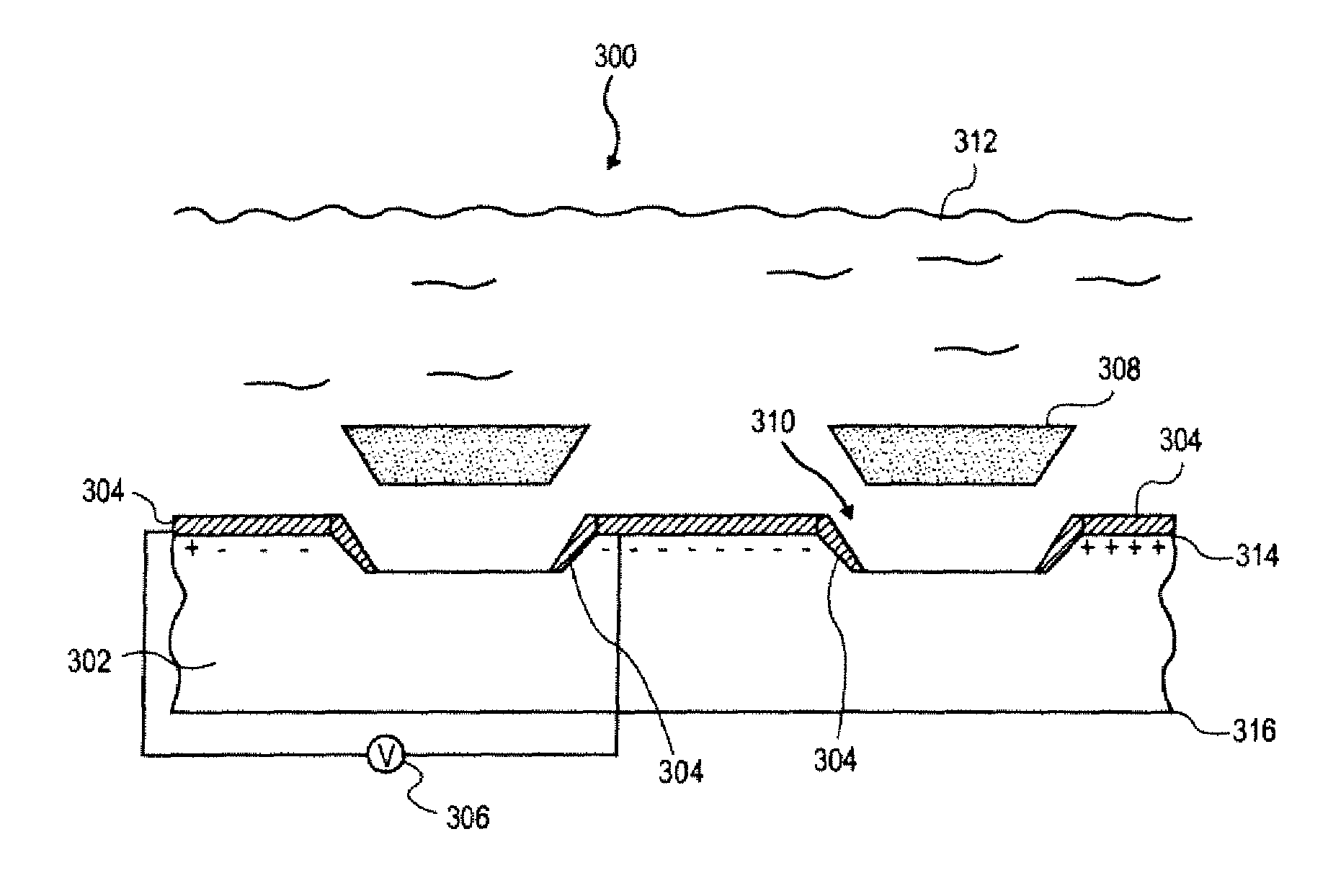

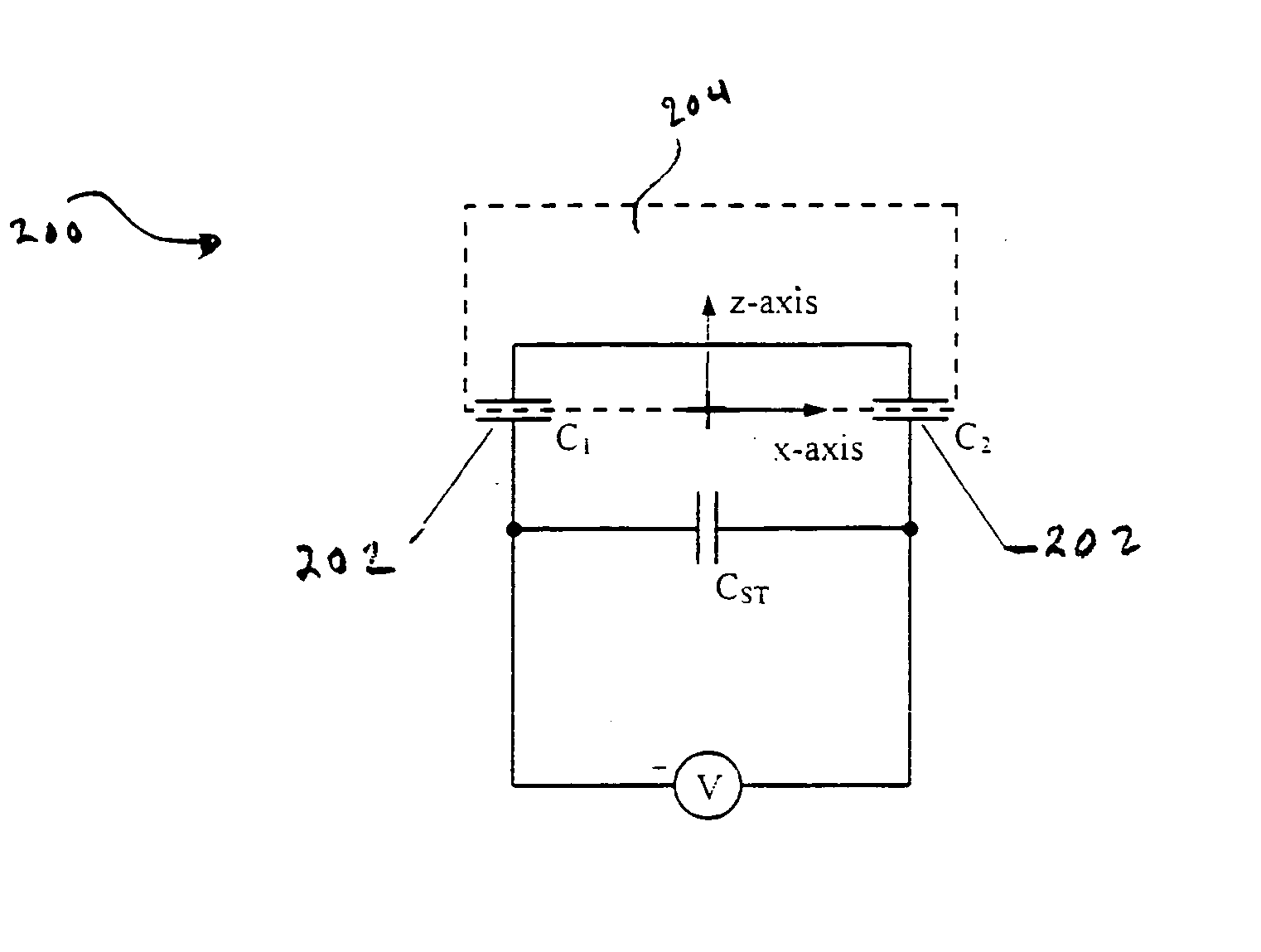

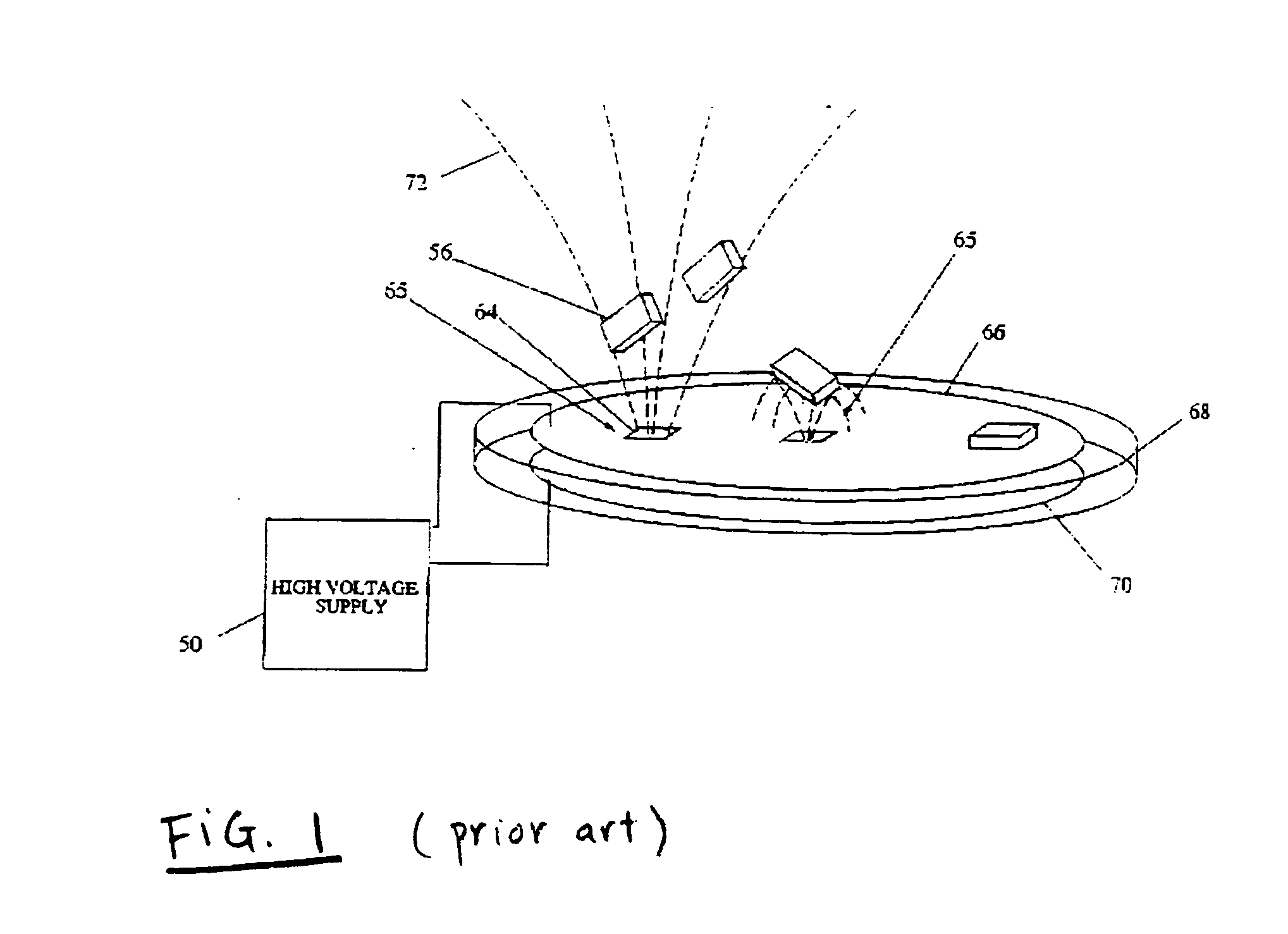

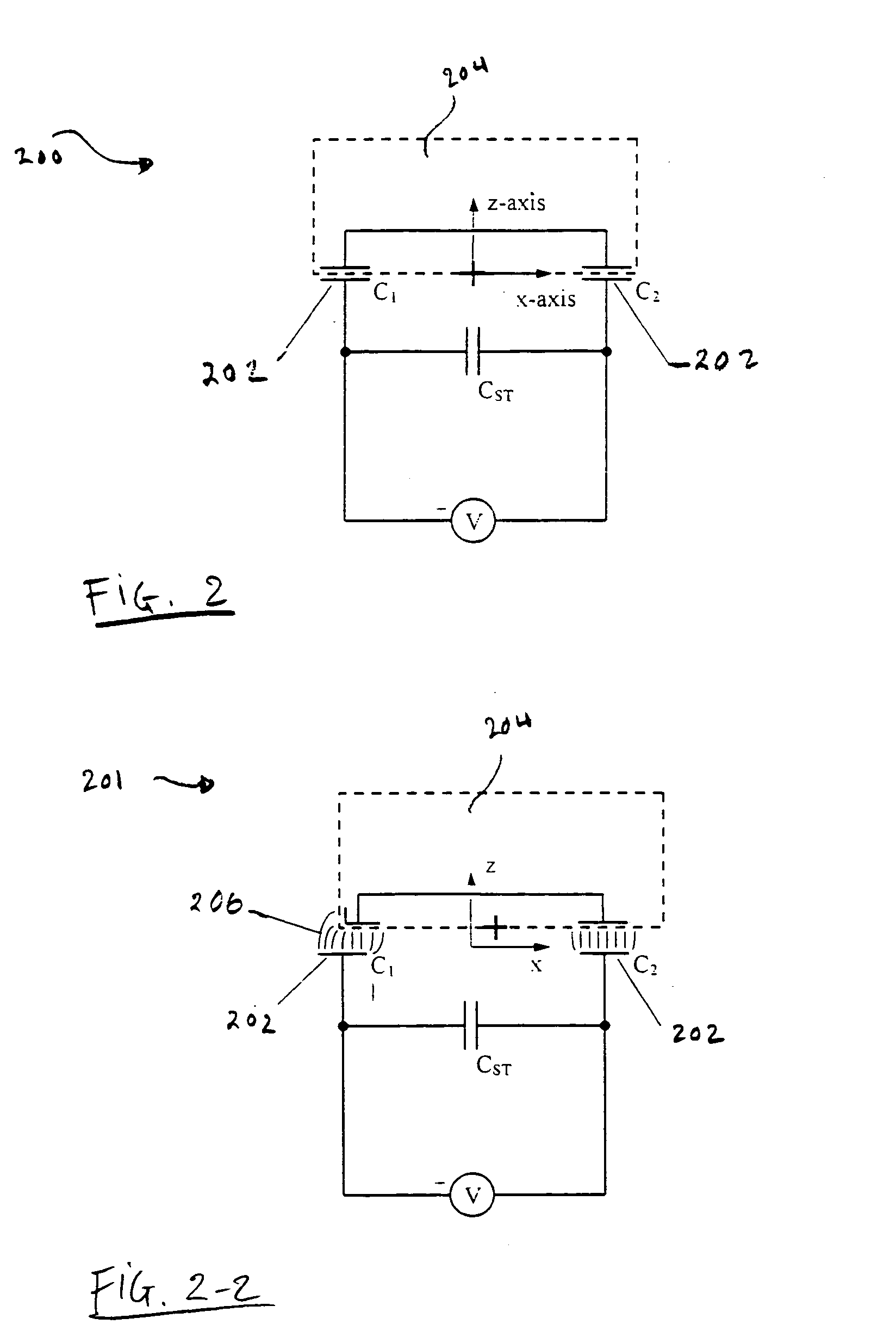

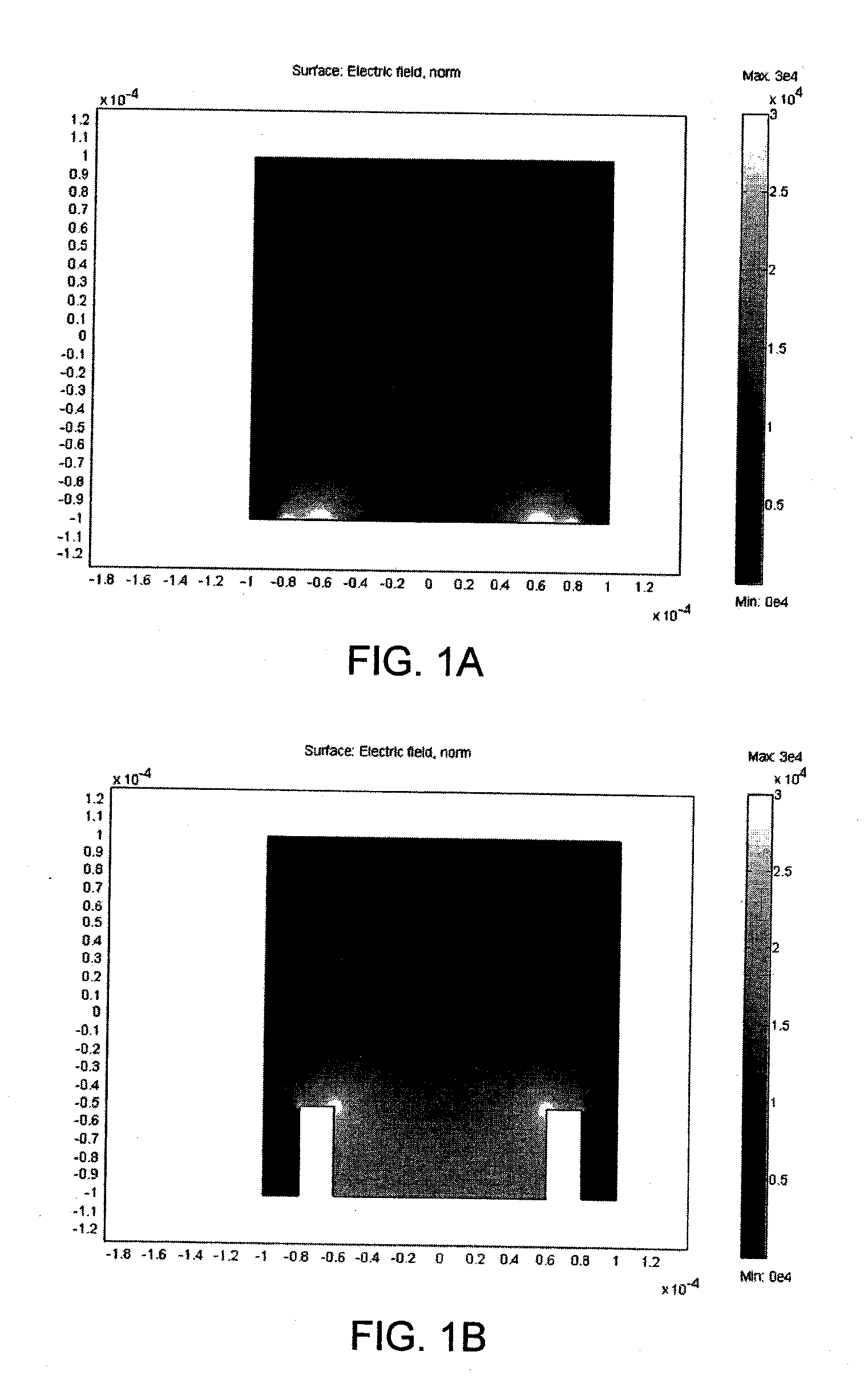

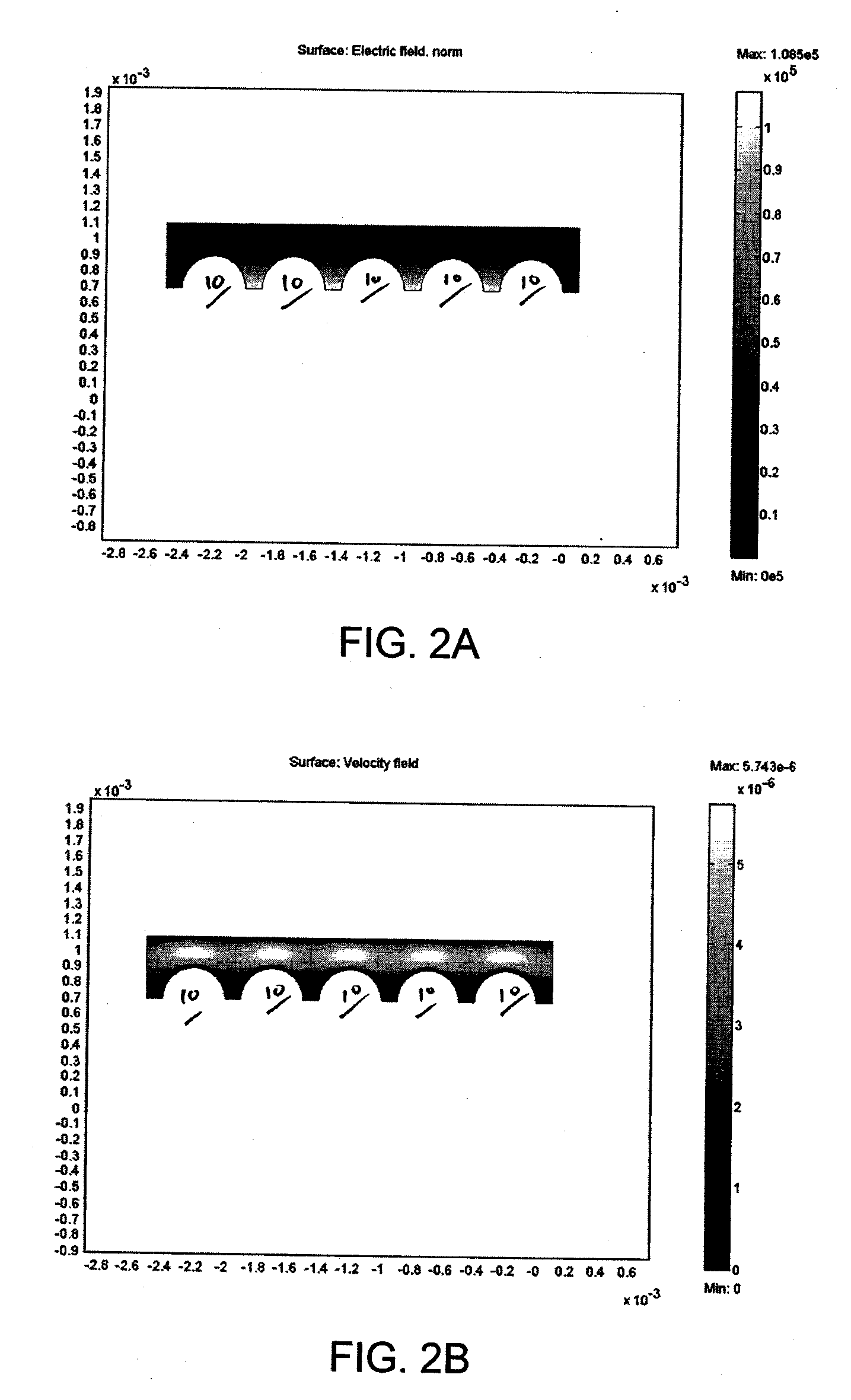

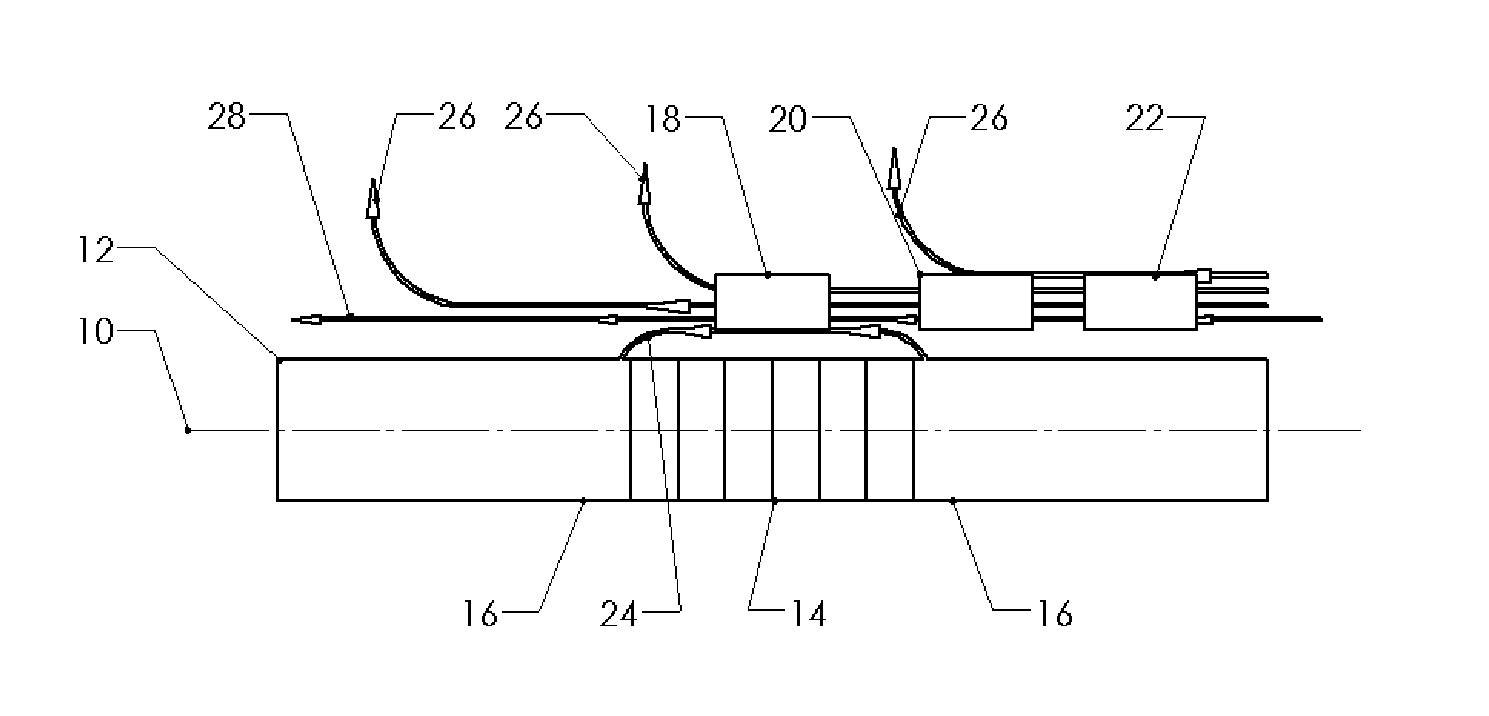

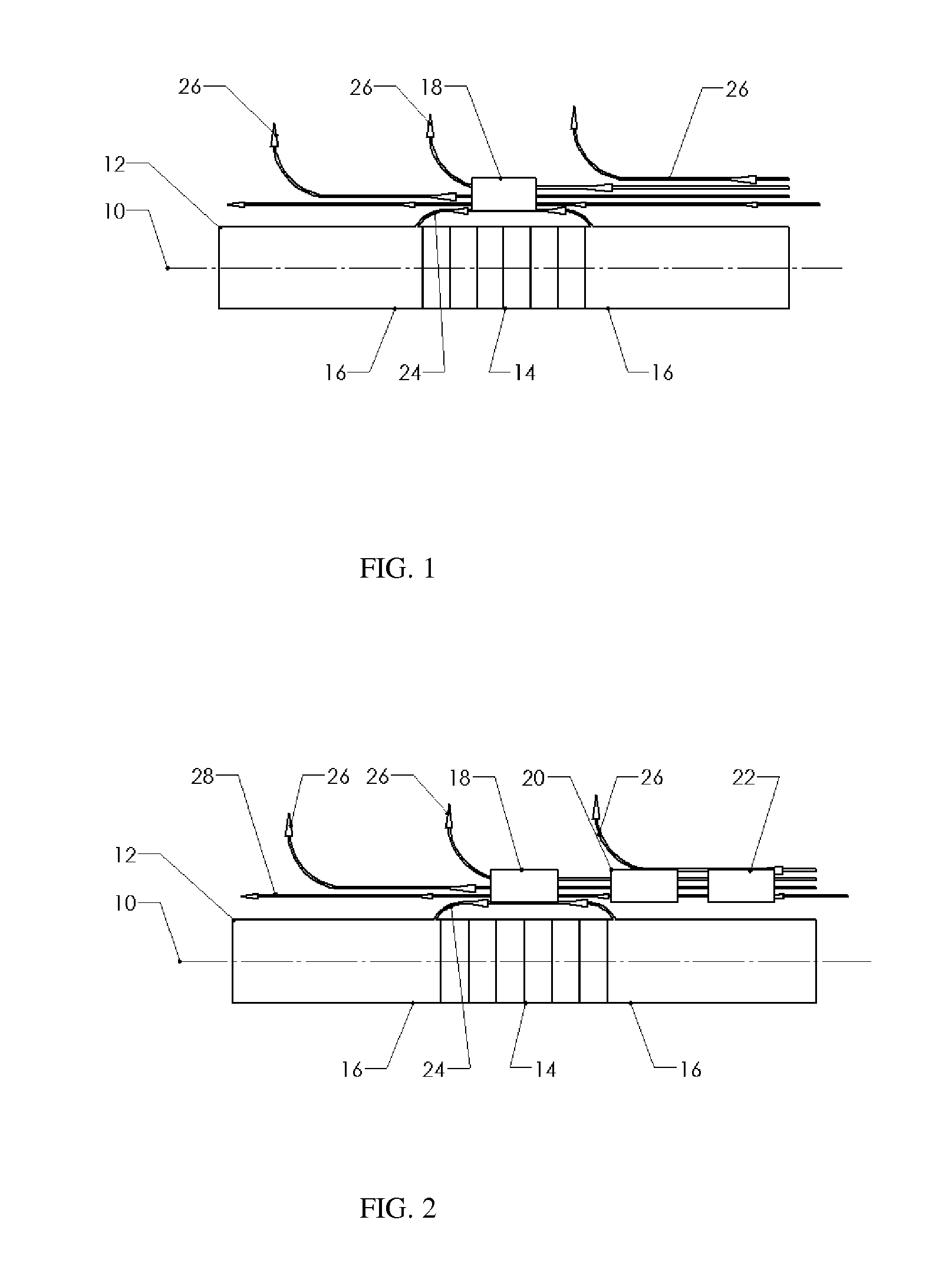

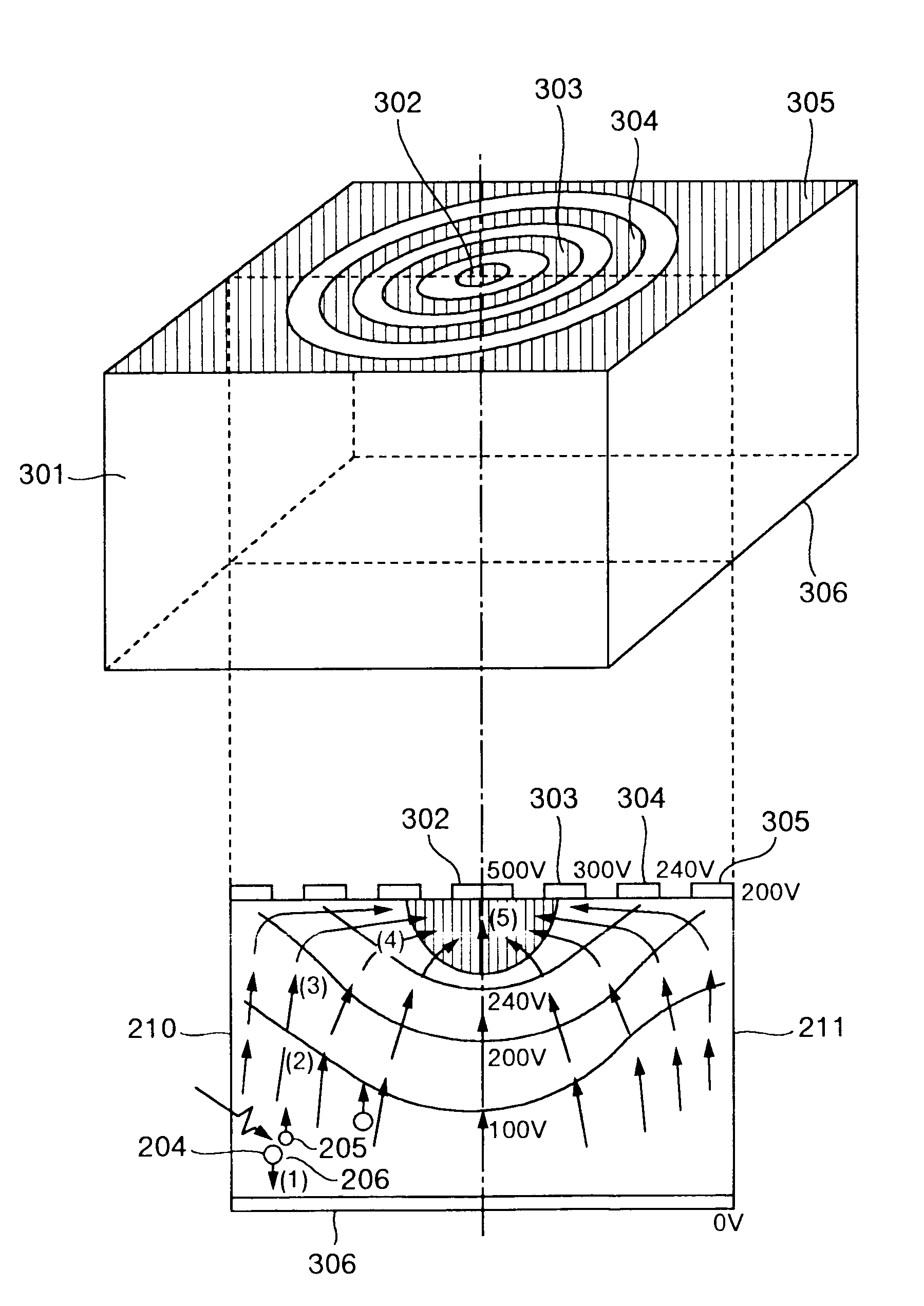

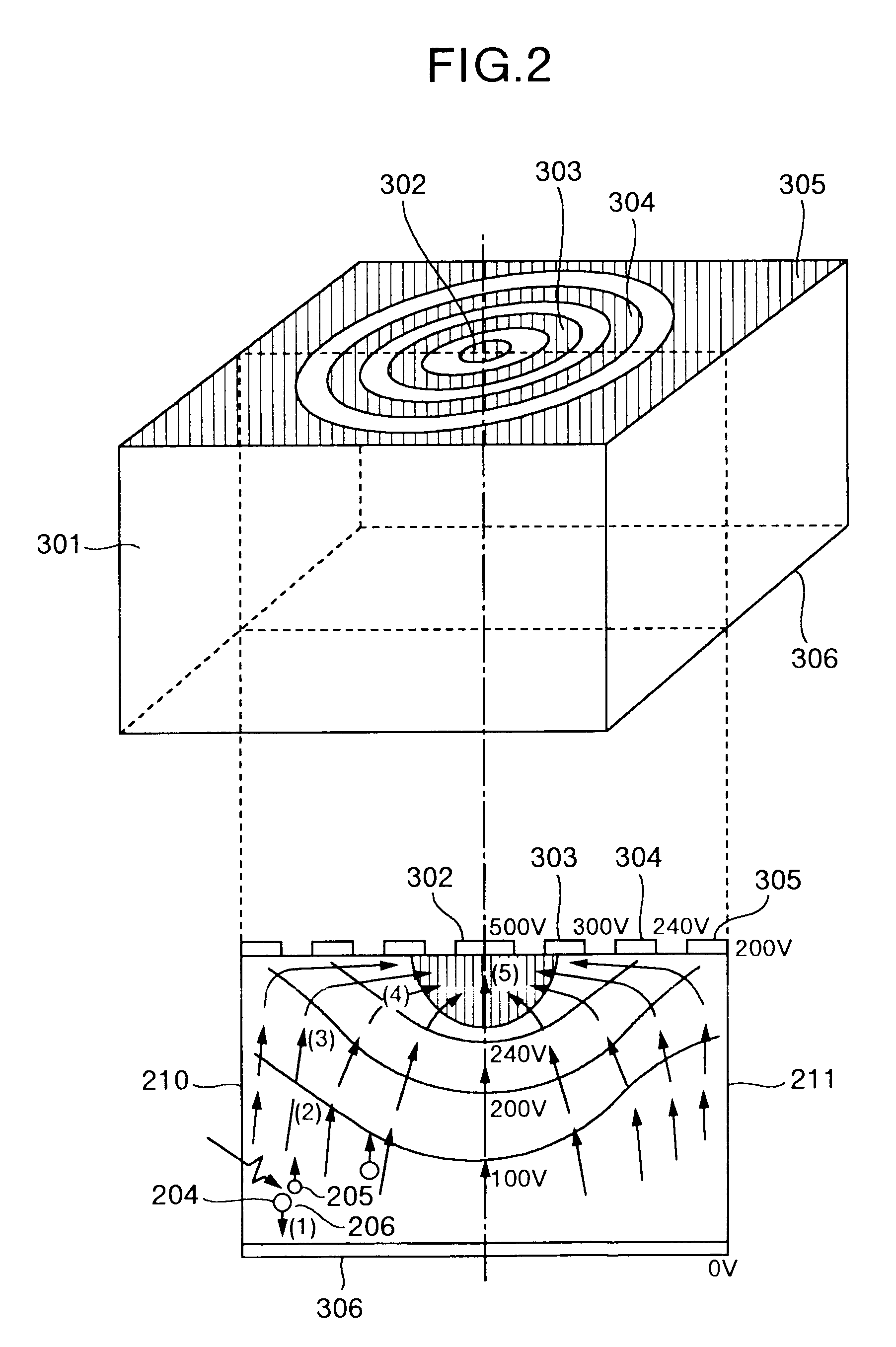

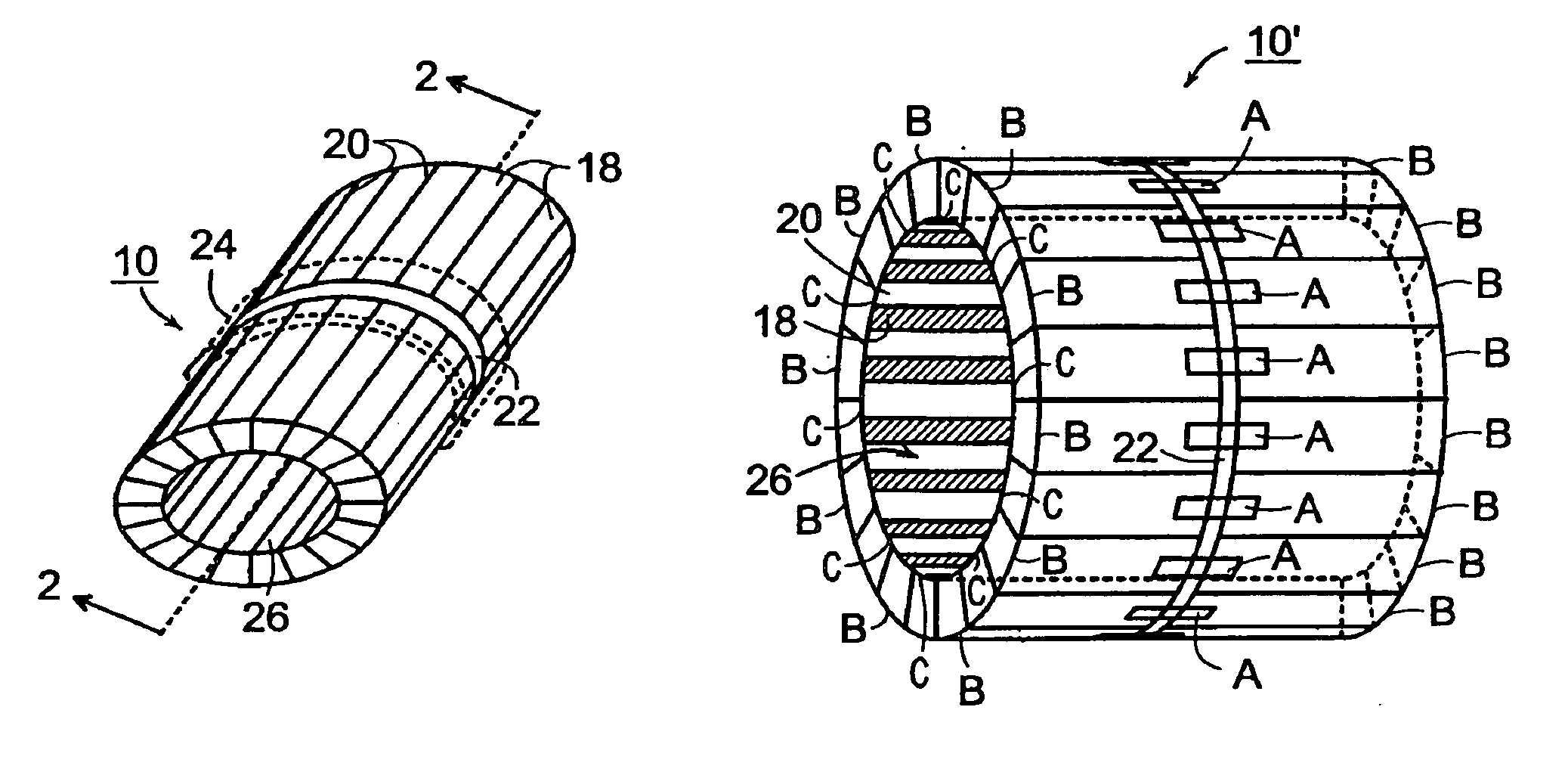

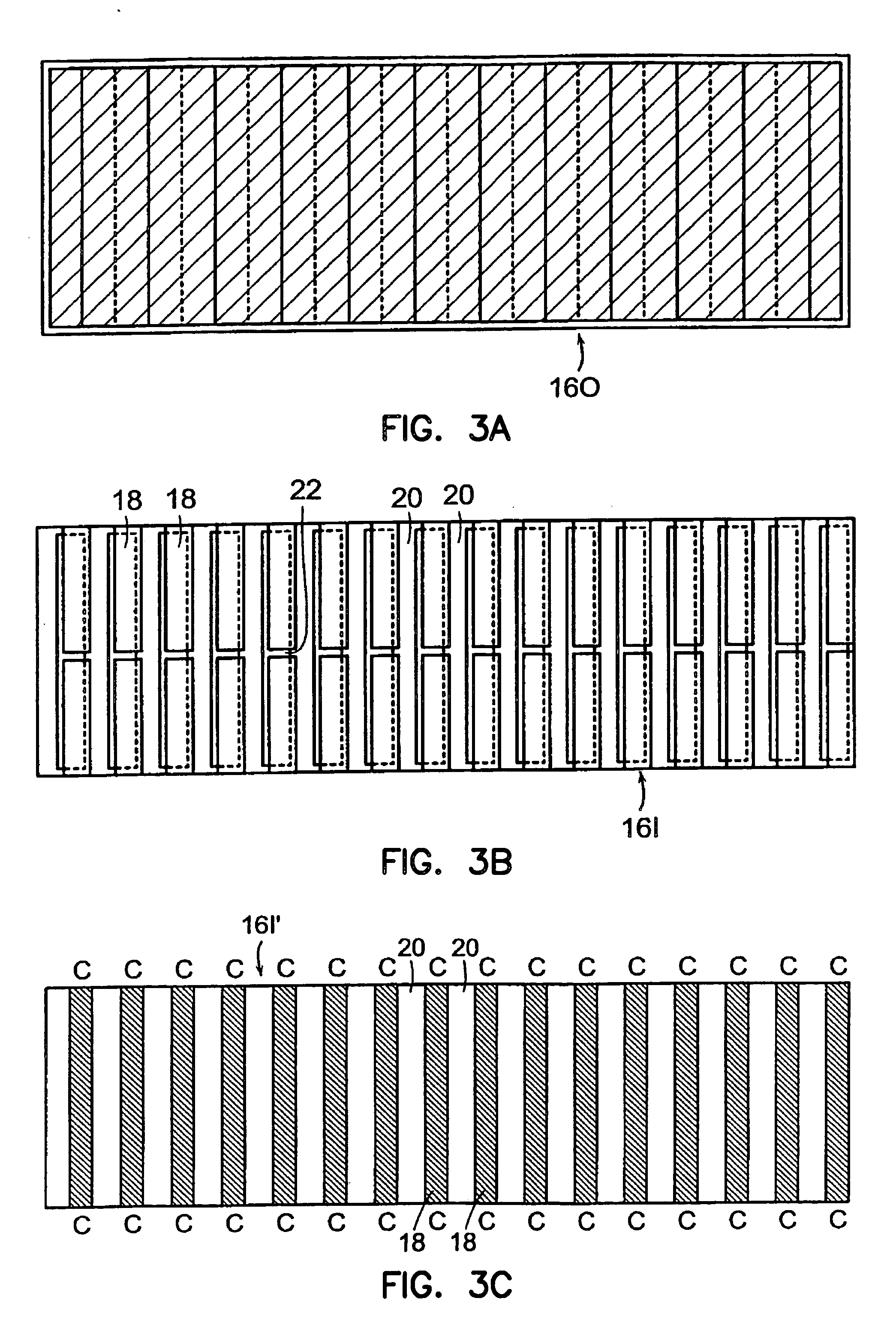

Method and apparatus for self-assembly of functional blocks on a substrate facilitated by electrode pairs

InactiveUS7321159B2Accurate couplingImprove permeabilitySolid-state devicesSemiconductor/solid-state device manufacturingSlurryOptoelectronics

Methods for fabricating an assembly having functional blocks coupling to a substrate. The method includes providing the substrate with receptor sites wherein each of the receptor sites is designed to couple to one of the functional blocks. Electrodes are coupled to the substrate. The electrodes cover the receptor sites such that portions of the receptor sites are coated with the electrodes. Applying a voltage source to the electrodes using a first electrical circuit such that each electrode has a voltage different from another electrode. The electrodes form an electric field. The functional blocks having electronic devices and being in a slurry solution are dispensed over the substrate. Each functional block is fabricated out of materials having a high dielectric constant such that said functional blocks are attracted to the higher field strength regions and are guided to the receptor sites.

Owner:RUIZHANG TECH LTD CO

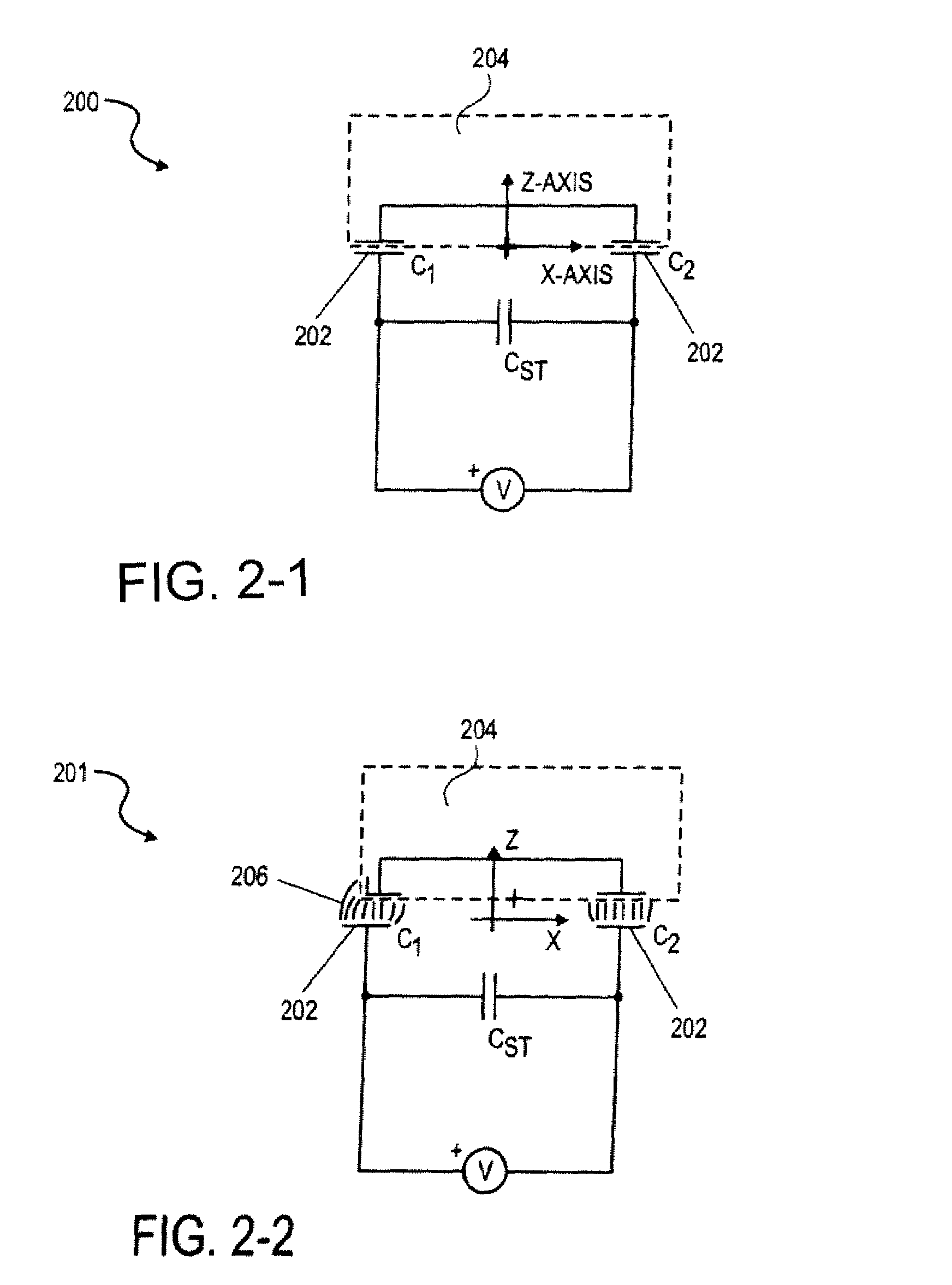

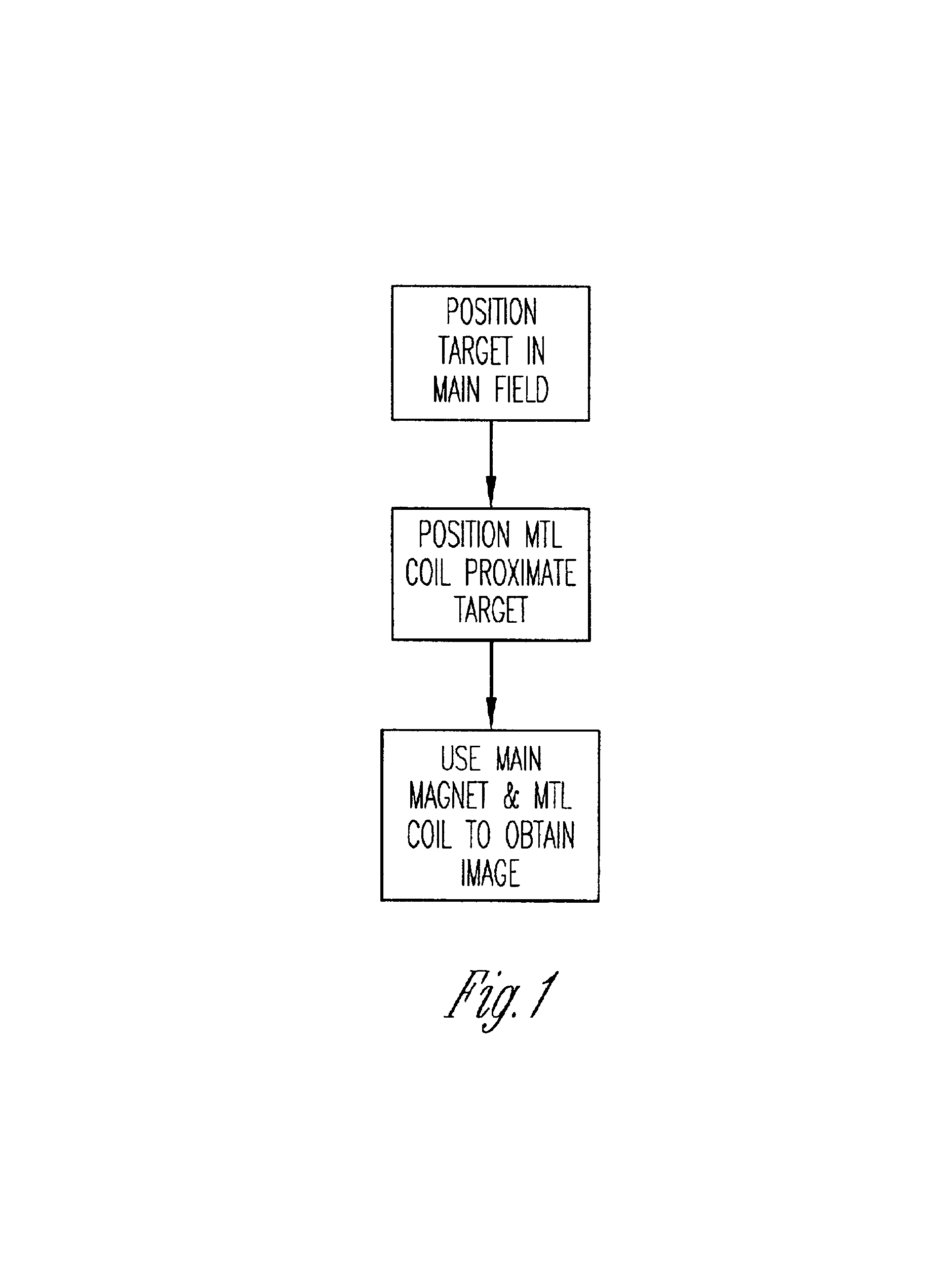

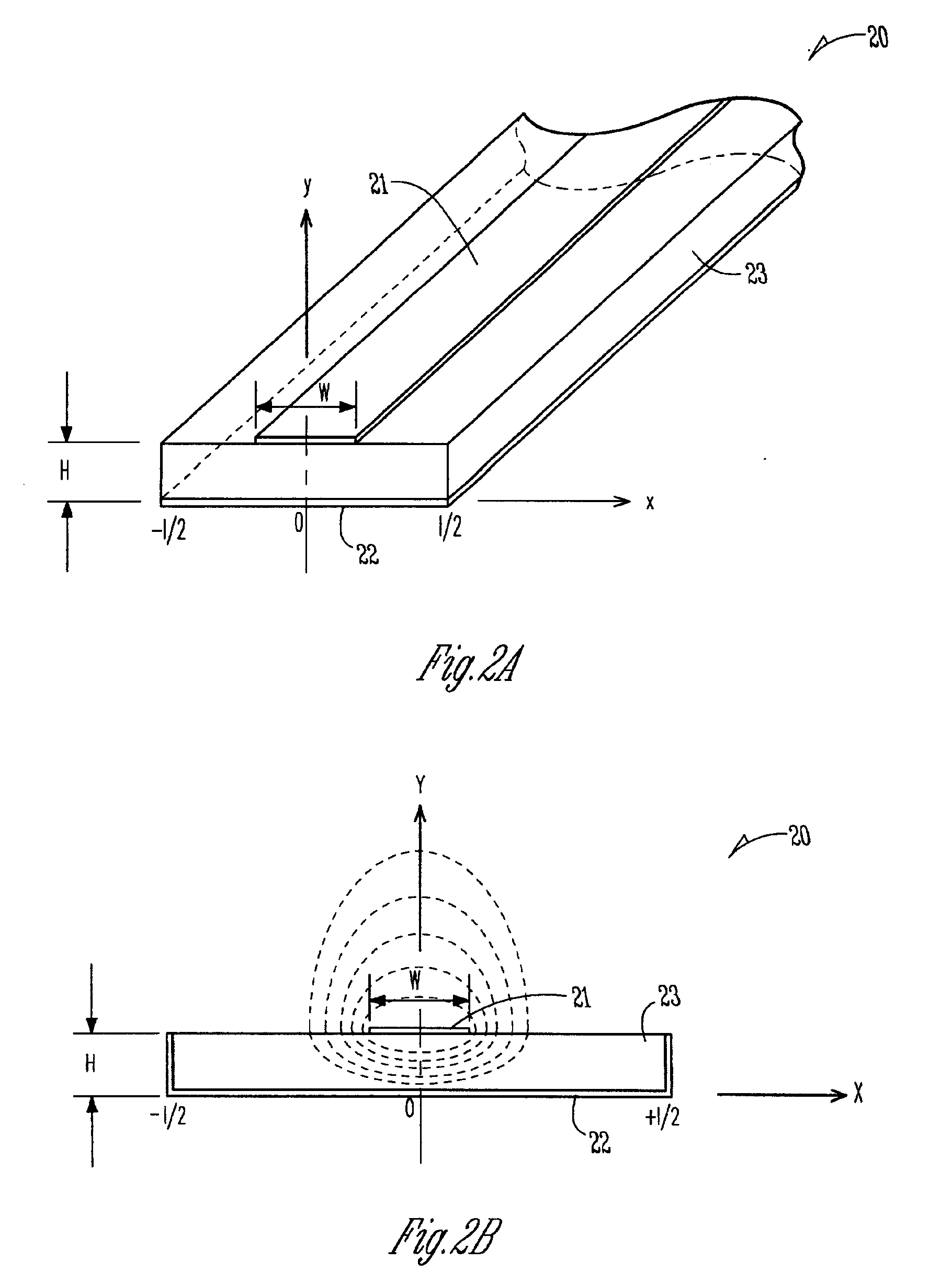

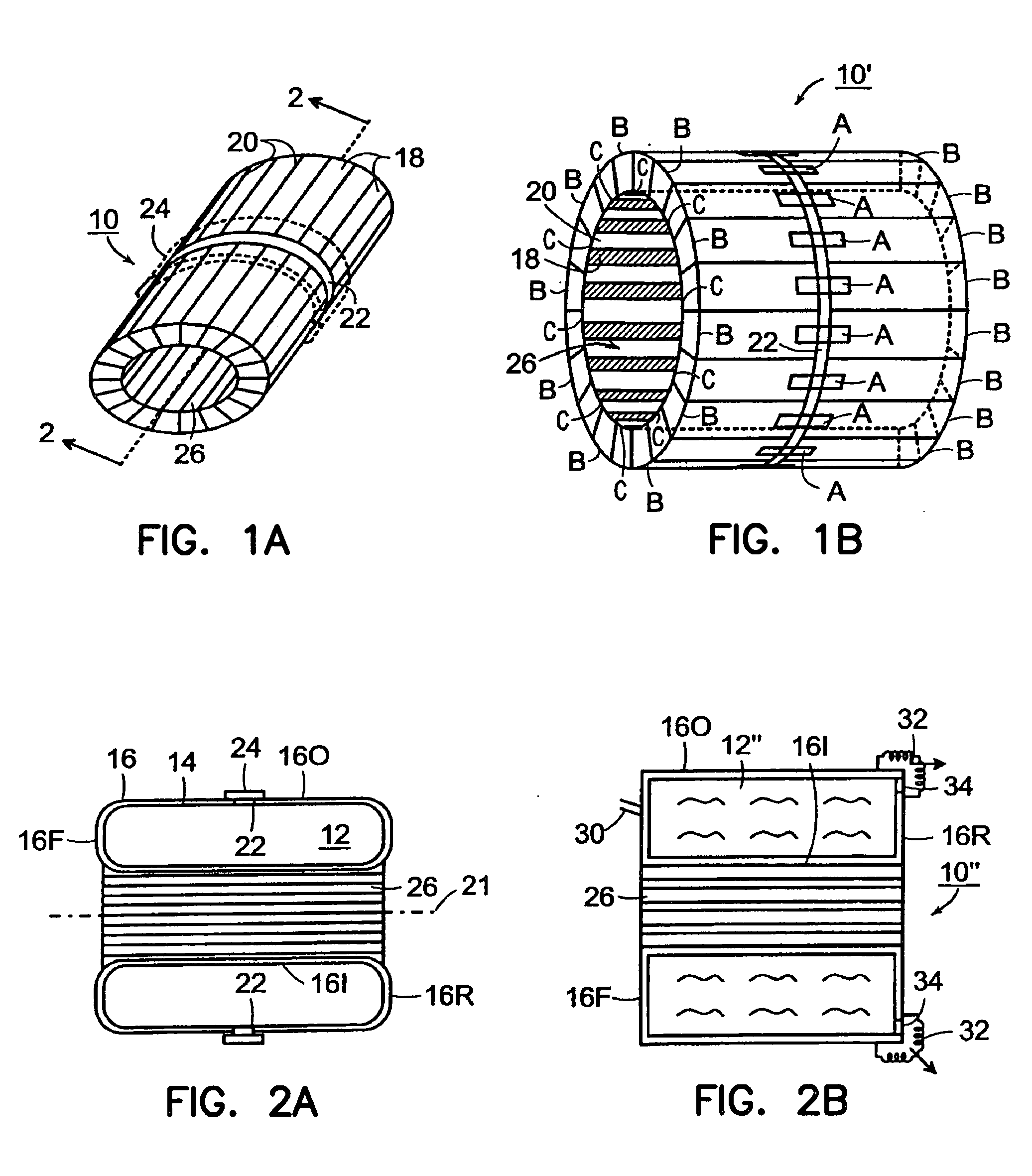

Method and apparatus for magnetic resonance imaging and spectroscopy using microstrip transmission line coils

InactiveUS7023209B2Easy to manufactureLow costMaterial analysis using microwave meansMagnetsSpectroscopyMri image

Owner:RGT UNIV OF MINNESOTA

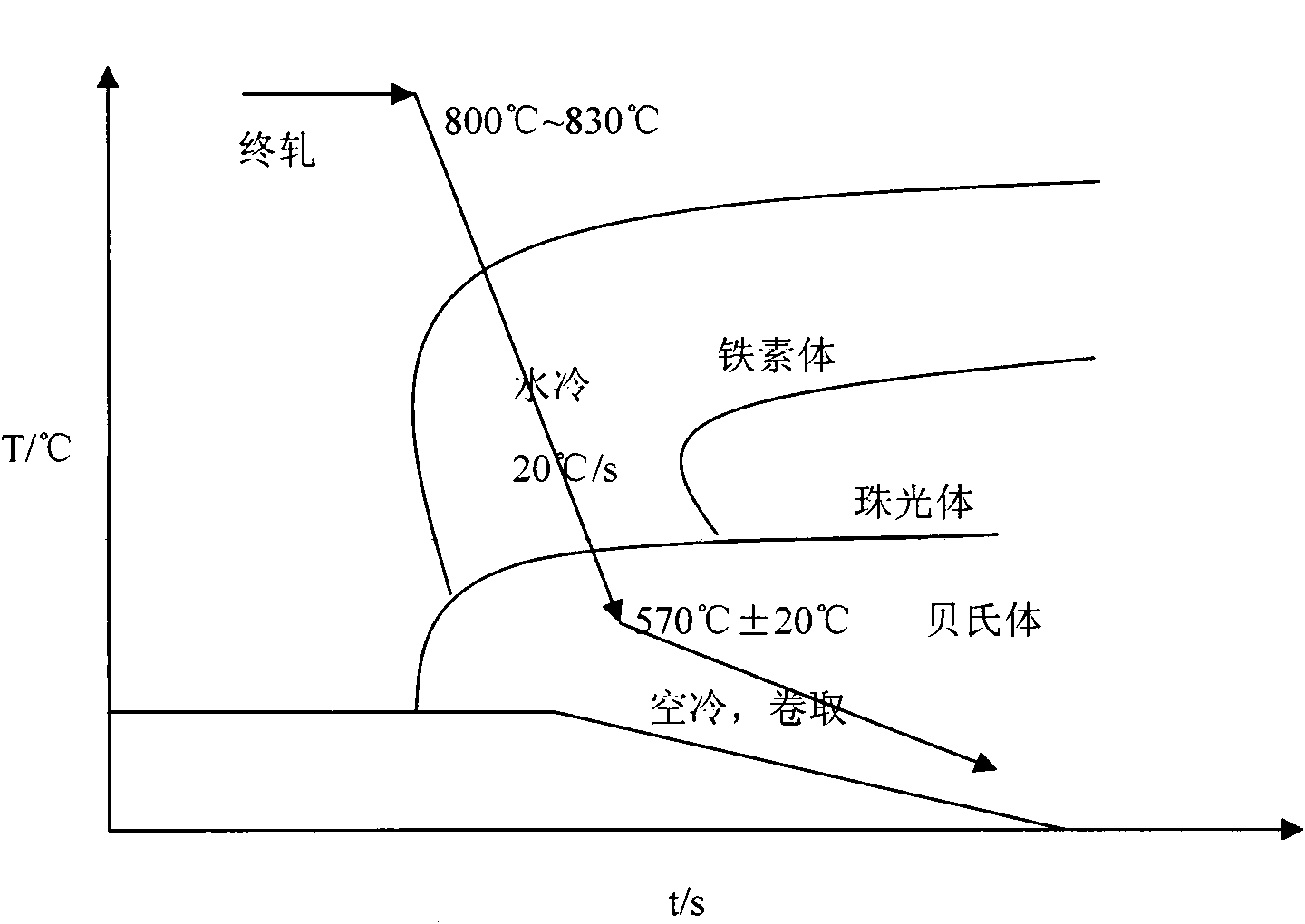

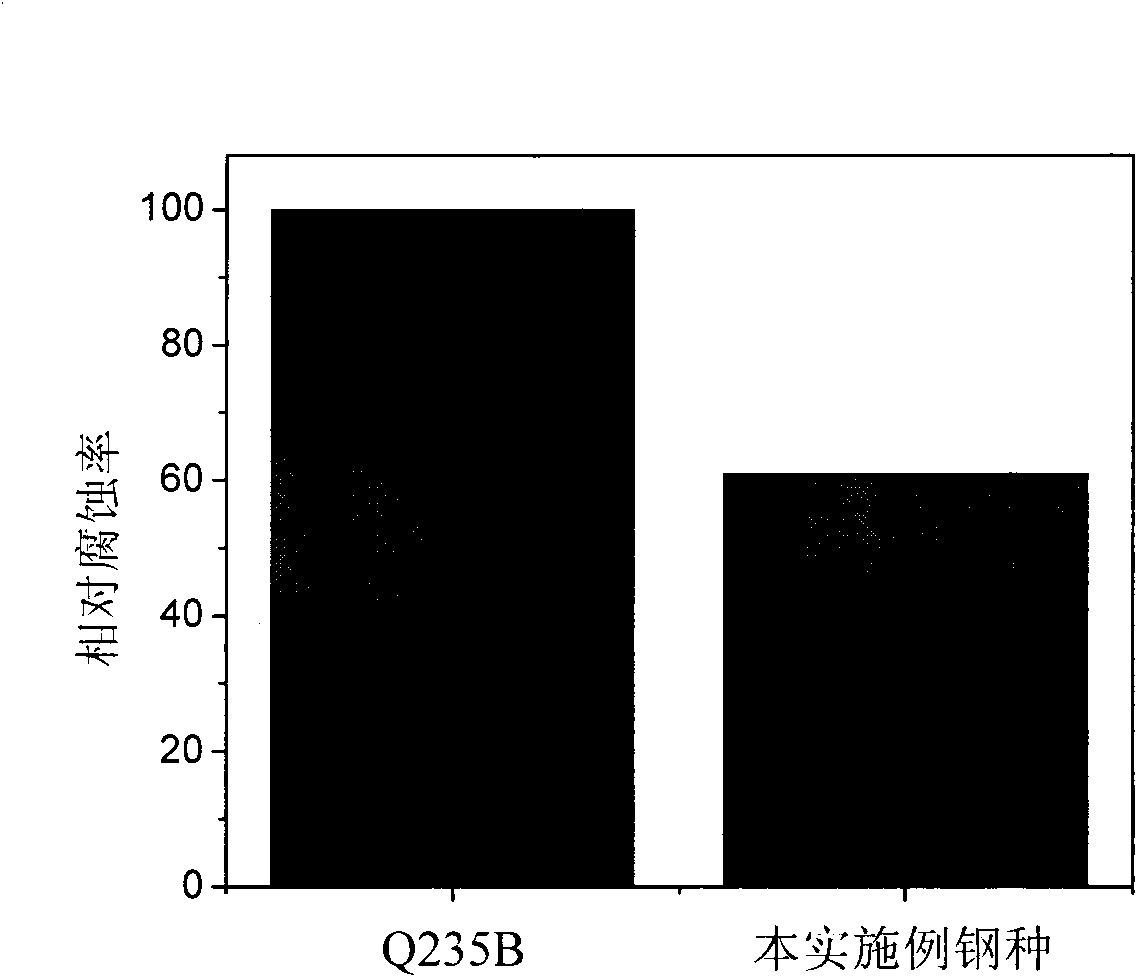

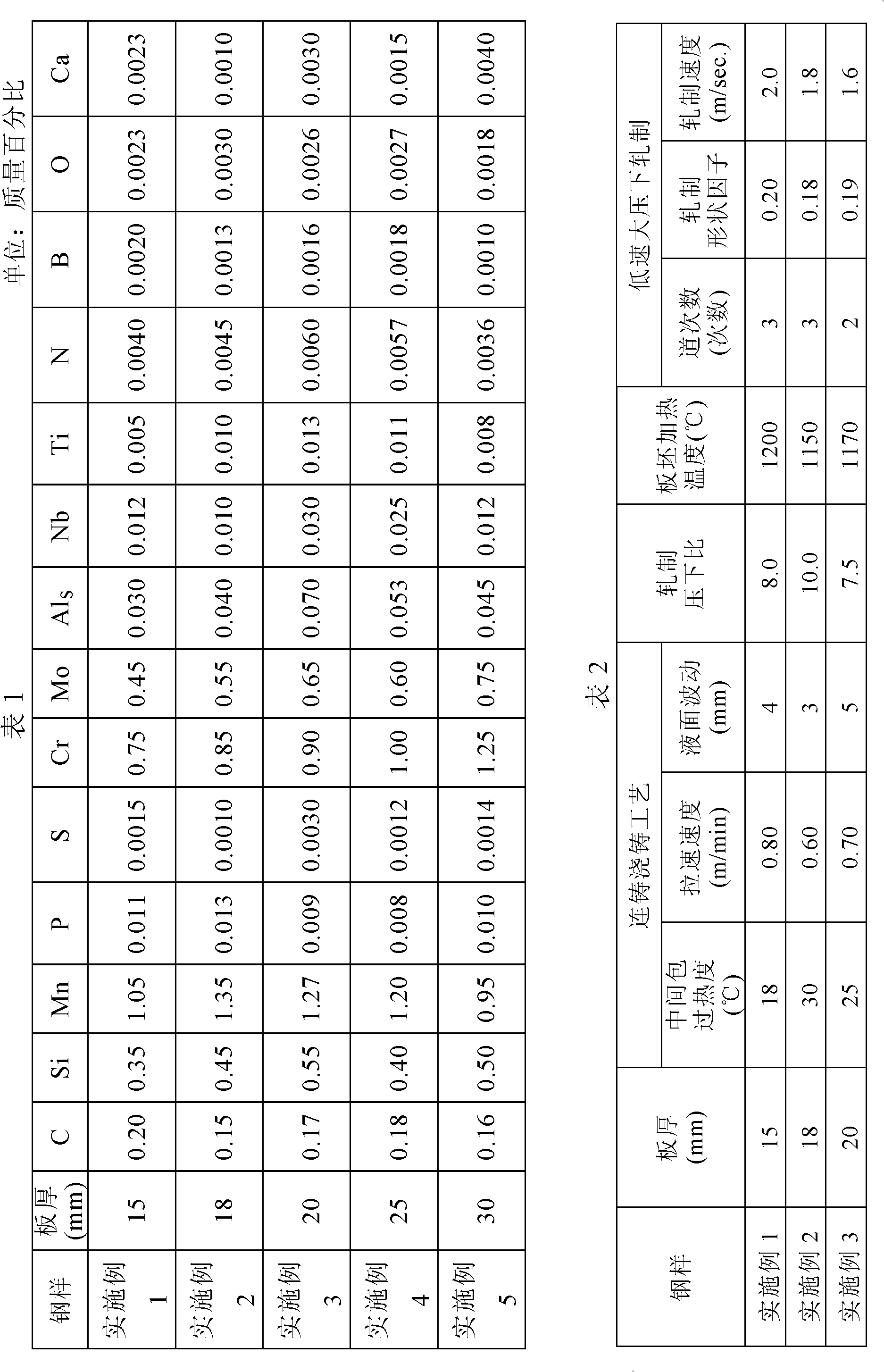

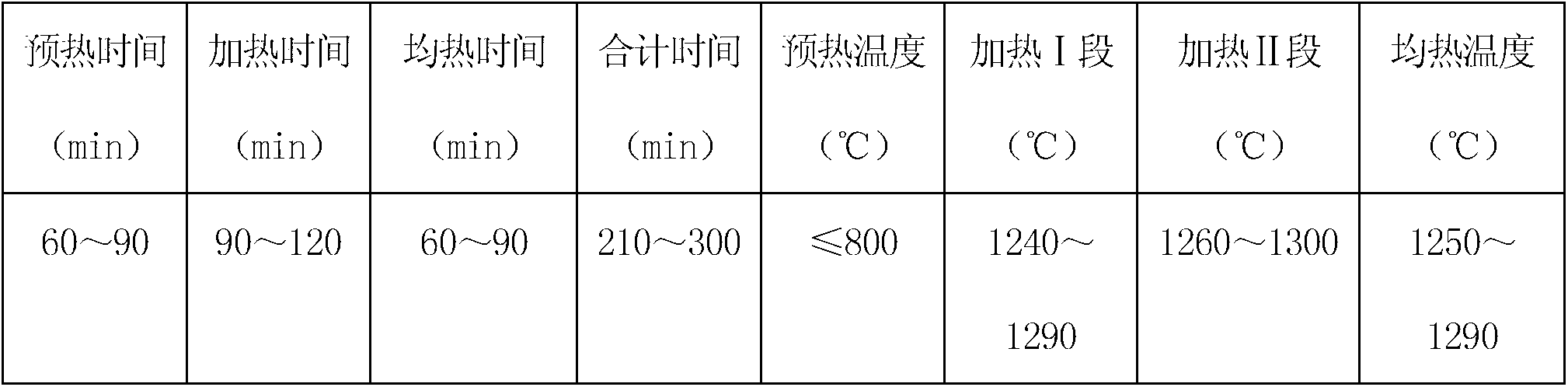

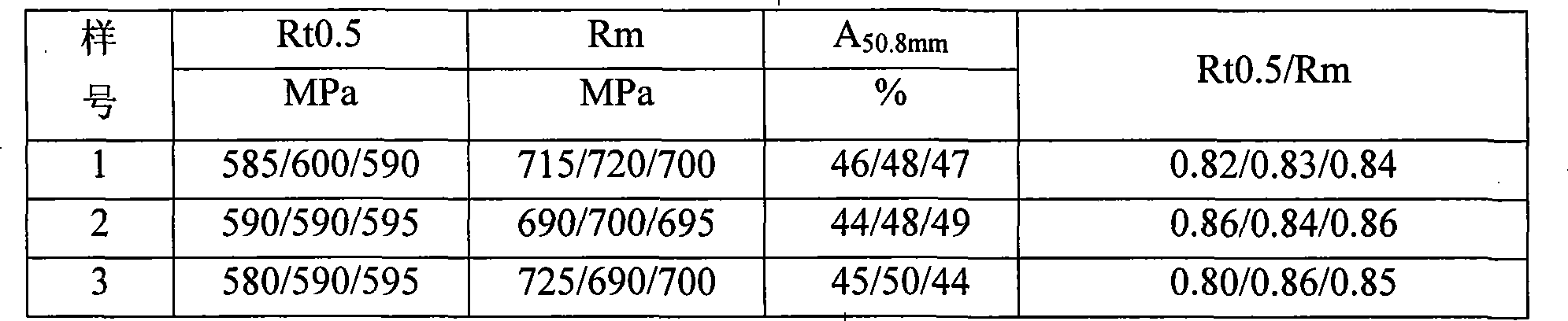

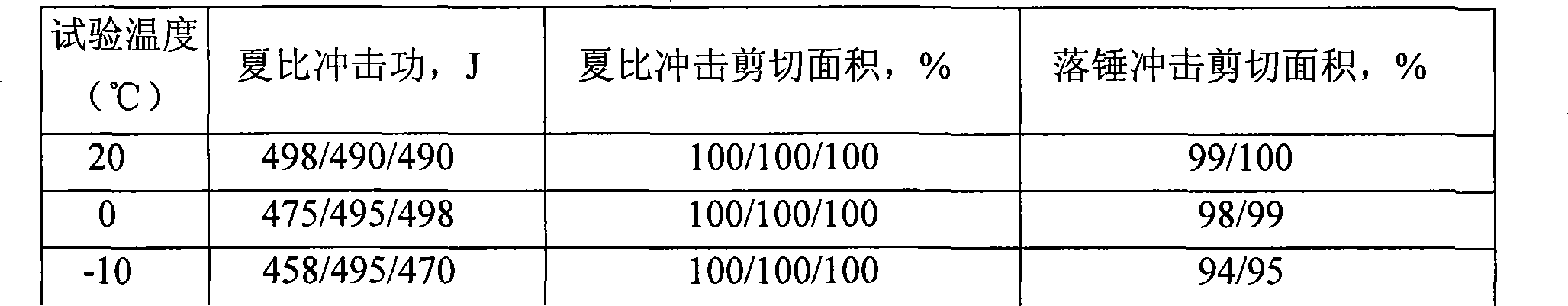

High strength low alloy hot rolling ferrite bainite weathering resistant steel and production method thereof

ActiveCN101660099AHigh strengthImprove toughnessTemperature control deviceManufacturing convertersNiobiumManganese

The invention relates to a high strength low alloy hot rolling ferrite bainite weathering resistant steel and a production method thereof. The steel comprises the components by weight percent: 0.05-0.10% of C, 0.30-0.45% of Si, 1.00-1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.01% of S, 0.50-0.70% of Cr, 0.20-0.30% of Ni, 0.20-0.40% of Cu, less than or equal to 0.05% ofAl, 0.01-0.025% of Ti, 0.03-0.05% of Nb and the rest of Fe and impurities; and the yield strength is more than or equal to 450MPa, and the welding cold crack susceptibility coefficient is less than orequal to 0.2. The invention has the advantages of low cost, high strength, low yield ratio, high weatherability, excellent weldability and low temperature toughness, simple process flow of the preparation technique and easy operation. Therefore, the invention can be widely applied to the fields such as bridges, buildings, containers, railway coaches, etc.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

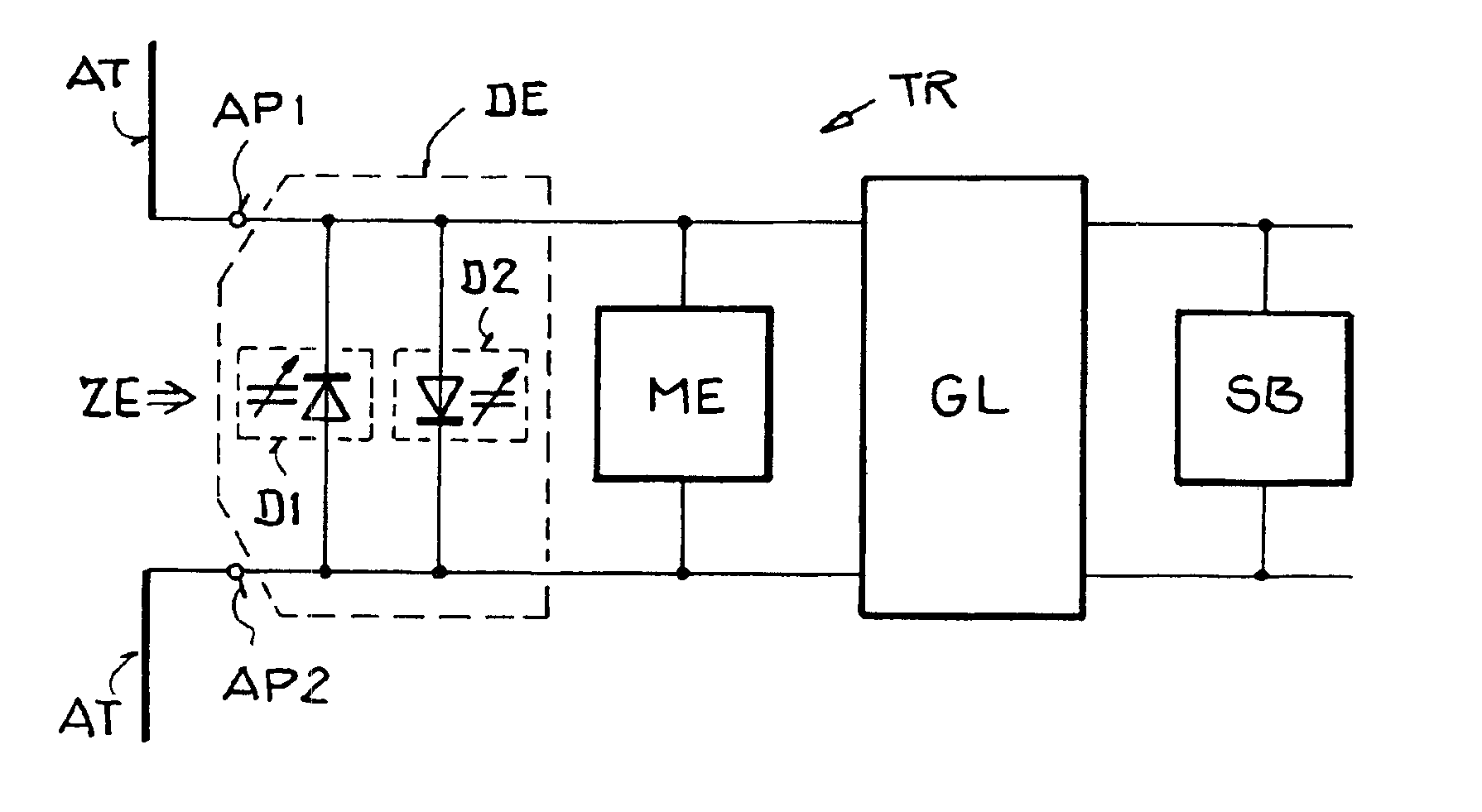

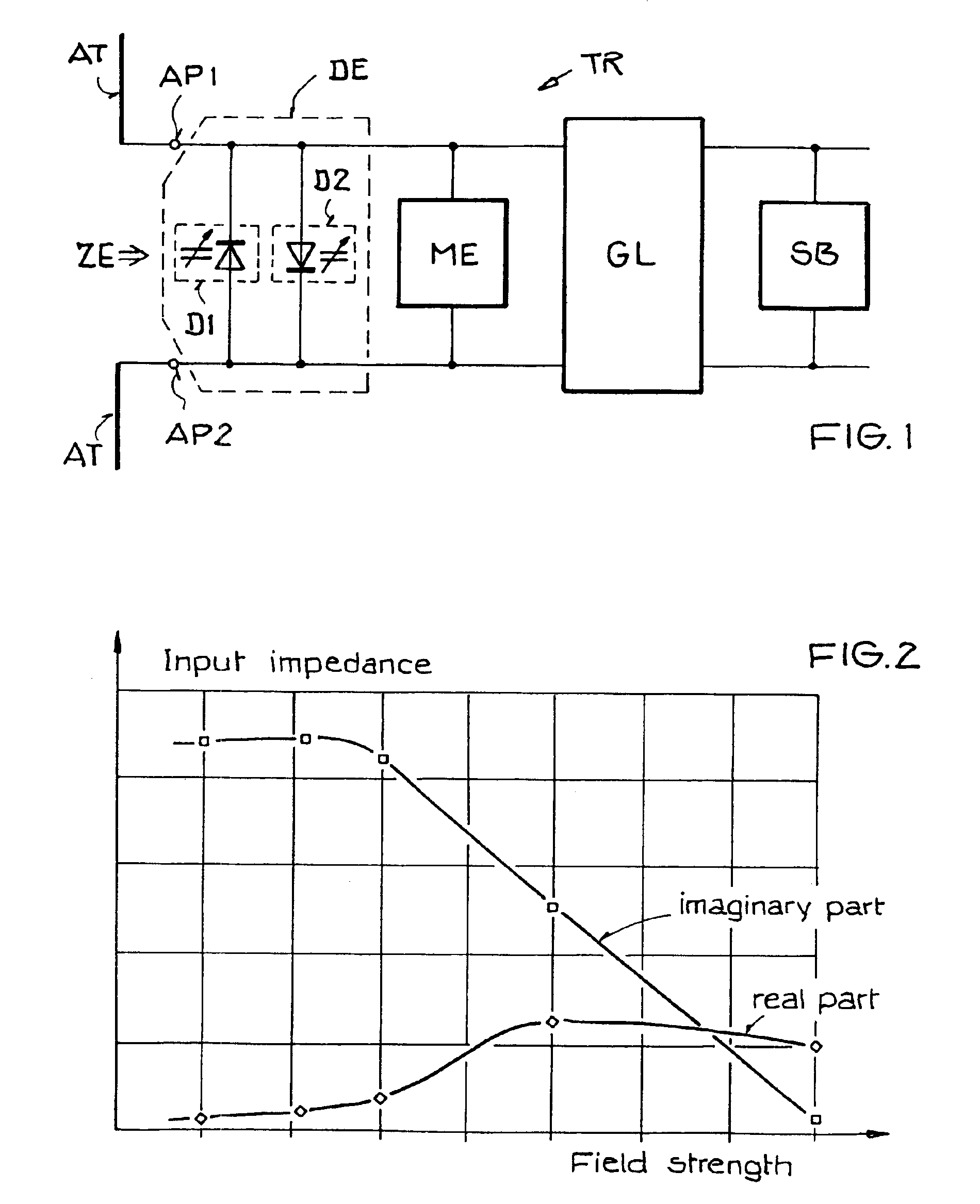

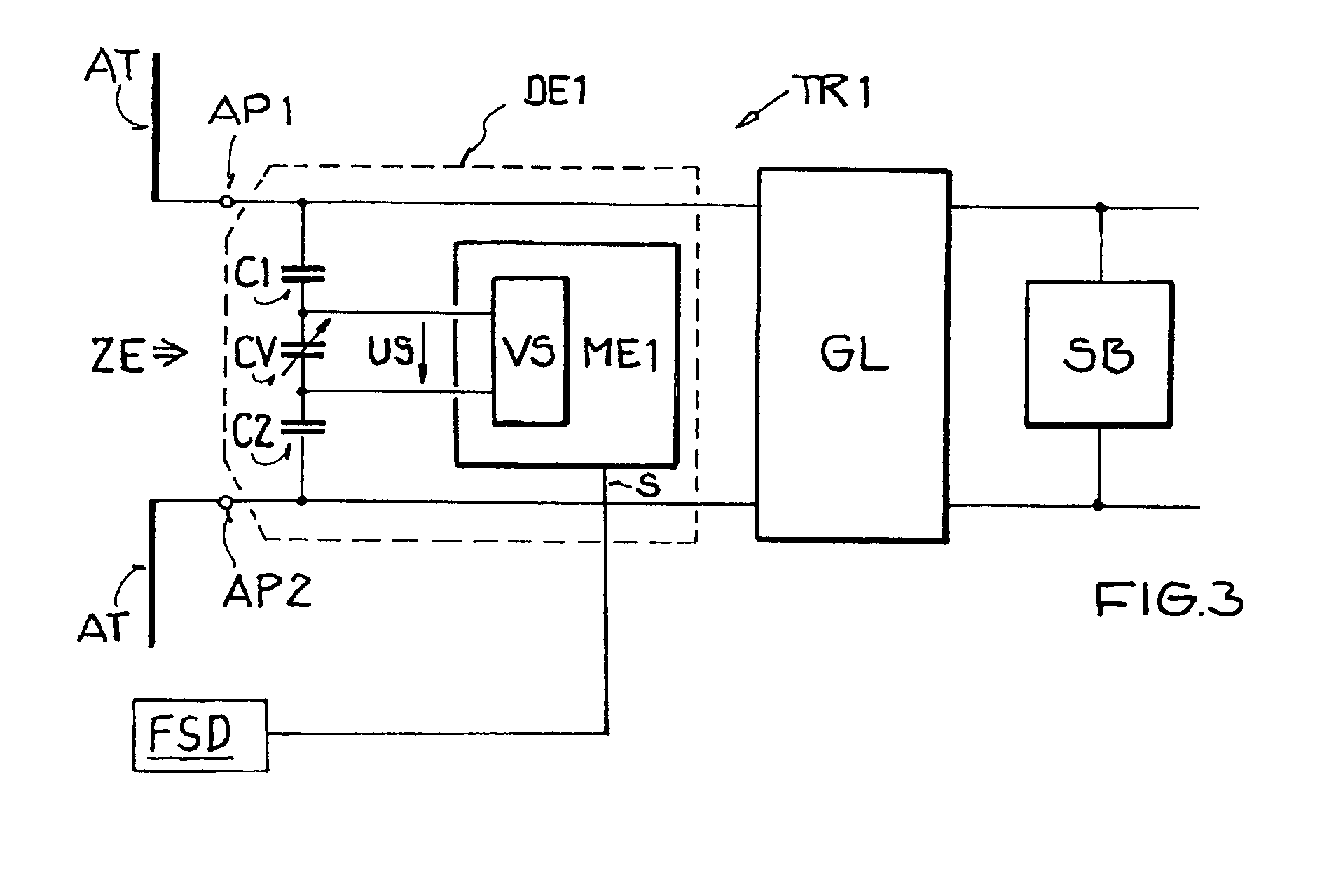

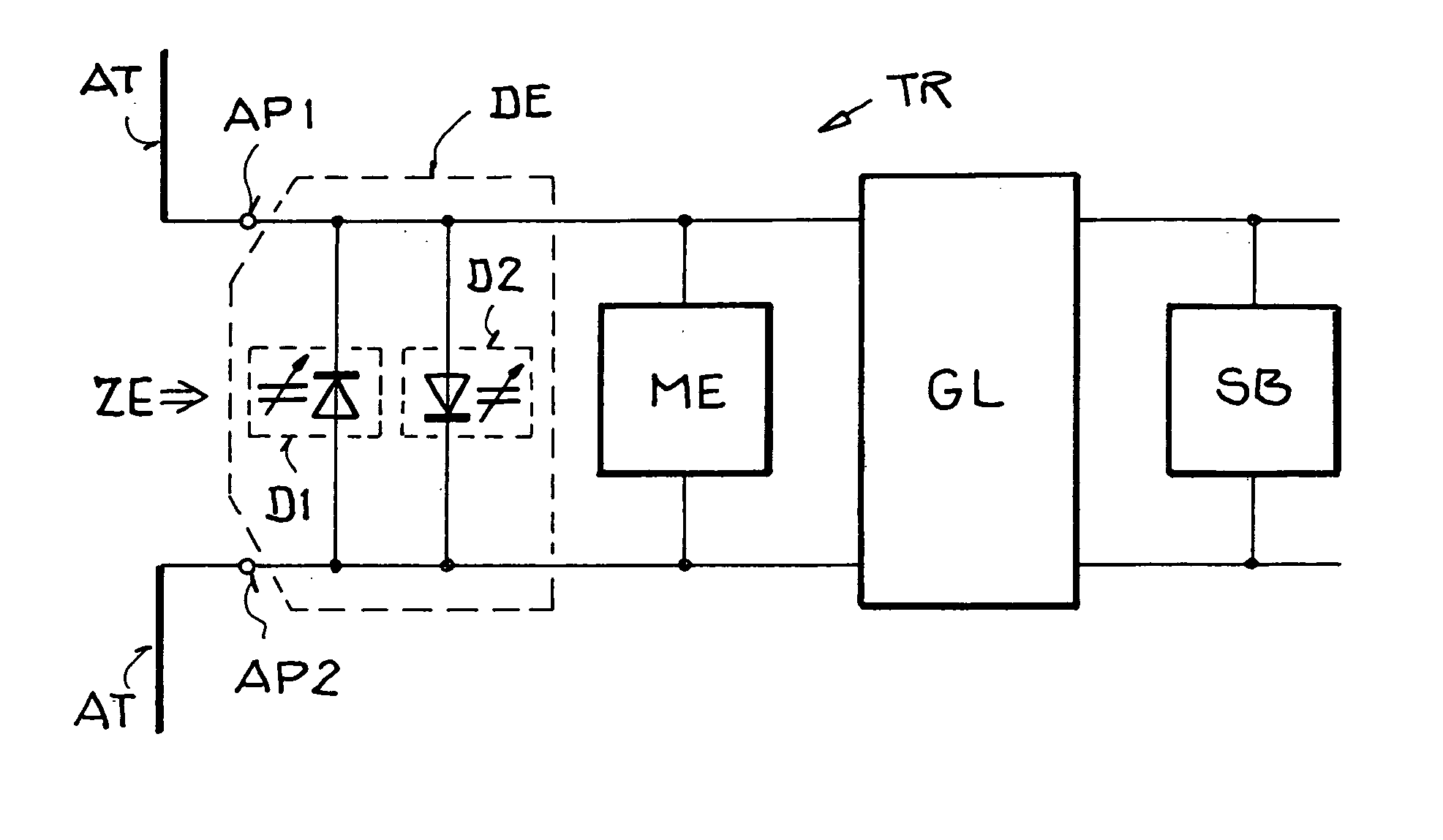

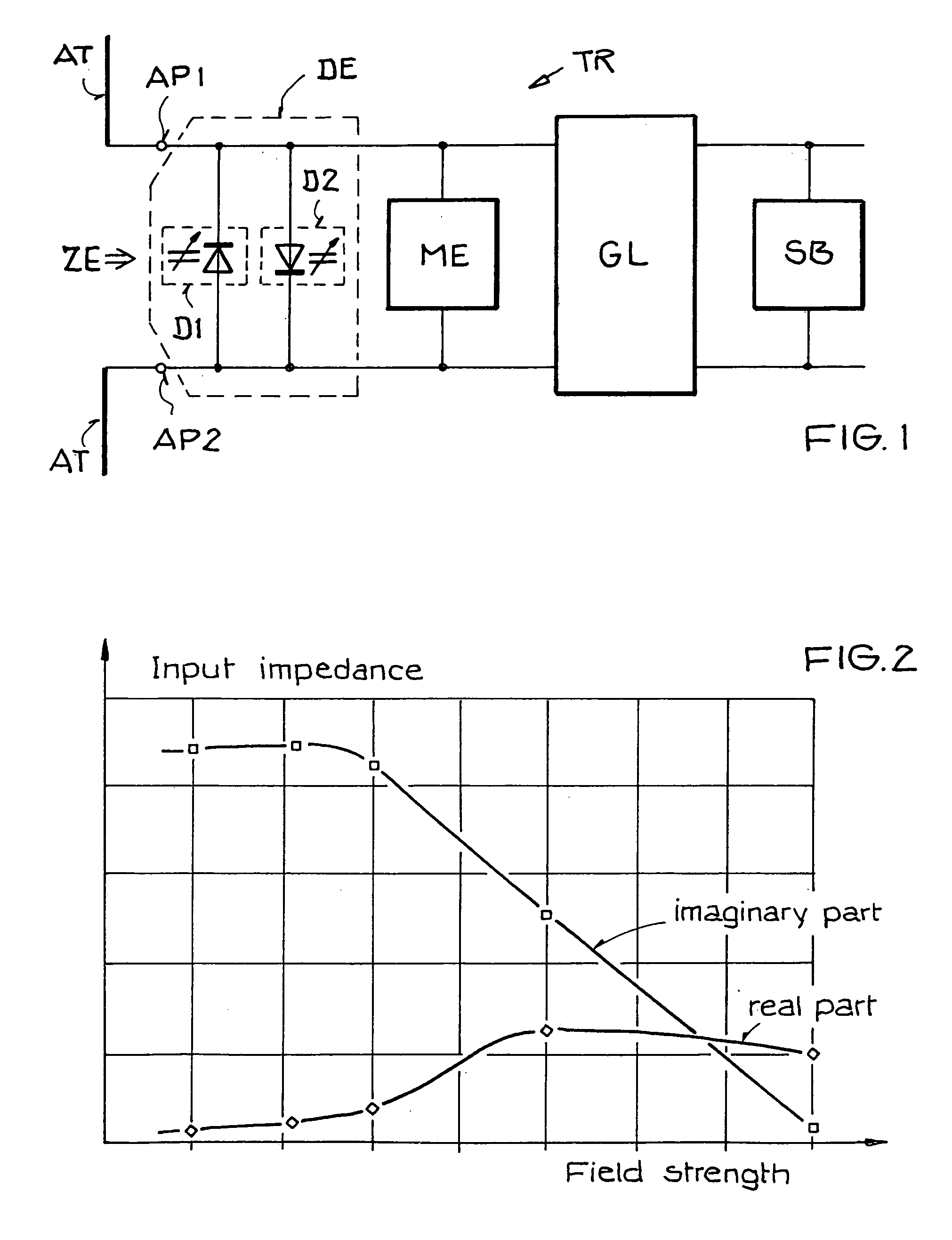

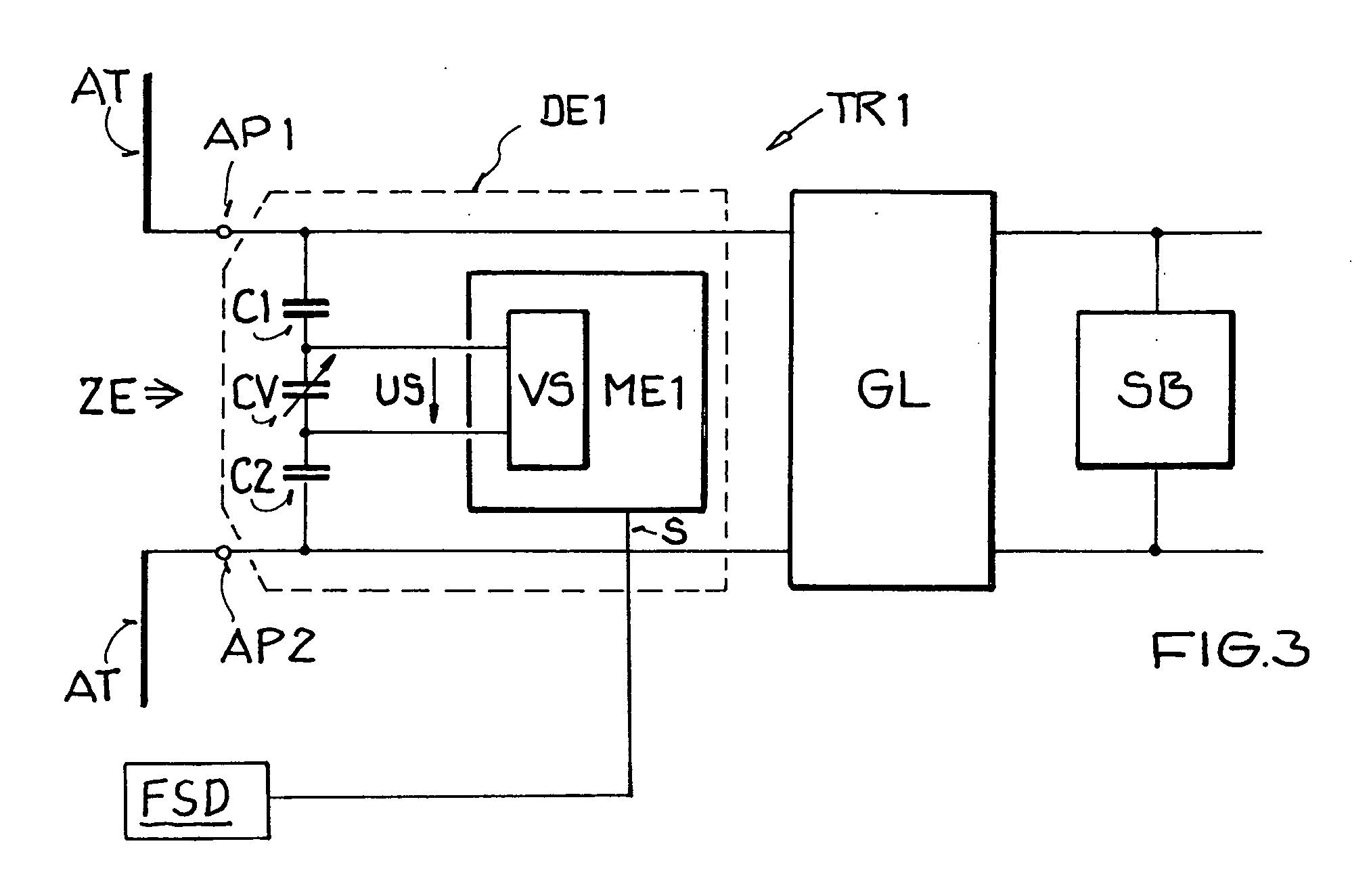

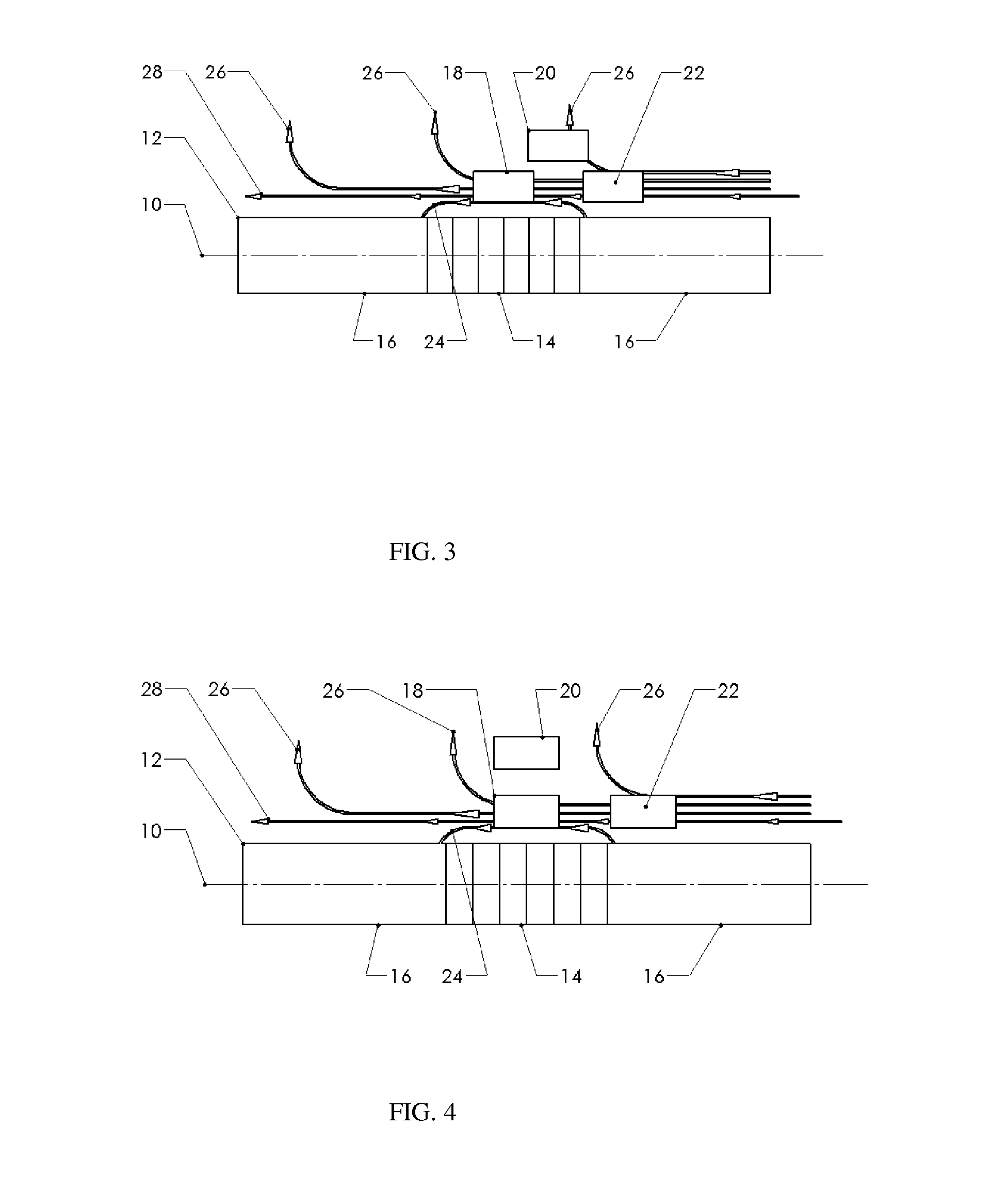

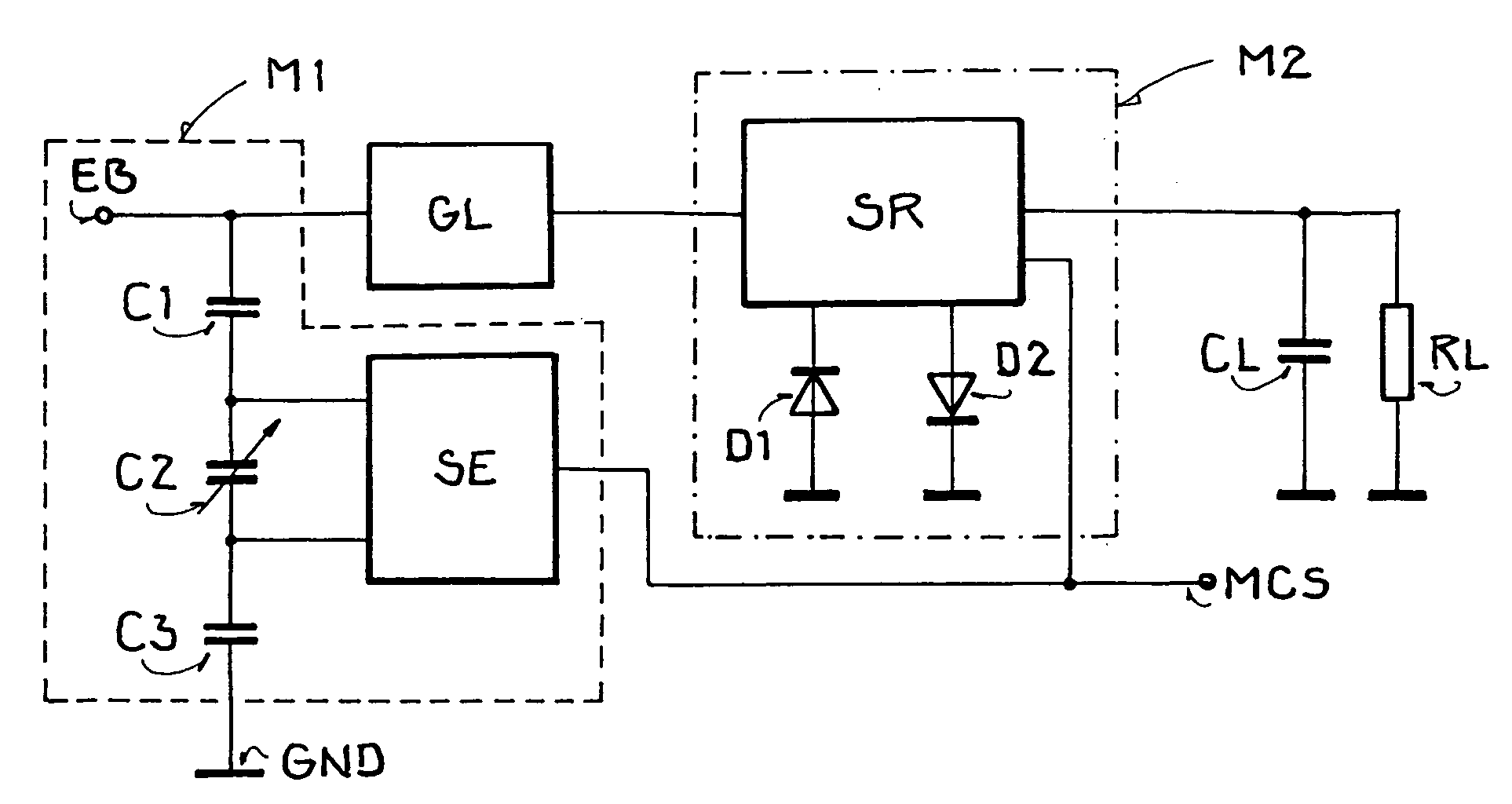

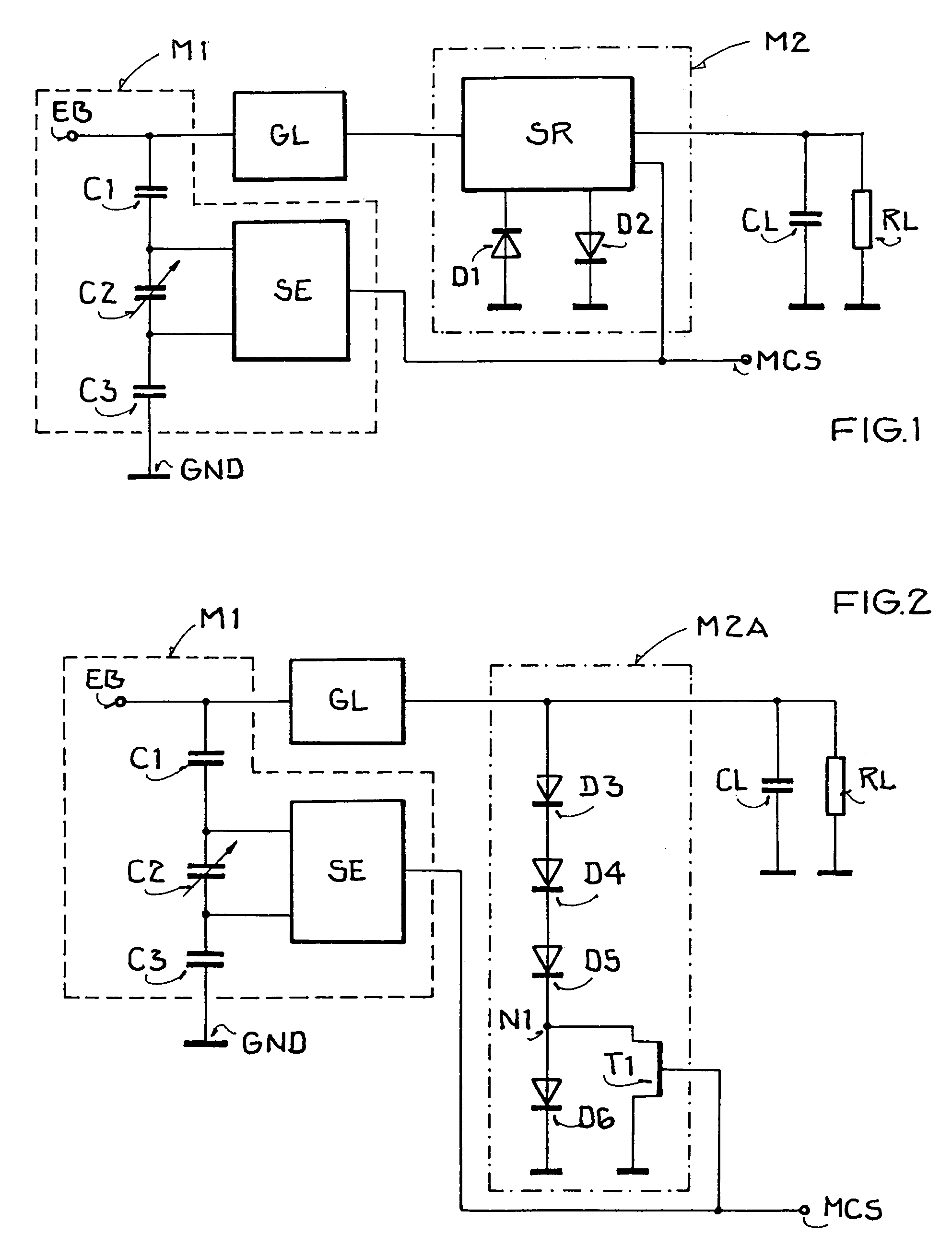

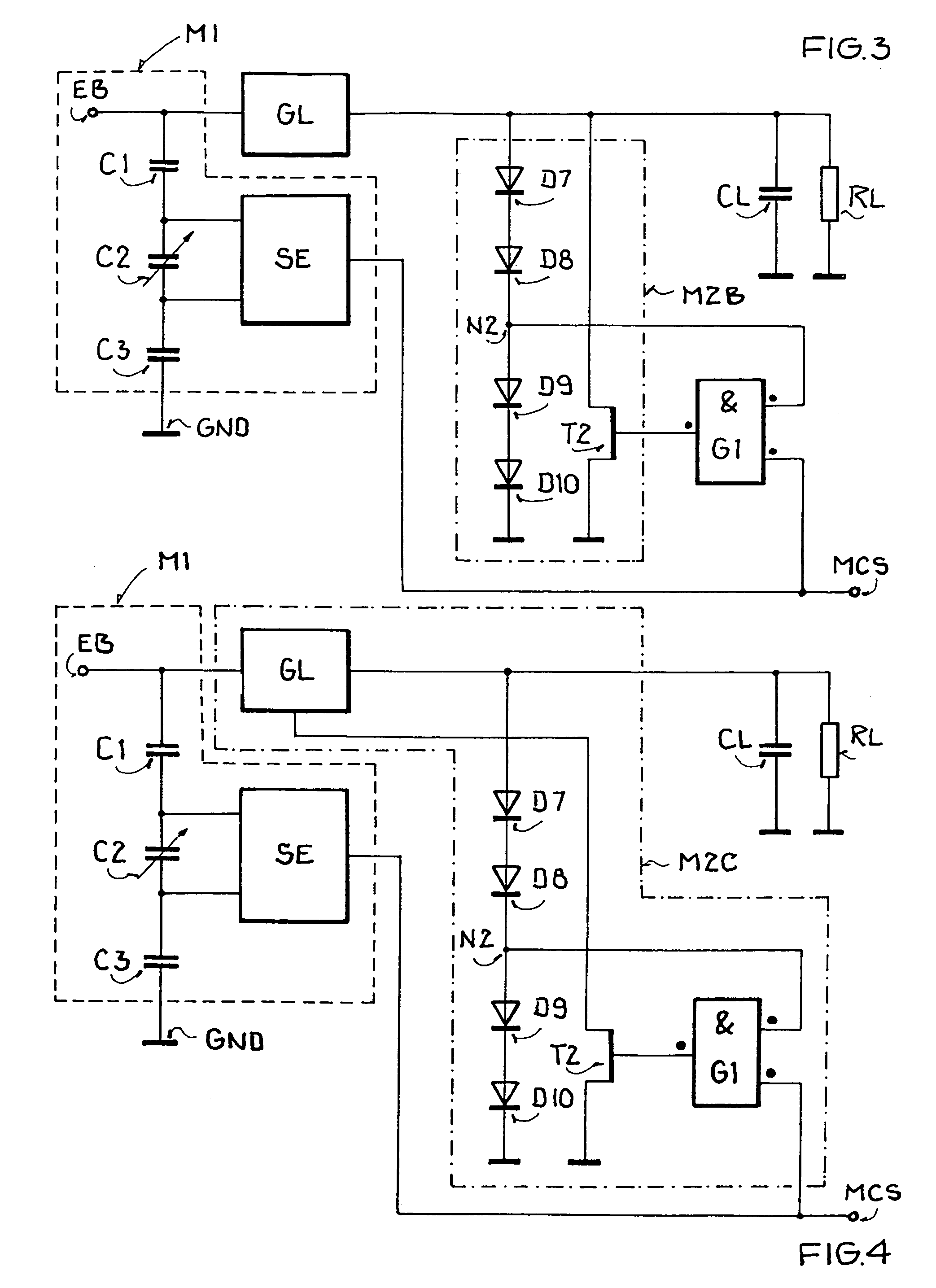

Circuit arrangement and method for deriving electrical power from an electromagnetic field

ActiveUS6940467B2Prevent destruction and damage and failureAvoiding excessive power absorptionNear-field transmissionElectromagnetic wave systemElectric forceImpedance matching

A circuit arrangement for deriving electrical power from a received electromagnetic field to power a transponder includes a detuning unit connected between two antenna terminals for limiting the power absorbed by the antenna. The detuning unit includes a component having an impedance that passively varies or is actively varied dependent on the field strength of the field prevailing at the antenna. One arrangement of the detuning unit includes two varactor diodes connected anti-parallel between the antenna terminals. Another arrangement of the detuning unit includes a varactor arranged in series between two capacitors between the antenna terminals, a field strength detector, and a controllable voltage source connected to apply to the varactor a control voltage that varies depending on the detected field strength. Thereby, the input impedance varies depending on the field strength, to achieve impedance matching for a low field strength, and a mis-matched condition for a high field strength.

Owner:ATMEL GERMANY +1

Method and apparatus for self-assembly of functional blocks on a substrate facilitated by electrode pairs

InactiveUS20050009303A1Accurate couplingImprove permeabilitySolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsSlurry

Methods for fabricating an assembly having functional blocks coupling to a substrate. The method includes providing the substrate with receptor sites wherein each of the receptor sites is designed to couple to one of the functional blocks. Electrodes are coupled to the substrate. The electrodes cover the receptor sites such that portions of the receptor sites are coated with the electrodes. Applying a voltage source to the electrodes using a first electrical circuit such that each electrode has a voltage different from another electrode. The electrodes form an electric field. The functional blocks having electronic devices and being in a slurry solution are dispensed over the substrate. Each functional block is fabricated out of materials having a high dielectric constant such that said functional blocks are attracted to the higher field strength regions and are guided to the receptor sites.

Owner:RUIZHANG TECH LTD CO

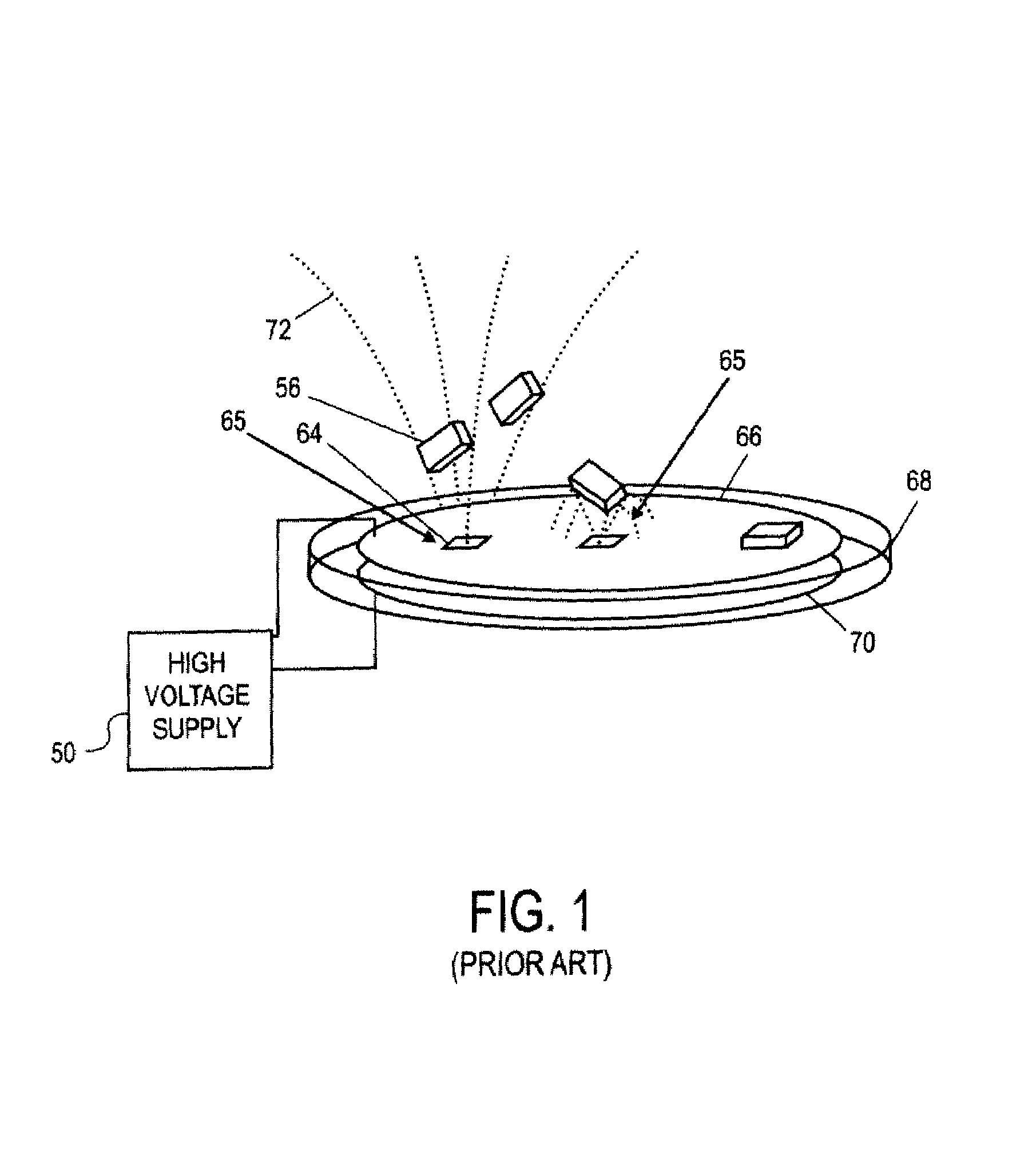

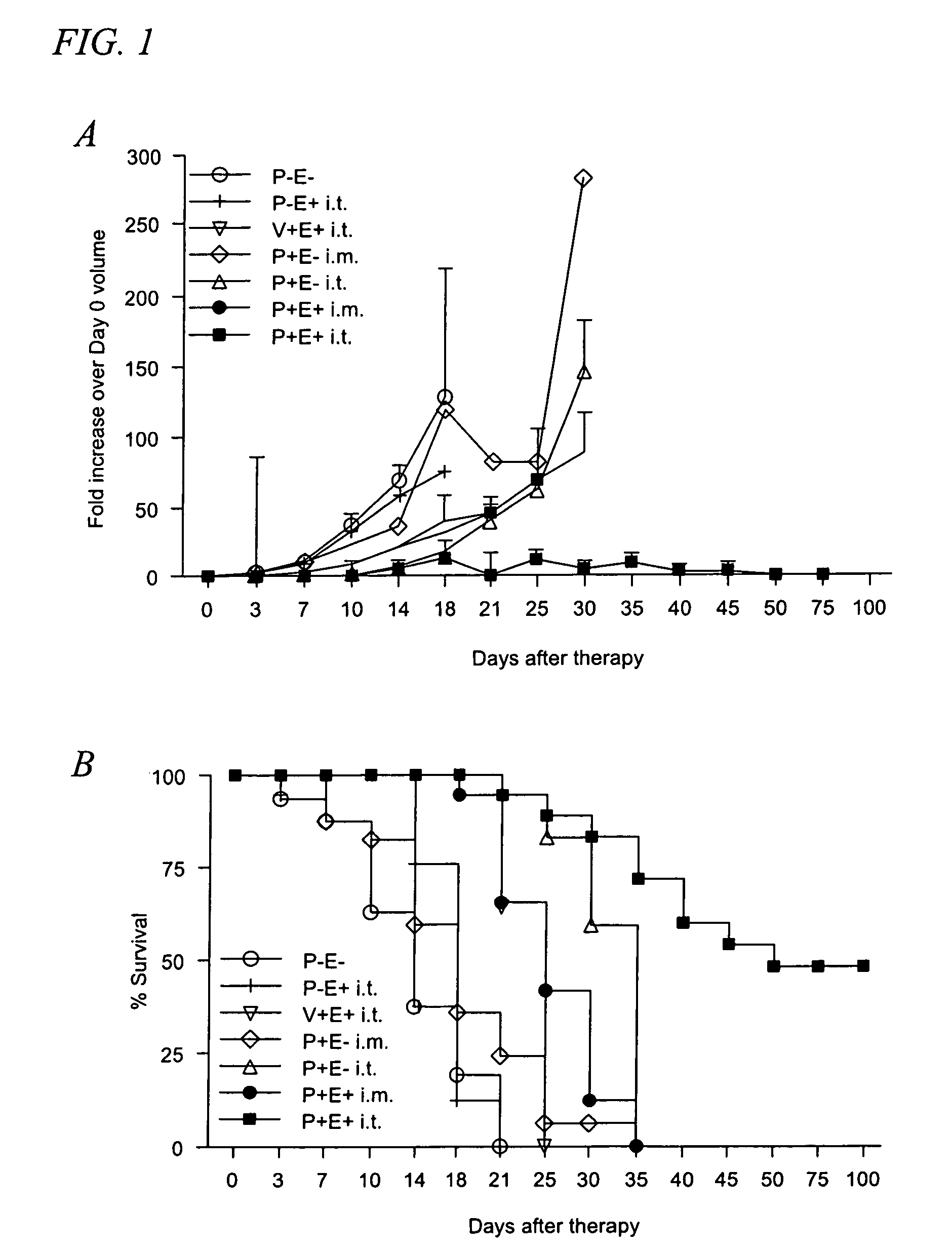

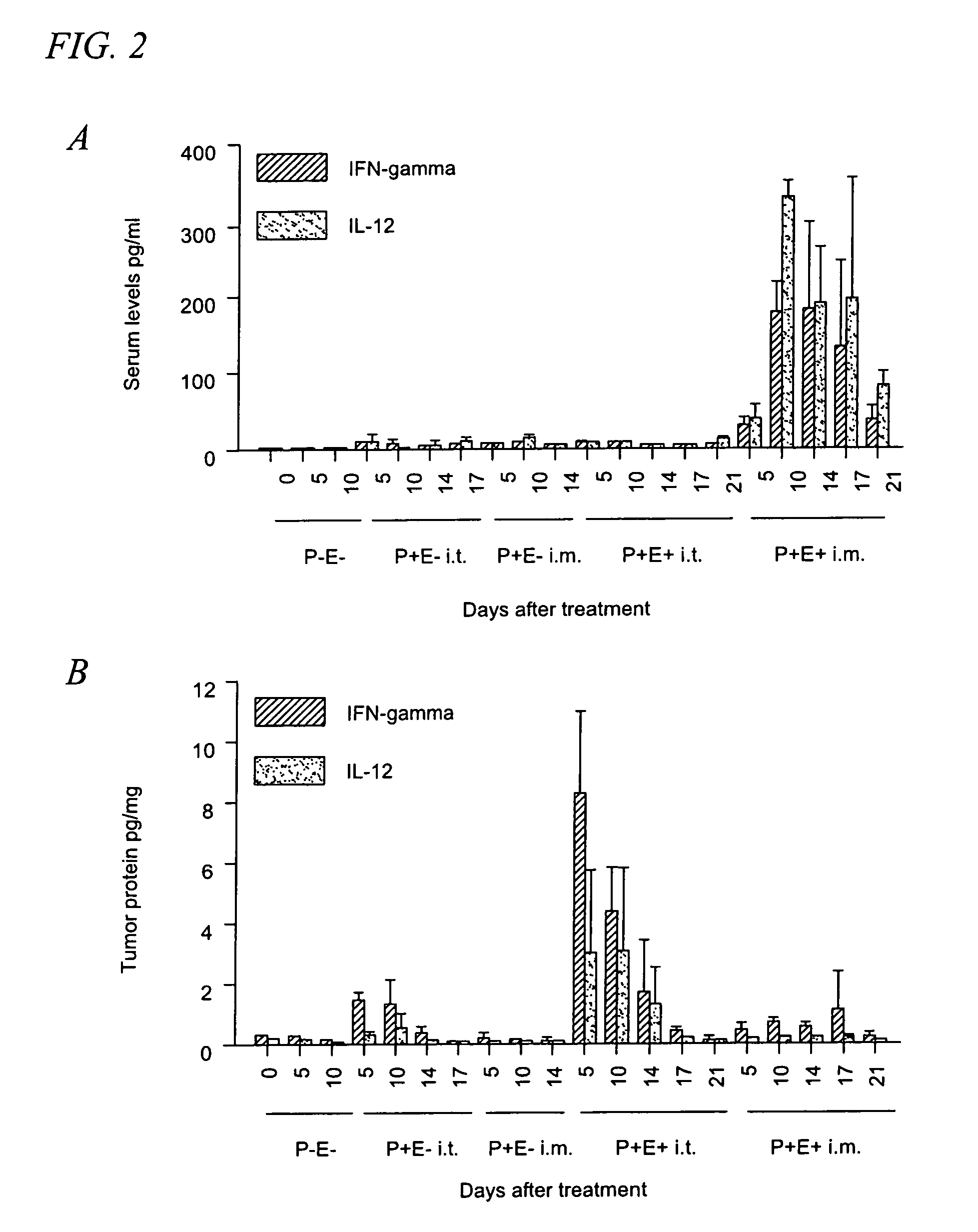

Treating malignant tumors with high field strength electroporation of plasmids encoding IL-12

ActiveUS8026223B1Improve survival rateBiocidePeptide/protein ingredientsElectroporation therapyTherapeutic protein

In accordance with the present invention is provided a method of treating a subject having a cancerous tumor. The treatment protocol methodology includes injecting the cancerous tumor with an effective dose of plasmid coding for a therapeutic protein followed by administering electroporation therapy to the tumor, the electroporation therapy includes the administration of at least one high voltage, short duration pulse to the tumor.

Owner:UNIV OF SOUTH FLORIDA

Circuit arrangement and method for deriving electrical power from an electromagnetic field

ActiveUS20040155754A1Avoiding excessive power absorptionField strengthNear-field transmissionElectromagnetic wave systemEngineeringImpedance matching

A circuit arrangement for deriving electrical power from a received electromagnetic field to power a transponder includes a detuning unit connected between two antenna terminals for limiting the power absorbed by the antenna. The detuning unit includes a component having an impedance that passively varies or is actively varied dependent on the field strength of the field prevailing at the antenna. One arrangement of the detuning unit includes two varactor diodes connected anti-parallel between the antenna terminals. Another arrangement of the detuning unit includes a varactor arranged in series between two capacitors between the antenna terminals, a field strength detector, and a controllable voltage source connected to apply to the varactor a control voltage that varies depending on the detected field strength. Thereby, the input impedance varies depending on the field strength, to achieve impedance matching for a low field strength, and a mis-matched condition for a high field strength.

Owner:ATMEL GERMANY +1

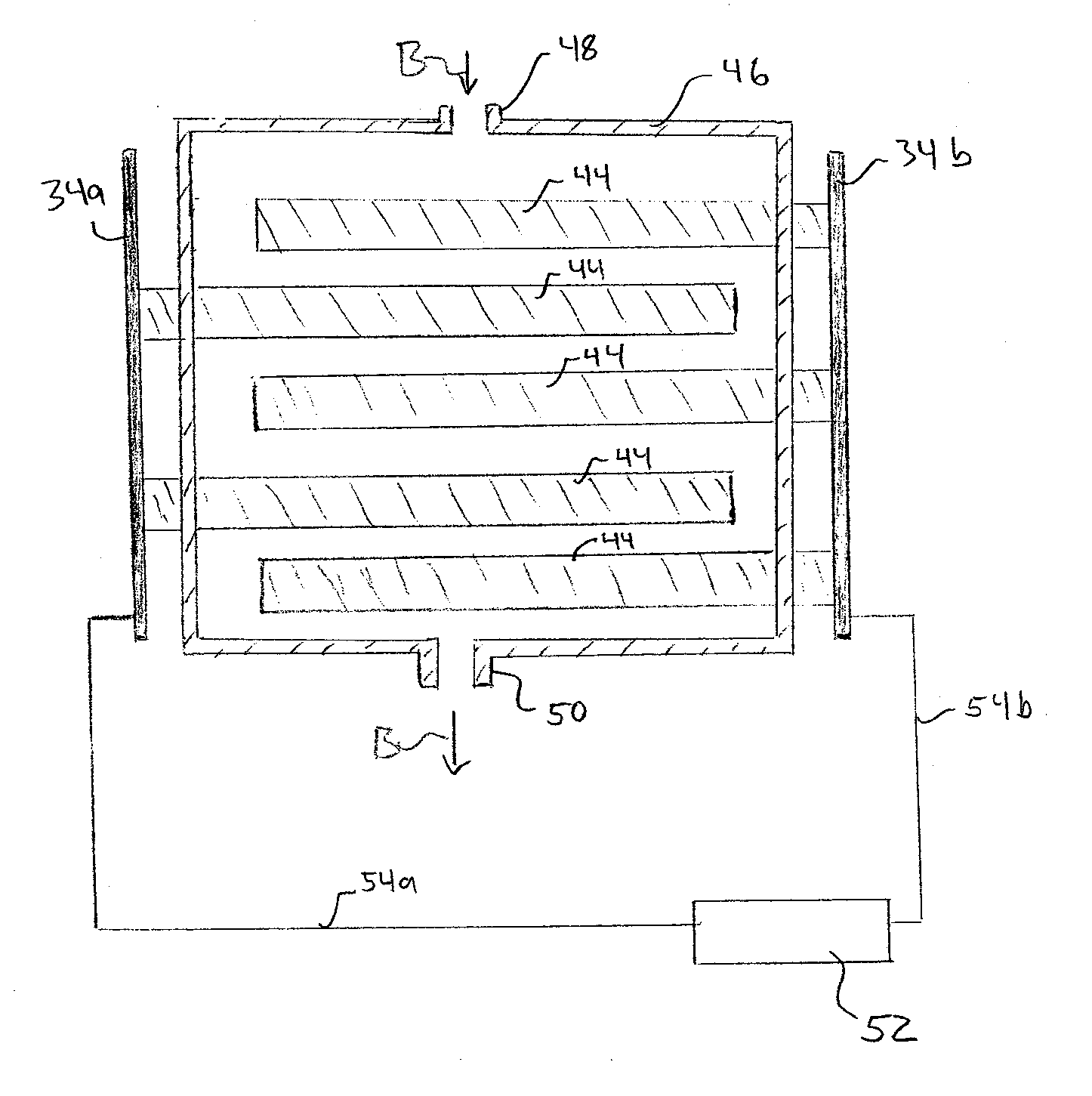

Method and apparatus for dielectrophoretic separation

A dielectrophoretic separation device includes a chamber including an inlet and an outlet disposed between the inlet and the outlet. A plurality of three dimensional electrodes are disposed in within the chamber. The electrodes may take the form of a wire or semi-cylindrical conductors disposed on a substrate. At least some of the electrodes include smooth surfaces so as to create an electric field (in response to an applied alternating current) that has a low strength in a region disposed away from the electrodes and an electric field having a high fields strength in a region between adjacent electrodes. Particulate matter or other species experiencing a positive DEP force may be separated and collected in the gaps or regions formed between adjacent electrodes.

Owner:RGT UNIV OF CALIFORNIA

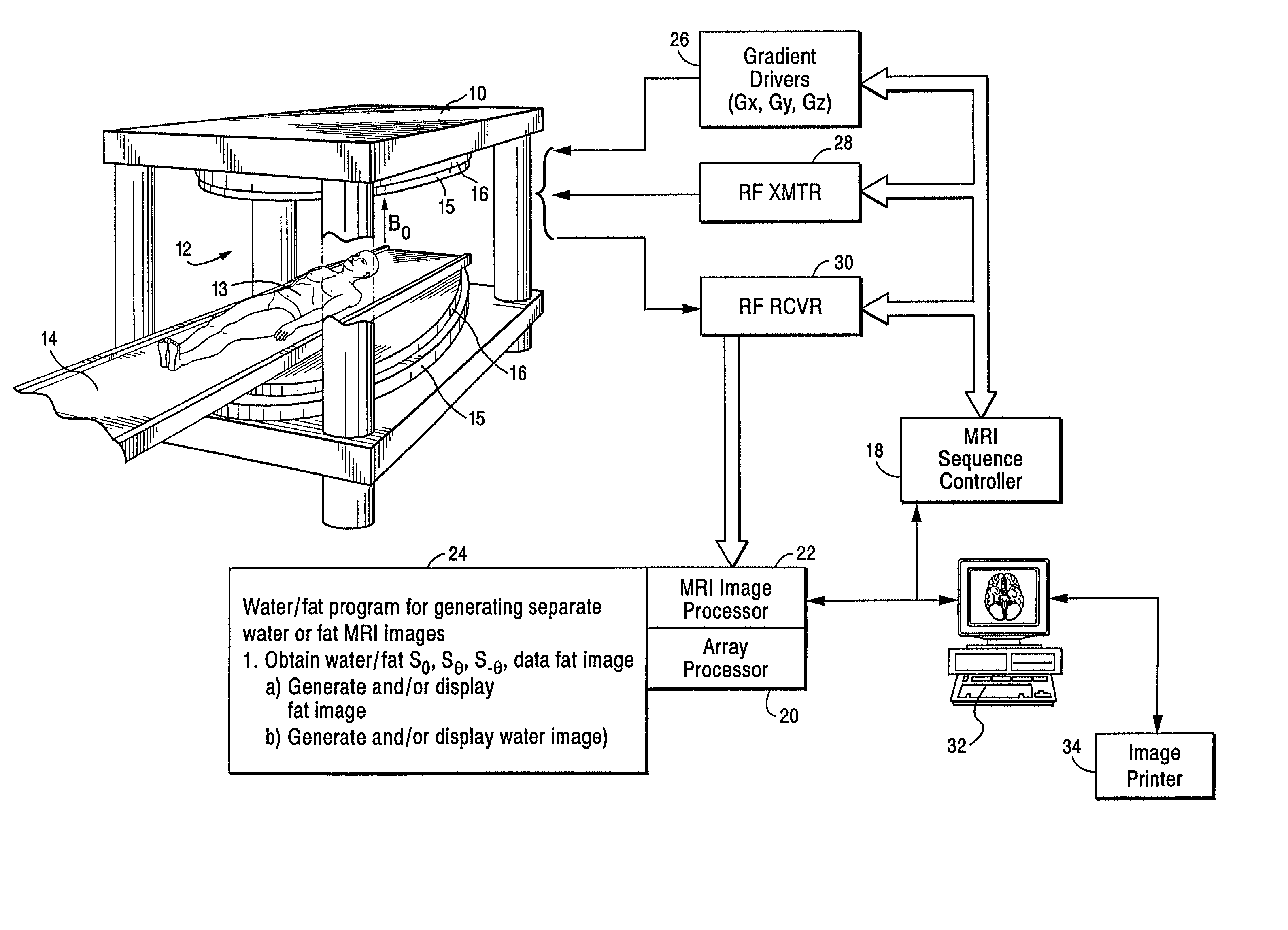

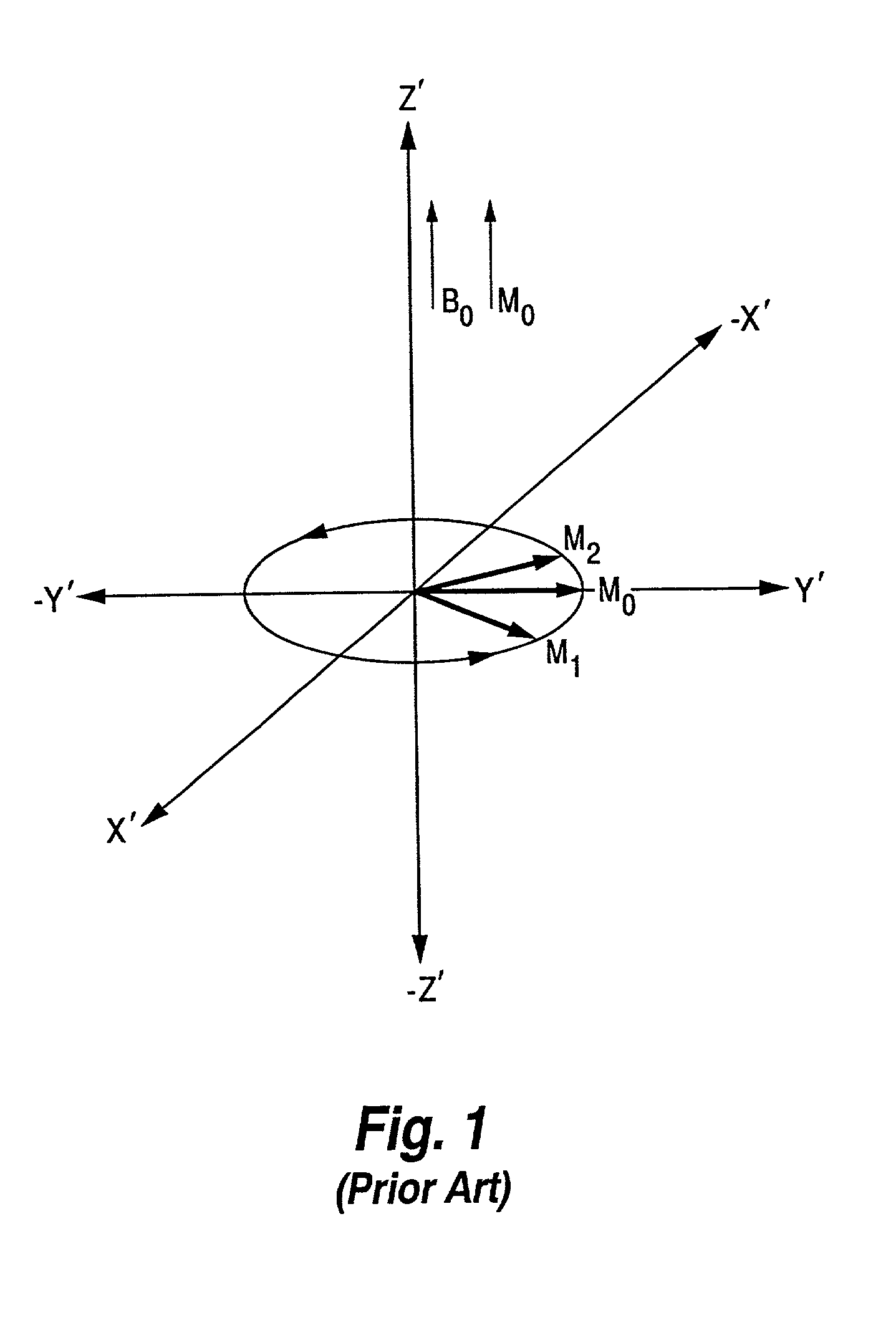

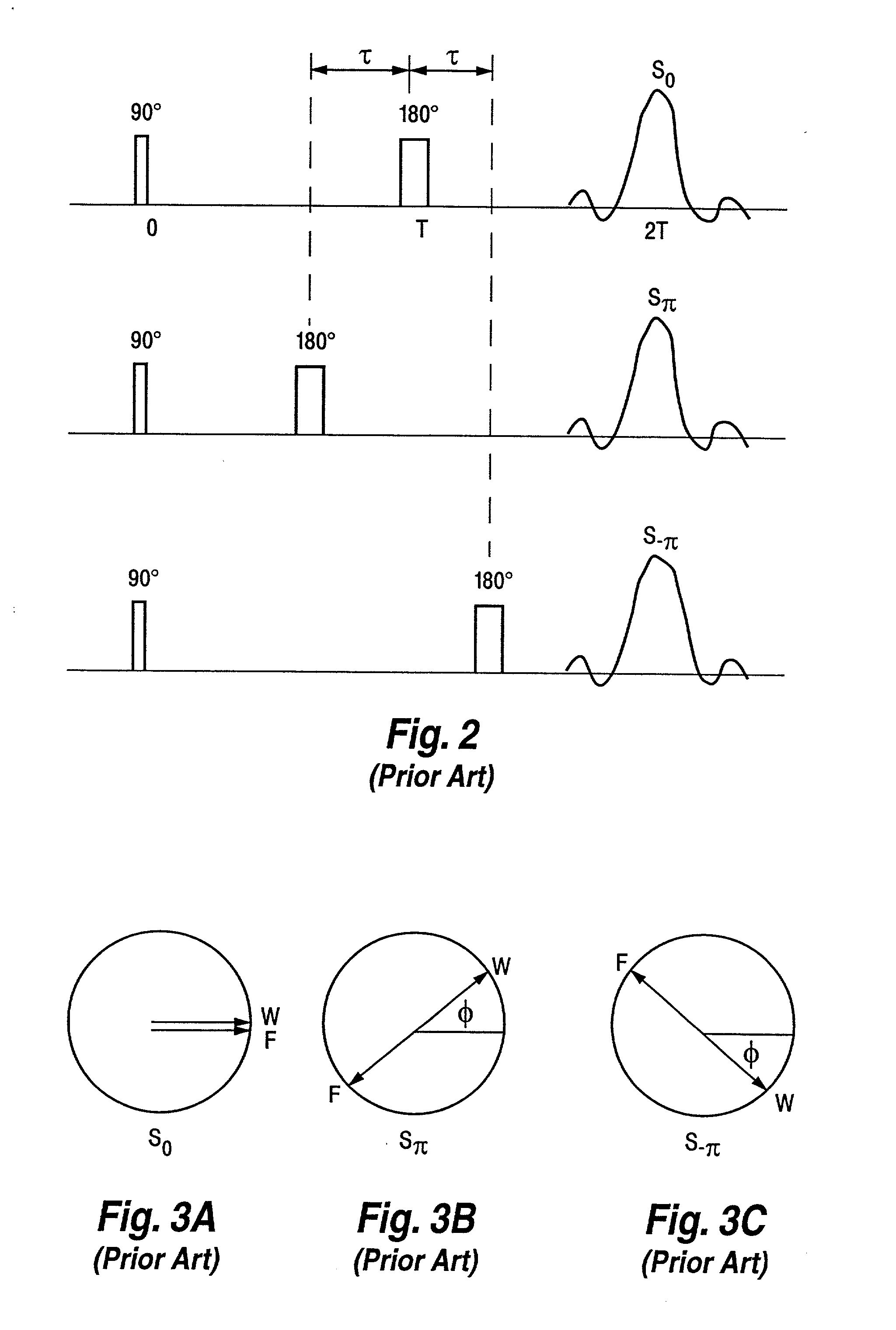

Separation and identification of water and fat MR images at mid-field strength with reduced T2/T2* weighting

InactiveUS20030060697A1Eliminate the effects ofCharacter and pattern recognitionDiagnostic recording/measuringField strengthMr images

A magnetic resonance imaging (MRI) method is disclosed for generating and identifying water and fat separated MR images. Image data is first acquired to obtain two echo images with the water and fat signals orthogonal in the first echo image, and parallel / anti-parallel in the second echo image. The effect of background field inhomogeneties are removed, and water and fat images are separated from each other. The separated water and fat images are identified according to the difference of their precessing frequencies.

Owner:TOSHIBA AMERICA MRI

Reduced Ambient Fields Error In A Magnetoelastic Torque Sensor System

InactiveUS20110162464A1Minimize error amountWork measurementTorque measurementHigh magnetic field strengthMagnetic source

An improved magnetic torque transducer involves a method and apparatus for compensating effects of uniform and / or non-uniform magnetic sources by placing three sets of magnetic field sensors around a shaft with at least one magnetized zone. The set of primary magnetic field sensor or sensors is placed proximate to the magnetized zone, both the second and third sets of secondary magnetic field sensors being placed by pre-determined distances to the primary set of magnetic field sensor or sensors, so that primary field sensors always in a position with higher magnetic field strength arise from applied torque than that of secondary sensors. And a method is developed to use the second and third signals from secondary sensors to adjust the primary signal to compensating for the effects of the uniform and / or non-uniform ambient magnetic field sources.

Owner:SMTS

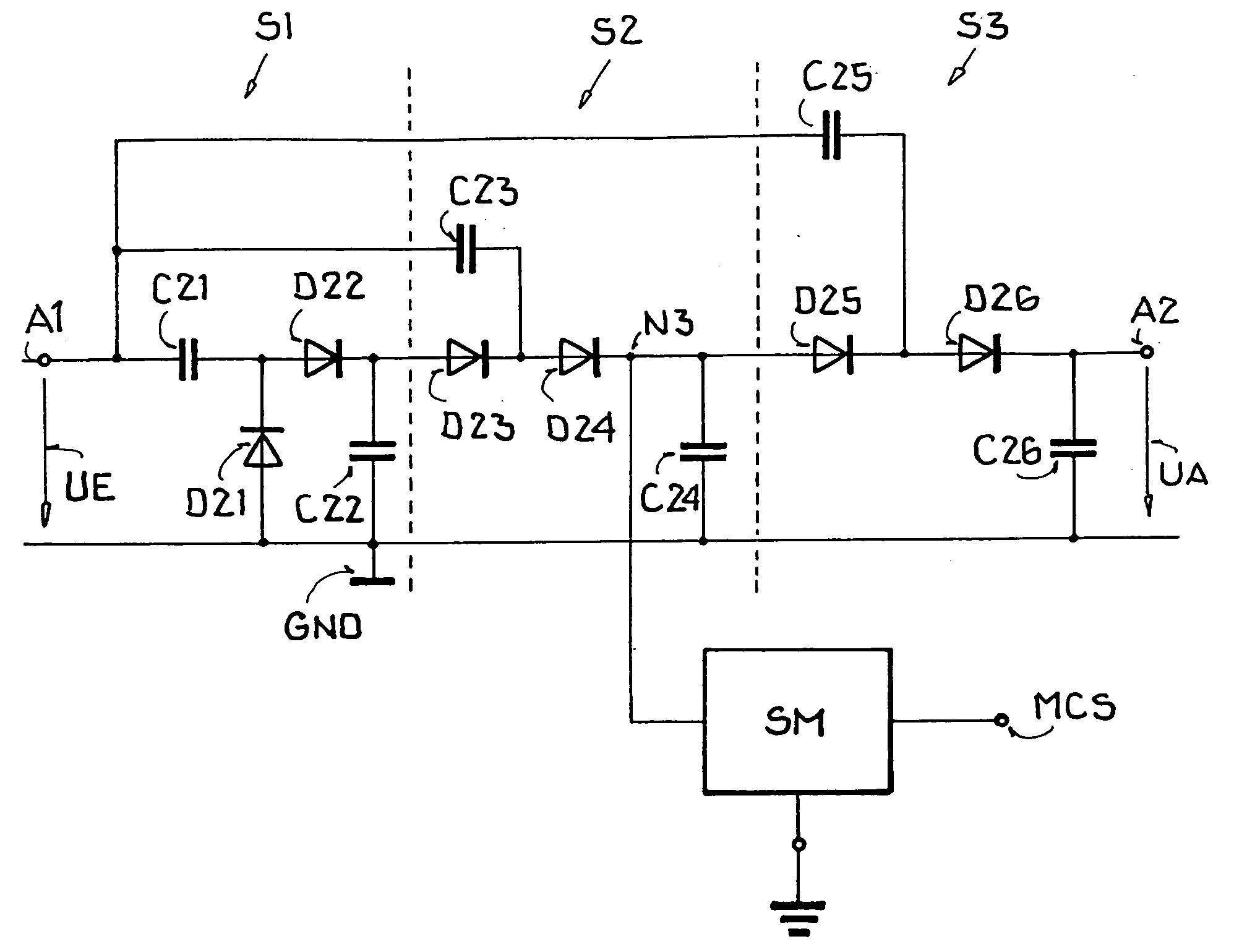

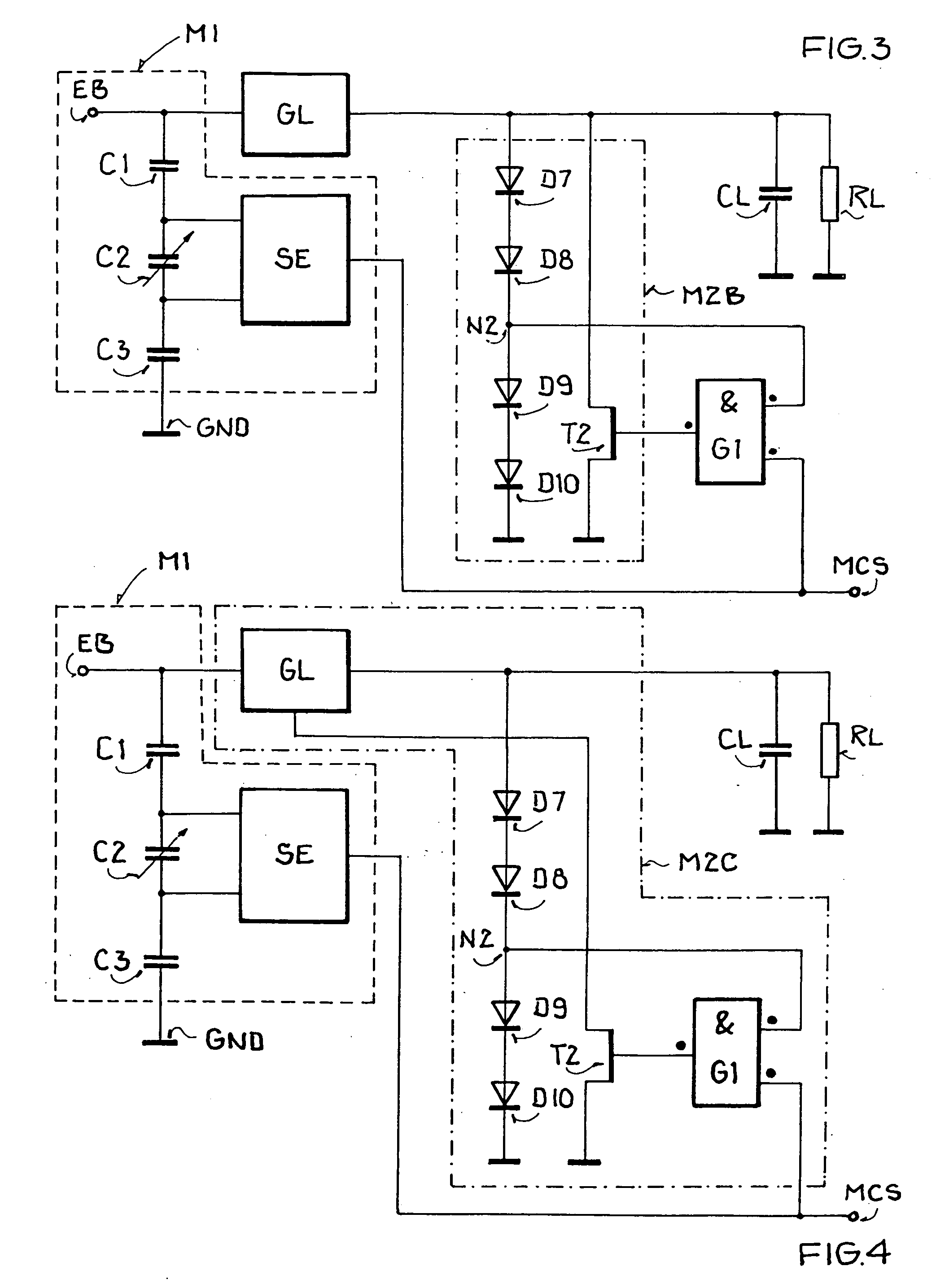

Receiving/backscattering arrangement and method with two modulation modes for wireless data transmission as well as modulation arrangement therefor

ActiveUS20040145452A1Guaranteed uptimeEfficient amplitude shiftSimultaneous amplitude and angle modulationElectric signal transmission systemsVoltage multiplierMethod selection

For transmitting data, a receiving / backscattering arrangement receives, modulates and reflects or backscatters electromagnetic waves emitted by a base station. The modulation corresponds to the data to be transmitted and is carried out selectively using first and / or second different modulation methods depending on the received field strength of the received electromagnetic waves. Preferably, phase shift keying is used especially or at least at low field strengths at far range, while amplitude shift keying is used additionally or alternatively for high field strengths at close range. The two modulation methods can be superimposed. A circuit arrangement includes two different modulator arrangements to perform the two modulation methods depending on the received field strength. The second modulator arrangement preferably comprises a multi-stage voltage multiplier circuit with a modulated switching device intervening in one of the stages to achieve the modulation.

Owner:ATMEL GERMANY +1

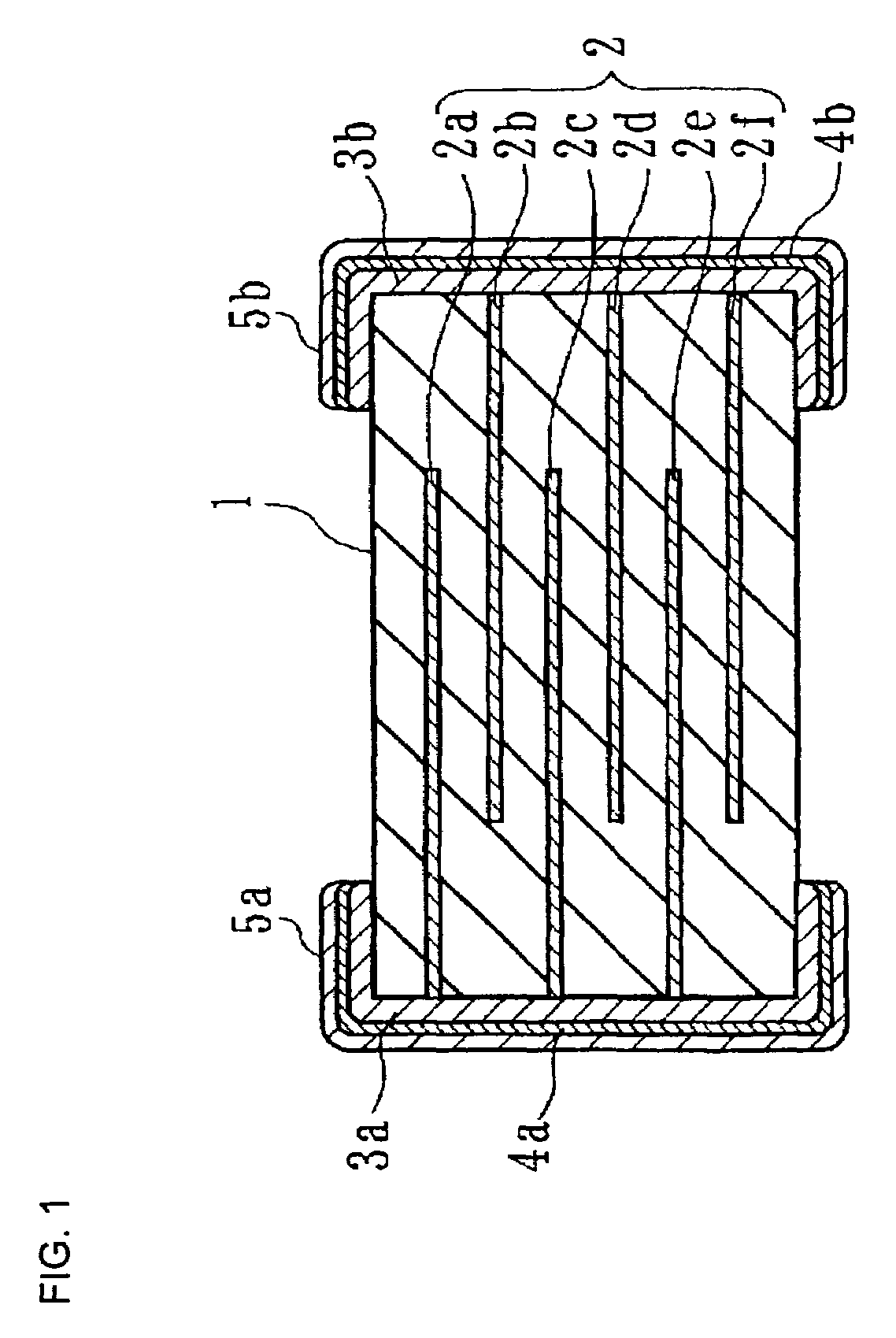

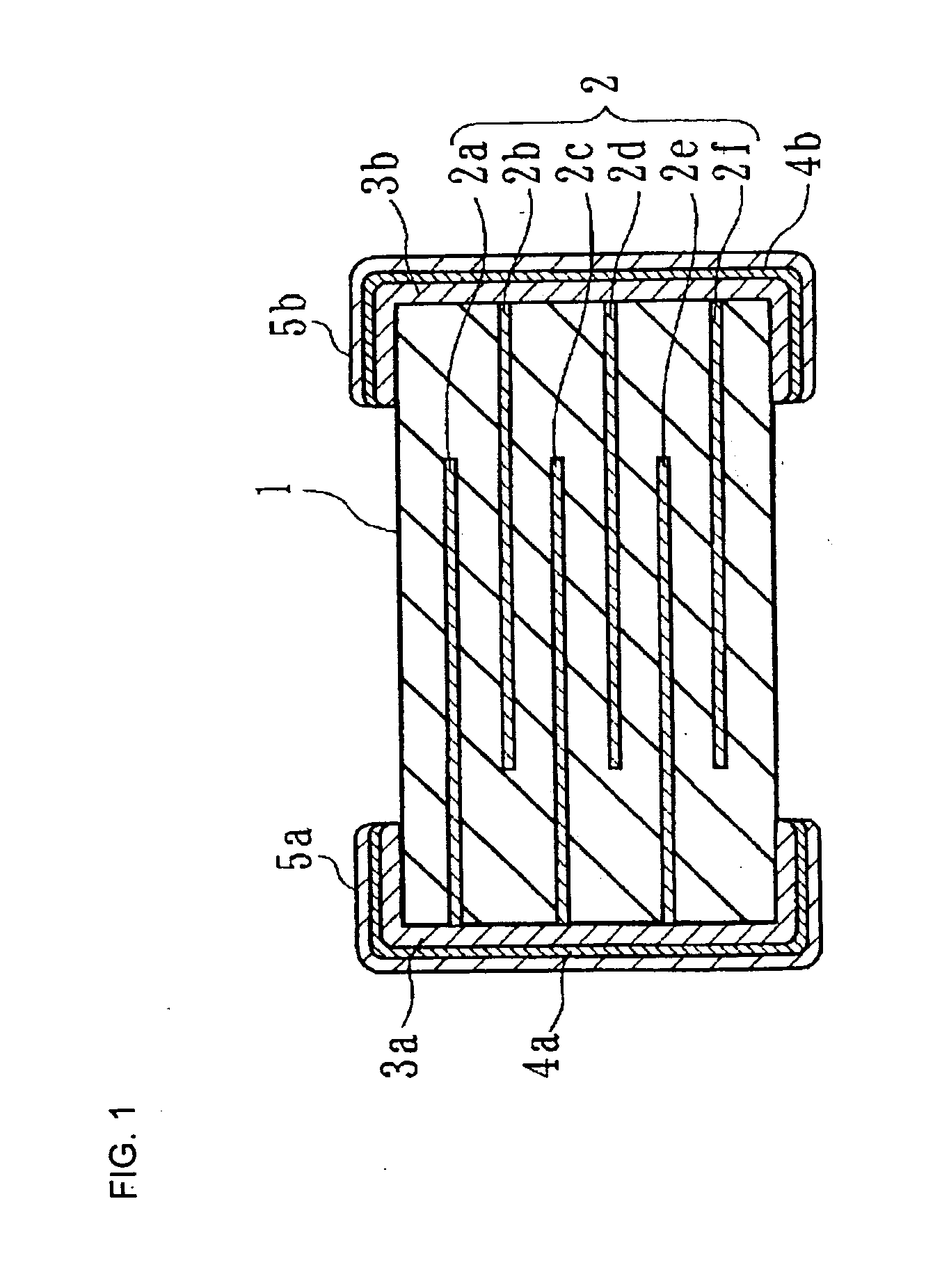

Dielectric ceramic and monolithic ceramic capacitor

ActiveUS7273825B2Prolong lifeMaintain good propertiesLayered productsFixed capacitor dielectricRare-earth elementCeramic capacitor

The dielectric ceramic has a composition represented by general formula 100(Ba1-x-ySrxCay)m(Ti1-zZrz)O3+aBaO+bR2O3+cMgO+dMnO+eCuO+fV2O5+gXuOv (where R is a rare-earth element such as La, Ce or Pr; and XuOv is an oxide group including at least Si); and 0≦x≦0.05, 0≦y≦0.08 (preferably 0.02≦y≦0.08), 0≦z≦0.05, 0.990≦m, 100.2≦(100 m+a)≦102, 0.05≦b≦0.5, 0.05≦c≦2, 0.05≦d≦1.3, 0.1≦e≦1.0, 0.02≦f≦0.15, and 0.2≦g≦2. With this composition, a monolithic ceramic capacitor retaining good dielectric characteristics and temperature characteristics even if a high field strength voltage is applied by further thinning the dielectric layers thereof and having excellent reliability achieving good isolating property, dielectric strength, and high-temperature load life is obtained.

Owner:MURATA MFG CO LTD

Receiving/backscattering arrangement and method with two modulation modes for wireless data transmission as well as modulation arrangement therefor

ActiveUS7151436B2Guaranteed uptimeEfficient amplitude shiftSimultaneous amplitude and angle modulationElectric signal transmission systemsVoltage multiplierMethod selection

For transmitting data, a receiving / backscattering arrangement receives, modulates and reflects or backscatters electromagnetic waves emitted by a base station. The modulation corresponds to the data to be transmitted and is carried out selectively using first and / or second different modulation methods depending on the received field strength of the received electromagnetic waves. Preferably, phase shift keying is used especially or at least at low field strengths at far range, while amplitude shift keying is used additionally or alternatively for high field strengths at close range. The two modulation methods can be superimposed. A circuit arrangement includes two different modulator arrangements to perform the two modulation methods depending on the received field strength. The second modulator arrangement preferably comprises a multi-stage voltage multiplier circuit with a modulated switching device intervening in one of the stages to achieve the modulation.

Owner:ATMEL GERMANY +1

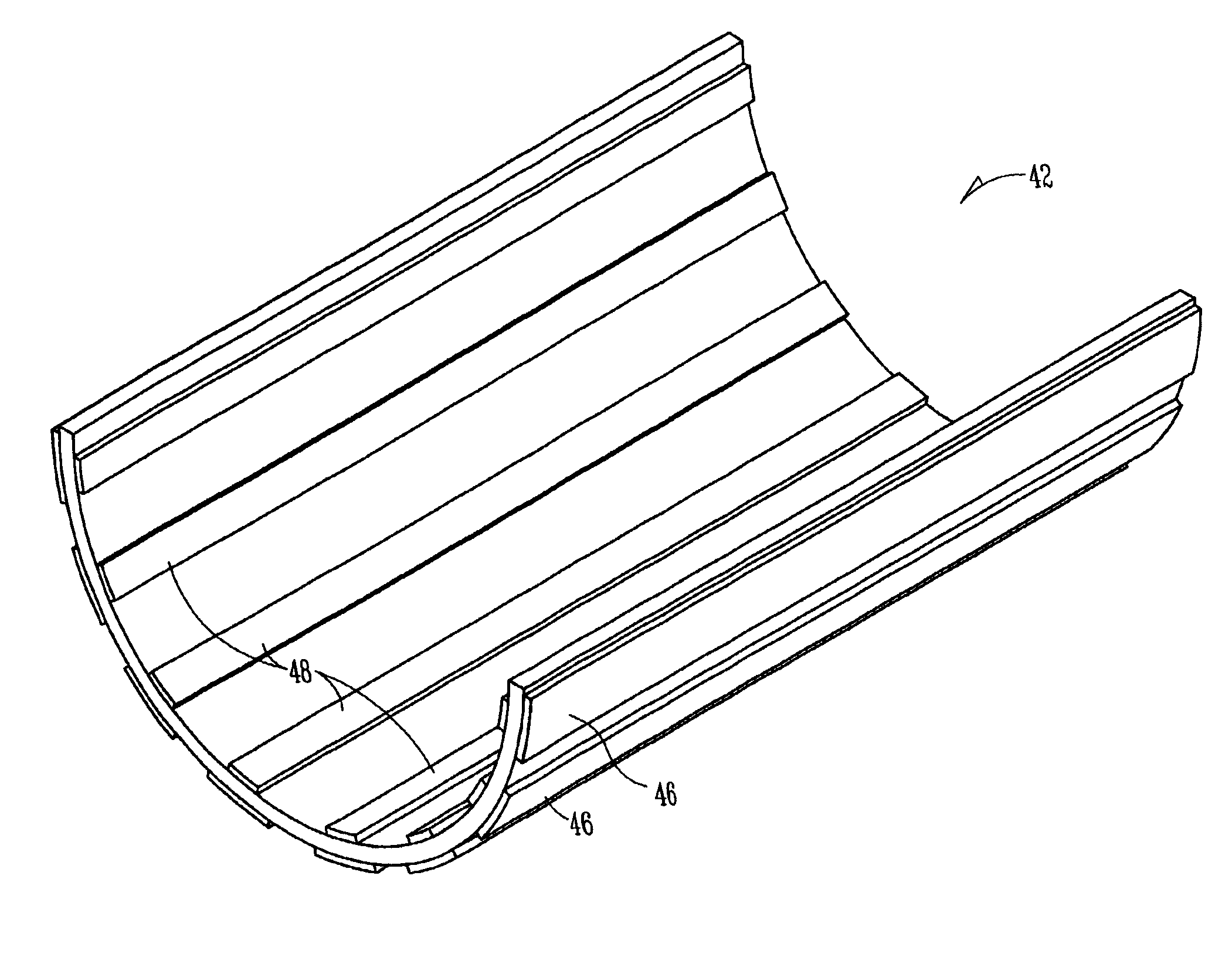

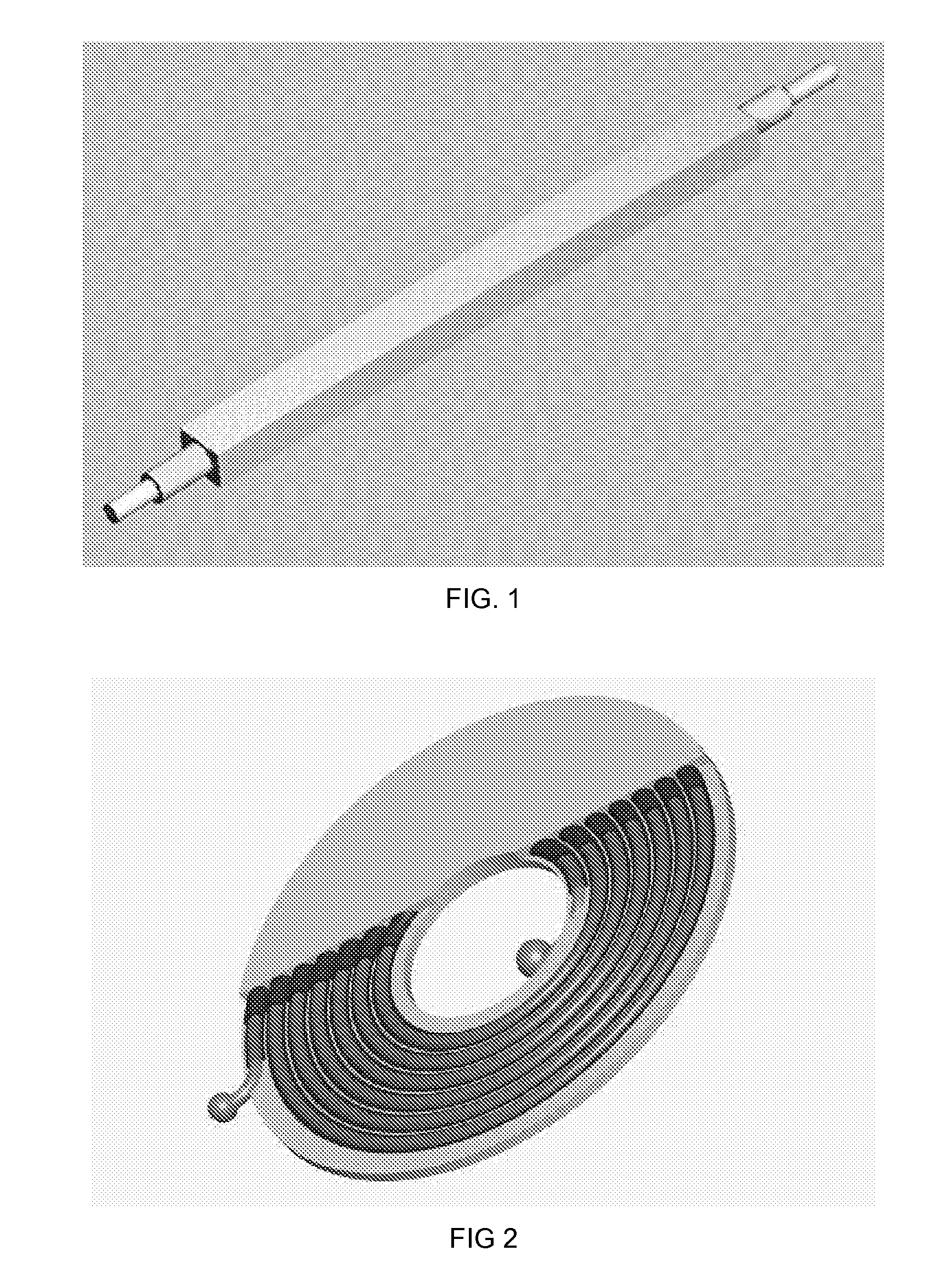

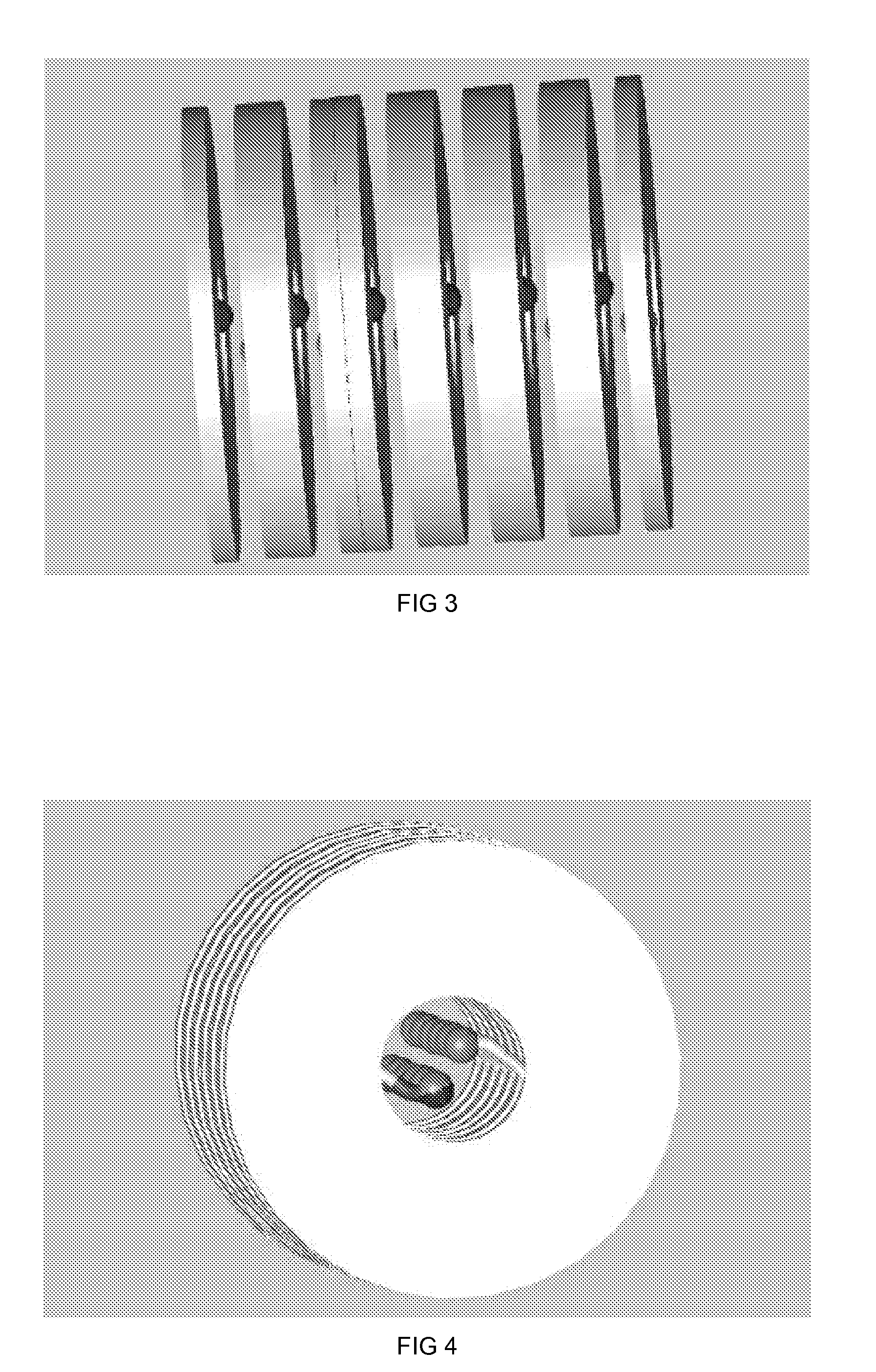

Coiled Transmission Line Pulse Generators

InactiveUS20080284276A1Increase pulse repetition rate capabilityImprove reliabilityMaterial nanotechnologyElectrostatic generators/motorsDielectricTransformer

Methods and apparatus are provided for fabricating and constructing solid dielectric “Coiled Transmission Line” pulse generators in radial or axial coiled geometries. The pour and cure fabrication process enables a wide variety of geometries and form factors. The volume between the conductors is filled with liquid blends of polymers and dielectric powders; and then cured to form high field strength and high dielectric constant solid dielectric transmission lines that intrinsically produce ideal rectangular high voltage pulses. Voltage levels may be increased by Marx and / or Blumlein principles incorporating spark gap or, preferentially, solid state switches (such as optically triggered thyristors) which produce reliable, high repetition rate operation. Moreover, these pulse generators can be DC charged and do not require additional pulse forming circuitry, pulse forming lines, transformers, or an output switch. The apparatus accommodates a wide range of voltages, impedances, pulse durations, pulse repetition rates, and duty cycles. The resulting mobile or flight platform friendly cylindrical geometric configuration is much more compact, light-weight, and robust than conventional linear geometries, or pulse generators constructed from conventional components. Installing additional circuitry may accommodate optional pulse shape improvements. The Coiled Transmission Lines can also be connected in parallel to decrease the impedance, or in series to increase the pulse length.

Owner:SCI ENG SOLUTIONS

Dielectric ceramic and monolithic ceramic capacitor

ActiveUS20070142210A1Good isolation propertiesHigh dielectric strengthLayered productsFixed capacitor dielectricRare-earth elementCeramic capacitor

The dielectric ceramic has a composition represented by general formula 100(Ba1-x-ySrxCay)m(Ti1-zZrz)O3+aBaO+bR2O3+cMgO+dMnO+eCuO+fV2O5+gXuOv (where R is a rare-earth element such as La, Ce or Pr; and XuOv is an oxide group including at least Si); and 0≦x≦0.05, 0≦y≦0.08 (preferably 0.02≦y≦0.08), 0≦z≦0.05, 0.990≦m, 100.2≦(100 m+a)≦102, 0.05≦b≦0.5, 0.05≦c≦2, 0.05≦d≦1.3, 0.1≦e≦1.0, 0.02≦f≦0.15, and 0.2≦g≦2. With this composition, a monolithic ceramic capacitor retaining good dielectric characteristics and temperature characteristics even if a high field strength voltage is applied by further thinning the dielectric layers thereof and having excellent reliability achieving good isolating property, dielectric strength, and high-temperature load life is obtained.

Owner:MURATA MFG CO LTD

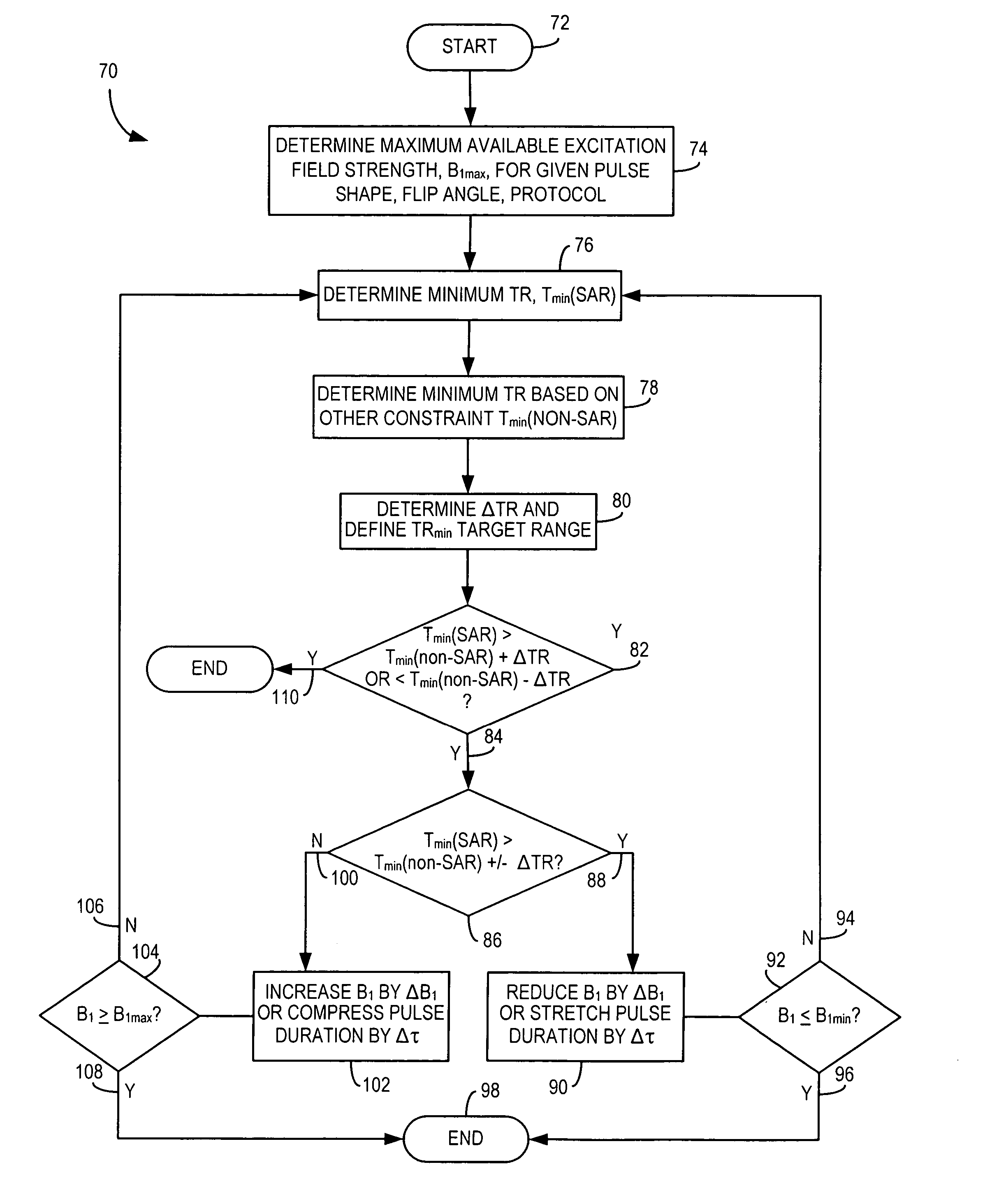

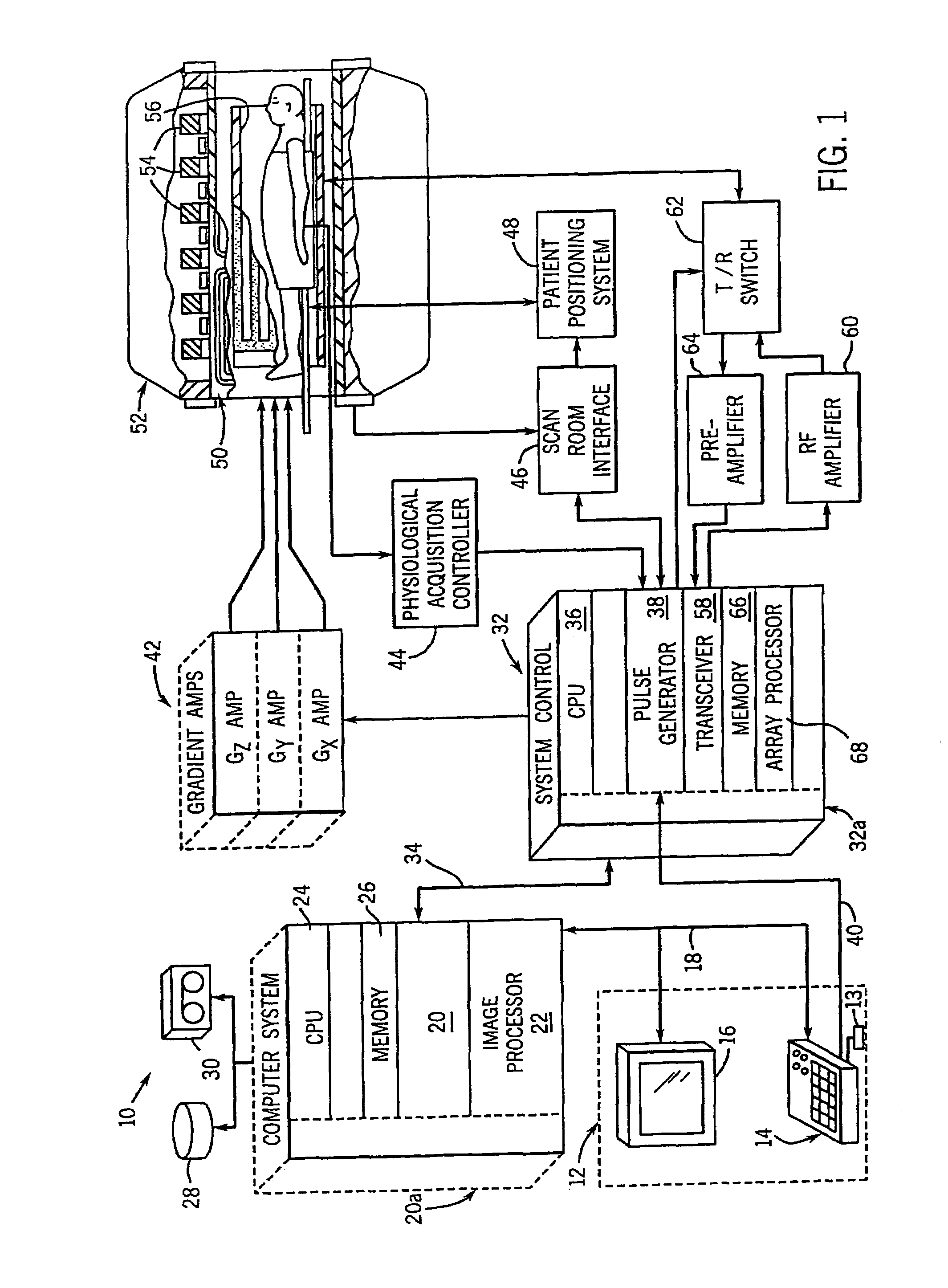

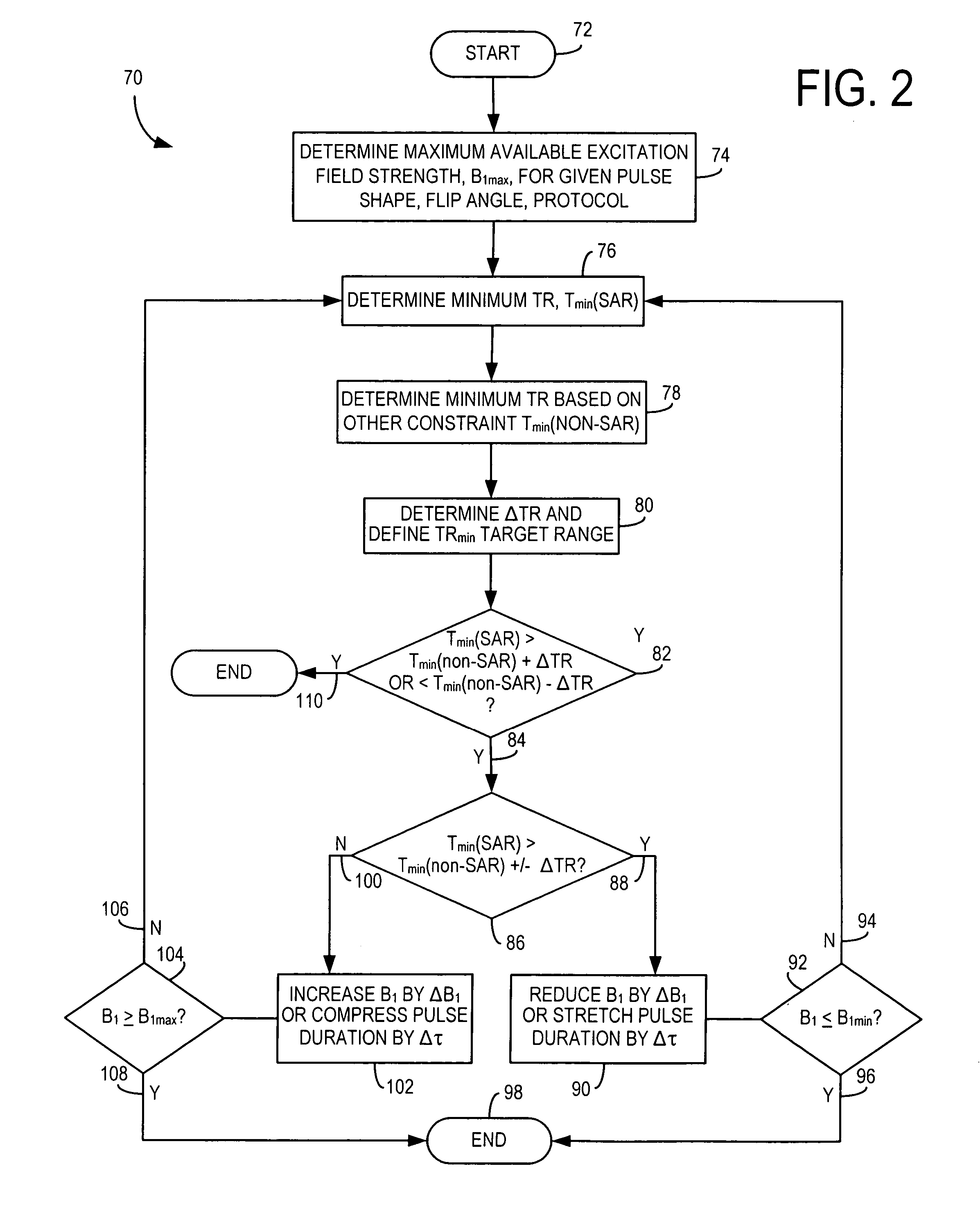

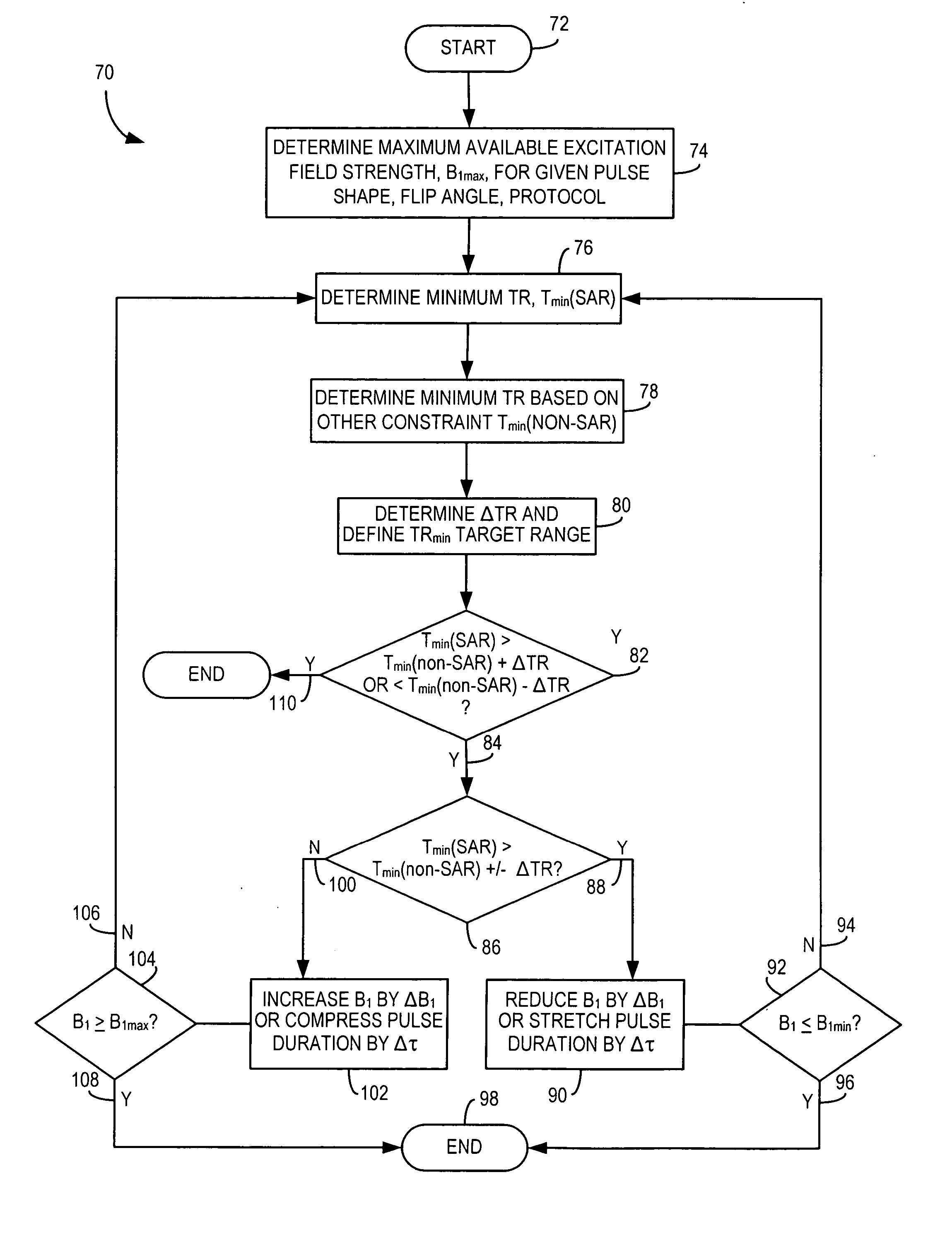

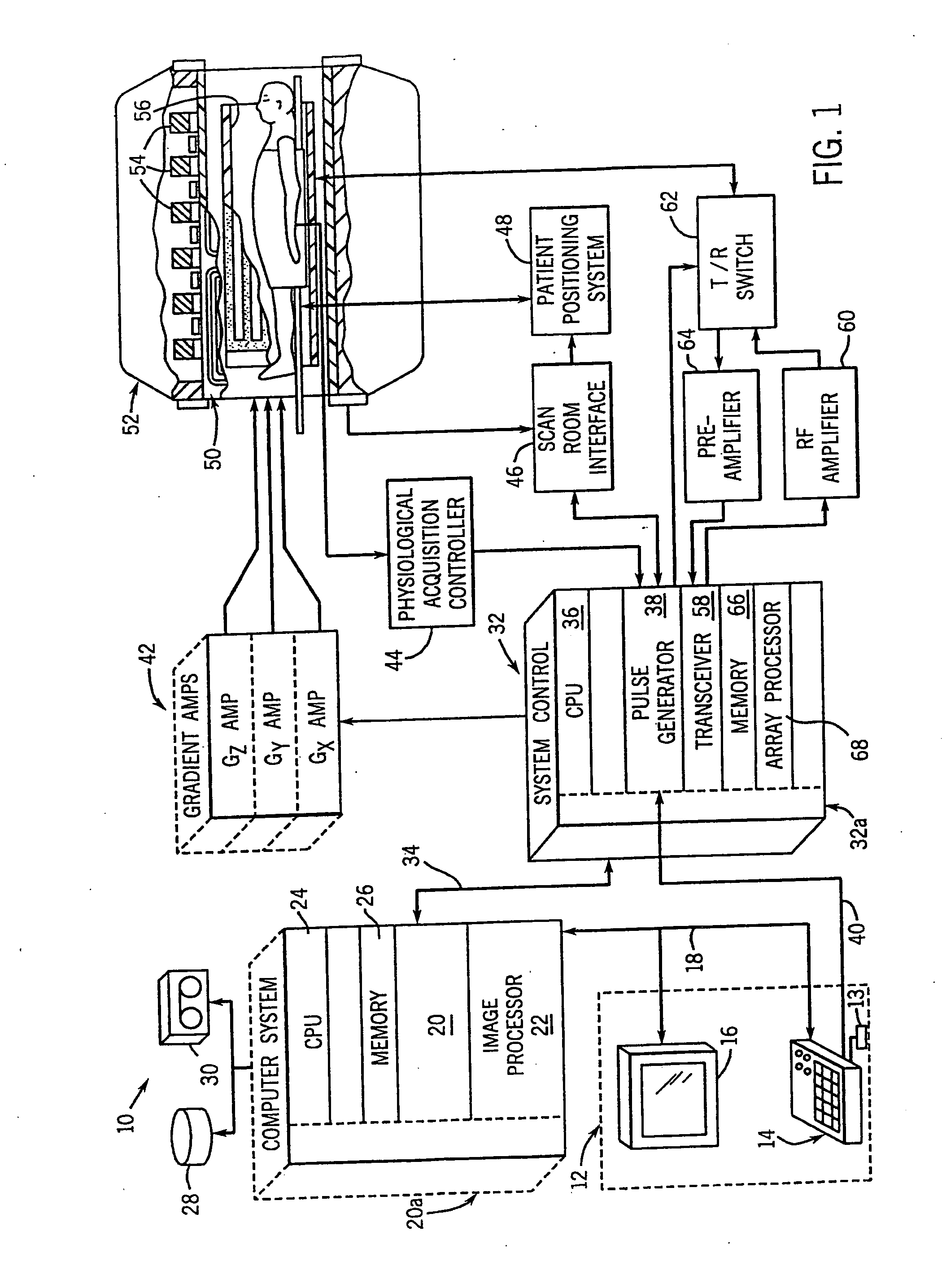

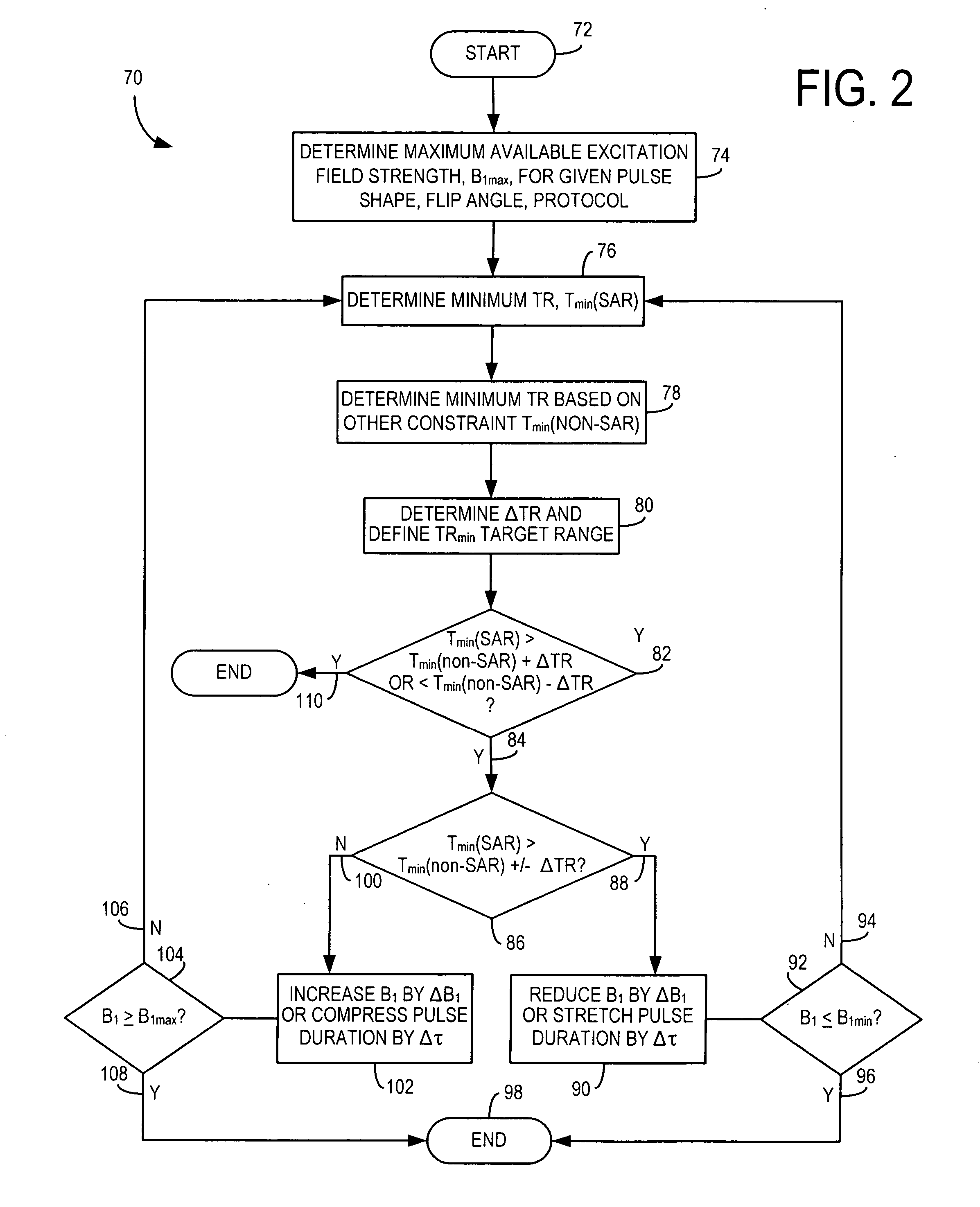

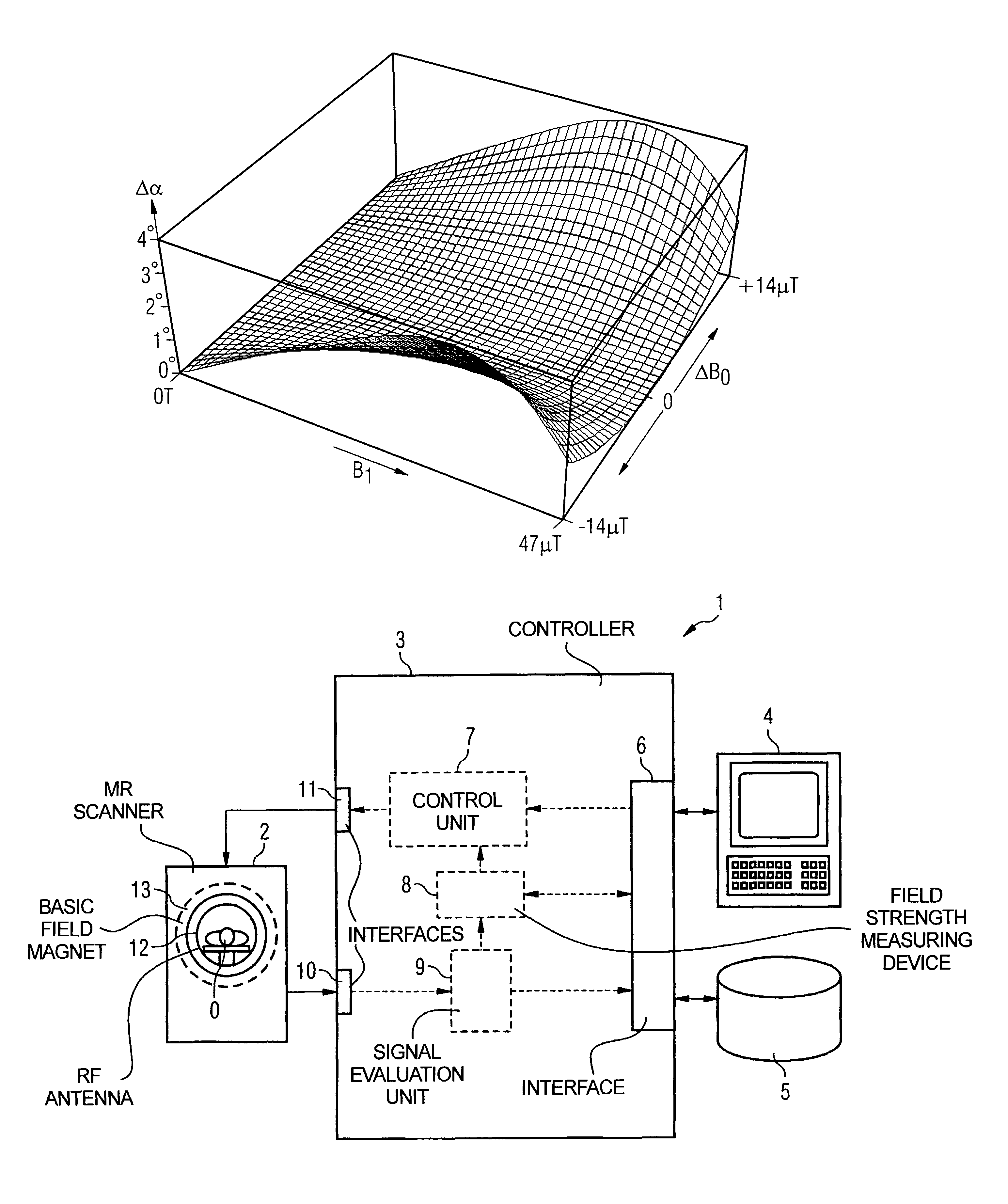

Method and system of determining parameters for MR data acquisition with real-time B1 optimization

ActiveUS7078900B2High resolutionFast and simple and effectiveMagnetic measurementsElectric/magnetic detectionData acquisitionPulse sequence

The present invention provides a system and method of MR scan prescription to achieve in a fast, simple, and effective manner the optimal peak excitation field strength for a given pulse shape and flip angle such that the minimum TR for the MR scan can be optimized and based on SAR constraints. The present invention provides a technique to obtain optimal B1 parameters for an arbitrary shape and flip angle of an excitation pulse in real-time while satisfying SAR and / or RF hardware limits to determine the minimum achievable repetition time for a pulse sequence. The present invention is particularly applicable with breath-hold and cardiac imaging techniques that are carried out at relatively high field strengths.

Owner:GENERAL ELECTRIC CO

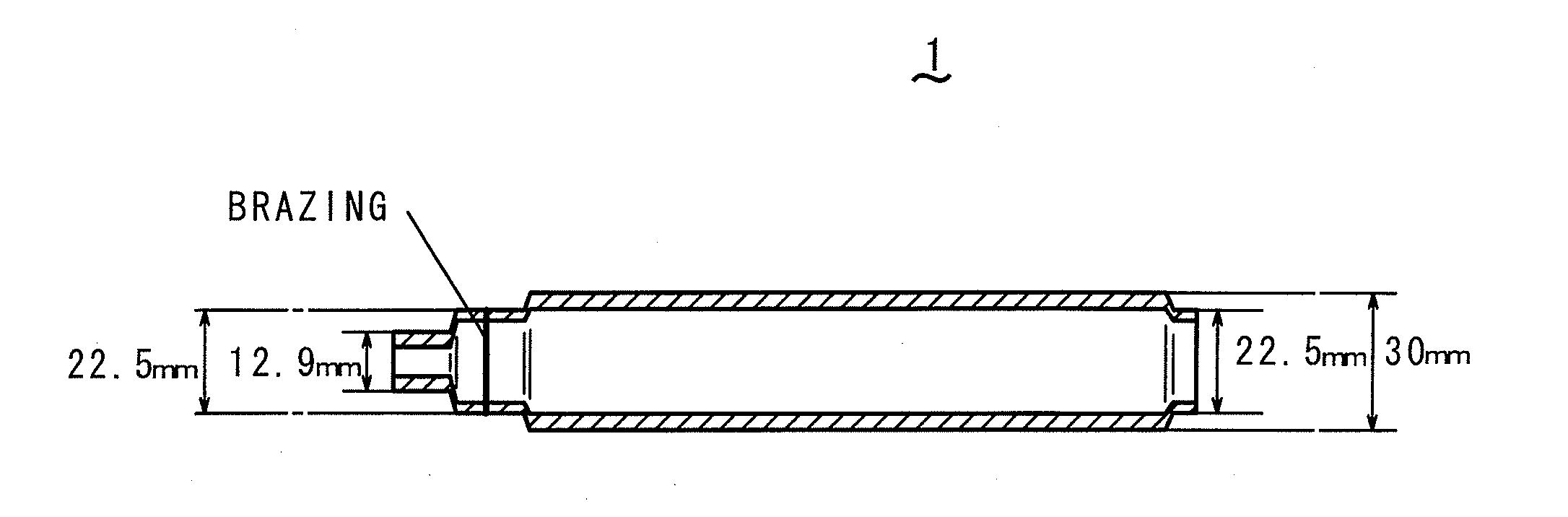

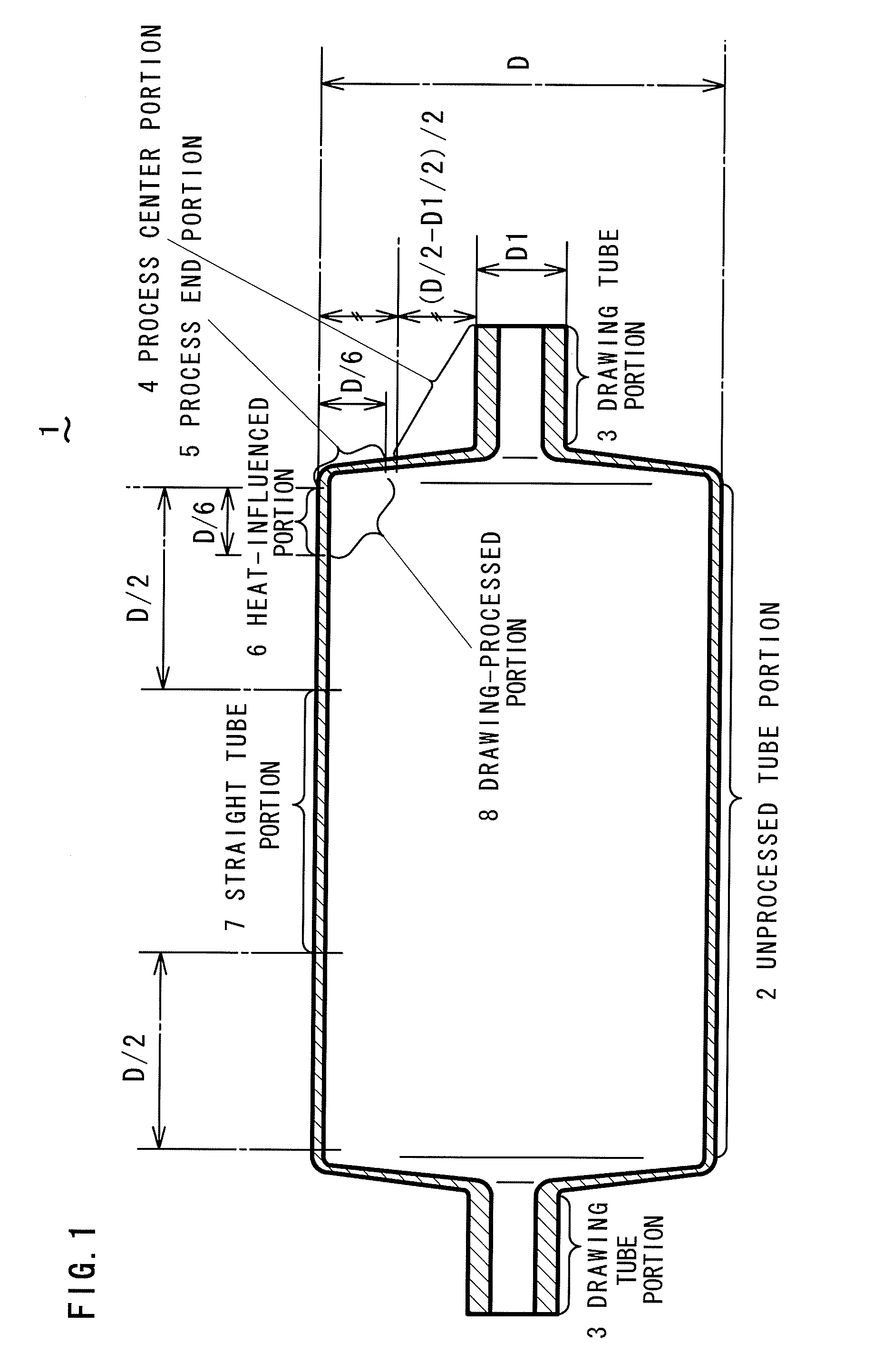

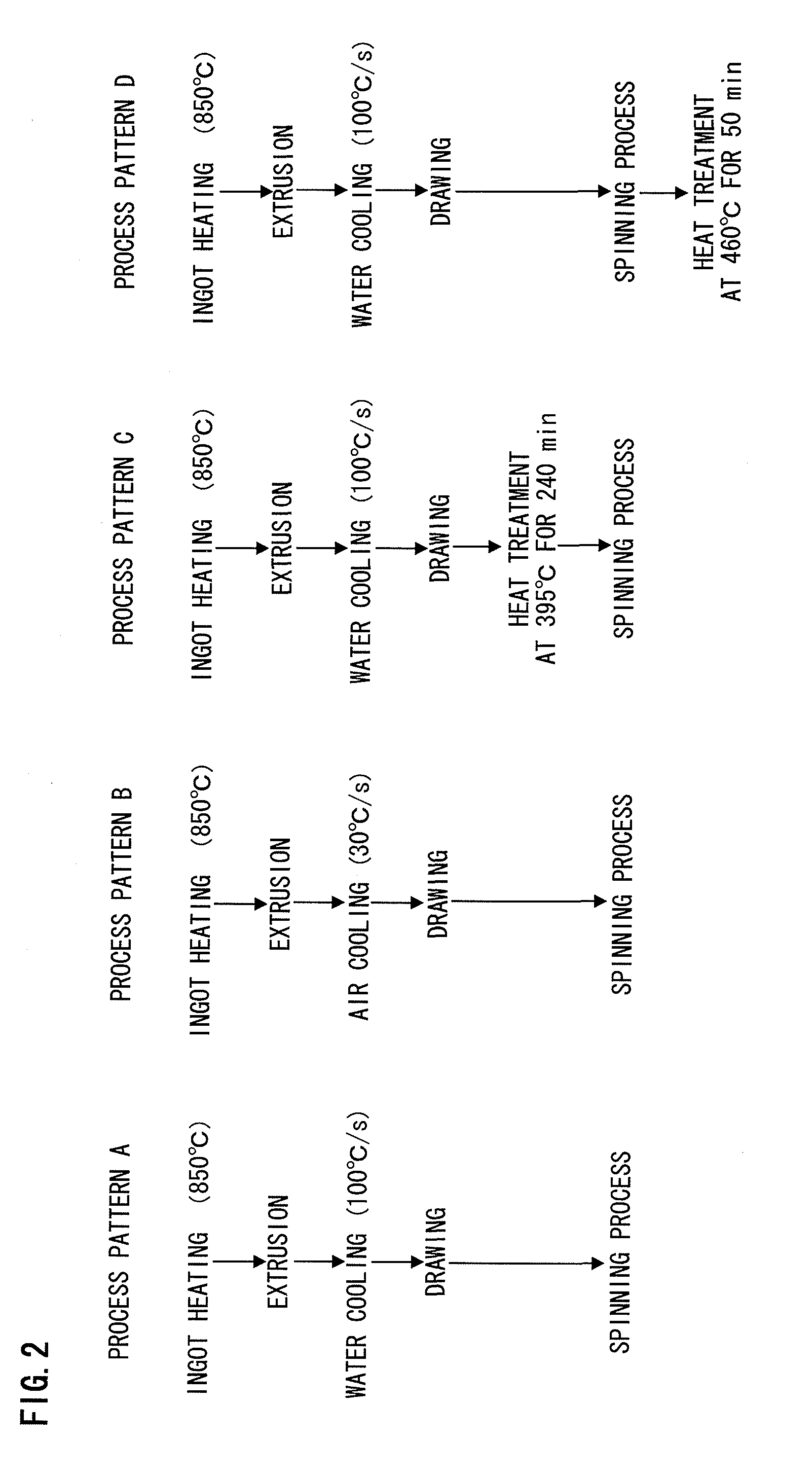

High strength and high thermal conductivity copper alloy tube and method for producing the same

ActiveUS20110056596A1High strengthMaintain strengthHeat exchange apparatusThin material handlingHeat resistanceHigh intensity

A high strength and high thermal conductivity copper alloy tube contains: Co of 0.12 to 0.32 mass %; P of 0.042 to 0.095 mass %; and Sn of 0.005 to 0.30 mass %, wherein a relationship of 3.0≦([Co]−0.007) / ([P]−0.008)≦6.2 is satisfied between a content [Co] mass % of Co and a content [P] mass % of P, and the remainder includes Cu and inevitable impurities. Even when a temperature is increased by heat generated by a drawing process, a recrystallization temperature is increased by uniform precipitation of a compound of Co and P and by solid-solution of Sn. Thus, the generation of recrystallization nucleuses is delayed, thereby improving heat resistance and pressure resistance of the high strength and high thermal conductivity copper alloy tube.

Owner:MITSUBISHI SHINDOH CO LTD

Method and system of determining parameters for MR data acquisition with real-time B1 optimization

ActiveUS20060017437A1Optimal peak excitation field strengthHigh resolutionMagnetic measurementsElectric/magnetic detectionData acquisitionPeak value

The present invention provides a system and method of MR scan prescription to achieve in a fast, simple, and effective manner the optimal peak excitation field strength for a given pulse shape and flip angle such that the minimum TR for the MR scan can be optimized and based on SAR constraints. The present invention provides a technique to obtain optimal B1 parameters for an arbitrary shape and flip angle of an excitation pulse in real-time while satisfying SAR and / or RF hardware limits to determine the minimum achievable repetition time for a pulse sequence. The present invention is particularly applicable with breath-hold and cardiac imaging techniques that are carried out at relatively high field strengths.

Owner:GENERAL ELECTRIC CO

Brazed aluminum alloy foil with high strength and high corrosion resistance and manufacturing method thereof

InactiveCN101724770AEasy to processImprove corrosion resistanceRoll force/gap control deviceTemperature control deviceHigh intensityImpurity

The invention relates to a brazed aluminum alloy foil with high strength and high corrosion resistance and a manufacturing method thereof. The brazed aluminum alloy foil comprises the following chemical ingredients in percentage by weight: 1.00-1.80 percent of Mn, 0.40-1.20 percent of Si, 0.50-1.30 percent of Fe, 0.10-0.50 percent of V, 0.05-0.25 percent of Cr, 0.06-0.25 percent of Zr, 0.08-0.30 percent of Ti, less than 0.03 percent of Cu, other added metals, and the balance of Al and unavoidable impurities. The ingredient alloys have high strength, high corrosion resistance and favorable shaping property; according to an ASTMG85-A3 standard, the brazed aluminum alloy foil with the thickness of 0.08mm, rolled by the alloys, has the penetration resistance time of over 15 days under the test , the corrosion resistance of three times of that of a 3003 alloy, and the tensile strength improved more than 15 percent under the same state.

Owner:长沙众兴新材料科技有限公司

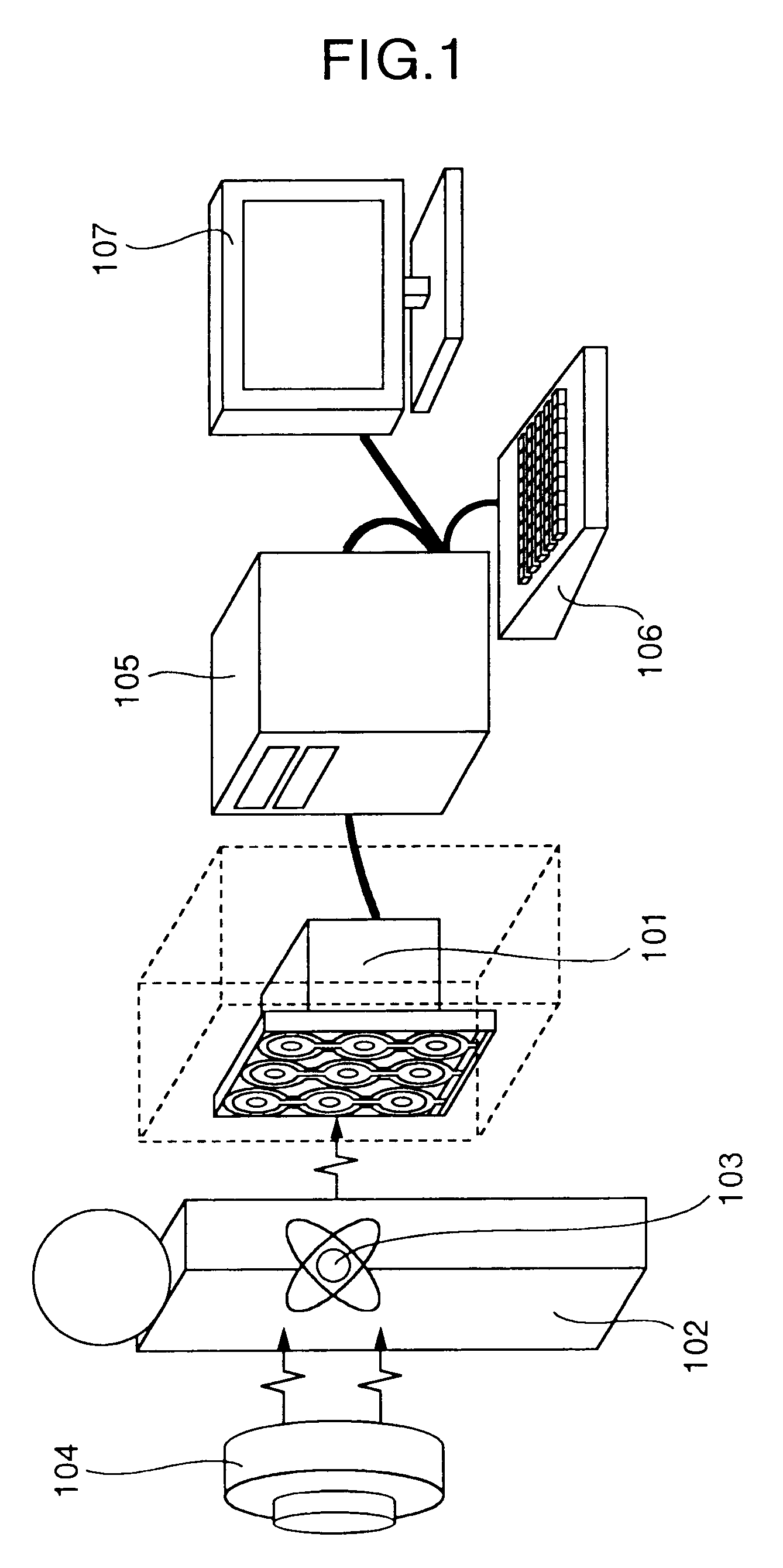

Radiation detector and radiation apparatus

InactiveUS20050098730A1Rapidly and efficiently collectSolve the low detection efficiencySolid-state devicesMaterial analysis by optical meansImage resolutionSemiconductor radiation detectors

A practical semiconductor radiation detector capable of collecting electrons rapidly with a large volume is disclosed. A multiple layers of grid electrodes around an anode formed on a semiconductor element limits the generation of the induced charge signal for the anode to the space in the neighborhood of the anode, while at the same time making it possible to collect the electrons rapidly. As a result of limiting the space for generating the induced charge by the grid electrodes, the energy resolution is improved even for a thick semiconductor element. Also, the capability of rapidly collecting the electrons due to the high field strength generated by the grid electrodes makes a sensitive volume of the whole semiconductor and thus achieves a high radiation detection efficiency.

Owner:HITACHI LTD

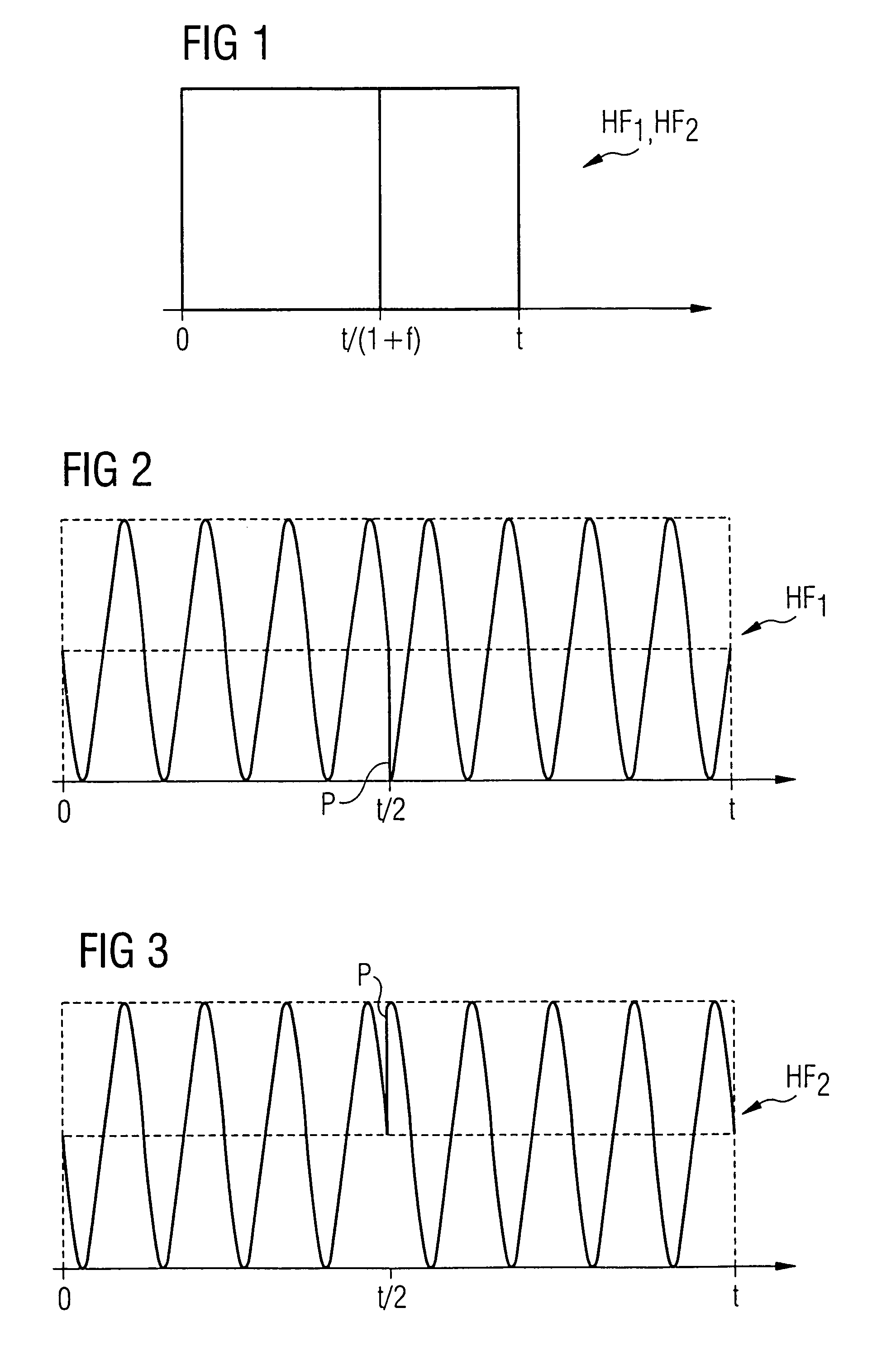

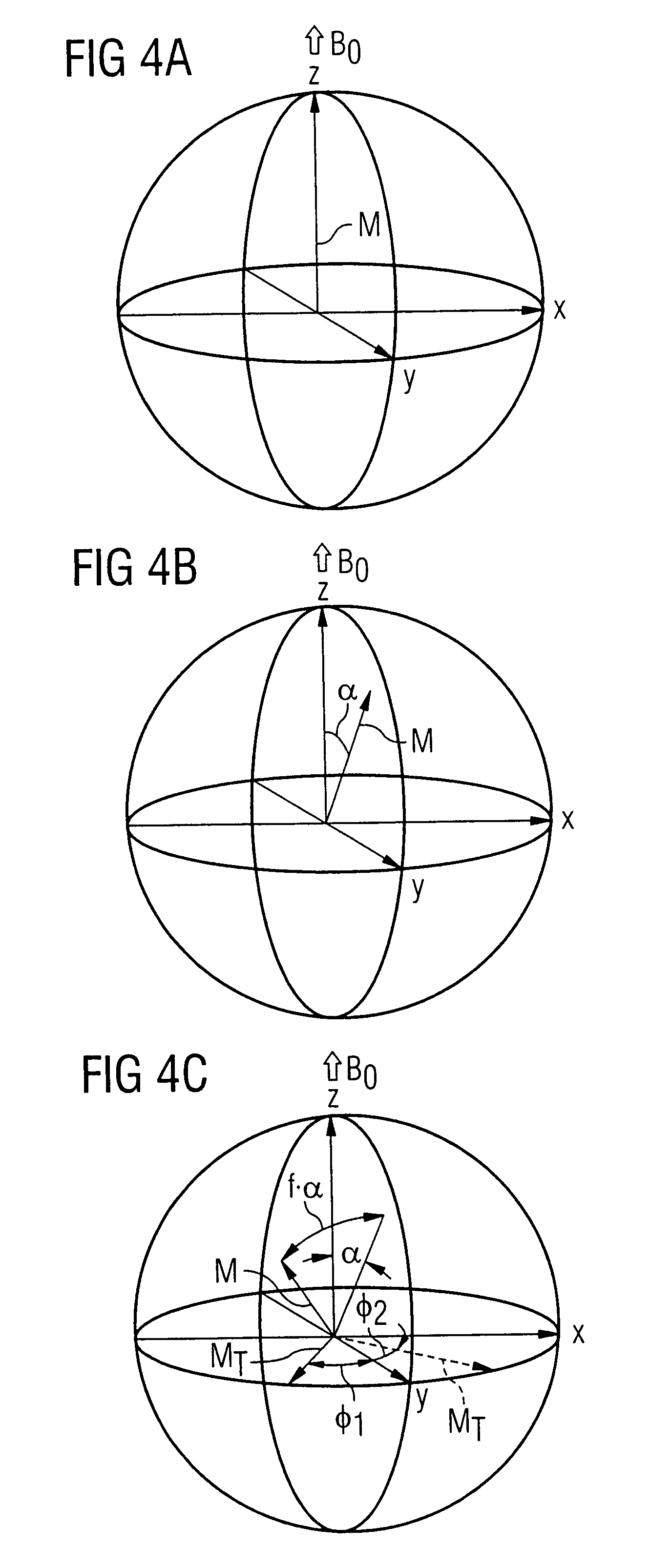

Method for determining the B1 field strength in MR measurements

ActiveUS7064546B2Rapid determinationMagnetic measurementsElectric/magnetic detectionResonance measurementTomography

In magnetic resonance tomography apparatus and method for determining the field strength of high-frequency pulses which are emitted during a magnetic resonance measurement by the antenna, a magnetic resonance signal excited by a radio-frequency pulse or a radio-frequency pulse sequence is measured, and a phase of the magnetic resonance signal is determined. Based on this phase, the field strength is then determined.

Owner:SIEMENS HEALTHCARE GMBH

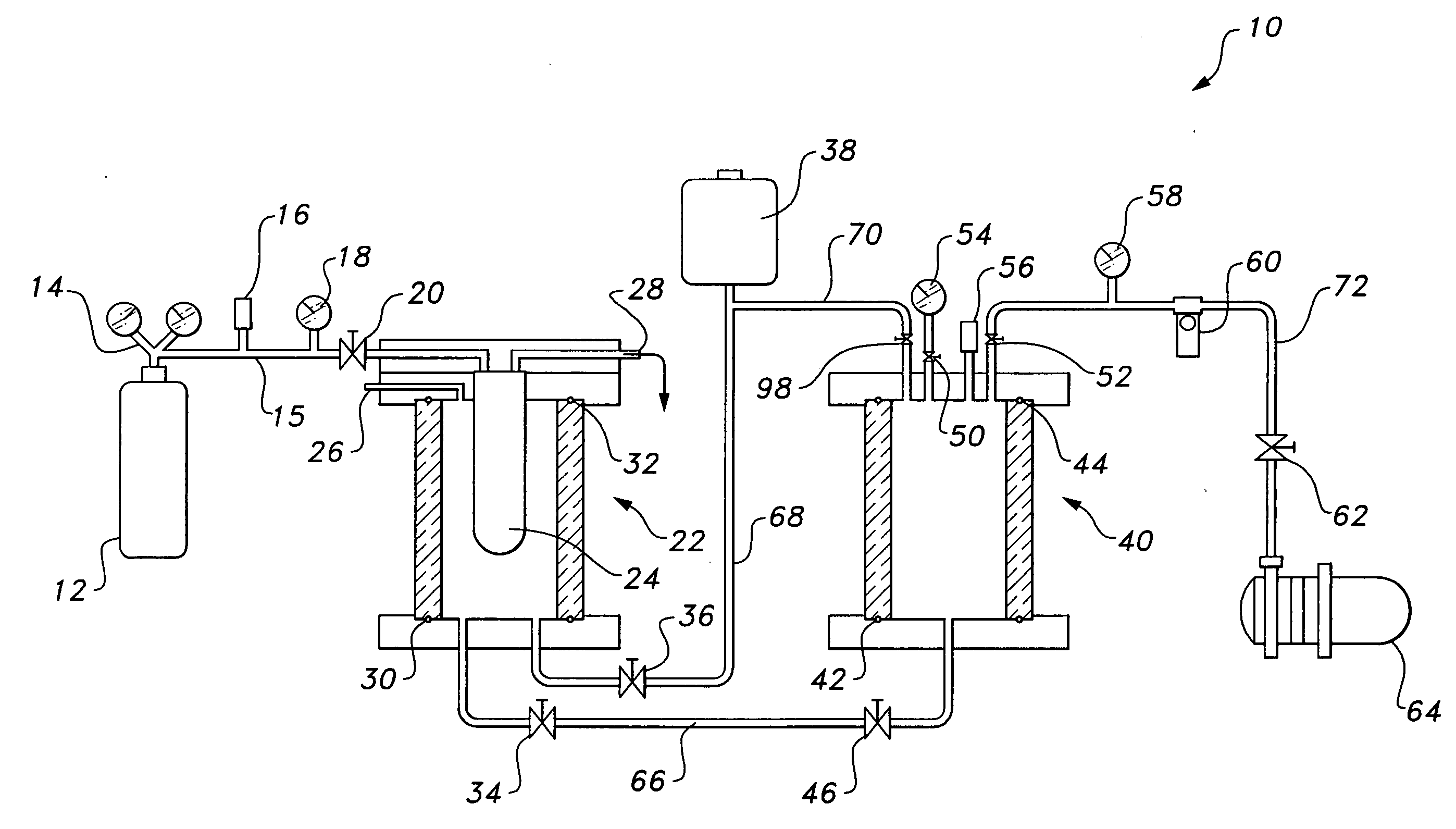

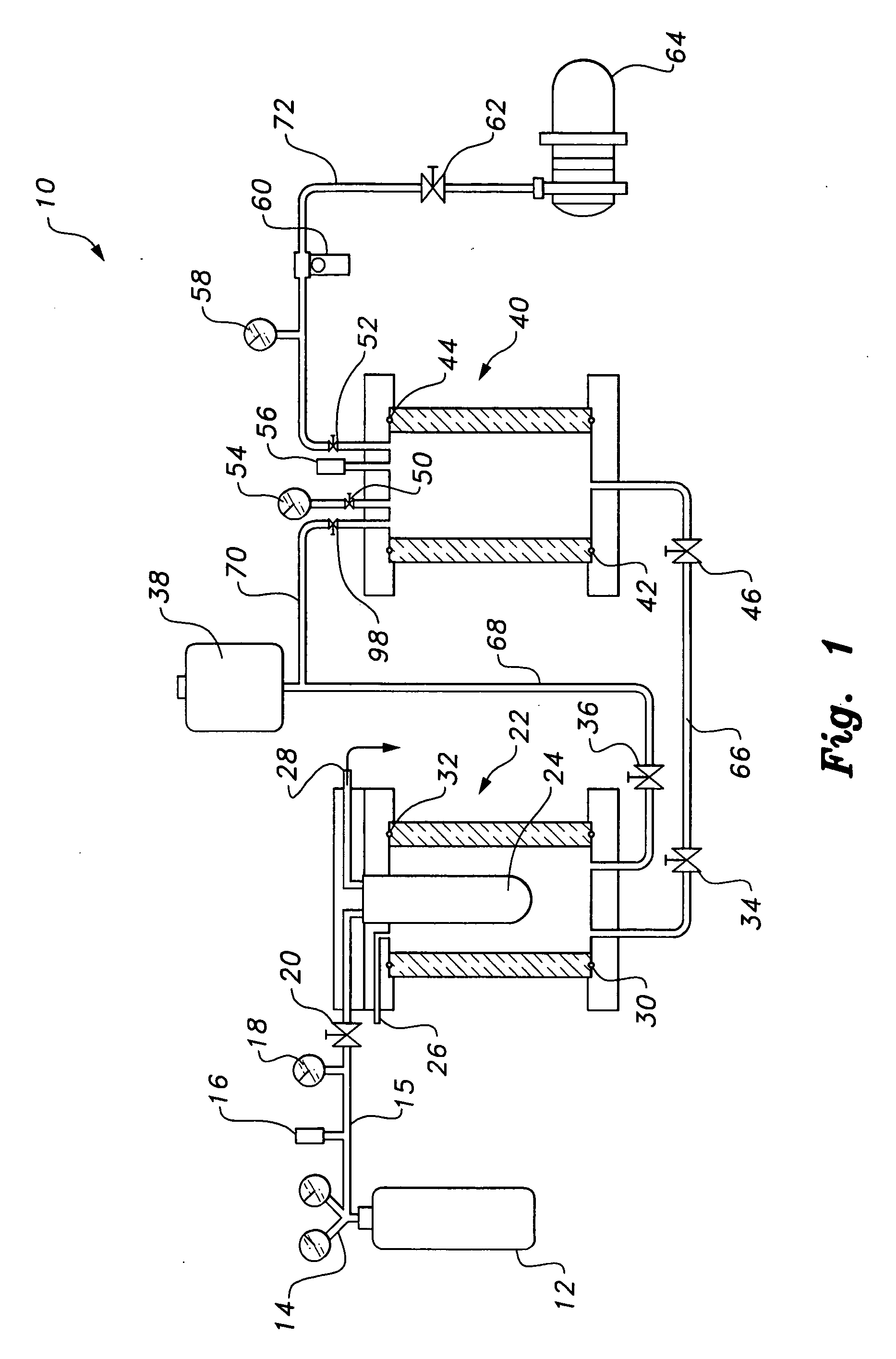

System and method for measuring porosity of high strength and high performance concrete using a vacuum-pressure saturation method

The method for measuring porosity of concrete is a vacuum pressure saturation-based method for calculating a porosity value of a sample of concrete. The method includes the steps of first drying a concrete sample and then making a first weight measurement of the concrete sample. Following the first weight measurement, the concrete sample is placed in a vacuum pressure vessel, where the sample is subjected to vacuum. The vacuum pressure vessel and a pressure cell are next filled with water. Water in the pressure cell and vacuum pressure vessel is pressurized, and the sample remains within the pressurized water for twenty-four hours. The sample remains submerged in the vacuum pressure vessel for another twenty-four hour period to achieve equilibrium. A second weight is then taken in the water, and a third weight measurement is taken in air. The porosity is calculated based upon the first, second and third weight measurements.

Owner:KING SAUD UNIVERSITY

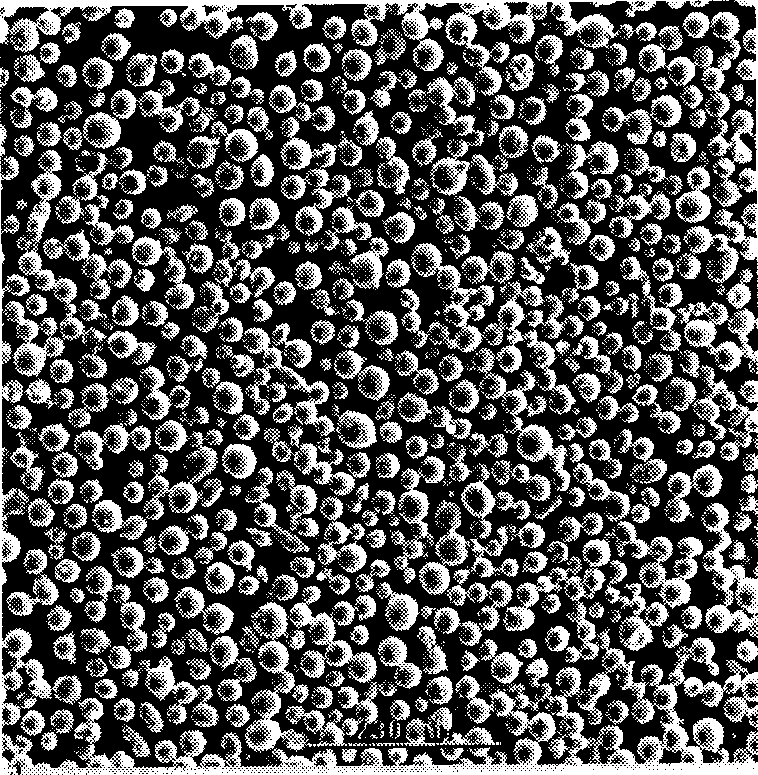

Powder catalyst for synthesizing high strength and excellent quality diamond with low prodn. cost

InactiveCN1903429AMany holesHigh activityUltra-high pressure processesMetal/metal-oxides/metal-hydroxide catalystsAlloyAdamite

A powdered catalyst for synthesizing high-strength and high-quality diamond with low cost contains proportionally Ni, Mn, C, N, O, one or more of Cr, Ce and Si, and Fe. The resultant diamond has high output rate, integrity, transparency and thermal stability.

Owner:石门县顺超科技发展有限公司

Non-magnetic high manganese steel sheet with high strength and manufacturing method thereof

InactiveUS20150211088A1Increased austenite stabilityHigh degreeFurnace typesHeat treatment furnacesHigh intensityNon magnetic

The present invention relates to a non-magnetic high manganese steel sheet with high-strength, which has superior strength and moldability, and at the same time, can obtain superior non-magnetic characteristics, and a method for manufacturing the same.

Owner:POHANG IRON & STEEL CO LTD

Method for producing high strength, high ductility steel strip

A method is provided for the manufacture of steel steel strip having high strength and high ductility. The method includes hot rolling steel consisting essentially of in weight percent C 0.05 / 0.20, Mn 3.0 / 8.0, Si less than 0.5, Al less than 0.1, the balance Fe and inevitable impurities at a minimum finishing temperature of Ar1+50 C, cooling the hot rolled steel strip at a rate sufficient to ensure that the microstructure of the strip consists of greater than 50 percent by volume of martensite, and then annealing the steel strip at a temperature within the range of Ac1 to Ac1+50° C. for a minimum time at temperature of one hour. The steel has a microstructure after annealing that consists essentially of ferrite and retained austenite.

Owner:USX CORP

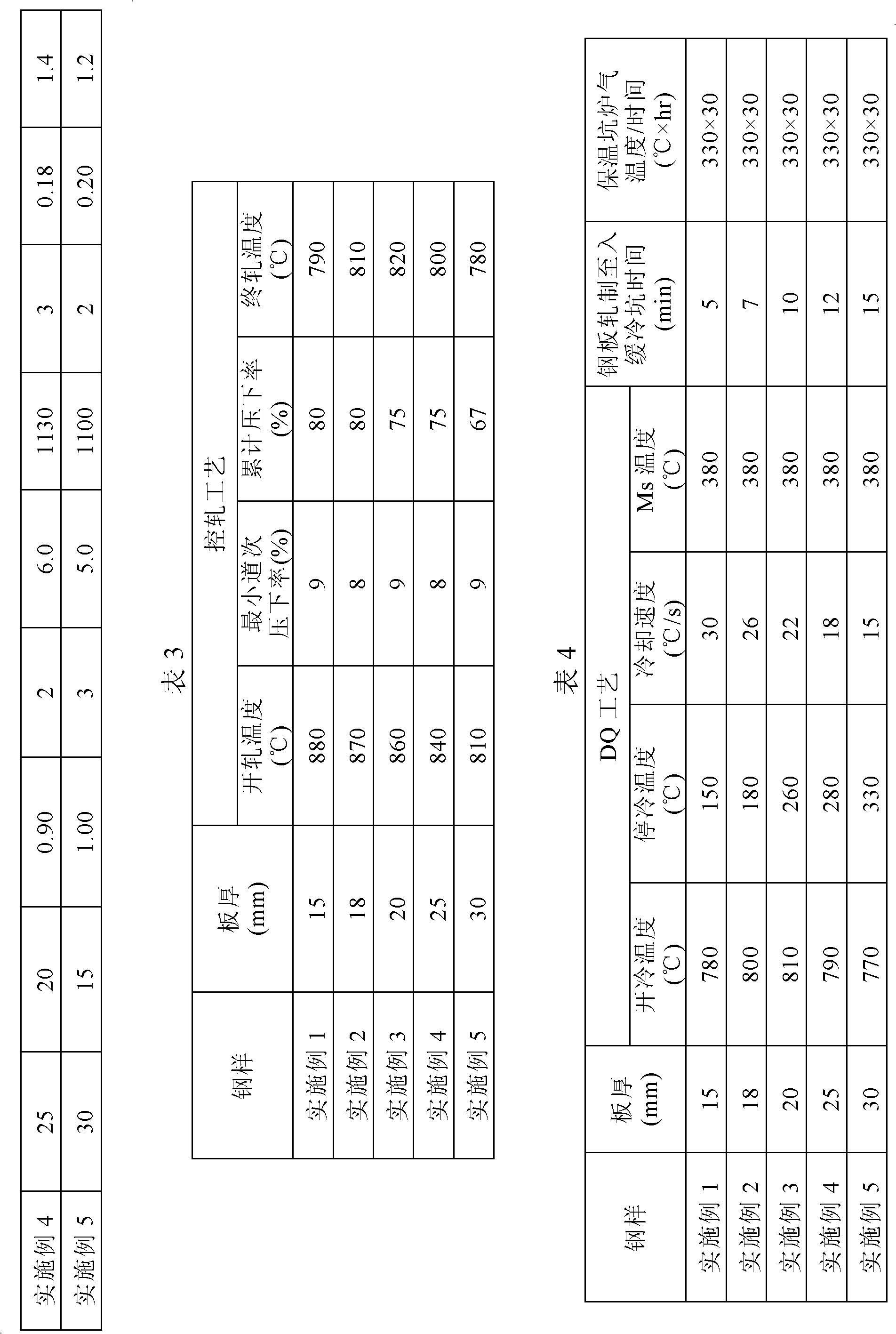

Steel with good property and ultra-high strength for engineering machinery and manufacturing method thereof

The invention discloses steel with good property and ultra-high strength for engineering machinery and a manufacturing method thereof. The steel comprises the following components by weight percent: 0.15 to 0.20 percent of C, 0.35 to 0.55 percent of Si, 0.95 to 1.35 percent of Mn, at most 0.013 percent of P, at most 0.0030 percent of S, 0.75 to 1.25 percent of Cr, 0.45 to 0.65 percent of Mo, 0.0010 to 0.0020 percent of B, 0.005 to 0.013 percent of Ti, 0.010 to 0.030 percent of Nb, 0.030 to 0.070 percent of Al, at most 0.0060 percent of N, at most 0.0030 percent of O, 0.001 to 0.004 percent of Ca, and Fe and inevitable impurities in balance. The invention optimizes the DQ and offline tempering process, adopts the ausforming process, ensures that the microscopic structure of finished steel plates becomes fine low-carbon tempered martensite and the average colony size is smaller than 20 micrometers, obtains ultra-high strength steel plates with good low-temperature flexibility, weldability and anti-delay cracks, solves the problem of overquenching of superficial layers of the ultra-high strength steel plates, and is particularly applicable to equipment manufacturing industries of large-scale engineering machinery and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

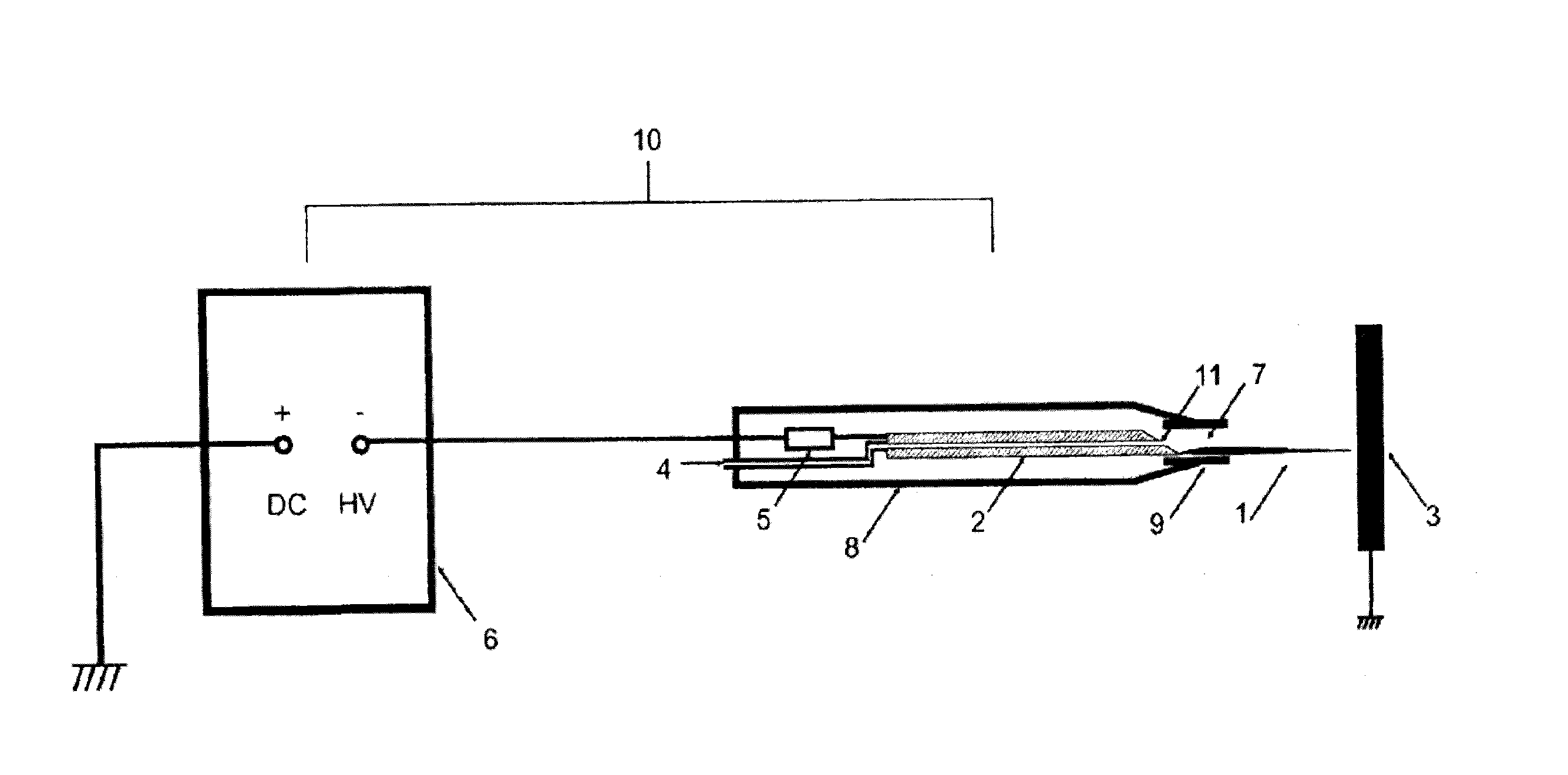

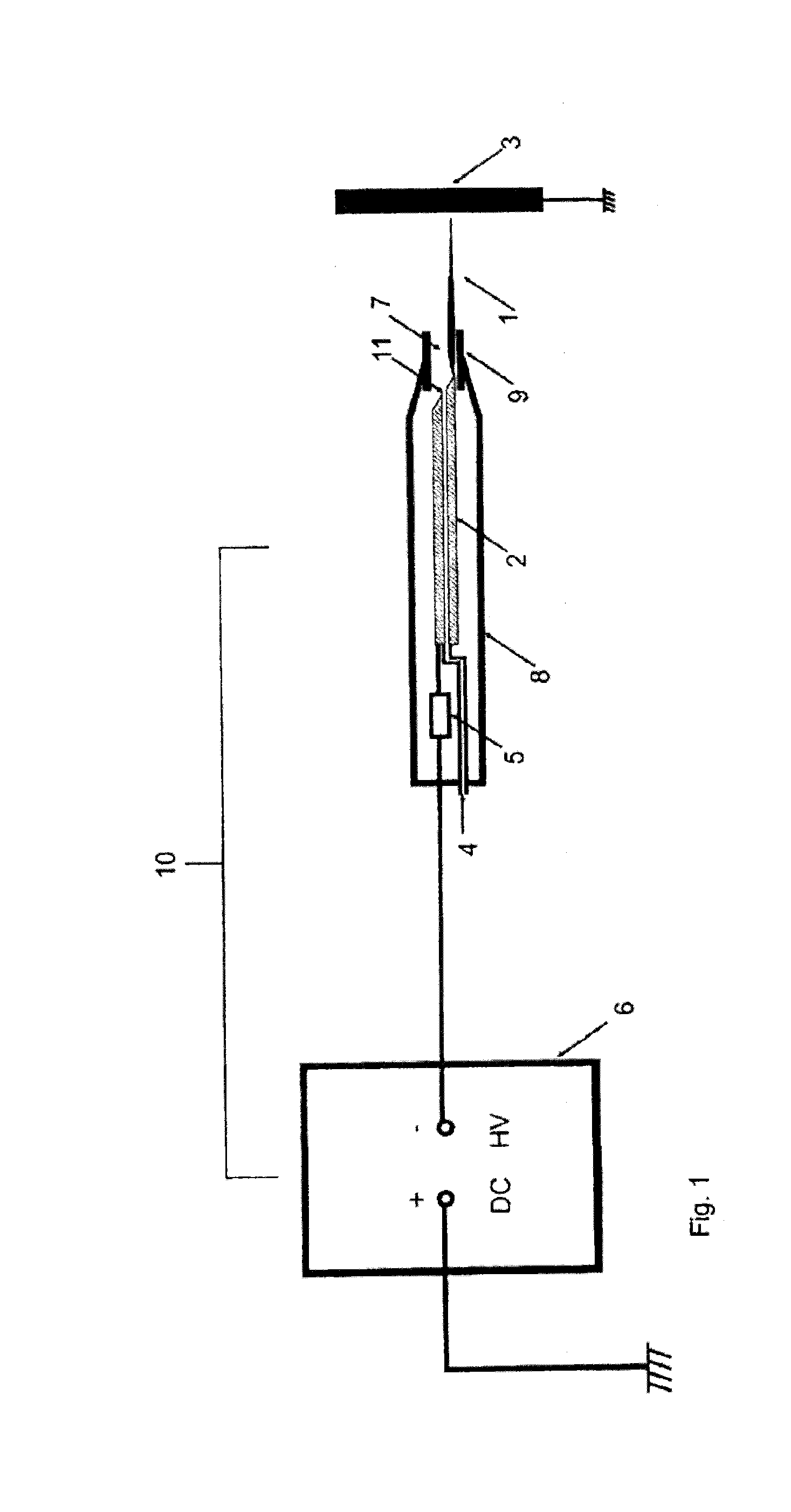

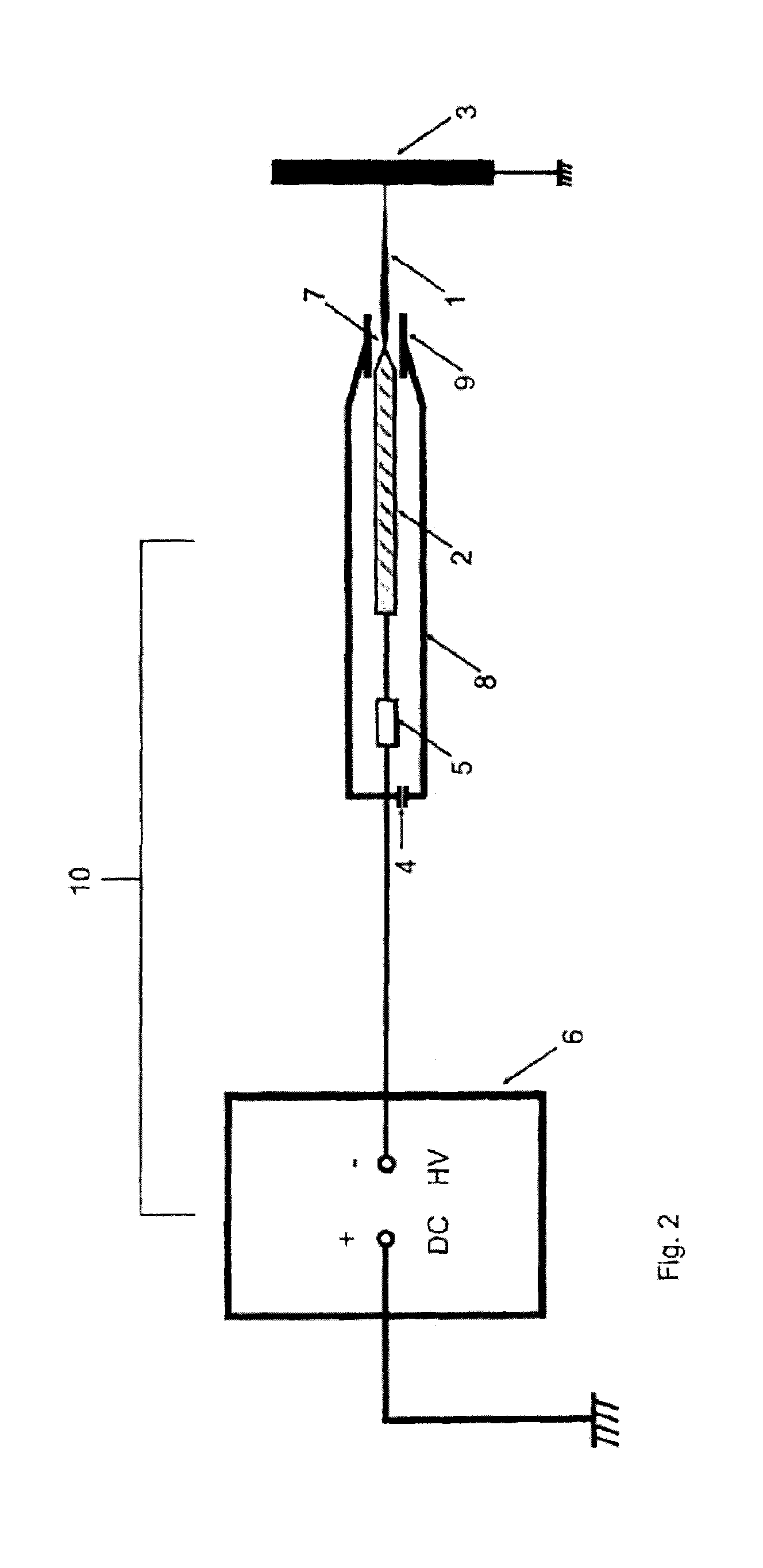

Device and method for generating a pulsed anisothermal atmospheric pressure plasma

InactiveUS20130026137A1Eliminate disadvantagesNot cause any irritationDecorative surface effectsElectrostatic cleaningCorona dischargeHigh field

The invention relates to a device and a method for generating a pulsed (intermittent), cold, atmospheric pressure plasma, preferably a thread, for precise antimicrobial plasma treatment (antisepsis, disinfection, sterilization, decontamination) of very small surfaces and cavities, including on living human and animal bodies, preferably in the field of medicine, by means of a negative direct-current corona discharge, the device comprising at least one electrode for generating high field strengths, through or around which electrode the gas to be ionized flows in a gas channel, wherein the electrically conductive structure (surface, cavity) to be treated is used as the counter-electrode. Said plasma can also be used in general for cleaning, coating, activating, and etching surfaces.

Owner:LEIBNIZ INST FUR PLASMAFORSCHUNG & TECH

Rare earth containing H profile steel with high strength and high toughness and production method thereof

InactiveCN103266279ALow elemental contentReduce residual stressProcess efficiency improvementMetal rolling arrangementsRare-earth elementDistillation

The invention relates to rare earth containing H profile steel with high strength and high toughness and a production method thereof, and belongs to the technical field of metallurgy and moulding. The raw material comprises 90wt% of blast furnace molten iron and 10wt% of high quality steel scrap. The casting blank comprises the following components in percentage by weight: 0.07-0.12% of C, 0.10-0.30% of Si, 1.40-1.70% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.30-0.60% of Cr, 0.20-0.50% of Ni, 0.06-0.20% of V, 0.01-0.03% of Ti, 0.01-0.01% of Al, 0.0005-0.010% of rare earth element RE, less than 0.10% of Cu and the balance of Fe and microelements which cannot be detected. The process flow is as follows: molten iron pre-treatment; smelting by a top-bottom combined blowing converter; refining by an LF (Ladle Furnace); VD (Vapor Distillation) vacuum treatment; continuous casting of square billets; cutting; heating the casting blank; dephosphorization by high pressure water; BD1 cogging; BD2 central rolling; dephosphorization by high pressure water; CCS (Cold Crushing Strength) universal rolling; straightening; cooling; flaw detection; and saw cutting. The mechanical properties of the steel are as follows: the yield strength is 490-570MPa, the strength of extension is 660-750Mpa, the yield ratio is greater than or equal to 0.80, the ductility is greater than or equal to 25%, and the horizontal impact value: aKV is greater than or equal to 100J / cm<2> (minus 40 DEG C). The product provided by the invention has the characteristics of low content of impurity elements, high strength, good toughness and excellent welding performance.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

RF coil for imaging system

InactiveUS20060033501A1Improved control of fieldWiden the optionsDiagnostic recording/measuringSensorsElectricityPath length

Owner:THE GENERAL HOSPITAL CORP

X80 hot rolled steel plate with good toughness, high strength and low tensile ratio and production method thereof

The invention relates to an X80 hot rolled steel plate with good toughness, high strength and low tensile ratio and a production method thereof, and belongs to the technical field of low-carbon structural steel production. The plate blank comprises the following components: 0.02 to 0.08 percent of C, 0.01 to 0.35 percent of Si, 1.40 to 1.85 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.004 percent of S, 0.01 to 0.06 percent of Alt, less than or equal to 0.008 percent of N, less than or equal to 0.0002 percent of H, 0.008 to 0.02 percent of Ti, 0.03 to 0.11 percent of Nb, 0.01 to 0.35 percent of Mo, less than or equal to 0.90 percent of Ni, Cr and Cu complex additive, and the balance of Fe and inevitable impurity elements. The heating temperature of the plate blank is between 1,120 and 1,220 DEG C; a fist stage of controlled rolling is finished in an austenite recrystallization area, the single-pass pressing rate is 15 to 30 percent, and the final rolling temperature is between 960 and 1,080 DEG C; a second stage of controlled rolling is finished in an austenite non-recrystallization area, and the final rolling temperature is between 770 and 830 DEG C; and the rolled steel is cooled to between 450 and 580 DEG C at a speed of 10 to 30 DEG C per second. The steel plate has the advantages of high strength, good toughness and low tensile ratio.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com